Experimental and Analytical Investigations on Shear Performance of Ambient-Cured Reinforced Geopolymer Concrete Beams

Abstract

1. Introduction

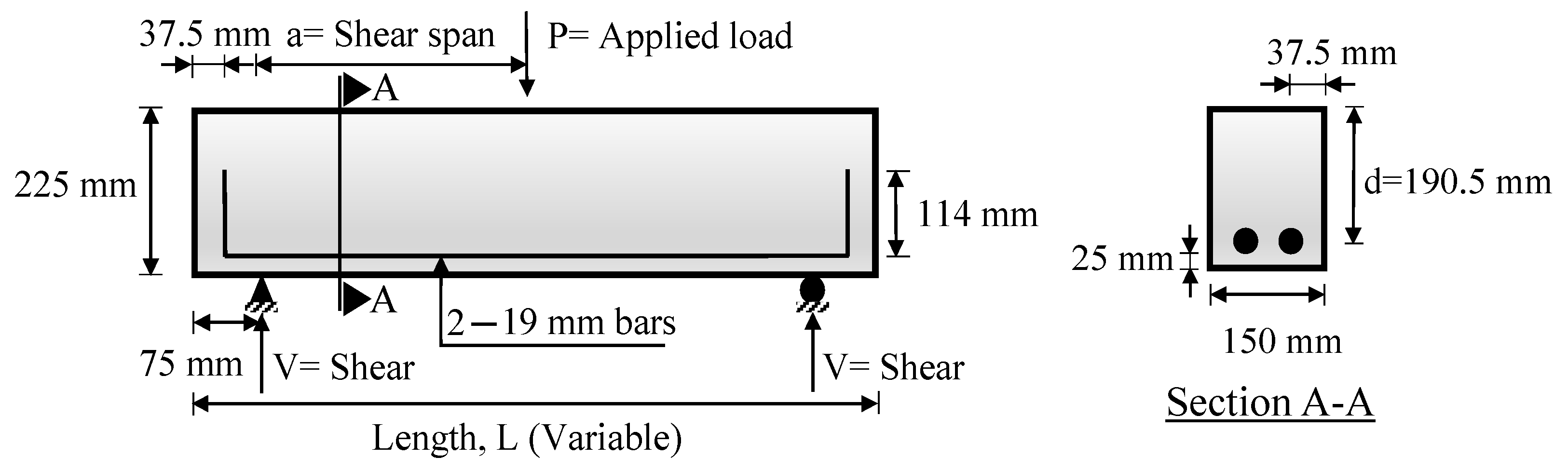

2. Experimental Program

2.1. Materials

2.1.1. Fly Ash

2.1.2. Aggregates

2.1.3. Alkaline Activator Solution

2.1.4. Steel Reinforcement

2.2. Test Matrix

2.3. Preparation of the Test Specimens

2.4. Test Setup

3. Test Results and Discussion

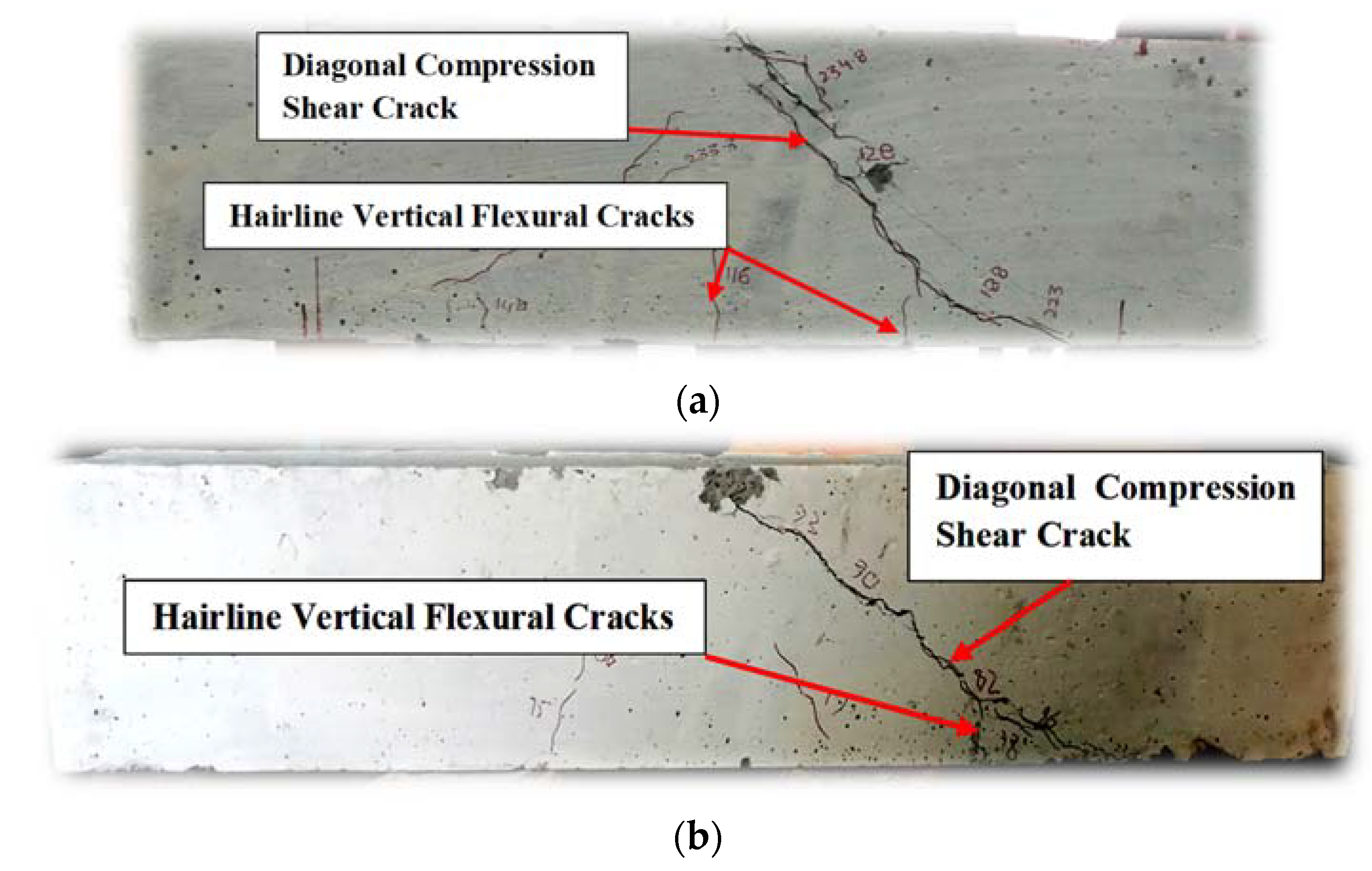

3.1. Failure Mechanism of Beams

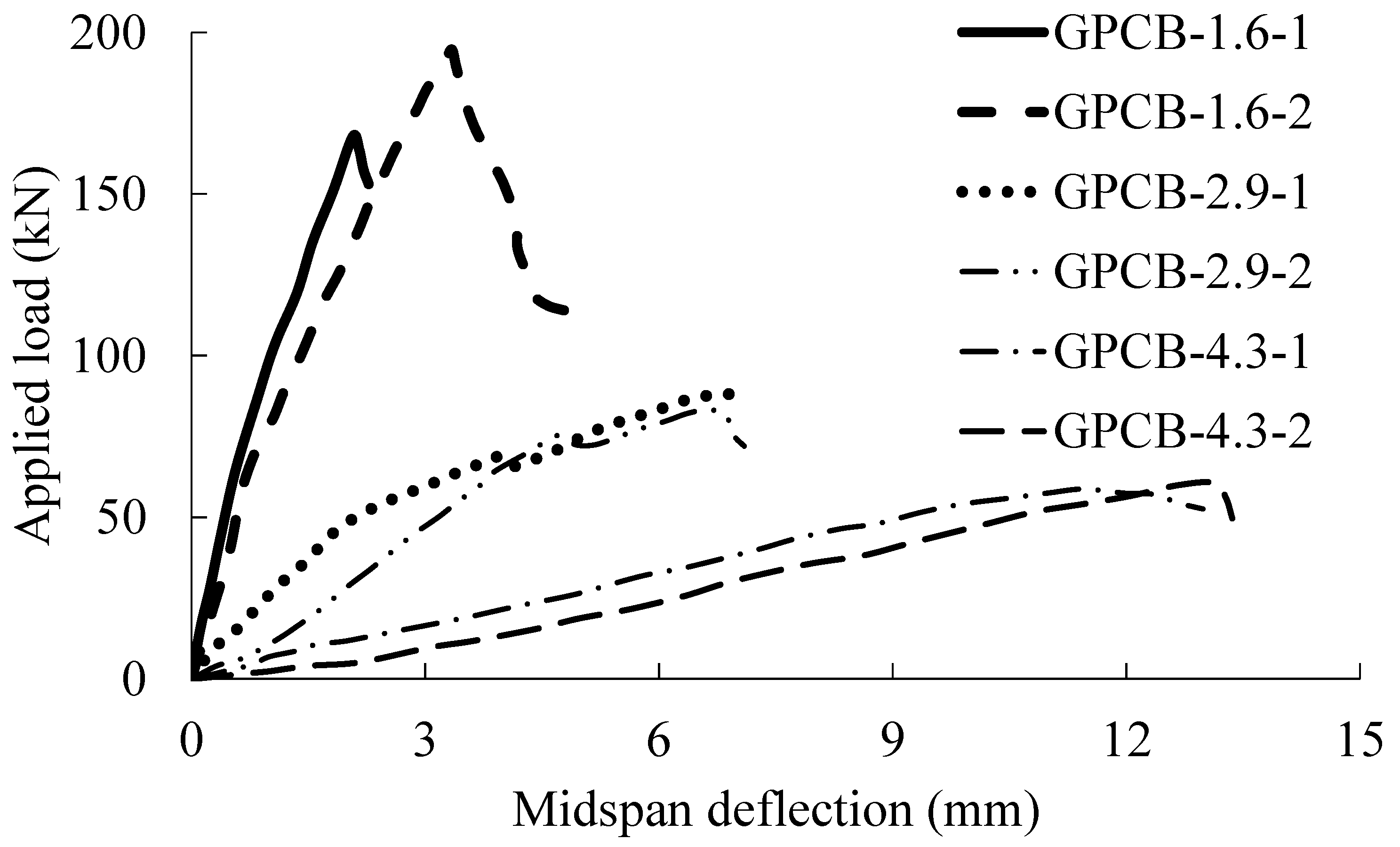

3.2. Load-Deflection Response

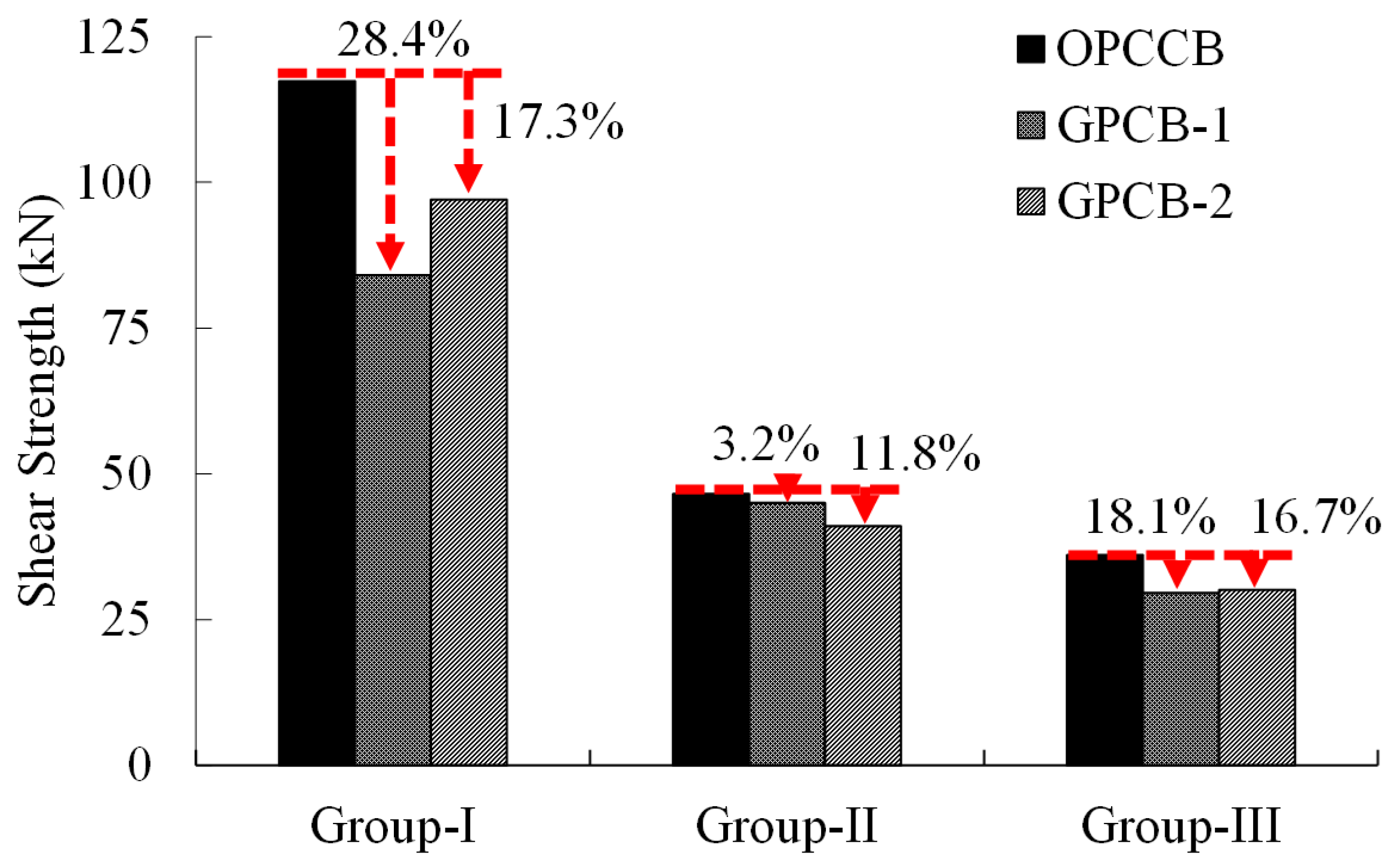

3.3. Shear Strength of the Tested Beams

4. Analytical Design Formulae

4.1. ACI 318-14 [41]

4.2. ACI 318-19 [40]

4.3. JSCE Standard Specifications for Concrete Structures-2007 [43]

4.4. Fib Model Code [42]

