Optimization Study on Stakeholder Capability Configuration in Green Construction

Abstract

:1. Introduction

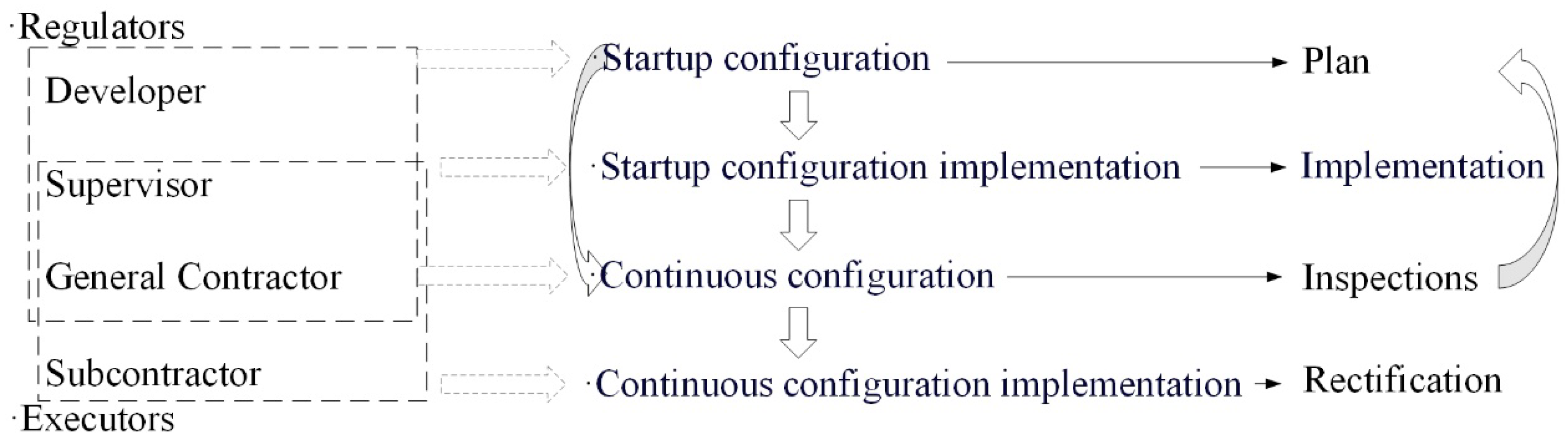

2. Configuration of Capability in Green Construction

3. Methodology

4. Results

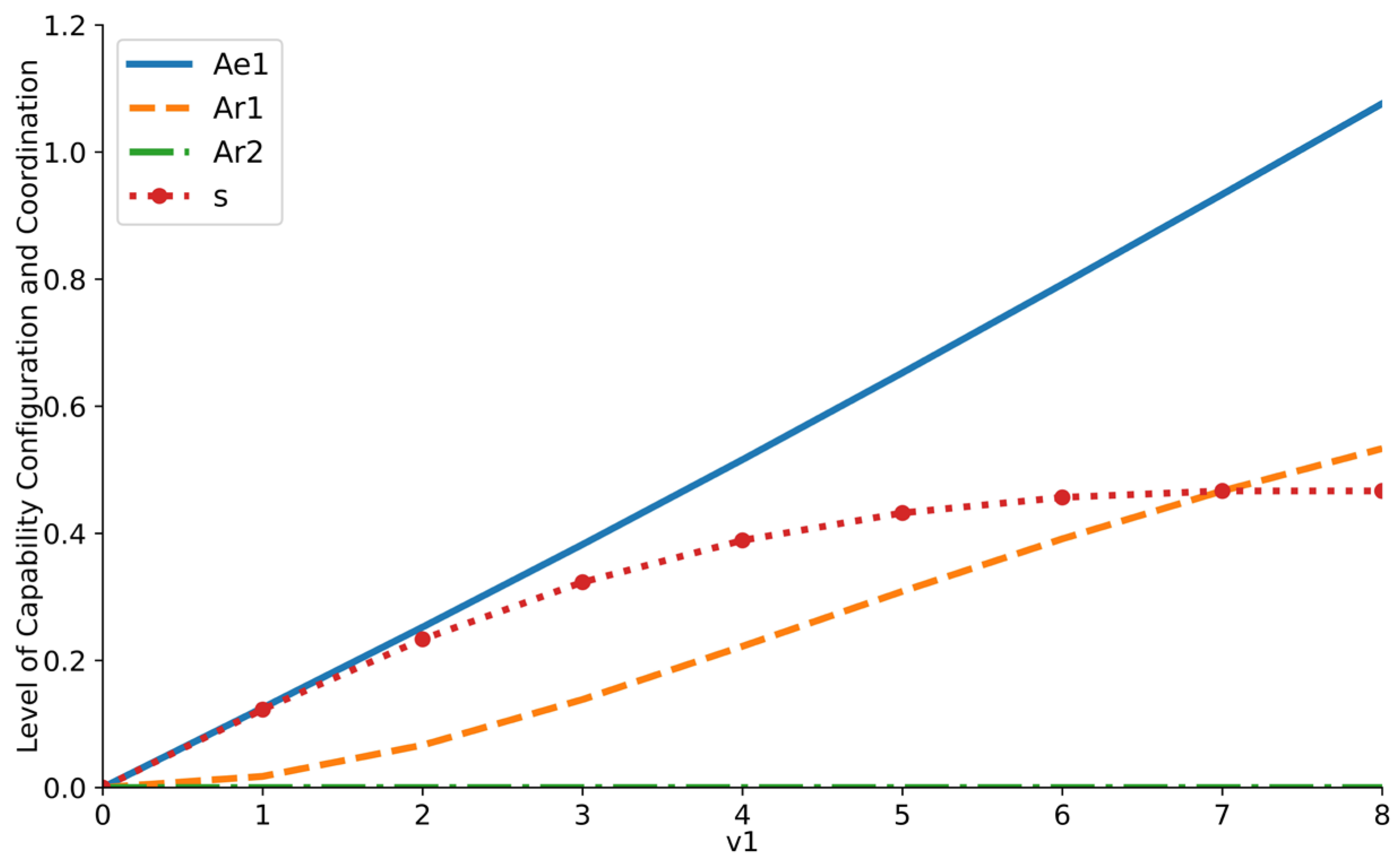

4.1. Results of the Utility Model

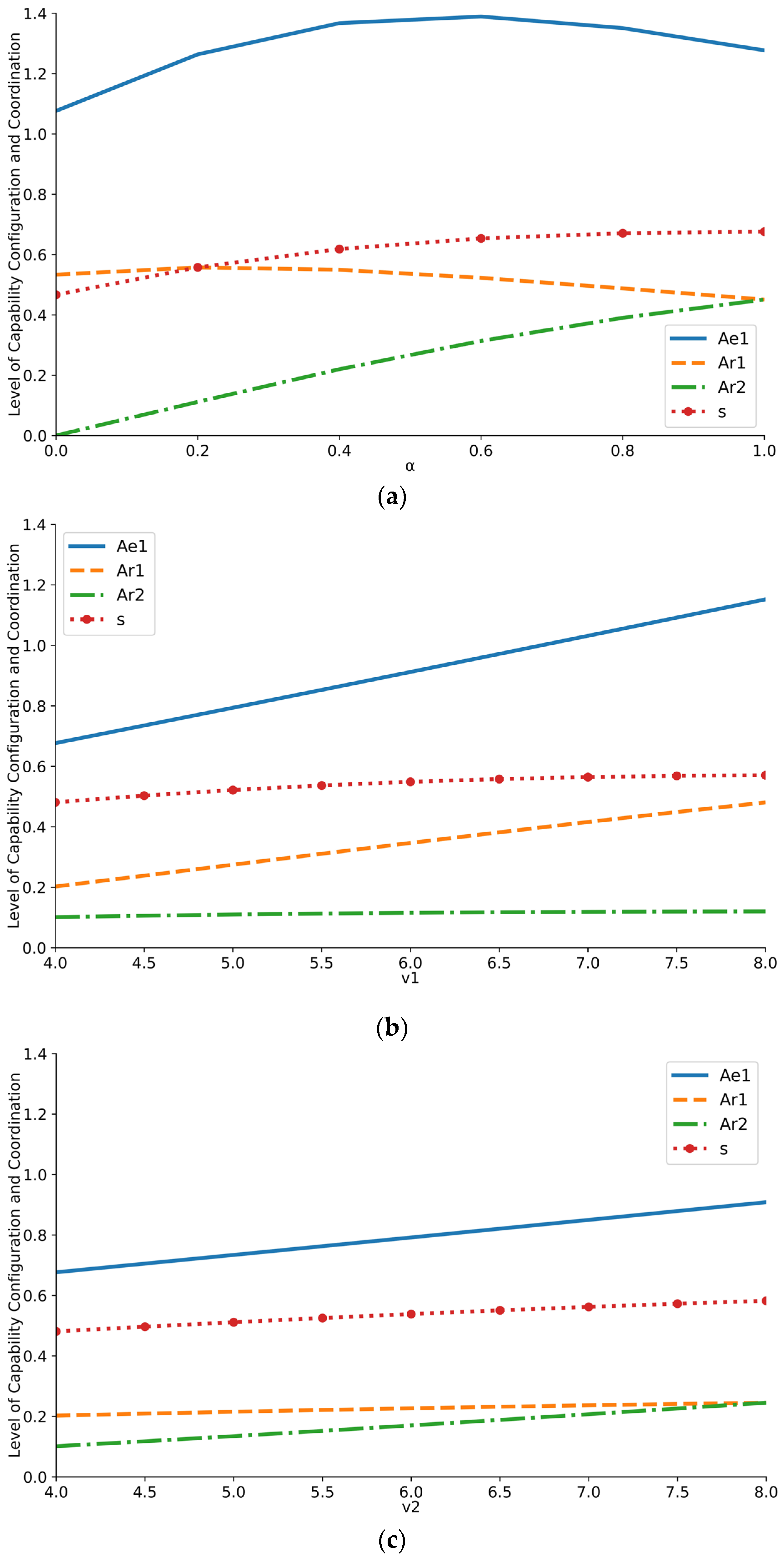

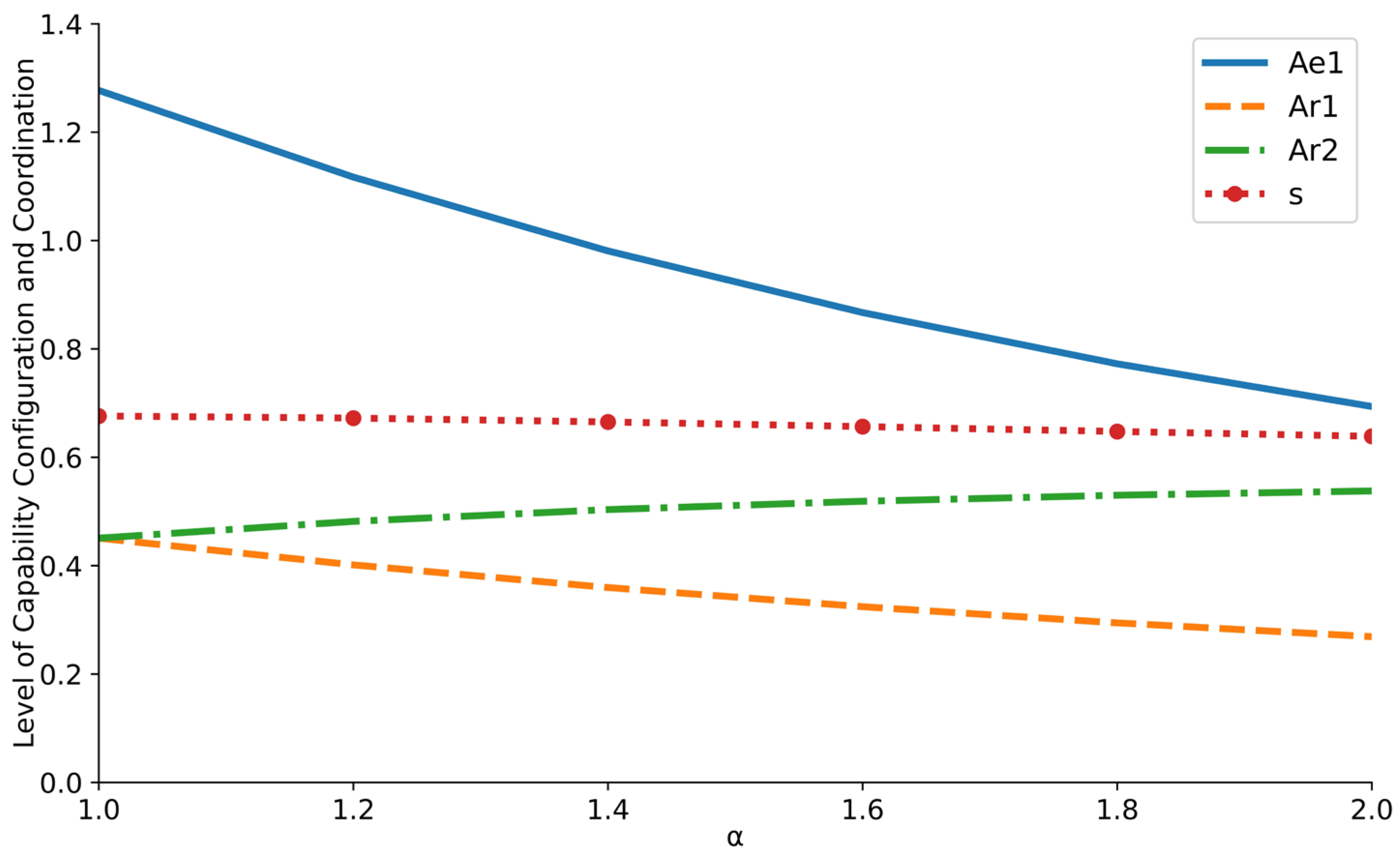

4.2. Static Comparative Analysis

- (1)

- Comparative Static Analysis of the Regulator’s Startup Configuration

- (2)

- Static Comparative Analysis of the Regulator’s Capability Configuration in Continuous Configuration

- (3)

- Static Comparative Analysis of the Synergy Coefficient

4.3. Sensitivity Analysis of the Green Construction Phase

