Abstract

Air-permeable building envelopes (APBEs) utilize the infiltrated or exfiltrated airflow within porous materials to directly change their temperature distribution to reduce heat loss/gain. APBEs effectively integrate building ventilation and heat recovery to achieve excellent thermal insulation while improving indoor air quality. This paper presents a comprehensive review of the fundamentals and classifications, historical evolution over time, opportunities and benefits, and future views on APBEs. It can be treated as a responsive building envelope that enables building envelopes to dynamically change the U-values by varying the infiltrated or exfiltrated airflow rate within a porous material. Previous studies have indicated that the U-value of 0.1 W/(m2·K) can be realized by employing APBEs. Moreover, some research demonstrates that APBEs could act as high-performance air filters that reduce over 90% of particulate matter within fresh, ventilated air. Some factors, such as airflow rate, thickness, and thermal conductivity of porous materials, have a significant influence on the effectiveness of APBEs. For practical applications, integrating the APBE with passive building ventilation can help reduce the initial cost and facilitate decarbonization in buildings. Moreover, advanced control strategies could collaboratively optimize the operation of ABPEs and build energy systems to maximize their energy-saving potential.

1. Introduction

Energy conservation in buildings is of great importance for the sustainable development of society and achieving the targets of carbon neutrality and climate action plans. It is estimated that the building sector contributes to about a quarter of global CO2 emissions and accounts for approximately a third of total energy consumption [1]. The percentage of energy use in the building sector accounts for a significant proportion (23~50%) of the total energy use in different countries [2]. This fact highlights the need for energy conservation in buildings. Therefore, improving the energy efficiency of buildings is becoming an increasingly crucial energy conservation issue.

High-performance building envelopes play a key role in energy efficiency. Passive and active techniques have been developed to improve the energy efficiency of building envelopes [3,4,5]. Much effort has been devoted to advanced wall technologies such as Trombe walls [6,7,8], double skin façades [9,10,11], active pipe-embedded walls [12,13,14], phase change material walls [15,16,17], and transpired solar collector walls [18,19,20].

Integrating air layers into building envelopes as an internal structure layer is a strategy that is attracting significant attention [21]. Trombe walls, double skin façades, hollow block ventilation walls [22,23,24], and others take advantage of favorable local environments by introducing an enclosed or ventilated air layer to achieve high thermal performance. Briga-Sá et al. [25] reported that 16.36% heating energy savings were achieved by adding a Trombe wall to the building envelope. Ghaffarianhoseini et al. [26] reviewed the advantages of double skin façades and reported such benefits as reduced energy consumption, enhanced thermal comfort, daylight, and glare control. Yu et al. [24] proposed a new kind of wall ventilation, called hollow block ventilation, where the supply air is forced to flow through the cavity of hollow blocks, and showed experimentally that hollow block ventilation increases the thermal resistance of building envelopes.

Employing porous materials as a thermal insulation layer is another advanced wall technology that increases thermal resistance [27]. Porous materials, such as mineral wool, polyester fiber, and coal fly ash, consist of a solid matrix with interconnected pores whose physical properties lower the thermal conductivity and raise the structural stability of a building’s thermal insulation. Zhang et al. [28] recommended a new type of thermal insulation material made of coal fly ash and fabricated by a foaming and slip casting process. The thermal conductivity of this material was as low as 0.0511 W/(m·K). Moretti et al. [29] developed innovative mineral fiber insulating panels with thermal conductivities in the range of 0.032–0.034 W/(m·K) using various densities, which suggested that mineral fiber panels were suitable for building refurbishment. Li et al. [30] investigated the thermo-physical properties of porous materials consisting of fumed silica, hollow glass microspheres, and polyester fibers. A porosity of 80–90% was achieved, and the resulting vacuum insulation panel (VIP) fabricated with this material had a total thermal conductivity of less than 0.0072 W/(m·K).

Building envelopes are traditionally designed to be impermeable to air. Air-permeable building envelopes (APBEs) made of lightweight porous material have been extensively studied in recent years. APBEs, which combine airflow and porous material layers, are a kind of dynamic insulation building envelope. Unlike the insulation approach that uses a layer of air or porous material alone, APBEs utilize the ventilated airflow within porous material layers to directly change the temperature profile within the building envelope to reduce the cooling/heating load [31,32]. Infiltrated airflow within the porous material of APBEs from outdoor to indoor recovers the heat loss through building envelopes in winter to preheat the ventilated fresh air. Moreover, exfiltrated airflow within porous materials of APBEs from indoor to outdoor reduces the heat gain through building envelopes in summer. The porous material layer in APBEs acts as a heat exchanger to transfer heat with ventilated airflow. The concept of APBE has existed for a long time in the literature [33,34,35,36]. In the past few years, the development of analytic or numerical models, thermal characteristics, parametric analysis, and the energy-saving potential of APBEs have been widely investigated. Therefore, it is necessary to present a comprehensive and systematic review of the research, development, and future perspectives of APBEs.

This review paper aims to present a comprehensive overview of the fundamentals and classifications, historical evolution and research trends over time, opportunities and benefits, and future views of APBEs. The main structure of this review is as follows: Section 2 introduces the basic principles, classification, and operation modes and the potential applications of APBE. The historical development, research trends, and bibliometric analysis of APBE over time are presented in Section 3. The opportunities and benefits of using APBEs for energy-saving, indoor thermal comfort, and indoor air quality are summarized in Section 4. Perspectives on future research, e.g., integrating with passive building design and smart control, are discussed. This paper provides a comprehensive review and clear picture of the development, research progress, and future perspectives of APBEs.

2. Fundamental and Classification of Air-Permeable Building Envelopes

2.1. Basic Principle

The APBE, as distinguished from conventional insulation, refers to a mechanism for insulating building envelopes (consisting of air-permeable porous materials) that allows ventilation air to travel through the building envelope either passively or mechanically. Hence, the conductive heat transfer through the building envelope is reduced to a very low level [37]. The building envelope acts as a heat exchanger that precools or preheats the air for ventilation purposes. By effectively integrating building ventilation and conventional thermal insulation, APBE emerges as a promising approach towards enhancing indoor air quality (IAQ) whilst achieving superior thermal efficiency.

An air-permeable porous material is the core component of APBE. When the ventilation air travels through the porous material at a relatively slow velocity, heat transfer is notably improved by the enormous surface area available for heat exchange and the incremental time that the airflow is in contact with the building envelope. This makes the surface temperature of the building envelope adjacent to the airflow extremely close to the temperature of the inflowing air; therefore, little or no heat transfer is caused by convection between the surface and the ambient air. Moreover, the ventilation air is being preheated in winter and precooled in summer; hence, the heat loss by conduction from the building envelope is substantially reduced. In general, the porous material can be made of mineral wool [31,38], rock wool [39], cellulose [34], polyester fiber [40], glass fiber [41], polyurethane foam [42], air-permeable concrete [43,44], or perforated aluminum sheets [45]. Using porous materials with different thermal conductivities could result in APBE with various thermal performance characteristics [46].

2.2. Operation Modes and Classification

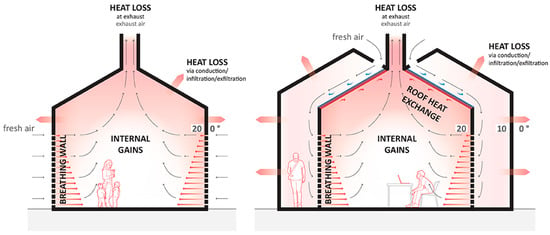

Depending on the direction of airflow in the porous material, there are two distinct operational modes of APBE: the infiltration mode [47] and the exfiltration mode [48], as shown in Figure 1. In the infiltration mode, outdoor fresh air infiltrates through APBEs to the inside from the outside, while the infiltration airflow within the porous material layer would be preheated or precooled in a heating or cooling season, respectively. The schematic of integrating DI into buildings is presented in Figure 2. The infiltration mode of APBE has been extensively applied and studied more than the exfiltration mode, owing to its advantages such as heat recovery, air filtering, energy savings, and building ventilation [49,50]. The infiltration mode of APBE is also called breathing wall (BW) or dynamic insulation (DI) in the literature. The DI is more suitable for the heating season because the continuous airflow from the colder side to the warmer side effectively ventilates the building in winter, and the heat loss through building envelopes will be recovered to preheat the infiltration airflow. Moreover, interstitial condensation does not occur within the DI in winter, while the use of the DI in summer (also called the cooling season) may lead to moisture condensation within porous material, which may lead to the growth of bacteria and an increase in the flow resistance of infiltration airflow via the DI. Hence, it may not be recommended as a practical application of DI in summer.

Figure 1.

Infiltration and exfiltration mode of APBE.

Figure 2.

