Cyclic Performance and Environmental Impact of Precast Demountable RCS Joints

Abstract

1. Introduction

2. Verification of Finite Element Models

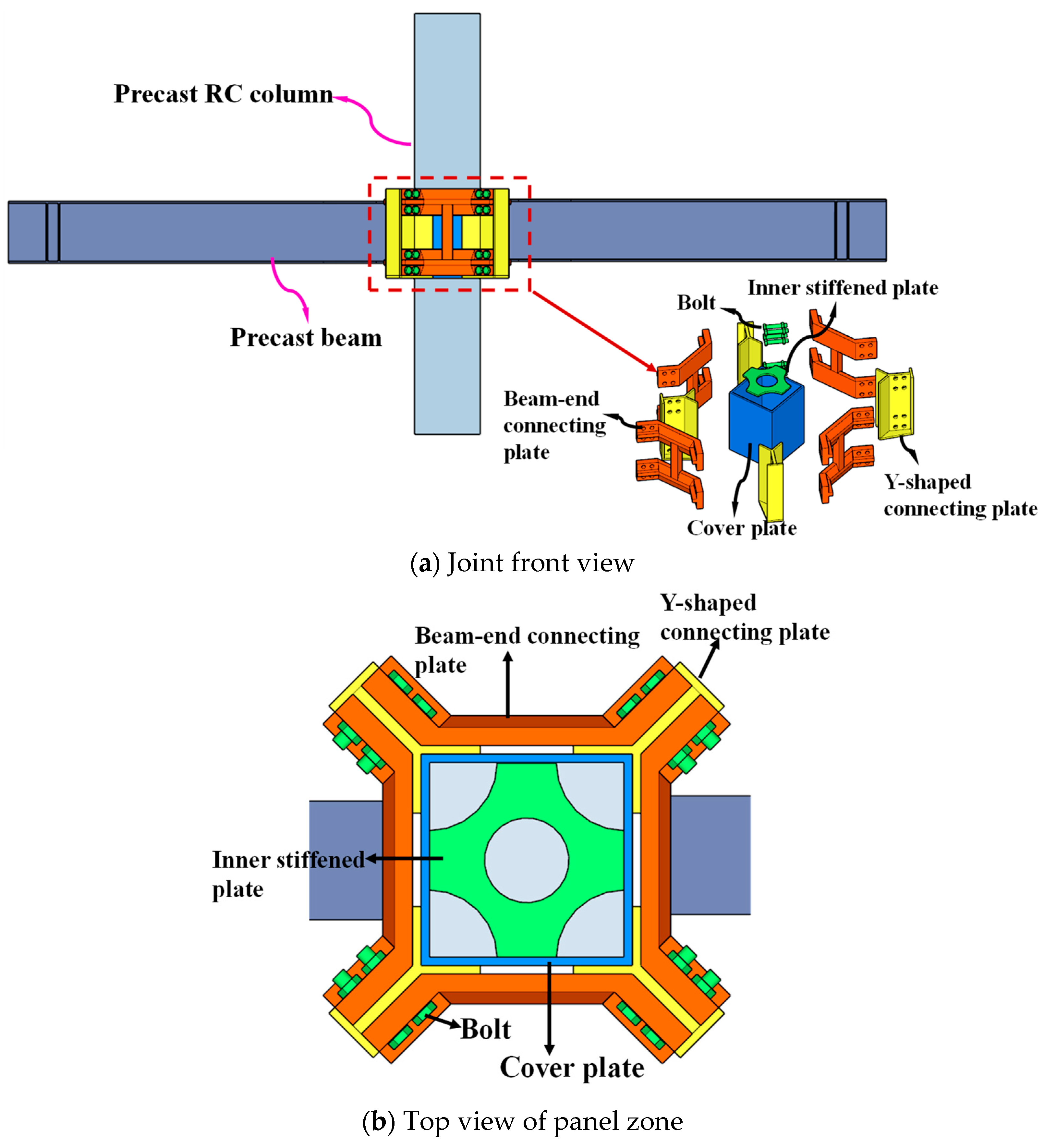

2.1. Selection of Joint Specimen Types

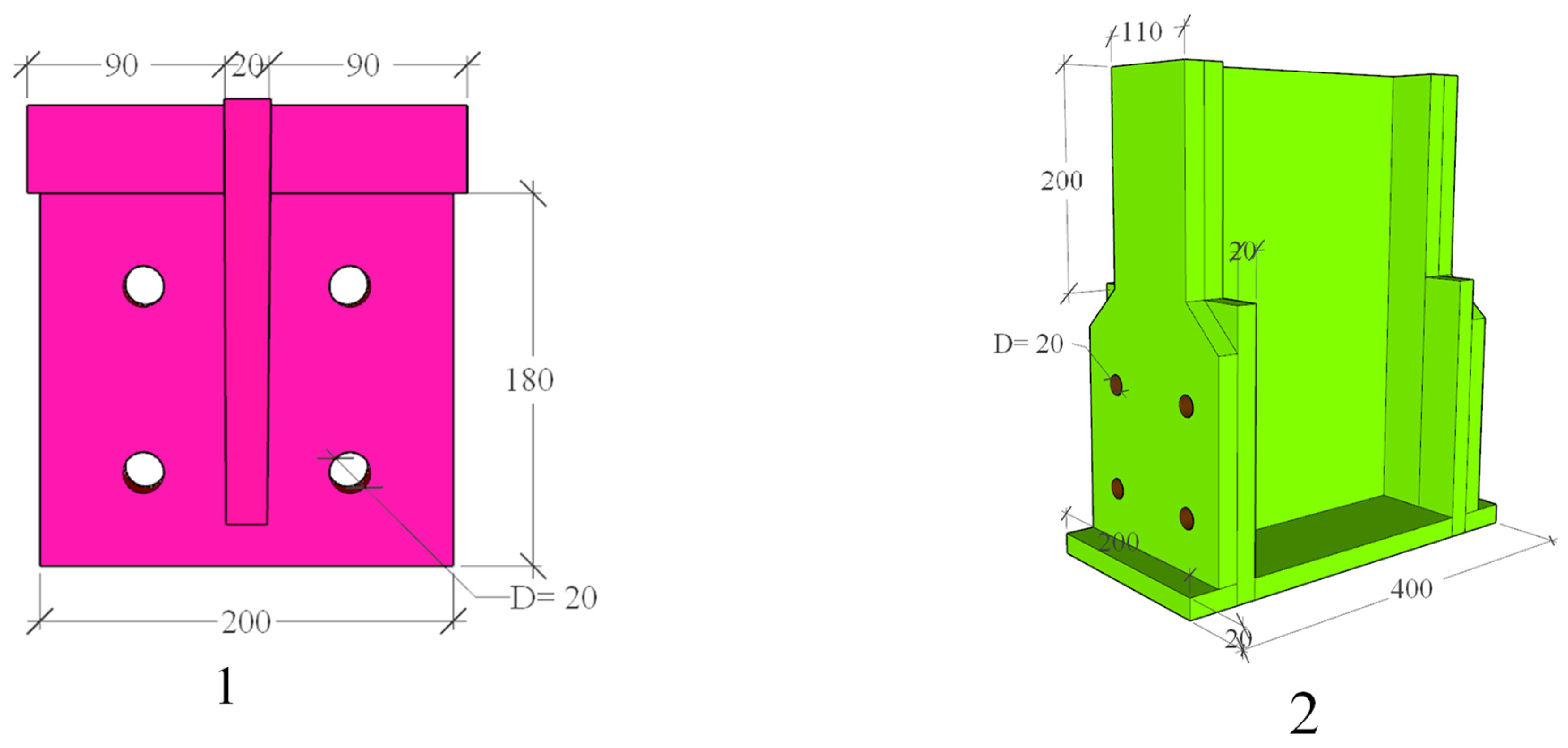

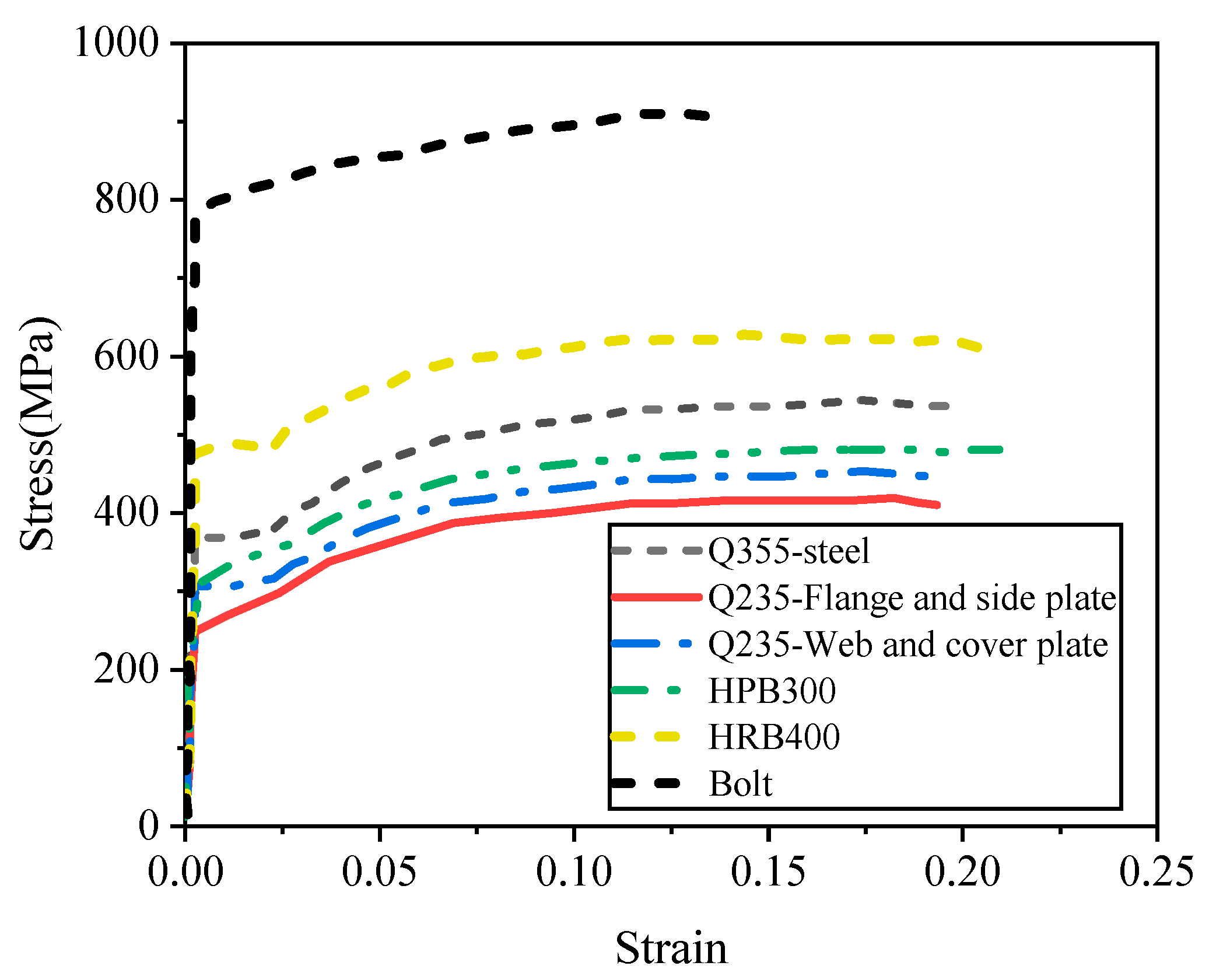

2.2. Determination of Material Constitutive Models

2.3. Mesh Generation and Boundary Conditions

