Abstract

Material selection in buildings profoundly affects project success, encompassing durability, maintenance, customer satisfaction, production systems, lifecycle, usage, environment, and costs. Yet, there is a need for further research on indicators for choosing materials in prefabricated buildings. Therefore, this study’s main objective was to identify the indicators (criteria and sub-criteria) for selecting materials for prefabricated wooden construction and, subsequently, categorize these criteria and sub-criteria based on the perspective of industry professionals. To achieve this goal, three phases were carried out. First, a literature review was conducted to identify potential criteria for choosing structural and envelope materials in wooden prefabricated buildings. Second, a pilot survey was conducted in Canada and the United States to classify the priority order of the criteria obtained from the literature based on professionals’ opinions. Finally, Monte Carlo simulations were conducted with different iterations (1000, 10,000, and 100,000) using the data obtained from the previous phase to improve decision-making and classification processes. For the indicators to select materials, the literature review identified seven main criteria: performance properties, green materials, energy efficiency, circular economy, site conditions and material logistics, standards, and social impact. These criteria contained a total of 25 sub-criteria. The pilot survey data analysis demonstrated that the performance properties, site conditions and material logistics, and social impact criteria were consistently prioritized. The critical sub-criteria identified were fire resistance, watertightness, local availability, occupant health, and safety and protection. For the Monte Calo simulations, the predictions aligned with the pilot study, enhancing the robustness of the results.

1. Introduction

Wooden buildings represent a significant percentage of single-family homes in North America (90%), Europe (70–45%), and Japan (45%) [1]. In addition, other countries, despite having lower percentages, boast substantial volumes of wooden construction. Approximately 20% of buildings in Chile are wooden, amounting to nearly 1.3 million homes—a significant market share [2]. In contrast, Brazil has around 6.7% of buildings made of wood, a smaller market share but representing over 3.8 million wooden houses due to its larger volume [3]. Prefabricated wood construction (wall and modules) is a method for fabricating building components in controlled factories and assembling them on-site [4]. However, there need to be more studies that provide a holistic overview and guidelines for material selection in prefabricated wood construction, despite the availability of research on material and building performance. Material selection during building design is crucial as it significantly impacts the project’s success, including durability, maintenance requirements, customer satisfaction, production systems, life cycle, use, operating environment, and costs [5,6].

To address this gap, multi-criteria decision analysis (MCDA) can be a valuable tool for selecting the most appropriate materials. MCDA is a comparative support tool that allows for assessing alternatives based on competing criteria [7]. It offers decision-makers a structured approach to selecting choices by considering various perspectives or measures. Survey analysis, which involves gathering and compiling insights from a selected group of professionals, can be used to analyze and classify these criteria [8,9,10,11,12,13]. In addition, surveys can enhance the understanding of specific themes or criteria and accelerate the decision-making process, leading to increased decisiveness [14]. Surveys have been used in various fields, such as medicine, infectious animal diseases, and education, to gather opinions and reach a professional consensus [15,16,17,18]. For example, [19] used surveys to obtain expert agreement in identifying critical success factors for transitioning toward sustainable universities, while [20] conducted surveys among professionals in the construction industry to develop a model for selecting facade materials with lower maintenance requirements. In addition, Monte Carlo Simulation, a statistical technique involving multiple simulations to predict scenarios by calculating probabilities, can be integrated into decision-making and classification processes to improve confidence in the results obtained, address the inconsistency, and mitigate small-sample bias [21,22,23]. In addition, Monte Carlo Simulation is a strategy commonly employed to assess theoretical situations and perform “what-if” examinations within systems or procedures where conducting experimental trials proves excessively expensive or unfeasible [24,25]. This technique uses random sampling and iterative approaches to create models based on different sets of randomly generated probability values, resulting in a stable output probability distribution. Monte Carlo simulations can help better forecast outcomes, minimize decision-making risks, and improve the accuracy and reliability of results [26,27]. Despite the potential of these methods, there need to be more studies in the scientific literature that summarize the criteria for choosing structural and envelope materials for prefabricated construction in North America, particularly in Canada and the United States. Therefore, this study’s main objective was to identify the indicators (criteria and sub-criteria) for selecting materials for prefabricated wooden construction and, subsequently, categorize these criteria and sub-criteria based on the perspective of industry professionals.

2. Methodology

The methodology for this study involved three phases. First, a literature review was conducted to identify potential criteria for choosing structural and envelope materials in wooden prefabricated buildings. Second, a pilot survey was conducted in Canada and the United States to classify the priority order of the criteria obtained from the literature based on professionals’ opinions. Finally, Monte Carlo simulations were conducted using the data obtained from the previous phase to improve decision-making and classification processes.

2.1. The Identification of Selection of Criteria

The identification of the selection criteria for building materials was carried out through a literature review. This search was carried out over the past twenty years (2000–2020), utilizing information from diverse specialized sources (e.g., scientific and technical journals, books, technical guides, and standards) published in English. To ensure a comprehensive search, a diverse range of keyword combinations was utilized across five searches using five databases (Compendex, Inspec, GEOBASE, GeoRef, and Knovel) via the Engineering Village platform. Search 1 used the following keywords: wood buildings, building materials, structures, envelopes, the United States, and Canada. Search 2 explored the following keywords: wood buildings, materials, use, and choice. Search 3 delved into construction, composites application, selection, and wood. Search 4 concentrated on the following keywords: buildings, materials selection, envelopes, structures, and wood. Lastly, Search 5 centered on buildings, materials selection, wood, and materials. These searches comprehensively cover various aspects of selecting structural and envelope materials for wood buildings. After reviewing the titles and abstracts, 54 articles were chosen meticulously and thoroughly. Furthermore, these documents contributed additional references, enriching the literature review and augmenting the process of identifying criteria.

2.2. Pilot Survey

The pilot survey was administered through an online questionnaire that utilized a 5-point Likert scale (very important = 5, important = 4, neutral = 3, not very important = 2, and not important = 1). The questionnaire was structured and designed with Google Forms®. The pilot study consisted of three main parts. First, descriptive information was obtained about the respondents to understand their responses according to their profiles. Secondly, professionals gave priority orders. Lastly, the results were examined. The respondents were chosen based on their professional experience in prefabricated wood construction in Canada or the United States, following the subsequent conditions: (i) professionals actively engaged in materials decision-making, such as architects, engineers, and project managers, (ii) specialists in prefabricated wood construction, covering both 2D systems (such as prefab wood systems) and 3D buildings (volumetric), and (iii) experts with a minimum of five years professional experience in these specific domains [28]. They were identified by reviewing their professional profiles, such as LinkedIn, resumes, and professional websites, across different regions in both countries to ensure a comprehensive industry perspective. After analyzing the profiles, a pilot survey was sent to 42 professionals, and 25 responses were received, resulting in a response rate of 59%. This response rate exceeds the minimum requirement of 50% for survey confirmation, as recommended by Biresselioglu et al. [29].

The survey was administered using links individually distributed via email. The email contained a cover letter that explained the purpose of the study, provided information about the researcher, and assured participants of confidentiality and anonymity. Anonymity prevents bias, reduces the influence of dominant individuals, mitigates socio-psychological pressure, and alleviates the fear of expressing opinions publicly [30]. The pilot survey consisted of two parts. The first part collected basic background information from the respondents, such as their education level, role held, work areas, and years of experience, to understand their answers better. The second part collected responses to prioritize criteria from the literature review using a Likert scale.

Furthermore, respondents were allowed to provide additional criteria and comments in the final section of the survey. Two separate reminder emails were sent in the two weeks following the initial email to increase participation rates. The pilot survey was conducted between 20 July and 31 August 2021.

The results were analyzed by grouping them in three different ways: Canada only, the United States only, and Canada and the United States together, to identify any differences in opinions. Two analyses were utilized to examine the results: consensus and severity index (SI), which complement each other. Consensus is strong when at least 75% of professionals rate a criterion as 4 or 5 on the Likert scale, moderate when 60% to 74% agree, and weak when less than 60% reach consensus. Lack of consensus (lower than 60%) indicates lower importance in the selection process. This rating is commonly used in studies to measure consensus and criterion acceptability and is adopted in this research [31,32,33]. Literature suggests using nonparametric procedures for data classification, as parametric statistics like mean and standard deviation may not yield meaningful results. Then, after verifying consensus, the SI was used to classify the criteria [34,35,36]. The following formula was used to determine the SI [35]:

where i = the point value given to each criterion by the respondent, ranging from 1 to 5; ωi = the weight of each point; fi = the frequency of point value i among all respondents; n = the total number of responses (n = 25 in this study); and α = the highest weight (α = 5 in this study). Furthermore, the notation indicated by [34] was used for the SI values calculated to categorize the criteria into five priority levels: High (H) (0.8 ≤ SI ≤ 1), High–Medium (H–M) (0.6 ≤ SI < 0.8), Medium (M) (0.4 ≤ SI < 0.6), Medium–Low (M–L) (0.2 ≤ SI < 0.4), and Low (L) (0 ≤ SI < 0.2).

Monte Carlo Simulation

According to Mundfrom et al. [37], Monte Carlo simulations for original studies typically start with 1000 interactions. However, for replicated studies and statistical calculations, it is generally suggested to use at least 10,000 interactions to improve the reliability and accuracy of the results. Furthermore, Heijungs et al. [38] recommend using 1000, 10,000, or 100,000 interactions depending on the situation, assuming perfect knowledge of input distributions for accurately estimating output distributions. Thus, in this study, probability distributions were computed through Monte Carlo simulations using varying numbers of interactions, including 1000, 10,000 and 100,000. The simulations were based on survey responses obtained, and the data was grouped in three ways: Canada only, the United States only, and Canada and the United States combined. This approach detected potential differences in opinions across the two countries. All simulations were conducted using the R programming language, with software R studio version 2023.03.0+386.

3. Results

3.1. Main Criteria and Sub-Criteria Identified for Choosing Building Materials

The literature review identified seven main criteria: performance properties, green materials, energy efficiency, circular economy, site conditions and material logistics, standards, and social impact. These criteria and their respective sub-criteria are listed in Table 1 and are described in the following sections.

