Abstract

Traditional seismic wave-based tunnel advanced geological forecasting techniques are primarily designed for drill and blast method construction tunnels. However, given the fast excavation speed and limited prediction space in tunnel boring machine (TBM) construction tunnels, traditional methods have significant technical limitations. This study analyzes the characteristics of different types of TBM construction tunnels and, considering the practical construction conditions, identifies an effective observation system and data acquisition method. To address the challenges in advanced forecasting for TBM construction tunnels, a method of ellipsoid positioning velocity analysis, which takes into account the constraints of three-component data directions, is proposed. Based on the characteristics of the advanced forecasting observation system, this method compares the maximum values on the spatial isochronous ellipsoidal surface to determine the average velocity of the geological layer rays, thereby enabling accurate inversion of the spatial distribution ahead. Utilizing numerical simulation, a model for the advanced detection of typical unfavorable geological formations is established by obtaining the wave field response characteristics of seismic waves in three-dimensional space, and the velocity structure of the model is retrieved through this velocity analysis method. In the engineering example, the fracture property, water content, and weathering degree of the surrounding rock are predicted accurately.

1. Introduction

With the development of China’s economy and the acceleration of urbanization, the need for various types of tunnels, such as highway tunnels, high-speed railway tunnels, subway tunnels, water conservancy tunnels, coal mine tunnels, and underground municipal pipeline tunnels, is growing rapidly. Consequently, there is increasing demand for tunnel boring machine (TBM) construction methods [1,2,3]. TBM construction methods have obvious advantages, such as fast excavation speed, high-quality tunnel formation, comprehensive economic benefits, and improved construction safety. TBM methods have become an important trend and development direction of tunnel engineering construction in China and will occupy a dominant position in future tunnel construction [4,5,6].

The applicability of TBM construction methods is limited by complex geological conditions and frequent geological disasters. It is more suitable for geological formations with little stratum change, good rock mass integrity, and medium rock strength [7,8]. However, the geological environment in many areas of China is very complex; there are serious geological hazards, such as rupture zones and groundwater, and areas where some tunnels are located in the crushed zone. It is very important to use modern and scientific advanced forecasting methods to predict the attributes, sizes, and states of undesirable geological bodies within the tunnel excavation range accurately [9,10,11]. Moreover, advanced geological predictions lay an important foundation for changing tunnel construction methods and support schemes and can reduce construction blindness to ensure construction progress and the safety of construction personnel and property [12,13,14,15,16,17,18,19].

Advanced geological forecasting is used in the excavation of tunnels and underground galleries. Based on the physical properties and structural differences of the medium, a forecast identifies the distribution and transformation patterns of underground physical fields. The forecast assesses whether there are geological anomalies ahead of the tunnel face as well as the conditions and scales of geological bodies [20,21,22,23,24,25,26,27]. Among the techniques employed, seismic wave reflection for advanced forecasting is widely used in tunnel geological prediction. It relies on the propagation characteristics of seismic waves across different geological interfaces, particularly those of typical disaster-prone geological bodies. By processing the data from received reflection waves, the spatial locations of the geological interfaces that generate the reflections as well as the seismic wave parameters of the surrounding rocks between the interfaces can be determined [28,29,30,31]. The geological features in front of the tunnel face are then inverted and combined with geological data to achieve a comprehensive advanced geological forecast for tunnel construction. This technology effectively reduces the impact of adverse geological conditions on TBM operations and enhances construction efficiency and safety [32,33].

Due to the poor adaptation of TBM construction tunnels to adverse geological conditions, research on TBM advanced geological forecasting based on ellipsoidal positioning velocity analysis has been initiated. This study aims to identify the types and scales of adverse geological bodies (heterogeneity, void, discontinuity, crack, broken, water content, weathering degree) that might appear ahead of the TBM excavation face to provide timely warnings for geological disasters and offer scientific bases for the construction party to reference in advance in order to prepare appropriate construction plans and engineering measures. This maximizes the reduction of losses due to adverse geological conditions and ensures the safety and smooth progression of TBM construction.

2. TBM Construction Tunnel Data Collection and Observation System

The implementation of seismic wave advanced forecasting and its observation system within the tunnel boring machine (TBM) construction environment poses significant challenges. The TBM advances the boring machine by relying on its own powerful thrust, while the rotation of the cutter head generates shear forces that fracture the rock in front of the advancement into debris. This enables continuous operations, such as tunnel grouting, advancement, debris removal, and segment installation, which results in exceptionally busy and crowded conditions within the narrow tunnel space. Our aim is for advanced forecasting to impede other construction processes minimally and to even be conducted during TBM downtime periods. During these periods, apart from the noise generated by fans, there are few other sources of significant signal interference within the tunnel. However, the downtime of the TBM is extremely valuable, with rapid ongoing construction processes such as cutter head replacement, track addition, and steel arch repair in front of the cutter head and beneath the worktable. This makes it impractical to employ large drilling equipment to drill 25 holes for geophone placement, as is undertaken in the TSP advanced forecasting method in tunnels constructed with an open-type boring machine, but retaining the advantages of a single-sided linear array arrangement is possible. Considering cost, environmental requirements, and convenience of construction, the choice of seismic sources must exclude explosive and electric spark sources. In the shield-type boring machine construction environment, the possibility of drilling and using explosive sources is extremely low.

