Anchor Behavior of One-Side Bolt with Flip-Top Collapsible Washer

Abstract

:1. Introduction

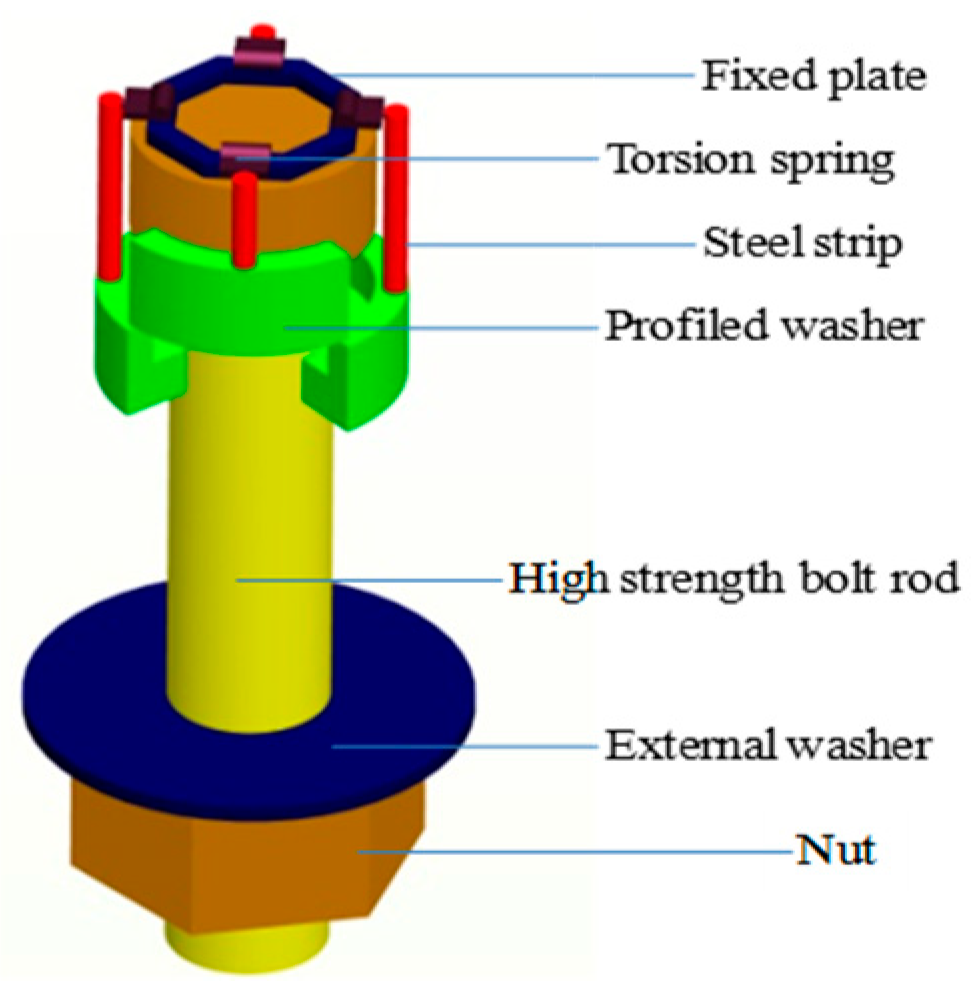

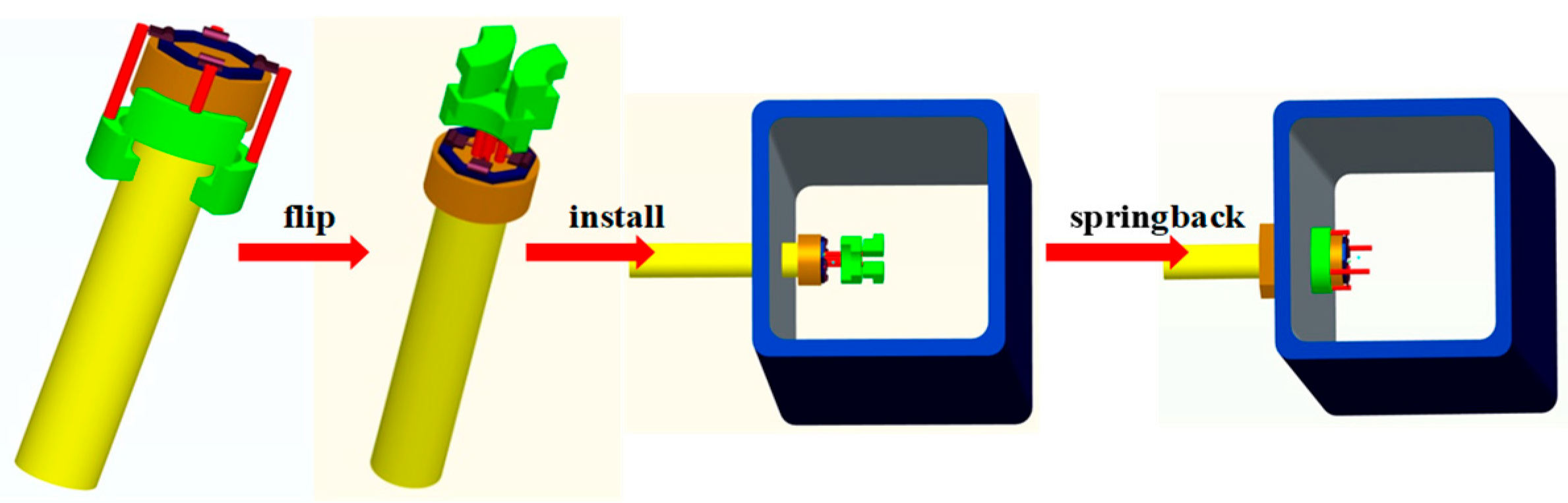

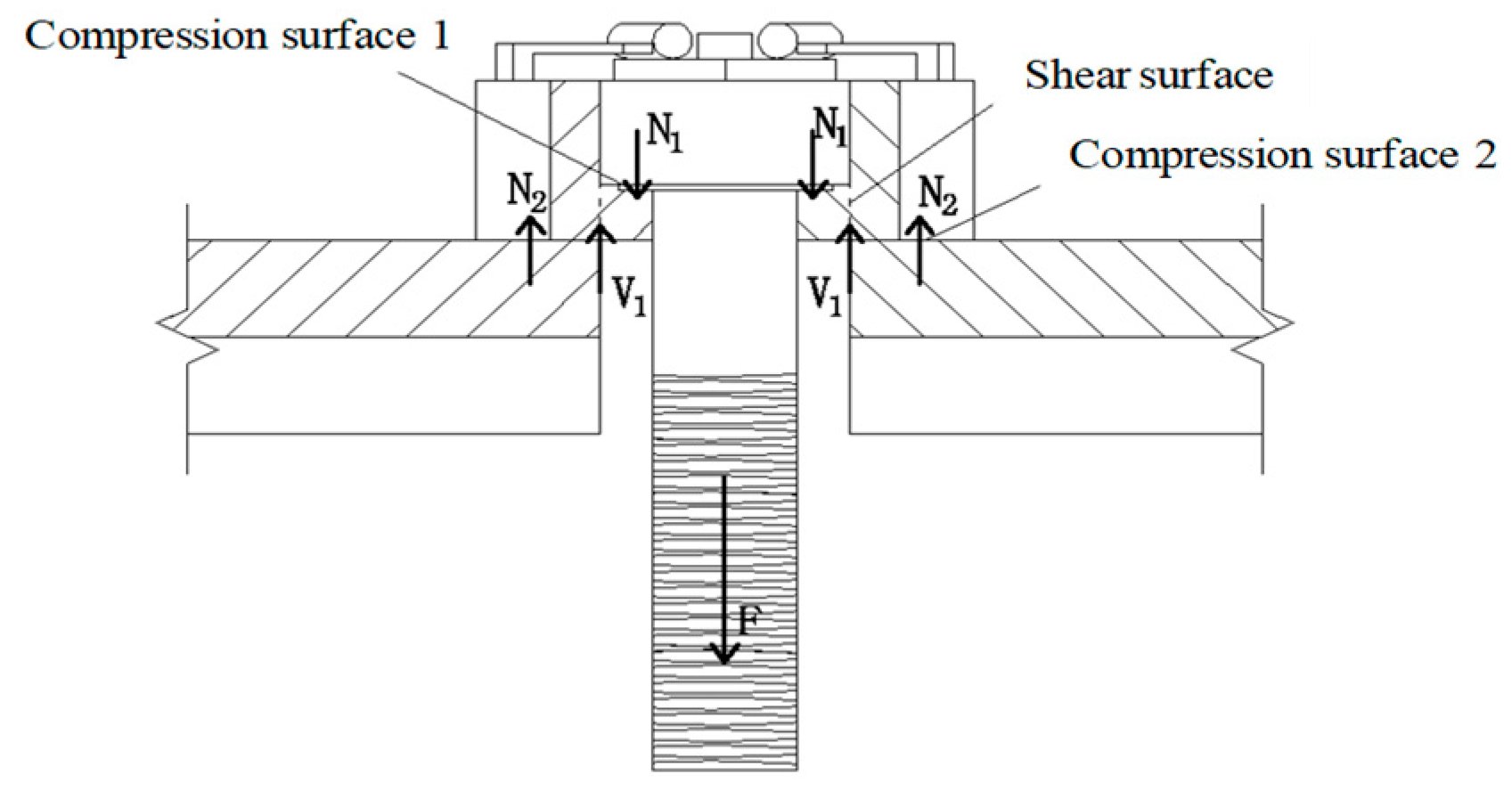

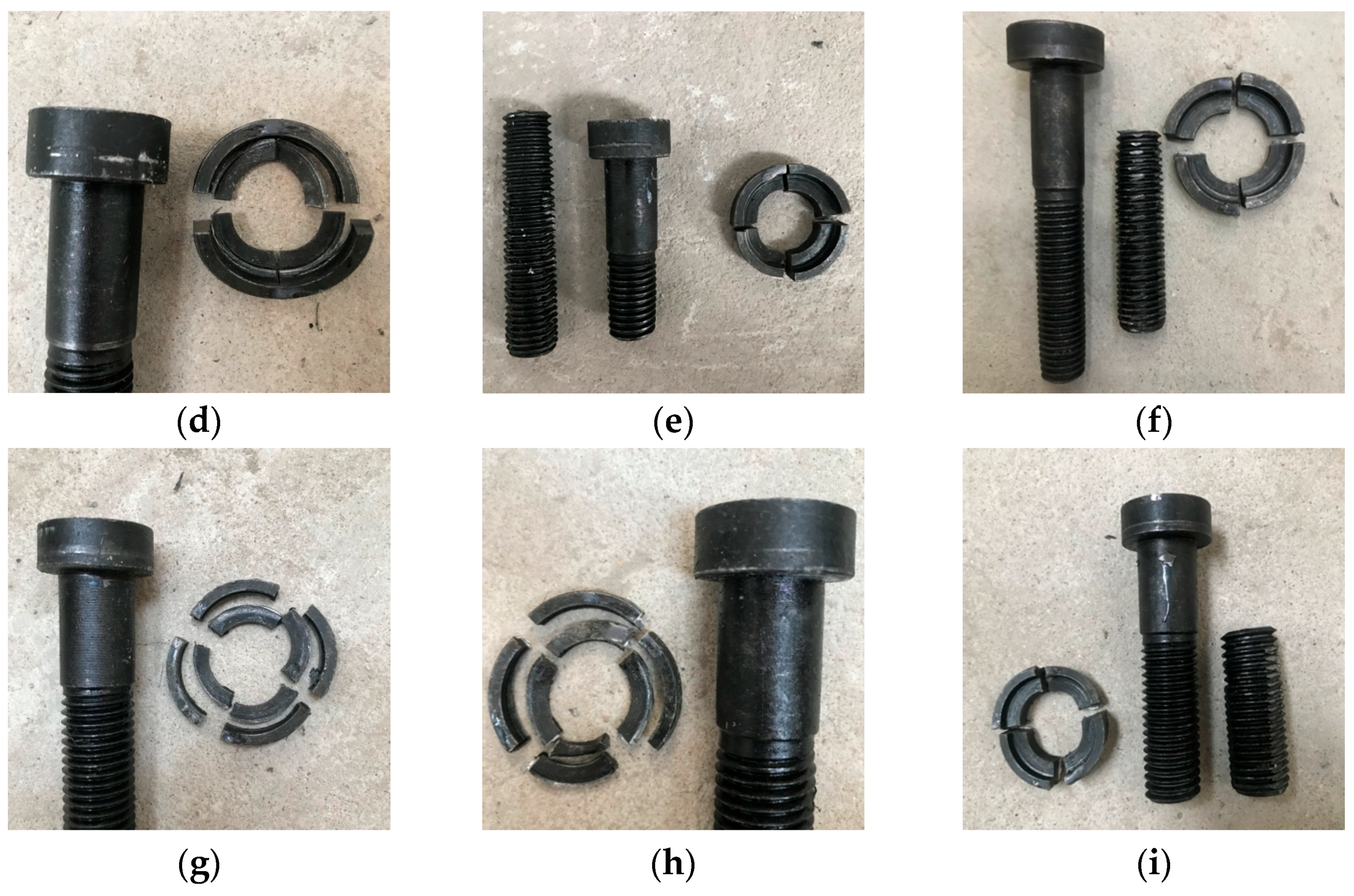

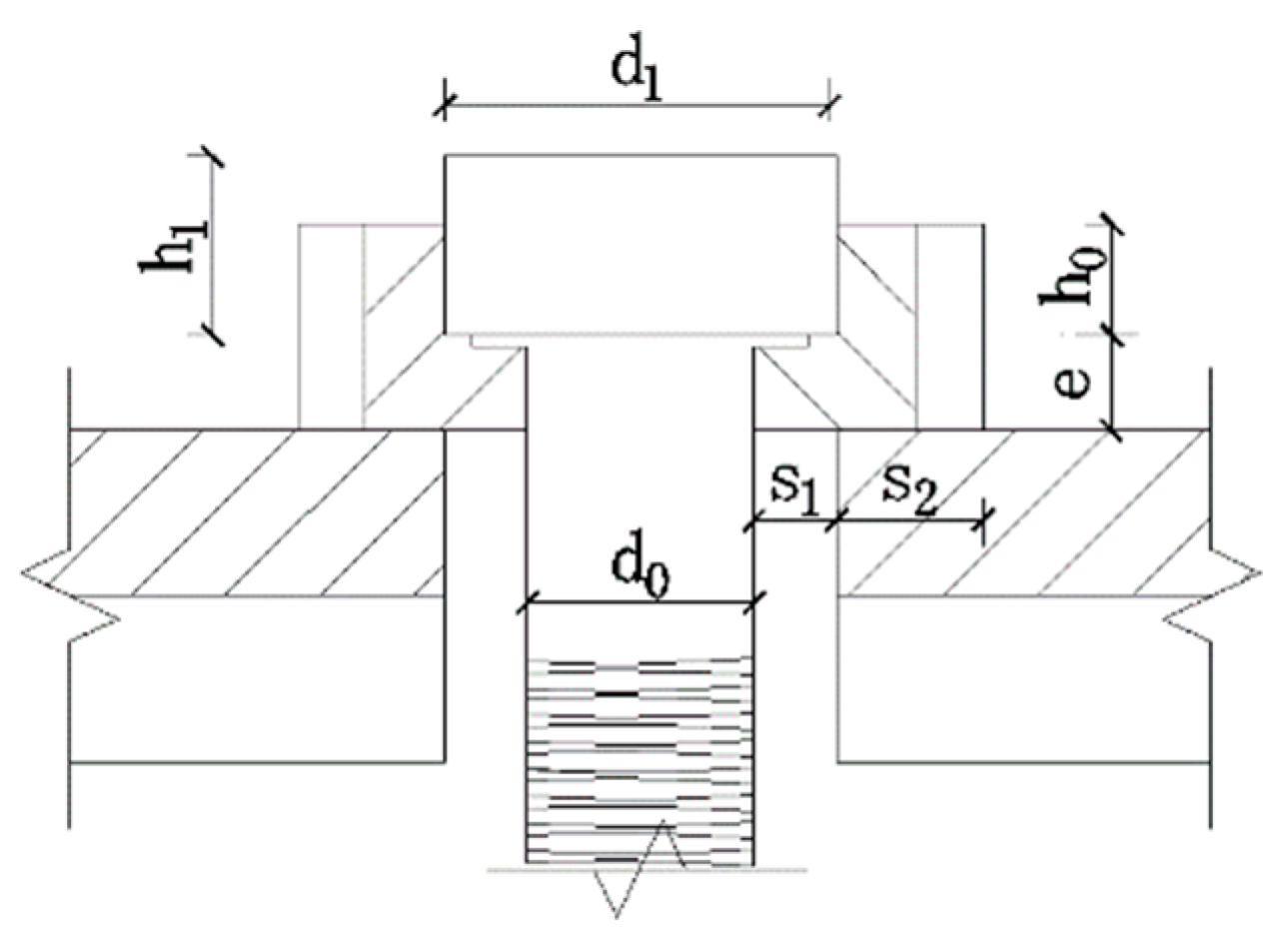

2. The Introduction of the FTW-OSB

3. Experimental Tests

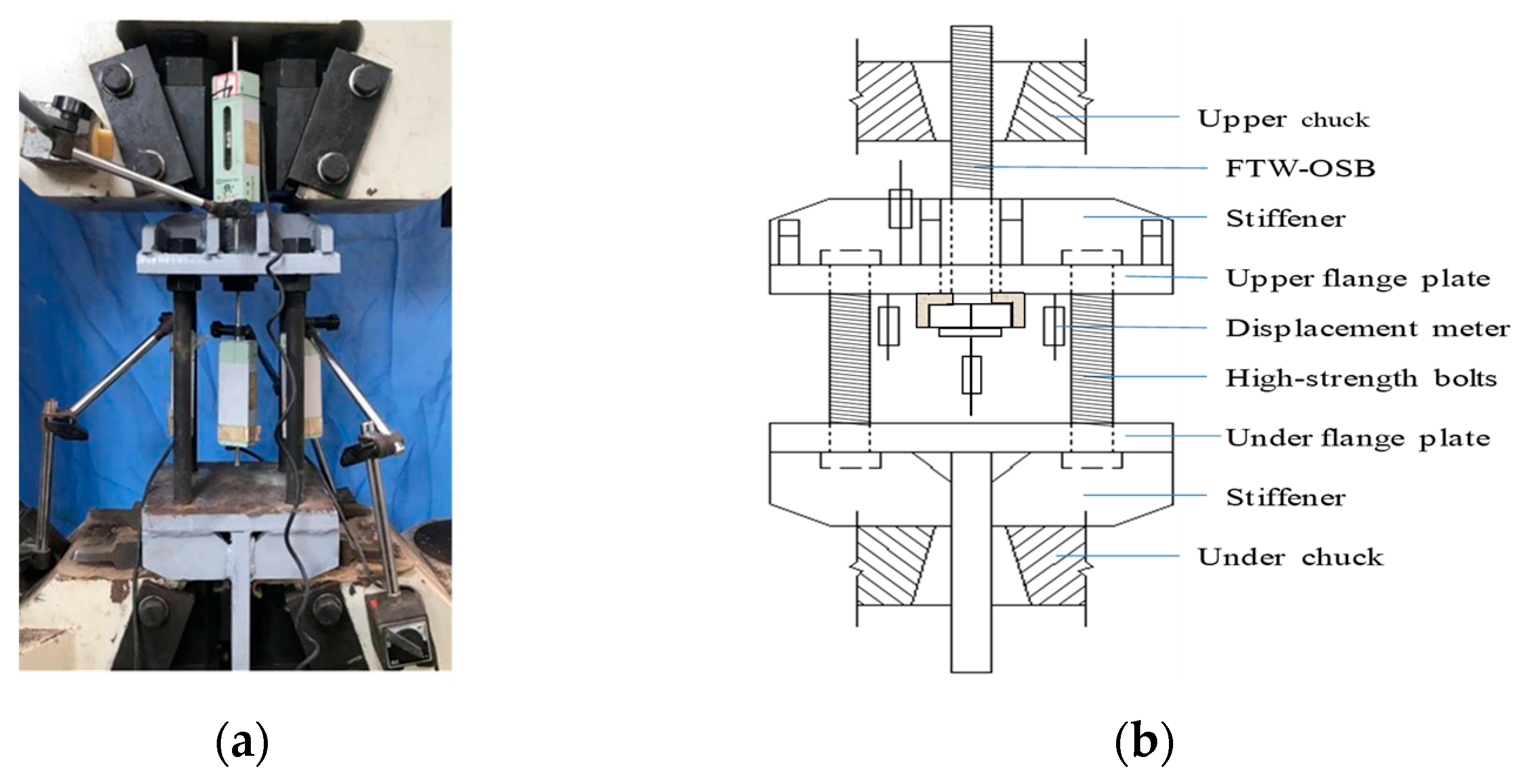

3.1. Design of the Test Specimens and Material Properties

3.2. Test Setup

3.3. Test Phenomena and Typical Failure Modes

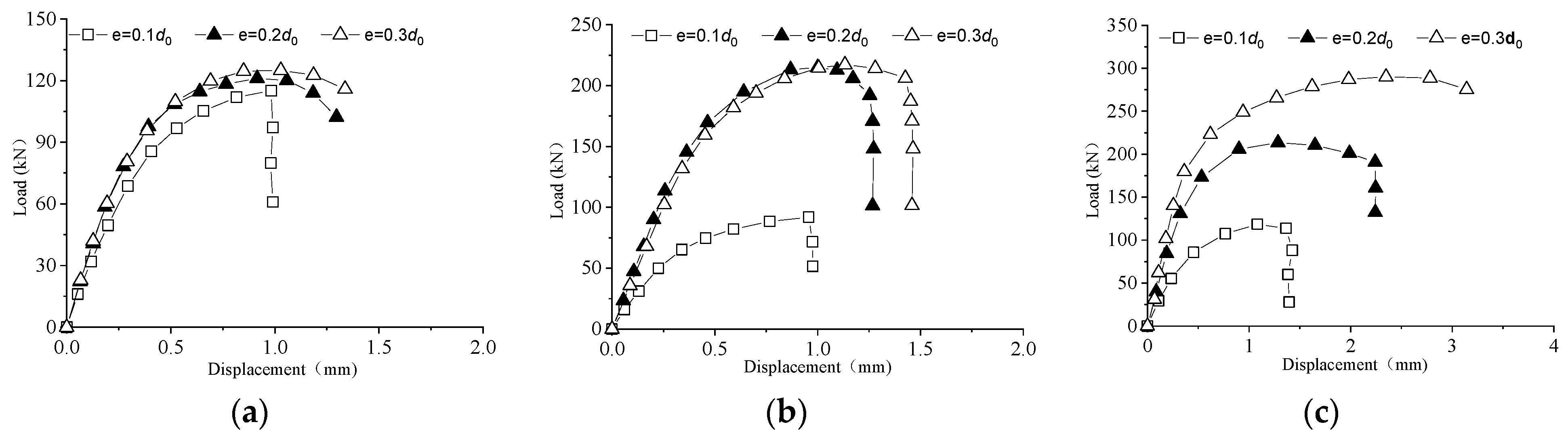

3.4. Load–Displacement Curves and Anchor Strength

4. Finite Element Model and Validation

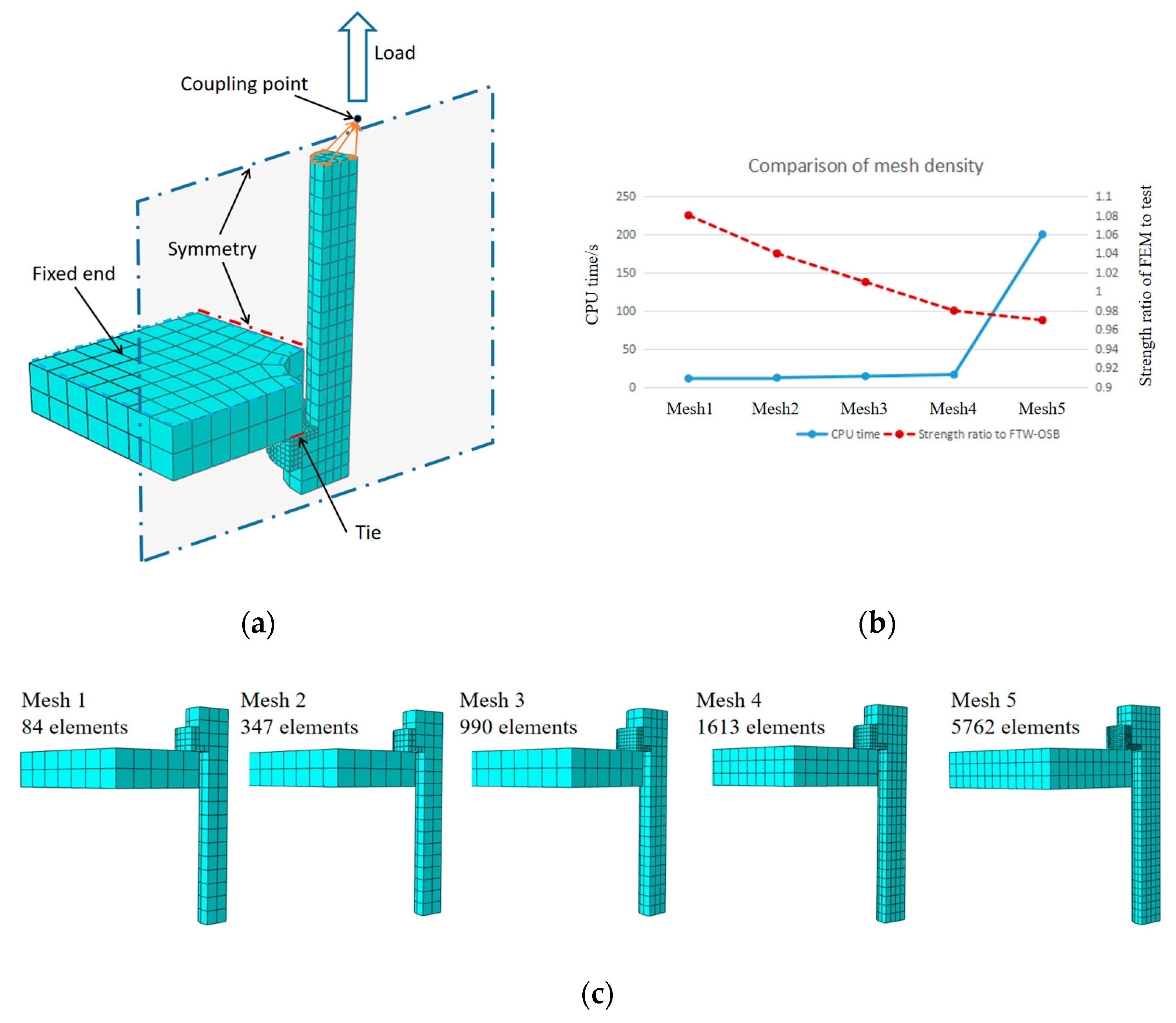