5. Analytical Results and Discussion

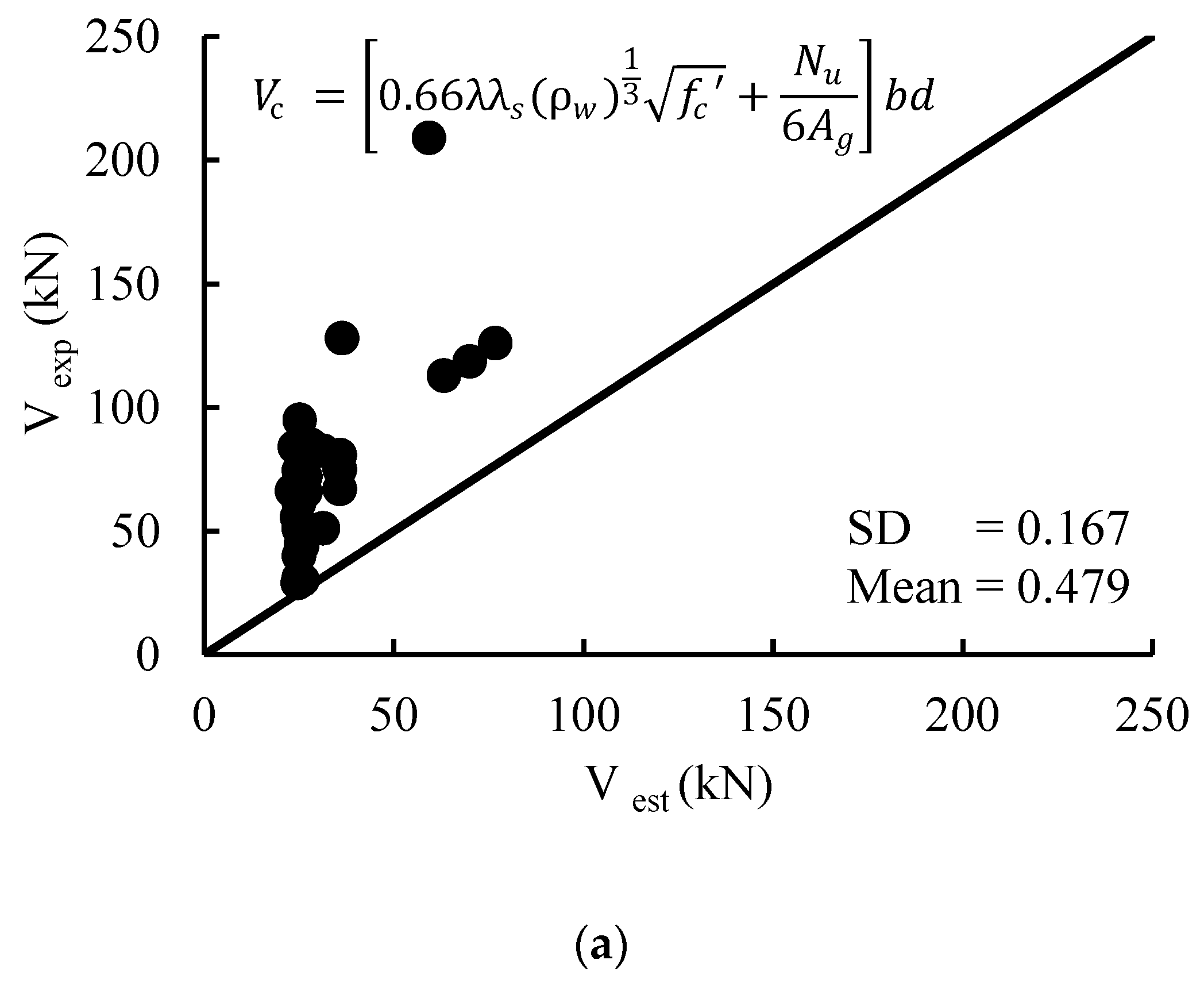

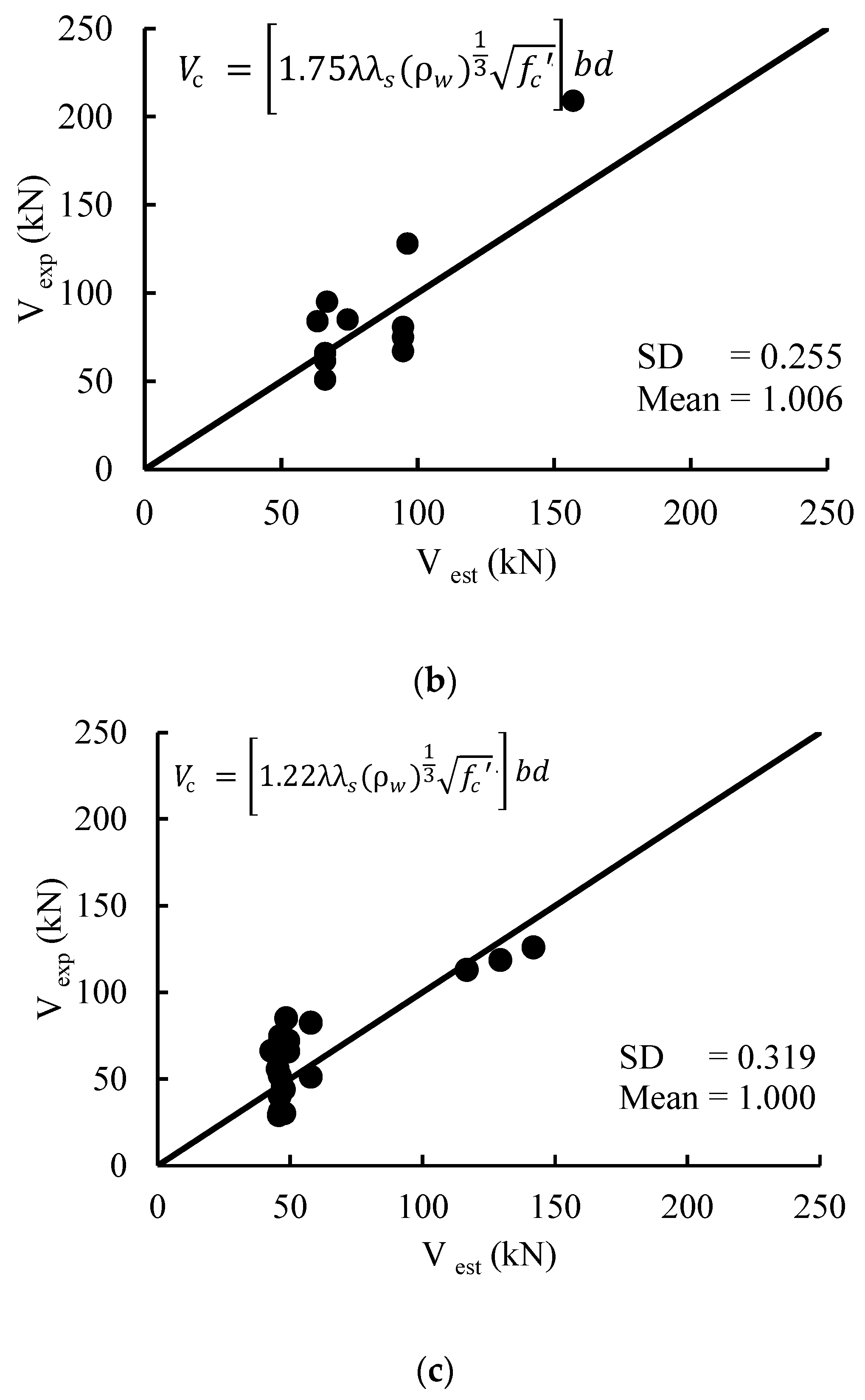

5.1. Ordinary Portland Cement Concrete Beams

5.2. Geopolymer Concrete Beams

5.3. Comparison of Experimental and Analytical Shear Strengths of OPCC and GPC Beams in the Existing Available Research

5.4. Modified Equation for Shear Strength of Geopolymer Concrete Beams at Various

6. Conclusions

- The applied loads and shear strengths of OPCCB and GPCB specimens decreased with an increase in ratio due to the change in the failure mechanism from the tie-arch action to the beam action. The reduction rate of the shear strength of OPCCB specimens was similar to GPCB specimens with increasing ratios. Moreover, the OPCC beams exhibited higher shear strength than ambient-cured GPC beams for a similar ratio.