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, X.; Zeng, S.; Zeng, R.; Shi, J.J.; Song, R. Multiple-stakeholders’ game and decision-making behaviors in green management of megaprojects. Comput. Ind. Eng. 2022, 171, 108392. [Google Scholar] [CrossRef]

- Liu, Q.L.; Qiu, Z.X.; Li, M.; Shang, J.P.; Niu, W.C. Evaluation and empirical research on green mine construction in coal industry based on the AHP-SPA model. Resour. Policy 2023, 82, 103503. [Google Scholar] [CrossRef]

- Fitriani, H.; Ajayi, S. Investigation of requisite measures for enhancing sustainable construction practices in Indonesia. Eng. Constr. Archit. Manag. 2023, 30, 2602–2620. [Google Scholar] [CrossRef]

- Shurrab, J.; Hussain, M.; Khan, M. Green and sustainable practices in the construction industry. Eng. Constr. Archit. Manag. 2019, 26, 1063–1086. [Google Scholar] [CrossRef]

- He, W.; Zhang, Y.; Li, S.; Li, W.; Wang, Z.; Liu, P.; Zhang, L.; Kong, D. Reducing betrayal behavior in green building construction: A quantum game approach. J. Clean. Prod. 2024, 463, 142760. [Google Scholar] [CrossRef]

- Shang, H.; Chen, R.; Li, Z. Dynamic sustainability capabilities and corporate sustainability performance: The mediating effect of resource management capabilities. Sustain. Dev. 2019, 28, 595–612. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, G.; He, Y.; Zhang, H. Greenwashing behaviors in construction projects: There is an elephant in the room! Environ. Sci. Pollut. Res. 2022, 29, 64597–64621. [Google Scholar] [CrossRef]

- Pourvaziri, M.; Mahmoudkelayeh, S.; Kamranfar, S.; Fathollahi-Fard, A.M.; Gheibi, M.; Kumar, A. Barriers to green procurement of the Iranian construction industry: An interpretive structural modeling approach. Int. J. Environ. Sci. Technol. 2024, 21, 3599–3616. [Google Scholar] [CrossRef]

- Onubi, H.O.; Yusof, N.; Hassan, A.S. Green construction practices: Ensuring client satisfaction through health and safety performance. Environ. Sci. Pollut. Res. 2022, 29, 5431–5444. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Wang, T.; Gu, X. Collective reputation cognition, network competence and enterprise innovation performance. Manag. Decis. 2022, 60, 567–588. [Google Scholar] [CrossRef]

