In-Plane Mechanical Properties Test of Prefabricated Composite Wall with Light Steel and Tailings Microcrystalline Foamed Plate

Abstract

:1. Introduction

2. Experimental Design

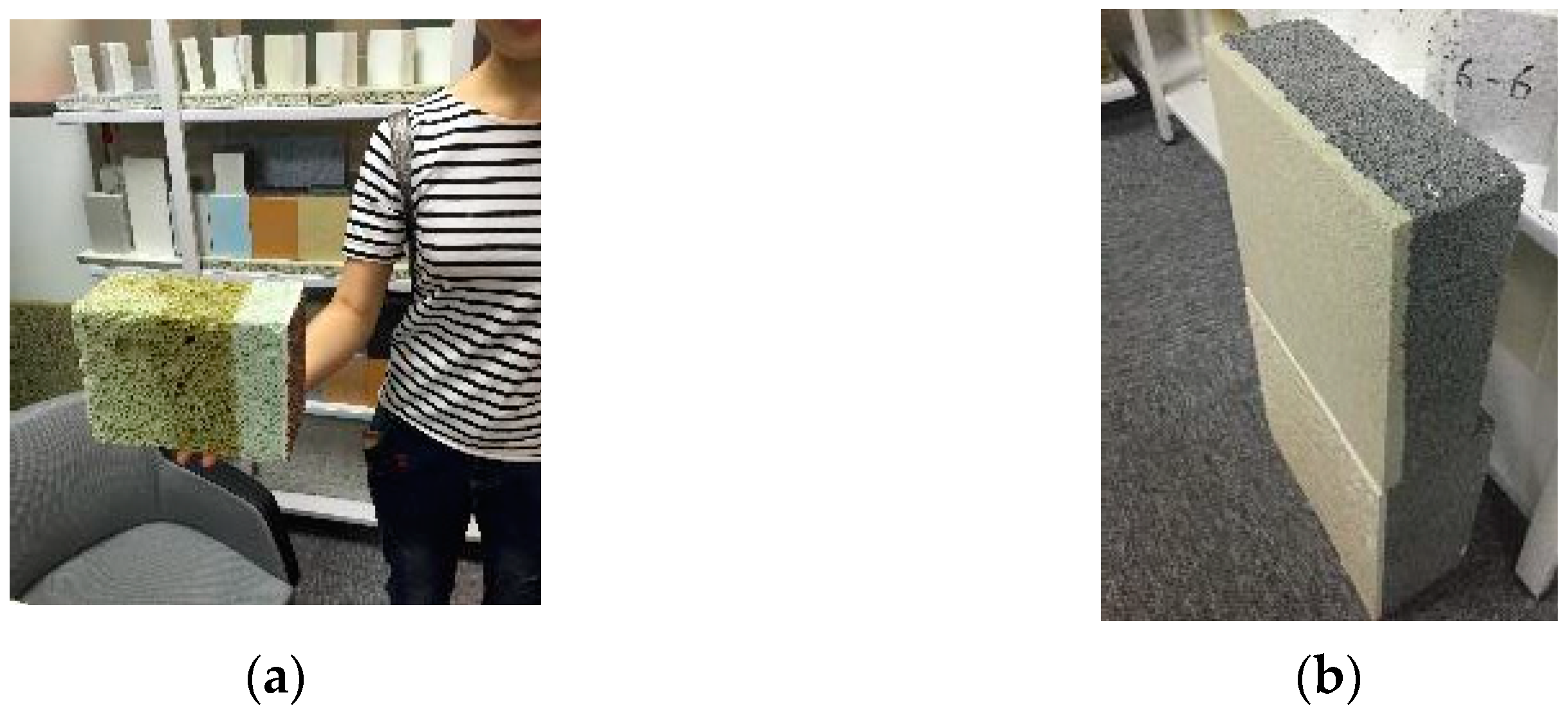

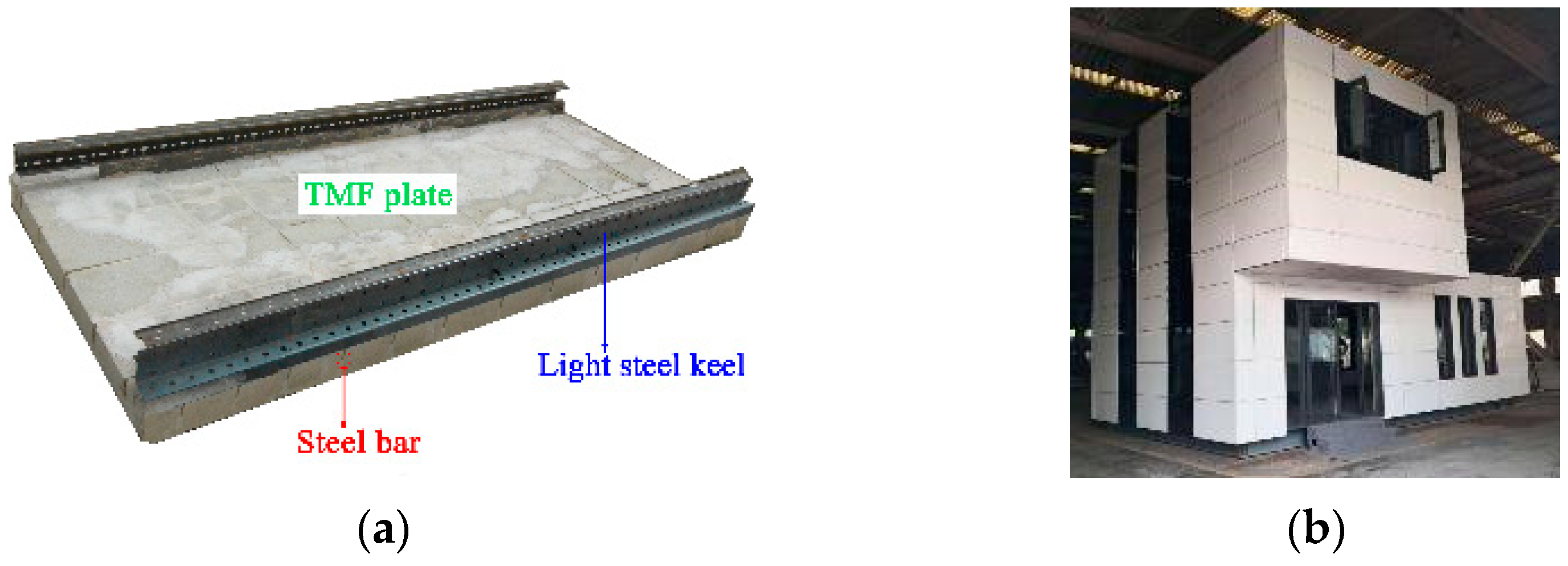

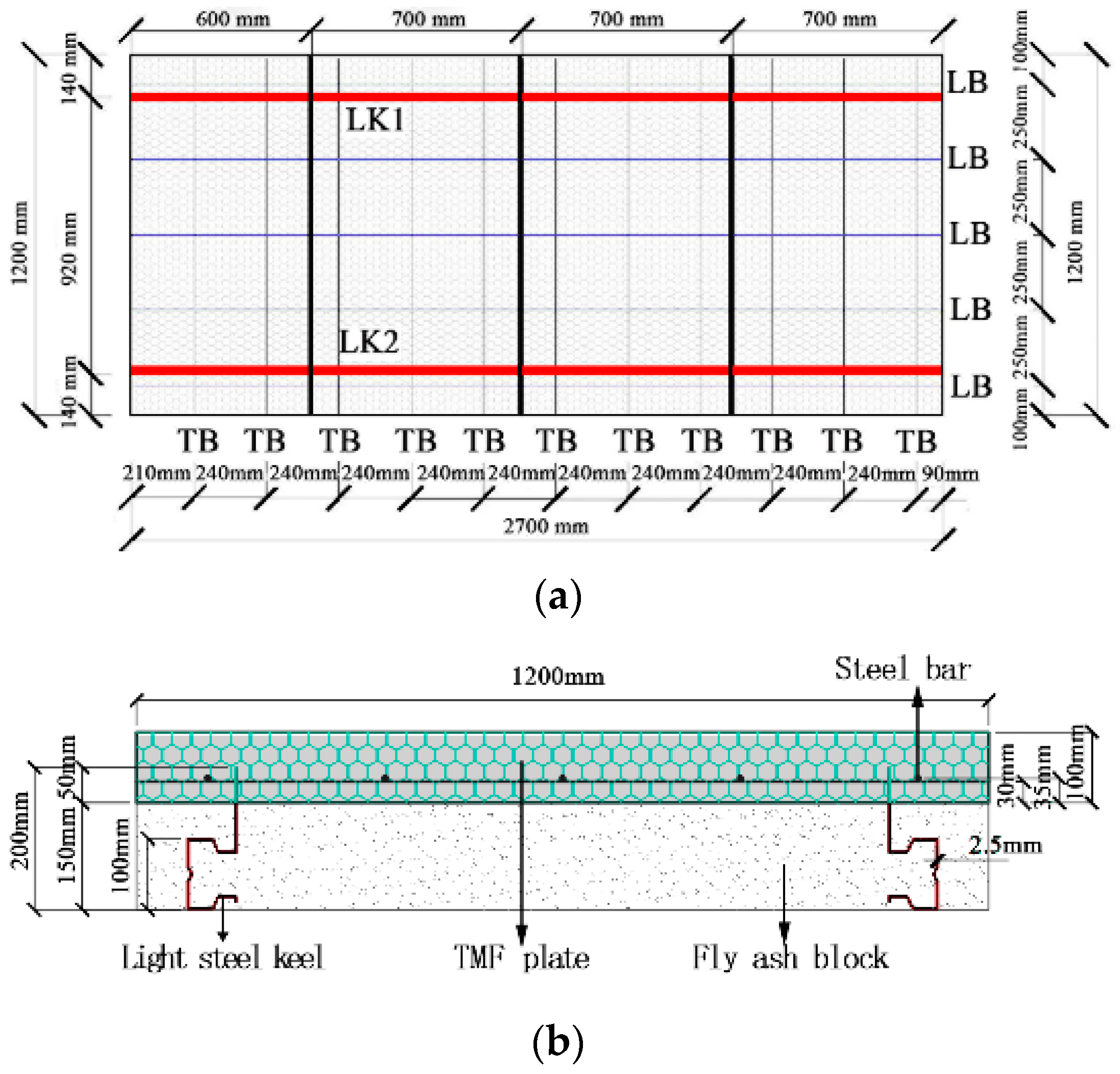

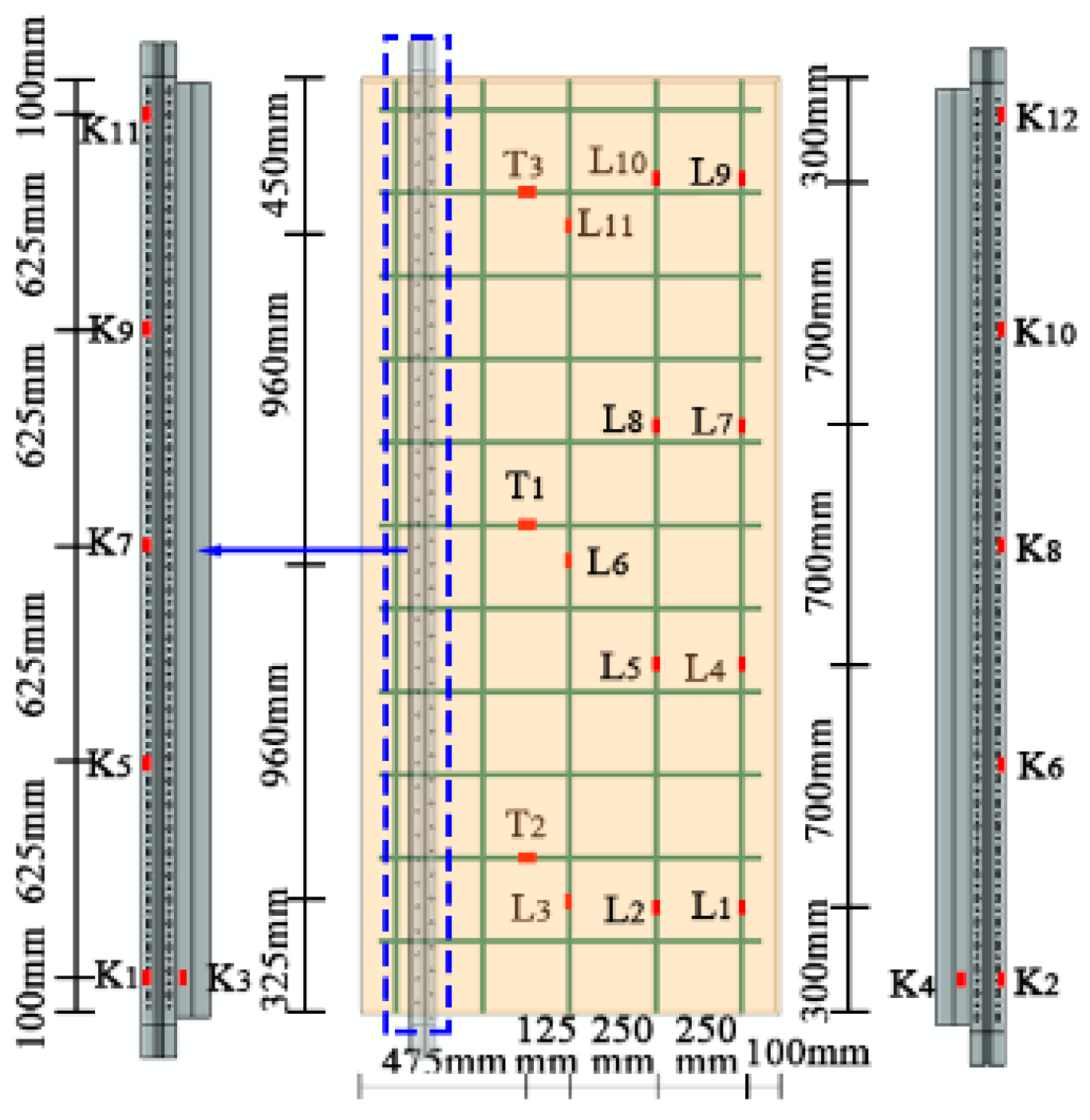

2.1. Test Specimen Design

2.2. Measured Mechanical Properties of Materials

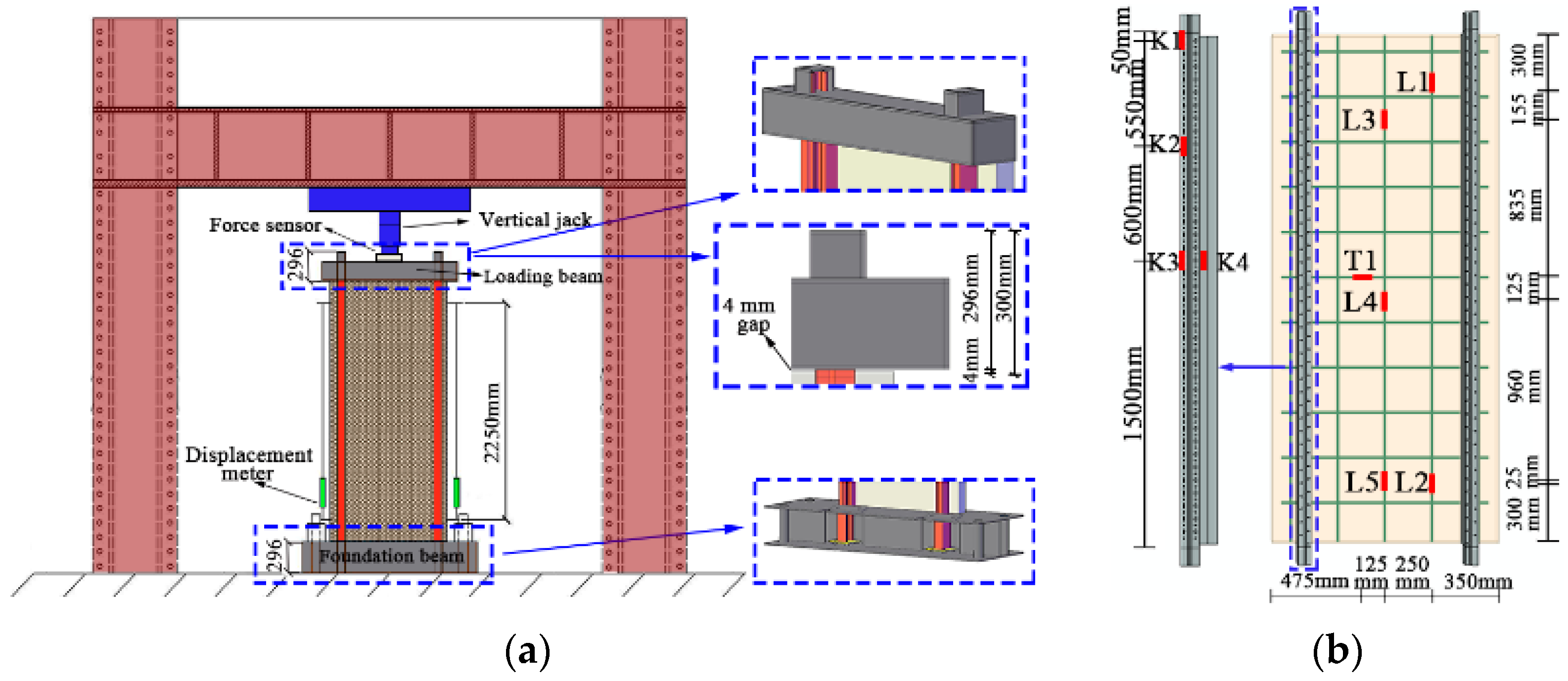

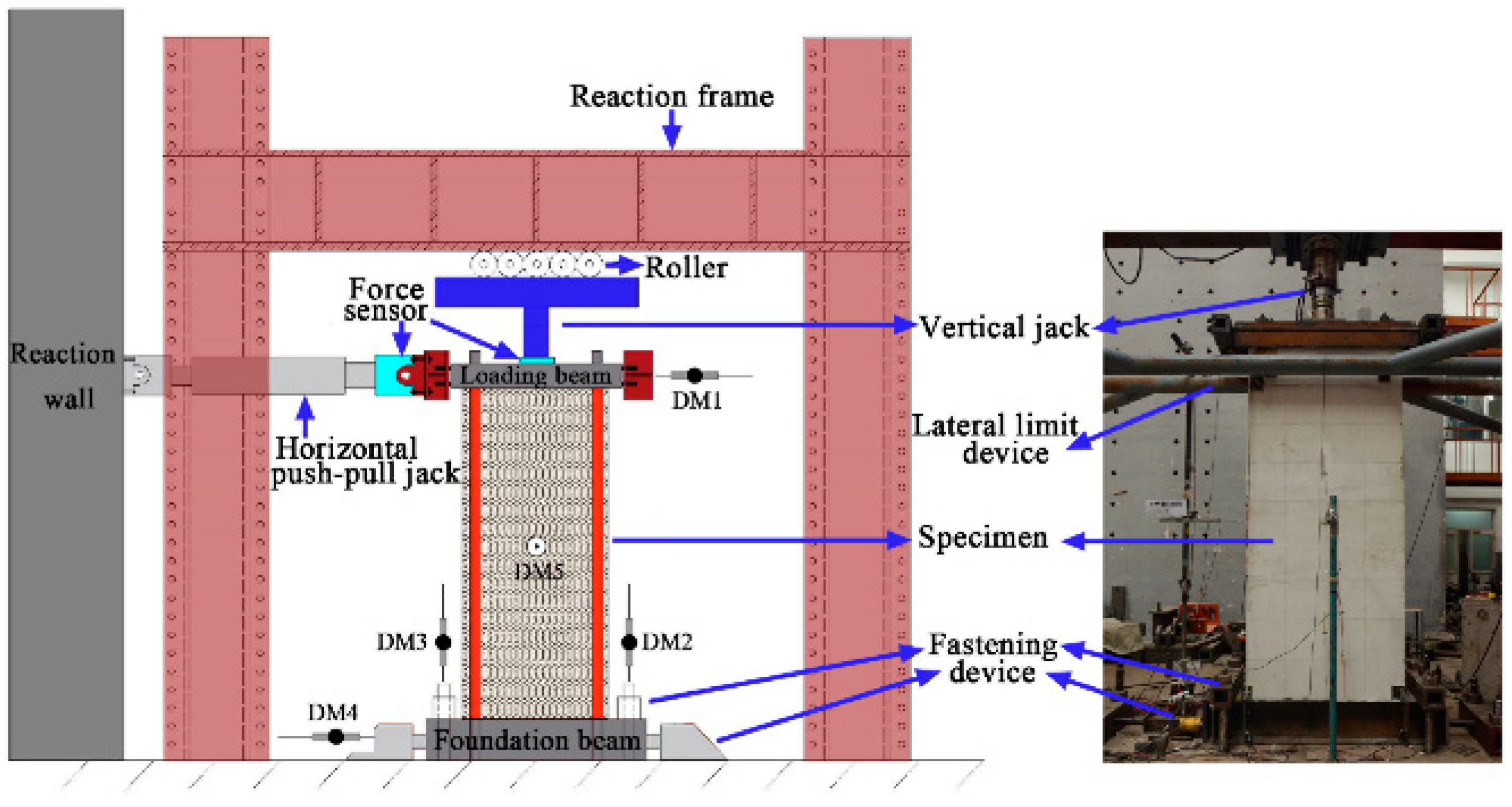

2.3. Loading Device and Test Scheme

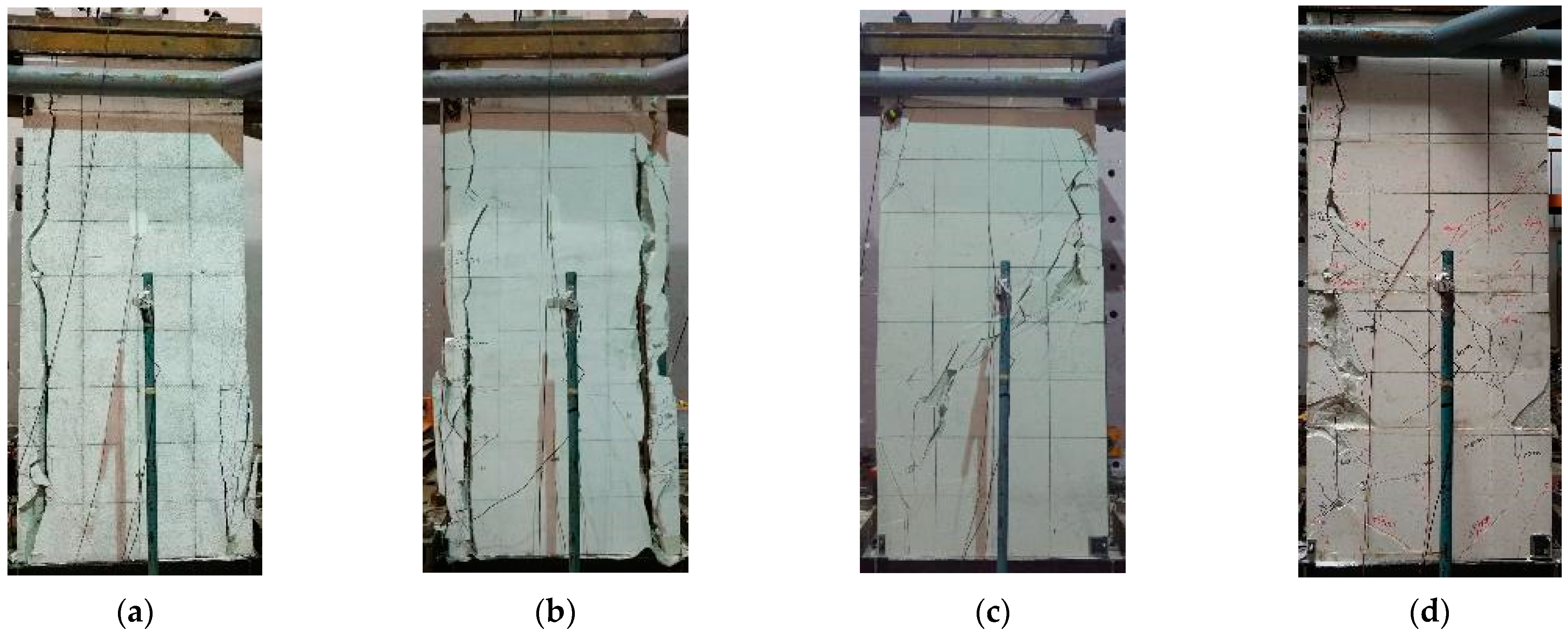

3. Damage Process and Failure Characteristics of Specimens

3.1. Compression Performance Test

3.2. Seismic Performance Test

4. Test Results and Analysis

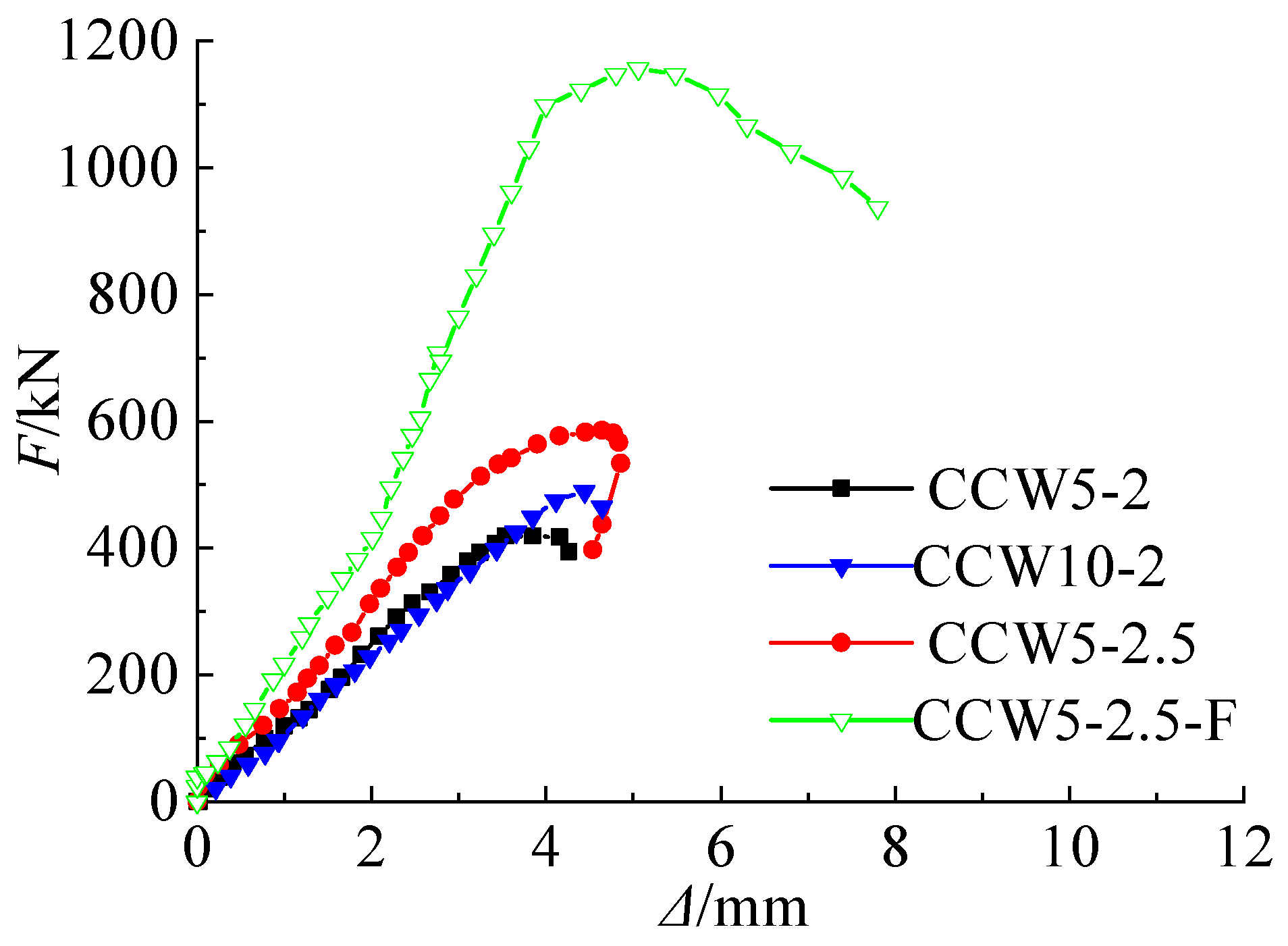

4.1. Analysis of Compression Test Results

4.1.1. Load-Displacement Curve of Compression Test