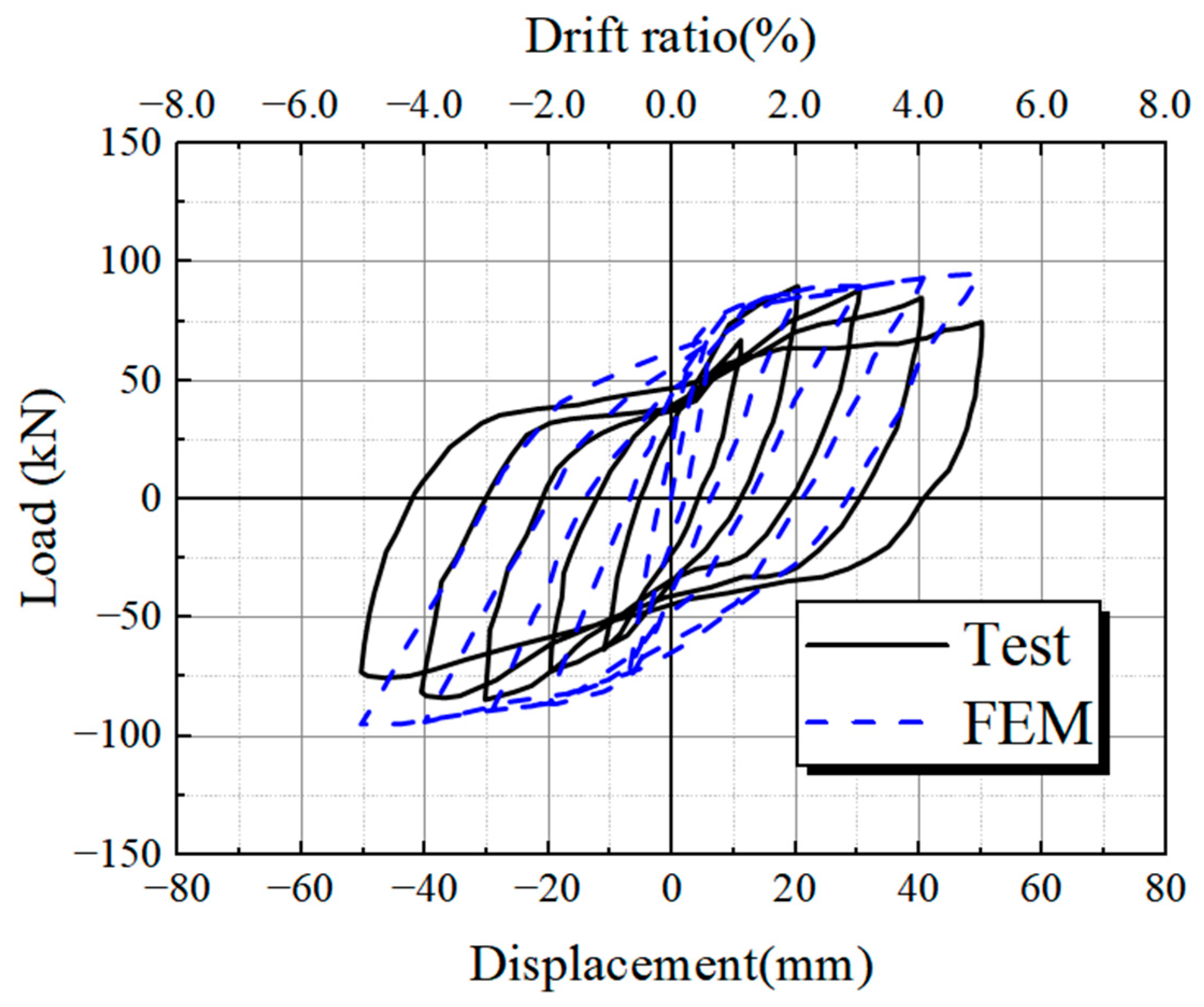

2.4. Comparison of Finite Element Model with Test Results

3. Selection of Finite Element Model for Demountable RCS Joint

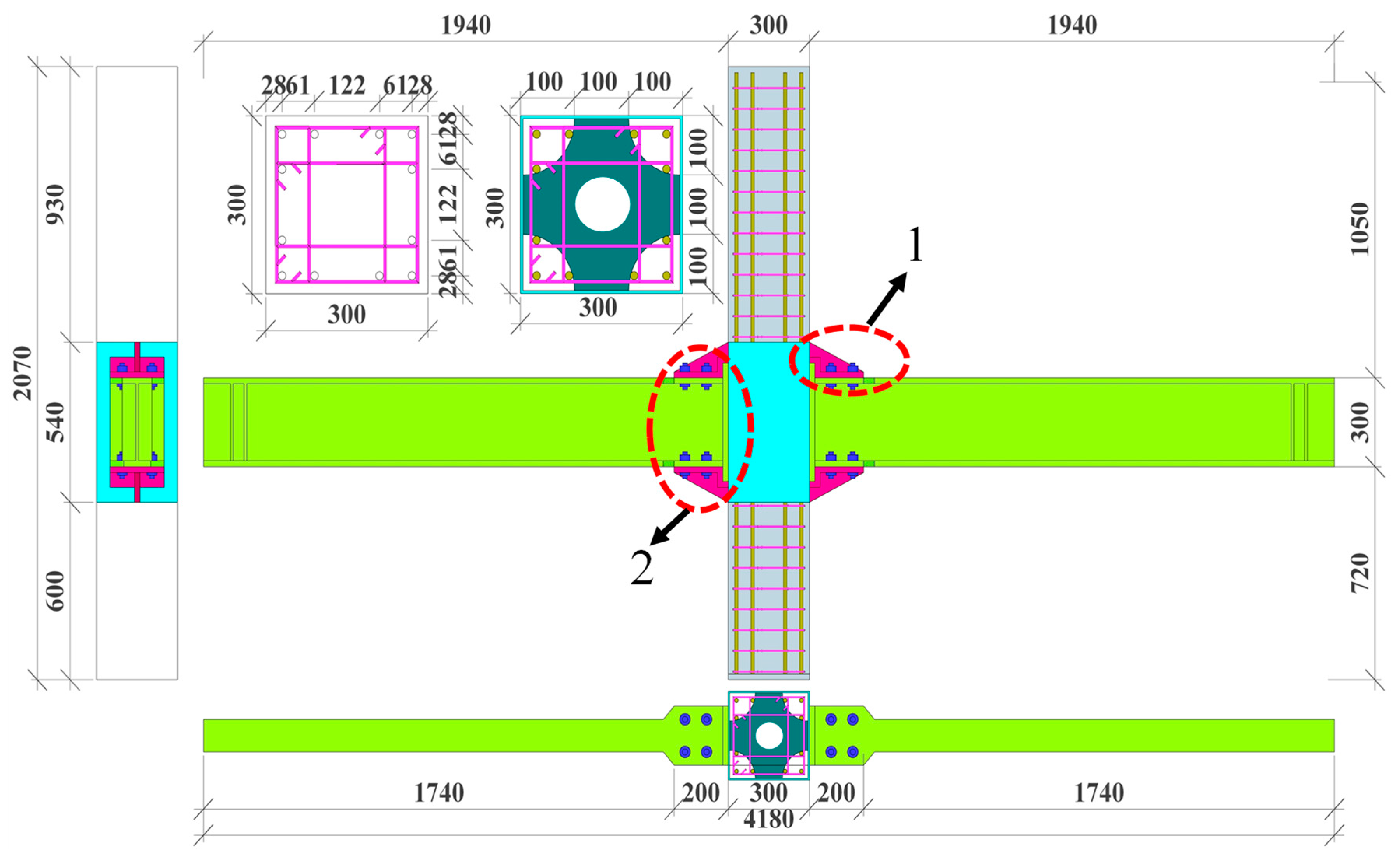

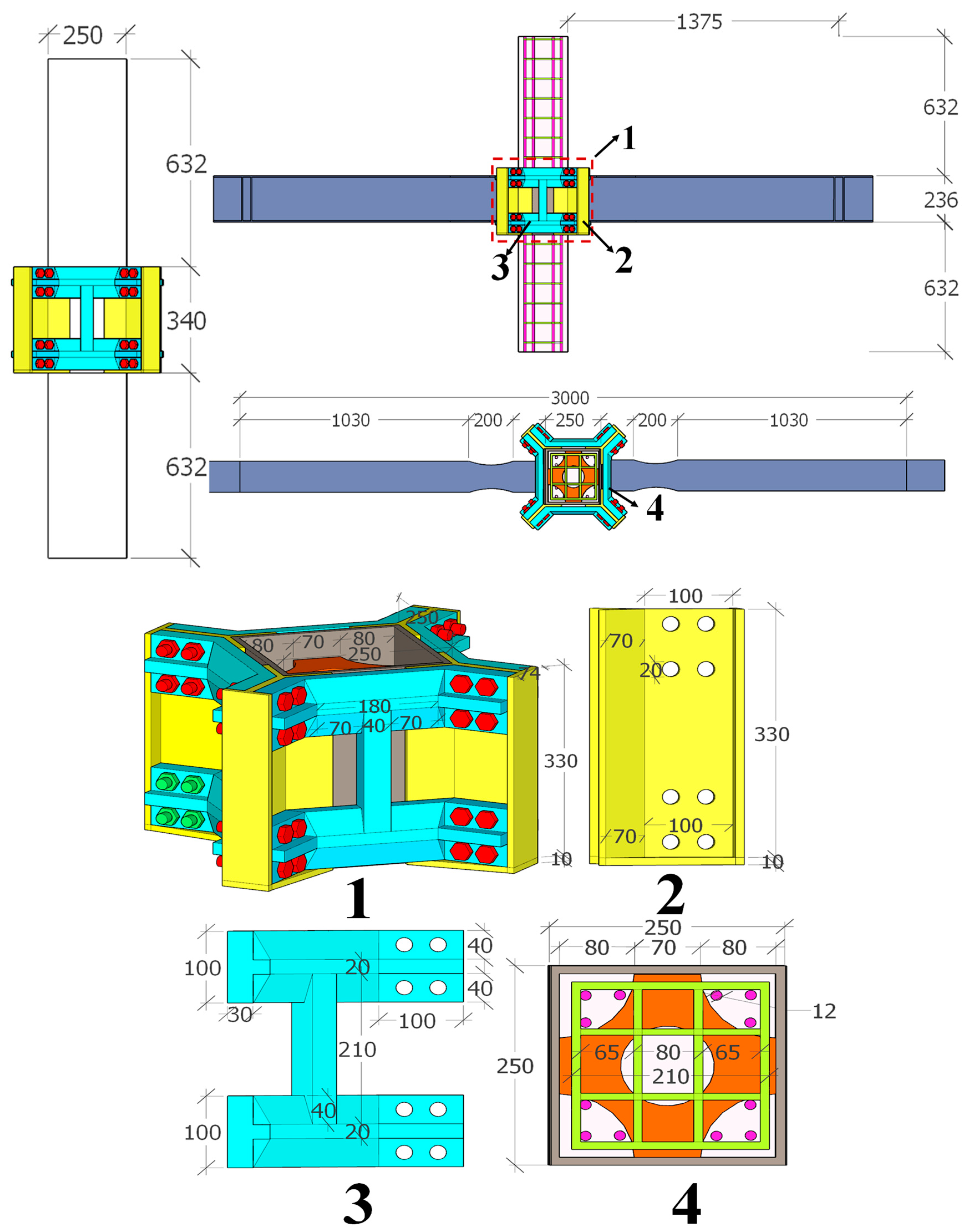

3.1. Specimen Design

3.2. Establishment of the Finite Element Model

3.3. Material Property Parameters

3.4. Loading Protocol