- All the considered design guides significantly underestimated the shear strengths of GPC beams by 11–77%. However, the prediction accuracy increases at higher ratios. It was noted that for higher ratio, i.e., GPC beam specimen with = 4.3, the prediction accuracy varies between 11.0–26.9% considering ACI 318-14 [41], ACI-318-19 [40], and fib 2010 [42].

- The modified equations proved better prediction accuracy. It is recommended to use Equation (21) for GPC beams with ratios ≤ 2.0 and Equation (22) for those with ratios > 2.0.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- McLellan, B.C.; Williams, R.P.; Lay, J.; van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Farhan, N.A.; Sheikh, M.N. Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Constr. Build. Mater. 2017, 140, 424–431. [Google Scholar] [CrossRef]

- Hason, M.M.; Al-Sulttani, A.O.; Abbood, I.S.; Hanoon, A.N. Emissions Investigating of Carbon Dioxide Generated by the Iraqi Cement Industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 928, 022041. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Axial load-bending moment (PM) Interactions of Geopolymer Concrete Column Reinforced with and without Steel Fiber. ACI Struct. J. 2020, 117, 133–144. [Google Scholar] [CrossRef]

- Sajjad, U.; Sheikh, M.N.; Hadi, M.N.S. Experimental study of the effect of graphene on properties of ambient-cured slag and fly ash-based geopolymer paste and mortar. Constr. Build. Mater. 2021, 313, 125403. [Google Scholar] [CrossRef]

- Qazi, A.U.; Khan, Q.S.; Ahmad, H.A.; Pham, T.M. Axial Behavior of FRP Confined Concrete Using Locally Available Low-Cost Wraps. Sustainability 2022, 14, 9989. [Google Scholar] [CrossRef]