4.1.2. Bearing Capacity of Compression Test

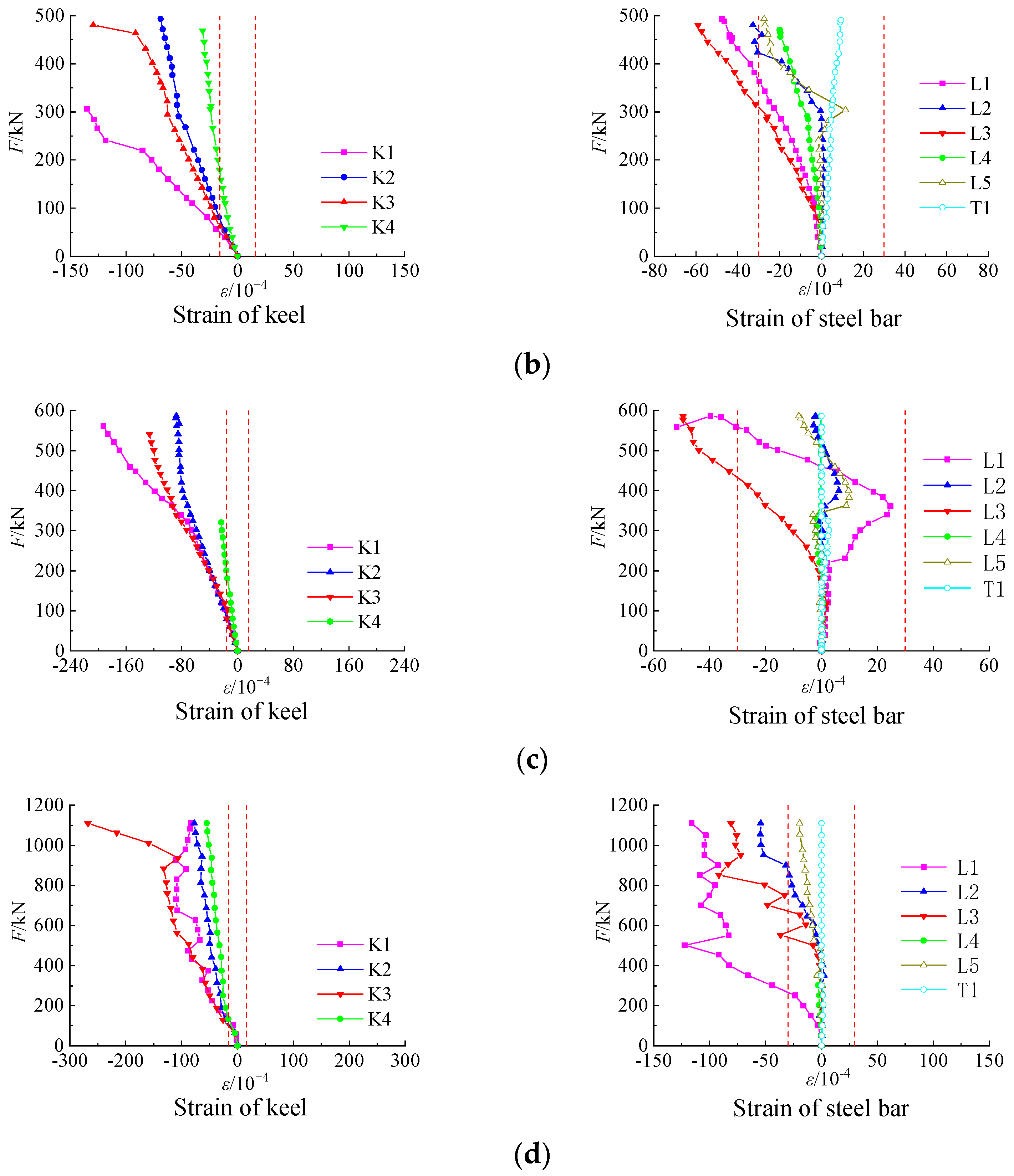

4.1.3. Strain Analysis of Compression Test

4.1.4. Formula for Compressive Bearing Capacity

4.2. Analysis of Seismic Test Results

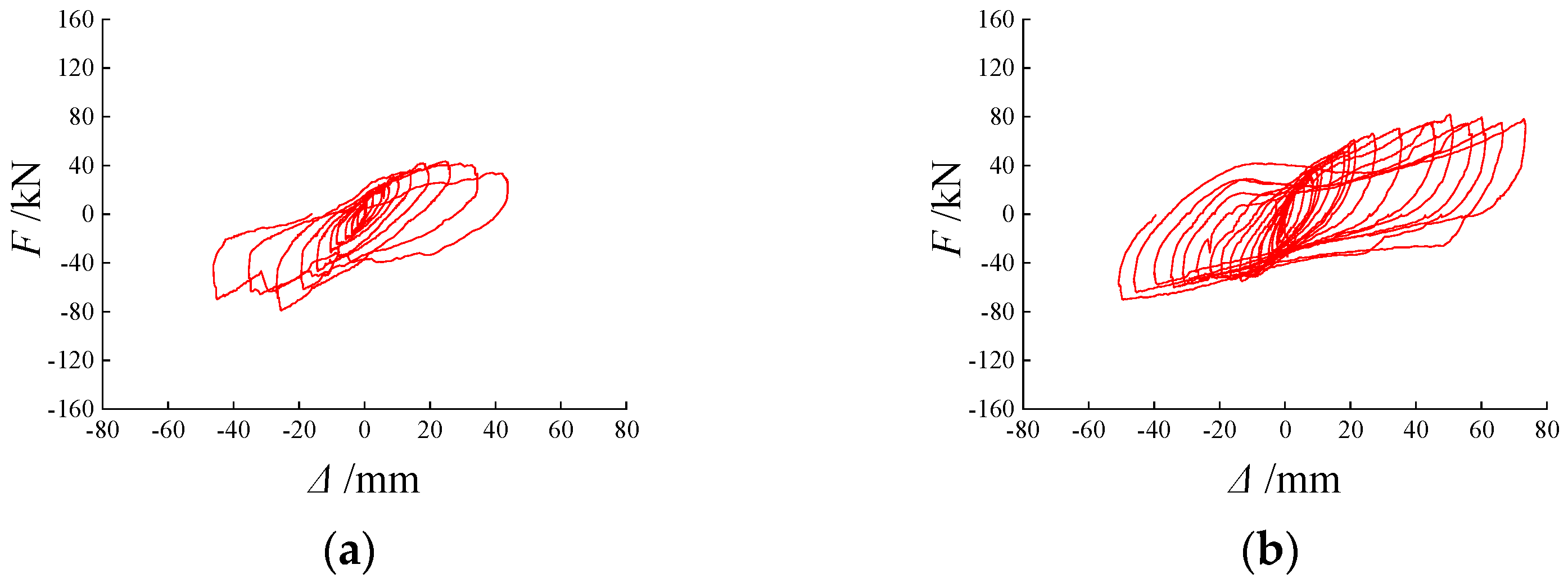

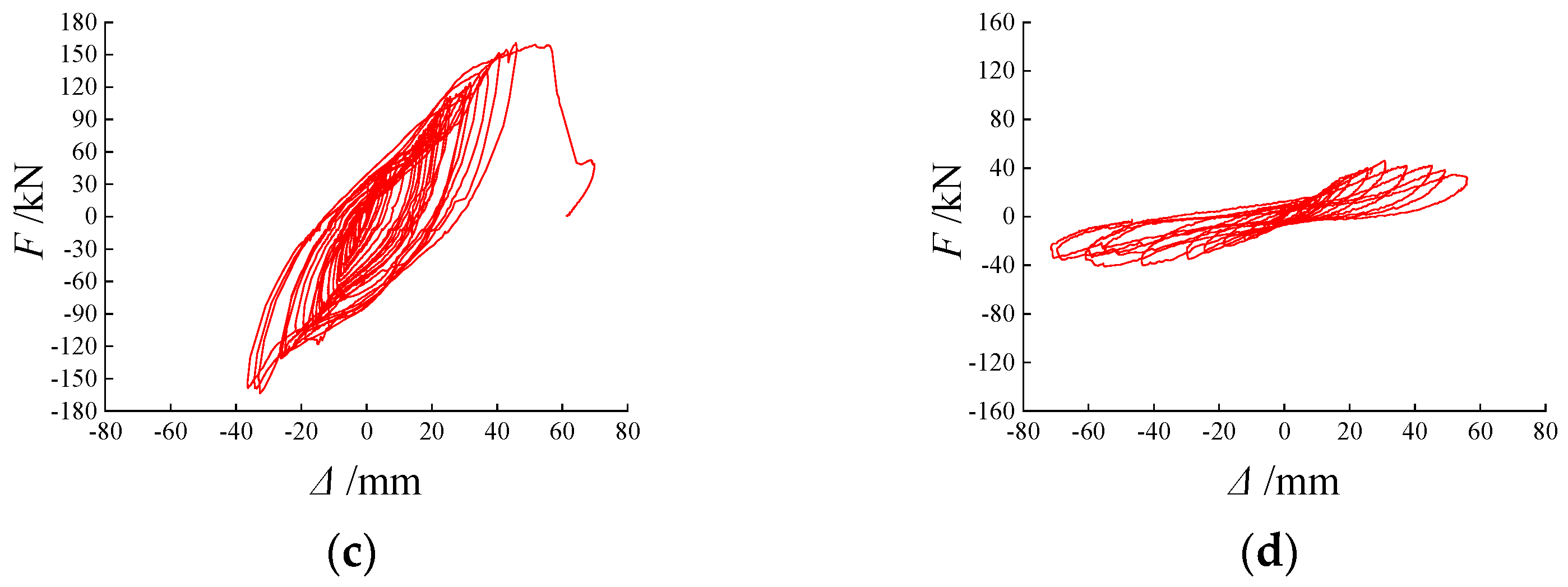

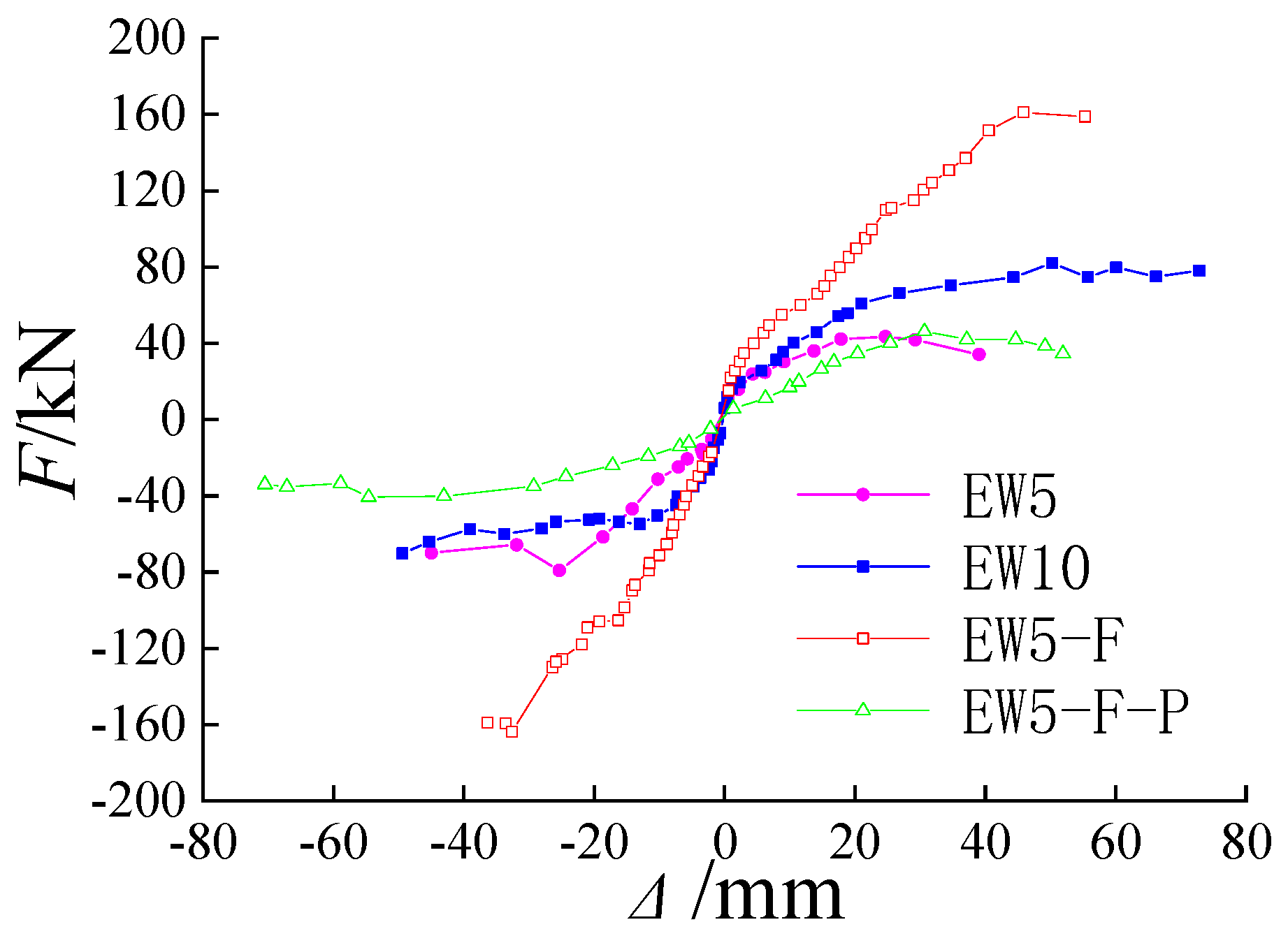

4.2.1. Load-Displacement Curve of Seismic Test

4.2.2. Bearing Capacity of Seismic Test

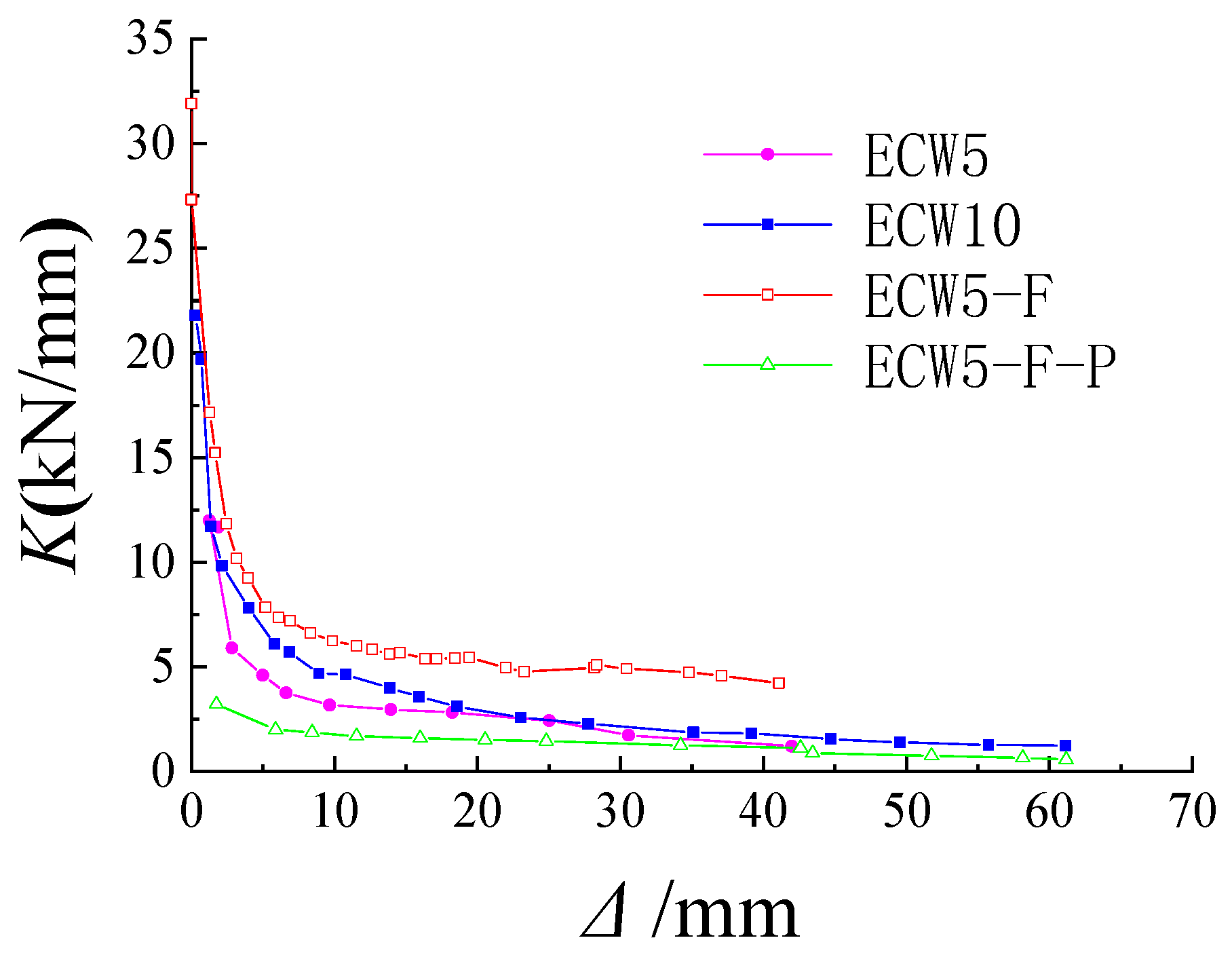

4.2.3. Stiffness Degradation

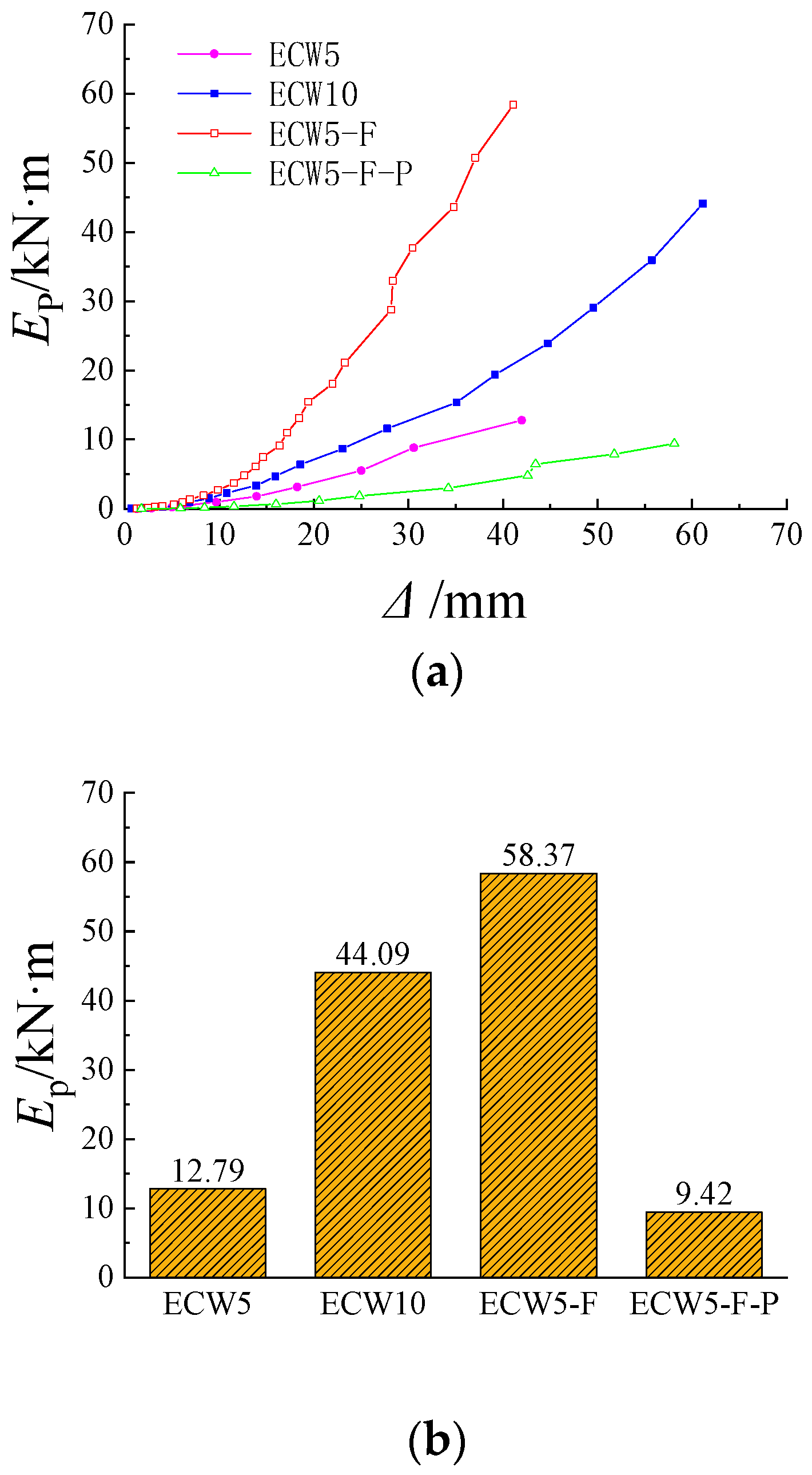

4.2.4. Energy Dissipation

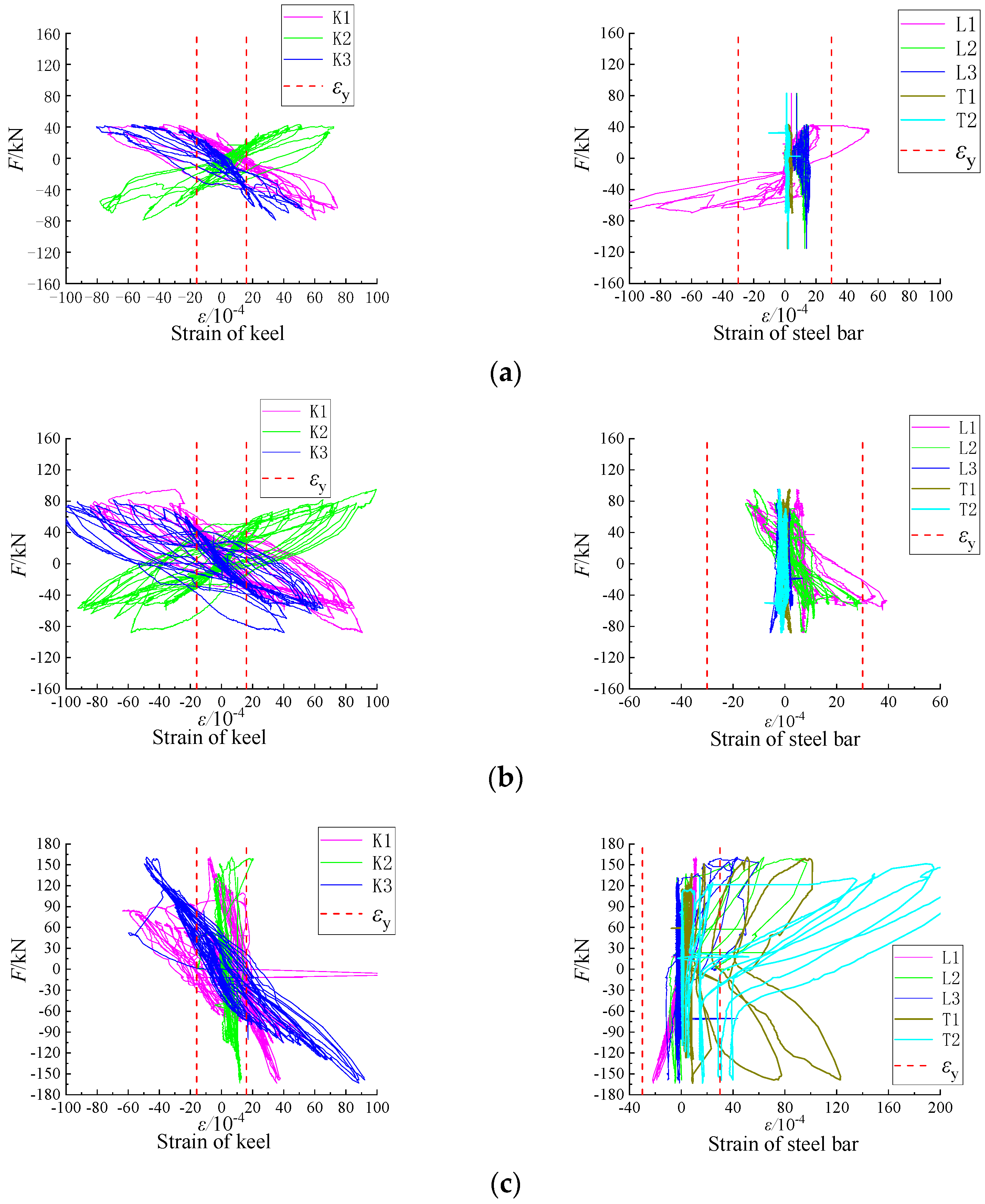

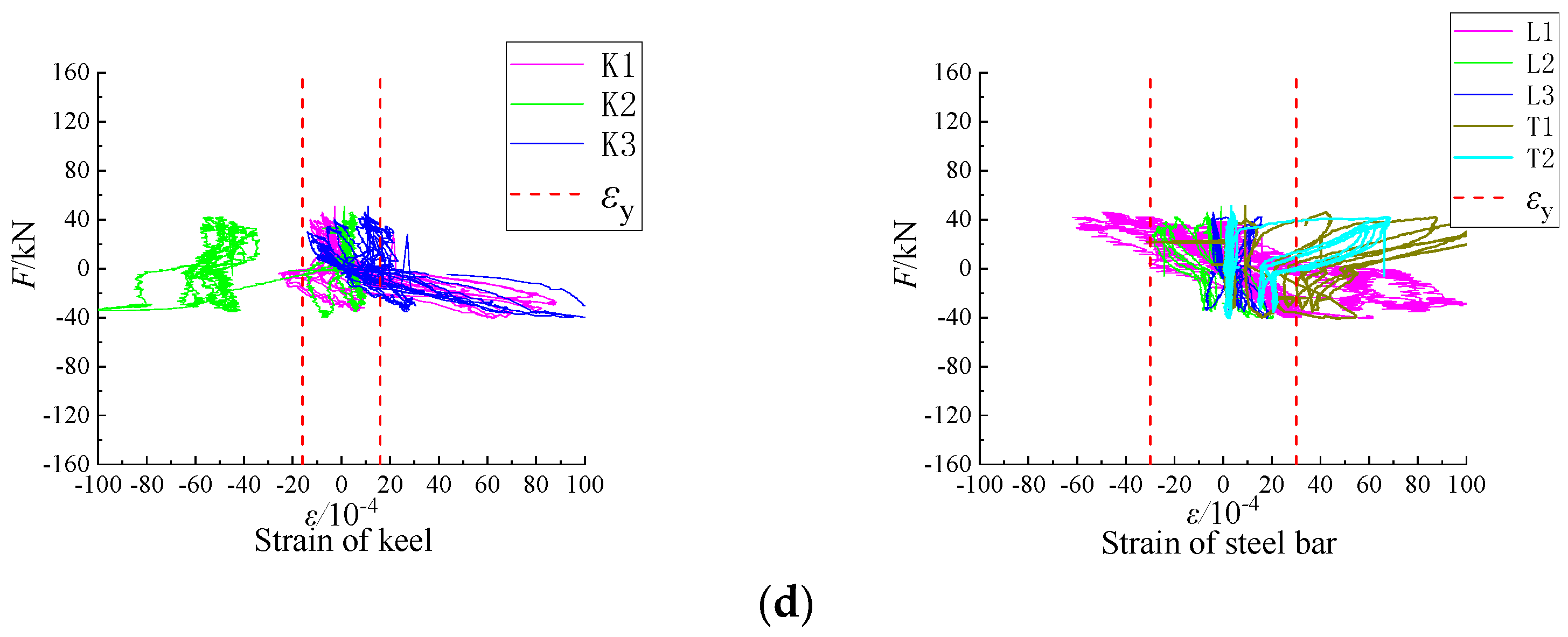

4.2.5. Strain Analysis of Seismic Test

5. Conclusions

- (1)

- The light steel keel, steel bar, and TMF plate in the composite wall demonstrated good working performance. The light steel keel served as the primary