3.5. Results of Finite Element Analysis

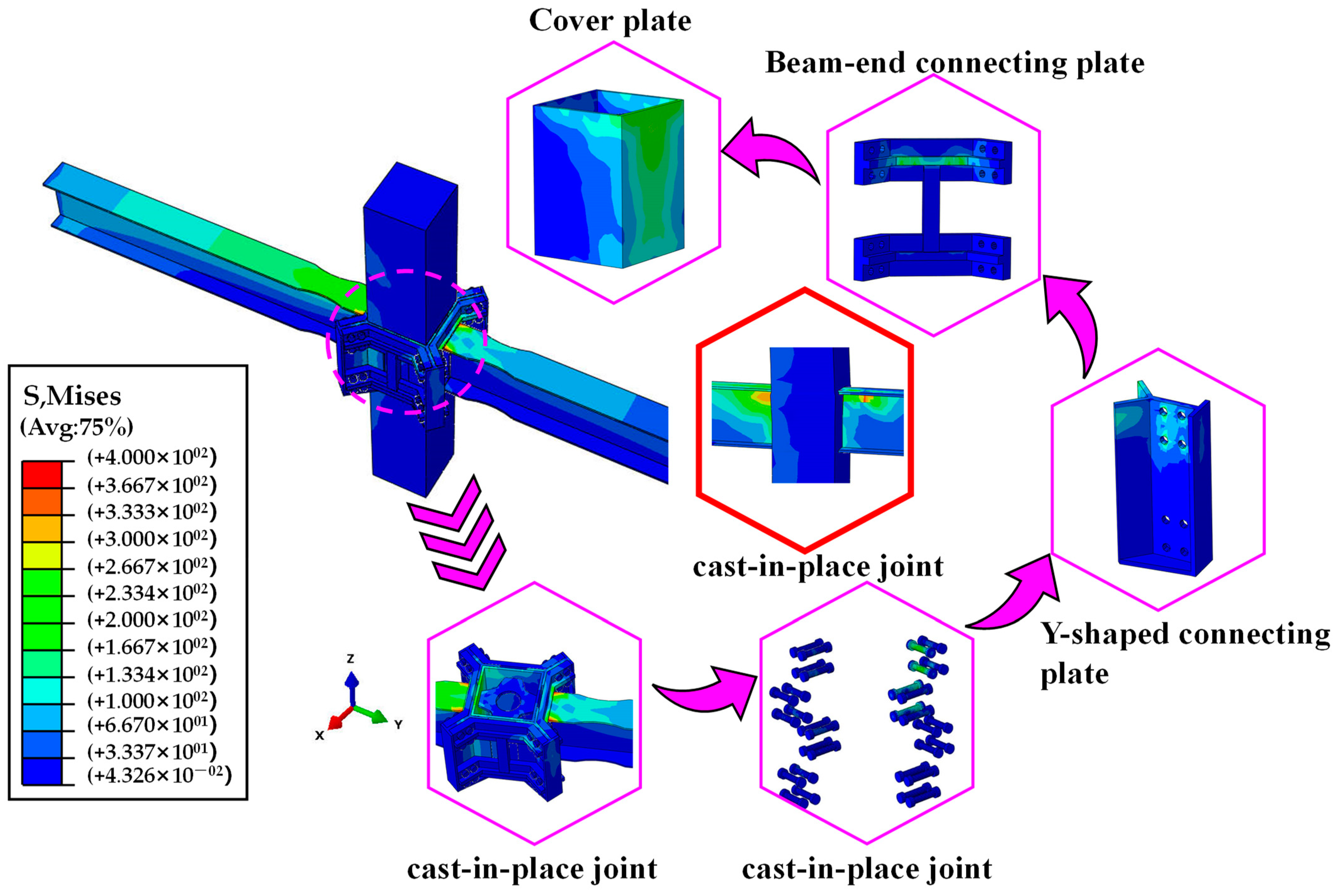

3.5.1. Comparison of Finite Element Stress Contour Plots

3.5.2. Comparison of Seismic Performance between Demountable RCS Joints and Cast-in-Place RCS Joints

4. Analysis of Demountable RCS Joint Parameters

4.1. Parameter Design

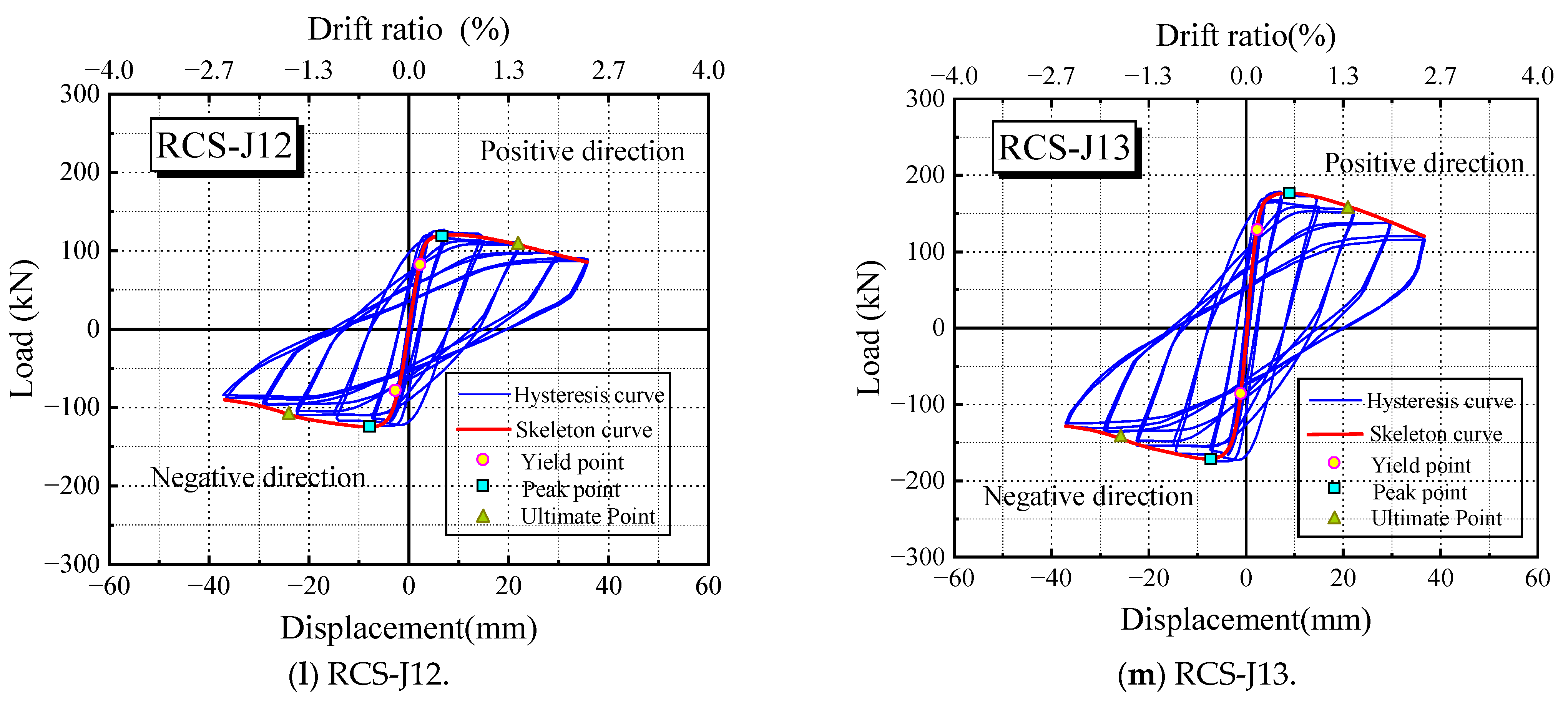

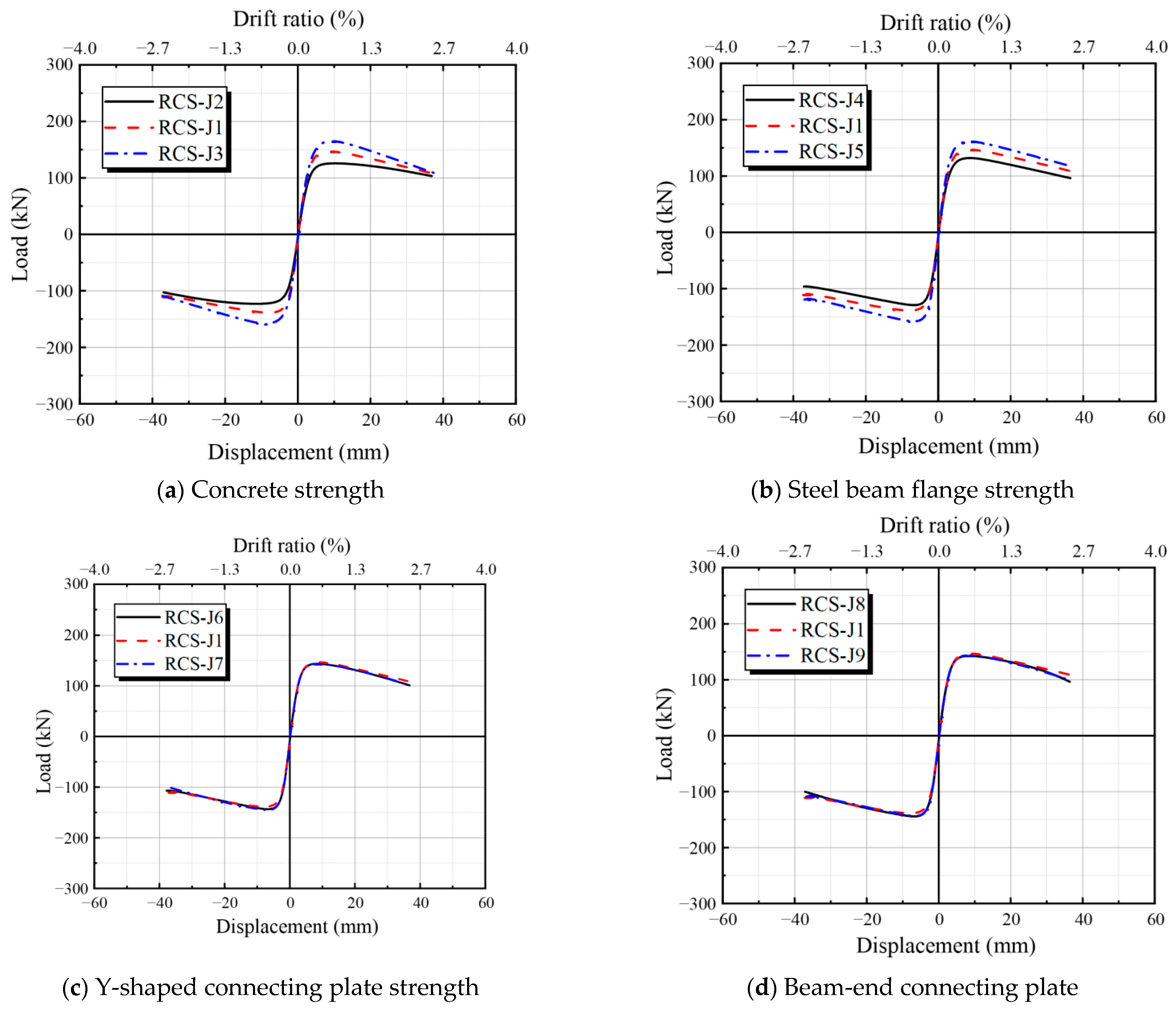

4.2. Analysis of Hysteresis Loops under Different Parameters

- (1)

- Elastic Stage: This occurs from the start of loading until a drift ratio of approximately 0.8%, where the lateral load-carrying capacity increases linearly with displacement. The hysteresis loop area is small, and no cracking is observed in any specimen.

- (2)

- Plastic Stage: Beyond a drift ratio of 0.8%, the specimens enter the plastic stage, with the lateral load-carrying capacity peaking around a 1.0% drift ratio.

- (3)

- Failure Stage: When the drift ratio exceeds 1.0%, concrete spalling in the joint core, reinforcement yielding, and steel beam deformation lead to a decline in lateral load-bearing capacity. Failure is defined as the point when load-carrying capacity drops to 85% of the peak load.

