Abstract

In the European Union, more than 20% of residential buildings were constructed prior to 1945 and are approaching the end of their projected lifespan. This necessitates renovations or demolitions of these structures. A study was conducted to analyze the quantity of waste generated during the dismantling of a representative building from that era. Construction waste is produced during the building process and its disposal can be costly. Sustainable material engineering offers a solution by promoting the reuse of waste materials. When designing new products, manufacturers should consider using waste materials and ensure they have an extended lifespan, efficient life cycle management, and sustainable consumption. A study has shown that researchers are currently exploring the potential use of waste steel, bricks, wood, and glass in composite materials. Direct reuse of waste in the construction industry has also been observed. However, users’ preferences show that while environmental concerns are important, good quality and price are still the primary factors that drive consumer demand. Therefore, materials made from waste materials must demonstrate excellent parameters to gain consumer acceptance. Education initiatives such as green building certifications and education programs for construction professionals and the general public can help promote sustainable practices. Despite progress made in sustainable development, there is still a need for further education to encourage the adoption of sustainable practices.

1. Introduction

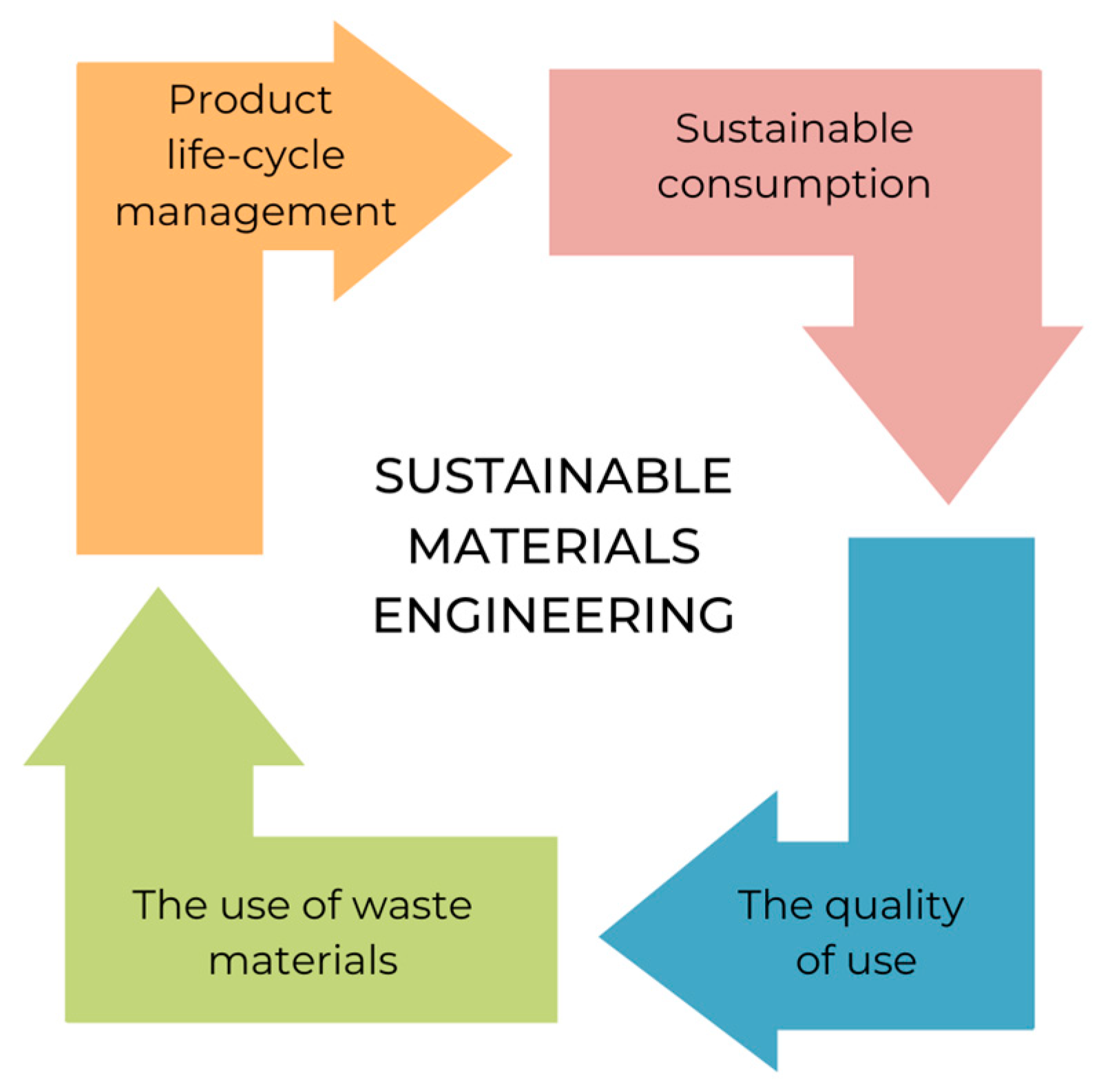

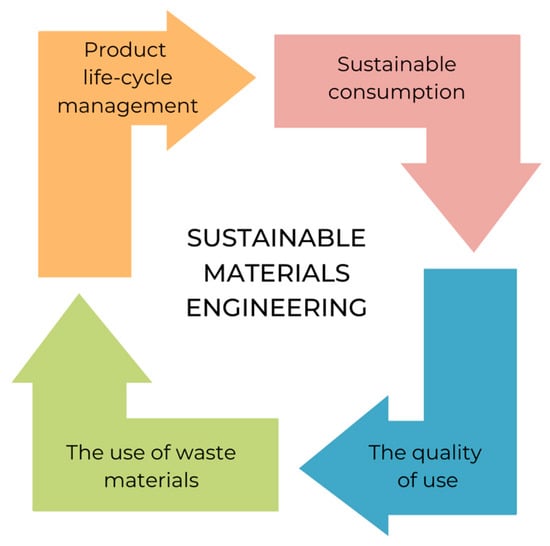

The construction industry is considered the key to achieving the goals of sustainable development [1]. The rapid economic development we have seen in recent years forces us to reflect on the costs and losses incurred by the environment. Sustainable development is the idea of socio-economic development, which consists of meeting the needs of modern society without limiting the development opportunities of future generations. According to Lean’s conceptual model [2], parallel development of the economy, society, and environment is assumed. The 2030 Agenda [3] sets out a universal blueprint for world development, defining a model of sustainable development at a global level. The seventeen goals defined therein must be achieved by 2030. In order to accomplish this task, cooperation is needed on many levels, in various fields. Construction is an extremely broad concept, but it is worth taking a closer look at the materials used in it. The model shown in Figure 1 describes the engineering of sustainable materials engineering as an interdependence of sustainable consumption, use of waste materials, quality of use, and life cycle management.

Figure 1.

Conceptual model for sustainable materials engineering.

The use of waste materials in the production of new products, is not only beneficial to the environment from the point of view of waste reduction, but is also a way to ensure significant cost savings. The raw material obtained as a by-product of industrial processes can be successfully used in construction materials.

An important aspect is the proper management of the product life cycle, understood as the period from the concept phase through manufacturing, distribution and operation, to decommissioning. In the view of a sustainable approach, it is desirable to keep a given material on the market for as long as possible. This minimizes the rapid substitution of a product with a new product. In addition, proper life-cycle management of a product should take into account many different aspects, including raw material management, recycling and remanufacturing, consumer education, and the application of appropriate standards and regulations to ensure sustainability.

