Experimental Study of the Bending Performance of Cold-Formed Steel Channel Beams Considering the Corner Hardening Effect

Abstract

:1. Introduction

2. Experimental Program

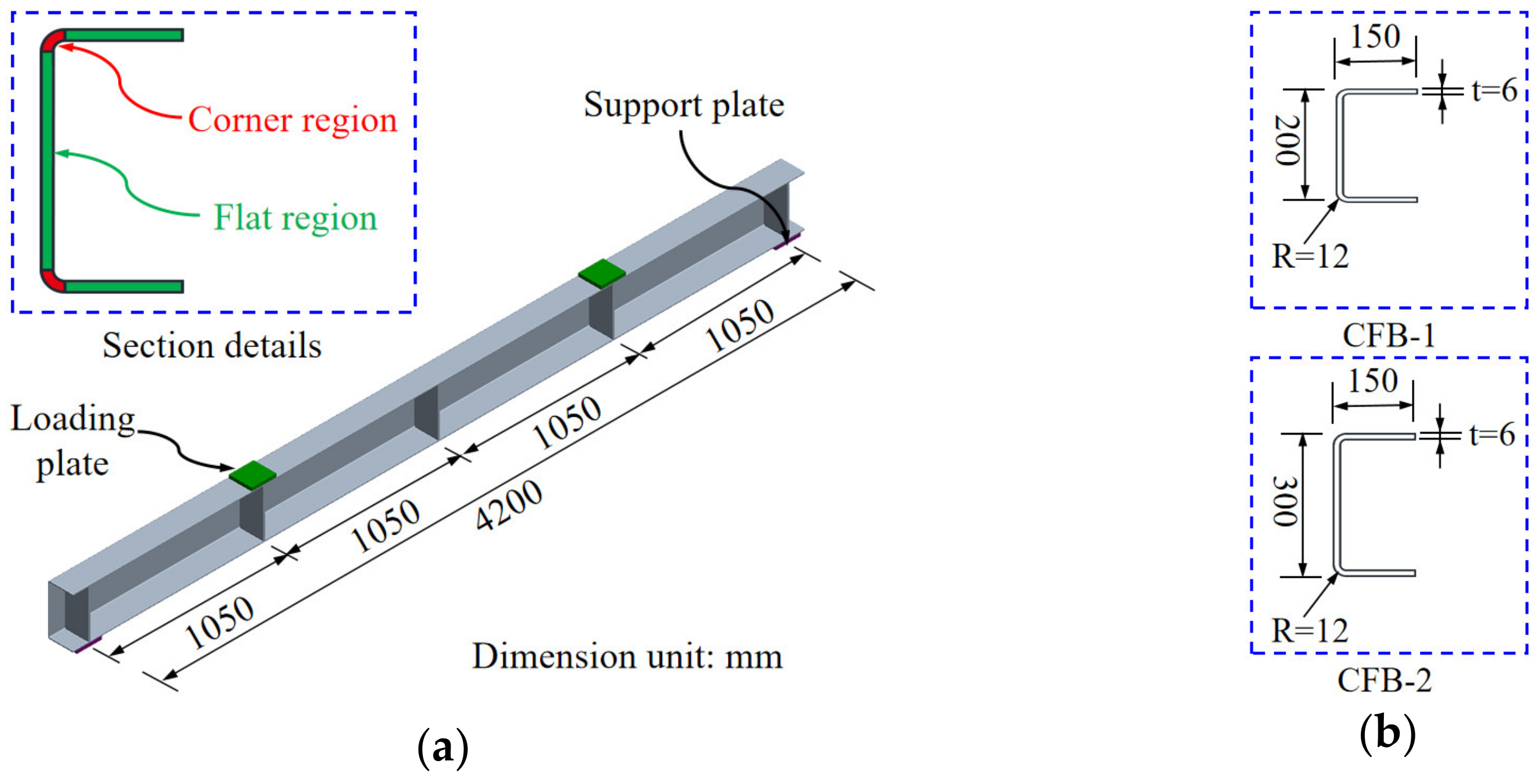

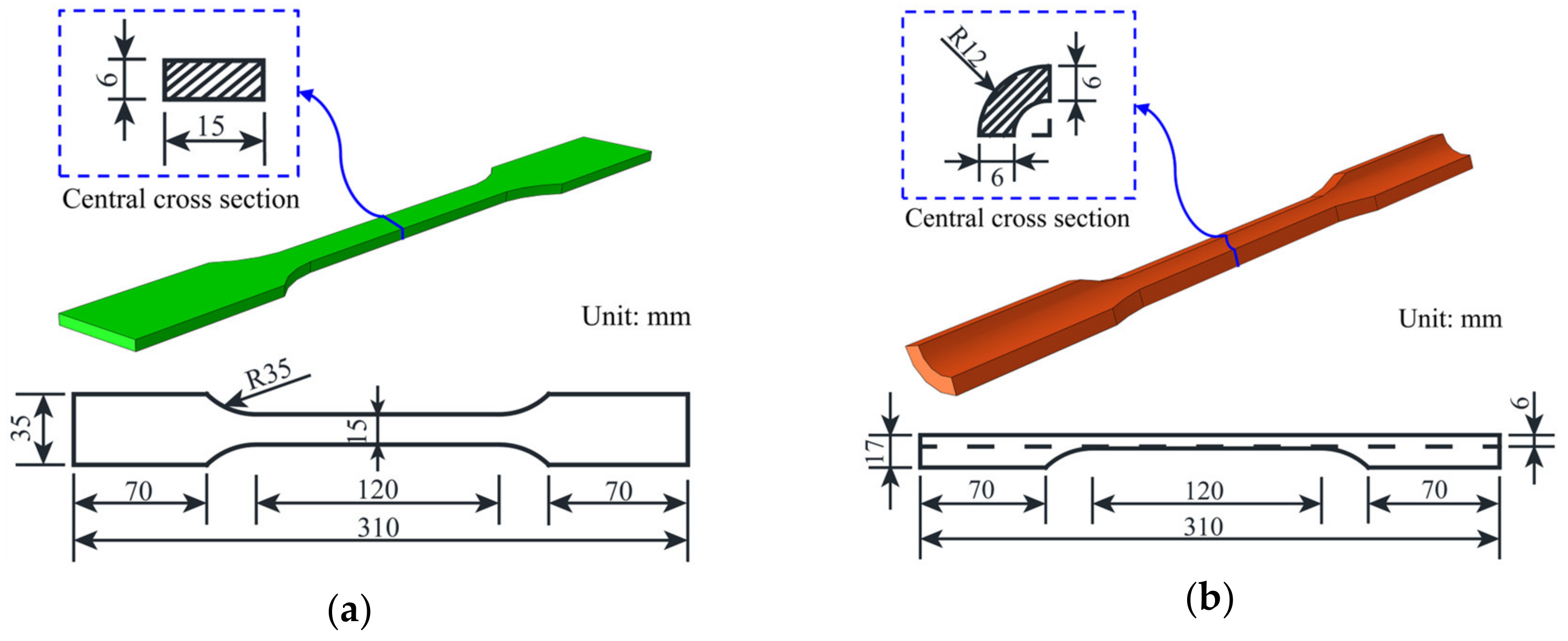

2.1. Details of Cold-Formed Steel Channel Specimens and Coupon Specimens

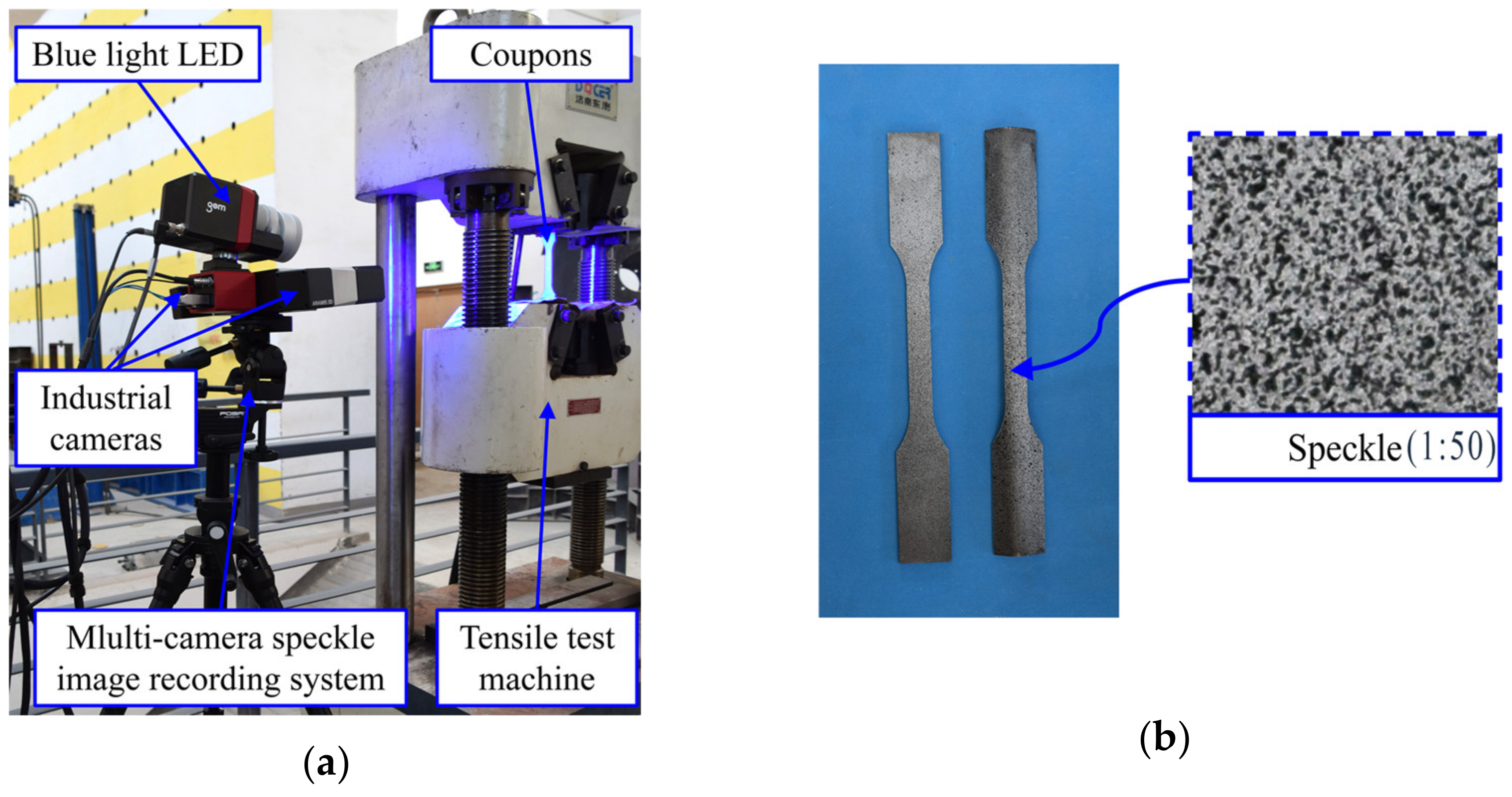

2.2. Tensile Test Set-Up of Corner and Flat Coupons

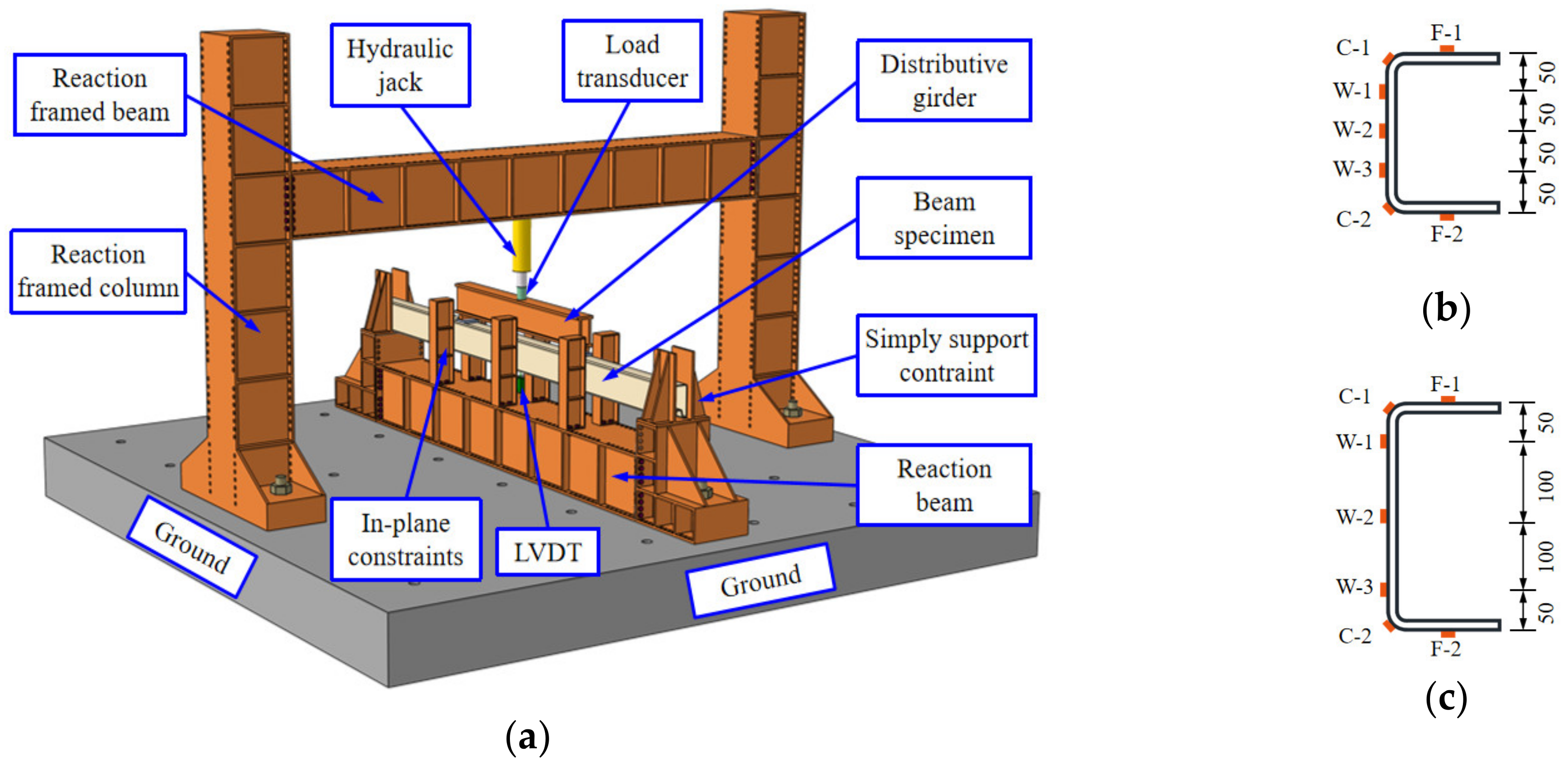

2.3. Bending Test Set-Up for Cold-Formed Steel Channels

3. Experimental Results

3.1. Evaluation of Flat and Corner Coupons in Tensile Tests

3.1.1. Deformation Process and Failures of Coupons

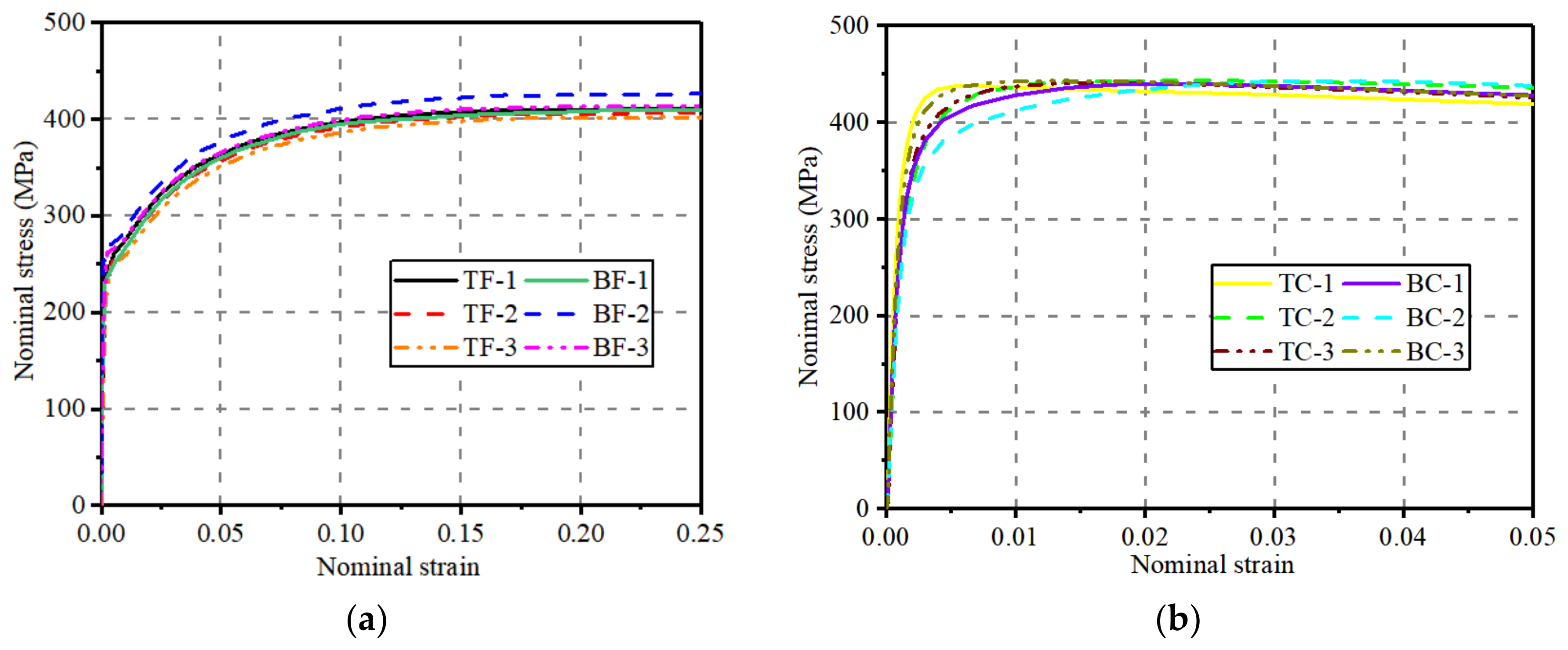

3.1.2. Engineering Stress–Strain Curves of Flat and Corner Coupons