- Bow-shaped: Specimens including RCS-J1, RCS-J2, RCS-J3, RCS-J6, RCS-J7, RCS-J8, RCS-J9, RCS-J12, and RCS-J13. These loops are relatively full, with a gentle descent, demonstrating good energy dissipation and deformation capabilities.

- Shuttle-shaped: The high longitudinal reinforcement ratio specimen like RCS-J11. Due to its increased longitudinal reinforcement ratio, this shows a shuttle shape as its load-bearing and deformation capacities are significantly enhanced.

- Butterfly shaped: The low longitudinal reinforcement ratio specimen like RCS-J10. This type of specimen has a steeper post-peak decay stage.

4.3. Comparative Analysis of Skeleton Curves under Different Parameters

4.4. Ductility Analysis of Specimens under Different Parameters

4.5. Comparison of Accumulated Energy Dissipation and Equivalent Viscous Damping Coefficients under Various Parameters

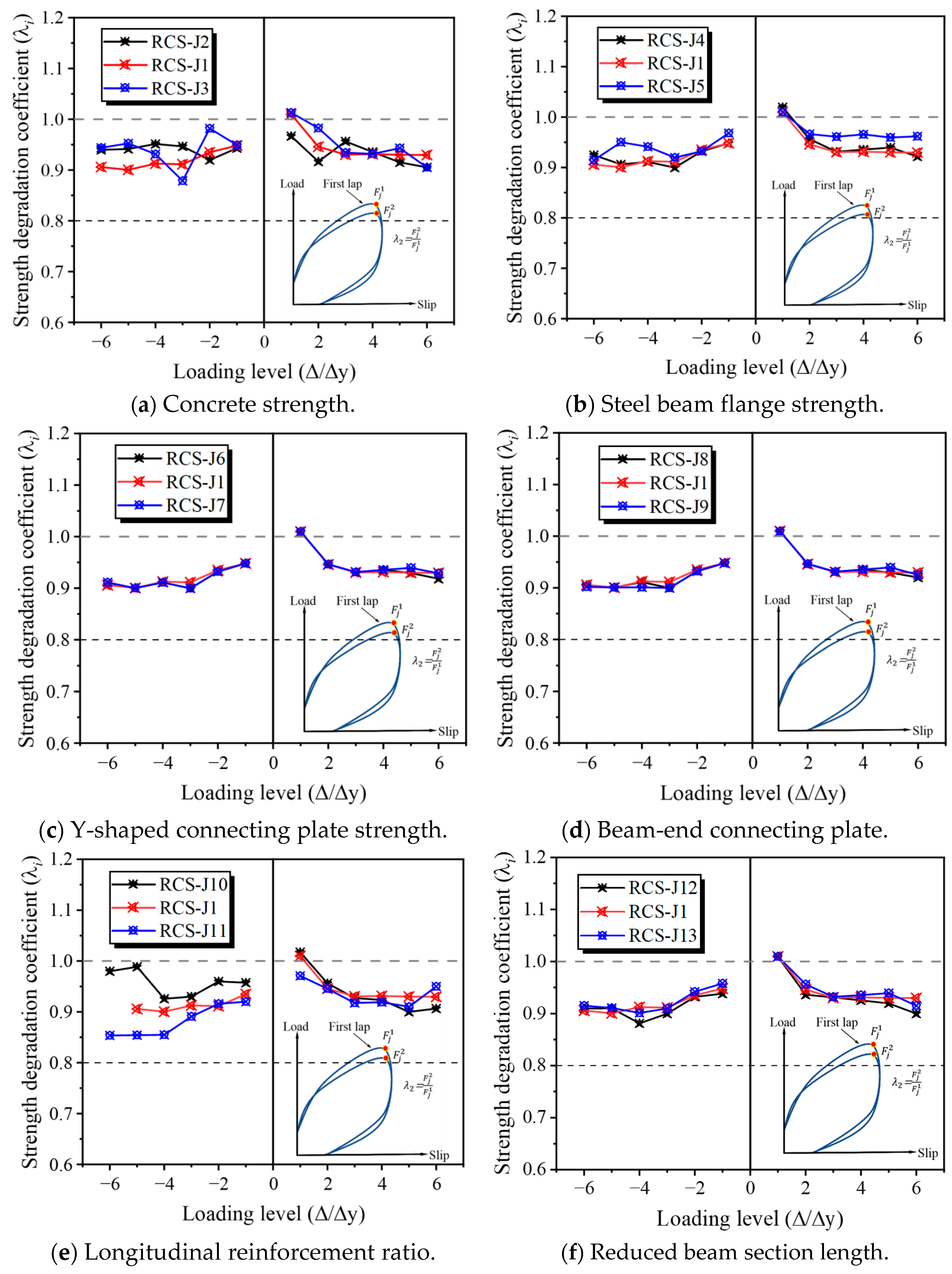

4.6. Analysis of Strength Degradation for Each Specimen

5. Environmental Impact over the Entire Life Cycle

5.1. Carbon Emissions Inventory for the Novel Demountable Structure

5.2. Policy Recommendations

6. Conclusions

- (1)

- The novel demountable RCS joint design, featuring a weakened steel beam flange, has been shown to exhibit a 1.5-fold increase in load-bearing capacity and a 3.5-fold increase in ductility compared to conventional cast-in-place joints, highlighting its superior seismic performance.

- (2)

- Parametric analyses revealed that the hysteretic behavior of the specimens could be categorized into three distinct patterns. With the increase in concrete strength, the bearing capacity increases by 30.38%, and the ductility coefficient decreases by 31.78%; with the increase in longitudinal reinforcement ratio, the bearing capacity of removable RCS nodes increases by 57.61%. Due to the wide range and large number of longitudinal reinforcements, the deformation capacity of the joints is constrained, and the ductility coefficient decreases by 26.50%. It can be concluded that the increase in concrete strength and reinforcement ratio of the specimens is positively correlated with the bearing capacity of the joints. The size of the weakened area of the steel beam flange is negatively correlated with the bearing capacity of the specimen, but the increase in the area improves the ductility of the specimen.

- (3)

- The development of cumulative energy consumption is consistent with the development trend in equivalent viscosity coefficient. The concrete strength and reinforcement ratio of longitudinal reinforcement have great influence on hysteretic properties of specimens, and the increase in the reinforcement ratio of longitudinal reinforcement has the greatest influence on hysteretic area, which increases cumulative energy consumption by 90.06%.