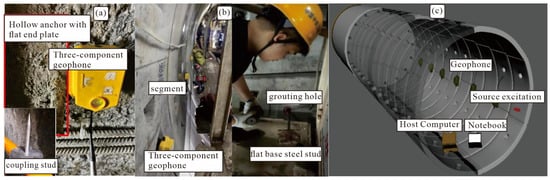

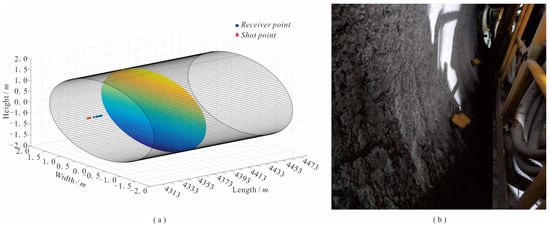

The unique construction environment of the TBM has made hammering and the use of magnetically attached triaxial seismic geophones the optimal seismic source solution. In open-type boring machines, geophones are magnetically attached to the flat trays of completed grout-filled hollow anchor rods or by using a pistol drill to create coupling bolts, 8 mm in diameter and 10 cm long, on the tunnel side walls, as shown in Figure 1a. The seismic source is activated by direct hammering on the side rock walls of the tunnel. For shield-type TBMs, satisfying the conditions for drilling on tunnel side walls and direct attachment to hollow anchor rod flat trays is not feasible; instead, geophones are magnetically attached to the rivets on shield segments. Shield-type TBM segments, which bear tunnel pressure, are not conducive to direct hammering. The segments that have been grouted are fully coupled with the surrounding rock, and seismic waves generated by hammering after inserting the flat tray steel nails into the grout holes can propagate into the underground space. The overall geophone array is shown in Figure 1b. The schematic of the observation system is depicted in Figure 1c.

Figure 1.

Observation instrument and system in TBM tunnel: (a) installation of open TBM detector; (b) location of shield TBM detector and source; (c) schematic diagram of observation system.

3. Ellipsoidal Positioning Velocity Analysis Algorithm

This paper introduces an ellipsoidal positioning velocity analysis method determined through the analysis of seismic wave polarization characteristics, three-dimensional seismic recording data, and spatial direction constraints. This method is suitable for geologically advanced forecasting observation systems and does not heavily rely on the pick-up speed of the first arrival wave. It provides a more accurate and intuitive three-dimensional geological velocity model and offers parameter indices for assessing the condition of the rock ahead of the tunnel face and for evaluating rock grades, thereby providing a solid foundation for the quality of offset imaging and the reliability of forecast results.

Seismic wave velocity information is an important carrier or indicator for predicting geological hazards ahead of the tunnel. The velocity model affects not only the effects of offset imaging but also the reliability of forecast interpretation. The ellipsoidal positioning velocity analysis method, based on the characteristics of the advanced forecasting observation system and combined with the constraints of three-component data direction, determines the average ray velocity of the layers and can accurately invert the spatial velocity model.

3.1. Method Principle

The polarization characteristics of seismic waves in advanced detection reveal that seismic waves, starting from source S, reflect at reflection point P and are recorded at detection point R. This can be represented as

where is the trajectory of seismic wave movement, is the velocity of the seismic wave, and is the travel time of the seismic wave.

In three-dimensional space, the mathematical relationship is

In the above formula, ; and are the coordinate values of source point , detection point , and reflection point . It is deduced that

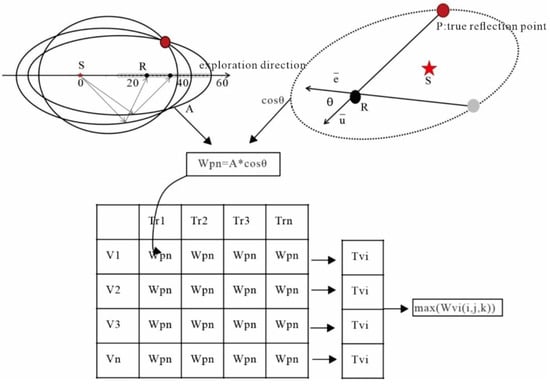

Derived from analysis, the above formula represents an ellipsoidal surface, where any point on this surface could be a reflection point. The source S and detection points R serve as the foci, with the offset serving as the focal length in Figure 2.

Figure 2.