Table 1.

Criteria and sub-criteria for the choice of building materials.

3.1.1. Performance Properties

The performance property sub-criteria are essential in selecting suitable building materials as they define the minimum values a material must meet to function effectively. Mechanical properties, such as strength, hardness, elasticity, plasticity, ductility, brittleness, and toughness, are often emphasized in previous studies when choosing building materials [39,48,60,123]. For instance, Innella et al. [60] conducted a study that evaluated the mechanical performance of prefabricated buildings during transport. The results revealed that plywood panels and their steel joints were sensitive to vibrations during transport, with shear stresses exceeding the material’s strength in 95.4% of the cases. Using lower-performance plywood in the building envelope may impact the building’s overall performance. Durability is another crucial property, as natural weathering factors such as UV light, moisture, temperature changes, fungi, and termites can reduce building materials’ mechanical and physical performance [124,125]. In envelope facades, plastics, particularly polymers, are commonly used as coverings, and studies have been conducted to enhance their durability [53,59,71]. For example, using commercial pigments, Butylina et al. [121] improved the durability of wood-polypropylene composites. Weathering tests for 3–12 months showed pigmented composites had less discoloration, lower water absorption, and higher Charpy impact strength. Fire resistance and fire safety are always a concern for wood buildings. As a result, increasing attention has been paid to innovative flame-retardant processing technologies [45,56,76,126]. Timber products and wood-based materials are typically treated with fire retardants through surface coatings and impregnation, among other methods, to enhance safety [57,66,127]. In addition, new structural technologies like mass timber components have been suggested as another route to improve fire resistance [43]. Thermal efficiency is also an important criterion, and the thermal performance of insulation materials and other building envelope and structural components has been investigated. Using materials with good thermal performance can reduce peak indoor temperatures and improve occupants’ thermal comfort [44,54,68,74,77]. In addition, building design, such as the distance between layers of walls and the type of material and joints used for exterior cladding, can also affect a building’s thermal performance [68].

Watertightness (i.e., materials that water cannot enter or escape) and water permeability (i.e., capacity to allow water through a material) are essential for building performance, as materials produced from bio-based sources are typically less resistant to water vapor permeation and more vulnerable to mold growth [42,49,52,55,67,72,75]. Maintaining relative humidity below 70% is recommended for wood construction to prevent mold and rot. Cross-laminated timber (CLT) panels have been found to help maintain recommended relative humidity levels in wood construction [41].

Acoustic comfort is essential for human well-being in buildings, and various materials, including bio-based and synthetic materials, have been developed to control noise [40,46,69]. For example, Faustino et al. [51] used corn cob particle boards to reduce building noise. This material is comparable to traditional construction materials such as glass wool and expanded polystyrene in terms of its noise reduction properties. In addition, D’Alessandro et al. [50] reported that green walls can absorb up to 80% of incident acoustic energy for frequencies above 1000 Hz, providing another approach for enhancing acoustic comfort in buildings.

3.1.2. Green Materials

The use of green materials in construction refers to materials made from renewable sources that have fewer adverse environmental effects. These materials typically have low toxicity, low levels of volatile organic compounds (VOCs), are made from recycled materials, and have a low environmental impact. High levels of VOCs in building materials can pose health risks to occupants and construction workers, making using low VOC materials crucial in sustainable construction. This practice is also recognized and rewarded with additional points when applying for environmental certifications [80,81,86,89,91,128,129,130]. Green materials are generally made from natural or recycled materials, requiring minimal energy and non-renewable resources, resulting in reduced environmental impact compared to conventional materials [79]. These materials have gained renewed interest in the past fifteen years, particularly in Europe and North America, as they effectively reduce the depletion of non-renewable resources and minimize the environmental impact of disposal processes at the end of a product’s life [87,131]. The production and use of recycled materials in construction are becoming increasingly popular as they prevent environmental pollution by managing bio-based waste from forestry and agriculture. They also avoid the environmental impacts of waste-to-energy conversion or landfill disposal [83]. The strategy of utilizing products from planted forests is also noteworthy. Despite their small proportion of global forests, these cultivated woodlands contribute significantly, supplying 35–40% of the global roundwood harvest [132,133]. Forecasts predict their potential expansion to reach 80% of the worldwide wood harvest by 2030. This growth promises larger, sustainable harvests, potentially reshaping the timber industry [134,135]. Moreover, recent studies suggest that using local and recycled building materials can reduce CO2 emissions, promote the construction of more eco-efficient buildings, and strengthen the local economy [88,90].

3.1.3. Energy Efficiency

The criteria for energy efficiency in buildings often consider materials with low embodied energy and those that have received low-energy certifications [92,93,94]. Embodied energy is used during the production, assembly, demolition, and disposal of building materials [95]. Therefore, choosing materials with low energy demand can result in energy savings in building operations [96,97,98]. One approach to achieving this is by using materials that have energy labels and certifications, such as Energy Star® (issued by the US Environmental Protection Agency), EnerGuide (issued by Natural Resources Canada), and Building EQ (published by ASHRAE), among others, which provide information to building operators and comply with quality management systems [99,100,101]. Furthermore, adopting energy certifications significantly affects energy policies that reduce building energy consumption. Energy certifications have been successfully implemented in developed countries, demonstrating their effectiveness as a tool for governments to promote energy-efficient buildings. To better understand the economic value of energy efficiency labels, [102] developed a pricing model for Metro Atlanta (US) and reported that buildings with energy certification are sold at an 11.7% premium in terms of price. The New Buildings Institute (NBI) conducted a study in 2008 and concluded that Leadership in Energy and Environmental Design (LEED) certification results in energy savings of 25 to 30% [136]. Another study by Newsham et al. [103] analyzed data from the NBI and similarly found that LEED-certified buildings consume 18 to 39% less energy compared to comparable non-certified buildings.

3.1.4. Circular Economy

The criteria referred to as the circular economy relates to the economical use of resources and materials, such as the cumulative cost during its useful life and the cost for disassembly or reuse. Considering its life cycle, it must also achieve its performance over time [104,105]. Buildings are generally designed to be permanent structures, expected to last 50–75 years. However, due to changing user needs, their lifespan often becomes shorter, around 20 years. When materials hinder replacements or disassembly, it results in higher energy and production consumption, increased waste production, and restricted adaptability [108]. Zhou et al. [107] emphasized that circular economy should be a primary consideration in material selection, encompassing procurement, processing, transportation, recycling, and disposal costs. In addition, research has been conducted on implementing prefabricated strategies to enhance the assembly and disassembly of structures based on lifecycle demands [109]. Thus, buildings should be designed as material banks for future construction to enable the reuse of building materials and facilitate the deconstruction of their components and parts. This approach promotes a closed-loop system, ensuring that members and materials can be effectively repurposed, thereby contributing to sustainable resource utilization in the construction industry [110,111]. Understanding the potential applications of a material is crucial in selecting the most suitable material for a specific purpose, as highlighted in previous studies [106].

3.1.5. Site Conditions and Material Logistics

The criteria for site conditions and logistics regarding the characteristics of the area and its surroundings, include the climate, material delivery logistics, and the type of buildings based on the chosen building materials. These criteria play a crucial role in determining the materials to be used in construction, considering factors such as ease of material use, location, shape, and height of the building, as well as material availability [20,49,112]. A study by Ogunkah et al. [88] surveyed professionals from various disciplines and geographic contexts to assess the likelihood of impacts from other factors that may influence strategic decision-making in material selection. The results revealed that 64% of the sample population considered general or site-specific variables. Moreover, the choice of materials for a specific location is influenced by material availability, climate, economy, and construction technique. However, the availability of materials should be considered at the construction stage and when replacements are required [112].

3.1.6. Documentation and Standardization

The documentation and standardization criteria are based on materials that have established codes. Documents play a crucial role in improving material selection and avoiding materials with inadequate performance. Adhering to materials that align with papers and standards helps professionals analyze the impact of materials on building costs and prevents the selection of materials with subpar performance [137,138]. The sub-criteria in this criterion encompass the availability of material selection guidelines, updated material information, and other relevant documentation. Standards for evaluating and classifying materials are of particular interest [20,129,139,140]. This information also aids professionals in analyzing the materials that can affect maintenance costs during the early design phase and helps avoid using faulty materials. These records provide factual information about the materials used in building construction, thereby ensuring accuracy and reliability.

3.1.7. Social Impact

The social impact criteria refer to the benefit that society derives from using certain materials in buildings and includes criteria such as aesthetics, health, and comfort of building occupants, among others [20,114,115]. Social impact means a healthy and safe environment for all stakeholders in the building industry, such as construction workers, building users, and operators. It must be considered during the sustainable design process [116,117]. However, social impact is much more complex than the other quantification criteria and has not received much attention in the architectural literature. Social and sensory factors or variables account for 24% of a material use survey conducted by Ogunkah et al. [88]. The aesthetic of the building is an additional value to be considered to preserve the architectural style of the built environment in the area or promote the image of a company. A company often encourages the construction of its buildings with a corporate image that identifies it and gives it more prestige and, in doing so, emphasizes the aesthetic requirement as a sustainable aspect [118]. In addition, according to a study by [88], 96% of respondents identified environmental and health factors or variables as the most desirable content information to enable efficient and sustainable decisions when choosing appropriate materials. More sustainable buildings benefit the environment and occupants. They can produce substantial economic benefits by reducing operating expenses and, in contrast, improving the market value of buildings, occupant productivity, and the ability to generate income from businesses renting space, and optimizing the economic performance throughout the construction life cycle [119,120,121].

3.2. Pilot Survey Responses

This section presents the results of the pilot survey’s two parts. In the first part, the main objective was to identify the sample’s characteristics, including basic information about respondents’ backgrounds such as education, role held, region of work, work areas and experience, and knowledge about the topic. The second part aimed to understand the respondents’ prioritization of the various criteria, verify the consensus, and classify the criteria based on their severity index.