- (4)

- Comparative analysis of the carbon emissions and material usage during the production and dismantling stages of the four types of nodes reveals that the carbon emissions of the demountable RCS nodes are significantly lower than those of the other three nodes. Therefore, the novel joints proposed in this study play a crucial role in reducing carbon emissions and mitigating the environmental impact of building materials.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pedrosa, B.; Buecking, L.; Veljkovic, M. Steel-reinforced resin for bolted shear connectors: Confined behaviour under quasi-static cyclic loading. Eng. Struct. 2022, 256, 114023–114045. [Google Scholar] [CrossRef]

- Yang, Y.M.; Yang, P.; Shu, Y. Experimental study on seismic behavior of the self-centering RCS joint with replaceable buckling restrained dampers. Eng. Struct. 2022, 261, 114288–1142300. [Google Scholar] [CrossRef]

- Pei, Q.J. Research on the Seismic Performance of New RCS Composite Structure Beam–Column Assemblies Under Different Axial Compression Ratios. Ph.D. Thesis, Huaqiao University, Quanzhou, China, 2016. [Google Scholar]

- Bai, J.L.; He, J.; Li, C. Experimental investigation on the seismic performance of a novel damage-control replaceable RC beam-to-column joint. Eng. Struct. 2022, 267, 114692. [Google Scholar] [CrossRef]

- Liu, X.C.; Wang, D.; Zhang, A.L. Study on the Seismic Behavior of Flange-connected L-shaped Concrete-Filled Steel Tube Columns with H-section Steel Beams using All-Bolted Connections. J. Build. Struct. 2021, 42, 98–109. [Google Scholar]

- Choi, H.K.; Choi, Y.C.; Choi, C.S. Development and testing of precast concrete beam-to-column connections. Eng. Struct. 2013, 56, 1820–1835. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Zhang, T.; Li, X.; Ding, Y.; Jia, L. Experimental Research on the Seismic Performance of Precast Concrete-filled Tube Column to Steel Beam Connection. Joints J. Build. Struct. 2022, 43, 143–155. [Google Scholar]

- Wu, Y.T.; Ming, L.; Xiao, Y. Experimental study on seismic performance of assembled steel beam-prefabricated column composite frame. Joints. J. Build. Struct. 2013, 43, 66–71. [Google Scholar]

- Vidjeapriya, R.; Jaya, K.P. Experimental study on two simple mechanical precast beam-column connections under reverse cyclic loading. J. Perform. Constr. Facil. 2013, 27, 402–414. [Google Scholar] [CrossRef]

- Zhang, S.H.; Zhao, L.Z.; Jin, M.C. Experimental Study on the Seismic Performance of Assembled Steel Beam-Precast Column Composite Frames. Ind. Constr. 2023, 53, 43–51. [Google Scholar] [CrossRef]

- Chen, H.; Guo, Z.X.; Basha, S.H. Seismic behavior of RCS frame joints applied with high-strength bolts-end plate connection. J. Build. Eng. 2022, 63, 10545–10560. [Google Scholar] [CrossRef]

- Li, W.; Ye, H.; Wang, Q. Experimental study on the seismic performance of demountable RCS joints. J. Build. Eng. 2022, 49, 104082. [Google Scholar] [CrossRef]

- Wang, Q. Research on the Seismic Performance of Demountable Precast RCS Joints. Ph.D. Thesis, Wenzhou University, Wenzhou, China, 2019. [Google Scholar]

- GB 50010-2010; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Code for Design of Concrete Structures. Architecture & Building Press: Beijing, China, 2015.

- Cai, J.G.; Deng, Z.; Li, W. Numerical study on seismic behavior of demountable joints consisting of RC columns and steel beams. Buildings 2023, 125, 2558. [Google Scholar] [CrossRef]

- Chen, Z.P.; Chen, J.W.; Jiang, X.S. Experimental research and finite element analysis on seismic behavior of square reinforced concrete columns with four interlocking spirals. Structures 2022, 39, 1–16. [Google Scholar] [CrossRef]

- Li, W.; Wang, Z.X. Cyclic tests and finite element analysis on hybrid fiber–cement-based composite encased CFST columns. Structures 2023, 58, 10559–10572. [Google Scholar] [CrossRef]

- Li, W.; Wang, Z.X.; Li, L.F. Study of the Seismic Behavior of Simplified RCS Joints via Nonlinear Finite Element Analysis. Buildings 2023, 13, 2718–2730. [Google Scholar] [CrossRef]

- Li, W.; Wang, Z.X.; Li, L.F. Seismic performance and damage analysis of steel-PVA hybrid fiber cementitious composites encased CFST columns. J. Build. Eng. 2024, 108771–108792. [Google Scholar] [CrossRef]

- Chen, Y.Z. Comparative Study of Domestic and International Policies on the Utilization of Construction Waste Resources. Archit. Technol. 2019, 50, 342–345. [Google Scholar]

- Fu, W.Z.; Pan, Y.; Wang, D. Quantitative Research on Construction Waste Resource Utilization Policy under Background of Carbon Peak and Carbon Neutrality. Constr. Econ. 2022, 43, 562–565. [Google Scholar]

- Nunes, K.R.A.; Mahler, C.F.; Valle, R. Evaluation of investments in recycling centres for construction and demolition wastes in Brazilian municipalities. Waste Manag. 2007, 27, 1531–1540. [Google Scholar] [CrossRef]

- Zhu, X.S.; Yan, R.J. Sustainable Building Materials and Their Promotion and Application in Residential Construction. Chem. Mater. Constr. 2001, 2, 1–5. [Google Scholar]

- Liu, J.; Sun, R.L. Fiscal and Tax Policy Choices for Promoting and Applying Low-Carbon Buildings: A Case Study of Prefabricated Modular Buildings. Sub Natl. Fisc. Res. 2018, 1, 53–61. [Google Scholar]

| Loading Direction | Yield Load py/kN | Yield Displacement Δy/mm | Peak Load Δu/kN | Peak Displacement | Ductility μ | |

|---|---|---|---|---|---|---|

| Test | Negative | −65.64 | −13.44 | −87.52 | −50.00 | 3.72 |

| Positive | 65.76 | 10.92 | 87.68 | 50.00 | 4.58 | |

| FEM | Negative | −71.64 | −7.84 | −95.52 | −50.00 | 6.38 |

| Positive | 73.64 | 7.95 | 95.19 | 50.00 | 6.29 |

| Specimen Number | Column Cross-Section (mm) | Beam Cross-Section (mm) | Column Height (mm) | Beam Length (mm) | Concrete Strength (MPa) | Axial Ratio (%) |

|---|---|---|---|---|---|---|

| RCS-J0 | 250 × 250 | 236 × 140 × 6 × 8 | 1500 | 3000 | 40 | 20 |

| RCS-J1 | 250 × 250 | 1500 | 3000 | 40 | 20 |

| Steel Type | Yield Strength (MPa) | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|

| Q355 | 366 | 470 | 206 |

| HRB400 | 465 | 639 | 200 |

| Specimen | Loading Direction | Equivalent Yield Point | Peak Point | Ultimate Point | Ductility Factor | Ultimate Drift Ratio (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| μ | θ | ||||||||

| RCS-J0 | Positive | 15.39 | 80.06 | 37.40 | 99.80 | 47.09 | 84.08 | 2.51 | 3.18 |

| Negative | 25.21 | 81.08 | 36.92 | 100.10 | 48.18 | 85.10 | |||

| RCS-J1 | Positive | 3.39 | 128.30 | 7.11 | 149.10 | 24.64 | 126.80 | 8.90 | 1.63 |

| Negative | 2.31 | 122.70 | 6.93 | 146.20 | 24.18 | 124.20 | |||

| Parameters | Specimen Number | Concrete Strength (MPa) | Axial Ratio (%) | Yield Strength (MPa) | Spacing of Bars (mm) | Beam Flange | Y-Shaped Connecting Plate | Reduced Beam Section | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flange | Web | Y-Shaped Connecting Plate | Beam-End Connecting Plate | Stirrups | Longitudinal Reinforcement | |||||||