Schematic diagram of ellipsoidal positioning velocity analysis.

A three-dimensional grid is created forward from the source point. represents the grid points . is obtained by the reflection surface determined by the p gun and the detection point, and the restriction condition represents amplitude. For the isochronous ellipsoid mentioned above, the value is assigned to represent the possibility of a true reflection point:

where is the amplitude and is the angle between the unit vector from the point to the detection point on the isochronous ellipsoid and the vector from the real reflection point to the detection point (that is, the vector composed of the three components of the data actually recorded). is 0 at the true reflection point, where is equal to and less than everywhere else.

Then, the data space can be obtained via every gun data(assuming there are actually N in total) with vi(assuming any speed value) as the speed:

When the data at the real reflection point in the data body are superimposed, their value is increased, and the value at the false anomaly is attenuated.

The 3D spatial data bodies obtained from the velocity are compared with the value of the same cell one by one, and the maximum value corresponds to the optimal velocity. The method is defined as the ellipsoidal positioning velocity analysis method.

3.2. Numerical Simulation Data Validation

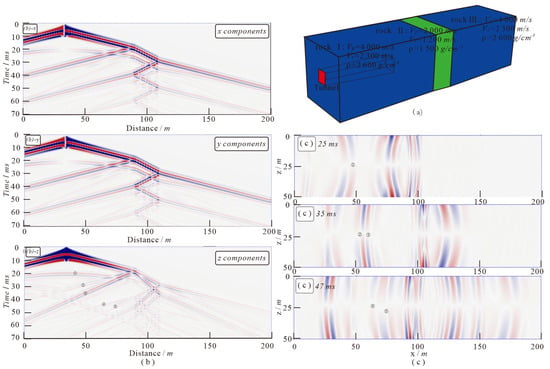

A layered tunnel geological model was established to simulate the common hazard of weak interlayered rock formations in tunnel construction, and corresponding seismic records were obtained to analyze its reliability and validate the model.

The interlayer model is shown in Figure 3a, with the tunnel face positioned 60 m ahead of the reference face. Surrounding rock formation 1 is hard rock, surrounding rock formation 2 is a weak geological body in front of the tunnel, and surrounding rock formation 3 is hard rock. Physical parameters of the rock are shown in Table 1. The source sub-wave is a Ricker wavelet, with a sampling rate of 0.01 ms, a recording duration of 70 ms, and a seismic wave main frequency of 200 Hz. In numerical modeling, we use rectangular element type. The size of each element is 1 cm * 1 cm, and the PML (perfectly matched layer) boundary is adopted. The source point coordinates (x, y, z) are (35, 30, 25), with detection points arranged along the x direction passing the source point and a track spacing of 1 m. To best mimic reality, ellipsoidal positioning velocity analysis is performed by taking 24 track data points from the source point forward along the x-axis, with P-wave velocity selection ranging from 1500 m/s to 4500 m/s and S-wave velocity selection ranging from 1000 m/s to 2500 m/s at intervals of 100 m/s.

Figure 3.

(a) sandwich model; (b) seismic records: (b) X-component seismic record; (b) Y-component seismic record; (b) Z-component seismic record; (c) wave field snapshot: (c) 25 ms wave field snapshot; (c) 35 ms wave field snapshot; (c) 47 ms wave field snapshot.

Table 1.

Forward simulation parameters.