- Kaya, M.; Koksal, F.; Gencel, O.; Munir, M.J.; Kazmi, S.M.S. Influence of Micro Fe2O3 and MgO on the Physical and Mechanical Properties of the Zeolite and Kaolin based Geopolymer Mortar. J. Build. Eng. 2022, 52, 104443. [Google Scholar] [CrossRef]

- Hardjito, D.E.; Wallah, S.M.J.; Sumajouw, D.; Rangan, B.V. On the Development of Fly Ash-Based Geopolymer Concrete. ACI Mater. J. 2004, 101, 467–472. [Google Scholar] [CrossRef]

- Subramanian, S.; Davis, R.; Thomas, B.S. Full-scale static behaviour of prestressed geopolymer concrete sleepers reinforced with steel fibres. Constr. Build. Mater. 2024, 412, 134693. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Engineering Properties of Ambient Cured Alkali-Activated Fly Ash–Slag Concrete Reinforced with Different Types of Steel Fiber. J. Mater. Civ. Eng. 2018, 30, 29–40. [Google Scholar] [CrossRef]

- Ahmad, J.; Ali, S.; Yu, T.; Sheikh, M.N.; Hadi, M.N.S. Analytical investigation on the load-moment interaction behavior of the FRP reinforced geopolymer concrete filled FRP tube circular columns. J. Build. Eng. 2021, 42, 102818. [Google Scholar] [CrossRef]

- Tauqir, M.; Qazi, A.U.; Khan, Q.S.; Munir, M.J.; Kazmi, S.M.S. Shear Behavior of Geopolymer Concrete Slender Beams. Buildings 2023, 13, 1191. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Behaviour of Ambient Cured Steel Fibre Reinforced Geopolymer Concrete Columns Under Axial and Flexural Loads. Structures 2018, 15, 184–195. [Google Scholar] [CrossRef]

- Pradhan, S.S.; Mishra, U.; Biswal, S.K.; Pramanik, S.; Jangra, P.; Aslani, F. Effects of rice husk ash on strength and durability performance of slag-based alkali-activated concrete. Struct. Concr. 2023. [Google Scholar] [CrossRef]

- Yacob, N.S.; ElGawady, M.A.; Sneed, L.H.; Said, A. Shear strength of fly ash-based geopolymer reinforced concrete beams. Eng. Struct. 2019, 196, 109298. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Effect of Steel Fiber on Engineering Properties of Geopolymer Concrete. ACI Mater. J. 2020, 117, 29–40. [Google Scholar] [CrossRef]

- Meesala, C.R.; Verma, N.K.; Kumar, S. Critical review on fly-ash based geopolymer concrete. Struct. Concr. 2020, 21, 1013–1028. [Google Scholar] [CrossRef]

- Diaz-Loya, E.I.; Allouche, E.N.; Vaidya, S. Mechanical properties of fly-ash-based geopolymer concrete. ACI Mater. J. 2011, 108, 300–306. [Google Scholar]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Investigation of engineering properties of normal and high strength fly ash based geopolymer and alkali-activated slag concrete compared to ordinary Portland cement concrete. Constr. Build. Mater. 2019, 196, 26–42. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2017, 130, 22–31. [Google Scholar] [CrossRef]

- Ghafoor, M.T.; Khan, Q.S.; Qazi, A.U.; Sheikh, M.N.; Hadi, M.N.S. Influence of alkaline activators on the mechanical properties of fly ash based geopolymer concrete cured at ambient temperature. Constr. Build. Mater. 2021, 273, 121752. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Salem, H.A. Effect of water addition, plasticizer and alkaline solution constitution on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 121, 694–703. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N. Sodium hydroxide effect on the mechanical properties of flyash-slag based geopolymer concrete. Struct. Concr. 2021, 22, E368–E379. [Google Scholar] [CrossRef]

- Adak, D.; Sarkar, M.; Mandal, S. Structural performance of nano-silica modified fly-ash based geopolymer concrete. Constr. Build. Mater. 2017, 135, 430–439. [Google Scholar] [CrossRef]

- Yost, J.R.; Radlińska, A.; Ernst, S.; Salera, M.; Martignetti, N.J. Structural behavior of alkali activated fly ash concrete. Part 2: Structural testing and experimental findings. Mater. Struct. 2013, 46, 449–462. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Hao, H. Experimental and analytical investigation on flexural behaviour of ambient cured geopolymer concrete beams reinforced with steel fibers. Eng. Struct. 2019, 200, 109707. [Google Scholar] [CrossRef]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of recycled concrete aggregates on the flexural properties of reinforced alkali activated slag concrete. Constr. Build. Mater. 2016, 102, 51–58. [Google Scholar] [CrossRef]

- Słowik, M. Shear Failure Mechanism in Concrete Beams. Proc. Mater. Sci. 2014, 3, 1977–1982. [Google Scholar] [CrossRef]

- Hu, B.; Wu, Y.F. Effect of shear span-to-depth ratio on shear strength components of RC beams. Eng. Struct. 2018, 168, 770–783. [Google Scholar] [CrossRef]

- Ismail, K.S.; Guadagnini, M.; Pilakoutas, K. Shear Behavior of Reinforced Concrete Deep Beams. ACI Struct. J. 2016, 114, 87–99. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P. Shear Behavior of Geopolymer Concrete Beams Reinforced with GFRP Bars. ACI Struct. J. 2017, 114, 337–348. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P.; Nguyen, T.Q. Flexural behavior of geopolymer-concrete beams longitudinally reinforced with GFRP and steel hybrid reinforcements. Eng. Struct. 2019, 182, 141–152. [Google Scholar] [CrossRef]

- Nagajothi, S.; Elavenil, S. Shear Prediction of geopolymer concrete beams using Basalt/Glass FRP bars. J. Adv. Concr. Technol. 2021, 19, 216–225. [Google Scholar] [CrossRef]

- Shibayama, A.; Nishiyama, M. Shear strength of reinforced fly-ash-based geopolymer concrete beams with and without shear reinforcement. Structures 2023, 50, 603–614. [Google Scholar] [CrossRef]

- Wu, C.; Hwang, H.J.; Shi, C.; Li, N.; Du, Y. Shear tests on reinforced slag-based geopolymer concrete beams with transverse reinforcement. Eng. Struct. 2020, 219, 110966. [Google Scholar] [CrossRef]

- Visintin, P.; Mohamed Ali, M.S.; Albitar, M.; Lucas, W. Shear behaviour of geopolymer concrete beams without stirrups. Constr. Build. Mater. 2017, 148, 10–21. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Structural performance of ambient-cured reinforced geopolymer concrete beams with steel fibres. Struct. Concr. 2021, 22, 457–475. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Hao, H. Effect of hybrid fibers on shear behaviour of geopolymer concrete beams reinforced by basalt fiber reinforced polymer (BFRP) bars without stirrups. Compos. Struct. 2020, 243, 112236. [Google Scholar] [CrossRef]

- ACI 318-19; Building Code Requirements for Structural Concrete ACI 318-19 and Commentary 318R-19. American Concrete Institute ACI Committee: Farmington Hills, MI, USA, 2019.