3.2.1. Sample Characteristics

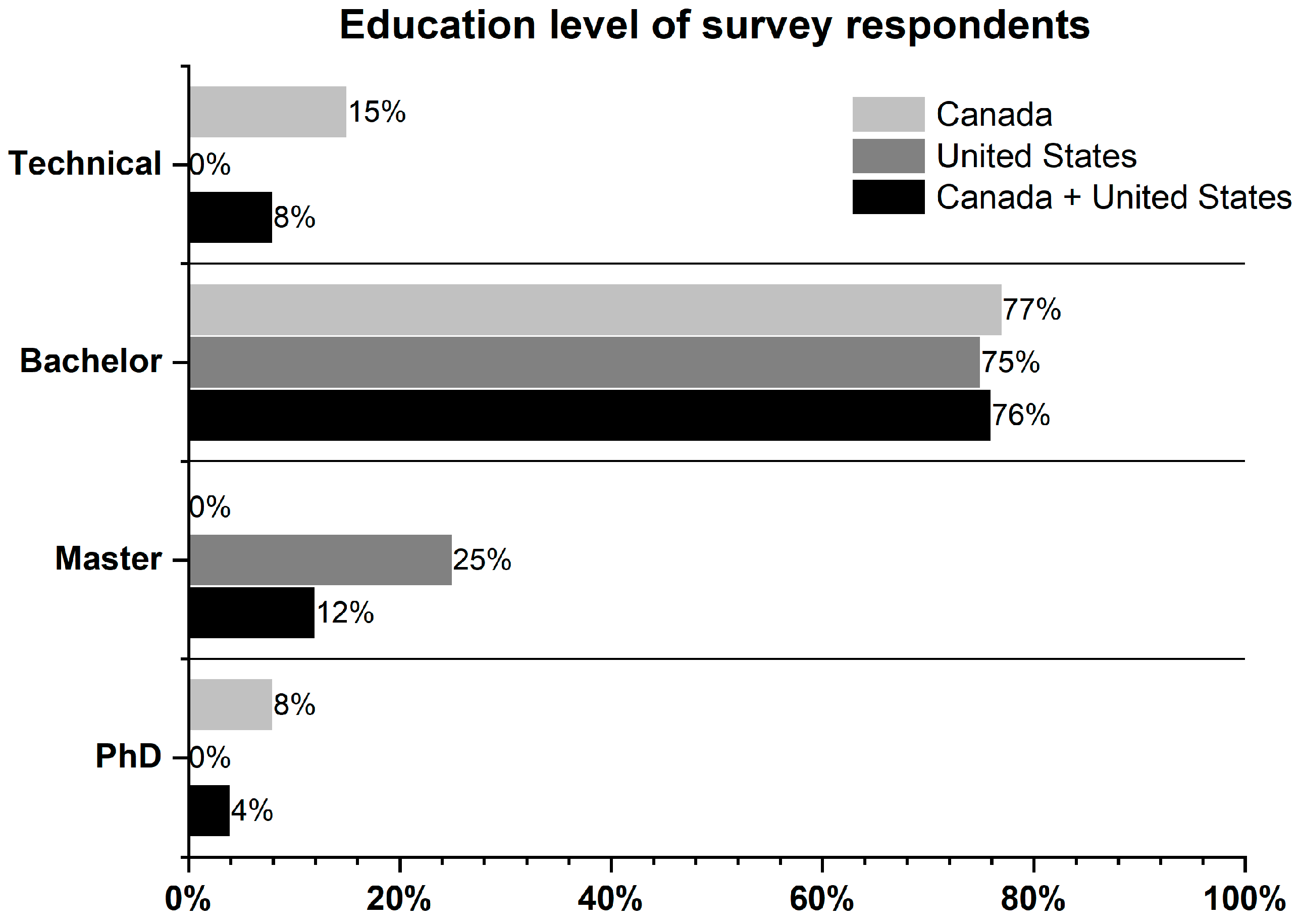

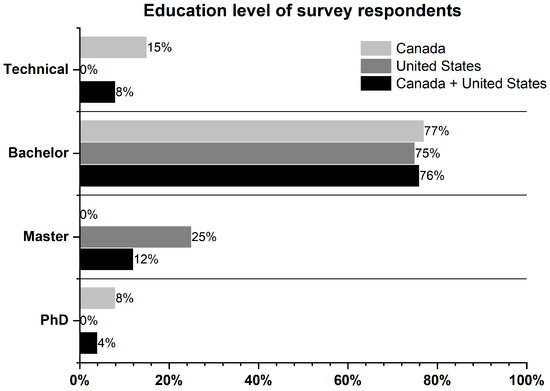

The pilot survey results were grouped in three different ways for analysis (Canada only, the United States only, and Canada and the United States together) to ascertain differences in opinion. Thirteen of the twenty-five respondents were from Canada, and twelve were from the United States. Figure 1 shows that 77% (10/13) of the Canadian respondents have a bachelor’s degree, 15% (2/13) have a technical education, and 8% (1/13) have a Ph.D. (see the light gray bar). As for the United States, 75% (9/12) hold a bachelor’s degree, while 25% (3/12) have a master’s degree (see the dark gray bar). The results for both Canada and the United States together show that 76% (19/25) of respondents have a bachelor’s degree, 12% (3/25) have a master’s degree, 8% (2/25) have a technical education, and 4% (1/25) have a Ph.D. (see the black bar).

Figure 1.

Education level of pilot survey respondents from Canada, the United States, and Canada and the United States together.

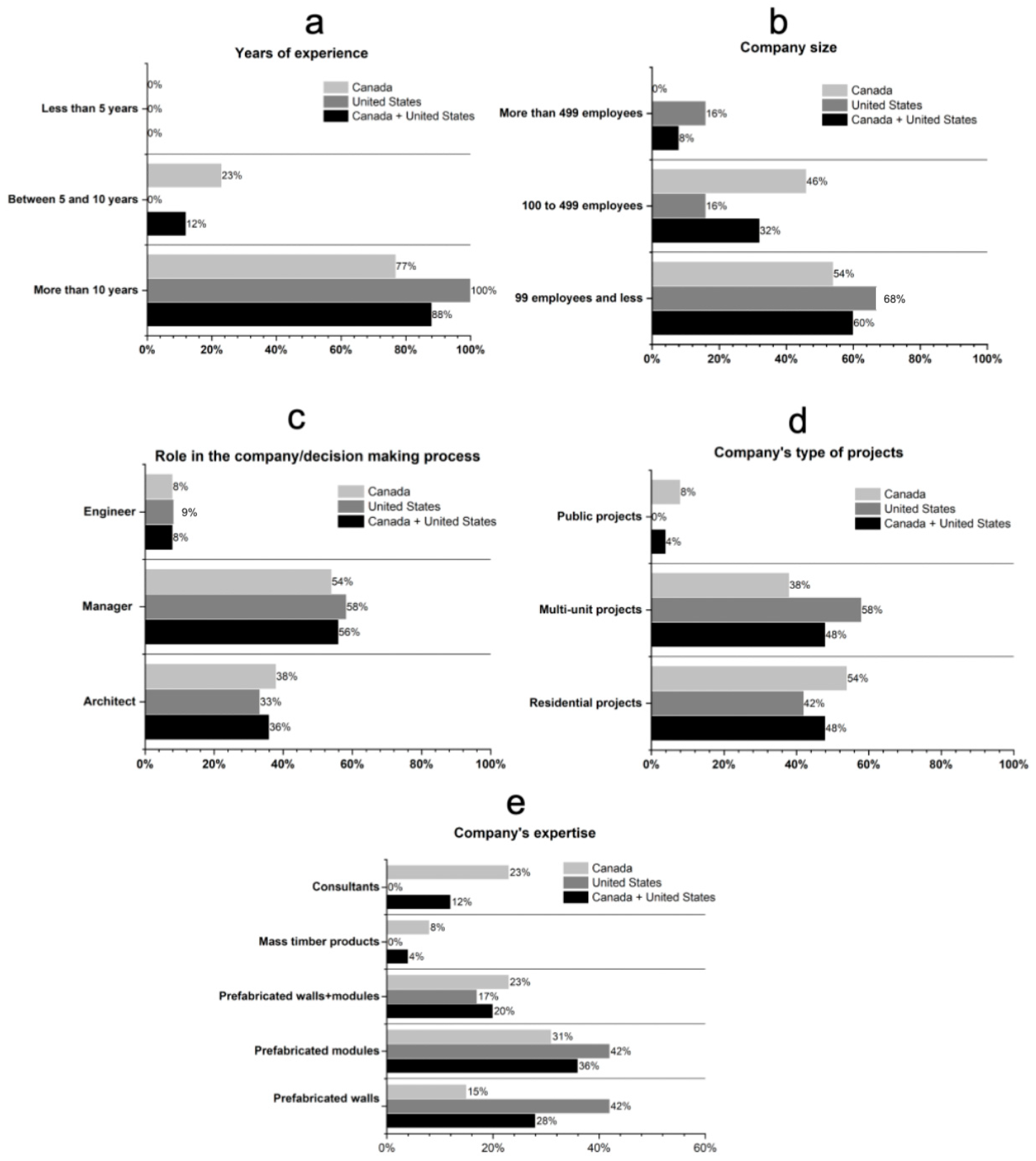

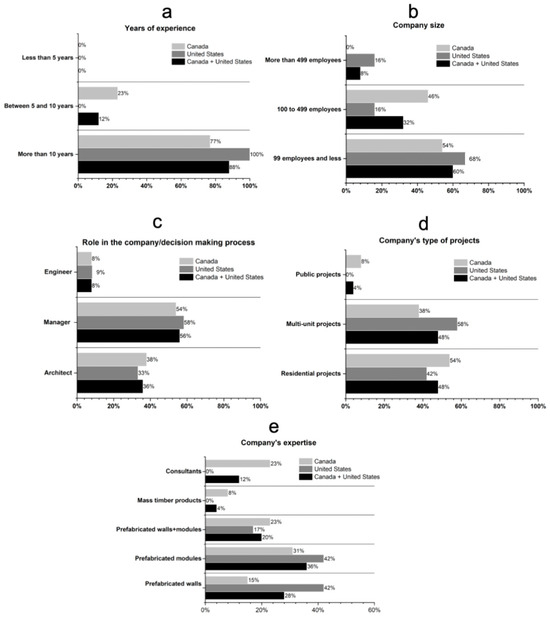

Figure 2 presents pilot survey respondent information, including years of experience (a), the size of the company they work for (b), their role in the company or the decision-making process (c), the types of construction projects in which the company is involved (d), and the company’s expertise (e). Pilot survey respondents were experienced prefabricated construction professionals from different organizations/institutions in Canada and the United States, including architectural and engineering firms, consulting firms, general contractors, and construction management firms. This study categorized coordinators, presidents, and project managers as “managers” due to their similar job characteristics.

