Experimental Study of the Concrete Cracking Behavior of an Immersed Tunnel under Fire

Abstract

:1. Introduction

2. Test Setup

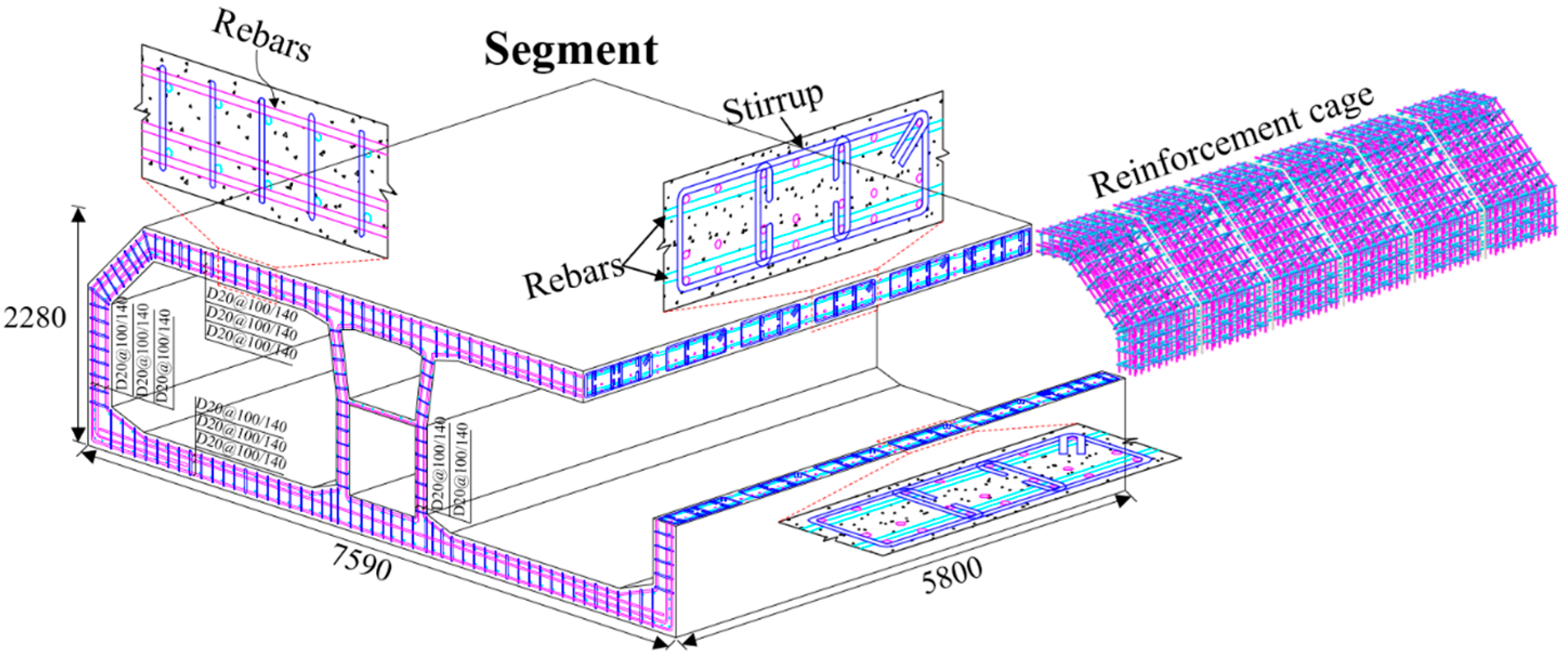