- Aka, K.G.; Labelle, F. The Collaborative Process of Sustainable Innovations under the Lens of Actor–Network Theory. Sustainability 2021, 13, 10756. [Google Scholar] [CrossRef]

- Zhang, Q.; Oo, B.L.; Lim, B.T.H. Linking corporate social responsibility (CSR) practices and organizational performance in the construction industry: A resource collaboration network. Resour. Conserv. Recycl. 2022, 179, 106113. [Google Scholar] [CrossRef]

- He, Q.; Wang, Z.; Wang, G.; Zuo, J.; Wu, G.; Liu, B. To be green or not to be: How environmental regulations shape contractor greenwashing behaviors in construction projects. Sustain. Cities Soc. 2020, 63, 102462. [Google Scholar] [CrossRef]

- Shi, Q.; Chen, X.; Xiao, C.; Han, Y. Network Perspective in Megaproject Management: A Systematic Review. J. Constr. Eng. Manag. 2022, 148, 03122002. [Google Scholar] [CrossRef]

- Zhang, J.; Ouyang, Y.; Philbin, S.P.; Zhao, X.; Ballesteros-Pérez, P.; Li, H. Green dynamic capability of construction enterprises: Role of the business model and green production. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2920–2940. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, Y.; Li, Z.; Wu, C. Dynamic reward and penalty strategies of green building construction incentive: An evolutionary game theory-based analysis. Environ. Sci. Pollut. Res. 2021, 28, 44902–44915. [Google Scholar] [CrossRef] [PubMed]

- Qin, X.; Wang, Y.; Cui, S.; Liu, S.; Liu, S.; Wangari, V.W. Post-assessment of the eco-environmental impact of highway construction—A case study of Changbai Mountain Ring Road. Environ. Impact Assess. Rev. 2023, 98, 106963. [Google Scholar] [CrossRef]

- Xue, J.; Shen, G.Q.; Yang, R.J.; Zafar, I.; Ekanayake, E.M.A.C.; Lin, X.; Darko, A. Influence of formal and informal stakeholder relationship on megaproject performance: A case of China. Eng. Constr. Archit. Manag. 2020, 27, 1505–1531. [Google Scholar] [CrossRef]

- Derakhshan, R.; Turner, R.; Mancini, M. Project governance and stakeholders: A literature review. Int. J. Proj. Manag. 2019, 37, 98–116. [Google Scholar] [CrossRef]

- Shen, Z.Z.; Min, H.; Wang, L.B.; Zhang, Y.C. Evaluation of Carbon Neutrality Capacity of Regional Construction Industry Based on the Entropy Weight TOPSIS Model. Buildings 2024, 14, 2363. [Google Scholar] [CrossRef]

- Cao, L.F.; Cong, W.Y.; Su, Y.K.; Zheng, Z.Z. Research on the Production Capacity Evaluation of Prefabricated Component Manufacturing Enterprises. Buildings 2024, 14, 1816. [Google Scholar] [CrossRef]

- Luo, W.; Sandanayake, M.; Hou, L.; Tan, Y.; Zhang, G. A systematic review of green construction research using scientometrics methods. J. Clean. Prod. 2022, 366, 132710. [Google Scholar] [CrossRef]

- Gu, J.; Guo, F.; Peng, X.; Wang, B. Green and Sustainable Construction Industry: A Systematic Literature Review of the Contractor’s Green Construction Capability. Buildings 2023, 13, 470. [Google Scholar] [CrossRef]

- Komurlu, R.; Ceceloglu, D.K.; Arditi, D. Exploring the Barriers to Managing Green Building Construction Projects and Proposed Solutions. Sustainability 2024, 16, 5374. [Google Scholar] [CrossRef]

- Sharghi, M.; Jeong, H. The Potential of Recycling and Reusing Waste Materials in Underground Construction: A Review of Sustainable Practices and Challenges. Sustainability 2024, 16, 4889. [Google Scholar] [CrossRef]