Figure 2.

Respondents’ backgrounds: (a) years of experience; (b) company size; (c) role in the company/decision-making process; (d) company’s types of projects; and (e) company’s expertise.

The results show that in Canada, about 77% (10/13) of the professionals had more than ten years of experience, and 23% (3/13) had between 5 and 10 years of experience (light gray bar). In the United States, 100% (12/12) of the professionals had more than ten years of experience (dark gray bar). When both countries are analyzed together (black bar), the professionals with more than ten years of experience represent 88% (22/25) of respondents (Figure 2a). Figure 2b shows the size of the company respondents work for. More than 50% (7/13) of Canadian respondents and 67% (8/12) of US respondents were from companies with fewer than 99 employees. As for respondents’ roles in the company or the decision-making process, Figure 2c shows that in Canada, about 54% (7/13) of respondents were managers, and 38% (5/13) were architects. In contrast, in the United States, 58% (7/12) were managers, 33% (4/12) were architects, and 8% (1/12) were engineers. When both Canada and the United States are analyzed together, 56% (14/25) of the sample is composed of managers, followed by 36% (9/25) of architects and 8% (2/25) of engineers who are the primary individuals responsible for choosing the products to be used in a construction project.

As shown in Figure 2d, about 54% (7/13) of Canadian respondents were involved in residential projects, followed by 38% (5/13) in multi-unit projects and 8% (1/13) in public projects (see the light gray bar). In the United States, 42% (5/12) of respondents were involved in residential projects and 58% (7/12) in multi-unit projects. When analyzing Canada and the United States together, 48% (12/25) of respondents were involved in residential projects, 48% (12/25) in multi-unit projects, and 4% (1/25) in public projects. Regarding the company’s expertise (Figure 2e), the results show that most of the Canadian respondents, i.e., 31% (4/13), were involved in companies that work with prefabricated modules, followed by 15% (2/13) that work with prefabricated walls. Furthermore, about 23% (3/13) of the Canadian respondents were involved in companies that work on both prefabricated walls and modules, 23% (3/13) are prefabricated wood construction consultants, and 8% (1/13) are specialized in mass timber products. Most of the US respondents were involved in companies that work with prefabricated modules, i.e., 42% (5/12), and prefabricated walls, i.e., 42% (5/12) (see the dark gray bar). When both Canada and the United States are analyzed together, prefabricated modules and walls, as well as both combined (wall and modules), represent the majority of the employer companies’ expertise, i.e., 36% (9/25), 28% (7/25) and 20% (5/25), respectively. Therefore, since respondents’ experience in prefabricated wooden buildings and their strategic positioning in the building material decision-making process is quite respectable, their opinions and points of view obtained through the pilot survey can be considered meaningful and reliable.

3.2.2. Criteria and Sub-Criteria Classification

Table 2 presents the SI analysis classification results for Canada, the United States, and Canada and the United States. They show each sub-criterion’s consensus, severity index (SI), priority level, and final priority, as proposed by [34]. The results of the analysis of Canadian respondents showed that fourteen sub-criteria obtained strong consensus since they were rated 4 or 5 on the Likert scale by at least 75% of the professionals, four sub-criteria received moderate consensus, i.e., 60% to 74% of respondents rated them 4 or 5. Seven sub-criteria obtained weak agreement since less than 60% of participants rated them 4 or 5. Thus, the professionals accepted only eighteen of the twenty-five sub-criteria selected from the literature. Subsequently, the SI-based classification results for Canada are also listed in Table 2. From these results, it can be seen that fourteen sub-criteria were classified as H (i.e., of high priority) in structural and envelope material decision-making for wooden buildings, with SI values between 0.9692 and 0.8153. Among those fourteen sub-criteria, the ones classified first and second highest are related to performance properties: watertightness was ranked first in priority, with an SI of 0.9692, followed by fire performance, with an SI of 0.9538.

Table 2.

Classification of building material selection criteria for Canada, the United States, and Canada and the United States.

On the other hand, the sub-criteria that classified third and fourth in terms of priority were the health of occupants and comfort and well-being, which fall under social impact criteria. The top ten classified criteria were watertightness, fire resistance, the health of occupants, comfort and well-being, local availability, ease of use/application, durability, proper standards, mechanical performance and location, shape, and height of the building. It was noted that five of those ten criteria pertain to the criteria performance properties and social impact. On the other hand, the results showed that the sub-criteria related to green materials, energy efficiency, and circular economy were among the least important at the time of selection.

The pilot survey results for the United States show that twelve criteria obtained strong consensus, five obtained moderate consensus, and eight obtained weak consensus. Therefore, the professionals accepted seventeen of the twenty-five criteria selected from the literature. On the other hand, the SI-based classification showed that only ten criteria were considered of high priority (H) in structural and envelope material decision-making for wooden buildings, with SI values between 0.9500 and 0.8166. Three of those ten criteria are in the site conditions and material logistics criteria, the first being location, shape, and height of the building with the highest severity index value (SI = 0.9500), followed by ease of material use and/or application, which was classified as fourth (SI = 0.9167), and availability of material which ranked seventh (SI = 0.8534). Moreover, the results showed that the social impact is of great importance when choosing materials in the United States, being two of its four criteria classified in the top five overall—comfort and well-being of building occupants ranked third and health of building occupants was classified as fifth.

Moreover, as was the case for respondents in Canada, respondents in the United States also considered the watertightness (second) and durability (sixth) sub-criteria essential for prefabricated wooden construction. In addition, using materials that are easy to apply (ease of material use and/or application criteria) was among the highest classified (fourth), with a severity index of 0.9167. In the Canadian classification for the top ten sub-criteria, there was dispersion observed for the criteria of site performance properties (4/8 in the top ten), conditions and logistics (3/3 in the top ten), documentation (1/2 in the top ten), and social impact (2/4 in the top ten) when selecting structural or envelope materials for prefabricated wooden construction. In contrast, in the United States, the top ten sub-criteria were primarily focused on social impact (4/4 in the top ten) and site conditions and logistics (3/3 in the top ten), as seen in Table 2.

Upon seeing this difference in response patterns, we analyzed respondents from both countries and their responses as a single sample group (see Table 2), as was mentioned earlier. It is essential to highlight that these findings do not claim to be statistically representative. They provide insight into the relative importance of the proposed criteria according to the respondents’ experience and their national context. The analysis results of Canada’s and the United States’ respondents show that thirteen criteria obtained strong consensus (i.e., were rated 4 or 5 by at least 75% of the professionals). At the same time, only two achieved moderate consensus, i.e., were rated 4 or 5 by 60% to 74% of respondents, and ten had weak agreement since less than 60% of participants rated them 4 or 5. When both countries were analyzed together, only twelve sub-criteria reached the minimum threshold to be considered relevant and classified as H priority by the professionals’ opinions, with SI values between 0.9200 and 0.8160. Watertightness was ranked as the most critical sub-criteria to consider when choosing materials. The improved water-tightness of materials is believed to enhance the durability of buildings, as excessive moisture content, particularly fluctuations in the moisture levels of wood materials, can result in repetitive shrinkage and swelling mechanisms. These mechanisms can weaken the material’s mechanical strength over time [141,142]. The second most important was the sub-criterion ease of material use and/or application, with an SI value of 0.9167. Furthermore, when both countries are considered together, four of the top ten criteria are in social impact, the health of occupants (third), comfort and well-being (eighth), safety and security (ninth), and aesthetics (tenth).

3.3. Monte Carlo Simulations

Table 3 presents the SI values and the final priorities calculated based on the Monte Carlo simulations (1000, 10,000, and 100,000) for Canada, the United States, and Canada and the United States, respectively. The prediction of the SI for different simulations in Canada and the United States yielded consistent results. In Canada, the top five crucial sub-criteria remained the same across the simulations: fire resistance, watertightness, local availability, the health of occupants, and safety and security. Only the places varied. These predictions align with the results obtained from the pilot survey, further validating their accuracy. It is worth noting that the top two sub-criteria consistently maintained their coherence throughout all simulations.

Table 3.

Monte Carlo simulations to predict the classification of building material selection criteria.

Similarly, for the United States, the prioritization of the top five sub-criteria for material selection was observed across the simulations. The most critical sub-criteria were location, shape and height, comfort and well-being, ease to use/apply, health of occupants, and durability. These predictions agree with the pilot survey results, where the top two sub-criteria remained consistent across all simulations. Furthermore, the sub-criterion location, shape, and height was identified as the most important, followed by comfort and well-being. For the simulations regarding Canada and the United States, the predictions showed that the five most relevant sub-criteria for selection were in line with the trends assessed in the surveys.

Furthermore, the predictions demonstrated that the sub-criteria of ease to use/apply, occupants’ health, and location, shape, and height were among the most critical factors in choosing products for envelopes and structures. In general, the three separate analyses conducted for Canada, the United States, and Canada and the United States combined produced consistent predictions that aligned with the respective pilot survey results. Through these findings, it is possible to have a sub-criteria indicators for selecting, or an indicator for future product development in each region in the combined analysis.