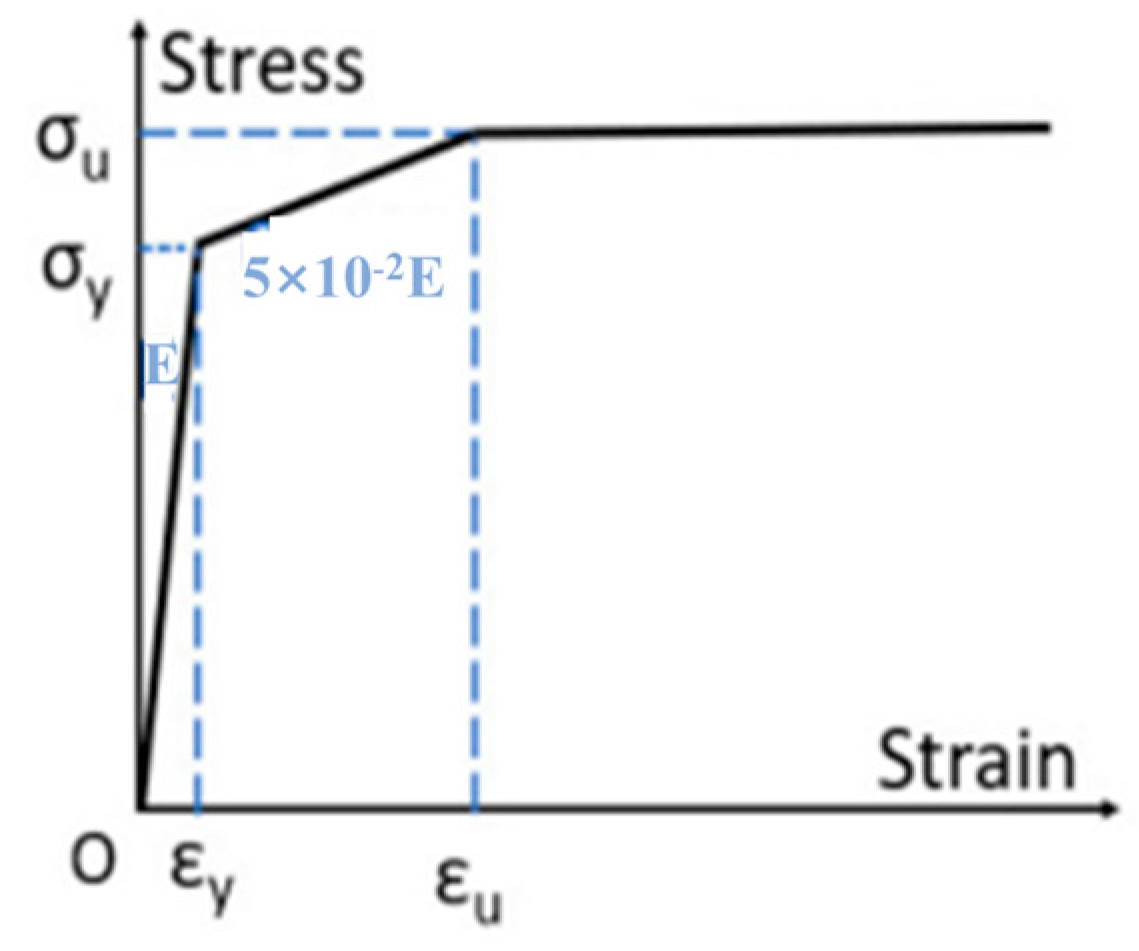

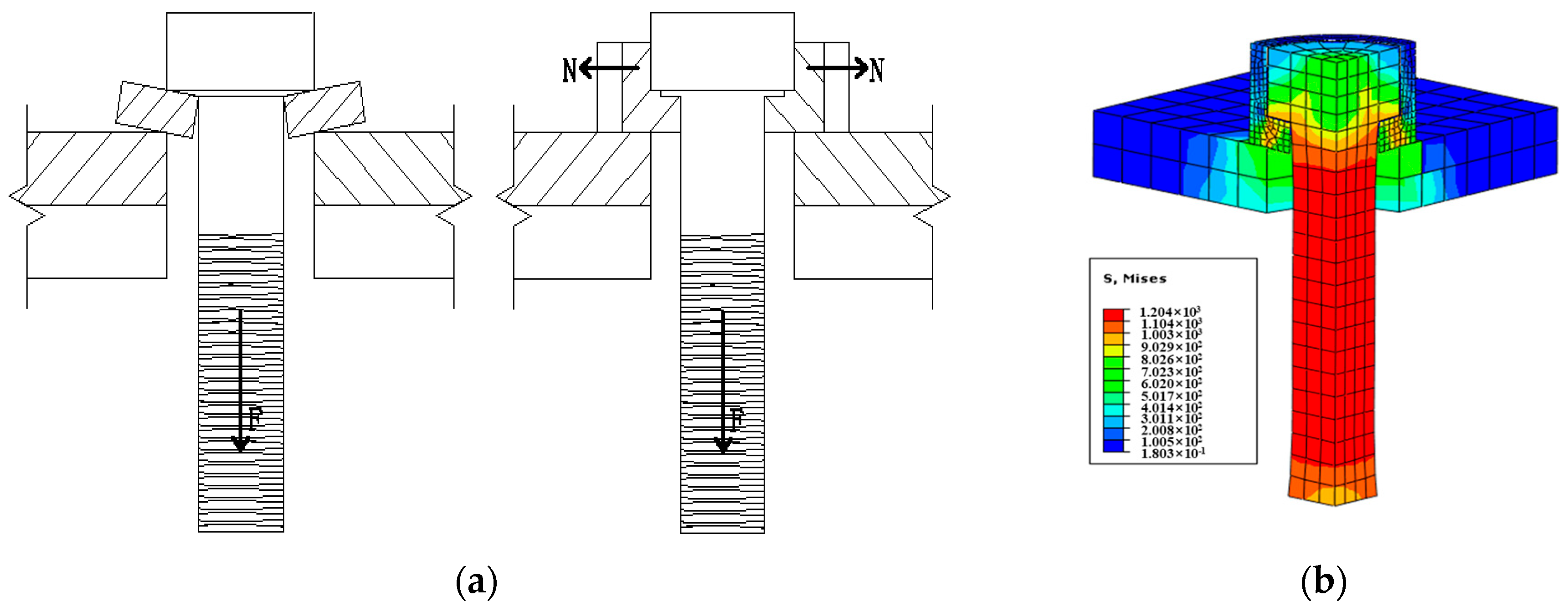

4.1. Finite Element Model

4.2. Element Type and Meshing

4.3. Validation of Models

5. Parameter Analysis

5.1. Parametric Analysis Scheme

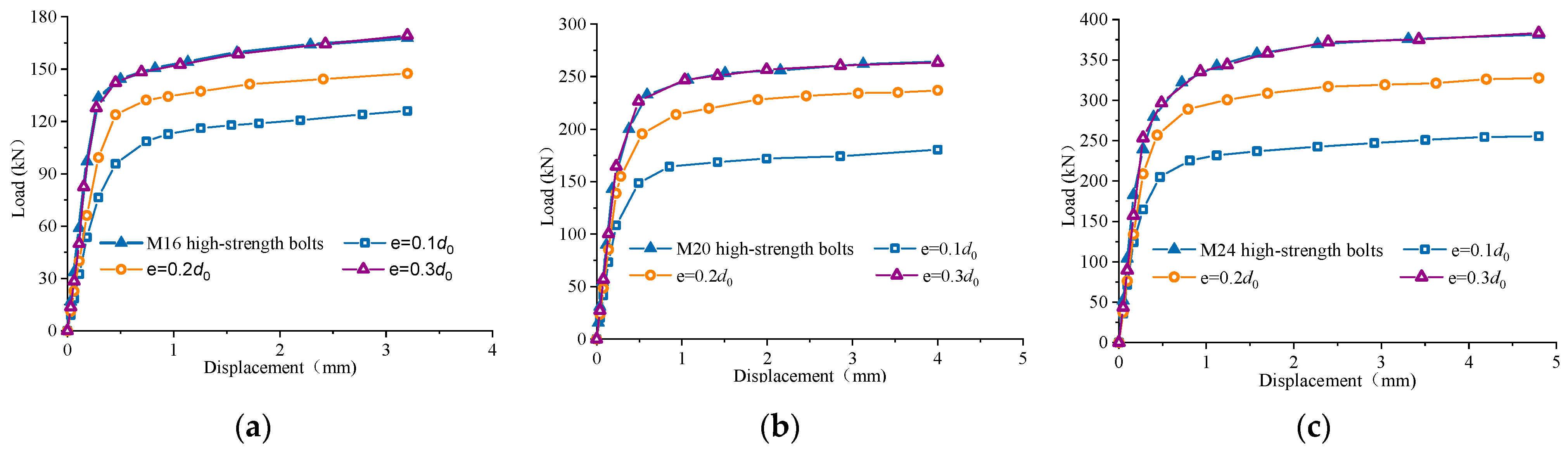

5.2. Thickness Effect of Flat Washer

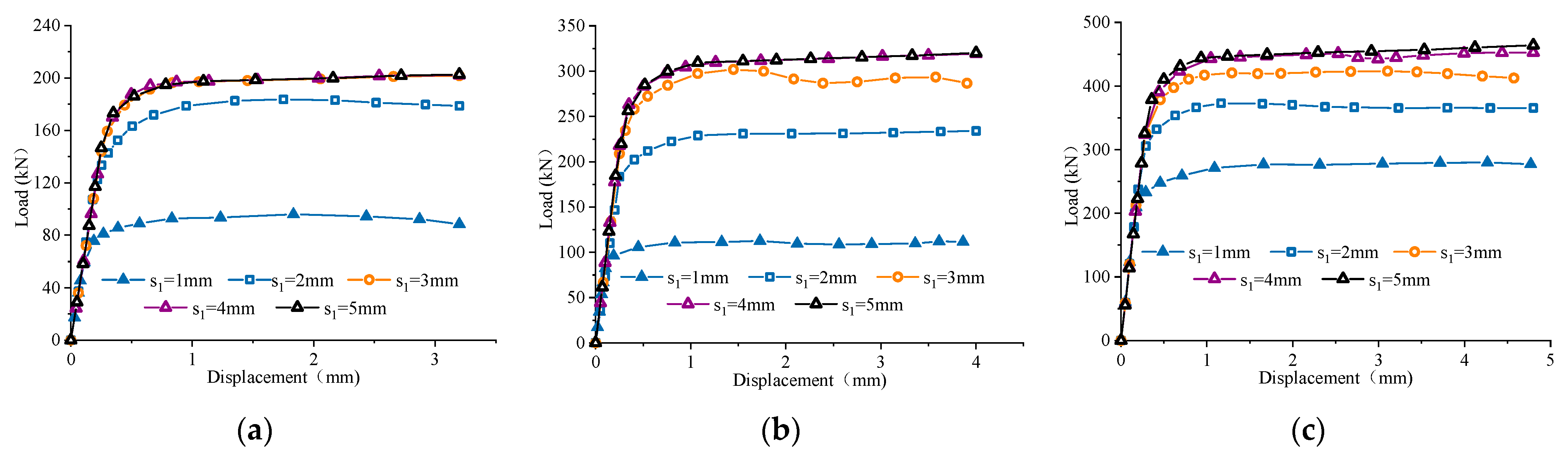

5.3. The Influence of Thickness for L-Shaped Washer

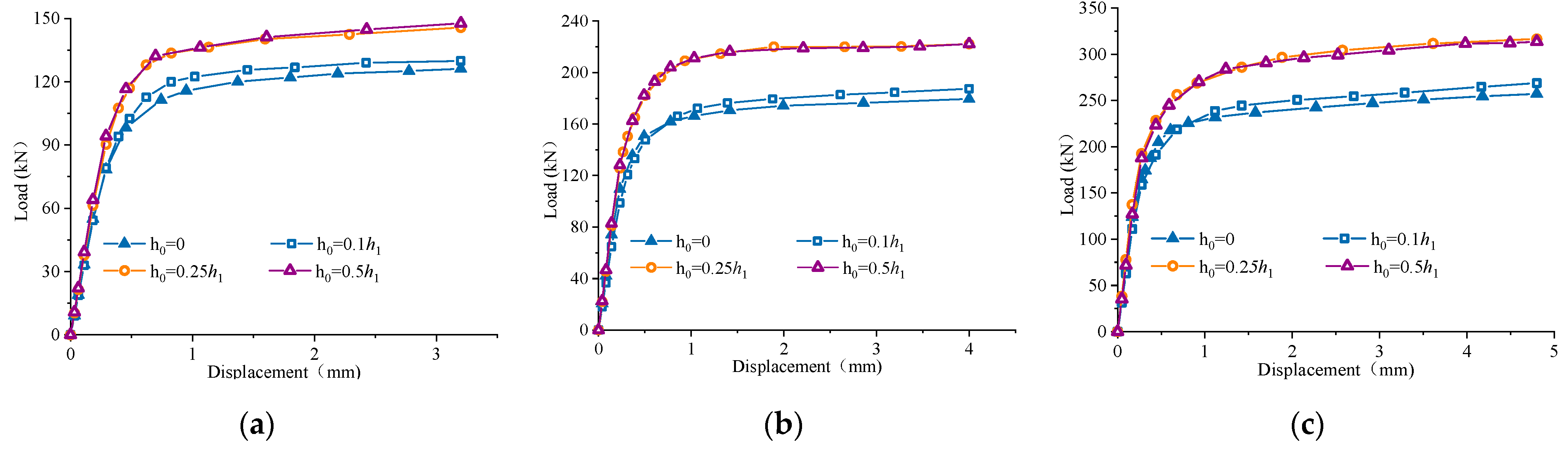

5.4. The Influence of the Side Wall Height

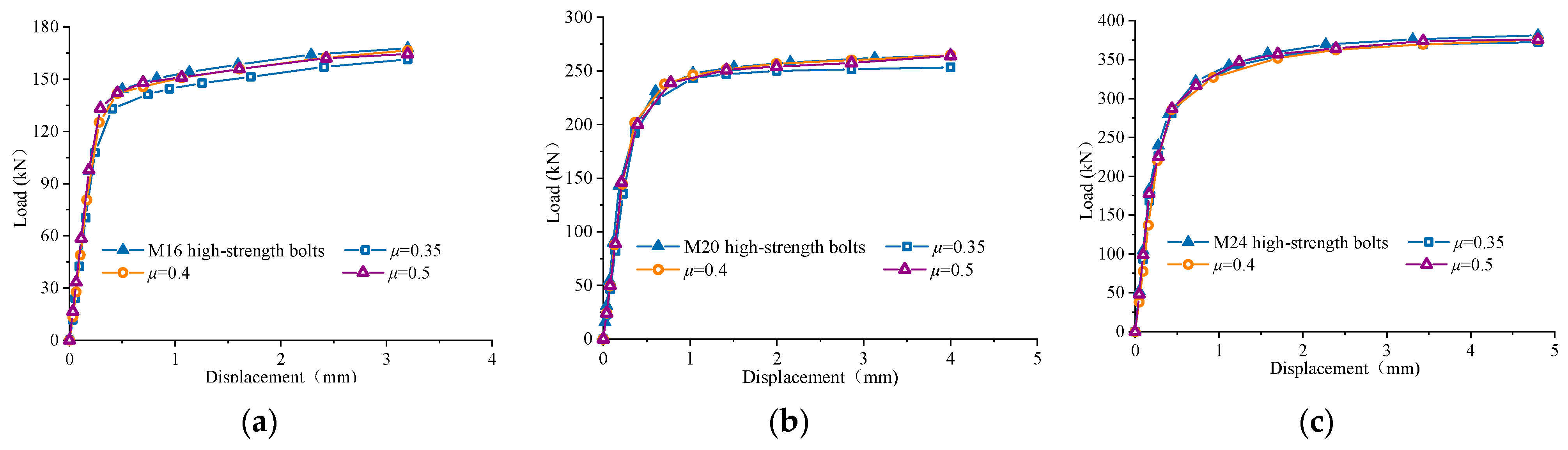

5.5. The Influence of Friction Coefficient

5.6. The Influence of Upper Contact Surface Size on Washer

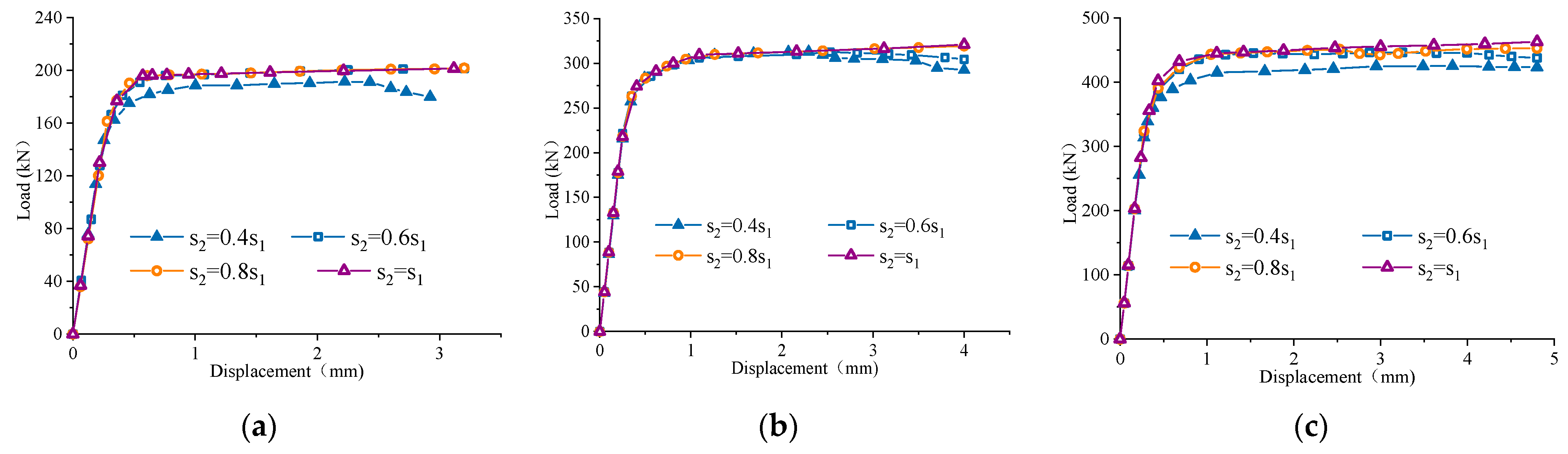

5.7. The Influence of under Contact Surface Size on Washer