2.1. The Reduced-Scale Model

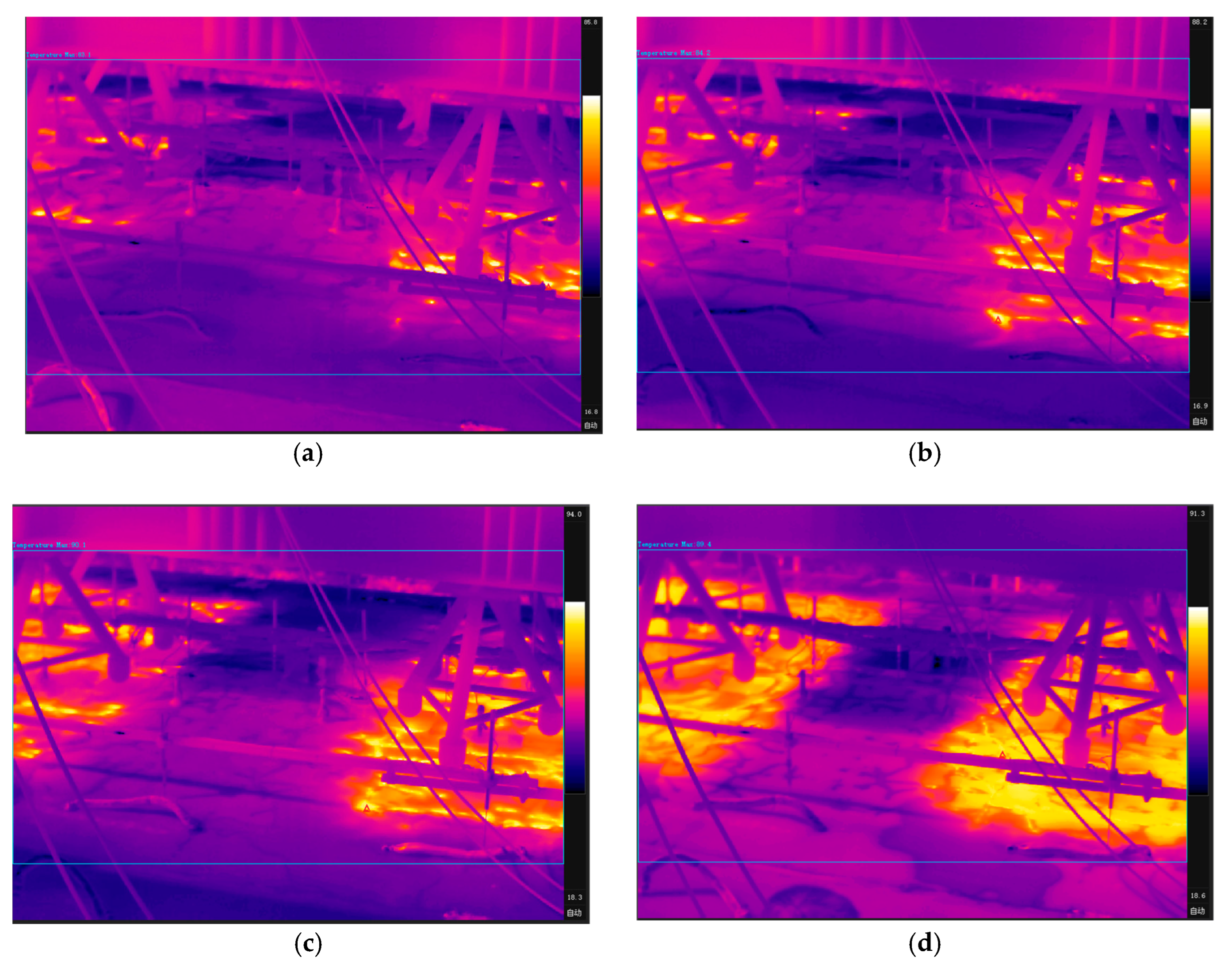

2.2. Infrared Thermography Recorded the Temperature of Ceiling

3. Analysis of Fire Test Results