4. Discussion and Limitations

The sub-criteria such as watertightness and durability are closely related in the decision-making process of wooden buildings since using a building component that could be more watertight will consequently lead to decreased durability. The exact parallel can be found when crossing the properties of the products used in wood building structures and envelopes with the safety and security of building occupants, i.e., the use of products with poor mechanical, physical, and durability performance might negatively impact occupants’ experience and health [143]. As stated in ASHRAE Standard 160 [144], the building envelope and structures are generally not utterly watertight independent of the water management system applied. A small amount of rainwater might, therefore, penetrate behind the cladding. Thus, as reported by the respondents, the use of materials that make it possible to eliminate the possibility of water infiltration or reduce it to a minimum in wooden construction is of great importance in decision-making.

Moreover, in the case of severe weather conditions, which are common in Canada and the United States, a lack of watertightness increases the risk of water ingress, which can lead to premature deterioration of the structural system and the envelope itself and is generally perceived as discomfort as some studies point out [145,146]. Regarding occupant health, indoor air quality is critical to occupant well-being. McArthur and Powell [147] and Wolkoff [148] indicate the effects of poor indoor air quality on occupants, including eye irritation, olfactory issues, and overall health. Therefore, selecting materials that promote good indoor air quality is essential to provide occupant comfort and well-being.

High importance was accorded to fire performance sub-criteria, and this result can be explained because of evacuation-related risks during fire situations [149]. A building fire can result in human casualties and facilitate the spread of fire through damaged walls or to neighboring compartments or buildings [150].

The high importance of the comfort and well-being sub-criterion in material selection can be attributed to its direct impact on human perception of immediate and long-term quality and its influence on psychological restoration. For example, Elsadek et al. [151] discuss how materials (green facades) might promote comfort and well-being and contribute to recovering physical and mental resources, enabling individuals to cope with and manage daily living situations effectively. This suggests that materials can positively impact individuals’ ability to manage and adapt to their environment. Chi et al. [152] emphasize the significance of visual comfort, highlighting how daylight availability creates a visually pleasing environment that positively impacts human well-being. Then, incorporating materials that can maximize natural light and create a visually appealing space might be a route to contribute to the occupant’s comfort and satisfaction. In addition to visual and thermal comfort, acoustic comfort plays a crucial role. Herranz-Pascual et al. [153] emphasize the impact of materials on acoustic conditions within a space, highlighting the importance of sound insulation and noise reduction for creating a comfortable environment.

Gou et al. [154] focus on thermal comfort, pointing out that good thermal properties can significantly enhance occupants’ comfort levels. Harkouss et al. [155] examine the perception of overheating and highlight the importance of providing an environment that helps regulate indoor temperature effectively.

On the other hand, the results show that sub-criteria related to sustainable development, such as those in the energy efficiency and green material criteria and the product with EPD and cost of dismantling and removal sub-criteria, are less critical in the decision-making process. However, some respondents claimed that such criteria might have a higher classification depending on the type of project, especially when it comes to projects aiming for LEED or other sustainability certifications. Furthermore, some respondents argued that it is important to choose local products, which can minimize logistics costs and strengthen the local economy. Moreover, as pointed out in reference [113], the use of local material is a criterion that is often considered to be synonymous with job creation due to growing awareness of its ramifications.

A study conducted by Si et al. [156] evaluated 39 criteria for buildings in the United Kingdom and China, and the engineers and architects consulted in both countries classified durability as the most crucial criterion for non-domestic buildings. In addition, it was found when analyzing both countries together that respondents gave less priority to the criteria related to sustainable development, e.g., those in the energy efficacy and green material criteria and the product with EPD and cost of dismantling and removal criteria. It is seen that the sub-criteria for site conditions and logistics criteria were among the top-ranked. These criteria were crucial during the building’s implementation phase, significantly impacted construction operations, and directly affected project quality. It is also critical for cost estimations, often accounting for up to 70% of total construction costs [157].

Furthermore, the criterion use of local materials was indicated in the final tab of the pilot survey by six professionals from Canada and three from the United States as an essential factor in the decision-making. Selecting local materials as much as possible—not only for sustainability but also for local economic benefit. Regarding the criterion of ease of use of materials, one of the respondents said that the leading time to acquire the components, the erection time, and the complexity demanded by certain materials must be considered. Moreover, it is argued that the skill level required from the labor and the machinery required to transport or erect need to be pondered in the decision.

This study offers valuable insights into material selection for prefabricated wood buildings. However, as pointed out in [28], limitations exist regarding the findings’ applicability beyond Canada and the United States due to differing climates, regulations, and cultural preferences. Additionally, ongoing changes in technology, regulations, and user preferences could affect the relevance of identified criteria over time. Implementing decisions based on these findings may also be influenced by budget constraints, material availability, and specific project needs, impacting their direct applicability.

5. Conclusions

In conclusion, this study has identified and classified the priority orders of sub-criteria crucial for material selection in prefabricated wood constructions. The insights drawn from the opinions of professionals from Canada, the United States, and both countries have provided comprehensive perspectives on the sub-criteria influencing decision-making in this domain.

From the literature review, seven main criteria were found i.e., performance properties, green materials, energy efficiency, material economy, site conditions and material logistics, standards, and social impact. From the pilot survey, sub-criteria under performance properties, site conditions, material logistics, and social impact emerged as focal indicators across the analysis, consistently ranking among the top priorities.

Through Monte Carlo simulations, the study revealed a remarkable consistency in the top-ranked sub-criteria for Canada and the United States, underscoring indicators such as fire resistance, watertightness, local availability, occupant health, safety, and protection. Furthermore, the simulations reinforced the significance of location, shape, height, comfort, well-being, ease of use/application, and durability in material selection processes, aligning with pilot study outcomes and demonstrating robustness within varying analyses.

This study offers valuable insights into material selection for prefabricated wood buildings. Also, it provides interesting practical implications for future research as it furnishes helpful indicators and guidelines to aid decision-making tools and models, specifically benefiting the selection of materials for prefabricated wood constructions in Canada and the United States. These insights also serve as a foundational resource for future product development in the construction of buildings, particularly those utilizing prefabricated wood materials.

However, limitations exist regarding the findings’ applicability beyond Canada and the United States due to differing climates, regulations, and cultural preferences. Additionally, ongoing changes in technology, regulations, and user preferences could affect the relevance of identified criteria over time. Implementing decisions based on these findings may also be influenced by budget constraints, material availability, and specific project needs, impacting their direct applicability.

Author Contributions

Methodology, M.R.C.; writing—original draft preparation, M.R.C.; writing—review and editing, M.R.C. and P.B.; supervision, P.B.; project administration, P.B.; funding acquisition, P.B. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful to Canada’s Natural Sciences and Engineering Research Council for the financial support through its IRC and CRD programs (IRCPJ 461745-18 and RDCPJ 514294-17).

Data Availability Statement

The data presented in this study are available in article.

Acknowledgments

The authors are grateful to the industrial partners of the NSERC Industrial Research Chair on Eco-responsible Wood Construction (CIRCERB), the industrial partners of the Industrialized Construction Initiative (ICI) and the Créneau Accord Bois Chaudière-Appalaches (BOCA).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Cabral, M.R.; Blanchet, P. A State of the Art of the Overall Energy Efficiency of Wood Buildings—An Overview and Future Possibilities. Materials 2021, 14, 1848. [Google Scholar] [CrossRef] [PubMed]

- Aguilera, M. Estudio Percepción Construcción en Madera; Instituto Forestal: Ñuñoa, Santiago, 2020. [Google Scholar]

- De Araujo, V.; Biazzon, J.; Cortez, J.; Gava, M.; Garcia, J. Production and Market of Timber Housing in Brazil. Proligno 2020, 16, 17–27. [Google Scholar]

- Yu, T.; Man, Q.; Wang, Y.; Shen, G.Q.; Hong, J.; Zhang, J.; Zhong, J. Evaluating Different Stakeholder Impacts on the Occurrence of Quality Defects in Offsite Construction Projects: A Bayesian-Network-Based Model. J. Clean. Prod. 2019, 241, 118390. [Google Scholar] [CrossRef]

- Jahan, A.; Edwards, K.L. The Importance of Decision Support in Materials Selection. In Multi-Criteria Decision Analysis for Supporting the Selection of Engineering Materials in Product Design; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1–15. [Google Scholar]

- Pajula, T.; Behm, K.; Vatanen, S.; Saarivuori, E. Managing the Life Cycle to Reduce Environmental Impacts. In Dynamics of Long-Life Assets: From Technology Adaptation to Upgrading the Business Model; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 93–113. ISBN 9783319454382. [Google Scholar]

- Martins, I.D.; Moraes, F.F.; Távora, G.; Soares, H.L.F.; Infante, C.E.; Arruda, E.F.; Bahiense, L.; Caprace, J.; Lourenço, M.I. A Review of the Multicriteria Decision Analysis Applied to Oil and Gas Decommissioning Problems. Ocean. Coast. Manag. 2019, 184, 105000. [Google Scholar] [CrossRef]

- Tsoukias, A.; Vincke, P. Multicriteria Decision-Aid. J. Oper. Res. Soc. 1993, 44, 317–318. [Google Scholar] [CrossRef]

- Hsu, C.C.; Sandford, B.A. The Delphi Technique: Making Sense of Consensus. Pract. Assess. Res. Eval. 2019, 12, 10. [Google Scholar] [CrossRef]

- Jahan, A.; Edwards, K.L. Multi-Criteria Decision-Making for Materials Selection. In Multi-Criteria Decision Analysis for Supporting the Selection of Engineering Materials in Product Design; Elsevier: Amsterdam, The Netherlands, 2013; pp. 31–41. [Google Scholar]

- Sirisalee, P.; Ashby, M.F.; Parks, G.T.; Clarkson, P.J. Multi-Criteria Material Selection in Engineering Design. Adv. Eng. Mater. 2004, 6, 84–92. [Google Scholar] [CrossRef]

- Nassar, K.; Thabet, W.; Beliveau, Y. A Procedure for Multi-Criteria Selection of Building Assemblies. Autom. Constr. 2003, 12, 543–560. [Google Scholar] [CrossRef]

- Perlingeiro, R.M.; Perlingeiro, M.S.P.L.; Chinelli, C.K.; Vazquez, E.G.; Qualharini, E.L.; Haddad, A.N.; Hammad, A.W.A.; Soares, C.A.P. Sustainable Assessment of Public Works through a Multi-Criteria Framework. Sustainability 2020, 12, 6896. [Google Scholar] [CrossRef]

- Turoff, M.; Linstone, H.A. The Policy Delphi. Delphi Method Tech. Appl. 2002.