6. Conclusions

- The novel flip-top washer one-side bolt (FTW-OSB) has been developed using high-strength bolts as the base material. The profiled washer, aided by the torsional force of the torsion spring, rebounds in the closed section to form the anchoring end. The load-bearing performance of the L-shaped washer surpasses that of the I-shaped washer.

- There are two types of failure modes for the FTW-OSB: one is the shear failure of the washer, and the other is the tensile failure of the bolt rod. As the thickness, side wall height, and contact surface size of the washer increase, the load-bearing capacity of the washer is enhanced, and the failure mode of the bolt changes from shear failure of the washer to tensile failure of the bolt rod. The single-side bolt fully utilizes its load-carrying capacity, and its anchoring performance reaches the same level as that of the same model of ordinary high-strength bolts.

- The main parameters that affect the anchoring performance of the FTW-OSB are the thickness of the washer e, the height of the washer side wall h0, and the size of the contact surfaces on the upper and under of the washer, s1 and s2, respectively. When e = 0.2 d0, h0 = 0.25 h1, s1 = 0.2 d0 (h1 is the bolt head height), and s2 = 0.8 s1, the anchoring performance of the FTW-OSB is equivalent to that of the same model of the high-strength bolt.

- The degree of influence on the anchoring performance of the FTW-OSB in descending order is washer thickness e > washer side wall height h0 > upper contact surface size of the washer s1 > under contact surface size of the washer s2 > friction coefficient μ of the contact surface.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Le, S.L.; Qi, L.Z.; Wu, L.; Li, C.; Jian, L.Y.; Liu, M.; Zhou, L.F.; Jun, W.P. Experimental and theoretical modeling for predicting bending moment capacity of T-head square-neck one-side bolted endplate to tube column connection. J. Build. Eng. 2021, 43, 103104. [Google Scholar]

- Xu, T.; Wang, W.; Yi, C.Y. A review on foreign research status of one-side bolt. Steel Constr. 2015, 8, 27–33. [Google Scholar]