In the sustainable materials engineering model, the user’s point of view is the last but an extremely important aspect. Users influence the sustainability of production through their purchasing decisions and quality preferences. In order to test the preferences of young people, a survey was conducted using an online platform. The questions presented to the respondents are shown in Figure 2.

Figure 2.

Question asked in the survey.

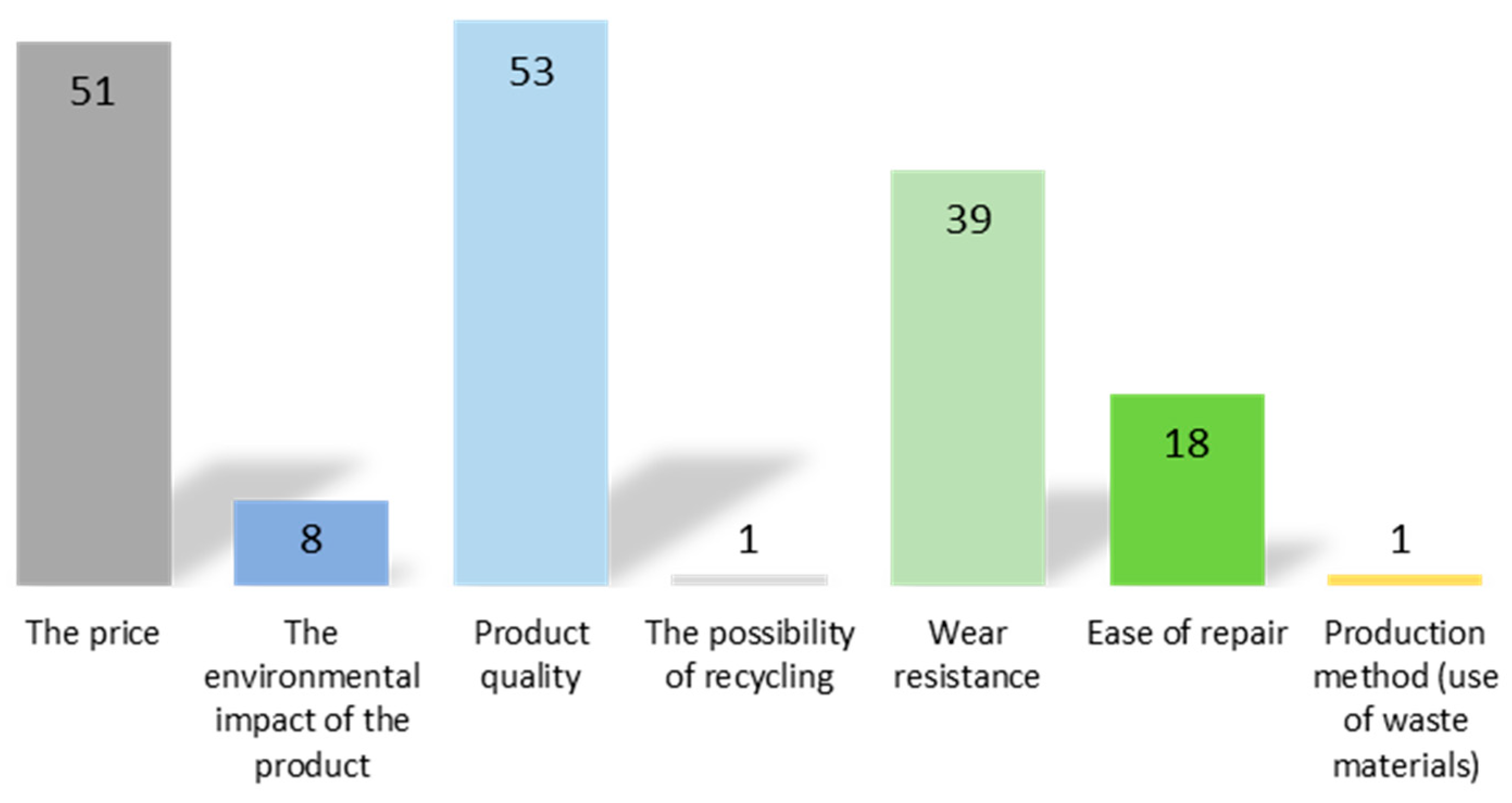

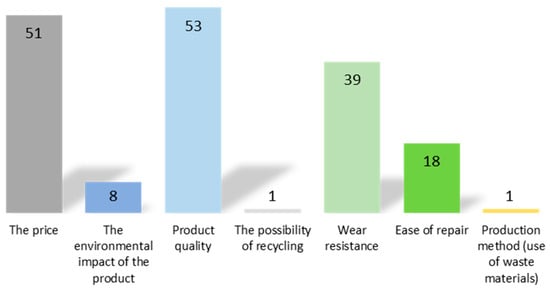

The question was multiple choice and open-ended. Respondents were also able to provide other reasons for their choice. The survey was conducted on a group of 65 people. These were 19–25-year-olds with secondary and tertiary education. All respondents are involved in the construction industry on a daily basis. Figure 3 shows the results obtained, according to the order of the multiple-choice answers given.

Figure 3.

Consumer preferences in purchasing construction materials.

The analysis shows that as many as 53 (81.5%) respondents are guided by the quality of the product. The price of the product, as indicated by 51 people, is in second place. Therefore, the quality of use, especially its durability, resistance to wear and tear and ease of repair, are key parameters for sustainable material engineering. Two people indicated additional factors that guide them when purchasing building materials. These were product availability and the opinion of other customers. Surprisingly, only one person indicated the parameter of recyclability and the use of waste materials in the production of the product. The person who paid attention to the production method also ticked the option of price and product quality. This shows that for a consumer to pay attention to the environmental performance of a product, it has to be cheap and good. The environmental aspect alone is not enough. Taking into account the requirements of the users, it will be possible to create products that meet their needs while being more environmentally and socially friendly. It is therefore important for engineers to focus not only on the technical aspects of production but also on the needs and preferences of users.