- ACI 318-14; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- International Federation for Structural Concrete (FIB). Model. Code 2010; FIB: Lausanne, Switzerland, 2012; Volume 2. [Google Scholar]

- Japan Society of Civil Engineers. Standard Specifications for concrete structures-2007 Design. JSCE Guidel. Concr. 2010, 15, 156–159. [Google Scholar]

- Albidah, A.S. Shear behviour of metakaolin-fly ash based geopolymer concrete deep beams. Eng. Struct. 2023, 275, 115271. [Google Scholar] [CrossRef]

- Prachasaree, W.; Limkatanyu, S.; Hawa, A.; Samakrattakit, A. Development of Equivalent Stress Block Parameters for Fly-Ash-Based Geopolymer Concrete. Arab. J. Sci. Eng. 2014, 39, 8549–8558. [Google Scholar] [CrossRef]

- ASTM C618-12a; Standard Specifications for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society of Testing and Materials: West Consshohocken, PA, USA, 2012.

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. American Society of Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM C29/C29M-17; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. American Society of Testing and Materials: West Conshohocken, PS, USA, 2017.

- ASTM C33/C33M-18; Standard Specifications for Concrete Aggregates. American Society of Testing and Materials: West Conshohocken, PA, USA, 2018.

- Özkılıç, Y.O.; Çelik, A.İ.; Tunç, U.; Karalar, M.; Deifalla, A.; Alomayri, T.; Althoey, F. The use of crushed recycled glass for alkali activated fly ash based geopolymer concrete and prediction of its capacity. J. Mater. Res. Technol. 2023, 24, 8267–8281. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Tunç, U.; Bahrami, A.; Karalar, M.; Mydin, M.A.O.; Alomayri, T.; Özkılıç, Y.O. Use of waste glass powder toward more sustainable geopolymer concrete. J. Mater. Res. Technol. 2023, 24, 8533–8546. [Google Scholar] [CrossRef]

- Çelik, A.L.I.; Özkılıç, Y. Geopolymer concrete with high strength, workability and setting time using recycled steel wires and basalt powder. Steel Compos. Struct. 2023, 46, 689–707. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Bahrami, A.; Hakeem, I.Y. Mechanical performance of geopolymer concrete with micro silica fume and waste steel lathe scraps. Case Stud. Constr. Mater. 2023, 19, e02548. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Bahrami, A.; Hakeem, I.Y. Effects of glass fiber on recycled fly ash and basalt powder based geopolymer concrete. Case Stud. Constr. Mater. 2023, 19, e02659. [Google Scholar] [CrossRef]

- ASTM A615/A615M-20; Standard Specification for Deformed and Plain Carbon Steel Bars for Concrete Reinforcement. American Society of Testing and Materials: West Conshohocken, PA, USA, 2020.

- ACI 445R-99; Recent Approaches to Shear Design of Structural Concrete. ACI-ASCE Committee 445; American Concrete Institute: Farmington Hills, MI, USA, 1999.

- Wight, J.K.; MacGregor, J.G. Reinforced Concrete Mechanics and Design; Pearson Education: London, UK, 2011. [Google Scholar]

- Kawamura, K.; Takemura, M.; Nakamura, H.; Miura, T. Experimental Study on the Effect of Different Shear Reinforcement Shapes on Shear Failure Behavior and Internal Crack Pattern of RC Beams. J. Adv. Concr. Technol. 2021, 19, 82–94. [Google Scholar] [CrossRef]

- Abdullah, M.; Nakamura, H.; Kawamura, K.; Takemura, M.; Miura, T. Experimental study on the effect of different shear reinforcement shapes and arrangement on 3D crack propagation and shear failure mechanism in RC beams. Structures 2023, 58, 105453. [Google Scholar] [CrossRef]

- ASTM C78/C78M-18; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). American Society of Testing and Materials: West Conshohocken, PA, USA, 2018.

- ASTM C39/C39M-20; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society of Testing and Materials: West Conshohocken, PA, USA, 2020.

- Fayed, S.; Madenci, E.; Özkılıç, Y.O. Flexural Behavior of RC Beams with an Abrupt Change in Depth: Experimental Work. Buildings 2022, 12, 2176. [Google Scholar] [CrossRef]

- Pham, D.Q.; Nguyen, T.N.; Le, S.T.; Pham, T.T.; Ngo, T.D. The structural behaviours of steel reinforced geopolymer concrete beams: An experimental and numerical investigation. Structures 2021, 33, 567–580. [Google Scholar] [CrossRef]

- Gunawan, D.; Okubo, K.; Nakamura, T.; Niwa, J. Shear Capacity of RC Beams Based on Beam and Arch Actions. J. Adv. Concr. Technol. 2020, 18, 241–255. [Google Scholar] [CrossRef]

- Mamdouh, H.; Ali, A.; Osman, M.; Deifalla, A.; Ayash, N. Effects of Size and Flexural Reinforcement Ratio on Ambient-Cured Geopolymer Slag Concrete Beams under Four-Point Bending. Buildings 2020, 12, 1554. [Google Scholar] [CrossRef]

- Du, Y.; Wang, J.; Shi, C.; Hwang, H.-J.; Li, N. Flexural behavior of alkali-activated slag-based concrete beams. Eng. Struct. 2021, 229, 111644. [Google Scholar] [CrossRef]

- Yeung, J.S.K.; Yam, M.C.H.; Wong, Y.L. 1-Year development trend of concrete compressive strength using Calcium Sulfoaluminate cement blended with OPC, PFA and GGBS. Constr. Build. Mater. 2019, 198, 527–536. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Effect of curing condition on the mechanical properties of fly ash-based geopolymer concrete. SN Appl. Sci. 2019, 1, 1694. [Google Scholar] [CrossRef]

- Sinik, M.; Arsalan, G. Effect of shear span to effective depth ratio on the shear strength of RC beams. Int. J. Adv. Sci. Eng. Technol. 2018, 6, 64–66. [Google Scholar]

- ACI 318-63 (1963); Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 1963.