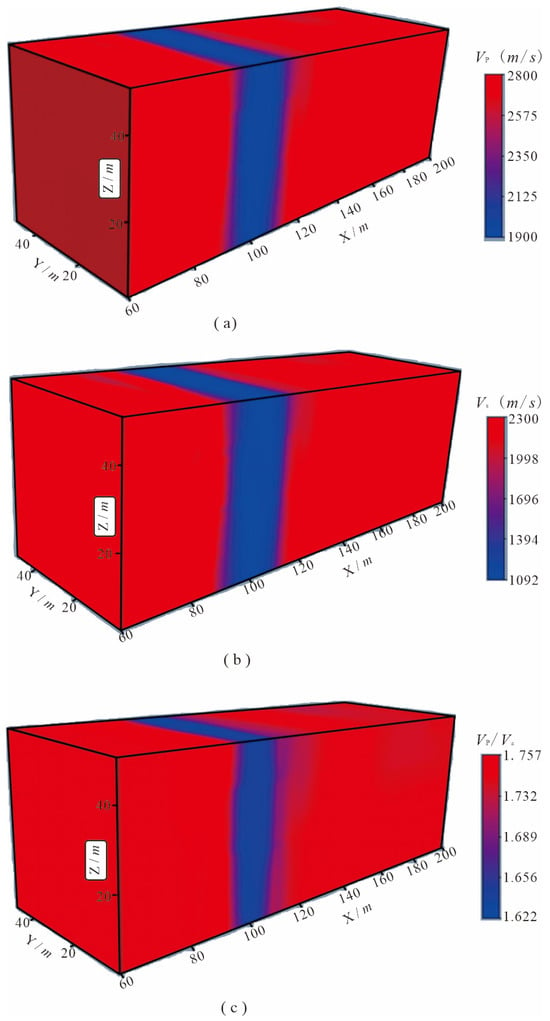

The obtained three-component original seismic records are shown in Figure 3b, and its wavefield snapshot is shown in Figure 3c. The wavefield snapshot is oriented along the x direction, with the z-axis as the vertical axis. Through analysis, the z-component seismic records include the following: ① seismic waves generated at the model’s starting interface, with wavefield propagation characteristics as marked in Figure 3c; ② and ③ direct waves and PP waves generated at the first interface of the interlayer, with wavefield propagation characteristics as marked in Figure 3c; and ③ and ④ transmitted P waves reflected after encountering the second interface, with wavefield propagation characteristics as marked in Figure 3c. Using the ellipsoidal positioning velocity analysis method, analysis was performed on this forward seismic record. Results are shown in Figure 4, with P-wave velocity in front of the tunnel surrounding rock at 4000 m/s, weak surrounding rock p-wave velocity at 2000 m/s, and thee reflection interface at 90 m and 110 m on the x-axis. The position of the rock interface, interlayer thickness, and velocity values were precisely predicted. The velocity ratio results are shown in Figure 4c and reflect changes in the water content of the surrounding rock.

Figure 4.

Speed results: (a) P-wave velocity distribution results; (b) S wave velocity distribution results; (c) results of wave velocity ratio.

4. Engineering Example

4.1. Engineering Example One—Application in TBM Construction Tunnels through Fractured Rock Zones

The tunnel is located within Tongcheng City, Anhui Province, approximately 80 km straight distance from Hefei and approximately 40 km from Anqing. The tunnel is a self-draining tunnel with a total length of 6120.8 m. There are no major faults along the self-draining tunnel line, with joints and fractures occurring primarily at steep angles. Most of the self-draining tunnel is deeply buried in weakly weathered or slightly-weathered-to-fresh rock, which predominantly consists of class II and III surrounding rock. In the section passing through Maojiadian No. 1 Ditch, the burial depth ranges from 220 to 230 m, while the Zhangling Ditch section ranges from 60 to 65 m, and the Nanchong River section ranges from 45 to 50 m. The tunnel depths are shallower in the Zhangling Ditch and Nanchong River sections, the river valleys are wider, and fractures and faults develop along the river, possibly with significant seepage. The surrounding rock is mainly class III, with fault zones classified as class IV. Approximately 180 m south of the Nanchong River, the tunnel section intersects almost perpendicularly with the F1 fault, which has an orientation of N50° to 70 °E/NW (SE) at an angle of 75° to 85°, a width of 4 to 7 m, and a distorted fault surface. This is at the contact line between the Liu Fan Group diorite and the Bengbu period mixed granite, with the fault zone commonly seeing late Yanshan period diorite intrusions, consisting of fractured rock, structural breccia, and compressed schist, primarily in a weakly weathered state, with some areas showing strong weathering. The surrounding rock is fractured and classified as class IV.