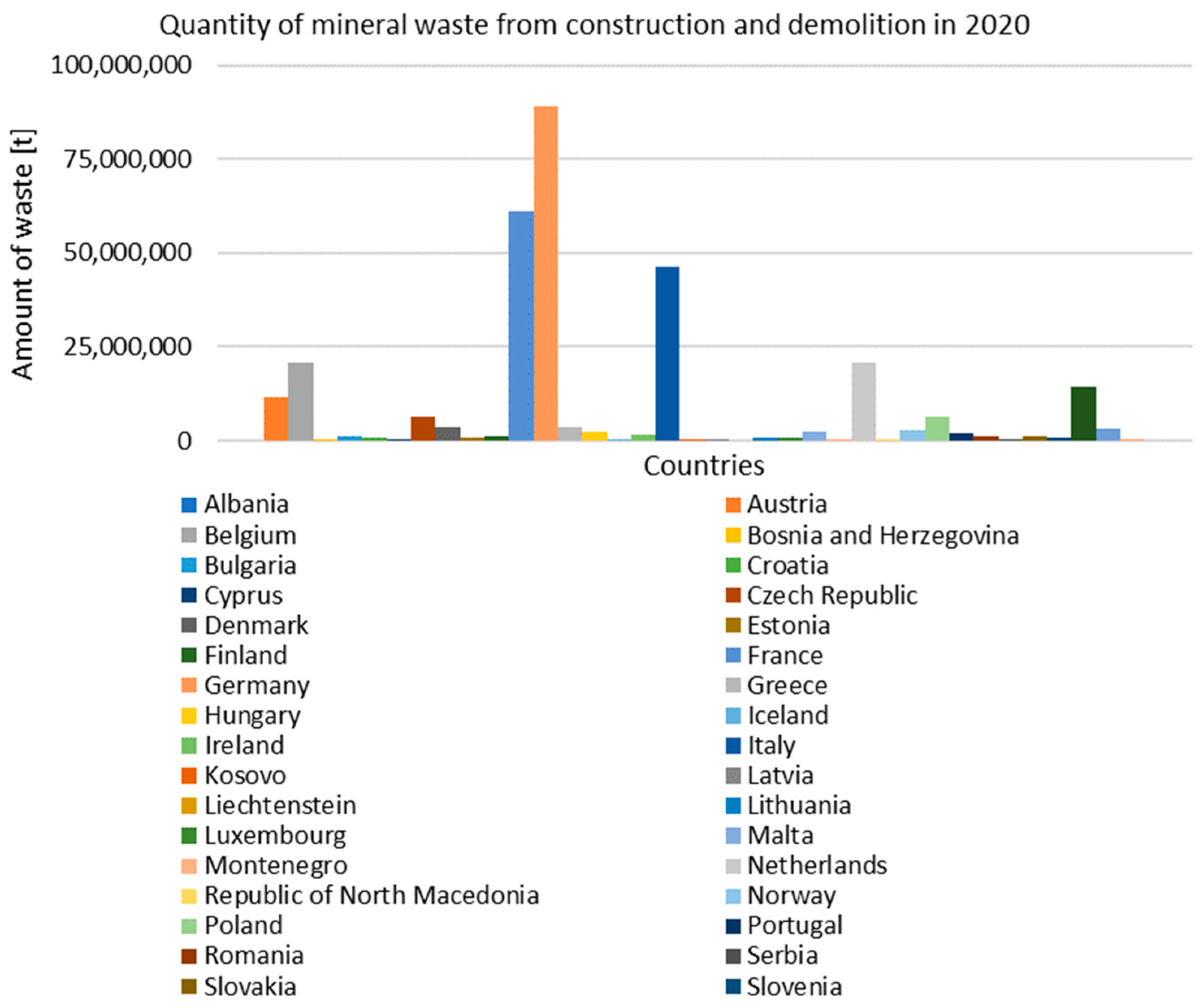

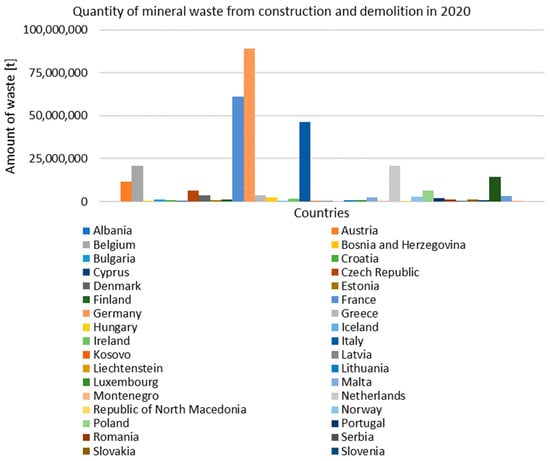

Rapid urbanization contributes to generate a huge amount of waste from construction and the demolition of buildings. Based on [4] statistics, the scale of the construction waste problem can be determined. The graph in Figure 4 shows the amount of waste from construction and the demolition of facilities in each European country in 2020.

Figure 4.

Quantity of mineral waste from construction and demolition in 2020 [4].

The literature [5] reports that China alone generates approximately 300 million tons of construction waste during construction, renovation, and demolition of facilities. Most of it ends up in landfills and pollutes the environment. The authors of the publication also point out that by recycling construction waste, natural resources can be conserved and the carbon footprint can be reduced.

To achieve the goals of sustainable materials engineering, it is necessary to look for a way to extend the life of a material. One way is to repair components, and when a material is no longer suitable for further use it becomes od waste. Then, it would be necessary to find another use for it. Scientists around the world are trying to find a solution.

