Model and Simulation of Benefit Distribution of Collaborative Cooperation in the Supply Chain of General Contracting Projects

Abstract

:1. Introduction

2. Research Overview

2.1. Research on the Distribution of Engineering Benefits

2.2. Research on the Benefit Distribution of Supply Chain Cooperation

2.3. Research in Benefit Distribution Models

3. Basic Assumptions and Modeling

- The general contractor engineering supply chain is a consortium consisting of two parts: the general contractor and the subcontractors.

- The quality of products provided by the upstream supply chain of subcontractors is qualified, i.e., there will not be any problems with the quality of work due to material aspects.

- The Cobb–Douglas function [42,43] is used to express the bonus function given by the owner to the general contractor, i.e., . The expected bonus for the general contractor and the subcontractor is , where e1 represents the level of effort of the general contractor and e2 represents the level of effort of the subcontractor; α represents the general contractor’s level of contribution, and (1 − α) represents the level of contribution of the subcontractor. In the past two years, with the normalization of the new COVID-19 epidemic, the general contractor and subcontractors are subject to uncertainties such as epidemics and natural disasters in engineering construction, and the field of engineering construction has encountered challenges. Let the risk factor obey the standard normal distribution, i.e., .

- 4.

- The owner and the main contractor enter into a contract in the form of a fixed lump sum price plus bonus, i.e., ; the contract between the main contractor and the subcontractor, which is also a fixed lump sum price plus bonus incentive, is , where W is the total price of the benefits received by the main contractor at the end of the project, P is the total price of the benefits received by the subcontractor at the end of the project, ( is the fixed total price of the project contracted by the general contractor and subcontractors, β (0 < β < 1) is the bonus allocation coefficient of the general contractor, and 1 − β is the bonus allocation coefficient of the subcontractors.

- 5.

- The effort cost function paid by the general contractor in the construction of the project is , and the effort cost function paid by the subcontractor in the construction process is , where k1 represents the effort–cost coefficient of the general contractor and k2 represents the effort cost coefficient of the subcontractor.

- 6.

- Assume that the general contractor is risk-neutral in the cooperation process, while the subcontractor is risk-averse, i.e., the general contractor—as the general manager—is neither risky nor conservative in its decision, but the subcontractor—as a member of the project—will choose the riskier option when the expected benefits are the same, as it may bring them greater benefits. For a subcontractor, the cost of risk is , where represents the degree of risk preference of the subcontractor, and 0 ≤ f2 ≤ 1; f2 = 0 represents that the subcontractor is in a risk-neutral state, and f2 → 1 represents the increasing risk preference possessed by the subcontractor.

- 7.

- The final benefit to the general contractor is:

- 8.

- In the one-time cooperation, the Cobb–Douglas function is applied to obtain the optimal allocation share, optimal effort level, and optimal return of the general contractor and subcontractor and supply chain system as a whole under the egoistic decision-making mode and the collectivist decision-making mode, respectively. For the distribution of benefits during multiple cooperations, the effort level of one-time cooperation is used to calculate the conditions under which the two parties will still choose cooperation in the n + 1 stage so as to realize the continuation of the two parties from one-time cooperation to multiple cooperation.