Schematic of infiltration mode of APBE [47].

In the exfiltration mode, indoor exhaust air due to the building ventilation system is exfiltrated through the building envelope. The exfiltration airflow within porous material can directly reduce heat gain/loss through APBE. The exfiltration mode of APBEs can be called exhaust air insulation wall (EAIW), which can achieve an integration of indoor exhaust air heat recovery and active thermal insulation of building envelopes [31,51]. Figure 3 illustrates the application of EAIW in an air-conditioned building. This wall can directly recover and use the indoor exhaust air within each conditioned room instead of installing additional mechanical fans and air ducts to collect exhaust air from different air-conditioned rooms, like air-to-air heat exchangers. It should be noticed that condensation may also occur within the EAIW in winter, which is detrimental to its practical application.

Figure 3.

Schematic of exfiltration mode of APBE [48].

The driving force of the infiltration or exfiltration airflow through APBE can be a mechanically ventilated fan or a pressure difference between indoors and outdoors. The pressure differential that drives infiltration or exfiltration airflow in DI or EAIW can be produced mechanically (by fan) or naturally (by using the buoyancy or stack effect). There are more site options available, mechanical ventilation is easier to design, and its performance is more reliable. It does, however, result in higher energy consumption and initial costs. Designing for natural ventilation can be more challenging because site circumstances and wind speed and direction have a significant impact on the building design [52]. Etheridge and Zhang [53] carried out a theoretical study to investigate the technical feasibility of natural ventilation alone applied to DI and suggested that DI and natural ventilation are compatible and that there is a strong synergy between DI and ambient wind.

2.3. Application and Advantages

APBE concepts can be applied to building envelopes such as walls, roofs, or other building areas. The most common application of APBEs is the air-permeable wall [31,40]. APBEs in roofs with large ventilation areas may be technically simpler than walls to design and construct [52], and it is more likely that ventilation air can travel through porous materials through natural ventilation [53]. In addition, some Japanese researchers have turned to a new research area that focuses on DI applied to window frames [54]. Moreover, the temperature of outdoor air is much lower than indoor temperatures in winter. To further improve the energy efficiency of DI systems, an air-to-air heat recovery unit can be integrated with the DI system, as shown in Figure 4, to utilize the warm exhaust air (18 to 22 °C) to preheat the infiltrated cold outdoor air.

Figure 4.

Integrating air-to-air heat recovery units with DI system [55].

Usually, APBEs show obvious advantages when compared with conventional building envelopes. Considerable energy can be saved due to the potential heat recovery for ventilation air and the near-zero U-value of porous building envelopes. It is estimated by Dalehaug et al. [56] that DI scaled up to a single-family house can reclaim 50% of conductive heat loss from the building. Indoor thermal comfort can also be improved because the supply of fresh air is preheated. In fact, for the exfiltration mode of APBE, the interior surface temperature of EAIW is extremely close to the indoor air temperature [31], which decreases the mean radiant temperature in the cooling season and improves indoor thermal comfort. Furthermore, the porous materials in DI theoretically provide air filtration, thereby improving the IAQ. Porous materials in DI also provide cost savings because of their superior thermal performance. An extremely low heat flux can be achieved by employing a thin DI, eliminating the need to use thick wall constructions to meet building regulations and reduce construction costs. DI also makes the wall act as the source of ventilation, thereby reducing the initial cost of ventilation systems. However, APBEs also have their disadvantages. For example, a successful APBE in a house requires it to be airtight, requiring careful design and precise engineering, which may increase capital investment and construction costs. Further, additional fan power may be needed to control the ventilation air optimally; hence, the increased energy consumption of the electrical system must be offset by savings from the APBE. This may make APBEs less attractive.

In both infiltration and exfiltration modes, where the air flows from the warm side to the cool side, there could be a risk of condensation when the cool side temperature is lower than the dew point temperature of the ventilated airflow. Long-term condensation within the porous material may decrease the thermal resistance of the building material, increase the pressure loss of airflow, and cause the growth of bacteria. Therefore, the exfiltration mode of APBE (i.e., EAIW) is more suitable for cooling-dominated climate conditions, while its infiltration mode (i.e., DI) is more applicable to heating-dominated climate conditions.

Regardless of these potential drawbacks, APBE can integrate building ventilation and heat recovery and provide promising thermal and energy performance.

3. Historical Development and Research Trend

3.1. Early Studies (before 1990)

The earliest records related to air-permeable BW or DI date back to the middle of the 19th century, when Max von Pettenkofer [57], a professor at the University of Munich in Germany, carried out studies on the transport of moisture and air through air-permeable building materials into buildings [58,59].

From the 1960s to the 1980s, DI emerged as a concept studied by researchers from Germany, Norway, Sweden, Austria, France, Finland, and Canada and was originally applied to farm buildings and animal houses (e.g., barns, poultry houses, and stables) [36]. However, much of this work remains undiscovered because it was published internally in non-English languages with limited distribution. The German term Porenlüftung alludes to the idea of “breathing” with ventilation through pores [60], while the Norwegian phrase Pustende bygningskonstrksjoner highlights the idea of “breathing building” construction [61]. In Swedish, dynamisk isolering refers to dynamic insulation [62]. A study conducted by Thoren [62] in Sweden examined the impact of air exchange on surface temperature and changes in heat transmission through radiation and convection. Similarly, in Norway, Grμe [61] found evidence of heat recovery in traditional steadings caused by the stack effect, which draws air across high-level stored hay.

In 1965, Pattie [63] developed the thermal principles, mathematical representation, and experimental evidence for the DI of an animal building. The heat and moisture transfer characteristics of a dynamically insulated ceiling operated in infiltration mode were carefully studied. This study developed a porous, insulated building with controlled indoor negative pressure, maintained by a mechanical fan. It aims to minimize building heat loss through infiltration, which permits the escape of water vapor and consequently reduces the requirement for ventilation. Turnbull and Hickman [64] and Turnbull and Darisse [65] carried out studies on negative-pressure ventilation of dairy barns with porous ceiling inlet systems during the 1970s, indicating that fully porous ceilings were effective in transporting considerable water vapor to the attic space without proportionally increasing the heat loss due to ventilation.

In 1981, Bartussek [66] measured the humidity profiles of DI for stables and showed experimentally that DI can behave as if it contained a vapor barrier on the inside. This study is the first known record of early researchers [33] in which humidity was considered and measured in experiments. Another significant study by Bartussek [36] in 1986 led to the first application of the concept of DI in residential buildings. Although this study is referred to by some researchers [34,59], it remains controversial because a French study [41] published the same year reported that several residential houses built in France had applied this unconventional insulating technique. Even earlier than residential buildings, a report in Sweden, referenced in [41,67], claimed that approximately 60,000 m2 of DI in Sweden and 500,000 m2 in Finland had been constructed for industrial building roofs in 1980.

In 1986, Arquis and Langlais [41] carried out systematic studies on DI, including full-scale laboratory tests, theoretical model development, and a discussion on limitations. In that study, three types of DI were formally defined based on ventilation and insulation mechanisms: parietodynamic insulation, permeodynamic insulation, and thermodynamic insulation. Parietodynamic insulation is defined as having ventilation air that travels along but not through the porous medium, while permeodynamic insulation has ventilation air that travels through the porous medium. For thermodynamic insulation, the air circulates in a closed circuit independent of the ventilation system. The first two types that have ventilation air circulating along or through the porous material are the general types of DI. The major difference between them is that the heat transfer process occurs either at the surface or in the interior of the porous material.

3.2. Medium-Term Development (from 1990 to 2009)

In the 1990s, there was considerable research interest in DI, mainly focusing on mathematical modeling and performance assessment. Significant work was conducted by Wallentén [67,68] (at the University of Lund, Sweden), and Taylor et al. [33,37,69] (at the University of Aberdeen, Scotland). In 1995, Wallentén [68] presented both the steady-state and transient heat transfer model in one dimension of DI and deduced an analytical solution. It was the first presentation of an unsteady-state model that considered time variation. In 1996, Wallentén reported a more detailed study [67] based on measurements in a house with a dynamically insulated ceiling. The single-story family house, called the OPTIMA house, was continuously monitored for one and a half years. The dynamic U-value and energy efficiency were analyzed theoretically and experimentally.

In 1996, Taylor et al. [33] reached a milestone in the study of DI by clearly presenting an analytical method under steady-state conditions in an international journal; this study is still cited today [31,44,70,71]. By presenting the temperature and humidity profiles for a three-layer permeable wall envelope, the physics of DI were readily understandable. The characteristics of the heat and water vapor fluxes were also analyzed. Subsequently, Taylor and Imbabi considered the inner and outer air films on both sides of air-permeable porous materials [37] and highlighted the effect of air films when assessing surface temperatures and heat transfer processes of the DI. Moreover, more practical conditions were considered with the dynamic insulation technology employed in full-scale houses. Energy efficiency [46], IAQ [69], fire safety, wind effect [72], and environmental design principles [52] have also been evaluated.