2. The Problems of Old Residential Buildings

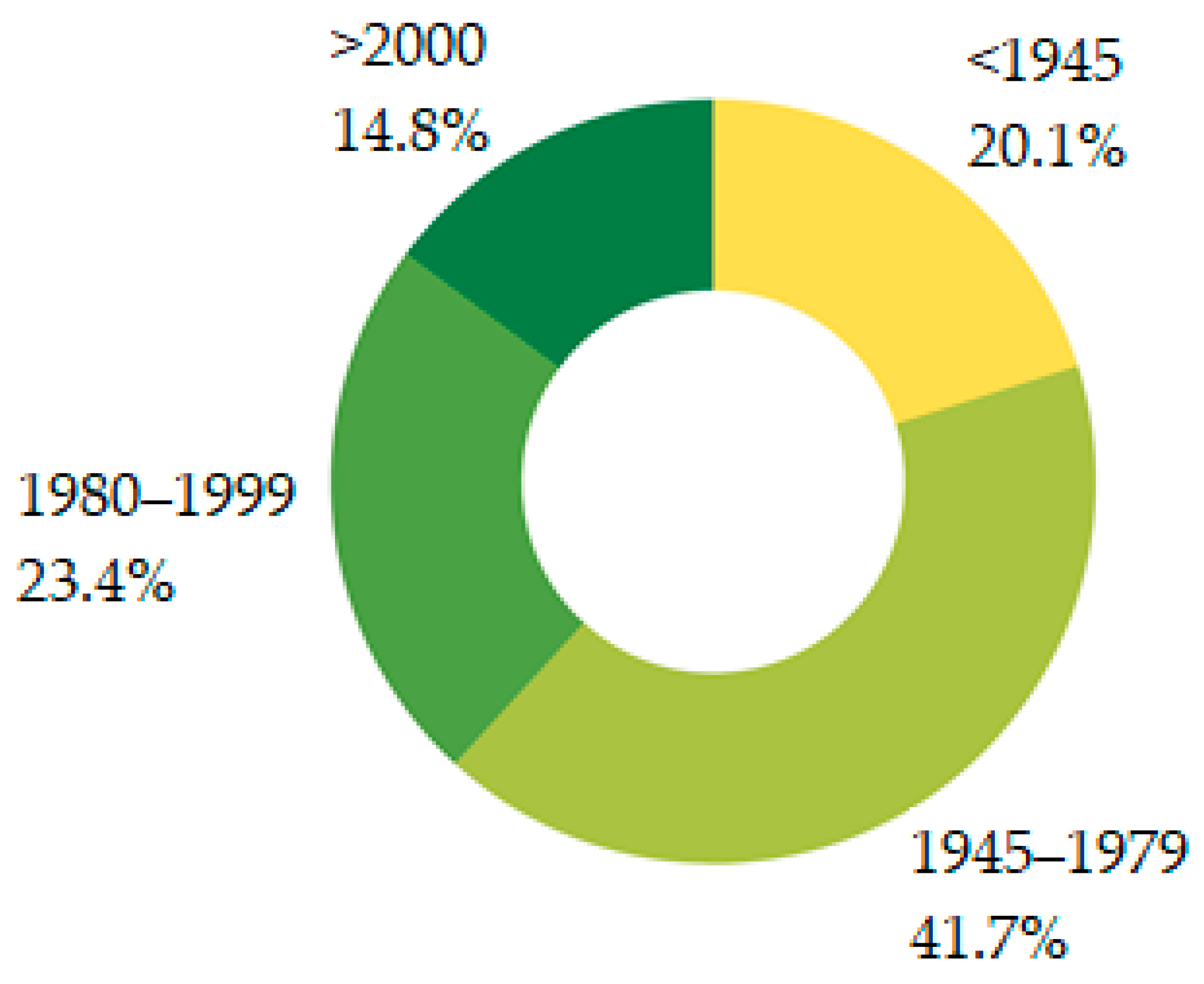

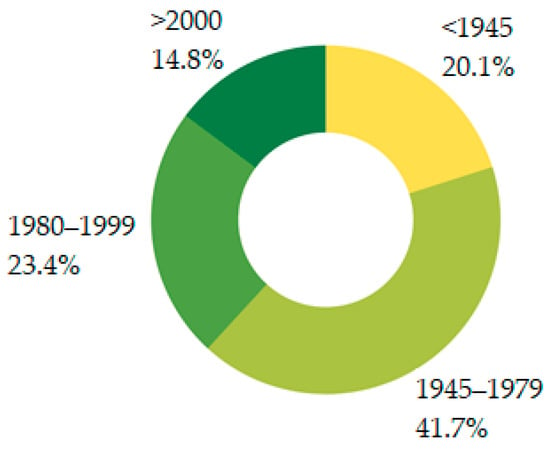

Available data [6] say that in the European Union, countries have more than 20% of their residential houses which were built before 1945. In contrast, as many as 41% of buildings were built between 1945 and 1979. Figure 5 shows the percentage distribution of the number of buildings built by time interval.

Figure 5.

Percentage distribution of the number of buildings built in the intervals [6].

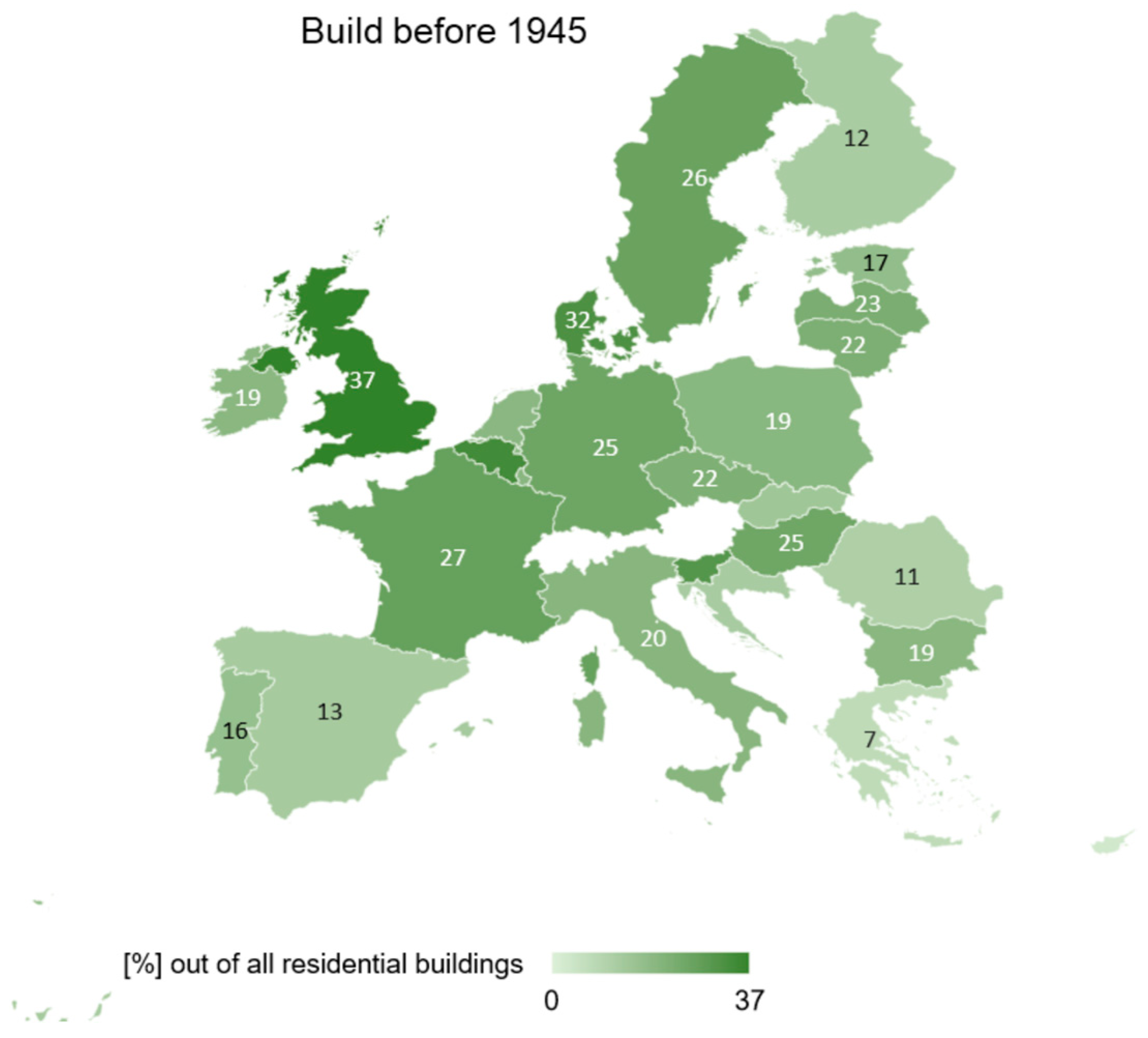

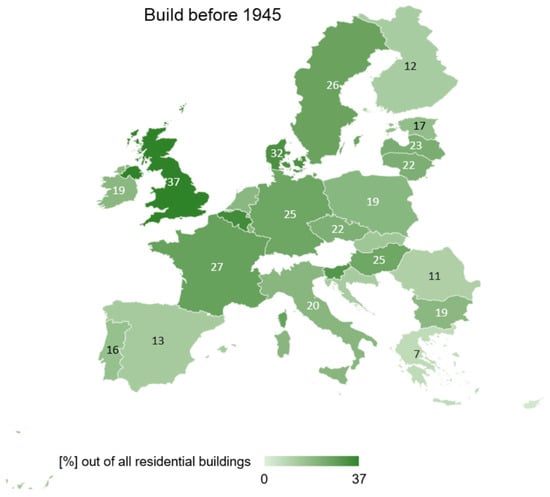

Considering the technical lifespan of traditionally built buildings to be 50–100 years, as many as 61.8% of buildings are reaching the end of their expected lifespan. This shows how much construction waste will have to be faced in the near future. It should also be emphasized that the problem will intensify as the development market continues to grow. Recently, there has been a trend of reducing the size of households. This is related to the increasing number of people living alone and lower fertility rates in families. Such behavior produces an increased demand for new places to live. The emergence of new trends in the market and amenities associated with new technologies also contributes to the construction of new facilities. Demand for new housing can have a significant impact on shortening the life of existing buildings and replacing them with new, more desirable ones. The percentage distribution of residential buildings built before 1945 in the EU is shown in Figure 6, illustrating the scale of the problem.