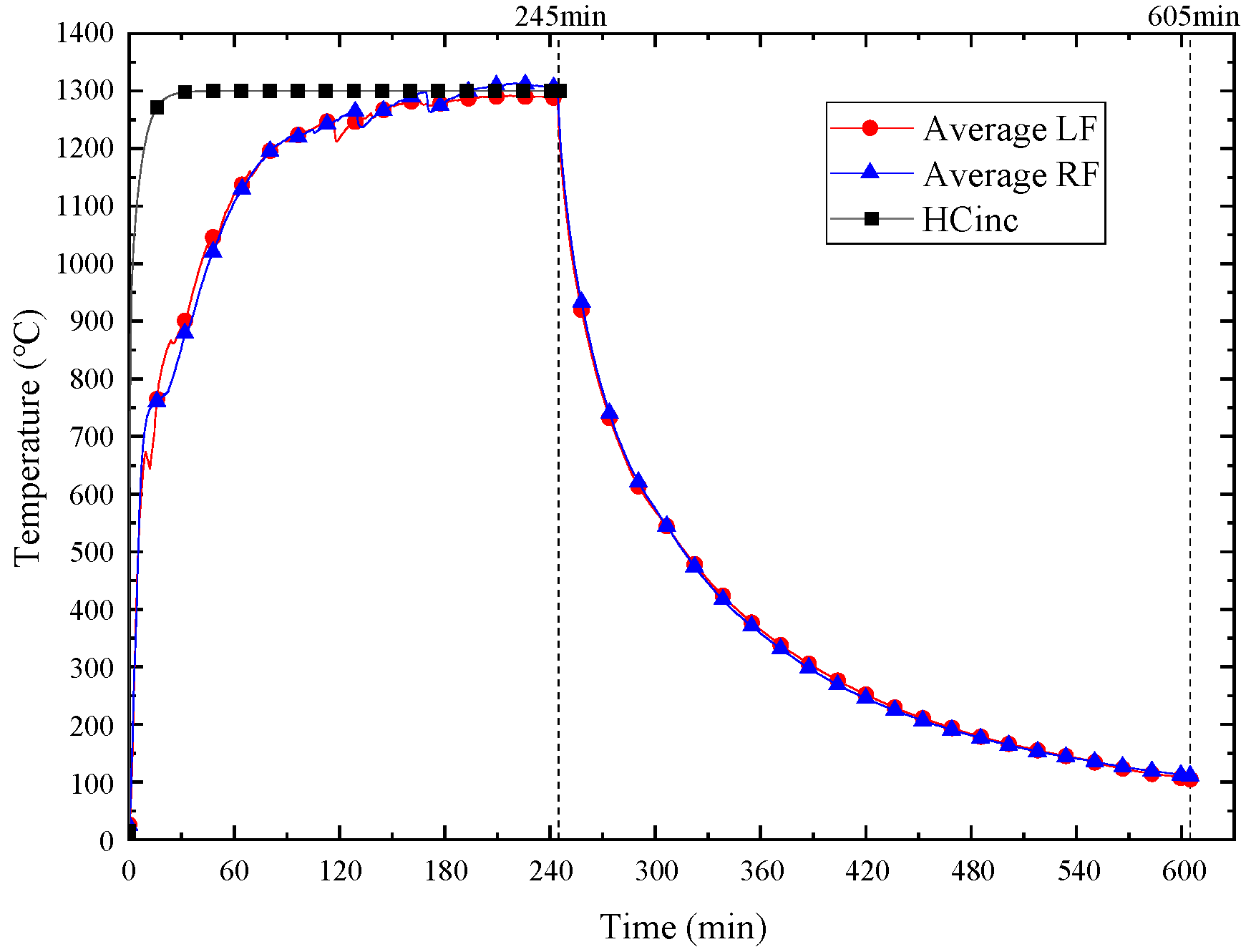

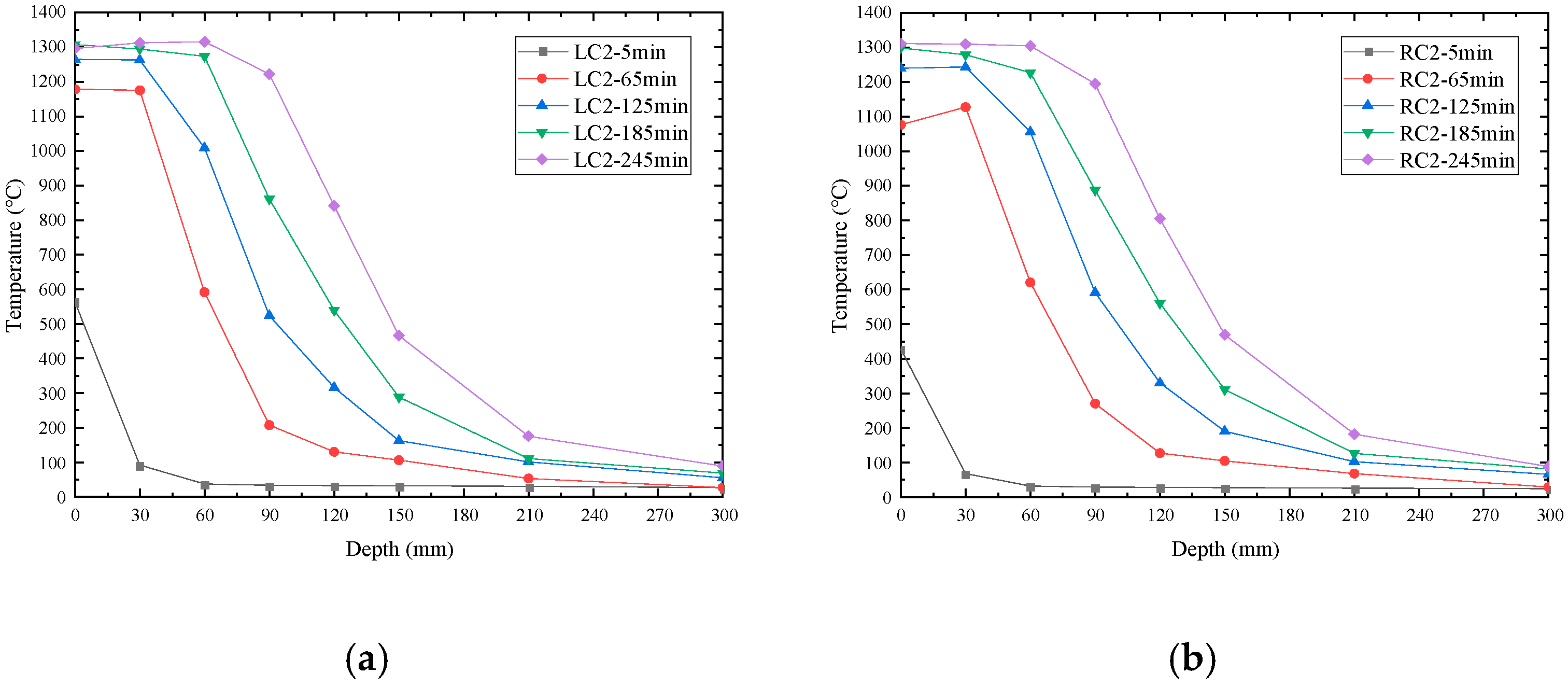

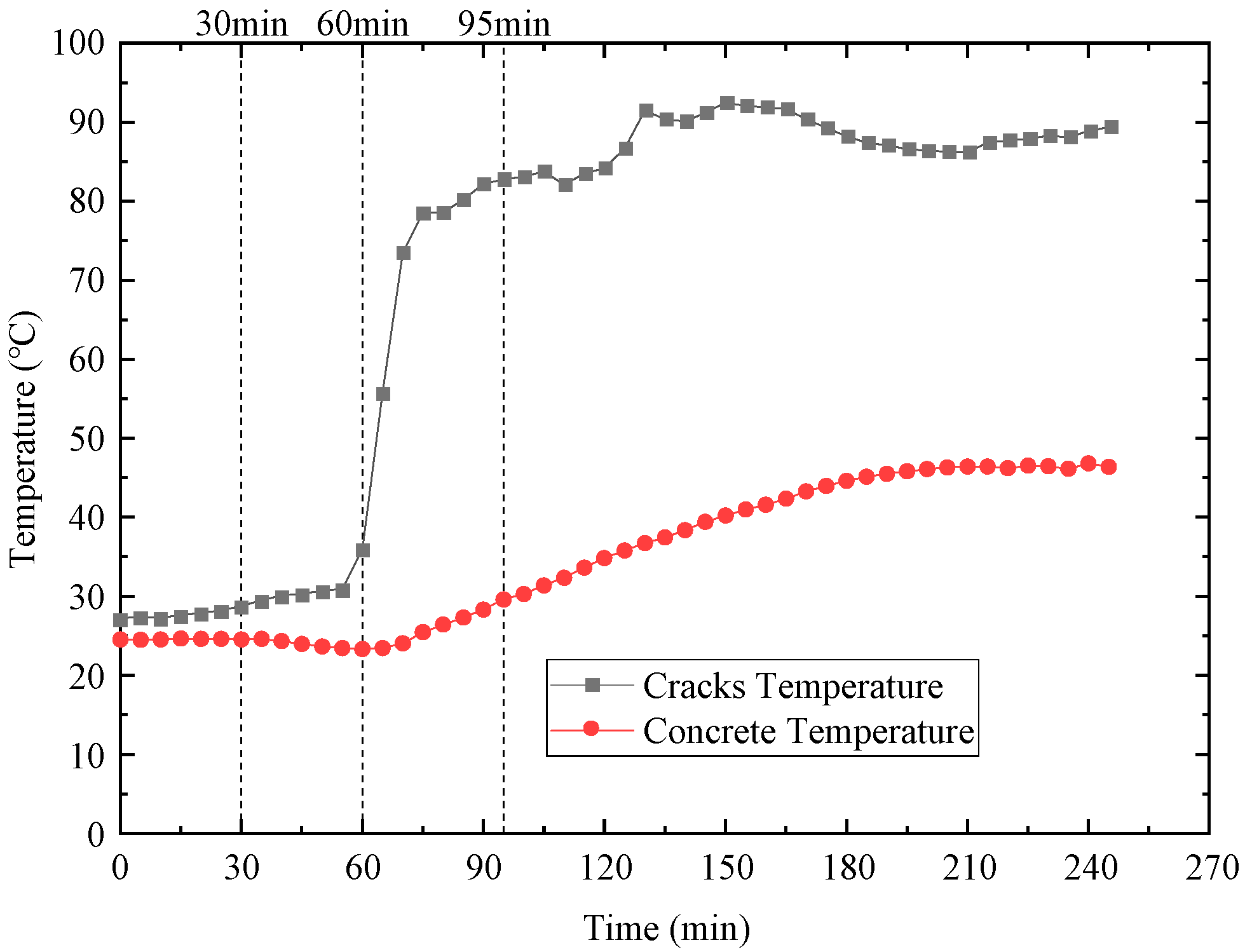

3.1. Temperature Field of the Immersed Tunnel