3.2. Evaluation of Cold-Formed Channel Beams in Bending Tests

3.2.1. Observations of Steel Channel Beams

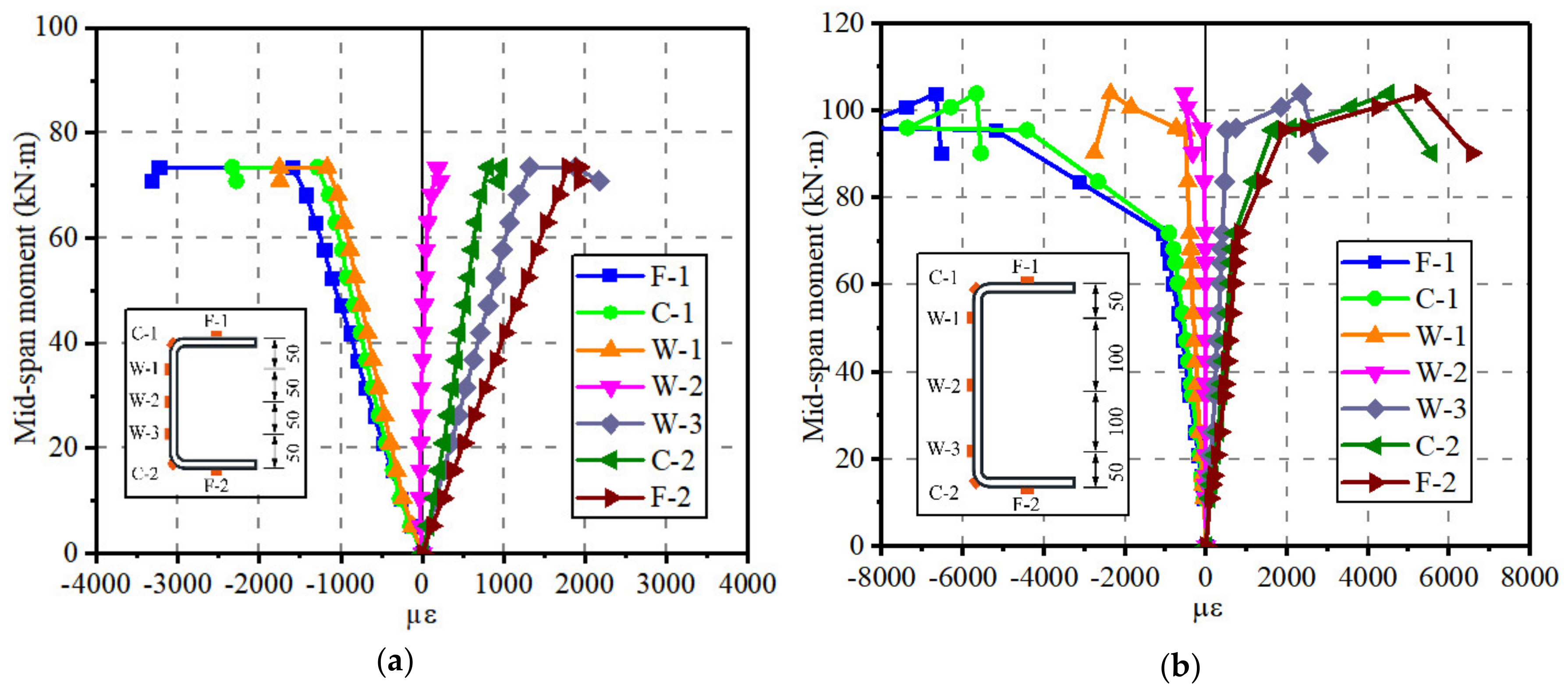

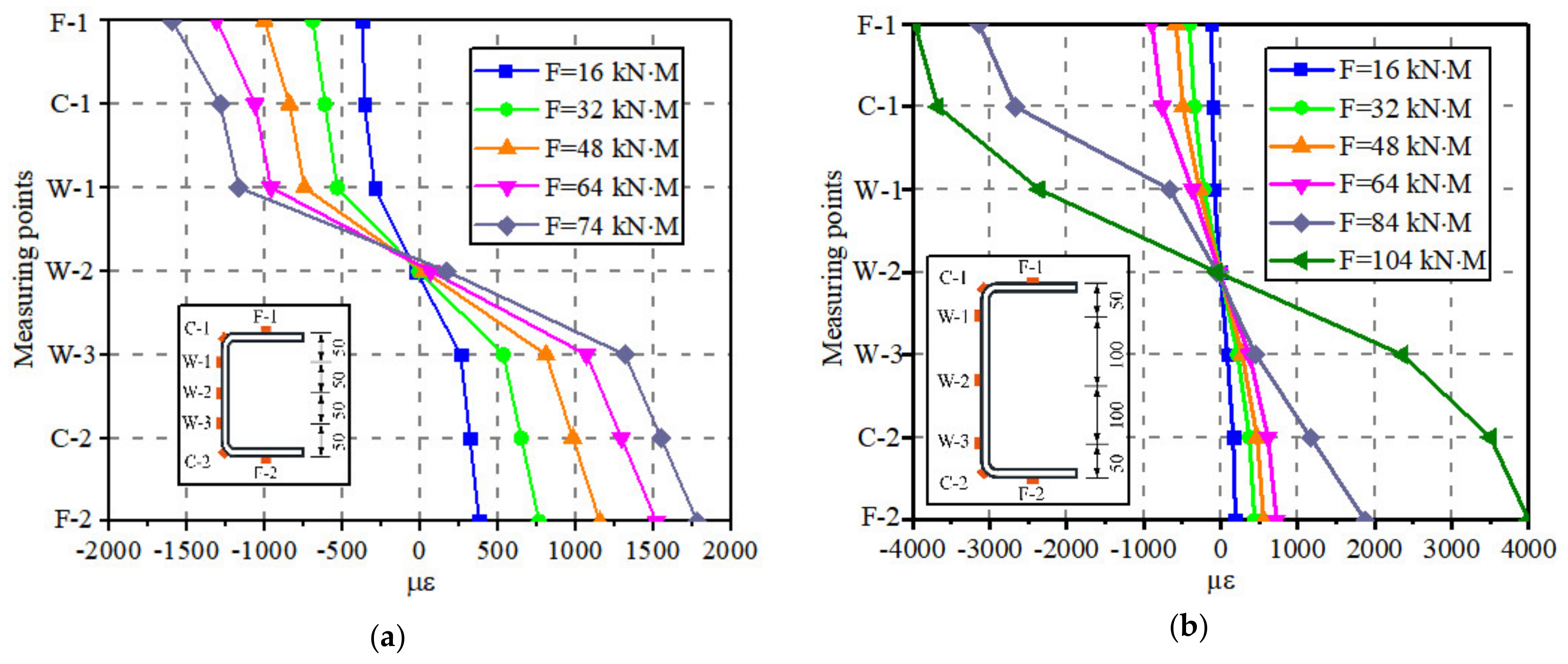

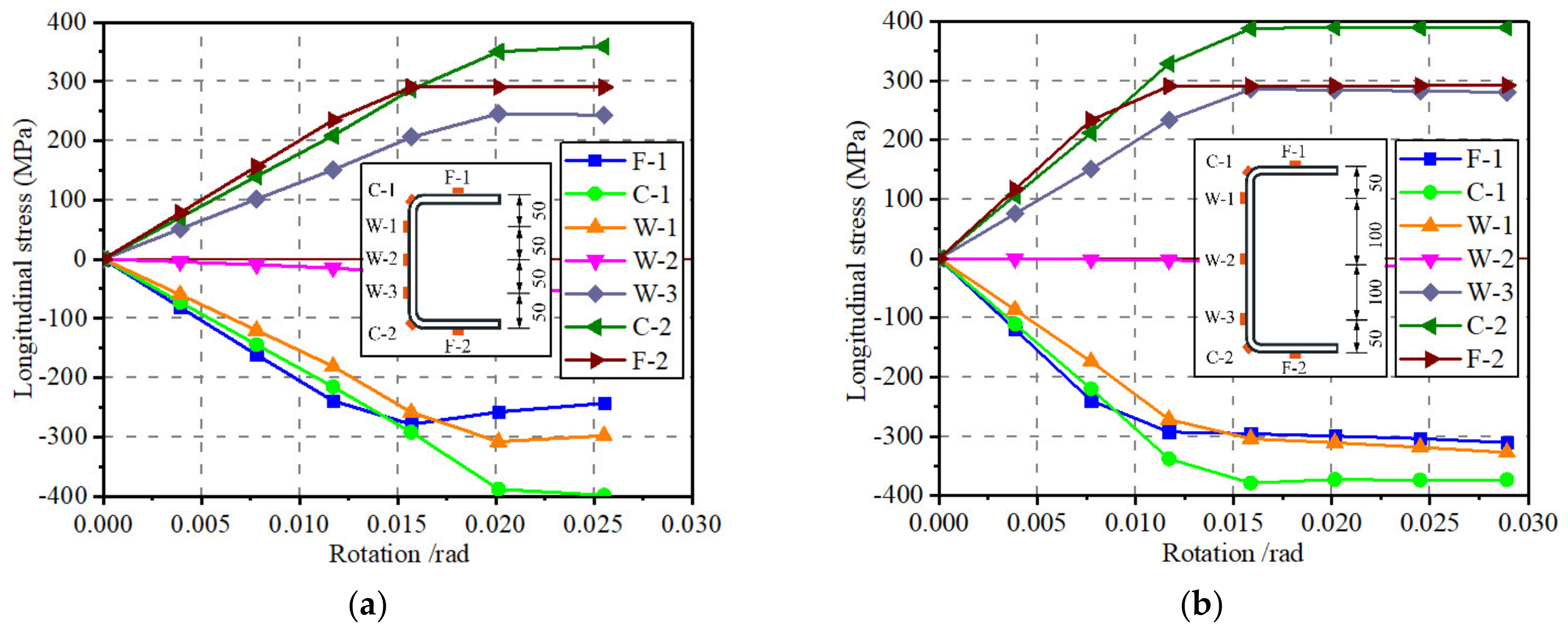

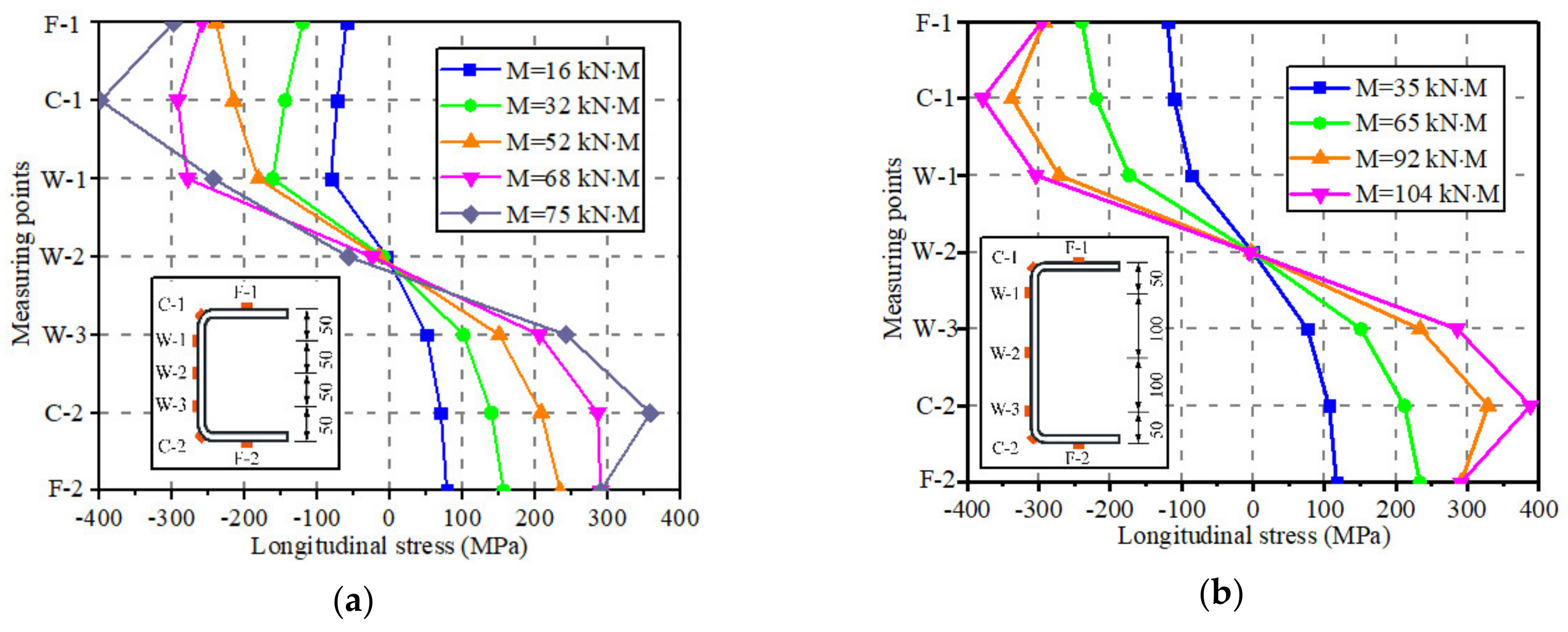

3.2.2. Bending Mechanical Response of Cold-Formed Steel Channel Beams

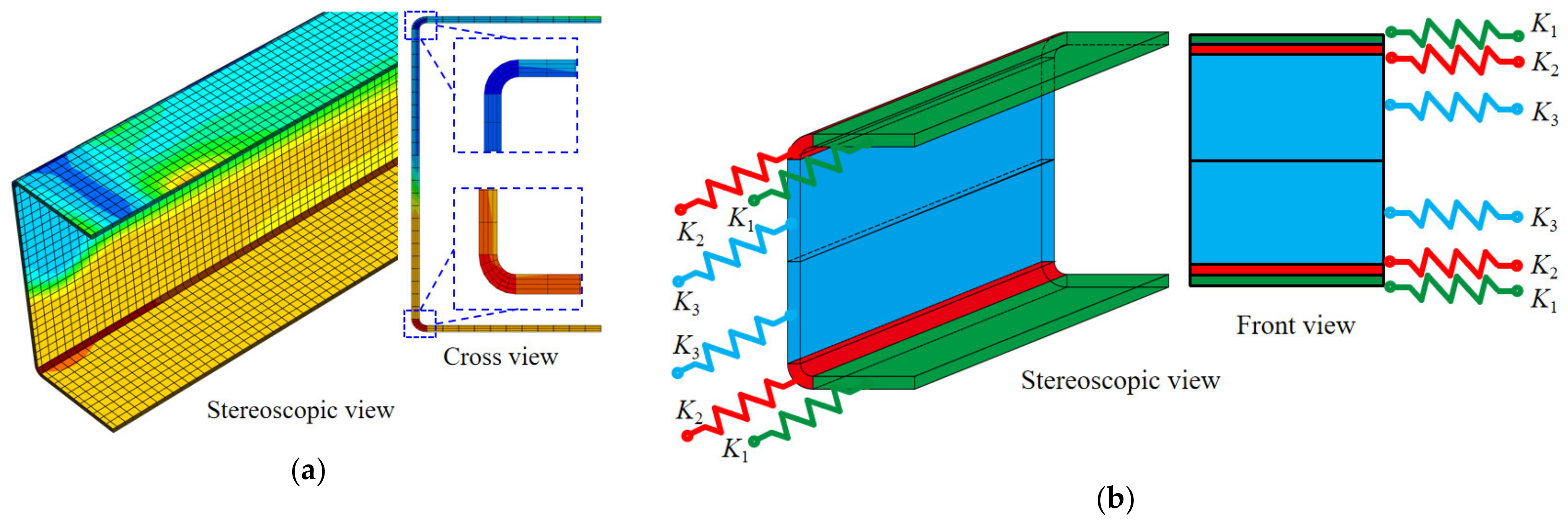

4. FE Simulations of Steel Channels with Different Constitutive Models

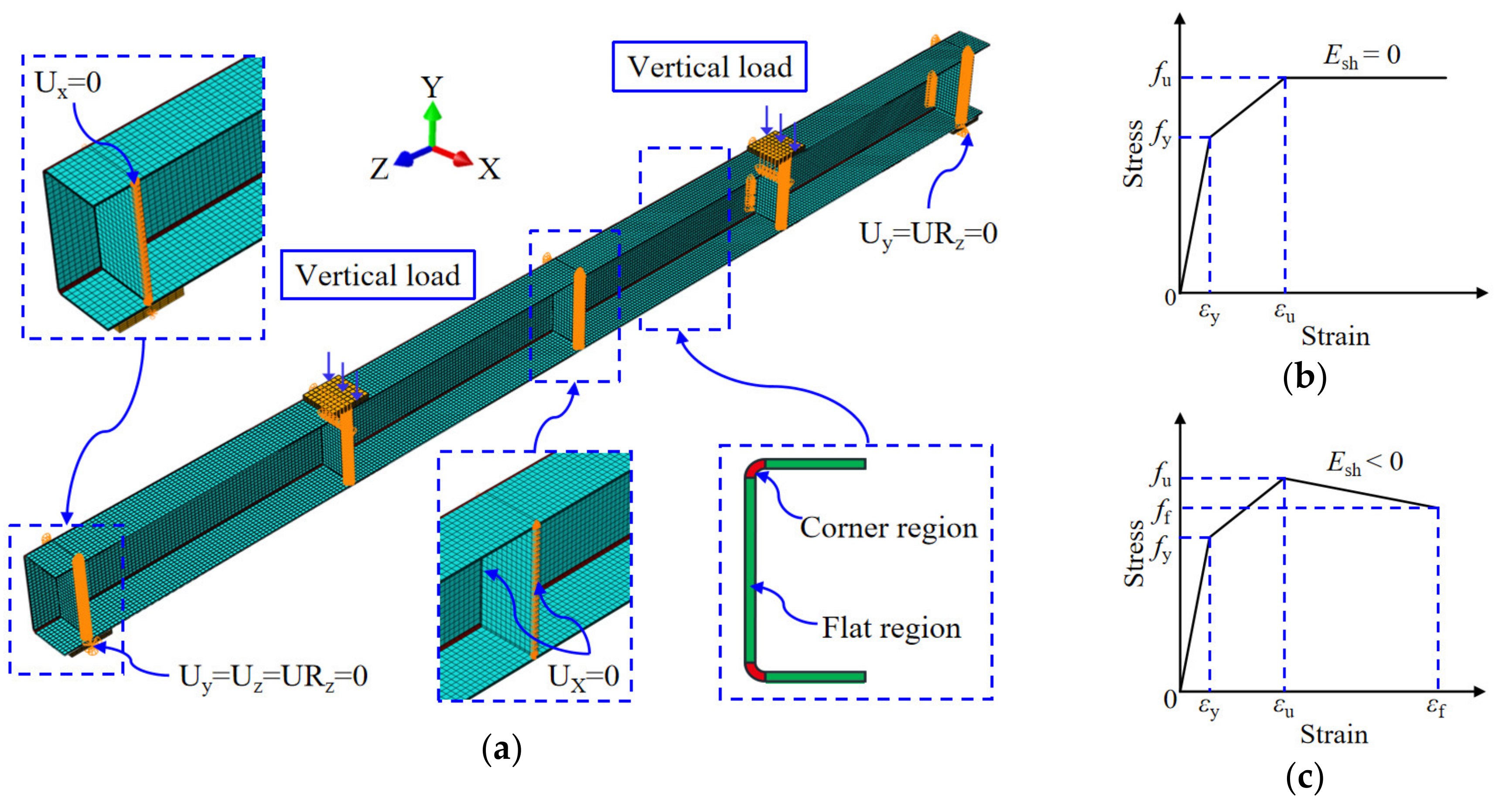

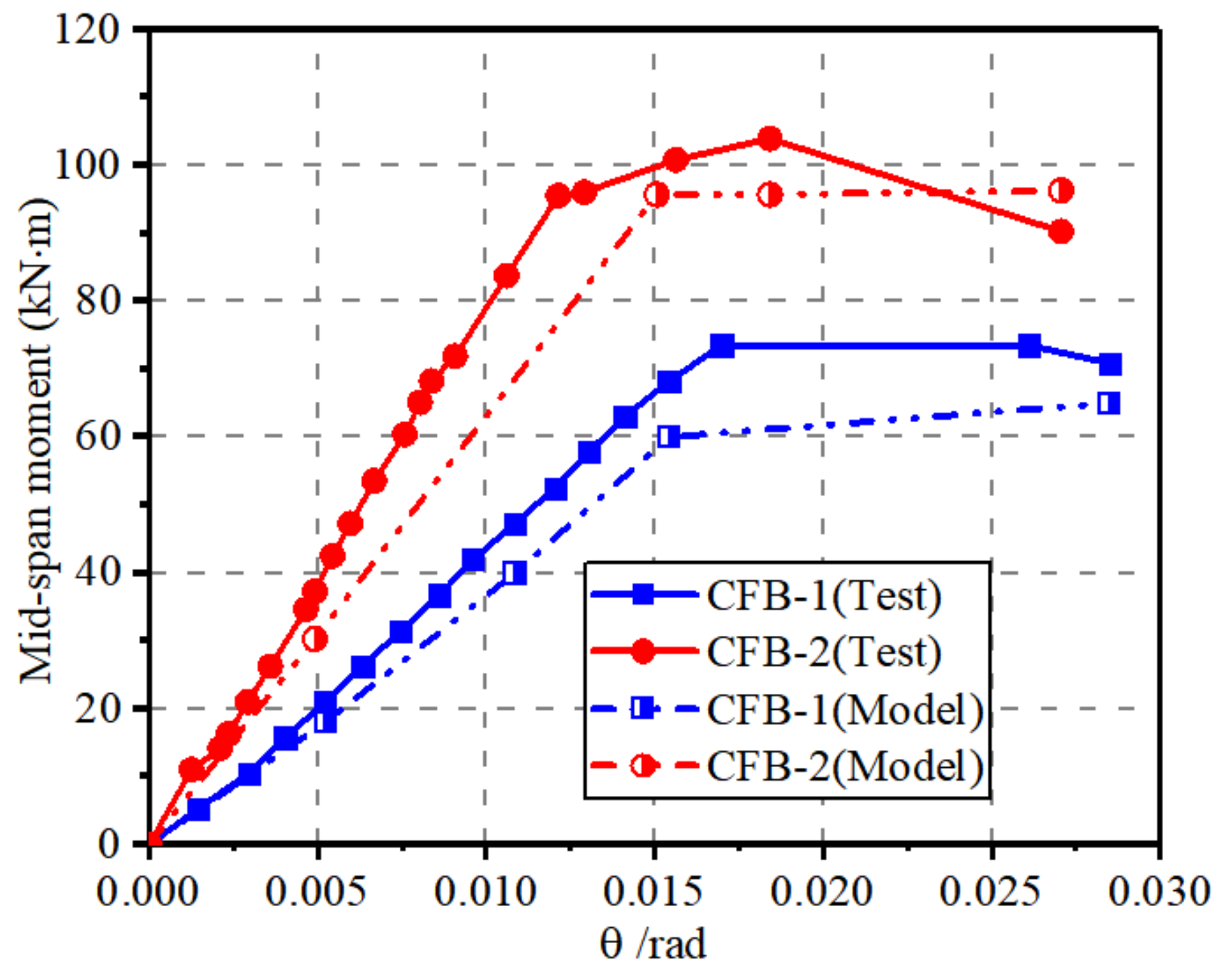

4.1. Establishment and Validation of Steel Channel Beams

4.2. Stress Development of Cold-Formed Channel Beams

5. Component-Based Model of Cold-Formed Steel Channels

5.1. Development of Component-Based Model

5.2. Validation of Component-Based Model