4. Model Solving and Analysis

4.1. Egoistic Decision-Making Model (Model I)

4.2. Collectivist Decision-Making Model (Model II)

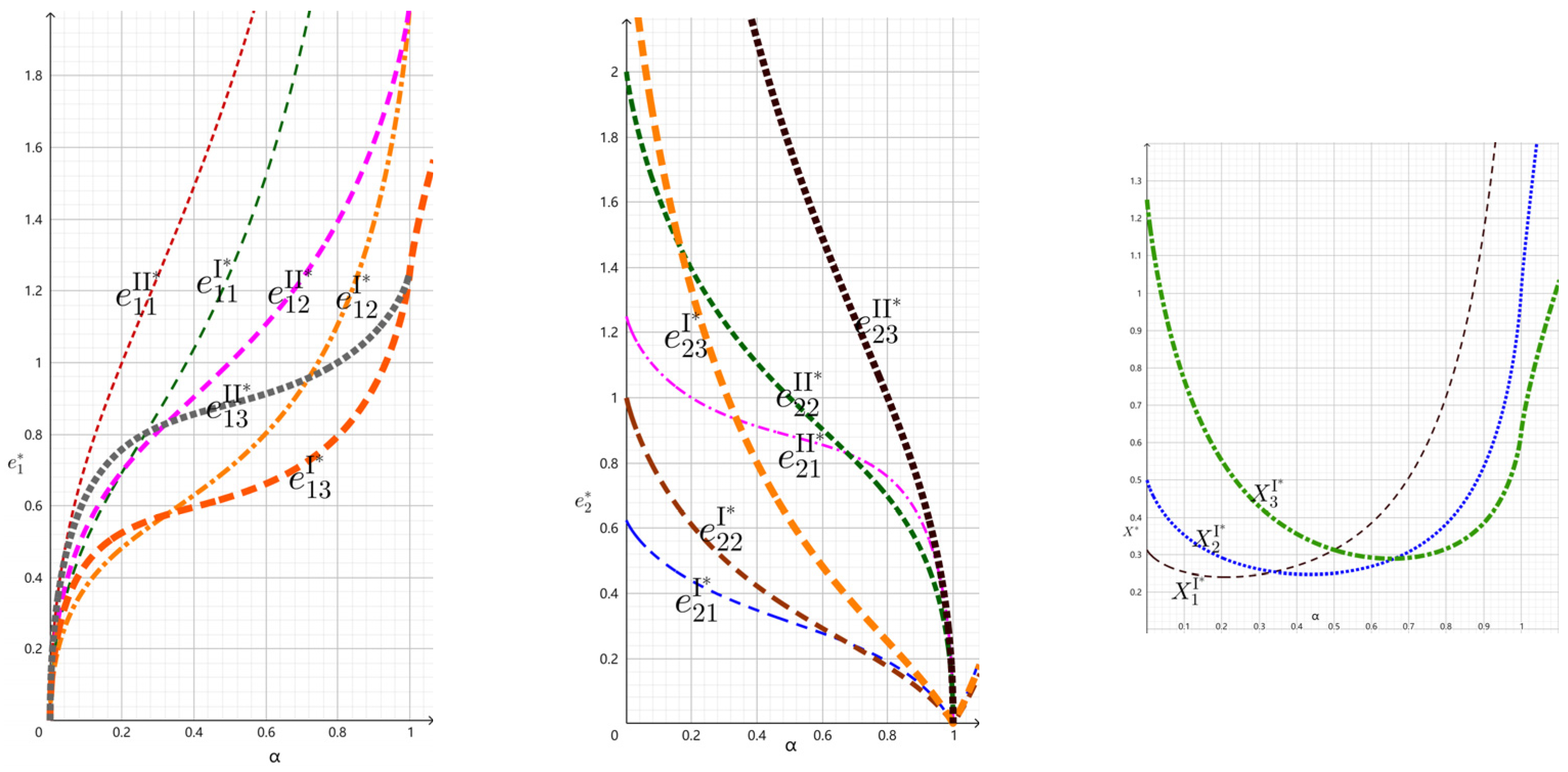

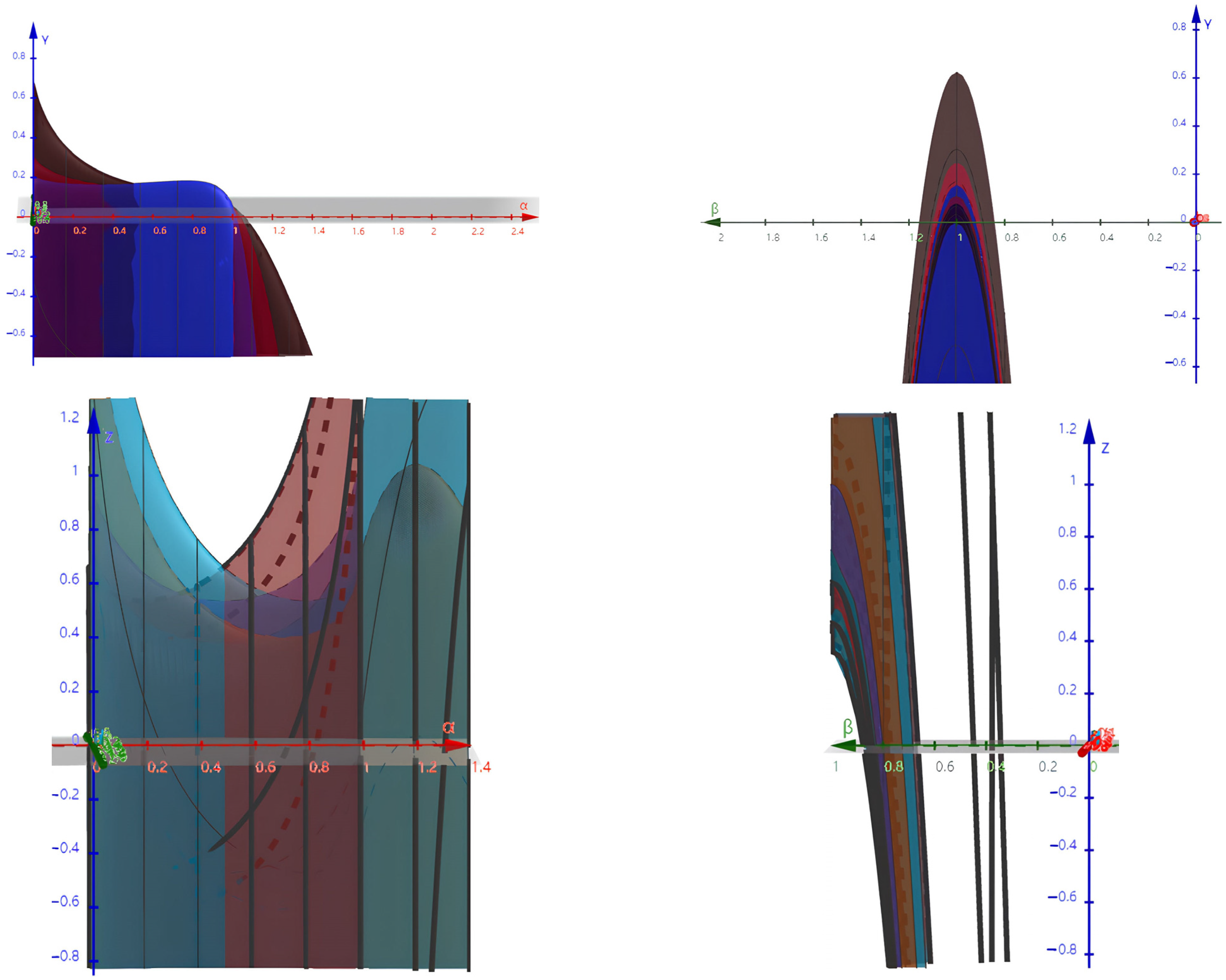

4.3. Numerical Analysis

5. Distribution of Benefits from Multiple Collaborations

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, E. Introduction to International Engineering Management; Tianjin University Press: Tianjin, China, 2005. [Google Scholar]

- Housing and Urban-Rural Construction, Development and Reform Commission. Measures for the Administration of General Contracting of Housing Construction and Municipal Infrastructure Projects. Ministry of Housing and Urban-Rural Development Website. 2019. Available online: https://www.gov.cn/zhengce/zhengceku/2019-12/31/content_5465928.htm. (accessed on 9 July 2023).

- Zhang, B.B. Analysis of structural model of green supply chain management of prefabricated buildings based on EPC model. Jushe 2022, 4, 142–144. [Google Scholar]

- Wu, Q.; Ren, H.; Shi, S.; Su, Y.; Lu, J.; Li, Q. Research on benefit distribution mode of regional integrated energy system considering both direct and indirect benefits. Energy Rep. 2023, 9, 626–633. [Google Scholar] [CrossRef]

- Huang, M.P.; He, R.H. Research on multilateral incentive mechanism of multi-level engineering supply chain. J. Eng. Manag. 2023, 37, 1–6. [Google Scholar] [CrossRef]

- Zhong, Z.; Jia, F.; Long, W.; Chen, K.Z. Risk sharing, benefit distribution and cooperation longevity: Sustainable development of dairy farmer cooperatives in China. Int. J. Agric. Sustain. 2022, 20, 982–997. [Google Scholar] [CrossRef]