- Wentholt, M.T.A.; Cardoen, S.; Imberechts, H.; Van Huffel, X.; Ooms, B.W.; Frewer, L.J. Defining European Preparedness and Research Needs Regarding Emerging Infectious Animal Diseases: Results from a Delphi Expert Consultation. Prev. Vet. Med. 2012, 103, 81–92. [Google Scholar] [CrossRef] [PubMed]

- Benson, H.; Lucas, C.; Williams, K.A. Establishing Consensus for General Practice Pharmacist Education: A Delphi Study. Curr. Pharm. Teach. Learn. 2020, 12, 8–13. [Google Scholar] [CrossRef] [PubMed]

- Windle, P.E. Delphi Technique: Assessing Component Needs. J. Perianesthesia Nurs. 2004, 19, 46–47. [Google Scholar] [CrossRef] [PubMed]

- Nayahangan, L.J.; Konge, L.; Møller-Skuldbøl, I.M.; Kolster, D.; Paltved, C.; Sørensen, J.L. A Nationwide Needs Assessment to Identify and Prioritize Technical Procedures for Simulation in Obstetrics and Gynaecology: A Delphi Study. J. Obstet. Gynaecol. Can. 2020, 42, 409–419. [Google Scholar] [CrossRef]

- Disterheft, A.; Caeiro, S.; Azeiteiro, U.M.; Filho, W.L. Sustainable Universities—A Study of Critical Success Factors for Participatory Approaches. J. Clean. Prod. 2015, 106, 11–21. [Google Scholar] [CrossRef]

- Kanniyapan, G.; Nesan, L.J.; Mohammad, I.S.; Tan, S.K.; Ponniah, V. Selection Criteria of Building Material for Optimising Maintainability. Constr. Build. Mater. 2019, 221, 651–660. [Google Scholar] [CrossRef]

- Karaivanova, A.; Ivanovska, S.; Gurov, T. Monte Carlo Method for Density Reconstruction Based on Insufficient Data. Procedia Comput. Sci. 2015, 51, 1782–1790. [Google Scholar] [CrossRef][Green Version]

- Zheng, D.; Yu, L.; Wang, L.; Tao, J. Integrating Willingness Analysis into Investment Prediction Model for Large Scale Building Energy Saving Retrofit: Using Fuzzy Multiple Attribute Decision Making Method with Monte Carlo Simulation. Sustain. Cities Soc. 2019, 44, 291–309. [Google Scholar] [CrossRef]

- Cui, H.; Dong, S.; Hu, J.; Chen, M.; Hou, B.; Zhang, J.; Zhang, B.; Xian, J.; Chen, F. A Hybrid MCDM Model with Monte Carlo Simulation to Improve Decision-Making Stability and Reliability. Inf. Sci. 2023, 647, 119439. [Google Scholar] [CrossRef]

- Benalcazar, P.; Komorowska, A. Prospects of Green Hydrogen in Poland: A Techno-Economic Analysis Using a Monte Carlo Approach. Int. J. Hydrog. Energy 2022, 47, 5779–5796. [Google Scholar] [CrossRef]

- Harrison, R.L.; Granja, C.; Leroy, C. Introduction to Monte Carlo Simulation; American Institute of Physics: College Park, MD, USA, 2010; pp. 17–21. [Google Scholar]

- Chan, F.T.S.; Chan, H.K. Design of a PCB Plant with Expert System and Simulation Approach. Expert. Syst. Appl. 2005, 28, 409–423. [Google Scholar] [CrossRef]

- Hsu, T.H.; Pan, F.F.C. Application of Monte Carlo AHP in Ranking Dental Quality Attributes. Expert. Syst. Appl. 2009, 36, 2310–2316. [Google Scholar] [CrossRef]

- Cabral, M.R.; Blanchet, P. Analytical Hierarchical Process as a Multicriteria Decision Tool in Material Selection for Prefabricated Wood Buildings. Buildings 2023, 13, 2973. [Google Scholar] [CrossRef]

- Biresselioglu, M.E.; Demir, M.H.; Rashid, A.; Solak, B.; Ozyorulmaz, E. What Are the Preferences of Household Energy Use in Pakistan? Findings from a National Survey. Energy Build. 2019, 205, 109538. [Google Scholar] [CrossRef]

- Skinner, R.; Nelson, R.R.; Chin, W.; Land, L. The Delphi Method Research Strategy in Studies of Information Systems. Commun. Assoc. Inf. Syst. 2015, 37, 2. [Google Scholar] [CrossRef]

- Maertens, H.; Aggarwal, R.; Macdonald, S.; Vermassen, F.; Van Herzeele, I.; Brodmann, M.; Devries, J.P.; Ferraresi, R.; Ansel, G.; Goverde, P.; et al. Transatlantic Multispecialty Consensus on Fundamental Endovascular Skills: Results of a Delphi Consensus Study. Eur. J. Vasc. Endovasc. Surg. 2016, 51, 141–149. [Google Scholar] [CrossRef]

- Attieh, R.; Gagnon, M.P.; Estabrooks, C.A.; Légaré, F.; Ouimet, M.; Vazquez, P.; Nuño, R. Organizational Readiness for Knowledge Translation in Chronic Care: A Delphi Study. BMC Health Serv. Res. 2014, 14, 534. [Google Scholar] [CrossRef]

- Witt, R.R.; Almeida, M.C.P. De Identification of Nurses’ Competencies in Primary Health Care through a Delphi Study in Southern Brazil. Public. Health Nurs. 2008, 25, 336–343. [Google Scholar] [CrossRef]

- Chen, Y.; Okudan, G.E.; Riley, D.R. Sustainable Performance Criteria for Construction Method Selection in Concrete Buildings. Autom. Constr. 2009, 19, 235–244. [Google Scholar] [CrossRef]

- Idrus, A.B.; Newman, J.B. Construction Related Factors Influencing the Choice of Concrete Floor Systems. Constr. Manag. Econ. 2010, 20, 13–19. [Google Scholar] [CrossRef]

- Guy-Plourde, S.; Blanchet, P.; de Blois, M.; Robichaud, F.; Barbuta, C. Cladding Materials in Non-Residential Construction: Consideration Criteria for Stakeholder in the Province of Quebec. J. Facade Des. Eng. 2018, 6, 71–88. [Google Scholar] [CrossRef]

- Mundfrom, D.J.; Schaffer, J.; Kim, M.J.; Shaw, D.; Thongteeraparp, A.; Preecha, P.; Supawan, P. Number of Replications Required in Monte Carlo Simulation Studies: A Synthesis of Four Studies. J. Mod. Appl. Stat. Methods 2011, 10, 4. [Google Scholar] [CrossRef]

- Heijungs, R. On the Number of Monte Carlo Runs in Comparative Probabilistic LCA. Int. J. Life Cycle Assess. 2020, 25, 394–402. [Google Scholar] [CrossRef]

- Akbar, A.; Liew, K.M.; Farooq, F.; Khushnood, R.A. Exploring Mechanical Performance of Hybrid MWCNT and GNMP Reinforced Cementitious Composites. Constr. Build. Mater. 2021, 267, 120721. [Google Scholar] [CrossRef]

- Altomonte, S.; Rutherford, P.; Wilson, R. Human Factors in the Design of Sustainable Built Environments. Intell. Build. Int. 2015, 7, 224–241. [Google Scholar] [CrossRef]

- ANSI/APA PRG320-2012; Standard for Performance-Rated Cross-Laminated Timber A. ANSI/APA: Tacoma, WA, USA, 2012.

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A Review of Structural, Thermo-Physical, Acoustical, and Environmental Properties of Wooden Materials for Building Applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Barber, D.; Gerard, R. Summary of the Fire Protection Foundation Report—Fire Safety Challenges of Tall Wood Buildings. Fire Sci. Rev. 2015, 4, 5. [Google Scholar] [CrossRef]

- Belussi, L.; Barozzi, B.; Bellazzi, A.; Danza, L.; Devitofrancesco, A.; Fanciulli, C.; Ghellere, M.; Guazzi, G.; Meroni, I.; Salamone, F.; et al. A Review of Performance of Zero Energy Buildings and Energy Efficiency Solutions. J. Build. Eng. 2019, 25, 100772. [Google Scholar] [CrossRef]

- Blondin, F.; Blanchet, P.; Dagenais, C.; Triantafyllidis, Z.; Bisby, L. Fire Hazard of Compressed Straw as an Insulation Material for Wooden Structures. Fire Mater. 2020, 44, 736–746. [Google Scholar] [CrossRef]

- Brager, G.; Baker, L. Occupant Satisfaction in Mixed-Mode Buildings. Build. Res. Inf. 2009, 37, 369–380. [Google Scholar] [CrossRef]

- Butylina, S.; Hyvärinen, M.; Kärki, T. A Study of Surface Changes of Wood-Polypropylene Composites as the Result of Exterior Weathering. Polym. Degrad. Stab. 2012, 97, 337–345. [Google Scholar] [CrossRef]

- Chew, M.Y.L.; De Silva, N. Factorial Method for Performance Assessment of Building Facades. J. Constr. Eng. Manag. 2004, 130, 525–533. [Google Scholar] [CrossRef]

- Chew, M.Y.L.; Tan, S.S.; Kang, K.H. A Technical Evaluation Index for Curtain Wall and Cladding Facades. Struct. Surv. 2004, 22, 210–227. [Google Scholar] [CrossRef]