During this time, other scholars focused on DI and promoting its development. Dalehaug et al. [56] carried out analytical calculations and experimental measurements on a single-story residential house and reported that 50% of conduction heat loss could be recovered by a DI system. Furthermore, Krarti [73] theoretically explored the temperature profiles and heat flux variations within an air-permeable wall and concluded that energy savings of up to 20% could be achieved. This increasing attention resulted in dynamic insulation being recognized as a ventilation heat recovery method by the Air Infiltration and Ventilation Centre [74] of the International Energy Agency (IEA). Their report briefly introduced the basic classification and the advantages and disadvantages of DI.

In addition to theoretical studies, several practical applications of DI under actual building conditions were designed and operated during the 1990s. Buildings such as the Camphill Trust building in Aberdeen, the OPTIMA House in Sweden [67], and the Rykkinnhallen Sports Hall in Norway were recognized as early applications but had few references [59]. However, fairly detailed descriptions of the McLaren Community Leisure Centre (MCLC) in Scotland were published [75]. The MCLC, built in 1998, was reported as the largest DI building in the world at the time and pioneered the use of a DI system in a swimming pool environment [75]. DI was introduced at the ceiling level for many spaces, including sports halls, bowling halls, squash courts, and swimming pools. Fans were used to slightly pressurize the roof voids above the ceilings by drawing outside air into the loft space. Likewise, exhaust fans were utilized to slightly depressurize the rooms below these ceilings by extracting air from the room. These fans established a pressure differential of 10 to 15 Pa, which pulled air through the insulation across the entire insulation surface.

In the 2000s, several developments facilitated the study of DI. A special test apparatus is needed to assess the thermal performance of full-scale DI systems. Baker [34] set up a PASSYS test cell in the UK and used a prototype wall to investigate the influence of airflow rate experimentally. A PASLINK test cell was designed by Dimoudi et al. [38] in Greece to examine the operational principle and thermal performance of a DI under real weather conditions.

During this time, researchers also began to explore air filtration effects and micro-scale heat transfer using numerical methods [76]. Gan [55] evaluated the thermal environment in a dynamically insulated room by means of CFD and demonstrated that airflow through infiltration would impair thermal comfort; therefore, airtightness was a crucial factor for the effectiveness of DI. To focus on air filtration, Qiu and Haghighat [77] developed numerical and analytical models for the diffusive DI building envelope. It was noted that heat exchange performance is determined primarily by airflow rate, with the infiltration path as a secondary influence. Jokisalo et al. [78] experimentally demonstrated that infiltration would cause an approximately 15–30% increase in heating load. Wong et al. [79] investigated the thermal conductivity in air-permeable dynamic concrete from a microscopic perspective. For practical application, Imbabi [80] constructed DI modules suitable for the market. Elsarrag et al. [81,82] carried out field trials with this module, demonstrating its energy savings, economic efficiency, and high IAQ.

3.3. Recent Studies (after 2010)

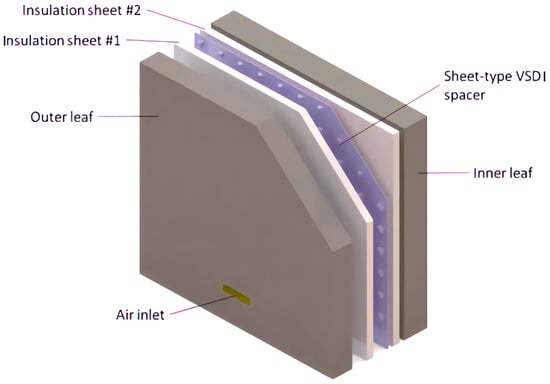

In the 2010s, new applications using the concepts of dynamic insulation were proposed [83] and continued to focus on evaluating its thermal performance and application feasibility. Imbabi [84] introduced a novel technology called void space dynamic insulation (VSDI), where airflow is confined within a coplanar void space bound by one or more layers of insulation material and the wall structure, as shown in Figure 5. The VSDI produces uniform and bidirectional airflow through the wall in a passive way. The VSDI can be installed either integrated or separately, making it a cost-effective and easily applicable solution for dynamically insulating various building envelopes, such as walls and roofs. Kato et al. [54] creatively applied the concept of DI to window frames. With the aid of a mechanical fan, the ventilation air is drawn into the DI window frame through porous materials. The high energy efficiency and low U-value of DI window frames were investigated by field tests and CFD.

Figure 5.

Schematic of void space dynamic insulation (VSDI) module [84].

Elsarrag et al. [81] first introduced dynamic insulation to the Gulf Region in hot-humid climates. The use of DI, in which the supply air enters the room through the air-permeable wall, decreased the U-value of the external wall envelope from 0.24 to 0.05 W/(m2·K). Elsarrag and Alhorr [85] further investigated the reduction of cooling load and carbon emissions by using the DI in hot-humid climates. Although most DI systems in the literature operate during the heating season, Ascione et al. [49] estimated the applicability of DI in the cooling season and demonstrated that the DI building envelope coupled with nocturnal free cooling could lower indoor air temperatures and improve thermal comfort. Di Giuseppe et al. [40] carried out a preliminary study of the thermal and filtration performance of DI for the temperate climate of Italy. The experimental and simulation results show promising thermal and filtration performance of DI for future applications. Murata et al. [43] carried out experiments to evaluate a breathing, dynamically insulated wall. They found that approximately 90% of heat and 80% of moisture in exhaust air and 22–30% heat loss in conduction could be recovered.

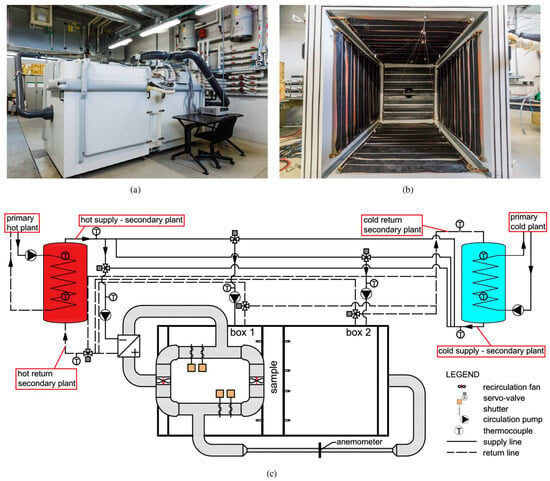

Alongi et al. [44,86] designed a novel laboratory apparatus named the Dual Air Vented Thermal Box (DAVTB), as shown in Figure 6, then experimentally investigated the unsteady-state and steady-state behavior of an air-permeable sample used in the DI system. The elaborate apparatus and elegant experiments helped validate the classical steady-state analytical model [44] and a steady-periodic analytic model [87] to calculate the temperature profile inside dynamically insulated walls. Alongi and Mazzarella [39] also studied the thermal performance of fibrous insulating materials at a microscopic scale for their application in DI.

Figure 6.

Schematic of Dual Air Vented Thermal Box for experimental measurement of DI: (a) general view; (b) internal view; (c) layout of experimental rig [44].

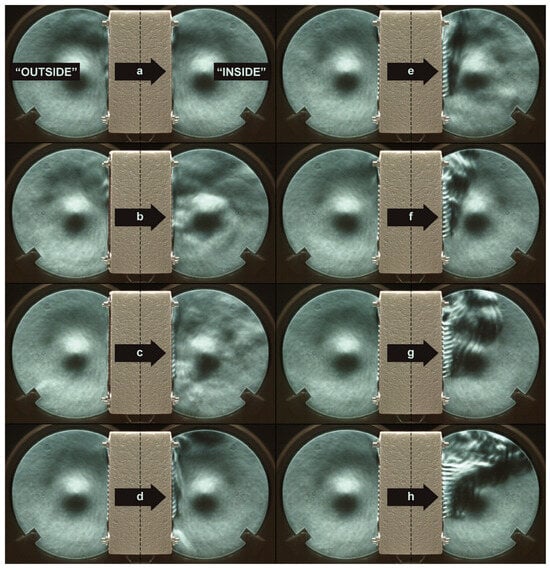

Craig and Grinham [47] conducted precise measurements on porous materials in order to examine the heat transfer mechanism on the surface of porous materials. They employed a schlieren imaging experiment, as illustrated in Figure 7, to demonstrate the correlation between the thickness of convection boundary layers on the two surfaces of air-permeable porous materials and the infiltration airflow within the DI. It was found that the blowing airflow on the interior surface of the DI increases the boundary layer thickness, thereby increasing thermal resistance. Conversely, the suction airflow on the exterior surface of the DI decreases the boundary layer thickness, thus reducing thermal resistance. Additionally, Craig et al. [70] developed and optimized a mass timber panel-based DI module to minimize operational and embodied carbon emissions in buildings.

