Non-Woven Fabric Filter Materials Used in Public Buildings for Filtering Particulate Matter Experience Performance Changes under Ultrasonic Cleaning Based on Dual Carbon Target

Abstract

:1. Introduction

2. Methods

2.1. Experimental Instruments

2.2. Evaluation of Performance Parameters

3. Results and Discussion

3.1. Determination of Ultrasonic Cleaning Parameters

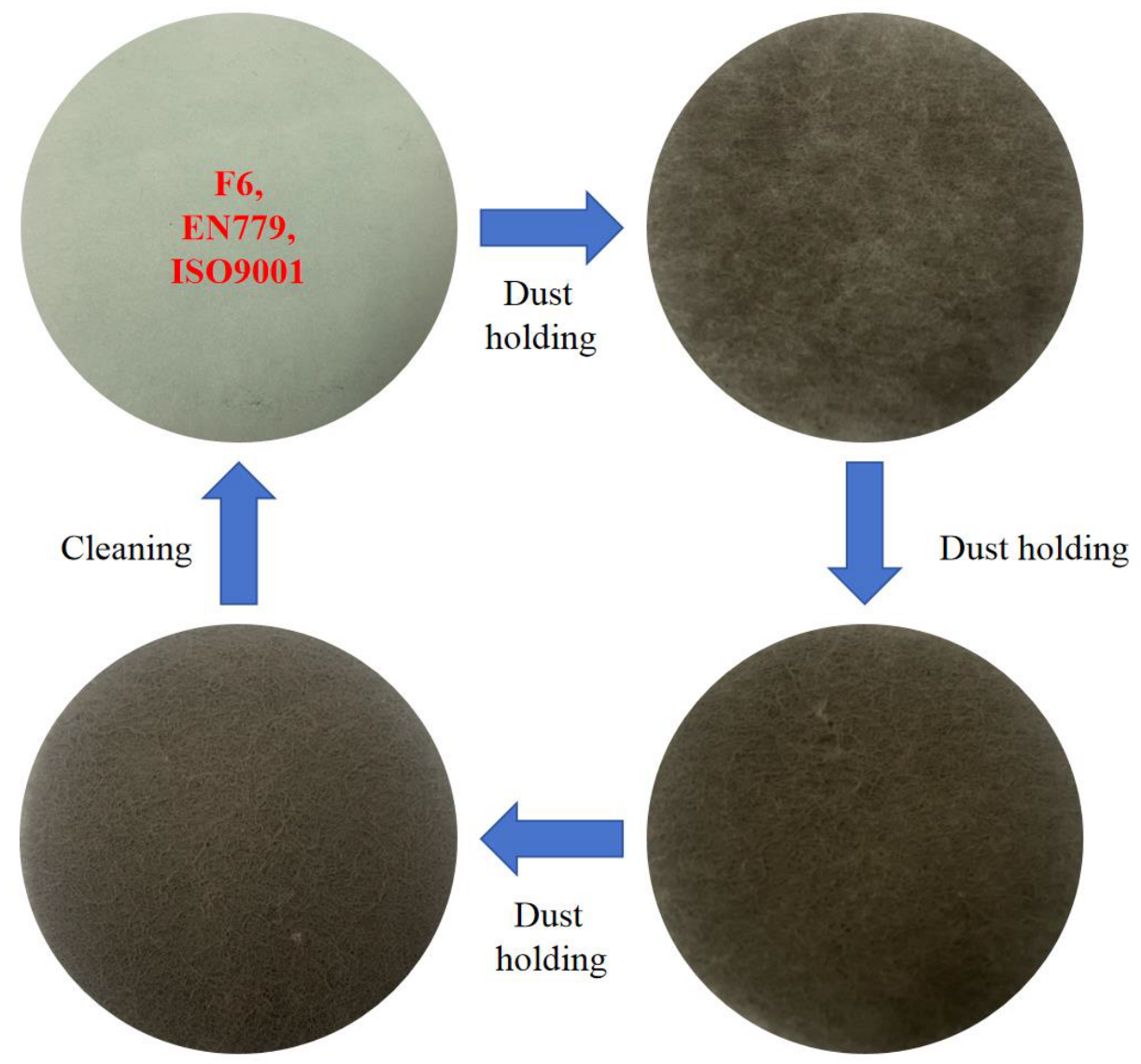

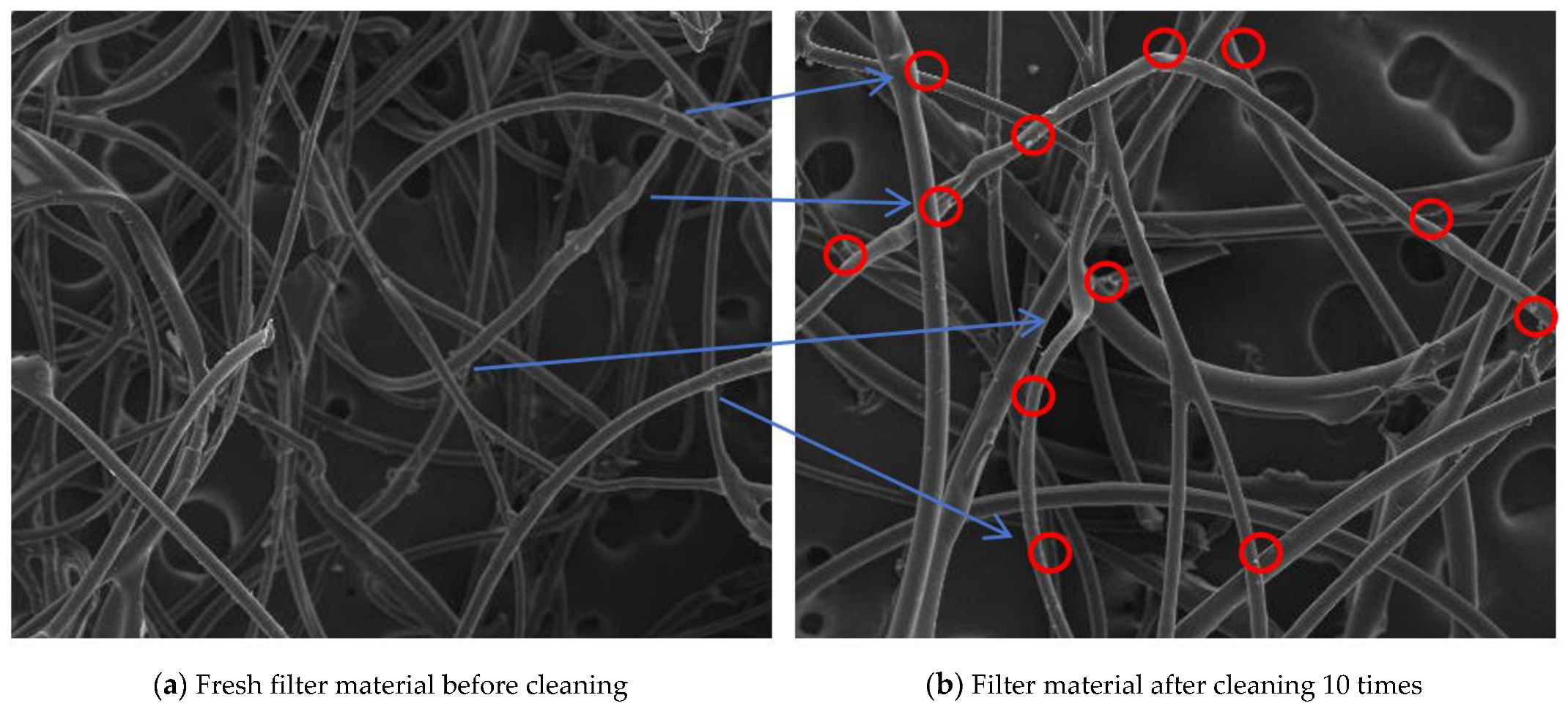

3.2. Filter Performance Testing and Analysis