- Kuchma, D.A.; Wei, S.; Sanders, D.H.; Belarbi, A.; Novak, L.C. Development of One-Way Shear Design Provisions of ACI 318-19 for Reinforced Concrete. ACI Struct. J. 2019, 116, 285–296. [Google Scholar] [CrossRef]

- Ma, C.; Guo, Z.; Wang, W.; Qin, Y. Shear Strength Models for Reinforced Concrete Slender Beams: Comparative Analysis and Parametric Evaluation. Buildings 2022, 13, 37. [Google Scholar] [CrossRef]

- Jayasinghe, T.; Gunawardena, T.; Mendis, P. Assessment of shear strength of reinforced concrete beams without shear reinforcement: A comparative study between codes of practice and artificial neural network. Case Stud. Const. Mater. 2022, 16, e01102. [Google Scholar] [CrossRef]

- Aguilar, V.; Barnes, R.W.; Nowak, A.S. Comparative Assessment of Shear Strength Equations for Reinforced Concrete. Pract. Period. Struct. Des. Constr. 2022, 27, 04021082. [Google Scholar] [CrossRef]

- Nikbakht, E.; Wong Weng Lok, J.; Teo, W. Structural behaviour of novel composite beams consisting of geopolymer concrete and high-performance concrete. Structures 2021, 32, 106–115. [Google Scholar] [CrossRef]

- Lee, K.M.; Choi, S.; Choo, J.F.; Choi, Y.C.; Yoo, S.W. Flexural and Shear Behaviors of Reinforced Alkali-Activated Slag Concrete Beams. Adv. Mater. Sci. Eng. 2017, 2017, 5294290. [Google Scholar] [CrossRef]

| SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | CaO (%) | SO3 (%) | MgO (%) | LOI a (%) |

|---|---|---|---|---|---|---|

| 59.96 | 14.02 | 6.29 | 14.12 | 2.84 | 0.41 | 0.445 |

| Specimen ID | Group | Width b, (mm) | Depth h, (mm) | Effective Depth d, (mm) | Length (mm) | Shear Span a, (mm) | a/d Ratio |

|---|---|---|---|---|---|---|---|

| OPCCB-1.6 | I | 150 | 225 | 190.5 | 762 | 306 | 1.6 |

| GPCB-1.6-1 | |||||||

| GPCB-1.6-2 | |||||||

| OPCCB-2.9 | II | 150 | 225 | 190.5 | 1268 | 559 | 2.9 |

| GPCB-2.9-1 | |||||||

| GPCB-2.9-2 | |||||||

| OPCCB-4.3 | III | 150 | 225 | 190.5 | 1774 | 812 | 4.3 |

| GPCB-4.3-1 | |||||||

| GPCB-4.3-2 |

| Type of Concrete | Coarse Aggregate (kg) | Fine Aggregate (kg) | Fly Ash (kg) | Cement (kg) | Alkali Solution (kg) | Na2SiO3 Solution (kg) | Water (L) |

|---|---|---|---|---|---|---|---|

| OPCC | 1215 | 570 | - | 375 | - | - | 169 |

| GPC | 1294 | 345 | 554 | - | 59.1 | 147.8 | 19.4 |

| Specimen ID | 28-Days Concrete Cylinder Strength , (MPa) | Shear Span to Effective Depth Ratio | Initial Diagonal Cracking Load , (kN) | Peak Applied Load (kN) | Experimental Shear Strength , (kN) |

|---|---|---|---|---|---|

| OPCCB-1.6 | 24.7 | 1.6 | 131.3 | 234.8 | 117.4 |

| GPCB-1.6-1 | 22.0 | 108.0 | 168.0 | 84.0 | |

| GPCB-1.6-2 | 24.5 | 99.5 | 194.0 | 97.0 | |

| OPCCB-2.9 | 25.2 | 2.9 | 69.0 | 93.0 | 46.5 |

| GPCB-2.9-1 | 25.6 | 69.0 | 90.0 | 45.0 | |

| GPCB-2.9-2 | 25.1 | 61.0 | 82.0 | 41.0 | |

| OPCCB-4.3 | 25.3 | 4.3 | 21.5 | 72.0 | 36.0 |

| GPCB-4.3-1 | 23.6 | 39.5 | 59.0 | 29.5 | |

| GPCB-4.3-2 | 25.9 | 29.4 | 60.1 | 30.0 |

| Specimen ID | 28-Days Concrete Cylinder Strength | (%) | (%) | (%) | Analytical Peak Load (kN) | Experimental Peak Applied Load (kN) | Experimental Shear Strength (kN) |

|---|---|---|---|---|---|---|---|

| OPCCB-1.6 | 24.7 | 1.98 | 2.52 | 1.60 | 131.3 | 234.8 | 117.4 |

| GPCB-1.6-1 | 22.0 | 1.98 | 2.24 | 1.43 | 108.0 | 168.0 | 84.0 |

| GPCB-1.6-2 | 24.5 | 1.98 | 2.50 | 1.59 | 99.5 | 194.0 | 97.0 |

| OPCCB-2.9 | 25.2 | 1.98 | 2.57 | 1.64 | 69.0 | 93.0 | 46.5 |

| GPCB-2.9-1 | 25.6 | 1.98 | 2.61 | 1.66 | 69.0 | 90.0 | 45.0 |

| GPCB-2.9-2 | 25.1 | 1.98 | 2.56 | 1.63 | 61.0 | 82.0 | 41.0 |

| OPCCB-4.3 | 25.3 | 1.98 | 2.58 | 1.64 | 21.5 | 72.0 | 36.0 |

| GPCB-4.3-1 | 23.6 | 1.98 | 2.41 | 1.53 | 39.5 | 59.0 | 29.5 |

| GPCB-4.3-2 | 25.9 | 1.98 | 2.64 | 1.68 | 29.4 | 60.1 | 30.0 |

| Specimen ID | Experimental Shear Strength (kN) | Computed/Experimental Results | |||