Figure 7.

Schlieren imaging experiment for determining the thickness of convection boundary layers at the two surfaces of air-permeable material [47]. Notes: a to h means different airflow velocity (e.g., a is non-ventilated condition, h has the highest airflow velocity).

To reduce the interior surface temperature of the external wall in summer, Wang et al. [31] proposed the concept of exhaust air insulation-based APBE, which is applicable to cooling-dominated buildings. The EAIW consists of air-permeable porous materials that allow the exhaust air to be forced out of the conditioned space. Heat exchange takes place between the exfiltrated exhaust air and the building envelope. Consequently, the interior surface temperature of the EAIW is very close to the indoor air temperature, resulting in enhanced indoor thermal comfort and a decrease in cooling load [88]. When utilizing an exfiltration airflow rate of 0.003 m/s and a 30 mm thickness of porous materials, the U-value of the EAIW can be reduced to 0.1 W/(m2·K) [89]. Moreover, the pressure loss of exfiltration airflow and infiltration airflow within EAIW (exfiltration mode of APBE) [48] and DI (infiltration mode of APBE) [90] were estimated based on Darcy’s law, and the energy requirements for driving a constant airflow in EAIW and DI were investigated, respectively.

3.4. A Bibliometric Analysis of Air-Permeable Building Envelopes

In this study, VOSviewer software version 1.6.19 was used to conduct a bibliometric analysis for exploring and visualizing the research trend and knowledge networks in the research area of APBEs based on the literature data. The Web of Science database was used to search for and collect the bibliometric data in APBE research. We noticed that the term dynamic insulation is also used in the research area of electrical engineering. To obtain more accurate and reliable bibliometric data, in this paper, the following query, (TI = (“dynamic insulation” OR “breathing wall*” OR “exhaust air insulation” OR “air permeable wall”) OR AB = (“dynamic insulation” OR “breathing wall*” OR “exhaust air insulation” OR “air permeable wall”) OR AK = (“dynamic insulation” OR “breathing wall*” OR “exhaust air insulation” OR “air permeable wall”)) AND (TI = (“window*” OR “wall*” OR “roof*” OR “building*”) OR AB = (“window*” OR “wall*” OR “roof*” OR “building*”) OR AK = (“window*” OR “wall*” OR “roof*” OR “building*”)), was used to extract the related English journal or conference articles in Web of Science Core Collection. Document types are limited to articles, review articles, and proceeding papers. The searching covers the period until the 2 December 2023. Some of the earlier studies, conference reports, dissertations, or publications in other languages are not indexed by the Web of Science Core Collection. A total of 83 articles were collected for bibliometric analysis according to the abovementioned search process.

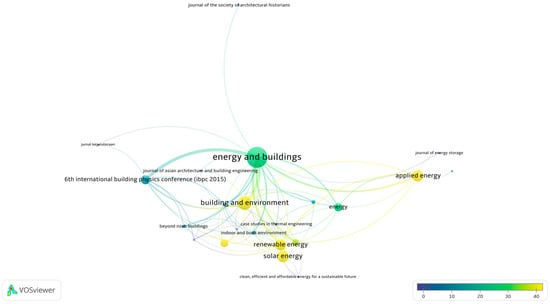

As shown in Figure 8, the number of publications in the research of APBE has seen an obvious increase since 2014. Table 1 presents a summary of the main sources of all the collected publications in the research area of APBE. The sources (journal/proceeding) with only one publication are aggregated in Others. The journal Energy and Buildings has published the largest number of articles in the research area of APBE. Moreover, the 6th International Building Physics Conference 2015 plays an important role in promoting the research of APBE. As shown in Figure 9, despite Building and Environment, Renewable Energy, Solar Energy, and Applied Energy having published fewer related articles than Energy and Buildings, these journals attract more attention and have higher average citations.

Figure 8.

Number of published articles from 1997 to 2023.

Table 1.

Main sources of APBE research from 1997 to 2023.

Figure 9.

Average citations of main journals and proceedings.

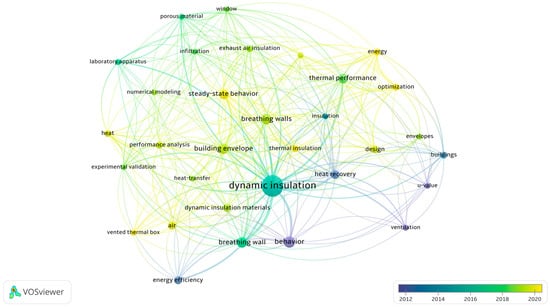

Figure 10 presents the evolution of the hot keyword and research trend in the research of APBE from 2012 to 2020. In this network, the minimum occurrence frequency of the keywords is three. A larger circle around each keywork means a higher occurrence frequency. It can be found that the hot topics in the research of APBE gradually change from heat recovery, behavior, energy efficiency, ventilation, U-value to design, optimization, energy, and thermal insulation. Moreover, the visualization of the co-citation network in the research of APBE is presented in Figure 11. This co-citation analysis only considers the first author of each publication. The visualization result indicates that Prof. Taylor B.J. is the most influential in this research of APBE because Prof. Taylor B.J. first clearly presents an analytical method of DI in an international journal and conducts a series of fundamental studies in this research area.

Figure 10.

Evolution of the hot topics in the research of APBE from 2012 to 2020.

Figure 11.

Visualizing the networks of co-citation analysis in the research of APBE.

4. Opportunities and Benefits

4.1. Thermal and Energy Performance

It is generally accepted that DI and EAIW yield energy savings when compared to conventional building envelopes [31,71]. With fresh or exhaust air ventilated through porous materials, heat exchange occurs in the building envelope, and part of the conduction heat loss within DI is recovered to preheat the infiltrated fresh air in winter. The sensible heat of indoor exhaust air is recovered and utilized to eliminate the conduction heat gain through EAIW. In this way, the heating/cooling load caused by building envelopes is effectively reduced by the infiltration/exfiltration airflow within porous material.

The energy-saving potential and thermal performance improvement reported in the literature are summarized in Table 2 from the perspectives of U-value reduction, heat gain/loss decrease, and energy saving. The collected information shows that the U-value of APBE can be effectively reduced by over 60% compared to unventilated conventional building envelopes. Furthermore, if the airflow increases, the U-value could be reduced even more [34]. It should be noted that APBEs can be treated as a responsive building envelope to reduce operational energy use in buildings by dynamically changing their U-value in response to outdoor thermal disturbances, as shown in Figure 12. According to the work by Zhang et al. [89], varying the exfiltration airflow velocity can effectively adjust the U-value of APBE. For instance, its U-value can decrease to almost 0 W/m2K when the porous material thickness is 50 mm and the exfiltration velocity reaches 0.004 m/s.

Table 2.

Summary of energy-saving potential and thermal performance improvement of APBE.

Figure 12.

Influence of exfiltration velocity and porous material thickness on the U-value of APBE according to the work by Zhang et al. [89].

With the installation of DI, conductive heat loss/gain from building envelopes can decrease by 15.3~41%, according to the previous studies [43,45,81]. Moreover, a reduction in the total energy use in buildings is typically lower than 23% by applying the DI as the building envelope. Further, if an additional air heat recovery system is incorporated to reclaim heat from the exhaust air, the energy savings would be much higher for buildings employing the DI system. For example, an additional 5% of energy-saving potential can be achieved by integrating such a heat recovery system with DI [59].

However, the additional energy required to transport the infiltration or exfiltration airflow within APBE and to maintain ventilation airflow meeting the requirement cannot be ignored. For example, in the infiltration mode, where air is drawn into the room during the winter, a mechanical fan is usually needed to create a de-pressured environment, and extra energy is consumed by the mechanical fan to maintain a constant infiltration airflow via porous material. The extra fan power consumed by the ventilation system has been evaluated by Ascione et al. [49], who concluded that the fan power should be minimal, with a magnitude of 10−3~10−2 W/m2. Regarding the additional heating energy consumption due to the infiltrated outdoor air, studies carried out by Imbabi [50] indicated that an optimal value of infiltrated ventilation rate for maximal energy efficiency exists for the DI system in winter. Beyond this ventilation rate, more energy is lost through the exhaust air than is recovered through the DI.