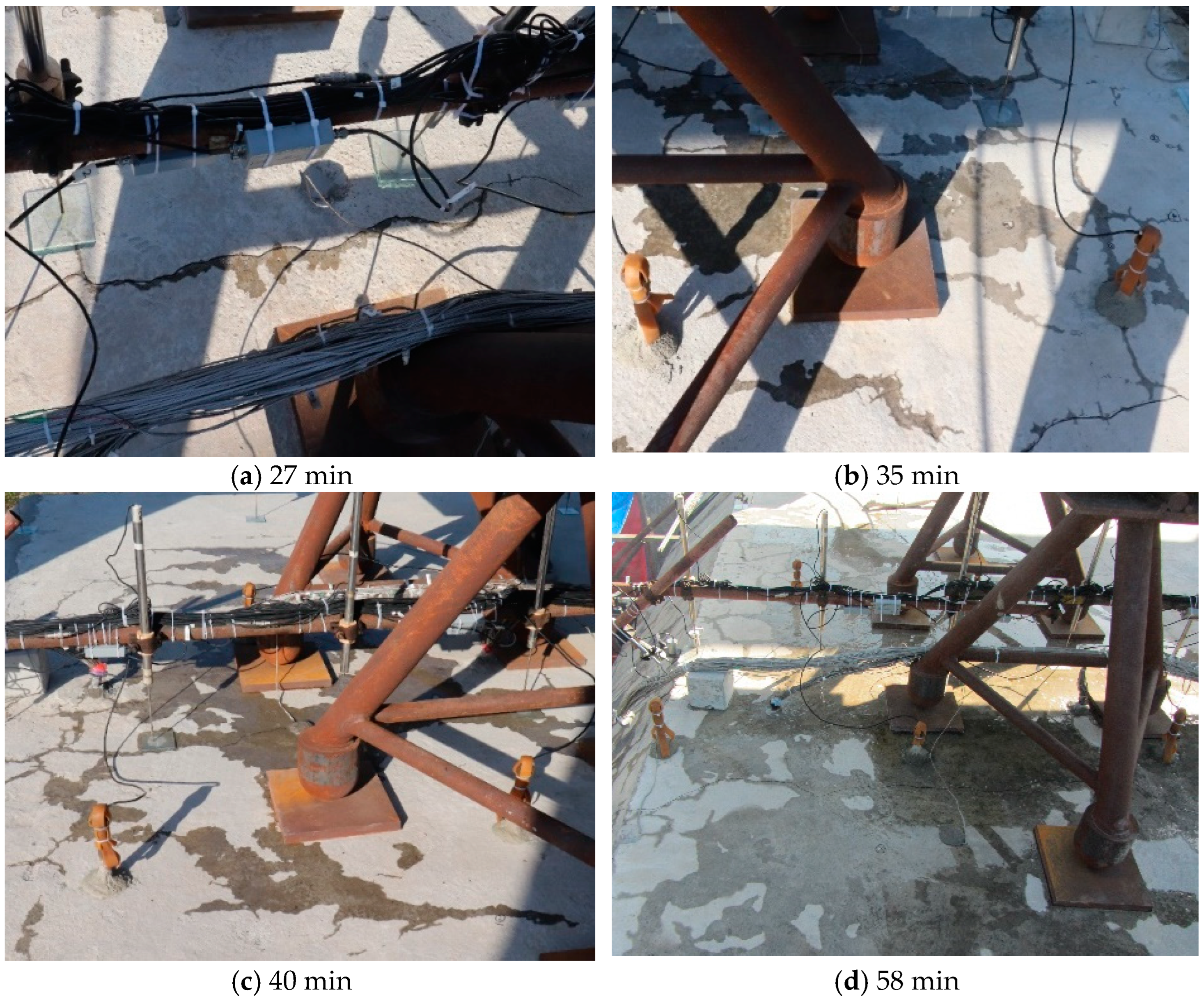

3.2. Analysis of Cracks Depth

4. Conclusions

- (1)

- The elevated temperature of fire induces the conversion of moisture in the concrete to water vapor, generating high pressure within the material and driving the migration of moisture. Nonetheless, due to the concrete’s low permeability and compactness, water and vapor predominantly traverse through cracks in the material. Consequently, water and vapor emanating from these fissures exhibit elevated temperatures.