Figure 6.

Percentage distribution of residential buildings built before 1945 in relation to all residential buildings in EU countries [6].

The buildings erected immediately after World War II mainly used wood, bricks, ceramics, and steel. Today, these buildings require structural modernization. During this process, some elements either repaired or replaced, become waste. Examples of the amount of waste generated from house demolition are shown in Table 1 below.

Table 1.

The amount of construction waste generated during the demolition of the building.

The basis for the waste calculation was a multi-family building built in the pre-war years, and the plan and cross-section are presented in Figure 6. It has a basement and one above-ground floor with a partially usable attic. The total building area in the plan was 187.5 m2 and the usable area was 284.3 m2. The foundations are brick footings with a width of approximately 65 cm. The exterior walls are 50 cm thick, and the interior walls are made of 25- and 12.5 cm-thick bricks. A wooden ceiling of 25 × 20 cm beams is supported on the external walls. This ceiling is only present over the first floor. Above the basement, the building has a Klein-type ceramic ceiling with steel beams 220 mm thick. The roof is covered with ceramic plain tile. In addition, the floor of the first floor and attic, as well as the ceiling, is finished with a 2.5 cm-thick board. The presented object is a representative example of a pre-war residential building. The calculation results obtained are presented in tons to better illustrate the scale of the problem of construction waste generated during the demolition of the building. Under CERAMICS, ceramic elements such as clay tile, solid bricks used in walls, chimneys, and foundations were included. STEEL includes waste in the form of pipes, gutters, flashing, and steel I-beams. WOOD comes from roof construction, ceilings, door and window frames, wooden doors, flooring and soffit, and stairs. GLASS is waste that comes from windows.

The data obtained show the scale of the problem that the coming generations will have to face. On average, a facility with a floor area of 200 m2 will generate, respectively: 338 tons of ceramics, 3.6 tons of steel, 11 tons of wood, and 0.7 tons of glass.

Based on the available price list of the Utilities Company [7], the price of disposal of the demolition materials was calculated. The amount, shown in Table 2, applies only to the export of materials. The price of steel disposal was assumed as a negative value, due to the possibility of selling it to a scrap yard.

Table 2.

The amount spent on the disposal of a facility with a floor area of 200 m2, based on [7].

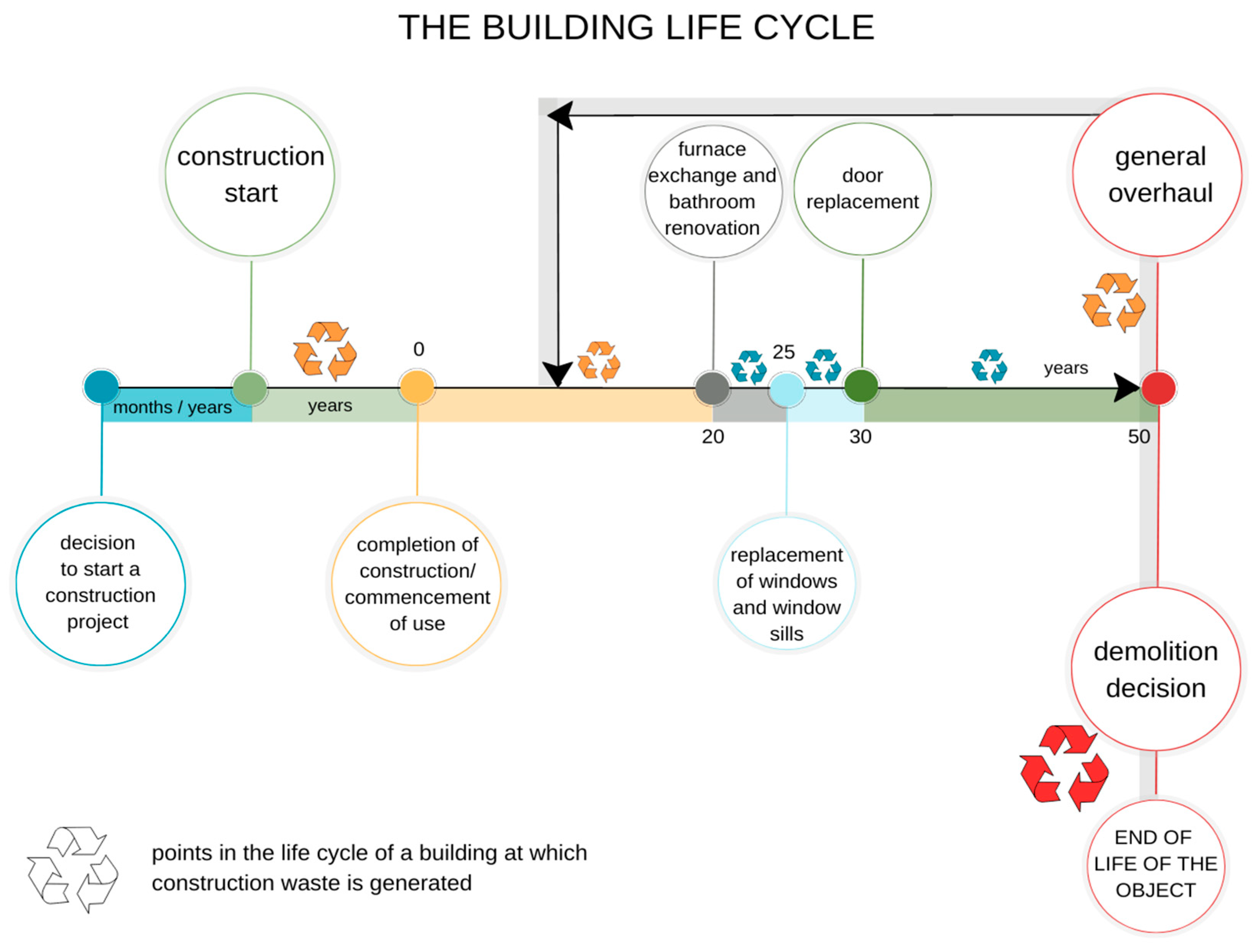

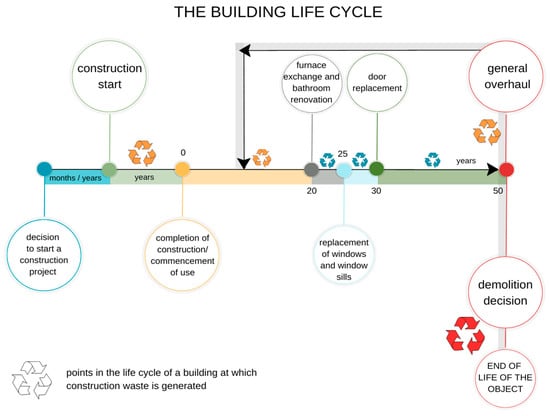

The situation presented above refers to the complete demolition of the facility, and it should also be remembered that a number of repairs need to be made during the 100-year service life. The article [8] shows the periods when individual components need to be replaced every:

- -

- 5 years it is recommended to paint the walls, ceiling, and windows.

- -

- 10 years it is recommended to paint the exterior doors.

- -

- 15 years it is recommended to paint the interior doors.

- -

- 20 years it is recommended to replace the stove and renovate the bathroom.

- -

- 25 years, it is recommended to replace windows and window sills, as well as to paint and maintain the facade and varnish the floor.

- -

- 30 it is recommended to replace the doors.