4.2. Data Collection

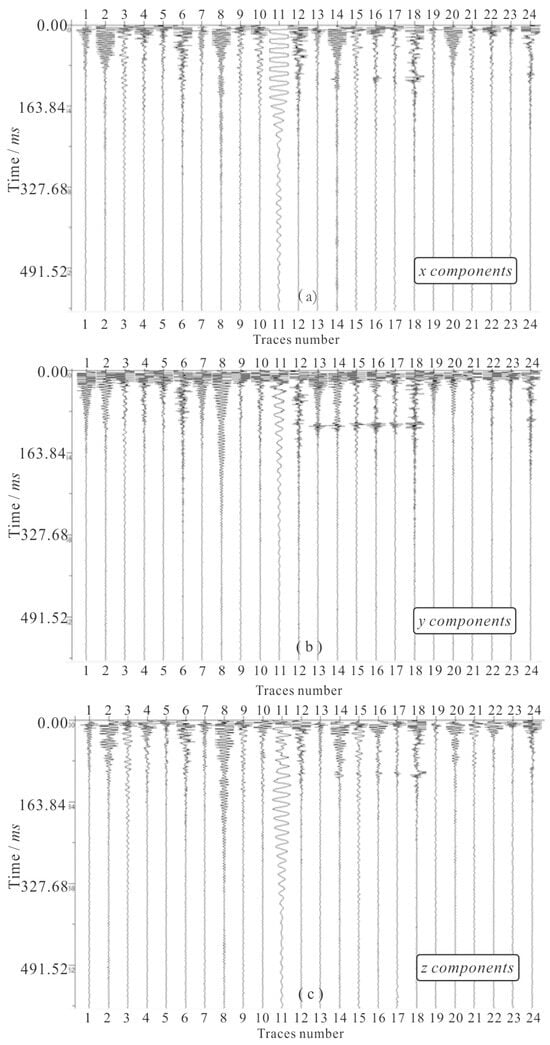

Source location: four excitation points are arranged on the side wall behind the receiving point, spaced 1 m apart, with each point activated three times for signal stacking to ensure effective seismic wave excitation in the surrounding rock. Receiver location: six triaxial geophones are placed between the source and the cutter head to receive full-space vibration signals, with a track spacing of 1.5 m, a minimum offset distance of 4 m, and a maximum offset distance of 16 m. Geophones are applied in a triaxial flush-wall manner, with the x-direction as the advancing direction, the y-direction perpendicular to the tunnel wall, and the z-direction perpendicular to the horizontal plane. The tunnel face mileage is ZLD4+373, advancing from the smaller to the larger mileage. The tunnel face is circular, with the top of the face at 0 degrees, the bottom at 180 degrees, and the angles increasing clockwise. In the two-dimensional plane, the center is at point (0, 0), with a diameter of 3.5 m. The hammer point record table is shown in Table 2, the geophone point record table is shown in Table 3, and the measurement system schematic is shown in Figure 5. The original seismic records are shown in Figure 6.

Table 2.

Hammer point record sheet.

Table 3.

Geophone point record sheet.

Figure 5.

(a) Schematic diagram of on-site observation system layout. (b) Layout diagram of on-site observation system.

Figure 6.

(a) X-component seismic record. (b) Y-component seismic record. (c) Z-component seismic record.

The collected original records contain 24 tracks of three-component seismic data, where tracks 1–6 were generated by the first hammer point, 7–12 by the second hammer point, 13–18 by the third hammer point, and 19–24 by the fourth hammer point.

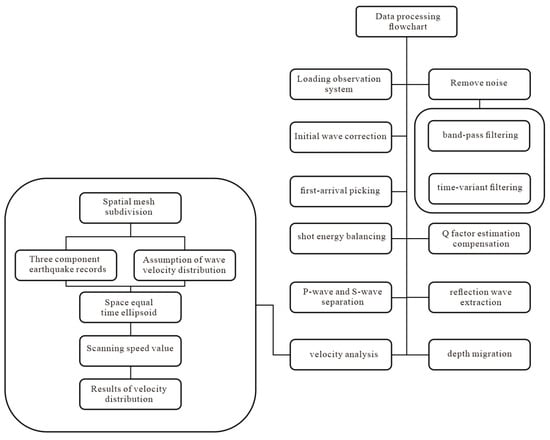

4.3. Data Processing

The raw data undergo several processing steps, including data preparation, bad track removal, band-pass filtering and time-variant filtering, first-arrival picking, shot energy balancing, Q factor estimation compensation, reflection wave extraction, P-wave and S-wave separation, velocity analysis, depth migration, and reflection layer extraction. These processes ultimately yield the physical parameters of the geological bodies in front of the tunnel and the positions of the reflection interfaces. The data processing flow is shown in Figure 7.

Figure 7.

Schematic diagram of data processing flow.

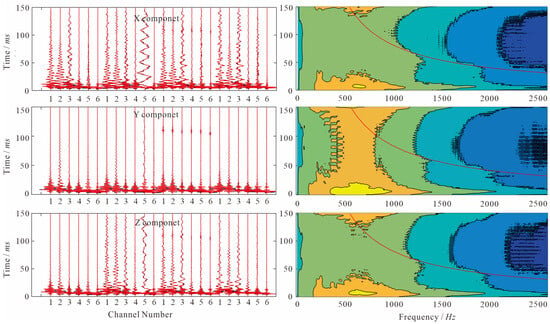

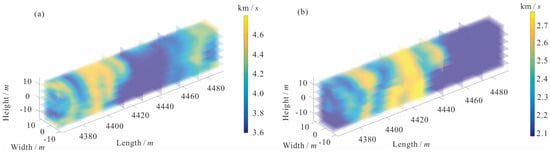

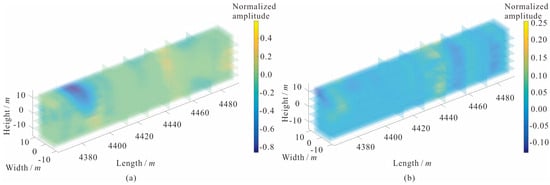

The original seismic record spectrum has an effective frequency range of 10–2000 Hz, with a dominant frequency of 800 Hz. Time–frequency filtering is illustrated in Figure 8, where the red waveform on the left represents the result after filtering, and the black waveform represents the seismic record after band-pass filtering. The red line on the right side of the figure demarcates the energy retained on the left and the energy filtered out on the right. The analysis results for the P-wave velocity are shown in Figure 9a, and the S-wave velocity analysis results are displayed in Figure 9b. The results for P-wave offset are shown in Figure 10a, and the results for S-wave offset are depicted in Figure 10b.