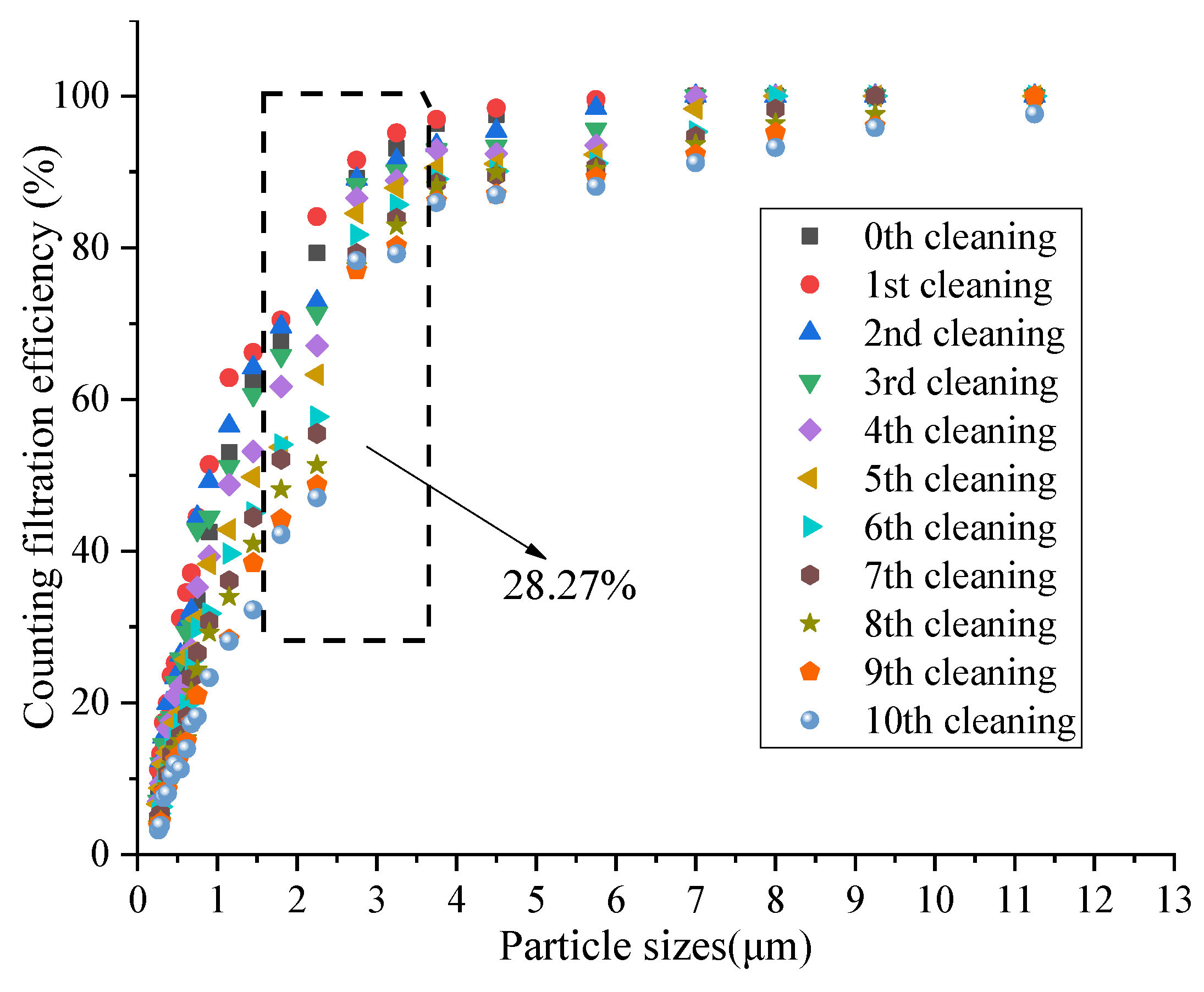

3.3. Counting Filtration Performance Testing and Analysis

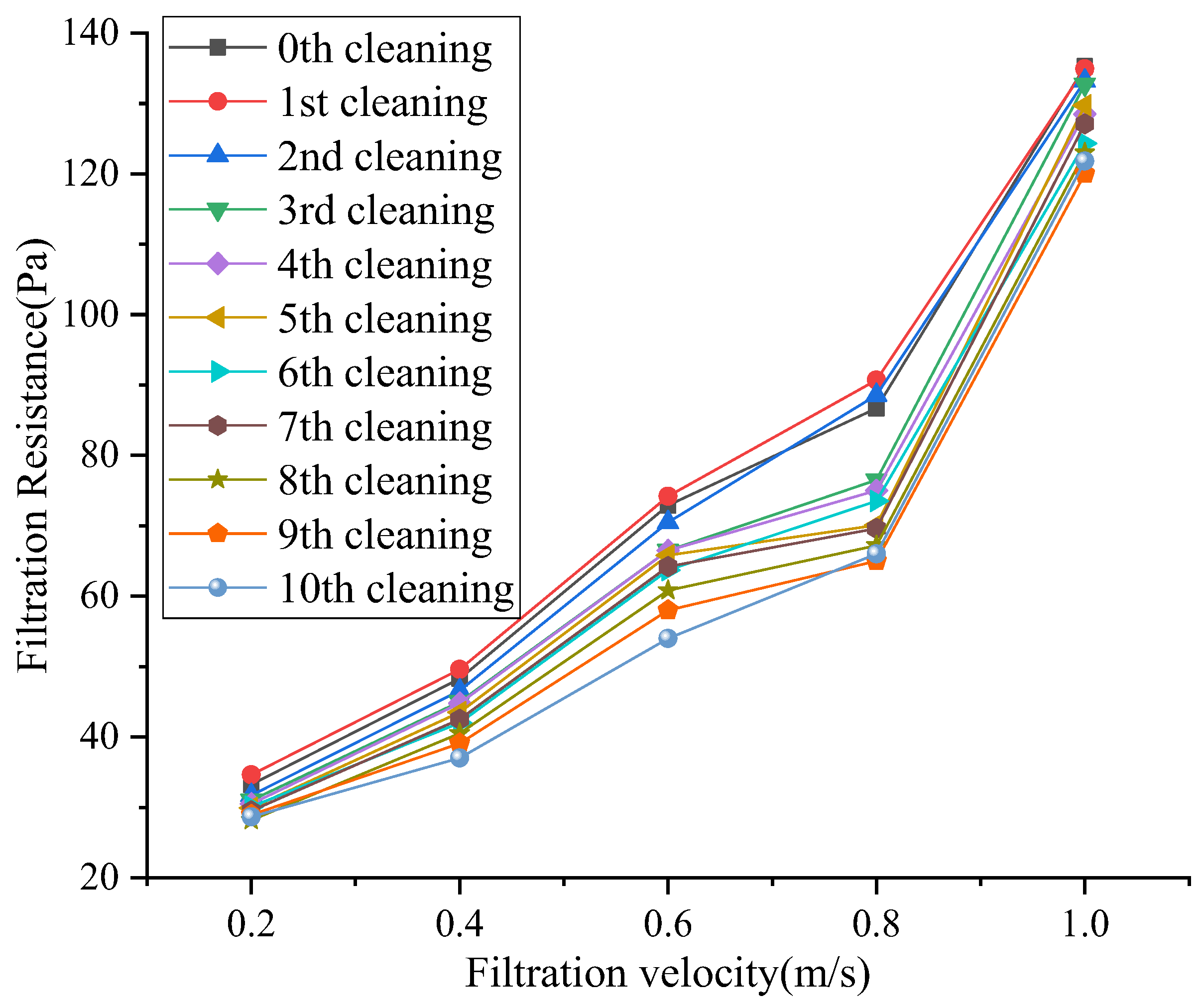

3.4. Filtration Resistance Testing and Analysis

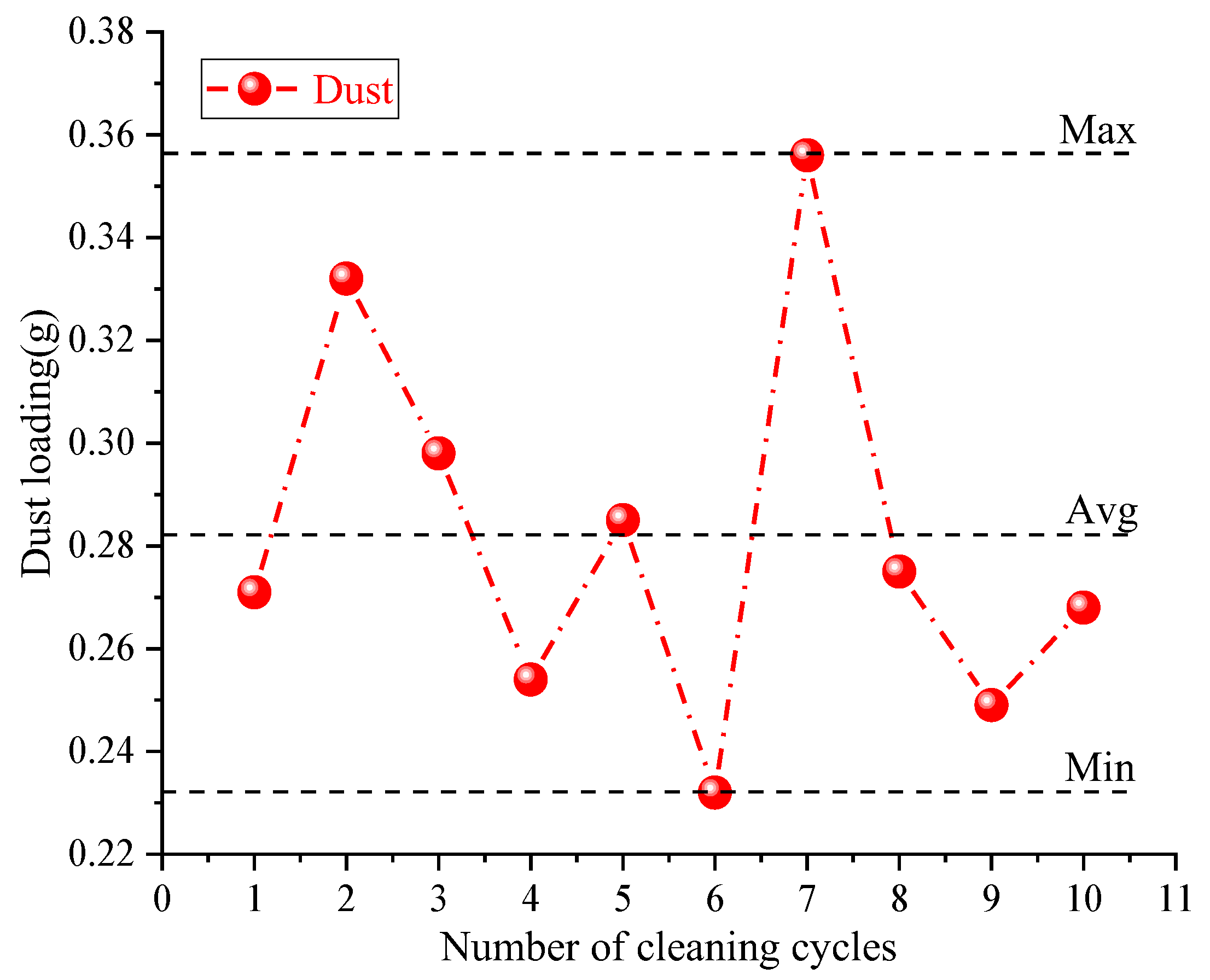

3.5. Influence of Consecutive Cleaning Cycles on Dust Loading

4. Conclusions

- The experiment was conducted using a cleanliness level that reached 85% of that for the fresh filter material. The parameters of 120 W ultrasonic power and 11.2 s cleaning time were selected for the best effects.