- -

- 50 years, it is recommended to replace the heating system, electrical system, plumbing system, replace guttering, roofing, and floor tiles (general renovation).

Renovation repairs also involve the production of waste materials such as wood from replacement windows or doors, ceramics, or steel. Thus, during the entire life cycle of the facility shown in Figure 7, there is generation of construction waste.

Figure 7.

The building life cycle, based on [8].

At the very beginning of the construction process, waste is generated as a result of construction. These include packaging from material deliveries or piles of paper from technical documentation. Waste from finishing work and hazardous waste, such as chemicals, paints, and varnishes, can also be found on the construction site. In the life cycle of a facility, there comes a point when property owners must face the choice of whether it is profitable to repair or demolish the facility. Consultation with a licensed civil engineer is recommended to make the decision.

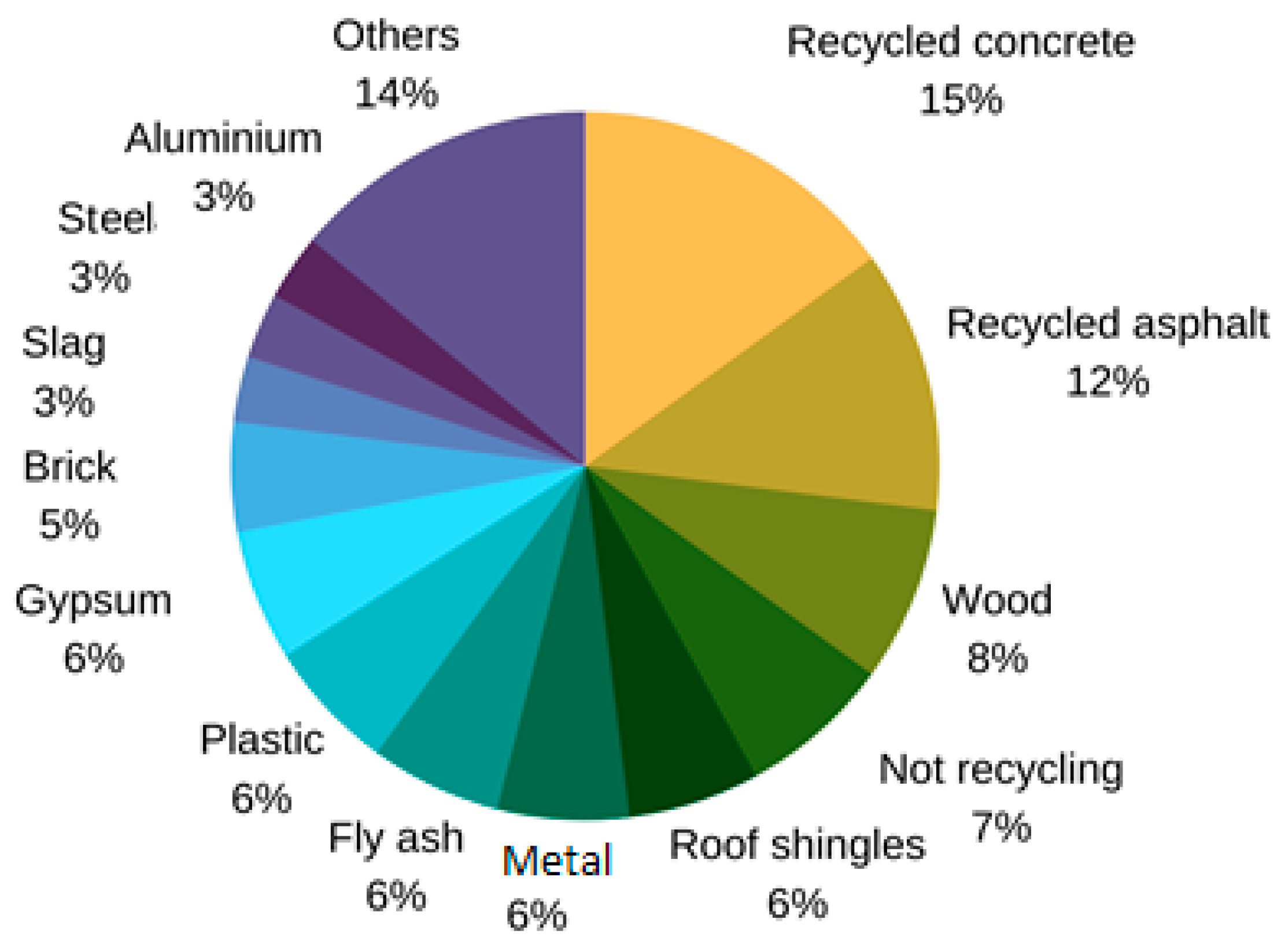

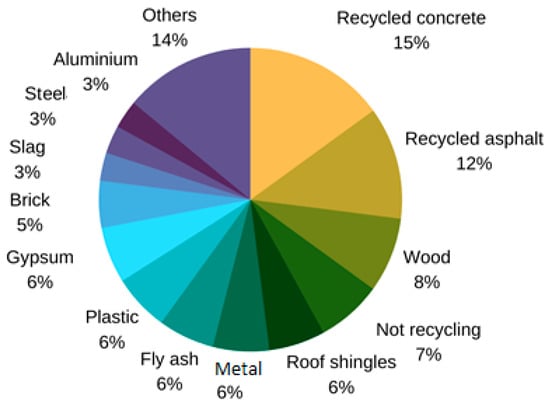

Construction and demolition waste accounts for as much as 40% of municipal solid waste, 54% of which is landfilled in Europe. Only 20–30% of it is recycled or reused. In the chart below (Figure 8) [9], it can be seen that a significant portion of recycled construction waste is concrete and asphalt. Next is wood, which makes up 8% of all materials. In contrast, as much as 7% of waste is not recycled.

Figure 8.

Percentage distribution of construction waste recycling [9].

Johny Bolden et al. [9] also listed reasons for not using recycled materials. Cost was indicated as the first. Education, especially environmental aspects was the next reason. The quality of the materials was indicated in only 5th place and accounted for approximately 10%. The remaining factors are contamination, permitting, separation, market, equipment, and storage. The availability problem is only 2%. Reasons were also given for why companies use waste materials. The most important of these is to reduce waste in landfills (approximately 46%), followed by quality (approximately 30%), and cost (approximately 23%). These figures show that many companies are unaware of the availability, quality of workmanship and cost, and, above all, the environmental benefits, in using recycled materials. It is therefore necessary to bring the worlds of science and industry together and better educate users, while developing composites using waste materials. Another reason why demolition materials are not widely used is the lack of regulations and standards for demolition materials. The lack of clear and unambiguous regulations puts off many potential investors. The preferences of the users themselves should not be forgotten either.

3. Direct Use of Waste Demolition Materials

Direct use of materials from the demolition of facilities can be a good way to reduce waste. However, special attention should be paid to the condition and quality of the materials obtained, and make sure that they are not contaminated with hazardous materials.