- Hoogenboom, A.J. Flow Drill for the Provision of Holes in Sheet Material. U.S. Patent No. 4,454,741, 19 June 1984. [Google Scholar]

- France, J.E.; Davison, J.B.; Kirby, P.A. Strength and Rotational Stiffness of Simple Connections to Tubular Columns Using Flowdrill Connectors. J. Constr. Steel Res. 1999, 50, 15–34. [Google Scholar] [CrossRef]

- Lee, J.; Goldsworthy, H.M.; Gad, E.F. Blind Bolted T-Stub Connections to Unfilled Hollow Section Columns in Low Rise Structures. J. Constr. Steel Res. 2010, 66, 981–992. [Google Scholar] [CrossRef]

- Ajax Engineered Fasteners. One Sided Structured Fastening System. Available online: https://www.westcoastfasteners.com.au/pdf/ajax%20handbook.pdf (accessed on 1 January 2019.).

- Mourad, S. Behaviour of Blind Bolted Moment Connections for Square HSS Columns. Ph.D. Thesis, McMaster University, Hamilton, ON, Canada, 1993. [Google Scholar]

- Mourad, S.; Korol, R.M.; Ghobarah, A. Design of Extended End-Plate Connections for Hollow Section Columns. Can. J. Civ. Eng. 1996, 23, 277–286. [Google Scholar] [CrossRef]

- Lindapter International. Type HB (Hollo-Bolt) Catalogue Pages. Available online: https://www.lindapterdistributor.com.au/wp-content/uploads/2020/11/Hollo-Bolt-Technical-DataUpdated.pdf (accessed on 3 March 2017).

- Blind Bolt Compay. Blind Bolt Installation and Removal Instructions. Available online: https://www.blindbolt.co.uk/wp-content/uploads/2022/07/BB_fitting_instructions_2020.pdf (accessed on 5 May 2018).