- The filtration efficiency shows a trend of first increasing, and then decreasing with the increase in filtration velocity and, when the filtration velocity is 0.8 m/s, the filtration efficiency reaches its maximum. Compared to the original group, the efficiency of PM10 filtration slightly increased by 2.52%, 1.11%, and 0.49% after one to three cycles of ultrasonic cleaning at the optimal filtration velocity; the efficiency of PM2.5 filtration increased slightly, by 4.02%, 3.59%, and 1.42%, respectively; the efficiency of PM1.0 filtration also increased slightly, by 2.11%, 1.34%, and 0.30%, respectively. The filtration efficiency of PM10 decreased by 1.72%, to 18.96%, after 4 to 10 ultrasonic cleanings; that of PM2.5 decreased by 1.56%, to 12.34%; and that of PM1.0 decreased by 1.74%, to 10.95%. The variation range for the filtration efficiency decay rate of PM10 after 10 ultrasonic cleanings is −17.65~4.45%; for PM2.5 is −22.77~12.33%; and for PM1.0 is −26.11% to 8.41%. It was thus determined that nine ultrasonic cleaning cycles is the limit for PM10, six is the limit for PM2.5, and seven is the limit for PM1.0, which are consistent with their requirements for reuse.

- The counting filtration efficiency shows a gradually increasing trend with increasing particle size. Ultrasonic cleaning is mainly more effective for particles smaller than 2.5 μm, as the counting efficiency after 10 consecutive ultrasonic cleanings decreases by 28.28% compared to the fresh filter material’s counting efficiency.