Three basic types of wood waste are generated in the construction industry. They are untreated wood waste, processed wood waste, and treated or painted wood waste [10]. Wood waste can take the form of offcuts, chips, sawdust, slabs, and beams. The authors also point out that due to the diversity of this type of material, the sorting and recycling process is not simple. The literature includes a publication [11] on the potential of using wood waste in architecture. The authors stress that in light of the problems of climate change and natural resources, it is necessary to change the ways of using raw materials and materials in construction. Using minimal processing of waste wood, the researchers created prototypes of a beam and a wall. The article presents the results of the study, which indicates that wood lying on the waste pile can be a valuable raw material for architectural applications. Another application of construction wood waste could be the production of sustainable bioenergy. The paper [12] described a bibliometric survey of the literature on this issue. The publication aimed to identify trends, gaps in knowledge, and prospects for the development of this field. The results of analysis of 120 scientific articles from the Web of Science database were compared. It was thus shown that the use of wood waste for energy production is a well-developing field. The most common method is incineration to generate electricity or heat. The author argues that these waste applications are a promising and sustainable alternative to traditional energy sources. However, the approach requires further research and innovation to ensure its effectiveness. Thus, an example of a wood use that has been classified as reusable is the production of new furniture, stairs, flooring, and interior trim. Alternatively, it can be used to renovate an existing structure or build outdoor structures such as terraces or gazebos. In the context of the home, the waste raw material can also find use as a source of heat. It should be remembered that wood from demolition may require additional processing, such as cleaning, sanding, cutting into appropriate dimensions, or drying.

Brick, coming from demolition, can be used depending on its state of preservation. When it is fully intact, with no defects that may affect the durability and strength of the structure, it can be reused for its original purpose. Examples include the construction of fences, driveways, and retaining walls. The damaged material can still find its new use. Pieces of brick can be used to fill the spaces between stones in a sidewalk, for example, to increase the durability and stability of the structure. A popular one is its use as a foundation material. Brick can also be used to build hearths or as a decorative element.

As with brick or wood, before reusing waste steel, its quality should be assessed. If it is contaminated, rusted, or damaged, it may jeopardize its safety for structural reuse. Steel can be used to build new structures or support existing ones. Alternatively, it can be recycled and used in the production of new steel products, reducing waste and environmental pollution.

Due to the fragility of glass, it may not even be possible to build it back into a structure. Glass can be difficult to dispose of because it is a non-biodegradable material. Glass lingers in landfills for up to hundreds of years [13]. However, it has the property to be recycled and re-melted many times without losing its quality and properties. Recycling glass is therefore more economical and environmentally friendly than producing new glass from natural resources. Of course, broken glass can also be directly used as a decorative element. The article [14] highlights that recycled glass materials have favorable properties, such as good thermal and acoustic insulation and corrosion resistance. It also presents ways of processing glass, such as grinding or melting, to obtain a material with properties similar to the original product. Researchers [15] described the use of waste glass in road construction. Its use is a sustainable method of soil stabilization in road construction. A description of the production and properties of the waste, such as the ability to bind to the soil and increase its load-bearing capacity, is presented. The effect of different amounts of glass on the mechanical properties of the soil mixture is also considered. By using waste glass, an increase in the bearing capacity of the soil and its compressive strength was achieved. The effect depended on the size of the glass particles. This indicates the need for appropriate selection of the amount of material for the construction of a particular road. The authors stress that such use of waste is a sustainable and economical alternative to traditional methods of soil stabilization.

4. Use of Waste Materials in Composites

Sustainable engineering seeks to reuse materials that are not fit for their original purpose. Researchers are seeking new uses for these materials. Most of them, i.e., wood waste [16], bricks [17,18], concrete [19] and steel [20] are being used as an additive for cement composites. Replacing cement allows for a significant reduction in the carbon dioxide released into the atmosphere. Cement production is an extremely energy-intensive process. At the same time, it is responsible for approximately 8% of global CO2 emissions [21]. The paper [22] presents ways to use waste glass. It can be used as fine aggregate in concrete, asphalt concrete, as a cementitious material, or in fiber-reinforced concrete. The applications of this type of waste in composite materials are numerous. Scientific papers describe in detail studies of these materials, are presented in Table 3.

Table 3.

Examples of waste material applications in composites.

One can see a certain regularity in the use of materials from construction waste. Indeed, the general idea is to use them as fillers for the composite and as a substitute for the material used in cementitious composite mixtures, such as binder or coarse aggregate. However, it should be noted that in order to reuse these materials, they must first be properly prepared.

5. Summary

The analyses carried out indicated that in order to achieve the provisions of sustainable materials engineering, it is necessary to use waste construction materials. This will not only avoid the landfill of waste concrete, but also save natural resources that would have to be used to produce new building materials. These waste materials, due to the high percentage of older buildings, will not only be readily available in the near future, but will be a major problem due to the need for storage. Estimation of the life cycle of materials plays a significant role in waste management and the prevention of excessive waste generation.

At present, the use of waste building materials to produce new products is being intensively studied by researchers around the world. The number of publications indicates a strong trend. The increased interest in this topic is related to growing environmental awareness and the need to reduce waste. Many of the resulting composites with the addition of materials from construction show properties superior to reference samples. This demonstrates the enormous potential of this type of product. Further research in the area of sustainable materials engineering can contribute to education and training, which is key to future construction and facing environmental challenges.

However, as presented in the introduction of the study, even the young civil engineering society is not highlighting the eco-friendliness of the materials as the most important factor. Therefore, taking this into account, we are firstly, aiming to achieve a zero-emission goal in the near future and, secondly, the waste from buildings will significantly increase as there is a need to further improve the awareness of young scientists and scholars.

Author Contributions

Conceptualization, S.C.; methodology, S.C.; software, S.C. and M.R.; investigation, S.C. and M.R.; resources, S.C.; data curation, S.C. and M.R.; writing—original draft preparation, S.C. and M.R.; writing—review and editing, S.C. and M.R; visualization, M.R.; supervision, S.C.; project administration, S.C.; funding acquisition, S.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science Centre, Poland within the SONATA 17 program, grant number 2021/43/D/ST8/02031, entitled “Experimental evaluation of the properties of epoxy composites modified with coarse aggregate sourced from the modernization of prewar residential buildings (CARMEL)”.

Data Availability Statement

Data available on request.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Ogunbiyi, O.E.; Oladapo, A.A.; Goulding, J.S. A Review of Lean Concept and Its Application to Sustainable Construction in the UK. IJSCET 2013, 4, 82–92. [Google Scholar]

- Nahmens, I.; Ikuma, L.H. An Empirical Examination of the Relationship between Lean Construction and Safety in the Industrialized Housing Industry. Lean Constr. J. 2009, 1, 1–12. [Google Scholar]

- Colglazier, W. Sustainable development agenda: 2030. Science 2015, 349, 1048–1050. [Google Scholar] [CrossRef]

- Eurostat. Waste Generation and Treatment. Available online: https://ec.europa.eu/eurostat/databrowser/view/ENV_WASGEN__custom_5790360/default/table?lang=en (accessed on 10 April 2023).

- Wang, X.; Yu, R.; Shui, Z.; Song, Q.; Liu, Z.; Liu, Z.; Wu, S. Optimized treatment of recycled construction and demolition waste in developing sustainable ultra-high performance concrete. J. Clean. Prod. 2019, 221, 805–816. [Google Scholar] [CrossRef]

- Eurostat—Census Hub HC 53: People in the EU—Statistics on Housing Conditions. Available online: https://ec.europa.eu/energy/eu-buildings-factsheets_en (accessed on 20 February 2023).

- Waste Management Plant. Available online: https://www.zzonowydwor.pl/oferta/cennik (accessed on 14 July 2023).