| Standard test piece | RCS-J1 | 40 | 20 | 355 | 355 | 355 | 355 | 100 | 12 | 8 | 10 | 200 |

| Concrete strength | RCS-J2 | 20 | 20 | 355 | 355 | 355 | 355 | 100 | 12 | 8 | 10 | 200 |

| RCS-J3 | 60 | 20 | 355 | 355 | 355 | 355 | 100 | 12 | 8 | 10 | 200 | |

| Steel beam flange strength | RCS-J4 | 40 | 20 | 235 | 355 | 355 | 355 | 100 | 12 | 8 | 10 | 200 |

| RCS-J5 | 40 | 20 | 460 | 355 | 355 | 355 | 100 | 12 | 8 | 10 | 200 | |

| Y-shaped connecting plate strength | RCS-J6 | 40 | 20 | 355 | 355 | 235 | 355 | 100 | 12 | 8 | 10 | 200 |

| RCS-J7 | 40 | 20 | 355 | 355 | 460 | 355 | 100 | 12 | 8 | 10 | 200 | |

| Beam-end connecting plate | RCS-J8 | 40 | 20 | 355 | 355 | 355 | 235 | 100 | 12 | 8 | 10 | 200 |

| RCS-J9 | 40 | 20 | 355 | 355 | 355 | 460 | 100 | 12 | 8 | 10 | 200 | |

| Longitudinal reinforcement ratio | RCS-J10 | 40 | 20 | 355 | 355 | 355 | 355 | 100 | 8 | 8 | 10 | 200 |

| RCS-J11 | 40 | 20 | 355 | 355 | 355 | 355 | 100 | 20 | 8 | 10 | 200 | |

| Reduced beam section length | RCS-J12 | 40 | 20 | 355 | 355 | 355 | 355 | 100 | 12 | 8 | 10 | 220 |

| RCS-J13 | 40 | 20 | 355 | 355 | 355 | 355 | 100 | 12 | 8 | 10 | 180 | |

| Specimen | Loading Direction | Equivalent Yield Point | Peak Point | Ultimate Point | Ultimate Drift Ratio (%) | |||

|---|---|---|---|---|---|---|---|---|

| θ | ||||||||

| RCS-J1 | Positive | 3.63 | 133.4 | 7.11 | 149.1 | 24.64 | 126.8 | 1.63 |

| Negative | 2.26 | 121.9 | 6.93 | 146.2 | 24.18 | 124.2 | ||

| RCS-J2 | Positive | 3.66 | 114.5 | 7.24 | 129.0 | 31.7 | 109.6 | 2.19 |

| Negative | 2.85 | 86.9 | 7.24 | 125.3 | 34.14 | 106.5 | ||

| RCS-J3 | Positive | 4.20 | 152.3 | 8.07 | 168.2 | 21.58 | 143.0 | 1.45 |

| Negative | 2.45 | 131.4 | 7.45 | 160.7 | 21.93 | 136.6 | ||

| RCS-J4 | Positive | 3.63 | 120.0 | 7.11 | 134.2 | 23.98 | 114.1 | 1.59 |

| Negative | 2.26 | 109.8 | 7.47 | 131.8 | 23.86 | 136.9 | ||

| RCS-J5 | Positive | 3.63 | 146.7 | 7.11 | 164.0 | 23.98 | 139.4 | 1.59 |

| Negative | 2.26 | 134.3 | 7.47 | 161.1 | 23.86 | 136.9 | ||

| RCS-J6 | Positive | 3.63 | 133.4 | 7.11 | 149.1 | 23.65 | 126.8 | 1.58 |

| Negative | 2.26 | 122.0 | 7.47 | 146.4 | 23.86 | 124.5 | ||

| RCS-J7 | Positive | 3.63 | 133.4 | 7.11 | 149.1 | 23.65 | 126.8 | 1.58 |

| Negative | 2.26 | 122.0 | 7.47 | 146.4 | 23.86 | 124.5 | ||

| RCS-J8 | Positive | 3.63 | 133.4 | 7.11 | 149.1 | 23.65 | 126.8 | 1.59 |

| Negative | 2.26 | 122.0 | 7.47 | 146.4 | 24.33 | 124.6 | ||

| RCS-J9 | Positive | 3.36 | 133.4 | 7.11 | 149.1 | 23.65 | 126.8 | 1.59 |

| Negative | 2.26 | 122.0 | 7.47 | 146.4 | 23.86 | 124.5 | ||

| RCS-J10 | Positive | 3.18 | 118.4 | 7.14 | 131.4 | 20.62 | 111.7 | 1.40 |

| Negative | 1.81 | 109.5 | 7.03 | 128.1 | 21.42 | 108.9 | ||

| RCS-J11 | Positive | 3.13 | 187.3 | 8.19 | 207.1 | 26.63 | 176.0 | 1.81 |

| Negative | 2.50 | 175.4 | 11.47 | 200.0 | 27.81 | 170.0 | ||

| RCS-J12 | Positive | 2.86 | 113.4 | 7.32 | 126.8 | 28.08 | 107.7 | 1.91 |

| Negative | 3.10 | 103.7 | 7.78 | 124.5 | 29.15 | 105.8 | ||

| RCS-J13 | Positive | 3.63 | 160.0 | 7.11 | 178.9 | 23.65 | 152.1 | 1.59 |

| Negative | 2.26 | 146.5 | 7.47 | 175.7 | 24.19 | 149.4 | ||

| Joints Name | Concrete Usage (kg) | Steel Usage (kg) | Concrete Carbon Emissions (kgCO2e/m³) | Steel Carbon Emissions (kgCO2e/t) | Concrete Demolition Carbon Emissions (kgCO2e/m³) |

|---|---|---|---|---|---|

| Cast-in-place RCS joint | 230 | 53 | 30.15 | 62.28 | 75.38 |

| Demountable RCS joint | 230 | 93 | 15.08 | 56.81 | 0 |

| Cast-in-place joint | 358 | 10 | 45.1 | 23.50 | 112.75 |

| Steel joint | 0 | 185 | 0 | 130.43 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Yang, Y.; Kong, Z.; Huang, W.; Wang, Y.; Wang, H. Cyclic Performance and Environmental Impact of Precast Demountable RCS Joints. Buildings 2024, 14, 3071. https://doi.org/10.3390/buildings14103071

Li W, Yang Y, Kong Z, Huang W, Wang Y, Wang H. Cyclic Performance and Environmental Impact of Precast Demountable RCS Joints. Buildings. 2024; 14(10):3071. https://doi.org/10.3390/buildings14103071

Chicago/Turabian StyleLi, Wei, Yang Yang, Zhengyi Kong, Wei Huang, Yaping Wang, and Haijing Wang. 2024. "Cyclic Performance and Environmental Impact of Precast Demountable RCS Joints" Buildings 14, no. 10: 3071. https://doi.org/10.3390/buildings14103071

APA StyleLi, W., Yang, Y., Kong, Z., Huang, W., Wang, Y., & Wang, H. (2024). Cyclic Performance and Environmental Impact of Precast Demountable RCS Joints. Buildings, 14(10), 3071. https://doi.org/10.3390/buildings14103071