- Wu, Y.N.; Al-duais, Z.A.M.; Zhu, X.Q.; Lin, S.Y. Digital economy’s role in shaping carbon emissions in the construction field: Insights from Chinese cities. J. Environ. Manag. 2024, 365, 121548. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Li, X.W.; Ding, Z.Y. Optimal supply chain performance: Risk aversion to green innovation. Manag. Decis. 2024. [Google Scholar] [CrossRef]

- Wang, Y.; Chong, D.; Liu, X. Evaluating the Critical Barriers to Green Construction Technologies Adoption in China. Sustainability 2021, 13, 6510. [Google Scholar] [CrossRef]

- Haniff, A.P.; Galloway, L. Modeling strategic alignment in project networks. Int. J. Proj. Manag. 2022, 40, 517–530. [Google Scholar] [CrossRef]

- Han, W.; Yin, Y. Influence of Project Governance on Opportunistic Behavior: Taking a Dynamic Perspective. Buildings 2022, 12, 1659. [Google Scholar] [CrossRef]

- Alattyih, W.; Haider, H.; Boussabaine, H. Risk Factors Impacting the Project Value Created by Green Buildings in Saudi Arabia. Appl. Sci. 2020, 10, 7388. [Google Scholar] [CrossRef]

- Fu, Y.; Dong, N.; Ge, Q.; Xiong, F.; Gong, C. Driving-paths of green buildings industry (GBI) from stakeholders’ green behavior based on the network analysis. J. Clean. Prod. 2020, 273, 122883. [Google Scholar] [CrossRef]

- Wang, C.; Loo, S.C.; Yap, J.B.H.; Abdul-Rahman, H. Novel Capability-Based Risk Assessment Calculator for Construction Contractors Venturing Overseas. J. Constr. Eng. Manag. 2019, 145, 04019059. [Google Scholar] [CrossRef]

- Chen, C.H. Development of green business strategies through green dynamic capabilities and environmental regulation: Empirical evidence from the construction sector. J. Clean. Prod. 2024, 438, 140826. [Google Scholar] [CrossRef]

- Ninan, J.; Sergeeva, N. Mobilizing Megaproject Narratives for External Stakeholders: A Study of Narrative Instruments and Processes. Proj. Manag. J. 2022, 53, 520–540. [Google Scholar] [CrossRef]

- Gunduz, M.; Elsherbeny, H.A. Critical assessment of construction contract administration using fuzzy structural equation modeling. Eng. Constr. Archit. Manag. 2020, 27, 1233–1255. [Google Scholar] [CrossRef]

- Li, Y.; Lu, Y.; Cui, Q.; Han, Y. Organizational Behavior in Megaprojects: Integrative Review and Directions for Future Research. J. Manag. Eng. 2019, 35, 04019009. [Google Scholar] [CrossRef]

- Gondia, A.; Ezzeldin, M.; El-Dakhakhni, W. Dynamic networks for resilience-driven management of infrastructure projects. Autom. Constr. 2022, 136, 104149. [Google Scholar] [CrossRef]

- Xie, L.; Xu, T.; Han, T.; Xia, B.; Chen, Q.; Skitmore, M. Influence of Institutional Pressure on Megaproject Social Responsibility Behavior. J. Civ. Eng. Manag. 2022, 28, 177–195. [Google Scholar] [CrossRef]

- Zeng, X.C.; Li, S.C.; Yin, S.; Xing, Z.Y. How Does the Government Promote the Collaborative Innovation of Green Building Projects? An Evolutionary Game Perspective. Buildings 2022, 12, 1179. [Google Scholar] [CrossRef]

- Wang, Y.C.; Guo, J.Y.; Geng, X.X.; Li, W. Research on Coupling Effect Measurement and Coupling Risk Simulation of Green Building Construction Safety Risk Factors. Buildings 2024, 14, 2195. [Google Scholar] [CrossRef]

- Tsukada, S. Hypothesis testing for mean vector and covariance matrix of multi-populations under a two-step monotone incomplete sample in large sample and dimension. J. Multivar. Anal. 2024, 202, 105290. [Google Scholar] [CrossRef]

- Abrudan, D.B.; Rafi, N.; Daianu, D.C.; Kalyar, M.N. Linking green intellectual capital with green innovation: Examining the roles of green dynamic capabilities and ‘motivation to achieve legitimacy’. Agric. Econ. (Zeměd. Ekon.) 2022, 68, 250–258. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, D.L.; Xu, H.F.; Zhang, S.N. Distributional utility preference robust optimization models in multi-attribute decision making. Math. Program. 2024, 1–47. [Google Scholar] [CrossRef]