- (2)

- The migration of high-temperature water and vapor through cracks to a lower-temperature region was driven by vapor pressure in the high-temperature region. By combining the temperature field distribution in the concrete with the temperature of the water and vapor in the cracks, the crack depth can be estimated. At 95 min, cracks on the ceiling’s outer surface extended to the inner surface, with a depth exceeding 150 mm.

- (3)

- During the heating stage, the fire induces thermal expansion of the concrete inside the tunnel, resulting in tensile cracking of the concrete outside the tunnel. During the cooling stage, decreased temperatures cause the fire-exposed tunnel surface to crack. In the internal and external cracking patterns, immersed tunnels are vulnerable to developing through-cracks during fires. Such through-cracks in the concrete present a direct safety threat to the immersed tunnel. Even when through-cracks are not present, concrete cracking exposes rebars to the marine chloride environment, accelerating their corrosion and diminishing the tunnel’s service life. Therefore, it is crucial to consider the potential for concrete cracking due to thermal strain during the fire-resistant design of immersed tunnels.

Author Contributions

Funding

Conflicts of Interest

References

- Pan, D. Study on Mechanical Properties and Damage Laws of Large Diameter Shield Tunnel Lining under Fire Scenario; Beijing Jiaotong University: Beijing, China, 2018. (In Chinese) [Google Scholar]

- Dong, Y.L.; Duan, J.T.; Zhang, D.S.; Zhu, S.F.; Qi, J.Q. Experimental research on fire resistance of the reduced scale immersed tunnel with fire in both traffic tubes. Tunn. Undergr. Space Technol. 2023, 132, 104922. [Google Scholar] [CrossRef]

- Zhang, J.C.; Shi, J.L.; Qu, Y.T. Technical specifications and operation of Seikan submarine tunnel. China Railw. 2017, 5, 91–97. (In Chinese) [Google Scholar]

- Xiao, J.Z.; Liu, L.L.; Dong, Y.L.; Luo, F.J.; Gao, W.Y. Progress of study on explosive spalling of high performance concrete at elevated temperatures. J. Archit. Civ. Eng. 2019, 36, 1–15. (In Chinese) [Google Scholar]

- Al-Bashiti, M.K.; Naser, M.Z. Verifying domain knowledge and theories on Fire-induced spalling of concrete through eXplainable artificial intelligence. Constr. Build. Mater. 2022, 348, 128648. [Google Scholar] [CrossRef]

- Khoury, G.A. Effect of fire on concrete and concrete structures. Prog. Struct. Mat. Eng. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- Wang, W.; Li, D. Thermal-mechanical coupling analysis and fire protection experiment on immersed tunnel exposed to fire. J. Saf. Sci. Technol. 2015, 11, 17–22. (In Chinese) [Google Scholar]

- Duan, J.T.; Dong, Y.L.; Zhu, S.F.; Luo, J.Q. Cross-section bearing capacity analysis of immersed tunnel of Hong Kong-Zhuhai-Macao bridge. J. Huaqiao Univ. (Nat. Sci.) 2020, 41, 8–18. (In Chinese) [Google Scholar]

- Wang, L.Y.; Xu, W. Internal force analysis of immersed tunnel cross-section during service stage. Struct. Eng. 2015, 31, 162–168. (In Chinese) [Google Scholar]

- Xu, P.; Xing, R.J.; Jiang, S.P.; Li, L.J. Theoretical prediction model and full-scale experimental study of central smoke extraction with a uniform smoke rate in a tunnel fire. Tunn. Undergr. Space Technol. 2019, 86, 63–74. [Google Scholar] [CrossRef]

- Guo, J.; Jiang, S.P.; Zhang, Z.Y. Fire thermal stress and its damage to subsea immersed tunnel. Procedia Eng. 2016, 166, 296–306. [Google Scholar] [CrossRef]