- Wang, W.; Li, M.; Chen, Y.; Jian, X. Cyclic behavior of endplate connections to tubular columns with novel slip-critical blind bolts. Eng. Struct. 2017, 148, 949–962. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Wang, Q.Y. Yield and ultimate strengths determination of a blind bolted endplate connection to square hollow section column. Eng. Struct. 2016, 111, 345–369. [Google Scholar] [CrossRef]

- Pokharel, T.; Goldsworthy, H.M.; Gad, E.F. Tensile behaviour of double headed anchored blind bolt in concrete filled square hollow section under cyclic loading. Constr. Build. Mater. 2019, 200, 146–158. [Google Scholar] [CrossRef]

- Yeomans, N.F. Rectangular Hollow Section Column Using Lindapter Hollobolt; Tubular Structures VIII, Choo and van der Vegte Balkema: Rotterdam, The Netherlands, 1998. [Google Scholar]

- Elghazouli, A.Y.; Málaga-Chuquitaype, C.; Castro, J.M. Experimental monotonic and cyclic behaviour of blind bolted angle connections. Eng. Struct. 2009, 31, 2540–2553. [Google Scholar] [CrossRef]

- Nakajima, K.; Suzuki, H.; Kawabe, Y. Experimental study on High strength One-sided bolted joints. In Proceedings of the Sixth International IABMAS Conference, Stresa, Italy, 8–12 July 2012. [Google Scholar]

- Agheshlui, H. Anchored Blind Bolted Connections within SHS Concrete Filled Columns. Aust. Earthq. Eng. Soc. 2011, 62, 378–390. [Google Scholar]

- Agheshlui, H.; Goldsworthy, H.; Gad, E.; Fernando, S. Tensile behaviour of anchored blind bolts in concrete filled square hollow sections. Mater. Struct. 2016, 49, 1511–1525. [Google Scholar] [CrossRef]

- Agheshlui, H.; Goldsworthy, H.; Gad, E. Tensile Behavior of Groups of Anchored Blind Bolts within Concrete-Filled Steel Square Hollow Sections. J. Struct. Eng. 2016, 142, 515–525. [Google Scholar] [CrossRef]

- Oktavianus, Y.; Chang, H.F.; Goldsworthy, H.; Gad, E. Component model for pull out beha- viour of headed anchored blind bolt within concrete filled circular hollow section. Eng. Struct. 2017, 148, 210–224. [Google Scholar] [CrossRef]

- Xu, W. Study on the Anchoring Performance of Novel One-Sided Bolt with Flip-Top Washer. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2019. [Google Scholar]

- Yue, Z.; Mei, L.; Jie, M.Q.; Hua, L.Z.; Jun, W.P.; Le, S.L. Yield line patterns of T-stubs connected by thread-fixed one-side bolts under tension. J. Constr. Steel. Res. 2020, 6, 105932. [Google Scholar]

- Gohari, S.; Sharifi, S.; Sharifishourabi, G.; Vrcelj, Z.; Abadi, R. Effect of temperature on crack initiation in gas formed structures. J. Mech. Sci. Technol. 2013, 27, 2745–3754. [Google Scholar] [CrossRef]

- Quesada, A.; Gauchia, A.; Álvarez-Caldas, C.; Román, J.L.S. Material Characterization for FEM Simulation of Sheet Metal Stamping Processes. Adv. Mech. Eng. 2014, 6, 167147. [Google Scholar] [CrossRef] [Green Version]

- JGJ 82—2011; Technical Specification for High Strength Bolt Connections of Steel Structures. China Architecture & Building Press: Beijing, China, 2011. (In Chinese)

- ASTM A370-18; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. American Society for Testing and Materials ASTM: Philadelphia, WC, USA, 2018.

- JGJ/T 101-2015; Specification for Seismic Test of Buildings. China Architecture & Building Press: Beijing, China, 2015. (In Chinese)

- GB 50017-2003; Code for Design of Steel Structures. China Planning Press: Beijing, China, 2003. (In Chinese)

| No. | Diameter of Bolt/mm | Thickness of Profiled Washer/mm | Height of Profiled Washer/mm | |

|---|---|---|---|---|

| M16 | F16-1 | 16 | 1.6 | 14.8 |

| F16-2 | 16 | 3.2 | 14.8 | |

| F16-3 | 16 | 4.8 | 14.8 | |

| M20 | F20-1 | 20 | 2.0 | 16.0 |

| F20-2 | 20 | 4.0 | 16.0 | |

| F20-3 | 20 | 6.0 | 16.0 | |

| M24 | F24-1 | 24 | 2.4 | 17.2 |

| F24-2 | 24 | 4.8 | 17.2 | |

| F24-3 | 24 | 7.2 | 17.2 | |

| Section | Thickness/mm | fy 1/MPa | fu 2/MPa | fu/fy 3 | δ 4/% | E5/105 Mpa |

|---|---|---|---|---|---|---|

| rectangle | 10 | 420.5 | 539.1 | 1.28 | 24.3 | 2.03 |

| rectangle | 20 | 424.3 | 545.1 | 1.28 | 23.1 | 2.06 |

| round | 12 | 710.2 | 864.5 | 1.22 | 25.3 | 1.95 |

| Label | Initial Stiffness N/m × 105 | Field Load/kN | Theoretical Yield Load/kN | Ultimate Capacity/kN | Theoretical Ultimate Capacity/kN |

|---|---|---|---|---|---|

| F16-1 | 273.23 | 92.05 | 111.50 | 115.06 | 135.73 |

| F16-2 | 321.37 | 95.58 | 111.50 | 122.10 | 135.73 |

| F16-3 | 329.65 | 95.67 | 111.50 | 124.95 | 135.73 |

| F20-1 | 238.65 | 71.71 | 174.00 | 91.85 | 211.80 |

| F20-2 | 448.57 | 169.62 | 174.00 | 214.95 | 211.80 |

| F20-3 | 478.17 | 173.06 | 174.00 | 217.23 | 211.80 |

| F24-1 | 275.68 | 87.82 | 250.70 | 118.37 | 305.17 |

| F24-2 | 446.18 | 170.15 | 250.70 | 213.36 | 305.17 |

| F24-3 | 443.10 | 216.02 | 250.70 | 289.95 | 305.17 |

| Parameters | Notation | Benchmark | Expansion |

|---|---|---|---|

| Washer thickness | e | 0.2 d0 | 0.1 d0, 0.3 d0 |

| Side wall height | h0 | 0.25 h1 | 0.1 h1, 0. 5 h1 |

| Friction coefficient | μ | 0.4 | 0.35, 0.5 |

| Upper contact surface size | s1 | 0.2 d0 | 0.1 d0, 0.3 d0 |

| Under contact surface size | s2 | 0.8 s1 | 0.6 s1, 1.0 s1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Mu, D.; Liu, Y.; Li, Z.; Yin, Q.; Chang, H. Anchor Behavior of One-Side Bolt with Flip-Top Collapsible Washer. Buildings 2023, 13, 1571. https://doi.org/10.3390/buildings13061571

Li L, Mu D, Liu Y, Li Z, Yin Q, Chang H. Anchor Behavior of One-Side Bolt with Flip-Top Collapsible Washer. Buildings. 2023; 13(6):1571. https://doi.org/10.3390/buildings13061571

Chicago/Turabian StyleLi, Lin, Dejun Mu, Yong Liu, Zhaowei Li, Qixiang Yin, and Hongfei Chang. 2023. "Anchor Behavior of One-Side Bolt with Flip-Top Collapsible Washer" Buildings 13, no. 6: 1571. https://doi.org/10.3390/buildings13061571

APA StyleLi, L., Mu, D., Liu, Y., Li, Z., Yin, Q., & Chang, H. (2023). Anchor Behavior of One-Side Bolt with Flip-Top Collapsible Washer. Buildings, 13(6), 1571. https://doi.org/10.3390/buildings13061571