6. Conclusions

- The strain hardening effect was observed in corner coupons, which highly influenced the mechanical properties of steel. As a result, the yielding and ultimate strengths of corner regions were 50% and 7% higher than that of flat regions, respectively. Moreover, the stress–strain curves of the flat coupons could be fitted as a trilinear model with platform, while that of the corner coupons could be simplified to a trilinear model with descent stage.

- The sectional strain development of the cold-formed steel channels was kept consistent with hot-rolled components, while the singularity of stress distribution was produced when subjected to the vertical loads. The stresses at corner locations in the channel beam section were highly increased compared to that of flanges at the same deformation.

- The component-based analytical model was established and verified, respectively, presenting the constitutive relationship of corner and flat parts of cold-formed steel channel beams.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Afshan, S.; Rossi, B.; Gardner, L. Strength enhancements in cold-formed structural sections—Part I: Material testing. J. Constr. Steel Res. 2013, 83, 177–188. [Google Scholar] [CrossRef]

- Xu, B.; Xia, J.; Ma, R.; Wang, J.; Chen, X.; Chang, H.; Zhang, L. Investigation on True Stress-Strain Curves of Flat and Corner Regions of Cold-Formed Section Using 3D Digital Image Correlation Method. Adv. Civ. Eng. 2019, 2019, 3138176. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, Y.; Tan, C. Experimental Investigation on Cold-Formed Steel Beams under Pure Bending. J. Teknol. (Sci. Eng.) 2012, 58, 13–20. [Google Scholar] [CrossRef]

- Ye, J.; Hajirasouliha, I.; Becque, J.; Pilakoutas, K. Development of more efficient cold-formed steel channel sections in bending. Thin-Walled Struct. 2016, 101, 1–13. [Google Scholar] [CrossRef]

- Schafer, B. Review: The Direct Strength Method of cold-formed steel member design. J. Constr. Steel Res. 2008, 64, 766–778. [Google Scholar] [CrossRef]

- Szymczak, C.; Kujawa, M. On local buckling of cold-formed channel members. Thin-Walled Struct. 2016, 106, 93–101. [Google Scholar] [CrossRef]

- Somodi, B.; Kövesdi, B. Flexural buckling resistance of cold-formed HSS hollow section members. J. Constr. Steel Res. 2017, 128, 179–192. [Google Scholar] [CrossRef]

- Hu, S.; Li, L.; Zhou, J.; Zhang, H.; Huang, N. Comparative Analysis on Strain Hardening of Thick-Wall Cold Formed Steel Tube with Square and Rectangular Hollow Section. J. Mater. Sci. Eng. 2010, 28, 76–80+129. [Google Scholar]

- Hu, S.; Li, L.; Zhou, J. Strain Hardening of Thick-Walled Cold Formed Steel Rectangular Hollow Section. J. Build. Struct. 2011, 32, 76–81. [Google Scholar]

- Wen, D.; Shen, Z.; Li, Y.; Zhu, S. Experimental Research on Cold-Formed Thick-Walled Steel Box Stubs and Comparison of Results with Related Codes. J. Tongji Univ. (Nat. Sci.) 2016, 44, 1190–1198. [Google Scholar]

- Li, Y.; Li, G.; Shen, Z.; Ma, Y.; Zhu, S. Modification Method for Yield Strength of Cold- Formed Thick- Walled Steel Sections Considering Cold- Forming Effect. J. Build. Struct. 2015, 36, 1–7. [Google Scholar]

- Fu, X.; Ren, H.; Wu, X. Study on Calculation Method of Yield Strength of Cold Formed Thick Wall Section Steel. Sci. Res. 2022, 44, 2243–2247. [Google Scholar]

- Tong, L.; Huo, T.; Hou, G. Research on Design Formula for Yield Strength of Cold-Formed Rectangular Steel Tubes with Medium-Thick Wall. J. Build. Struct. 2018, 39, 81–90. [Google Scholar]

- Cai, Y.; Ben, Y. Behavior of Cold-Formed Stainless Steel Single Shear Bolted Connections At Elevated Temperatures. Thin-Walled Struct. 2014, 75, 63–75. [Google Scholar]

- Huang, Y.; Ben, Y. Experimental Investigation of Cold-Formed Lean Duplex Stainless Steel Beam-Columns. Thin-Walled Struct. 2014, 76, 105–117. [Google Scholar]