load-bearing component. The interaction between the TMF plate and the light steel keel enhanced the stability of the keel. Increasing the thickness of the light steel keel significantly improved the composite wall’s ultimate bearing capacity and stability. Strengthening the TMF plate enhanced the restraint on the light steel keel and improved the composite wall’s compressive performance. When the composite wall was filled with fly ash blocks, its compression performance was significantly improved, with the ultimate bearing capacity of CCW5-2.5-F increasing by 90.37% compared to CCW5-2.5. When designing the compressive bearing capacity of composite walls, it was recommended to calculate the compressive bearing capacity of the light steel keel based on the strength calculation formula.

- (2)

- Under horizontal seismic action, failure typically occurred at the location where the light steel keel was embedded in the TMF plate. Improving the TMF plate’s strength enhanced its restraint on the light steel keel, leading to increased horizontal bearing capacity, stiffness, and energy dissipation capacity of the composite wall. Specifically, the horizontal ultimate load, initial stiffness, and cumulative energy dissipation of the ECW10 specimen were 1.24 times, 1.86 times, and 3.45 times those of the ECW5 specimen, respectively.

- (3)

- After filling fly ash blocks between the keels, the restraint effect on the keels was enhanced, resulting in a change in damage pattern from vertical through crack failure to shear oblique crack failure. The combination of fly ash blocks, light steel keels, and TMF plates significantly improved the horizontal bearing capacity, stiffness, and energy dissipation of the composite wall. Specifically, the