4.2. Indoor Thermal Comfort

APBEs were originally applied to farm buildings as a starting point for energy savings, but when they were applied to residential buildings, the advantage of higher thermal comfort emerged. For the exfiltration mode of ABPEs operating during a cooling season, the EAIW is cooled by the exhaust air, and its interior surface temperature becomes very close to the indoor air temperature. For this reason, the mean radiant temperature is decreased and the thermal comfort for indoor occupants is improved. Zou [92] calculated the PMVs in a room with EAIW and made comparisons between EAIW, brick wall, and external insulation wall. The study showed that EAIW provided a more uniform thermal environment and better thermal comfort.

Gan [55] evaluated thermal comfort in a dynamic insulation room by means of CFD. The south and north walls, consisting of thick felted mineral wool, were set as dynamic insulation walls, and the outdoor air was pulled into the room through the insulation by thermal buoyancy. The effects of air infiltration and clothing level were investigated in the work. Results showed that a room with dynamic insulation could improve thermal comfort with energy savings. The mean radiant temperature was reduced, and the mean value of PMV was −0.1. Nevertheless, careful design and airtightness are required since air leakage reduces thermal comfort. Samuel [59] studied the thermal comfort levels of dynamic insulation in the light of PPD and showed that dynamic insulation provided internal air temperatures that were slightly higher in winter and lower in summer. Therefore, better comfort levels are achieved by dynamic insulation when compared with conventional insulation.

4.3. Indoor Air Quality

Another advantage achieved by APBE is the provision of better IAQ. For the infiltration mode of APBE, when outdoor air is drawn into the room through the DI, the porous material acts as a high-performance air filter, which can filter out most particulate matter (PM) effectively due to the large intake surface and the low air velocity.

A theoretical filtration model has been developed by Taylor et al. [69]. Filtration efficiency is influenced by such factors as airflow rate, filter thickness, and packing density. The results show that DI is an efficient filter that can capture particles with diameters less than 0.5 μm and larger than 5 μm, while particles with diameters between 0.5 and 5 μm can be filtered by increasing the thickness of the porous material. The theoretical model relating to multilayer porous materials was developed by Imbabi and Lafougere [93] to evaluate the natural ventilation and filtration performance of multi-layer DI panels under urban air pollution conditions. The filtration efficiency of DI is very high, commonly over 90% [50]. A PM10 filtration model developed by Imbabi et al. [80] predicted that the filtration efficiency of DI was over 99.9% during a one-day operation. A two-day experiment for a DI roof conducted by Brown et al. [83] revealed that the average mass value of particles in infiltration airflow was reduced by 90%.

DI with a high filtration efficiency can substantially reduce the amount of outdoor particulate matter that enters a dwelling. On the other hand, it is easy to imagine that particulate matters may remain in the porous layer and cause clogging. However, both a theoretical study [80] and field trials [50] conducted by Imbabi revealed that it would take approximately 60 years for clogging in a DI layer to become a problem. The clogging rate for DI is very low and acceptable.

4.4. Influence Factors

There are many factors that influence the performance of APBEs. Table 3 presents a summary of some of the key influence factors of APBE in the literature from the perspectives of airflow, porous materials, and environmental factors. Airflow velocity is the most important factor that influences the performance of APBE. The inner surface temperature of DI decreases as the airflow increases [37]. Similar conclusions are also made by Wang et al. [31], indicating that the conduction heat gain through the EAIW significantly decreases with increasing exfiltration airflow rate. However, considering ventilation energy loss, the total energy savings of employing the DI reaches a maximum at an appropriate infiltration airflow rate, which can achieve a compromise between conductive heat loss reduction and ventilation heat loss increase [41,73,93]. Physical characteristics of porous materials, such as thickness, thermal conductivity, and air permeability also affect the performance of APBE. The dynamic U-value as well as the heat flux within the APBE decrease with the increasing thickness of the porous material [31,46]. From the point of view of improving the IAQ, more particles would be blocked and trapped by the thicker porous material layer, indicating that DI may potentially serve as a high-efficiency particulate air filter [69]. Environmental conditions like pressure differences, temperature difference, and airtightness are also important factors that influence the performance of APBE. It is noteworthy that airtightness is of vital importance to the effectiveness of DI [38] and the thermal comfort of the whole room [55].

Table 3.

Summary of the influence factors of APBE in the literature.

5. Future Outlook

5.1. Passive Building Design

Passive design strategies are frequently employed nowadays to enhance natural ventilation in buildings. Natural ventilation plays a vital role in reducing the need for heating, ventilation, and air conditioning (HVAC) systems and lowering the associated lifecycle emissions. For the practical application of APBE, mechanical ventilation driven by an additional fan is easier to design, permits a greater choice of site, and is more predictable and controllable in operation. However, it will incur additional initial costs and operational energy consumption. Zhang et al. [48] conducted a quantitative assessment of the pressure loss caused by exfiltration airflow within EAIW and its associated energy consumption resulting from an additional mechanical fan. The findings demonstrate that when the porous material layer of EAIW is thicker than 40 mm, the energy demand of a mechanical fan may be even higher than that of space cooling and heating due to the heat gain and loss via the EAIW. Therefore, natural ventilation-based DI is able to save on the costs of installing ventilation ducts and facilitate the decarbonization due to HVAC in buildings.

Some researchers have examined the possibility of coupling DI with natural ventilation [45,49,53]. Craig and Grinham [47] proposed two possibilities for integrating the DI with natural ventilation, as shown in Figure 13. The left figure illustrates the schematic diagram of the original natural ventilation-based DI. The infiltrated ventilation airflow via DI is powered by buoyancy, but the low-grade heat within the exhaust air is not recovered. The right figure illustrates a novel natural ventilation based DI structure with a heat recovery loop that can recover low-grade heat within the exhaust using a double shell. It should be noted that the practical application of a natural ventilation-based DI needs precise passive building design considering the effects of solar exposure, the direction of prevailing wind, and potential shading to ensure effective ventilation. Moreover, the exfiltration mode of APBE can be integrated with a passive downdraught evaporative tower system [95] for passive ventilation, building cooling, and thermal insulation in an arid climate.

Figure 13.

Two possibilities of DI integrating with natural ventilation [70].

5.2. Smart Control Strategy

As we know, APBEs enable building envelopes to regulate the U-value by varying the infiltration or exfiltration airflow rate within porous material. It can be treated as a responsive building envelope to reduce the operational energy use for space cooling or heating in buildings by dynamically changing its U-value in response to an outdoor thermal disturbance. During the operation phase, especially APBEs with mechanical ventilation, an illogical control may influence the building ventilation and energy performance of the APBE and even result in an increase in energy consumption in buildings. For example, for the exfiltration mode in summer, an extremely low U-value of the building envelope may restrict the heat released from indoors to outdoors when the outdoor air temperature is lower than the indoor air temperature. In this case, exfiltration airflow across the building envelope can be suspended accordingly. Conversely, exfiltration airflow velocity should be increased when outdoor air temperature rises or the building envelope is exposed to high incident solar radiation. For the infiltration mode in winter, the infiltration airflow from outdoors to indoors is preheated by the heat loss of DI. Increasing the infiltration velocity does indeed reduce the equivalent U-value of DI. However, excessive infiltration airflow will significantly decrease the interior surface temperature of the wall and also increase the energy demand for heating the ventilated fresh air. Therefore, a suitable control strategy is needed to guarantee the effectiveness of APBE for building ventilation and energy savings.

Menyhart and Krarti [71] conducted a study comparing the energy-saving potentials of a DI system employing two control strategies: temperature-based automatic control and seasonal control, in US residential buildings. The findings demonstrate that implementing an automatic control strategy, which dynamically adjusts the U-value of the DI system, can effectively decrease energy consumption in buildings. The authors further emphasize the importance of designing the DI system and its control strategy to seamlessly integrate with the building’s energy system. Moreover, Cui et al. [96] developed a model predictive control (MPC) for DI to optimize the U-value and simultaneously determine the operation of the HVAC system to maximizing the energy-saving potential of the whole system. So far, many studies have explored the smart control of APBEs for building energy efficiency. However, few studies experimentally deploy and validate the proposed control strategy ion-site.

6. Conclusions

High-performance building envelope techniques are being actively studied to improve both the energy efficiency and the indoor living environment of buildings. The infiltration and exfiltration of airflow within porous material is a promising thermal insulation mechanism that can directly change the temperature profile within the building envelope, reduce heat flux via the building envelope, and achieve building energy efficiency. In the past several decades, researchers have devoted much effort to investigating the performance, feasibility, and structure of the APBE. This comprehensive review presents the fundamentals and classification, historical evolution over time, opportunities and benefits, and future outlook of the APBE. The infiltration mode of APBE, called dynamic insulation or breathing wall, has been extensively applied and studied more than the exfiltration mode, owing to its advantages such as heat recovery, air filtering, energy savings, and building ventilation. The exfiltration mode of APBE, called exhaust air insulation wall, enables the indoor exhaust air to exfiltrate through the porous material within the building envelope for buffering the conduction heat gain in summer.