- After 10 cycles of ultrasonic cleaning, the filtration resistance decreased, in the range of 4.6~20.7 Pa. However, it is necessary to comprehensively consider other factors in practical use, such as labor costs, ease of operation, and applicable site requirements. Overall, ultrasonic cleaning has significant advantages, and the findings herein provide data reference value for regeneration performance method and filter material evaluation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Asbach, C.; Todea, A.M.; Kaminski, H. Evaluation of a Partector Pro for atmospheric particle number size distribution and number concentration measurements at an urban background site. Aerosol Res. 2024, 2, 1–12. [Google Scholar] [CrossRef]

- Song, H.; Dong, Y.H.; Yang, J.Y.; Zhang, X.; Nie, X.X.; Fan, Y.X. Concentration Characteristics and Correlations with Other Pollutants of Atmospheric Particulate Matter as Affected by Relevant Policies. Int. J. Environ. Res. Public. Health 2023, 20, 1051. [Google Scholar] [CrossRef] [PubMed]

- Feng, T.; Sun, Y.C.; Shi, Y.T.; Ma, J.; Feng, C.M.; Chen, Z.N. Air pollution control policies and impacts: A review. Renew. Sust. Energy Rev. 2024, 191, 114071. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, Y.S.; Wei, S.X.; Wang, H.; Zhang, J.X. Spatiotemporal Distribution of PM2.5 and Its Correlation with Other Air Pollutants in Winter During 2016~2018 in Xi’an, China. Pol. J. Environ. Stud. 2021, 30, 1457–1464. [Google Scholar] [CrossRef]

- Yang, Y.; Østergaard, P.A.; Wen, W.; Zhou, P. Heating transition in the hot summer and cold winter zone of China: District heating or individual heating? Energy 2024, 290, 130283. [Google Scholar] [CrossRef]

- Jandacka, D.; Durcanska, D.; Nicolanska, M.; Holubcik, M. Impact of Seasonal Heating on PM10 and PM2.5 Concentrations in Sučany, Slovakia: A Temporal and Spatial Analysis. Fire 2024, 7, 150. [Google Scholar] [CrossRef]

- Jones, R.R.; Fisher, J.A.; Hasheminassab, S.; Kaufman, J.D.; Freedman, N.D.; Ward, M.H.; Sioutas, C.; Vermeulen, R.; Hoek, G.; Silverman, D.T. Outdoor ultrafine particulate matter and risk of lung cancer in Southern California. Am. J. Resp. Crit. Care 2024, 209, 307–315. [Google Scholar] [CrossRef] [PubMed]

- Deng, Q.S.; Cuesta, L.; Alvarado, R.; Murshed, M.; Tillaguango, B.; Işık, C.; Rehman, A. Nexus between government stability and environmental pollution. J. Clean. Prod. 2024, 434, 140061. [Google Scholar] [CrossRef]

- Zhou, F.R.; Yang, J.R.; Wen, G.; Ma, Y.; Pan, H.; Geng, H.; Cao, J.; Zhao, M.; Xu, C. Estimating spatio-temporal variability of aerosol pollution in Yunnan Province, China. Atmos. Pollut. Res. 2022, 13, 101450. [Google Scholar] [CrossRef]

- Desservettaz, M.; Pikridas, M.; Stavroulas, I.; Bougiatioti, A.; Liakakou, E.; Hatzianastassiou, N.; Sciare, J.; Mihalopoulos, N.; Bourtsoukidis, E. Emission of volatile organic compounds from residential biomass burning and their rapid chemical transformations. Sci. Total Environ. 2023, 903, 166592. [Google Scholar] [CrossRef] [PubMed]

- GB3095-2012; Ambient Air Quality Standards. China Environmental Science Press: Beijing, China, 2012.

- Tian, Y.L.; Li, X.Y.; Sun, H.T.; Xue, W.H.; Song, J.X. Characteristics of atmospheric pollution and the impacts of environmental management over a megacity, northwestern China. Urban Clim. 2022, 42, 101114. [Google Scholar] [CrossRef]

- Burnett, R.T.; Spadaro, J.V.; Garcia, G.R.; Pope, C.A. Designing health impact functions to assess marginal changes in outdoor fine particulate matter. Environ. Res. 2022, 204, 112245. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, A.B.; Arora, T.; Singh, S.; Singh, R. Critical review on emerging health effects associated with the indoor air quality and its sustainable management. Sci. Total Environ. 2023, 872, 162163. [Google Scholar] [CrossRef]

- Zacharias, N.; Haag, A.; Lamprecht, R.B.; Gebel, J.; Essert, S.M.; Kistemann, T.; Exner, M.; Mutters, N.T.; Engelhart, S. Air filtration as a tool for the reduction of viral aerosols. Sci. Total Environ. 2021, 772, 144956. [Google Scholar] [CrossRef]