- Bai, Z.Y. Profit allocation model of general contracting engineering construction considering investment efforts. J. Eng. Manag. 2016, 30, 120–124. [Google Scholar] [CrossRef]

- Guan, B.H. Research on profit distribution between general contractors and subcontractors of engineering projects. J. Railw. Eng. 2010, 2703, 123–127. [Google Scholar]

- Sun, G.; Zhang, W.; Dong, J.; Wan, S.; Feng, J. Behavioral Decision-Making of Key Stakeholders in Public-Private Partnerships: A Hybrid Method and Benefit Distribution Study. Comput. Model. Eng. Sci. 2023, 136, 2895–2934. [Google Scholar] [CrossRef]

- Ren, K.; Liu, Y.M.; Zhang, L.Y. Research on profit distribution of total subcontracting in railway EPC projects. J. Eng. Manag. 2020, 34, 131–136. [Google Scholar] [CrossRef]

- Lv, P.; Zhang, Y.; Mu, F.F. A study on the distribution of supply chain benefits between general contractors and subcontractors based on the improved Shapley value method. Oper. Res. Manag. 2012, 2106, 211–216. [Google Scholar]

- Shi, Q.Q.; Zhu, J.B.; Sheng, Z.H. Research on benefit distribution of collaborative cooperation in major engineering supply chains. China Manag. Sci. 2017, 2505, 42–51. [Google Scholar] [CrossRef]

- Feng, J.C.; Wang, T.; Wang, L.B. Multi-level and multi-stage benefit distribution mechanism of collaborative construction projects based on building information model—Design procurement construction model scenario. Sci. Technol. Manag. Res. 2021, 41, 194–203. [Google Scholar]

- Wang, L.; Peng, L.; Meng, Q.L. Construction of profit game and distribution mechanism for three-level supply chain cooperation. Oper. Res. Manag. 2010, 19, 59–65. [Google Scholar]

- Zhong, C.B.; Wei, X.P.; Nie, M.L.; Jiang, D.Y. A two-stage method for distributing supply chain benefits considering risk—Orthogonal projection entropy method. China Manag. Sci. 2010, 1802, 68–74. [Google Scholar] [CrossRef]

- Han, T.; Li, D.F. Shapley value method for benefit distribution of cooperative enterprises with intuitionistic fuzzy coalition. Syst. Sci. Math. 2016, 3605, 719–727. [Google Scholar]

- Zou, Y. Benefit allocation mechanism of VMI&TPL model based on maximum entropy value method. J. Syst. Sci. 2018, 26, 100–104. [Google Scholar]

- Mahjoub, S.; Hennet, J.-C. A Cooperative Game Based Approach for Resource Pooling and Profit Sharing in Supply Chains. IFAC Proc. Vol. 2012, 45, 554–559. [Google Scholar] [CrossRef]

- Chen, C.-L.; Wang, B.-W.; Lee, W.-C.; Huang, H.-P. The optimal profit distribution problem for a supply chain network. Comput. Aided Chem. Eng. 2003, 15, 422–427. [Google Scholar] [CrossRef]

- Xi, Y.H.; Cheng, Y.Y. Research on benefit distribution mechanism based on supply chain partnership. Stat. Decis. Mak. 2019, 35, 59–63. [Google Scholar] [CrossRef]

- Kumoi, Y.; Matsubayashi, N. Vertical integration with endogenous contract leadership: Stability and fair profit allocation. Eur. J. Oper. Res. 2014, 238, 221–232. [Google Scholar] [CrossRef]

- Liao, R.; Li, S.; Wu, C.; Zhang, X.; Jiang, C.; Li, R. Modeling and simulation of extended ant colony labor division for benefit distribution of the all-for-one tourism supply chain with front and back decoupling. Front. Bioeng. Biotechnol. 2023, 11, 985550. [Google Scholar] [CrossRef]

- Liu, J.; Bao, H. Research on interest coordination model of wind power supply chain with energy storage participation. J. Energy Storage 2022, 49, 104107. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, Z.; Li, X. Research on the Coordination of Quality Behavior of Supply 3 Chain of E-Commerce Platform under C2B Model of High-Grade E-Commerce Based on Differential Game. J. Theor. Appl. Electron. Commer. Res. 2022, 17, 1409–1430. [Google Scholar] [CrossRef]