The main conclusions of this paper are listed as follows: (1) The infiltration mode of the APBE is not suitable for practical application in summer, while the exfiltration mode is not recommended in winter because interstitial condensation will occur in DI during summer and in EAIW during winter; (2) the APBE enables the building envelope to dynamically change the U-value by varying the airflow rate within porous material. A U-value of 0.1 W/(m2·K) or nearly 0 W/(m2·K) can be realized by using a thicker porous material and a higher airflow rate; (3) APBE shows a high filtration efficiency, commonly over 90%, which can substantially reduce the amount of outdoor particulate matter within ventilation fresh air and improve IAQ; (4) for the practical application of the APBE, a mechanical ventilation-based APBE is easier to design and more predictable and controllable in operation. For the APBE to be integrated with passive natural ventilation, it needs precise passive building design considering various influence factors and is able to reduce the costs of installing ventilation ducts and facilitate decarbonization in buildings; (5) the smart control strategies should be further explored to collaboratively optimize the operation of the APBE and HVAC system to maximize the energy-saving potential.

Overall, APBEs show attractive advantages such as reducing energy consumption, providing building ventilation, and improving IAQ in buildings when compared with conventional building envelopes. Further investigation and practical application of the APBE are deserved.

Author Contributions

Conceptualization, C.Z. and X.X.; methodology, C.Z.; formal analysis, Z.Y. (Zhanzhi Yu); investigation, Q.Z. and H.S.; resources, Q.Z. and H.S.; data curation, Z.Y. (Zhongyi Yu); writing—original draft preparation, C.Z.; writing—review and editing, X.X.; visualization, Z.Y. (Zhanzhi Yu); supervision, X.X.; funding acquisition, C.Z. and X.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant numbers 51808239, 52378099 and the CITIC Limited, grant number 2022ZXKYD30100.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Zhongyi Yu was employed by the company CITIC General Institute of Architectural Design and Research Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Nomenclature

| APBE | air-permeable building envelope |

| BW | breathing wall |

| CFDs | computational fluid dynamics |

| DI | dynamic insulation |

| EAIW | exhaust air insulation wall |

| HVAC | heating, ventilation, and air conditioning |

| IAQ | indoor air quality |

| MPC | model predictive control |

| PM | particulate matter |

| PMV | predicted mean vote |

| PPD | predicted percentage of dissatisfied |

| VSDI | void space dynamic insulation |

References

- IEA. World Energy Balances; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Abu Bakar, N.N.; Hassan, M.Y.; Abdullah, H.; Rahman, H.A.; Abdullah, M.P.; Hussin, F.; Bandi, M. Energy Efficiency Index as an Indicator for Measuring Building Energy Performance: A Review. Renew. Sustain. Energy Rev. 2015, 44, 1–11. [Google Scholar] [CrossRef]

- Berardi, U.; Sprengard, C. An Overview of and Introduction to Current Researches on Super Insulating Materials for High-Performance Buildings. Energy Build. 2020, 214, 109890. [Google Scholar] [CrossRef]

- Matour, S.; Garcia-Hansen, V.; Omrani, S.; Hassanli, S.; Drogemuller, R. Thermal Performance and Airflow Analysis of a New Type of Double Skin Façade for Warm Climates: An Experimental Study. J. Build. Eng. 2022, 62, 105323. [Google Scholar] [CrossRef]

- Zhang, C.; Gang, W.; Wang, J.; Xu, X.; Du, Q. Numerical and Experimental Study on the Thermal Performance Improvement of a Triple Glazed Window by Utilizing Low-Grade Exhaust Air. Energy 2019, 167, 1132–1143. [Google Scholar] [CrossRef]

- Gu, W.; Li, G.; Xiermaimaiti, A.; Ma, T. A Review of Recent Techniques in Performance Augmentation and Evaluation Metrics of Trombe Walls. Energy Build. 2023, 301, 113693. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Bruno, R.; Szyszka, J.; Cirone, D.; Rollo, A. Summer and Winter Performance of an Innovative Concept of Trombe Wall for Residential Buildings. Energy 2022, 258, 124798. [Google Scholar] [CrossRef]

- Singh, H.; O’Brien, P.G. Semi-Transparent Water-Based Trombe Walls for Passive Air and Water Heating. Buildings 2022, 12, 1632. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Li, C. Energy Performance and Applicability of Naturally Ventilated Double Skin Façade with Venetian Blinds in Yangtze River Area. Sustain. Cities Soc. 2020, 61, 102348. [Google Scholar] [CrossRef]

- Jankovic, A.; Goia, F. Control of Heat Transfer in Single-Story Mechanically Ventilated Double Skin Facades. Energy Build. 2022, 271, 112304. [Google Scholar] [CrossRef]

- Zomorodian, Z.S.; Tahsildoost, M. Energy and Carbon Analysis of Double Skin Façades in the Hot and Dry Climate. J. Clean. Prod. 2018, 197, 85–96. [Google Scholar] [CrossRef]

- Zhao, Y.; Zha, F.; Li, X. A Simplified Method for the Thermal Performance Analysis of Double-Layer Pipe-Embedded External Wall. J. Build. Eng. 2023, 80, 108155. [Google Scholar] [CrossRef]

- Jiang, S.; Zha, F.; Zhao, Y.; Li, X. Thermal Performance of Double-Layer Pipe-Embedded Envelope with Low-Grade Energy for Heating. J. Build. Eng. 2023, 77, 107489. [Google Scholar] [CrossRef]

- Li, L.; Zhang, C.; Xu, X.; Yu, J.; Wang, F.; Gang, W.; Wang, J. Simulation Study of a Dual-Cavity Window with Gravity-Driven Cooling Mechanism. Build. Simul. 2022, 15, 1339–1352. [Google Scholar] [CrossRef]

- Tunçbilek, E.; Arıcı, M.; Krajčík, M.; Li, D.; Nižetić, S.; Papadopoulos, A.M. Enhancing Building Wall Thermal Performance with Phase Change Material and Insulation: A Comparative and Synergistic Assessment. Renew. Energy 2023, 218, 119270. [Google Scholar] [CrossRef]

- You, Z.; Sun, Y.; Mo, S.; Zou, W.; Zhang, X.; Gao, D.-C. Experimental Evaluation of the Effects of Passive Phase Change Material Walls on the Building Demand Response for Smart Grid Applications. Buildings 2022, 12, 1830. [Google Scholar] [CrossRef]

- Jiang, L.; Gao, Y.; Zhuang, C.; Feng, C.; Zhang, X.; Guan, J.; Dong, S. Experimental and Numerical Study on Thermal Performance of Phase-Change-Material Cool Roofs in Summer. Sustain. Cities Soc. 2023, 99, 104936. [Google Scholar] [CrossRef]

- Shukla, A.; Nkwetta, D.N.; Cho, Y.J.; Stevenson, V.; Jones, P. A State of Art Review on the Performance of Transpired Solar Collector. Renew. Sustain. Energy Rev. 2012, 16, 3975–3985. [Google Scholar] [CrossRef]

- Bejan, A.-S.; Croitoru, C.; Bode, F.; Teodosiu, C.; Catalina, T. Experimental Investigation of an Enhanced Transpired Air Solar Collector with Embodied Phase Changing Materials. J. Clean. Prod. 2022, 336, 130398. [Google Scholar] [CrossRef]

- Berville, C.; Bode, F.; Croitoru, C. Numerical Simulation Investigation of a Double Skin Transpired Solar Air Collector. Appl. Sci. 2022, 12, 520. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, S. Thermal Insulation Solutions for Opaque Envelope of Low-Energy Buildings: A Systematic Review of Methods and Applications. Renew. Sustain. Energy Rev. 2022, 167, 112738. [Google Scholar] [CrossRef]

- Huang, X.-Y.; He, J.-W.; Huang, Y.-X.; Cai, Y.; Wang, W.-W.; Zhao, F.-Y. Numerical Analysis of Solar Ventilated Façade Integrated Thermoelectric Energy Harvesting Panel for Simultaneous Building Thermal Insulation and Power Generation. J. Build. Eng. 2023, 76, 107304. [Google Scholar] [CrossRef]

- Huang, J.; Yu, J.; Yang, H. Effects of Key Factors on the Heat Insulation Performance of a Hollow Block Ventilated Wall. Appl. Energy 2018, 232, 409–423. [Google Scholar] [CrossRef]

- Yu, J.; Ye, H.; Xu, X.; Huang, J.; Liu, Y.; Wang, J. Experimental Study on the Thermal Performance of a Hollow Block Ventilation Wall. Renew. Energy 2018, 122, 619–631. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Martins, A.; Boaventura-Cunha, J.; Lanzinha, J.C.; Paiva, A. Energy Performance of Trombe Walls: Adaptation of ISO 13790:2008(E) to the Portuguese Reality. Energy Build. 2014, 74, 111–119. [Google Scholar] [CrossRef]

- Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Berardi, U.; Tookey, J.; Li, D.H.W.; Kariminia, S. Exploring the Advantages and Challenges of Double-Skin Façades (DSFs). Renew. Sustain. Energy Rev. 2016, 60, 1052–1065. [Google Scholar] [CrossRef]

- Rashidi, S.; Esfahani, J.A.; Karimi, N. Porous Materials in Building Energy Technologies—A Review of the Applications, Modelling and Experiments. Renew. Sustain. Energy Rev. 2018, 91, 229–247. [Google Scholar] [CrossRef]

- Zhang, R.; Feng, J.; Cheng, X.; Gong, L.; Li, Y.; Zhang, H. Porous Thermal Insulation Materials Derived from Fly Ash Using a Foaming and Slip Casting Method. Energy Build. 2014, 81, 262–267. [Google Scholar] [CrossRef]

- Moretti, E.; Belloni, E.; Agosti, F. Innovative Mineral Fiber Insulation Panels for Buildings: Thermal and Acoustic Characterization. Appl. Energy 2016, 169, 421–432. [Google Scholar] [CrossRef]

- Li, C.; Li, B.; Pan, N.; Chen, Z.; Saeed, M.U.; Xu, T.; Yang, Y. Thermo-Physical Properties of Polyester Fiber Reinforced Fumed Silica/Hollow Glass Microsphere Composite Core and Resulted Vacuum Insulation Panel. Energy Build. 2016, 125, 298–309. [Google Scholar] [CrossRef]

- Wang, J.; Du, Q.; Zhang, C.; Xu, X.; Gang, W. Mechanism and Preliminary Performance Analysis of Exhaust Air Insulation for Building Envelope Wall. Energy Build. 2018, 173, 516–529. [Google Scholar] [CrossRef]

- Qiu, K.; Haghighat, F.; Guarracino, G. Thermal Behaviour of the Diffusive Building Envelope: State-of-the-Art Review. Adv. Build. Energy Res. 2007, 1, 213–226. [Google Scholar] [CrossRef]

- Taylor, B.J.; Cawthorne, D.A.; Imbabi, M.S. Analytical Investigation of the Steady-State Behaviour of Dynamic and Diffusive Building Envelopes. Build. Environ. 1996, 31, 519–525. [Google Scholar] [CrossRef]

- Baker, P.H. The Thermal Performance of a Prototype Dynamically Insulated Wall. Build. Serv. Eng. Res. Technol. 2003, 24, 25–34. [Google Scholar] [CrossRef]

- Perino, M. State of the Art Review of Responsive Building Elements. IEA Annex 44: Vol_2A. 2008. Available online: https://iris.polito.it/handle/11583/2484618 (accessed on 15 October 2023).

- Bartussek, H. Luftdurchlässige Konstruktionen: Eine Übersicht über den Stand der Entwicklung (Air-permeable constructions: A state of the art review). Schweiz. Ing. Und Archit. 1986, 104, 725–733. [Google Scholar]

- Taylor, B.J.; Imbabi, M.S. The Effect of Air Film Thermal Resistance on the Behaviour of Dynamic Insulation. Build. Environ. 1997, 32, 397–404. [Google Scholar] [CrossRef]

- Dimoudi, A.; Androutsopoulos, A.; Lykoudis, S. Experimental Work on a Linked, Dynamic and Ventilated, Wall Component. Energy Build. 2004, 36, 443–453. [Google Scholar] [CrossRef]

- Alongi, A.; Mazzarella, L. Characterization of Fibrous Insulating Materials in Their Application in Dynamic Insulation Technology. Energy Procedia 2015, 78, 537–542. [Google Scholar] [CrossRef]

- Di Giuseppe, E.; D’Orazio, M.; Di Perna, C. Thermal and Filtration Performance Assessment of a Dynamic Insulation System. Energy Procedia 2015, 78, 513–518. [Google Scholar] [CrossRef][Green Version]

- Arquis, E.; Langlais, C. What scope for ‘dynamic insulation’? Bâtim. Int. Build. Res. Pract. 1986, 14, 84–93. [Google Scholar] [CrossRef]

- Crockford, G.W.; Goudge, J. Dynamic insulation: An equation relating airflow, assembly thickness and conductance. Proc. R. Soc. Med. 1970, 10, 1012–1013. [Google Scholar]

- Murata, S.; Tsukidate, T.; Fukushima, A.; Abuku, M.; Watanabe, H.; Ogawa, A. Periodic Alternation between Intake and Exhaust of Air in Dynamic Insulation: Measurements of Heat and Moisture Recovery Efficiency. Energy Procedia 2015, 78, 531–536. [Google Scholar] [CrossRef][Green Version]

- Alongi, A.; Angelotti, A.; Mazzarella, L. Experimental Investigation of the Steady State Behaviour of Breathing Walls by Means of a Novel Laboratory Apparatus. Build. Environ 2017, 123, 415–426. [Google Scholar] [CrossRef]

- Park, K.-S.; Kim, S.-W.; Yoon, S.-H. Application of Breathing Architectural Members to the Natural Ventilation of a Passive Solar House. Energies 2016, 9, 214. [Google Scholar] [CrossRef]

- Taylor, B.; Imbabi, M. The Application of Dynamic Insulation in Buildings. Renew. Energy 1998, 15, 377–382. [Google Scholar] [CrossRef]

- Craig, S.; Grinham, J. Breathing Walls: The Design of Porous Materials for Heat Exchange and Decentralized Ventilation. Energy Build. 2017, 149, 246–259. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, F.; Wang, J. Design Optimization of Multi-Functional Building Envelope for Thermal Insulation and Exhaust Air Heat Recovery in Different Climates. J. Build. Eng. 2021, 43, 103151. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; De Stasio, C.; Mauro, G.M.; Vanoli, G.P. Dynamic Insulation of the Building Envelope: Numerical Modeling under Transient Conditions and Coupling with Nocturnal Free Cooling. Appl. Therm. Eng. 2015, 84, 1–14. [Google Scholar] [CrossRef]

- Imbabi, M.S.-E. Modular Breathing Panels for Energy Efficient, Healthy Building Construction. Renew. Energy 2006, 31, 729–738. [Google Scholar] [CrossRef]

- Li, L.; Zhang, C.; Gang, W.; Wang, J. Frequency Thermal Characteristic and Parametric Study of Multi-Functional Building Envelope for Coolth Recovery and Thermal Insulation: Modelling and Experimental Validation. Energy Build. 2021, 253, 111541. [Google Scholar] [CrossRef]

- Taylor, B.J.; Imbabi, M.S. Environmental design using dynamic insulation. ASHRAE Trans. 2000, 106, 15–28. [Google Scholar]

- Etheridge, D.W.; Zhang, J.J. Dynamic insulation and natural ventilation: Feasibility study. Build. Serv. Eng. Res. Technol. 1998, 19, 203–212. [Google Scholar] [CrossRef]

- Kato, S.; Lee, S.; Hiyama, K. Experimental evaluation for the dynamic insulation applied to window frame. In Proceedings of the 33rd AIVC Conference, Copenhagen, Denmark, 10–11 October 2012. [Google Scholar]

- Gan, G.H. Numerical evaluation of thermal comfort in rooms with dynamic insulation. Build. Environ. 2000, 35, 445–453. [Google Scholar] [CrossRef]

- Dalehaug, A.; Fukushima, A.; Honma, Y. Dynamic insulation in a wall: Insulation, ventilation, energy conservation. Rep. Collect. Archit. Inst. Jpn. 1993, 66, 261–264. [Google Scholar]

- Pettenkofer, M.V. Über den Luftwechsel in Wohngebäuden (About the Air Exchange in Residential Buildings). Cotta, Munich, 1858. Available online: https://www.digitale-sammlungen.de/de/view/bsb10767804?page=5 (accessed on 15 October 2023).

- Research, G. Performance of Dynamic Insulation. 1997. Available online: http://www.gaiagroup.org/Research/RI/DI/cibse_di.pdf (accessed on 15 October 2023).

- Samuel, A.A. Simulation Modelling of Dynamic Insulaiton as Means of Energy Saving and Human Comfort; University of Strathclyde: Glasgow, UK, 2002. [Google Scholar]

- Bartussek, H. Porenluftung, eine zugfreie Stalluftung (Pore ventilation, a draft-free ventilation for stables). Die Landtech. Z. (DLZ) 1981, 32, 48–58. [Google Scholar]

- Liddell, H.; Roalkvam, D.; McKenzie, I. Pore ventilation. Proceedings of CIBSE/ASHRAE Joint National Conference, Harrogate, UK, 29 September–1 October 1996; Volume 2, pp. 18–27. Available online: https://www.aivc.org/sites/default/files/airbase_10308.pdf (accessed on 15 October 2023).