- Yu, W.Q. The Experimental Study of Air Filter Re-Cleaning Based on Ultrasonic Method. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2022. (In Chinese). [Google Scholar]

- Berry, G.; Beckman, I.; Cho, H. A comprehensive review of particle loading models of fibrous air filters. J. Aerosol Sci. 2023, 167, 106078. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, Y.T.; Zhang, C.W.; Zhou, Y.Q.; Yu, D.G. Electrospun nanofiber as building blocks for high-performance air filter: A review. Nano Today 2024, 55, 102161. [Google Scholar] [CrossRef]

- Liu, C.; Hsu, P.C.; Lee, H.W.; Ye, M.; Zheng, G.Y.; Liu, N.; Li, W.Y.; Cui, Y. Transparent air filter for high-efficiency PM2.5 capture. Nat. Commun. 2015, 6, 6205. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.P.; Bian, S.S.; Chang, D.Q.; Mao, N.; Liu, J.X.; Sun, X. Effect of Water Cleaning on Performance of Air Filtration Medias. J. Filtr. Sep. 2012, 22, 6–10. (In Chinese) [Google Scholar] [CrossRef]

- Yeganeh, F.; Chiewchan, N.; Chonkaew, W. Cellulose nanofiber/polyimide composites for highly-efficient air filters. Cellulose 2023, 30, 4421–4436. [Google Scholar] [CrossRef]

- Tang, M.; Thompson, D.; Chang, D.Q.; Chen, S.C.; Pui, D.Y.H. Filtration efficiency and Loading characteristics of PM2.5 through commercial electret filter media. Sep. Purif. Technol. 2018, 195, 101–109. [Google Scholar] [CrossRef]

- Zeng, Y.X.; Liu, Q.; Zhang, X.; Wang, Z.; Yu, T.; Ren, F.; He, P.C. Comparative Filtration Performance of Composite Air Filter Materials Synthesized Using Different Impregnated Porous Media. Materials 2023, 16, 4851. [Google Scholar] [CrossRef] [PubMed]

- Azimi, B.; Sepahvand, S.; Ismaeilimoghadam, S.; Kargarzadeh, H.; Ashori, A.; Jonoobi, M.; Danti, S. Application of cellulose-based materials as water purification filters; a state-of-the-art review. J. Polym. Environ. 2024, 32, 345–366. [Google Scholar] [CrossRef]

- Yang, M.; Yang, B.; Zhang, X.; Wu, S.S.; Yu, T.; Song, H.; Ren, F.; He, P.C.; Zhu, Y.H. Experimental Study of the Factors Influencing the Regeneration Performance of Reduced Graphite Oxide Filter Materials under Water Cleaning. Materials 2023, 16, 4033. [Google Scholar] [CrossRef] [PubMed]

- Cigeroglu, Z.; El Messaoudi, N.; Şenol, Z.M.; Baskan, G.; Georgin, J.; Gubernat, S. Clay-based nanomaterials and their adsorptive removal efficiency for dyes and antibiotics: A review. Mater. Today Sustain. 2024, 26, 100735. [Google Scholar]

- Zhang, X.; Ma, J.Y.; Wang, J.H.; Shi, H.X.; Guo, J.P.; Fan, Y.S.; Nie, X.X.; Guo, T.; Luo, X.X. Modifying the Fiber Structure and Filtration Performance of Polyester Materials Based on Two Different Preparation Methods. Langmuir 2023, 39, 3502–3511. [Google Scholar] [CrossRef]

- Qin, J.D.; Zhang, Y.H.; Yi, Y.L. Water washing and acid washing of gasification fly ash from municipal solid waste: Heavy metal behavior and characterization of residues. Environ. Pollut. 2023, 320, 121043. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.; Wang, Z.; Wang, X. Ultrasonic cleaning in the membrane process: From phenomenon to mechanism and mathematical model. Chem. Eng. Sci. 2023, 282, 119267. [Google Scholar] [CrossRef]

- Wang, A.; Xu, H.; Chen, C.G.; Liu, C.; Lin, T.; Ma, J.; Ding, M. Critical review on advances and perspectives of ultrasound assisted membrane technologies for water purification. Chem. Eng. J. 2024, 482, 148873. [Google Scholar] [CrossRef]