|---|---|---|---|---|---|

| ACI 318-14 [41] | ACI 318-19 [40] | JSCE 2007 [43] | Fib 2010 [42] | ||

| OPCCB-1.6 | 117.4 | - | 0.258 | 0.508 | 0.184 |

| GPCB-1.6-1 | 84.0 | - | 0.341 | 0.669 | 0.238 |

| GPCB-1.6-2 | 97.0 | - | 0.311 | 0.609 | 0.220 |

| OPCCB-2.9 | 46.5 | 0.549 | 0.579 | 0.475 | 0.468 |

| GPCB-2.9-1 | 45.0 | 0.575 | 0.598 | 0.491 | 0.483 |

| GPCB-2.9-2 | 41.0 | 0.625 | 0.654 | 0.535 | 0.528 |

| OPCCB-4.3 | 36.0 | 0.708 | 0.750 | 0.303 | 0.604 |

| GPCB-4.3-1 | 29.5 | 0.834 | 0.873 | 0.360 | 0.706 |

| GPCB-4.3-2 | 30.0 | 0.864 | 0.908 | 0.373 | 0.731 |

| Research Study | Concrete Type | Curing | (MPa) | a/d | Experimental Shear Strength (kN) | Computed/Experimental Results | |||

|---|---|---|---|---|---|---|---|---|---|

| ACI 318-14 [41] | ACI 318-19 [40] | JSCE 2007 [41] | fib 2010 [42] | ||||||

| Yacob et al. [15] | GPC | Heat | 37.2 | 2.0 | 209.0 | 0.27 | 0.26 | 0.36 | 0.21 |

| GPC | 2.0 | 128.0 | 0.37 | 0.36 | 0.50 | 0.30 | |||

| Visintin et al. [37] | GPC | Ambient | 21.0 | 2.0 | 79.0 | 0.37 | 0.32 | 0.46 | 0.30 |

| Sinik and Arsalan [69] | OPC | Ambient | 24.8 | 2.5 | 84.9 | 0.30 | 0.28 | 0.28 | 0.25 |

| Visintin et al. [37] | GPC | Ambient | 24.0 | 2.5 | 72.0 | 0.43 | 0.38 | 0.37 | 0.35 |

| GPC | Ambient | 33.0 | 2.5 | 82.4 | 0.44 | 0.39 | 0.38 | 0.36 | |

| GPC | Ambient | 21.0 | 2.5 | 51.8 | 0.68 | 0.66 | 0.58 | 0.52 | |

| Visintin et al. [37] | GPC | Ambient | 24.0 | 3.0 | 65.8 | 0.47 | 0.41 | 0.29 | 0.38 |

| GPC | Ambient | 21.0 | 3.0 | 40.0 | 0.88 | 0.68 | 0.54 | 0.67 | |

| Lee et al. [76] | GPC | NA * | 55.3 | 3.0 | 112.9 | 0.56 | 0.57 | 0.39 | 0.45 |

| GPC | NA * | 55.3 | 3.0 | 118.6 | 0.53 | 0.60 | 0.41 | 0.43 | |

| OPC | NA * | 55.3 | 3.0 | 125.9 | 0.50 | 0.62 | 0.42 | 0.41 | |

| Sinik and Arsalan [69] | OPC | Ambient | 24.9 | 3.5 | 74.5 | 0.34 | 0.32 | 0.18 | 0.29 |

| Visintin et al. [37] | GPC | Ambient | 21.0 | 3.5 | 31.1 | 0.94 | 0.82 | 0.44 | 0.76 |

| GPC | Ambient | 33.0 | 3.5 | 51.2 | 0.72 | 0.62 | 0.33 | 0.58 | |

| Tauqir et al. [12] | GPC | Ambient | 25.0 | 4.5 | 35.9 | 0.66 | 0.68 | 0.24 | 0.55 |

| OPC | Ambient | 22.0 | 4.5 | 38.0 | 0.59 | 0.61 | 0.21 | 0.49 | |

| Sinik and Arsalan [69] | OPC | Ambient | 21.4 | 4.5 | 66.2 | 0.36 | 0.33 | 0.12 | 0.30 |

| Tauqir et al. [12] | GPC | Ambient | 31.0 | 5.0 | 39.5 | 0.66 | 0.69 | 0.20 | 0.56 |

| OPC | Ambient | 21.4 | 5.0 | 28.7 | 0.77 | 0.80 | 0.23 | 0.65 | |

| Sinik and Arsalan [69] | OPC | Ambient | 23.8 | 6.0 | 55.6 | 0.45 | 0.42 | 0.08 | 0.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdullah, M.; Qazi, A.U.; Khan, Q.S.; Kazmi, S.M.S.; Munir, M.J. Experimental and Analytical Investigations on Shear Performance of Ambient-Cured Reinforced Geopolymer Concrete Beams. Buildings 2024, 14, 204. https://doi.org/10.3390/buildings14010204

Abdullah M, Qazi AU, Khan QS, Kazmi SMS, Munir MJ. Experimental and Analytical Investigations on Shear Performance of Ambient-Cured Reinforced Geopolymer Concrete Beams. Buildings. 2024; 14(1):204. https://doi.org/10.3390/buildings14010204

Chicago/Turabian StyleAbdullah, Muhammad, Asad Ullah Qazi, Qasim S. Khan, Syed Minhaj Saleem Kazmi, and Muhammad Junaid Munir. 2024. "Experimental and Analytical Investigations on Shear Performance of Ambient-Cured Reinforced Geopolymer Concrete Beams" Buildings 14, no. 1: 204. https://doi.org/10.3390/buildings14010204

APA StyleAbdullah, M., Qazi, A. U., Khan, Q. S., Kazmi, S. M. S., & Munir, M. J. (2024). Experimental and Analytical Investigations on Shear Performance of Ambient-Cured Reinforced Geopolymer Concrete Beams. Buildings, 14(1), 204. https://doi.org/10.3390/buildings14010204