- Thoren, T. Hallbygnader Med Dynamisk Isolering (Hall Buildings with Dynamic Insulation); Building Research Council: Stockholm, Sweden, 1986. [Google Scholar]

- Pattie, D.R. Heat Transmission of Porous Materials in Ventilation. Trans. ASAE 1966, 9, 409. [Google Scholar] [CrossRef]

- Turnbull, J.E.; Hickman, C.G. Ventilation of dairy barns with porous ceiling inlet systems-part I. Can. Agric. Eng. 1974, 16, 91–95. [Google Scholar]

- Turnbull, J.E.; Darisse, J.P.F. Ventilation of dairy barns with porous ceiling inlet systems-part II. Can. Agric. Eng. 1975, 17, 59–62. [Google Scholar]

- Bartussek, H. Poren-Luftung (Porous Ceilings); Osterreichisches Kuratorium fur Landtechnik: Vienna, Austria, 1981. [Google Scholar]

- Wallentén, P. Dynamic Insulation: Analysis and Field Measurements; Lund Institute of Technology: Lund, Sweden, 1996. [Google Scholar]

- Wallentén, P. Analytical and Numerical Analysis of Dynamic Insulation. In Proceedings of the 4th Building Simulation International Conference, Madison, WI, USA, 14–16 August 1995. [Google Scholar]

- Taylor, B.J.; Webster, R.; Imbabi, M.S. The Building Envelope as an Air Filter. Build. Environ. 1998, 34, 353–361. [Google Scholar] [CrossRef]

- Craig, S.; Halepaska, A.; Ferguson, K.; Rains, P.; Elbrecht, J.; Freear, A.; Kennedy, D.; Moe, K. The Design of Mass Timber Panels as Heat-Exchangers (Dynamic Insulation). Front. Built Environ. 2021, 6, 606258. [Google Scholar] [CrossRef]

- Menyhart, K.; Krarti, M. Potential Energy Savings from Deployment of Dynamic Insulation Materials for US Residential Buildings. Build. Environ. 2017, 114, 203–218. [Google Scholar] [CrossRef]

- Taylor, B.J.; Imbabi, M.S. Dynamic insulation in multistorey buildings. Build. Serv. Eng. Res. Technol. 1999, 20, 179–184. [Google Scholar] [CrossRef]

- Krarti, M. Effect of Air Flow on Heat Transfer in Walls. J. Sol. Energy Eng. 1994, 116, 35–42. [Google Scholar] [CrossRef]

- Liddament, M.W. A Guide to Efficient Ventilation; The Air Infiltration and Ventilation Centre, University of Warwick Science Park: Coventry, UK, 1996. [Google Scholar]

- Hines, J. Dynamic insulation—Insulation that acts as a heat exchanger—Is part of the McLaren leisure centre at Callander, Scotland A breath of warm air. Archit. J. 1999. Available online: https://www.architectsjournal.co.uk/archive/dynamic-insulation-insulation-that-acts-as-a-heat-exchanger-is-part-of-the-mclaren-leisure-centre-at-callander-scotland-a-breath-of-warm-air (accessed on 15 October 2023).

- Oura, Y.; Sawaki, S.; Nomura, Y.; Mori, K.; Lee, S.; Tanaka, M.; Kato, S. Dynamic insulation applied to the residential building (Part 1). Numerical Evaluation of Window Frame applied Various Dynamic Insulation Patterns. In Proceedings of the 12th Conference of International Building Performance Simulation Association, Sydney, Australia, 14–16 November 2011. [Google Scholar]

- Qiu, K.; Haghighat, F. Modeling the combined conduction—Air infiltration through diffusive building envelope. Energy Build. 2007, 39, 1140–1150. [Google Scholar] [CrossRef]

- Jokisalo, J.; Kurnitski, J.; Korpi, M.; Kalamees, T.; Vinha, J. Building Leakage, Infiltration, and Energy Performance Analyses for Finnish Detached Houses. Build. Environ. 2009, 44, 377–387. [Google Scholar] [CrossRef]

- Wong, J.M.; Glasser, F.P.; Imbabi, M.S. Evaluation of Thermal Conductivity in Air Permeable Concrete for Dynamic Breathing Wall Construction. Cem. Concr. Compos. 2007, 29, 647–655. [Google Scholar] [CrossRef]

- Imbabi, M.S. Smart Breathing Walls for Integrated Ventilation, Heat Exchange, Energy Efficiency & Air Filtration. In Proceedings of the ASHRAE/CIBSE Conference 2003, Edinburgh, Scotland, 24–26 September 2003. [Google Scholar]

- Elsarrag, E.; Al-Horr, Y.; Imbabi, M.S.-E. Improving building fabric energy efficiency in hot-humid climates using dynamic insulation. Build. Simul. 2012, 5, 127–134. [Google Scholar] [CrossRef]

- Elsarrag, E.; Aboulnaga, M.; Peacock, A.; Imbabi, M.S. Dynamic insulation for energy conservation and improved indoor air quality in hot humid climates. In Proceedings of the ASHRAE 5th Chapter Regional Conference (CRC) 2006, Dubai, United Arab Emirates, 1–3 November 2006. [Google Scholar]

- Imbabi, M.S.; Brown, A.R.; Peacock, A.; Murphy, J. The transforming technology of dynamic breathing building. In Proceedings of the Ecocity World Summit 2008, San Francisco, CA, USA, 26 April 2008. [Google Scholar]

- Imbabi, M.S.-E. A Passive–Active Dynamic Insulation System for All Climates. Int. J. Sustain. Built Environ. 2012, 1, 247–258. [Google Scholar] [CrossRef]

- Elsarrag, E.; Alhorr, Y. A Novel Integrated Building Energy System for High Performance Façade. Energy Procedia 2016, 91, 938–944. [Google Scholar] [CrossRef][Green Version]

- Alongi, A.; Mazzarella, L. The Dual Air Vented Thermal Box: A Laboratory Apparatus to Test Air Permeable Building Envelope Technologies. Energy Procedia 2015, 78, 1543–1548. [Google Scholar] [CrossRef]

- Alongi, A.; Angelotti, A.; Mazzarella, L. Experimental Validation of a Steady Periodic Analytical Model for Breathing Walls. Build. Environ. 2020, 168, 106509. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Li, L.; Gang, W. Dynamic Thermal Performance and Parametric Analysis of a Heat Recovery Building Envelope Based on Air-Permeable Porous Materials. Energy 2019, 189, 116361. [Google Scholar] [CrossRef]

- Zhang, C.; Gang, W.; Xu, X.; Li, L.; Wang, J. Modelling, Experimental Test, and Design of an Active Air Permeable Wall by Utilizing the Low-Grade Exhaust Air. Appl. Energy 2019, 240, 730–743. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J. Determining the Critical Insulation Thickness of Breathing Wall: Analytical Model, Key Parameters, and Design. Case Stud. Therm. Eng. 2021, 27, 101326. [Google Scholar] [CrossRef]

- Tanaka, M.; Lee, S.; Kato, S. The energy saving effects for the dynamic insulation system applied to window frames for residential buildings. J. Environ. Eng. 2011, 76, 689–696. [Google Scholar] [CrossRef]

- Zou, F. A Study of Thermal Performance and Load Characteristic for Exfiltration Thermal Insulation; Huazhong University of Science and Technology: Wuhan, China, 2013. [Google Scholar]

- Imbabi, M.S.; Campbell, J.; Lafougere, S. Multi-Layer Dynamic Insulation Panels for Natural Ventilation and Filtration of Urban Air Pollution. In Proceedings of the World Renewable Energy Congress VII, Frankfurt, Germany, 29 June–5 July 2002. [Google Scholar]

- Qiu, K.; Haghighat, F. Assessment of impact of building envelope porosity on energy. In Proceedings of the Ninth International IBPSA Conference, Montréal, QC, Canada, 15–18 August 2005. [Google Scholar]

- Alshenaifi, M.A.; Mesloub, A.; Hassen, W.; Abuhussain, M.A.; Kolsi, L. Numerical Analysis of Building Cooling Using New Passive Downdraught Evaporative Tower Configuration in an Arid Climate. Mathematics 2022, 10, 3616. [Google Scholar] [CrossRef]

- Cui, B.; Dong, J.; Lee, S.; Im, P.; Salonvaara, M.; Hun, D.; Shrestha, S. Model Predictive Control for Active Insulation in Building Envelopes. Energy Build. 2022, 267, 112108. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).