- Yang, L.L.; Liu, Z.Y.; Liu, J.X. Experiment on Cleaning and Regeneration of Filter Material. Ind. Saf. Environ. Prot. 2021, 47, 94–98. (In Chinese) [Google Scholar]

- Sun, F.G.; Zhang, X.; Xue, T.; Cheng, P.; Yu, T. The Performance Testing and Analysis of Common New Filter Materials: A Case of Four Filter Materials. Materials 2024, 17, 2802. [Google Scholar] [CrossRef] [PubMed]

- Perrin, L.; Desobry-Banon, S.; Gillet, G.; Desobry, S. Study and optimization of oil-in-water emulsions formulated by low-and high-frequency ultrasounds. Int. J. Cosmetic Sci. 2023, 45, 198–213. [Google Scholar] [CrossRef] [PubMed]

- GB/T 14295-2019; Air Filter. China Environmental Science Press Administration for Market Regulation, Standardization Administration of the People’s Republic of China: Beijing, China, 2019.

- Shi, Z.P.; Yang, Z.H.; Wang, Z.D.; Liu, L.Y. Ultrasonic intensification of flocculation filtration for kaolinite: Unraveling mechanisms and performance gains. Sep. Purif. Technol. 2024, 332, 125773. [Google Scholar] [CrossRef]

- Zhou, Z.Q.; You, T.; Wang, D.; Pan, Z.Y.; Xu, G.L.; Liang, Y.; Tang, M. Conformal Build-Up of Functionalized Air Filters with Improved Air Cleaning and Bioprotective Traps. Adv. Funct. Mater. 2024, 34, 2306777. [Google Scholar] [CrossRef]

- Werkneh, A.A.; Gebru, S.B. Development of ecological sanitation approaches for integrated recovery of biogas, nutrients and clean water from domestic wastewater. Resour. Environ. Sustain. 2023, 11, 100095. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Li, X.; Teng, Y.; Bai, S.J.; Chen, Z. Two-list genetic algorithm for optimizing work package schemes to minimize project costs. Automat Constr. 2024, 165, 105595. [Google Scholar] [CrossRef]

| Cleaning Cycle | Fitting Formula | R2 |

|---|---|---|

| 0th | = 100.29v2 + 0.84v + 36.65 | R2 = 0.9799 |

| 1st | = 89.86v2 + 12.99v + 29.48 | R2 = 0.9879 |

| 2nd | = 95.82v2 + 7.51v + 27.44 | R2 = 0.9900 |

| 3rd | = 100.29v2 + 0.84v + 36.65 | R2 = 0.9799 |

| 4th | = 116.43v2 − 26.61v + 33.80 | R2 = 0.9593 |

| 5th | = 132.14v2 − 45.47v + 36.94 | R2 = 0.9387 |

| 6th | = 117.68v2 − 31.26v + 33.70 | R2 = 0.9668 |

| 7th | = 129.82v2 − 44.64v + 36.24 | R2 = 0.9444 |

| 8th | = 130.54v2 − 48.49v + 35.60 | R2 = 0.9484 |

| 9th | = 138.82v2 − 62.56v + 38.66 | R2 = 0.9507 |

| 10th | = 160.54v2 − 84.99v + 41.85 | R2 = 0.9668 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, T.; Zhang, X.; Cheng, P.; Sun, F.; Liu, F.; Yu, T. Non-Woven Fabric Filter Materials Used in Public Buildings for Filtering Particulate Matter Experience Performance Changes under Ultrasonic Cleaning Based on Dual Carbon Target. Buildings 2024, 14, 3105. https://doi.org/10.3390/buildings14103105

Xue T, Zhang X, Cheng P, Sun F, Liu F, Yu T. Non-Woven Fabric Filter Materials Used in Public Buildings for Filtering Particulate Matter Experience Performance Changes under Ultrasonic Cleaning Based on Dual Carbon Target. Buildings. 2024; 14(10):3105. https://doi.org/10.3390/buildings14103105

Chicago/Turabian StyleXue, Tao, Xin Zhang, Ping Cheng, Fenggang Sun, Fuquan Liu, and Tao Yu. 2024. "Non-Woven Fabric Filter Materials Used in Public Buildings for Filtering Particulate Matter Experience Performance Changes under Ultrasonic Cleaning Based on Dual Carbon Target" Buildings 14, no. 10: 3105. https://doi.org/10.3390/buildings14103105