Figure 8.

Time–frequency analysis waveform data and time–frequency spectrum.

Figure 9.

Speed results: (a) P-wave velocity distribution results; (b) S-wave velocity distribution results.

Figure 10.

Wave migration result graph: (a) P-wave migration result graph; (b) S-wave velocity distribution results.

4.4. Data Interpretation

This forecast covers the mileage from 4373 to 4493, where the surrounding rock primarily consists of diorite, and the construction is designated as class III.

Combining engineering surveys and borehole revelations from the excavation, the area exhibits uneven weathering, faults, and jointing. The anomalous reflection positions correlate with the degree of weathering and the fractured zones of the surrounding rock, with specific forecast results shown in Table 4.

Table 4.

Table of results of advanced geological prediction.

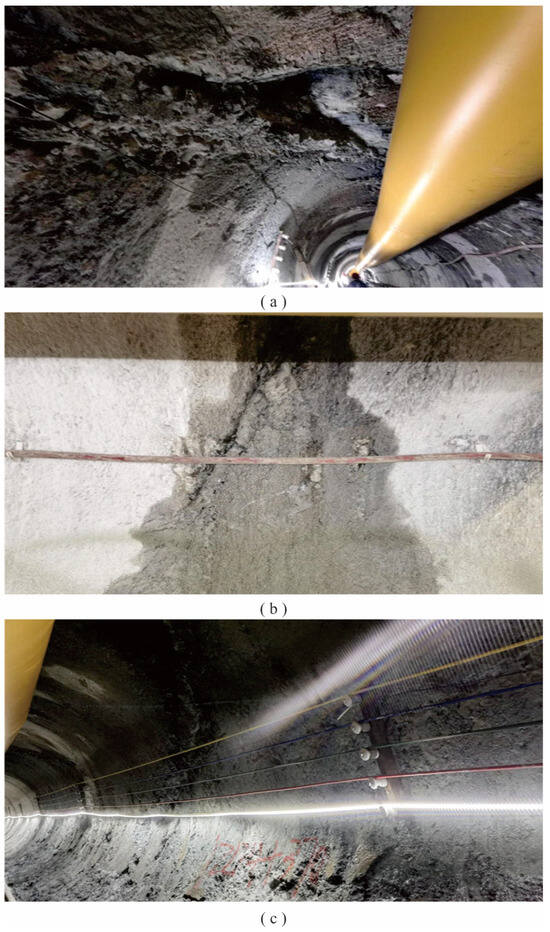

4.5. Field Verification

After the TBM excavation, field results confirmed the accuracy and reliability of our findings. Figure 11a shows that the surrounding rock at the top of the tunnel is noticeably fractured with falling blocks; Figure 11a,b indicate the presence of fissure water in the tunnel; and Figure 11b,c demonstrate that the integrity of the tunnel’s surrounding rock is poor, with evidence of significant cracking.

Figure 11.

Site verification photos: (a) 4410 on-site photos; (b) site photos at S4455; (c) 4437 on-site photos.

5. Conclusions

This paper focused on the application of advanced geological forecasting for TBM construction methods based on ellipsoidal positioning velocity analysis. The layout of an observation system suitable for advanced forecasting in TBM construction tunnels was developed along with key technologies for data processing based on an ellipsoidal positioning velocity analysis, including a simulation of three-dimensional seismic waves for advanced forecasting. The method has achieved good results in practical engineering applications. The main conclusions are as follows:

- A linear observation system was developed based on the spatial feasibility of advanced geological forecasting within TBM tunnels, the characteristics of the observation system setup, general regulations, signal collection requirements, data analysis and interpretation requirements, and the standards for classifying surrounding rock. A method for installing geophones in different types of tunnels was proposed. Numerical simulations of seismic waves demonstrated that this approach could acquire seismic information ahead of the tunnel face, thus maximizing the limited observation space available and proving suitable for TBM construction tunnels.

- For TBM tunnel advanced geological forecasting, a data processing workflow based on ellipsoidal positioning velocity analysis was established. This workflow effectively processes the collected triaxial seismic data, including three-dimensional velocity bodies, three-dimensional velocity ratios, and three-dimensional offset imaging results, by extracting information about geological bodies approximately one hundred meters ahead of the tunnel face. Considering the small amount of seismic signal data and the high requirements for interpretation precision, the ellipsoidal positioning velocity analysis method was proposed. Based on the characteristics of the advanced forecasting observation system, and combining the constraints of the three-component data direction, it accurately inverts the spatial velocity model.