- D’Alessandro, F.; Asdrubali, F.; Mencarelli, N. Experimental Evaluation and Modelling of the Sound Absorption Properties of Plants for Indoor Acoustic Applications. Build. Environ. 2015, 94, 913–923. [Google Scholar] [CrossRef]

- Faustino, J.; Pereira, L.; Soares, S.; Cruz, D.; Paiva, A.; Varum, H.; Ferreira, J.; Pinto, J. Impact Sound Insulation Technique Using Corn Cob Particleboard. Constr. Build. Mater. 2012, 37, 153–159. [Google Scholar] [CrossRef]

- Foliente, G.C.; Leicester, R.H.; Wang, C.; Mackenzie, C.; Cole, I. Durability Design for Wood Construction. Prod. J. 2002, 52, 10–20. [Google Scholar]

- Friedrich, D. Effects from Natural Weathering on Long-Term Structural Performance of Wood-Polymer Composite Cladding in the Building Envelope. J. Build. Eng. 2019, 23, 68–76. [Google Scholar] [CrossRef]

- Gagliano, A.; Nocera, F.; Aneli, S. Thermodynamic Analysis of Ventilated Façades under Different Wind Conditions in Summer Period. Energy Build. 2016, 122, 131–139. [Google Scholar] [CrossRef]

- Gasparri, E.; Aitchison, M. Unitised Timber Envelopes. A Novel Approach to the Design of Prefabricated Mass Timber Envelopes for Multi-Storey Buildings. J. Build. Eng. 2019, 26, 100898. [Google Scholar] [CrossRef]

- Gunasekaran, U.; Emani, P.; Aruna Malini, T.P. Facades of Tall Buildings—State of the Art. Mod. Appl. Sci. 2010, 4, 116. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Q.; Yin, Y.; Pu, J. Fire Retardancy of Graphene Oxide/Wood Composite (GOW) Prepared by a Vacuum-Pulse Dipping Technique. Holzforschung 2018, 72, 375–378. [Google Scholar] [CrossRef]

- Homkhiew, C.; Ratanawilai, T.; Thongruang, W. Effects of Natural Weathering on the Properties of Recycled Polypropylene Composites Reinforced with Rubberwood Flour. Ind. Crops Prod. 2014, 56, 52–59. [Google Scholar] [CrossRef]

- Hung, K.C.; Chen, Y.L.; Wu, J.H. Natural Weathering Properties of Acetylated Bamboo Plastic Composites. Polym. Degrad. Stab. 2012, 97, 1680–1685. [Google Scholar] [CrossRef]

- Innella, F.; Bai, Y.; Zhu, Z. Mechanical Performance of Building Modules during Road Transportation. Eng. Struct. 2020, 223, 111185. [Google Scholar] [CrossRef]

- Limam, A.; Zerizer, A.; Quenard, D.; Sallee, H.; Chenak, A. Experimental Thermal Characterization of Bio-Based Materials (Aleppo Pine Wood, Cork and Their Composites) for Building Insulation. Energy Build. 2016, 116, 89–95. [Google Scholar] [CrossRef]

- Liu, L.; Zou, S.; Li, H.; Deng, L.; Bai, C.; Zhang, X.; Wang, S.; Li, N. Experimental Physical Properties of an Eco-Friendly Bio-Insulation Material Based on Wheat Straw for Buildings. Energy Build. 2019, 201, 19–36. [Google Scholar] [CrossRef]

- Lizana, J.; Chacartegui, R.; Barrios-Padura, A.; Valverde, J.M. Advances in Thermal Energy Storage Materials and Their Applications towards Zero Energy Buildings: A Critical Review. Appl. Energy 2017, 203, 219–239. [Google Scholar] [CrossRef]

- Lstiburek, J. RR-0203: Relative Humidity. Building Science Corporation. Available online: https://www.buildingscience.com/documents/reports/rr-0203-relative-humidity/view (accessed on 14 March 2021).

- Martabid, J.E.; Mourgues, C. Criteria Used for Selecting Envelope Wall Systems in Chilean Residential Projects. J. Constr. Eng. Manag. 2015, 141, 05015011. [Google Scholar] [CrossRef]

- Merk, V.; Chanana, M.; Keplinger, T.; Gaan, S.; Burgert, I. Hybrid Wood Materials with Improved Fire Retardance by Bio-Inspired Mineralisation on the Nano- and Submicron Level. Green. Chem. 2015, 17, 1423–1428. [Google Scholar] [CrossRef]

- Osanyintola, O.F.; Simonson, C.J. Moisture Buffering Capacity of Hygroscopic Building Materials: Experimental Facilities and Energy Impact. Energy Build. 2006, 38, 1270–1282. [Google Scholar] [CrossRef]

- Pujadas-Gispert, E.; Alsailani, M.; van Dijk, K.C.A.; Rozema, A.D.K.; ten Hoope, J.P.; Korevaar, C.C.; Moonen, S.P.G. Design, Construction, and Thermal Performance Evaluation of an Innovative Bio-Based Ventilated Façade. Front. Archit. Res. 2020, 9, 681–696. [Google Scholar] [CrossRef]

- Seddeq, H.S.; Aly, N.M.; Marwa, A.A.; Elshakankery, M. Investigation on Sound Absorption Properties for Recycled Fibrous Materials. J. Ind. Text. 2013, 43, 56–73. [Google Scholar] [CrossRef]

- Setter, L.; Smoorenburg, E.; Wijesuriya, S.; Tabares-Velasco, P.C. Energy and Hygrothermal Performance of Cross Laminated Timber Single-Family Homes Subjected to Constant and Variable Electric Rates. J. Build. Eng. 2019, 25, 100784. [Google Scholar] [CrossRef]

- da Silva, C.B.; Martins, A.B.; Catto, A.L.; Santana, R.M.C. Effect of Natural Ageing on the Properties of Recycled Polypropylene/Ethylene Vinyl Acetate/Wood Flour Composites. Rev. Mater. 2017, 22, e11835. [Google Scholar] [CrossRef]

- Sonderegger, W.; Niemz, P.; Sonderegger, W.; Niemz, P. Thermal Conductivity and Water Vapour Transmission Properties of Wood-Based Materials. J. Wood Prod. 2009, 67, 313–321. [Google Scholar] [CrossRef]

- Suleiman, B.M.; Larfeldt, J.; Leckner, B.; Gustavssor, M. Thermal Conductivity and Diffusivity of Wood. Wood Sci. Technol. 1999, 33, 465–473. [Google Scholar] [CrossRef]

- Toman, J.; Vimmrová, A.; Černý, R. Long-Term on-Site Assessment of Hygrothermal Performance of Interior Thermal Insulation System without Water Vapour Barrier. Energy Build. 2009, 41, 51–55. [Google Scholar] [CrossRef]

- Vololonirina, O.; Coutand, M.; Perrin, B. Characterization of Hygrothermal Properties of Wood-Based Products—Impact of Moisture Content and Temperature. Constr. Build. Mater. 2014, 63, 223–233. [Google Scholar] [CrossRef]

- Wei, X.; Guo, Y. Fire and Shock Resistance of Wooden Frame of Buildings. Int. Wood Prod. J. 2019, 10, 3–8. [Google Scholar] [CrossRef]

- Wright, J.A.; Loosemore, H.A.; Farmani, R. Optimization of Building Thermal Design and Control by Multi-Criterion Genetic Algorithm. Energy Build. 2002, 34, 959–972. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of a Sustainable Building: A Conceptual Framework for Implementing Sustainability in the Building Sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef]

- Asdrubali, F.; Schiavoni, S.; Horoshenkov, K.V. A Review of Sustainable Materials for Acoustic Applications. Build. Acoust. 2012, 19, 283–311. [Google Scholar] [CrossRef]

- Braulio-Gonzalo, M.; Bovea, M.D. Environmental and Cost Performance of Building’s Envelope Insulation Materials to Reduce Energy Demand: Thickness Optimisation. Energy Build. 2017, 150, 527–545. [Google Scholar] [CrossRef]

- Doan, D.T.; Ghaffarianhoseini, A.; Naismith, N.; Zhang, T.; Ghaffarianhoseini, A.; Tookey, J. A Critical Comparison of Green Building Rating Systems. Build. Environ. 2017, 123, 243–260. [Google Scholar] [CrossRef]

- Gilani, G.; Pons, O.; De La Fuente, A. Sustainability-Oriented Approach to Assist Decision Makers in Building Facade Management. J. Constr. Eng. Manag. 2021, 148, 04021182. [Google Scholar] [CrossRef]

- Ingrao, C.; Lo Giudice, A.; Bacenetti, J.; Tricase, C.; Dotelli, G.; Fiala, M.; Siracusa, V.; Mbohwa, C. Energy and Environmental Assessment of Industrial Hemp for Building Applications: A Review. Renew. Sustain. Energy Rev. 2015, 51, 29–42. [Google Scholar] [CrossRef]

- Lertsutthiwong, P.; Khunthon, S.; Siralertmukul, K.; Noomun, K.; Chandrkrachang, S. New Insulating Particleboards Prepared from Mixture of Solid Wastes from Tissue Paper Manufacturing and Corn Peel. Bioresour. Technol. 2008, 99, 4841–4845. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, X. Measurement of Formaldehyde and VOCs Emissions from Wood-Based Panels with Nanomaterial-Added Melamine-Impregnated Paper. Constr. Build. Mater. 2014, 66, 132–137. [Google Scholar] [CrossRef]

- Mattoni, B.; Guattari, C.; Evangelisti, L.; Bisegna, F.; Gori, P.; Asdrubali, F. Critical Review and Methodological Approach to Evaluate the Differences among International Green Building Rating Tools. Renew. Sustain. Energy Rev. 2018, 82, 950–960. [Google Scholar] [CrossRef]

- Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Environmental Impacts of Natural and Conventional Building Materials: A Case Study on Earth Plasters. J. Clean. Prod. 2014, 80, 179–186. [Google Scholar] [CrossRef]