horizontal ultimate load, initial stiffness, and cumulative energy consumption of the ECW5-F specimen were 2.65 times, 2.73 times, and 4.56 times those of the ECW5 specimen, respectively. This structural configuration—incorporating light steel keels, TMF plates, and fly ash blocks—improved thermal insulation and enhanced in-plane stress performance.

- (4)

- When a splicing structure was used for the TMF plate, its overall integrity was compromised. This led to a weakened restraint capability of the light steel keel and a reduction in the composite wall’s horizontal bearing capacity, stiffness, and energy dissipation capacity. The ultimate load, initial stiffness, and cumulative energy dissipation of the ECW5-F-P specimen were 0.71 times, 0.26 times, and 0.74 times those of the ECW5 specimen, respectively. The splicing plate structure adversely affected the seismic performance of the composite wall, making it unsuitable for seismic design applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency (IEA). Buildings. Available online: https://www.iea.org/reports/buildings (accessed on 24 September 2024).

- Mallum, I.; Mohd.Sam, A.R.; Lim, N.H.A.S.; Omolayo, N. Sustainable Utilization of Waste Glass in Concrete: A Review. Silicon 2021, 14, 3199–3214. [Google Scholar] [CrossRef]

- Shi, J.; Li, Q.; Li, H.; Li, S.; Zhang, J.; Shi, Y. Eco-design for recycled products: Rejuvenating mullite from coal fly ash. Resour. Conserv. Recycl. 2017, 124, 67–73. [Google Scholar] [CrossRef]

- Dong, H.; Qin, J.; Cao, W.; Yang, L.; Yin, F.; Wang, R. Shaking table tests on concrete-filled steel tubular-framed building assembled with microcrystalline foam boards. Structures 2021, 34, 2098–2114. [Google Scholar] [CrossRef]

- Llantoy, N.; Chàfer, M.; Cabeza, L.F. A comparative life cycle assessment (LCA) of different insulation materials for buildings in the continental Mediterranean climate. Energy Build. 2020, 225, 110323. [Google Scholar] [CrossRef]

- Ameri, F.; Zareei, S.A.; Behforouz, B. Zero-cement vs. cementitious mortars: An experimental comparative study on engineering and environmental properties. J. Build. Eng. 2020, 32, 101620. [Google Scholar] [CrossRef]

- Deng, F.; Wang, F.; Shi, X.; Liu, L.; Liao, Q. Synthesis and properties of foam glass-ceramics from granite tailings by using SiC and MnO2 as the mixed foaming agent. Ceram. Int. 2023, 49, 34647–34656. [Google Scholar] [CrossRef]

- Fernandes, H.R.; Tulyaganov, D.U.; Ferreira, J.M.F. Production and characterisation of glass ceramic foams from recycled raw materials. Adv. Appl. Ceram. 2009, 108, 9–13. [Google Scholar] [CrossRef]