- In this study, a TBM advanced geological forecasting system based on ellipsoidal positioning velocity analysis was developed and validated for TBM tunnels. The practical application in engineering verified the design of the observation system, the settings of the data processing workflow, and the reasonableness and accuracy of the data interpretation. According to the geological data obtained after TBM advancement, the results indicated that this method could be effectively applied to the advanced forecasting of TBM tunnels, could accurately predict the fractured zones ahead of the TBM cutterhead in Engineering Example One, and could accurately forecast the hazards of weak interlayers in Engineering Example Two. The results confirmed the practicality and reliability of the advanced geological forecasting application based on ellipsoidal positioning velocity analysis.

Author Contributions

Conceptualization, Z.G. and W.W.; methodology, W.W.; software, W.W.; validation, W.W., B.H. and X.R.; formal analysis, Z.G., W.W. and J.L.; investigation, Z.G., X.R., J.L. and B.H.; writing—original draft preparation, Z.G. and W.W.; writing—review and editing, W.W.; funding acquisition, W.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the Science and Technology Plan Project of Linzhi, Xizang under Grant SYQ2024-12. This research is supported by the “Research on Three dimensional Advanced Geological Prediction Technology for Shield Tunnel Induced Polarization Dipole” project and NSFC (grant no. 41641040).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Zhen Gao was employed by the company China Aerospace Planning and Design Group Co., Ltd. Author Xin Rong was employed by the company Zhejiang Design Institute of Water Conservancy & Hydroelectric Power Co., Ltd. Author Bin Huang was employed by the company China Railway Engineering Service Co., Ltd. Author Junqiang Liu was employed by the company Zhejiang Engineering Geophysical Prospecting and Design Institute Co., Ltd. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhao, Y.; Tian, S.M.; Yi, S. The Development and Planning of High-Speed Railway Tunnels in China. Tunn. Constr. 2017, 37, 11. [Google Scholar]

- Zi-Tong, Z.; Shao-Hua, Y.; Wei-Sheng, Z.; Qun-Wen, L. Research progress of tunneling magnetoresistance sensor. Wuli Xuebao/Acta Phys. Sin. 2022, 71, 058504. [Google Scholar]

- Ma, J.; Sun, S.Z.; Zhao, W.Y. A Review of Academic Research on Tunnel Engineering in China 2015. China Highw. 2015, 28, 1–65. [Google Scholar]

- Wang, M.S.; Tan, Z.S. Chinese Tunnel and Underground Engineering Construction Technology. Chin. Eng. Sci. 2010, 12, 4–10. [Google Scholar]

- Jing, L.J.; Zhang, N.; Yang, C. Development and Trends of TSP and Its Construction Technology in China. Tunn. Constr. 2016, 36, 331–337. [Google Scholar]

- Kan, H.; Bingyong, W. Research on the Data Analysis and Detection Technology of TSP Advance Forecast. J. Railw. Eng. Soc. 2020, 37, 72–77. [Google Scholar]

- Liu, D.P. Discussion on the Construction Plan of TBM in Fault Karst and Other Adverse Geological Sections. Sci. Technol. Innov. Her. 2017, 14, 2. [Google Scholar]

- Chen, H. Research on the Correlation between TBM Excavation Efficiency and Surrounding Rock. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2010. [Google Scholar] [CrossRef]

- Liu, B.; Nie, C.C.; Li, S.C.; Li, L.P.; Song, J.; Liu, Z.Y. Numerical Simulation and Experimental Study on Real-time Monitoring of Tunnel Water Inrush Disaster by Electrical Resistivity Tomography Method. Chin. J. Geotech. Eng. 2012, 34, 2026–2035. [Google Scholar]

- Johari, A.; Fazeli, A.; Javadi, A.A. An investigation into application of jointly distributed random variables method in reliability assessment of rock slope stability. Comput. Geotech. 2013, 47, 42–47. [Google Scholar] [CrossRef]

- Shahsavar, J.; Johari, A.; Binesh, S. Stochastic analysis of rock slope stability considering cracked rock masses. In Proceedings of the International Conference on Civil Engineering: Modern and Practical Findings, Shiraz, Iran, 15 December 2021. [Google Scholar]

- Li, B. Experimental Study on Downhole Seismic Method in Mines. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2015. [Google Scholar]

- Xiang, H. Evaluating the Excavability of TBM Tunneling in Composite Strata. Master’s Thesis, Chongqing University, Chongqing, China, 2016. [Google Scholar]

- Cheng, J.L.; Xie, C.; Sun, X.Y.; Chen, Q.; Liu, H. Preliminary Exploration of the Theory and Method of Seismic Prospecting Ahead of Tunneling. In Proceedings of the Chinese Earth Sciences Joint Academic Annual Meeting, Beijing, China, October 2015; pp. 1765–1766. [Google Scholar]