- Ogunkah, I.; Yang, J. Investigating Factors Affecting Material Selection: The Impacts on Green Vernacular Building Materials in the Design-Decision Making Process. Buildings 2012, 2, 1–32. [Google Scholar] [CrossRef]

- Raut, S.P.; Ralegaonkar, R.V.; Mandavgane, S.A. Development of Sustainable Construction Material Using Industrial and Agricultural Solid Waste: A Review of Waste-Create Bricks. Constr. Build. Mater. 2011, 25, 4037–4042. [Google Scholar] [CrossRef]

- Seyfang, G. Community Action for Sustainable Housing: Building a Low-Carbon Future. Energy Policy 2010, 38, 7624–7633. [Google Scholar] [CrossRef]

- Shrubsole, C.; Dimitroulopoulou, S.; Foxall, K.; Gadeberg, B.; Doutsi, A. IAQ Guidelines for Selected Volatile Organic Compounds (VOCs) in the UK. Build. Environ. 2019, 165, 106382. [Google Scholar] [CrossRef]

- Annunziata, E.; Rizzi, F.; Frey, M. Enhancing Energy Efficiency in Public Buildings: The Role of Local Energy Audit Programmes. Energy Policy 2014, 69, 364–373. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; De Gracia, A.; Fernández, A.I. Materials Used as PCM in Thermal Energy Storage in Buildings: A Review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Marszal, A.J.; Heiselberg, P.; Bourrelle, J.S.; Musall, E.; Voss, K.; Sartori, I.; Napolitano, A. Zero Energy Building—A Review of Definitions and Calculation Methodologies. Energy Build. 2011, 43, 971–979. [Google Scholar] [CrossRef]

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, C.H. Need for an Embodied Energy Measurement Protocol for Buildings: A Review Paper. Renew. Sustain. Energy Rev. 2012, 16, 3730–3743. [Google Scholar] [CrossRef]

- Thormark, C. The Effect of Material Choice on the Total Energy Need and Recycling Potential of a Building. Build. Environ. 2006, 41, 1019–1026. [Google Scholar] [CrossRef]

- Zabalza Bribián, I.; Valero Capilla, A.; Aranda Usón, A. Life Cycle Assessment of Building Materials: Comparative Analysis of Energy and Environmental Impacts and Evaluation of the Eco-Efficiency Improvement Potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Yang, W.M.; Yan, J. Achieving Better Energy-Efficient Air Conditioning—A Review of Technologies and Strategies. Appl. Energy 2013, 104, 87–104. [Google Scholar] [CrossRef]

- Berardi, U. A Cross-Country Comparison of the Building Energy Consumptions and Their Trends. Resour. Conserv. Recycl. 2017, 123, 230–241. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Kalaiselvam, S.; Harikrishnan, S.; Elayaperumal, A. Sustainable Thermal Energy Storage Technologies for Buildings: A Review. Renew. Sustain. Energy Rev. 2012, 16, 2394–2433. [Google Scholar] [CrossRef]

- Berardi, U. Sustainability Assessment in the Construction Sector: Rating Systems and Rated Buildings. Sustain. Dev. 2012, 20, 411–424. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Y.; Stephenson, R.; Ashuri, B. Valuation of Energy Efficient Certificates in Buildings. Energy Build. 2018, 158, 1226–1240. [Google Scholar] [CrossRef]

- Newsham, G.R.; Mancini, S.; Birt, B.J. Do LEED-Certified Buildings Save Energy? Yes, But. Energy Build. 2009, 41, 897–905. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon Emission of Global Construction Sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Sirisalee, P.; Ashby, M.F.; Parks, G.T.; John Clarkson, P. Multi-Criteria Material Selection of Monolithic and Multi-Materials in Engineering Design. Adv. Eng. Mater. 2006, 8, 48–56. [Google Scholar] [CrossRef]

- Zhou, C.C.; Yin, G.F.; Hu, X.B. Multi-Objective Optimization of Material Selection for Sustainable Products: Artificial Neural Networks and Genetic Algorithm Approach. Mater. Des. 2009, 30, 1209–1215. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards Circular and More Sustainable Buildings: A Systematic Literature Review on the Circular Economy in the Built Environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Mesa, J.; González-Quiroga, A.; Maury, H. Developing an Indicator for Material Selection Based on Durability and Environmental Footprint: A Circular Economy Perspective. Resour. Conserv. Recycl. 2020, 160, 104887. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; do Freitas, M.C.D.; Tavares, S.F. Circular Economy in the Construction Industry: A Systematic Literature Review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Hopkinson, P.; Chen, H.M.; Zhou, K.; Wang, Y.; Lam, D. Recovery and Reuse of Structural Products from End-of-Life Buildings. Proc. Inst. Civ. Eng. Eng. Sustain. 2018, 172, 119–128. [Google Scholar] [CrossRef]

- De Silva, N.; Dulaimi, M.F.; Ling, F.Y.Y.; Ofori, G. Improving the Maintainability of Buildings in Singapore. Build. Environ. 2004, 39, 1243–1251. [Google Scholar] [CrossRef]

- Behm, M. Linking Construction Fatalities to the Design for Construction Safety Concept. Saf. Sci. 2005, 43, 589–611. [Google Scholar] [CrossRef]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material Efficiency: A White Paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Li, D.H.W.; Yang, L.; Lam, J.C. Zero Energy Buildings and Sustainable Development Implications—A Review. Energy 2013, 54, 1–10. [Google Scholar] [CrossRef]

- Wong, K.D.; Fan, Q. Building Information Modelling (BIM) for Sustainable Building Design. Facilities 2013, 31, 138–157. [Google Scholar] [CrossRef]

- Bocchini, P.; Frangopol, D.M.; Ummenhofer, T.; Zinke, T. Resilience and Sustainability of Civil Infrastructure: Toward a Unified Approach. J. Infrastruct. Syst. 2014, 20, 04014004. [Google Scholar] [CrossRef]

- San-José Lombera, J.T.; Cuadrado Rojo, J. Industrial Building Design Stage Based on a System Approach to Their Environmental Sustainability. Constr. Build. Mater. 2010, 24, 438–447. [Google Scholar] [CrossRef]

- Wu, M.H.; Ng, T.S.; Skitmore, M.R. Sustainable Building Envelope Design by Considering Energy Cost and Occupant Satisfaction. Energy Sustain. Dev. 2016, 31, 118–129. [Google Scholar] [CrossRef]

- USGBC. LEED Reference Guide for Building Design and Construction; U.S. Green Building Council: Washington, DC, USA, 2010. [Google Scholar]

- USEPA. Green Building; USEPA: Washington, DC, USA, 2012. [Google Scholar]

- Del Casanovas, M.M.; Armengou, J.; Ramos, G. Occupational Risk Index for Assessment of Risk in Construction Work by Activity. J. Constr. Eng. Manag. 2014, 140, 04013035. [Google Scholar] [CrossRef]

- Wang, Y.; Naleway, S.E.; Wang, B. Biological and Bioinspired Materials: Structure Leading to Functional and Mechanical Performance. Bioact. Mater. 2020, 5, 745–757. [Google Scholar] [CrossRef] [PubMed]

- Matuana, L.M.; Kamdem, D.P. Accelerated Ultraviolet Weathering of PVC/Wood-Flour Composites. Polym. Eng. Sci. 2002, 42, 1657–1666. [Google Scholar] [CrossRef]

- Pilarski, J.M.; Matuana, L.M. Durability of Wood Flour-Plastic Composites Exposed to Accelerated Freeze-Thaw Cycling. Part I. Rigid PVC Matrix. J. Vinyl Addit. Technol. 2005, 11, 1–8. [Google Scholar] [CrossRef]

- Lu, J.; Jiang, P.; Chen, Z.; Li, L.; Huang, Y. Flame Retardancy, Thermal Stability, and Hygroscopicity of Wood Materials Modified with Melamine and Amino Trimethylene Phosphonic Acid. Constr. Build. Mater. 2021, 267, 121042. [Google Scholar] [CrossRef]

- Li, J.; Yu, H.; Sun, Q.; Liu, Y.; Cui, Y.; Lu, Y. Growth of TiO2 Coating on Wood Surface Using Controlled Hydrothermal Method at Low Temperatures. Appl. Surf. Sci. 2010, 256, 5046–5050. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. Potential of Macroencapsulated PCM for Thermal Energy Storage in Buildings: A Comprehensive Review. Constr. Build. Mater. 2019, 225, 723–744. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Olomolaiye, P.O. Development of Sustainable Assessment Criteria for Building Materials Selection. Eng. Constr. Archit. Manag. 2012, 19, 666–687. [Google Scholar] [CrossRef]

- Tian, G.; Zhang, H.; Feng, Y.; Wang, D.; Peng, Y.; Jia, H. Green Decoration Materials Selection under Interior Environment Characteristics: A Grey-Correlation Based Hybrid MCDM Method. Renew. Sustain. Energy Rev. 2018, 81, 682–692. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Evaluation of Thermal Conductivity, Mechanical and Transport Properties of Lightweight Aggregate Foamed Geopolymer Concrete. Energy Build. 2014, 72, 238–245. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Oliver, C.D.; Nassar, N.T.; Lippke, B.R.; McCarter, J.B. Carbon, Fossil Fuel, and Biodiversity Mitigation with Wood and Forests. J. Sustain. For. 2014, 33, 248–275. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The Wood from the Trees: The Use of Timber in Construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Blanchet, P.; Perez, C.; Cabral, M.R. Wood Building Construction: Trends and Opportunities in Structural and Envelope Systems. Curr. For. Rep. 2023. [CrossRef]

- Turner, C.; Analyst, S.; Frankel, M. Energy Performance of LEED® for New Construction Buildings; New Buildings Institute: Portland, OR, USA, 2008. [Google Scholar]

- Iwaro, J.; Mwasha, A. A Review of Building Energy Regulation and Policy for Energy Conservation in Developing Countries. Energy Policy 2010, 38, 7744–7755. [Google Scholar] [CrossRef]