- Fernandes, H.R.; Tulyaganov, D.U.; Ferreira, J.M.F. Preparation and characterization of foams from sheet glass and fly ash using carbonates as foaming agents. Ceram. Int. 2009, 35, 229–235. [Google Scholar] [CrossRef]

- Francis, A.A.; Abdel Rahman, M.K. Experimental design for optimisation of density and water absorption capacity of glass–ceramic foams prepared from silica rich wastes. Powder Metall. 2013, 56, 295–303. [Google Scholar] [CrossRef]

- Ding, L.; Ning, W.; Wang, Q.; Shi, D.; Luo, L. Preparation and characterization of glass-ceramic foams from blast furnace slag and waste glass. Mater. Lett. 2015, 141, 327–329. [Google Scholar] [CrossRef]

- Ivanov, K.S. Extrusion Method for Producing Microgranular Foam-Glass Ceramic from Zeolite Rocks. Refract. Ind. Ceram. 2021, 62, 157–161. [Google Scholar] [CrossRef]

- Yio, M.H.; Xiao, Y.; Ji, R.; Russell, M.; Cheeseman, C. Production of foamed glass-ceramics using furnace bottom ash and glass. Ceram. Int. 2021, 47, 8697–8706. [Google Scholar] [CrossRef]

- Karamanov, A.; Hamzawy, E.M.; Karamanova, E.; Jordanov, N.B.; Darwish, H. Sintered glass-ceramics and foams by metallurgical slag with addition of CaF2. Ceram. Int. 2020, 46, 6507–6516. [Google Scholar] [CrossRef]

- Gao, H.T.; Liu, X.H.; Chen, J.Q.; Qi, J.L.; Wang, Y.B.; Ai, Z.R. Preparation of glass-ceramics with low density and high strength using blast furnace slag, glass fiber and water glass. Ceram. Int. 2018, 44, 6044–6053. [Google Scholar] [CrossRef]

- Vereshagin, V.I.; Sokolova, S.N. Granulated foam glass–ceramic material from zeolitic rocks. Constr. Build. Mater. 2008, 22, 999–1003. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, H.; Luan, L.; Xu, X.; Liu, Y.; Du, X. Three failure modes of High-Strength Steel (HSS) perfobond connector embedded in UHPC. Eng. Struct. 2023, 286, 116147. [Google Scholar] [CrossRef]

- Hao, Y.; Qin, L.; He, X.; Su, T.; Sun, H.; Wang, H. Experimental study on seismic behavior of fabricated lightweight steel solid waste High-strength foam concrete composite wall. Structures 2023, 52, 921–932. [Google Scholar] [CrossRef]

- Nicoletti, V.; Arezzo, D.; Carbonari, S.; Gara, F. Detection of infill wall damage due to earthquakes from vibration data. Earthq. Eng. Struct. Dyn. 2022, 52, 460–481. [Google Scholar] [CrossRef]

- Furtado, A.; Rodrigues, H.; Rodrigues, M.F.; Arêde, A.; Varum, H. A novel holistic approach for the seismic-energy performance assessment of masonry infill walls. Soil Dyn. Earthq. Eng. 2023, 173, 108129. [Google Scholar] [CrossRef]

- GB/T 5486-2008; Test Method for Inorganic Hard Insulation Products. Standards Press of China: Beijing, China, 2008.

- Bian, J.; Cao, W.; Yang, L.; Xiong, C. Experimental Research on the Mechanical Properties of Tailing Microcrystalline Foam Glass. Materials 2018, 11, 2048. [Google Scholar] [CrossRef]

- GB/T228-2002; Metallic Materials-Tensile Testing at Ambient Temperature. China Architecture & Building Press: Beijing, China, 2002.

- GB/T 11969-2008; Test Method of Autoclaved Aerated Concrete. Standards Press of China: Beijing, China, 2008.

- GB 50018-2002; Technical Code of Cold-Formed Thin-Walled Steel Structures. China Planning Press: Beijing, China, 2002.

- Bian, J.; Cao, W.; Qiao, Q.; Zhang, J. Experimental and numerical studies of prefabricated structures using CFST frame and composite wall. J. Build. Eng. 2022, 48, 103886. [Google Scholar] [CrossRef]

| Type of Test | Specimen | B/mm | H/mm | b/mm | h/mm | L/mm | t/mm | TMF Plate Strength | Fly Ash Block | Spliced TMF Plate |

|---|---|---|---|---|---|---|---|---|---|---|

| Compression test | CCW5-2 | 1200 | 100 | 70 | 150 | 2700 | 2.0 | A5 | No | No |

| CCW10-2 | 1200 | 100 | 70 | 150 | 2700 | 2.0 | A10 | No | No | |

| CCW5-2.5 | 1200 | 100 | 70 | 150 | 2700 | 2.5 | A5 | No | No | |

| CCW5-2.5-F | 1200 | 100 | 70 | 150 | 2700 | 2.5 | A5 | Yes | No | |

| Seismic test | ECW5 | 1200 | 100 | 70 | 150 | 2700 | 2.5 | A5 | No | No |

| ECW10 | 1200 | 100 | 70 | 150 | 2700 | 2.5 | A10 | No | No | |

| ECW5-F | 1200 | 100 | 70 | 150 | 2700 | 2.5 | A5 | Yes | No | |

| ECW5-F-P | 1200 | 100 | 70 | 150 | 2700 | 2.5 | A5 | Yes | Yes |

| Group | fcu/MPa | SDc | fc/MPa | SDp | E/MPa |

|---|---|---|---|---|---|

| A5 | 5.43 | 0.42 | 5.26 | 0.07 | 4717.10 |

| A10 | 10.30 | 1.21 | 9.80 | 0.30 | 6752.50 |

| Materials | fy/MPa | fu/MPa | E/MPa | Rate of Elongation A/% |

|---|---|---|---|---|

| Light steel keel | 323 | 448 | 2.08 × 105 | 32.9 |

| Steel bar | 605 | 749 | 1.98 × 105 | 4.6 |

| Type of Test | Np/kN | Peak Load Ratio | Δp/mm | Δu/mm | Δu/Δp |

|---|---|---|---|---|---|

| CCW5-2 | 419.48 | 1.00 | 3.85 | 4.26 | 1.11 |

| CCW5-2.5 | 585.93 | 1.39 | 5.07 | 5.19 | 1.02 |

| CCW10-2 | 489.79 | 1.17 | 4.44 | 4.65 | 1.05 |

| CCW5-2.5-F | 1115.43 | 2.66 | 5.97 | 7.8 | 1.31 |

| Specimen | Test Value/kN | Strength Calculation Value/kN | Error | Stability Calculation Value/kN | Error |

|---|---|---|---|---|---|

| CCW5-2 | 419.48 | 433.45 | 3.33% | 298.21 | −28.91 |

| CCW5-2.5 | 585.93 | 537.61 | −8.25 | 369.88 | −36.87 |

| CCW10-2 | 489.79 | 433.45 | −11.50 | 298.21 | −39.11 |

| Average | −5.47% | −34.96 |

| Specimen | Yield Load Point | Point of Ultimate Load | Failure Load Point | μ | |||

|---|---|---|---|---|---|---|---|

| Fy/kN | Δy/mm | Fu/kN | Δu/mm | Fd/kN | Δd/mm | ||

| ECW5 | 54.95 | 18.27 | 61.23 | 25.01 | 53.10 | 40.75 | 2.24 |

| ECW10 | 60.87 | 27.82 | 76.06 | 49.74 | 74.15 | 61.26 | 2.20 |

| ECW5-F | 142.22 | 33.32 | 162.33 | 39.34 | 158.82 | 45.80 | 1.41 |

| ECW5-F-P | 38.87 | 29.22 | 43.46 | 42.71 | 36.25 | 59.85 | 2.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, J.; Cao, W.; Chen, J.; Zhao, L.; Yu, Y. In-Plane Mechanical Properties Test of Prefabricated Composite Wall with Light Steel and Tailings Microcrystalline Foamed Plate. Buildings 2024, 14, 3196. https://doi.org/10.3390/buildings14103196

Bian J, Cao W, Chen J, Zhao L, Yu Y. In-Plane Mechanical Properties Test of Prefabricated Composite Wall with Light Steel and Tailings Microcrystalline Foamed Plate. Buildings. 2024; 14(10):3196. https://doi.org/10.3390/buildings14103196

Chicago/Turabian StyleBian, Jinliang, Wanlin Cao, Jianwei Chen, Lidong Zhao, and Yuanyuan Yu. 2024. "In-Plane Mechanical Properties Test of Prefabricated Composite Wall with Light Steel and Tailings Microcrystalline Foamed Plate" Buildings 14, no. 10: 3196. https://doi.org/10.3390/buildings14103196

APA StyleBian, J., Cao, W., Chen, J., Zhao, L., & Yu, Y. (2024). In-Plane Mechanical Properties Test of Prefabricated Composite Wall with Light Steel and Tailings Microcrystalline Foamed Plate. Buildings, 14(10), 3196. https://doi.org/10.3390/buildings14103196