- Chen, L.; Li, S.-C.; Li, B.; Li, M.; Xu, X.-J.; Li, N.-B.; Nie, L.-C. Imaging method of seismic advanced detection in tunnels based on ellipse evolving CRP stacking and its application. Chin. J. Geotech. Eng. 2018, 40, 1029–1038. [Google Scholar]

- Li, H.-M.; Zhang, J.-F.; Shang, T.-X.; Hu, Z.-P.; Shi, Y.; Cai, L.-J.; Huang, P. The Whole-Space Modeling of the Hazardous Geological Body ahead of the Tunnel Face by the Transient Electromagnetic Method. J. Environ. Eng. Geophys. 2022, 27, 89–102. [Google Scholar] [CrossRef]

- Cai, J.H.; Wang, Y.G.; Zhang, G.B. Advanced geological forecasting of landslide at tunnel body during construction. J. Eng. Geol. 2015, 23, 778–783. [Google Scholar]

- Lu, J.W.; Chen, Z.; Hu, J.; Guo, L. The application of multi-electrode resistivity method in tunnel geological prediction. J. Eng. Geol. 2016, 24, 1417–1421. [Google Scholar]

- Gao, Z.Z. The application of the Beam geological advance prediction system for the TBM construction of Jinping diversion tunnel. Railw. Constr. Technol. 2009, 11, 65–67. [Google Scholar]

- Gao, S.; Jiang, L.; Mou, Y.; Li, X.; Wang, S.; Zhao, S.; Wang, G.; Yin, X. Advanced Geological Forecasting Techniques for Railway Tunnels in the Complex and Treacherous Mountainous Areas of Southwest China. Mod. Tunn. Technol. 2024, 61, 52–59. [Google Scholar]

- Du, Q.Z.; Tong, Q. Multi-Component Pre-Stack Reverse Time Migration of Elastic Waves in Transversely Isotropic Media. Chin. J. Geophys. 2009, 52, 801–807. [Google Scholar]

- Wei, M.; Zhang, N.; Tong, Y.; Song, Y. Research on the Advanced Prediction Model of the Tunnel Geological Radar Based on Cluster Computing. Intell. Autom. Soft Comput. 2020, 26, 597–607. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Y.S.; Xu, T.; Bai, Z.-M. Stable Excited Amplitude Imaging Conditions in Elastic Wave Reverse Time Migration. Chin. J. Geophys. 2013, 56, 3523–3533. [Google Scholar]

- Zeng, Y.; Liu, J.; Nie, L. Application of comprehensive advanced forecasting technology carried by tbm in gaoligongshan tunnel of dali-ruili railway. Tunn. Constr. 2021, 41, 419–442. [Google Scholar]

- Hewen, L.; Zhifa, Y.; Hao, Z. Application of comprehensive advanced geological prediction technology in Da-puling tunnel. E3S Web Conf. 2021, 283, 1013. [Google Scholar]

- Ashida, Y. Seismic imaging ahead of a tunnel face with three-component geophones. Int. J. Rock Mech. Min. Sci. 2001, 38, 823–831. [Google Scholar] [CrossRef]

- Gray, S.H.; Etgen, J.; Dellinger, J.; Whitmore, D. Seismic migration problems and solutions. Geophysics 2001, 66, 1622–1640. [Google Scholar] [CrossRef]

- Lu, X.L.; Wang, W.; Yang, C.; Hu, X.; Liao, X.; Fu, Z. Exploring the Influence of Seismic Source and Improvement Methods on Tunnel Seismic Prediction. Lithosphere 2024, 2, 334–348. [Google Scholar] [CrossRef]

- Fu, W.; Zhang, W.; Liu, Z.; Zhao, W.; Lu, S.; Chen, X.; Wang, H.; Cai, S. Study on the Suitability of Advanced Geological Prediction Methods for TBM Tunnel Construction. J. Railw. Eng. Soc. 2023, 94, 81–85. [Google Scholar]

- Liu, B.; Chen, L.; Li, S.C.; Xu, X.J.; Liu, L.B.; Song, J.; Li, M. A new 3D observation system designed for a seismic ahead prospecting method in tunneling. Bull. Eng. Geol. Environ. 2018, 77, 1547–1565. [Google Scholar] [CrossRef]

- Bellino, A.; Garibaldi, L.; Godio, A. An automatic method for data processing of seismic data in tunneling. J. Appl. Geophys. 2013, 98, 243–253. [Google Scholar] [CrossRef]

- Zhang, Y.; Hao, L.; Chen, L.; Xu, X.; Zhang, F. Tunnel-and-surface integrated seismic detection method based on passive and active sources. J. Appl. Geophys. 2024, 222, 105302. [Google Scholar] [CrossRef]

- Masaru, K.; Takeshi, I. Prediction of seismic loadings on wind turbine support structures by response spectrum method considering equivalent modal damping of support structures and reliability level. Wind Energy 2020, 23, 1422–1443. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).