- Raza, S.A. Supply chain coordination under a revenue-sharing contract with corporate social responsibility and partial demand information. Int. J. Prod. Econ. 2018, 205, 1–14. [Google Scholar] [CrossRef]

- Liu, B.; Yao, K.; Wang, F.; Chi, X.; Gong, Y. Benefit Sharing in Hydropower Development: A Model Using Game Theory and Cost–Benefit Analysis. Water 2022, 14, 1208. [Google Scholar] [CrossRef]

- Ryu, C.S. Review of Revenue Sharing Contract: Evaluating its Role for Supply Chain Coordination. J. Ind. Distrib. Bus. 2022, 13, 1–12. [Google Scholar]

- Ryu, C.S. Investigation of Impact of Revenue Sharing Contract on Performance of Two-Stage Supply Chain System. J. Distrib. Sci. 2022, 20, 125–135. [Google Scholar] [CrossRef]

- Liang, P.; Sima, M.; Huang, Y.; Sun, X. Assessing the coordinated revenue-sharing contract of China’s farmer-supermarket direct-purchase model. Int. Food Agribus. Manag. Rev. 2022, 25, 229–243. [Google Scholar] [CrossRef]

- Chen, J.; Shi, J.; Liu, J. Capacity Sharing Strategy with Sustainable Revenue-Sharing Contracts. Technol. Econ. Dev. Econ. 2022, 28, 76–100. [Google Scholar] [CrossRef]

- Heydari, J.; Govindan, K.; Nasab, H.R.E.; Taleizadeh, A.A. Coordination by quantity flexibility contract in a two-echelon supply chain system: Effect of outsourcing decisions. Int. J. Prod. Econ. 2020, 225, 107586. [Google Scholar] [CrossRef]

- Luo, C.L. Supply chain coordination by risk-averse retailers based on repurchase contracts. Econ. Math. 2010, 27, 7. [Google Scholar]

- Xiao, Q.; Ma, S.H. Supply chain coordination mechanism considering information prediction cost under CVaR criterion. Syst. Eng. Theory Pract. 2014, 34, 7. [Google Scholar]

- Arizono, I.; Takemoto, Y. Collaborative bargaining solution in tandem supply chain through cooperative game theoretical approach. Rairo-Op. Res. 2022, 56, 2581–2593. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Z.; Baležentis, T. Benefit distribution in shared private charging pile projects based on modified Shapley value. Energy 2023, 263, 125720. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, Z.; Yu, X.; Chen, J.; Li, P.; Wang, Z. Research on Profit Allocation of Agricultural Products Co-Delivery Based on Modified Interval Shapley Value. Sustainability 2023, 15, 3303. [Google Scholar] [CrossRef]

- Tan, Z.F.; Yu, C.; Li, L.; Jiang, H.Y.; Cai, C.K. Optimization model for joint energy saving and SO2 emission reduction benefit distribution between power generation side and power supply side. Syst. Eng. Theory Pract. 2011, 31, 9. [Google Scholar]

- Wang, L.; Li, Y.; Wang, Y.; Guo, J.; Xia, Q.; Tu, Y.; Nie, P. Compensation benefits allocation and stability evaluation of cascade hydropower stations based on Variation Coefficient-Shapley Value Method. J. Hydrol. 2021, 599, 126277. [Google Scholar] [CrossRef]

- Li, L.; Liu, S.H.; Fan, F.F. A dynamic benefit allocation method for collaborative innovation projects. Stat. Decis. Mak. 2017, 13, 59–62. [Google Scholar] [CrossRef]

- Ngo, H.T.; Nguyen, T.H.; Nguyen, H.A.; Mo, V.N.Q.; Le, Q.L.; Vu, T.A.; Mach, A.; Thai, T.T. Model and simulation of tracking motion for accurate welding using a universal Cobot. Int. J. Comput. App. Technol. 2023, 71, 33–42. [Google Scholar] [CrossRef]

- Wang, H.; Kan, X.; Jiang, X. Imbalance and balance: The distribution of land value-added benefits in postmining land use. Extr. Ind. Soc. 2023, 13, 101220. [Google Scholar] [CrossRef]

- Wang, X.S.; Hu, H.; Liu, X.X.; An, X.J. Benefit allocation of shared contractual water conservation management based on bargaining model. Syst. Eng. Theory Pract. 2020, 40, 9. [Google Scholar]