- Zarębska, J.; Joachimiak-Lechman, K. Ekonomiczne i ekologiczne skutki zagospodarowania odpadów budowlanych w kontekście rozwoju zrównoważonego. Syst. Wspomagania W Inżynierii Prod. 2014, 3, 261–282. [Google Scholar]

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of recycled and waste materials in various construction applications. Am. J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Jahan, I.; Zhang, G.; Bhuiyan, M.A.R.; Navaratnam, S. Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability 2022, 14, 10478. [Google Scholar] [CrossRef]

- Browne, X.; Larsen, O.P.; Friis, N.C.; Kühn, M.S. Material Value(s): Motivating the architectural application of waste wood. Archit. Struct. Constr. 2022, 2, 575–584. [Google Scholar] [CrossRef]

- Maier, D. The use of wood waste from construction and demolition to produce sustainable bioenergy—A biblio-metric review of the literature. Int. J. Energy Res. 2022, 46, 11640–11658. [Google Scholar] [CrossRef]

- Thompson, R.C.; Swan, S.H.; Moore, C.J.; Vom Saal, F.S. Our plastic age. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1973–1976. [Google Scholar] [CrossRef]

- Ogundairo, T.O.; Adegoke, D.D.; Akinwumi, I.I.; Olofinnade, O.M. Sustainable use of recycled waste glass as an alternative material for building construction—A review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 640, 012073. [Google Scholar] [CrossRef]

- Bayandor, S. A sustainable method of soil stabilization using waste glass in road construction. Rangahau Aranga AUT Grad. Rev. 2022, 1, 1–12. [Google Scholar] [CrossRef]

- Ince, C.; Tayancli, S.; Derogar, S. Recycling waste wood in cement mortars towards the regeneration of sustainable environment. Constr. Build. Mater. 2021, 299, 123891. [Google Scholar] [CrossRef]

- Ma, Z.; Yao, P.; Yang, D.; Shen, J. Effects of fire-damaged concrete waste on the properties of its preparing recycled aggregate, recycled powder and newmade concrete. J. Mater. Res. Technol. 2021, 15, 1030–1045. [Google Scholar] [CrossRef]

- Ma, K.; Huang, X.; Shen, J.; Hu, M.; Long, G.; Xie, Y.; Zeng, X.; Xu, Z.; Zhang, W. The morphological characteristics of brick-concrete recycled coarse aggregate based on the digital image processing technique. J. Build. Eng. 2021, 44, 103292. [Google Scholar] [CrossRef]

- Ellis, L.A.; Leon, L.P.; Charran, A.V. Investigating the Use of Recycled Concrete as Aggregates in the Construction of Structural Beams. West Indian J. Eng. 2023, 45, 4–13. [Google Scholar] [CrossRef]

- Ochoa-Díaz, R.; Grimaldo-León, G.E.; Pérez-Rojas, Y.A. Characterizing steel waste and analyzing its use as a material in pavement constructions. J. Phys. Conf. Ser. 2021, 2046, 012033. [Google Scholar] [CrossRef]

- Abbas, R.; Khereby, M.A.; Ghorab, H.Y.; Elkhoshkhany, N. Preparation of Geopolymer Concrete Using Egyptian Kaolin Clay and the Study of Its Environmental Effects and Economic Cost. Clean Technol. Environ. Policy 2020, 22, 669–687. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Al-Kaseasbeh, Q.; Al-Qaralleh, M. Valorization of hydrophobic wood waste in concrete mixtures: Investigating the micro and macro relations. Results Eng. 2023, 17, 100877. [Google Scholar] [CrossRef]

- Siciliano, A.P.; Zhao, X.; Fedderwitz, R.; Ramakrishnan, K.; Dai, J.; Gong, A.; Jiang, L.; Hu, L. Sustainable Wood-Waste-Based Thermal Insulation Foam for Building Energy Efficiency. Buildings 2023, 13, 840. [Google Scholar] [CrossRef]

- Pařil, P.; Baar, J.; Rousek, R. Innovative, Low-cost and Eco Composite Boards Produced From High-energy Milled Wood, Plastic Waste and Bio-polymer. Polymers 2023, 15, 726. [Google Scholar] [CrossRef]

- Sharba, A.A.K.; Al-kaabi, J.J.F.; Al-Taai, S.R. The Feasibility of Improving Concrete Strength Properties by Adding Waste Wood Chips. J. Appl. Eng. Sci. 2023, 21, 462–469. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2010, 114, 103807. [Google Scholar] [CrossRef]

- Gencel, O.; Oguz, M.; Gholampour, A.; Ozbakkaloglu, T. Recycling waste concretes as fine aggregate and fly ash as binder in production of thermal insulating foam concretes. J. Build. Eng. 2021, 38, 102232. [Google Scholar] [CrossRef]

- Frazao, C.; Barros, J.; Bogas, J.A.; Garcia-Cortes, V.; Valente, T. Technical and environmental potentialities of recycled steel fiber reinforced concrete for structural applications. J. Build. Eng. 2022, 45, 103579. [Google Scholar] [CrossRef]

- Łasica, W. Wpływ Dodatku Odpadowych Wiórów Stalowych na Wartości Modułu Young’a Ekokompozytów Cementowo-Szklanych. In Rozwiązania Technologiczne XXI Wieku—Skutki i Perspektywy Rozwoju—Tom 3; Wydawnictwo Naukowe TYGIEL Sp. Z O.O.: Lublin, Poland, 2023; Chapter 4; pp. 52–75. [Google Scholar]

- Villoria Sáez, P.; del Río Merino, M.; Atanes Sánchez, E.; Santa Cruz Astorqui, J.; Porras-Amores, C. Viability of gypsum composites with addition of glass waste for applications in construction. J. Mater. Civ. Eng. 2019, 31, 04018403. [Google Scholar] [CrossRef]

- Lauermannová, A.M.; Jankovský, O.; Sedmidubský, D.; Lojka, M.; Pavlíková, M.; Pivák, A.; Pavlík, Z. Case Study on MOC Composites Enriched by Foamed Glass and Ground Glass Waste: Experimental Assessment of Material Properties and Performance. Case Stud. Constr. Mater. 2023, 18, e01836. [Google Scholar] [CrossRef]

- Camilleri, J.; Montesin, F.E.; Sammut, M. The Use of Waste Glass and Pulverized Fuel Ash in Concrete Construction. In Sustainable Waste Management and Recycling: Glass Waste: Proceedings of the International Conference Organised by the Concrete and Masonry Research Group and Held at Kingston University-London on 14–15 September 2004; Thomas Telford: London, UK, 2004; p. 83. [Google Scholar]

- Ani, F.M.; Hossain, M.A.; Shahril, R.N. Recycling of Glass Waste on the Concrete Properties as a Partial Binding Material Substitute. Eur. J. Eng. Technol. Res. 2022, 7, 138–142. [Google Scholar] [CrossRef]

- Çelik, A.I.; Tunç, U.; Bahrami, A.; Karalar, M.; Mydin, A.O.; Alomayri, T.; Özkılıç, Y.O. Use of waste glass powder toward more sustainable geopolymer concrete. J. Mater. Res. Technol. 2023, 24, 8533–8546. [Google Scholar] [CrossRef]

- Ursua, J.R.S.; Borlan, A.S. The Effect of Construction Wastes in Concrete Bricks for Load Bearing Wall. Am. J. Innov. Sci. Eng. 2023, 2, 38–42. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).