- Duan, J.T.; Dong, Y.L.; Xiao, J.Z.; Zhang, D.S.; Zheng, W.; Zhang, S.Y. A large-scale fire test of an immersed tunnel under the protection of fire resistive coating. Tunn. Undergr. Space Technol. 2021, 111, 103844. [Google Scholar] [CrossRef]

- Lu, L.M.; Qiu, J.N.; Yuan, Y.; Tao, J.; Yu, H.T.; Wang, H.; Mang, H. Large-scale test as the basis of investigating the fire-resistance of underground RC substructures. Eng. Struct. 2019, 178, 12–23. [Google Scholar] [CrossRef]

- Ring, T.; Zeiml, M.; Lackner, R. Underground concrete frame structures subjected to fire loading: Part I–Large-scale fire tests. Eng. Struct. 2014, 58, 175–187. [Google Scholar] [CrossRef]

- China Communications Construction Co. Ltd. Immersed Tunnel Design and Construction Manual—Design; Science Press: Beijing, China, 2019. (In Chinese) [Google Scholar]

- Hu, Z.N.; Xie, Y.L.; Xu, G.P.; Bin, S.L.; Liu, H.Z.; Lai, J.X. Advantages and potential challenges of applying semi-rigid elements in an immersed tunnel: A case study of the Hong Kong-Zhuhai-Macao bridge. Tunn. Undergr. Space Technol. 2018, 79, 143–149. [Google Scholar] [CrossRef]

- Duan, J.T.; Dong, Y.L.; Lin, J.Q.; Zhu, S.F. Simulation and analysis of fire test furnace based on improved heat balance method. J. Huaqiao Univ. (Nat. Sci.) 2019, 40, 483–488. (In Chinese) [Google Scholar]

- Lin, Z.Z.; Tang, C.S.; Zeng, H.; Cheng, Q.; Tian, B.G.; Shi, B. Soil evaporation based on infrared thermal imaging technology. Chin. J. Geotech. Eng. 2021, 43, 743–750. (In Chinese) [Google Scholar]

- Stelzner, L.; Powierza, B.; Oesch, T.; Dlugosch, R.; Weise, F. Thermally-induced moisture transport in high-performance concrete studied by X-ray-ct and H~1h-nmr. Constr. Build. Mater. 2019, 224, 600–609. [Google Scholar] [CrossRef]

- Li, M. The Fire Damage of High Strength Concrete and Its Comprehensive Evaluation; Southeast University: Nanjing, China, 2005. (In Chinese) [Google Scholar]

| Granite gravel (big) (kg/m3) | 726 |

| Granite gravel (small) (kg/m3) | 311 |

| Mix sand (kg/m3) | 636 |

| Portland cement (kg/m3) | 390 |

| Water (kg/m3) | 165 |

| Slag powder (kg/m3) | 75 |

| Fly ash (kg/m3) | 35 |

| Water reducer (L/m3) | 11.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, J.; Qiu, P.; Liu, J.; Wu, X. Experimental Study of the Concrete Cracking Behavior of an Immersed Tunnel under Fire. Buildings 2023, 13, 1412. https://doi.org/10.3390/buildings13061412

Duan J, Qiu P, Liu J, Wu X. Experimental Study of the Concrete Cracking Behavior of an Immersed Tunnel under Fire. Buildings. 2023; 13(6):1412. https://doi.org/10.3390/buildings13061412

Chicago/Turabian StyleDuan, Jintao, Peiyun Qiu, Jianyong Liu, and Xin Wu. 2023. "Experimental Study of the Concrete Cracking Behavior of an Immersed Tunnel under Fire" Buildings 13, no. 6: 1412. https://doi.org/10.3390/buildings13061412

APA StyleDuan, J., Qiu, P., Liu, J., & Wu, X. (2023). Experimental Study of the Concrete Cracking Behavior of an Immersed Tunnel under Fire. Buildings, 13(6), 1412. https://doi.org/10.3390/buildings13061412