- Zhang, S.Y.; Li, X.J.; Wu, Z.Y. A pilot study on the allocation of strategic alliances. App. Syst. Eng. Theory Methods 2002, 11, 5. [Google Scholar]

- Sun, L.L.; Zhao, Y.; Liu, L.J. Research on benefit allocation of whole process engineering consulting based on modified SHAPLEY value. J. Eng. Manag. 2022, 36, 41–45. [Google Scholar] [CrossRef]

- Liu, Z.C.; Chu, J.Y.; Ma, D.X.; Du, J.J. Research on benefit distribution of whole process engineering consulting consortium based on asymmetric Nash negotiation model. J. North China Univ. Technol. (Nat. Sci. Ed.) 2022, 44, 46–51+67. [Google Scholar]

- Wu, C.F.; Lin, S.C.; Xu, C.F. Research on pricing and coordination mechanism of dual-channel green supply chain under retailers’ fairness concern. Econ. Manag. Rev. 2022, 38, 112–123. [Google Scholar] [CrossRef]

- Yang, W. Research on Stakeholder Benefit Distribution of Hospital Projects under IPD Mode; Shandong Jianzhu University: Jinan, China, 2021. [Google Scholar]

- Ma, D.Q.; Hu, J.S. A dynamic synergistic strategy for quality improvement inputs and marketing efforts considering the delay phenomenon. Op. Res. Manag. 2021, 30, 181–190. [Google Scholar]

- Fan, B.L.; Zhong, Z.H.; Luo, Y.; Liu, J.C. Improved Shapley value based on triangular fuzzy number based on the excess contribution of intellectuals and its application in the distribution of cooperative benefits of flower supply chain alliance. Fuzzy Syst. Math. 2023, 37, 98–108. [Google Scholar]

- Wan, F.; Wang, Y.; Zhou, X.; Zheng, X.; Wu, J.; Xiao, L. Study on Balanced Allocation of Water Resources in the Yellow River Basin Based on Water Benefit Sharing. Sustainability 2023, 15, 559. [Google Scholar] [CrossRef]

- Hoenig, L.C.; Pliskin, R.; De Dreu, C.K.W. Political ideology and moral dilemmas in public good provision. Sci. Rep. 2023, 13, 2519. [Google Scholar] [CrossRef]

- Xu, Z.; Cao, J.; Xu, Y.; Sun, Y.; Zhang, X. Decision-Making Mechanism of Cooperative Innovation between Clients and Service Providers Based on Evolutionary Game Theory. Discret. Dyn. Nat. Soc. 2022, 2022, 8774462. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, Y.; Jin, X.; Zhao, N.; Sun, J. Risk allocation and benefit distribution of PPP projects for construction waste recycling: A case study of China. Eng. Constr. Arch. Manag. 2022, ahead-of-print. [Google Scholar] [CrossRef]

- Baruk, A.I.; Grzesiak, M. Benefits Achieved by Energy Suppliers through Cooperation with Individual Recipients and Their Readiness for This Cooperation. Energies 2022, 15, 3843. [Google Scholar] [CrossRef]

| Decision Variables | Egoistic Decision Making | Collectivist Decision-Making |

|---|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Gao, W. Model and Simulation of Benefit Distribution of Collaborative Cooperation in the Supply Chain of General Contracting Projects. Buildings 2023, 13, 1788. https://doi.org/10.3390/buildings13071788

Wang D, Gao W. Model and Simulation of Benefit Distribution of Collaborative Cooperation in the Supply Chain of General Contracting Projects. Buildings. 2023; 13(7):1788. https://doi.org/10.3390/buildings13071788

Chicago/Turabian StyleWang, Dan, and Wenwen Gao. 2023. "Model and Simulation of Benefit Distribution of Collaborative Cooperation in the Supply Chain of General Contracting Projects" Buildings 13, no. 7: 1788. https://doi.org/10.3390/buildings13071788

APA StyleWang, D., & Gao, W. (2023). Model and Simulation of Benefit Distribution of Collaborative Cooperation in the Supply Chain of General Contracting Projects. Buildings, 13(7), 1788. https://doi.org/10.3390/buildings13071788