- Ashill, N.; Williams, P.; Khan, M.S.; Naumann, E. Dynamic and Ordinary Capabilities: A Project Management Perspective. IEEE Trans. Eng. Manag. 2022, 69, 2173–2186. [Google Scholar] [CrossRef]

- Wang, L.Z.; Wang, X.N.; Liu, X.M. Project Governance and Governance of Interorganizational Project Networks: Toward Understanding Their Relationships and Future Research Agenda. Proj. Manag. J. 2024. [Google Scholar] [CrossRef]

- Li, J.; Wu, Q.; Wang, C.C.; Du, H.; Sun, J. Triggering factors of construction waste reduction behavior: Evidence from contractors in Wuhan, China. J. Clean. Prod. 2022, 337, 130396. [Google Scholar] [CrossRef]

| Research Topics | Responses to Promote Green Construction Success | |

|---|---|---|

| Capability (%) | Others (%) | |

| Systematic assessment of elements to overcome barriers to green construction [22] | 75.0 | 25.0 |

| Drivers of green construction capability implementation [23] | 100.0 | 0 |

| Measures to overcome barriers to green construction management [24] | 90.0 | 10.0 |

| Research on the standardisation of green construction [25] | 67.0 | 33.0 |

| Management of carbon emissions during the construction phase [26] | 80.0 | 20.0 |

| How to drive green construction practices [9] | 100.0 | 0 |

| Addressing risks in green construction [27] | 88.0 | 12.0 |

| Addressing barriers to the adoption of green construction technologies [28] | 67.0 | 33.0 |

| Parameter | Description |

|---|---|

| The capability input level of the executor in advancing startup configuration. | |

| The capability input level of the executor in advancing continuous configuration. | |

| The progressive coefficient of the executor in advancing startup configuration and continuous configuration. | |

| The marginal value obtained by the executor during the advancement of startup configuration. | |

| The marginal value obtained by the executor during the advancement of continuous configuration. | |

| The construction plan and the exogenous variables affecting the executor’s losses in green construction. | |

| , | External uncertainty factors. |

| The output benefit of the executor in green construction. In which, are the benefit functions for advancing startup configuration and continuous configuration, respectively. | |

| Strength of regulators’ guidance to implementers in developing programmes and green construction, respectively. | |

| Random errors in the guidance process. | |

| External uncertainty factors in random errors. | |

| The dynamic guidance support that the executor receives in green construction. | |

| The synergy coefficient. | |

| The risk aversion coefficient. | |

| The benefits obtained by the executor. | |

| Utility of the capability of executors. | |

| and | The fixed inputs for advancing startup configuration and continuous configuration, respectively. |

| and | The variable cost coefficients for advancing startup configuration and continuous configuration, respectively. |

| The input costs of executors. | |

| The risk cost for the executor. | |

| The cost of supervision and guidance borne by the regulators. | |

| and | The average costs for establishing cooperative processes and for guiding and supervising in green construction, respectively. |

| and | The fixed incentive rewards provided by the regulator to the executor. |

| and | The capabilities invested by the regulator in startup configuration and continuous configuration, respectively. |

| The benefits obtained by the executor in green construction. | |

| The expected benefit of executors. | |

| Benefits gained by regulators. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.; Su, Y.; Liu, J.; Zhou, Z.; Wang, X. Optimization Study on Stakeholder Capability Configuration in Green Construction. Buildings 2024, 14, 3135. https://doi.org/10.3390/buildings14103135

Zheng Z, Su Y, Liu J, Zhou Z, Wang X. Optimization Study on Stakeholder Capability Configuration in Green Construction. Buildings. 2024; 14(10):3135. https://doi.org/10.3390/buildings14103135

Chicago/Turabian StyleZheng, Zhizhe, Yikun Su, Junhao Liu, Zhichao Zhou, and Xing Wang. 2024. "Optimization Study on Stakeholder Capability Configuration in Green Construction" Buildings 14, no. 10: 3135. https://doi.org/10.3390/buildings14103135