- Ben, Y. Experimental and Numerical Investigation of High Strength Stainless Steel Structures. J. Constr. Steel Res. 2008, 64, 1225–1230. [Google Scholar]

- Ma, J.-L.; Chan, T.-M.; Young, B. Design of cold-formed high strength steel tubular beams. Eng. Struct. 2017, 151, 432–443. [Google Scholar] [CrossRef]

- Han, J.; Yang, F.; Yang, J.; Li, Z. Experimental Study and Analysis on Effect of Cold-Formed Procedures to Cold-Formed Thick-Walled Steel Members. Build. Struct. 2010, 40, 200–203. [Google Scholar]

- Wang, H.; Zhang, Y. Experimental and numerical investigation on cold-formed steel C-section flexural members. J. Constr. Steel Res. 2009, 65, 1225–1235. [Google Scholar] [CrossRef]

- Ayhan, D.; Schafer, B.W. Cold-formed steel member bending stiffness prediction. J. Constr. Steel Res. 2015, 115, 148–159. [Google Scholar] [CrossRef]

- Rossi, B.; Afshan, S.; Gardner, L. Strength enhancements in cold-formed structural sections—Part II: Predictive models. J. Constr. Steel Res. 2013, 83, 189–196. [Google Scholar] [CrossRef]

- Schafer, B.; Li, Z.; Moen, C. Computational modeling of cold-formed steel. Thin-Walled Struct. 2010, 48, 752–762. [Google Scholar] [CrossRef]

- Misiūnaitė, I.; Rimkus, A.; Jakuboskis, R.; Sokolov, A.; Gribniak, V. Analysis of local deformation effects in cold-formed tubular profiles subjected to bending. J. Constr. Steel Res. 2019, 160, 598–612. [Google Scholar] [CrossRef]

- Alireza, F.; Iman, M.; Seyed, M.; Jong, H. Force–Displacement Relationship of the Butterfly Shaped Beams Based on Gene Expression Programming. Int. J. Steel Struct. 2020, 20, 2009–2019. [Google Scholar]

- Alireza, F.; Iman, M.; Hamzeh, D. Incremental Dynamic Analysis for Estimating Seismic Performance of Multi-Story Buildings with Butterfly-Shaped Structural Dampers. Buildings 2019, 9, 78. [Google Scholar]

- Young, K.; Seyed, M.; Alireza, F.; Jong, H.; Iman, M.; Paul, A. Optimization of the Curved Metal Damper to Improve Structural Energy Dissipation Capacity. Buildings 2022, 12, 67. [Google Scholar]

- Alireza, F.; Mohsen, K.; Iman, M. Shape Optimization of Butterfly-Shaped Shear Links using Grey Wolf Algorithm. Ing. Sismica 2019, 36, 27–41. [Google Scholar]

- Alireza, F.; Matthew, R.E.; Jong, H. Effect of Flexural and Shear Stresses Simultaneously for Optimized Design of Butterfly-Shaped Dampers: Computational Study. Korea Sci. 2019, 23, 329–335. [Google Scholar]

- GB/T 228.1-2010; National Standard of the People’s Republic of China. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. China Standard Press: Beijing, China, 2010.

- Simulia. ABAQUS-6.14; Systems Simulia Corporation: Johnston, RI, USA, 2014. [Google Scholar]

- Luo, Z.; Shi, Y.; Xue, X.; Gao, T. Experimental and numerical investigation on patch loading capacity of longitudinally stiffened hybrid titanium-clad bimetallic steel plate girder. Eng. Fail. Anal. 2023, 146, 107117. [Google Scholar] [CrossRef]

- Wang, L.; An, Y.; Ding, F.; Kuang, Y.; Ma, Q.; Tan, S.; Zhang, W.; Zhao, P.; Ren, E. Numerical Investigation of Composite Behavior and Strength of Rectangular Concrete-Filled Cold-Formed Steel Tubular Stub Columns. Materials 2021, 14, 6221. [Google Scholar] [CrossRef]

| Types of Coupons | Specimens | σy (MPa) | εy | σu (MPa) | εu |

|---|---|---|---|---|---|

| Flat coupons | TF-1 | 260.64 | 0.0013 | 410.77 | 0.244 |

| TF-2 | 254.26 | 0.0012 | 406.66 | 0.264 | |

| TF-3 | 247.88 | 0.0012 | 402.55 | 0.232 | |

| BF-1 | 253.58 | 0.0013 | 410.42 | 0.264 | |

| BF-2 | 265.67 | 0.0013 | 426.44 | 0.243 | |

| BF-3 | 261.97 | 0.0012 | 413.91 | 0.244 | |

| Corner coupons | TC-1 | 410.62 | 0.002 | 437.99 | 0.013 |

| TC-2 | 383.75 | 0.002 | 441.94 | 0.018 | |

| TC-3 | 370.78 | 0.002 | 441.35 | 0.02 | |

| BC-1 | 380.78 | 0.002 | 440.13 | 0.023 | |

| BC-2 | 380.78 | 0.002 | 443.23 | 0.024 | |

| BC-3 | 395.22 | 0.002 | 443.44 | 0.013 | |

| Average values of flat coupons | 257.33 | 0.0013 | 411.79 | 0.249 | |

| Average values of corner coupons | 386.99 | 0.002 | 441.35 | 0.0185 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.-G.; Xu, B.; Zhang, F.; Peng, S.-N.; Yang, C.; Chen, M.-W.; Chen, S.-H.; Xie, M.-Z. Experimental Study of the Bending Performance of Cold-Formed Steel Channel Beams Considering the Corner Hardening Effect. Buildings 2023, 13, 2149. https://doi.org/10.3390/buildings13092149

Liu R-G, Xu B, Zhang F, Peng S-N, Yang C, Chen M-W, Chen S-H, Xie M-Z. Experimental Study of the Bending Performance of Cold-Formed Steel Channel Beams Considering the Corner Hardening Effect. Buildings. 2023; 13(9):2149. https://doi.org/10.3390/buildings13092149

Chicago/Turabian StyleLiu, Rong-Gui, Bo Xu, Feng Zhang, Sheng-Nan Peng, Chen Yang, Mao-Wei Chen, Su-Hang Chen, and Ming-Zhi Xie. 2023. "Experimental Study of the Bending Performance of Cold-Formed Steel Channel Beams Considering the Corner Hardening Effect" Buildings 13, no. 9: 2149. https://doi.org/10.3390/buildings13092149

APA StyleLiu, R.-G., Xu, B., Zhang, F., Peng, S.-N., Yang, C., Chen, M.-W., Chen, S.-H., & Xie, M.-Z. (2023). Experimental Study of the Bending Performance of Cold-Formed Steel Channel Beams Considering the Corner Hardening Effect. Buildings, 13(9), 2149. https://doi.org/10.3390/buildings13092149