Abstract

The evaluation of the environmental impacts of a living wall (LW) system cannot leave out the effects on the buildings’ sustainability during its life cycle. Consequently, to consider the embodied impacts of all the components, an LCA of the whole system is recommended. Therefore, this paper was targeted to evaluate the environmental performances of four LW solutions considering a combination of energy performances and system LCA. In the first step, the yearly energy consumption of a reference building equipped with LWs was determined through simulations carried out in the EnergyPlus environment. Subsequently, the LCA completed the evaluation of the environmental impact of the different building configurations. To quantify the effects related to the implementation of LWs, the results were compared to those obtained for the reference building without vegetation. The analyses refer to a real university’s four-floor housing located in the city of Reggio Calabria (38°07′21.4″ N 15°39′45.2″ E), which is currently under construction. The results confirm the benefits achievable through the LW integration, measuring both energy savings and the increase in the hours with indoor temperature within the well-being zone. At an annual level, the best LW solution produces 24% of energy saving and LCA highlights a limitation of 2.1 × 105 kg of CO2eq when compared to the reference case. These data confirm the effectiveness of implementing LWs as a reliable intervention to enhance building environmental impact, especially for edifices requiring renovation.

1. Introduction

To satisfy heating and cooling requirements, buildings are responsible for around 40% of the EU’s energy consumption and more than half of gas consumption, contributing to 35% of greenhouse emissions. This is primarily due to the low thermal performance of existing building envelopes, considering that the majority of them are aged [1]. At present, about 35% of the EU’s buildings are over 50 years old and almost 75% of the building stock is energy inefficient. The Energy Performance of Buildings Directive, in accordance with the European Green Deal [2], sets the framework for Member States to reduce emissions and energy use in buildings across the EU, from homes and workplaces to schools, hospitals and other public buildings, but always concerns health and quality of life. This Directive allows each Member State to adopt its national policy to reduce the energy spent by residential buildings by 16% by 2030 and 22% by 2035. In particular, at least 16% of the worst-performing non-residential buildings must be renovated by 2030 and a further 26% of buildings by 2033. To make refurbishment more affordable and feasible, citizens have to be supported in their efforts to improve home energy efficiency by stimulating the establishment of one-stop shops for advice on building renovations, technical education on new energy-saving technologies and provisions for public and private financing, such as Energy Performances Contracts (EPC) [3,4]. In this field, an appealing renovation solution producing an enhancement of the quality of life for occupants is represented by systems based on the integration of bio-based materials in the building envelope. The improvement attainable in terms of energy performance is strongly dependent on the interaction between the vegetable species and the climatic conditions, and in this context, the Mediterranean area represents a suitable location because the weather is favourable for the implementation and management of living plants around the building envelope. The main benefit in the limitation of the building energy demand is represented by the evapotranspiration processes, which determine the air temperature reduction around the envelope; this solution is highly appreciated in the Mediterranean area where cooling energy requirements often prevail compared to the heating ones. Different bio-based materials can be adopted for the renovation of existing buildings, and they can be divided into two main categories:

- −

- Passive vegetable materials (vegetable fibres, wood, giant reeds, agricultural waste, etc.) [5];

- −

- Living plants (plants, green roofs, living walls, green facades, etc.) [6].

The integration of nature-based solutions made of living plants is more attractive because it involves interdisciplinary fields such as [7]

- The built environment, because the implementation of living plants on building facades impacts the summer microclimate by limiting the heat island effects;

- The global environment, due to the attainment of energy saving with a correspondent reduction in greenhouse gas emissions;

- The water urban drainage, because living plants improve the capacity for the retention of rainwater and support the correct management of water drainage;

- Water quality, because the vegetation allows for the removal of pollutants as soluble and insoluble metal traces with a corresponding enhancement of the water drainage quality;

- Biodiversity, because plants can make available an ideal habitat for insects and arthropods, stimulating biodiversity in urban areas;

- Air quality, as vegetation is able to release oxygen to the urban environment absorbing carbon dioxide.

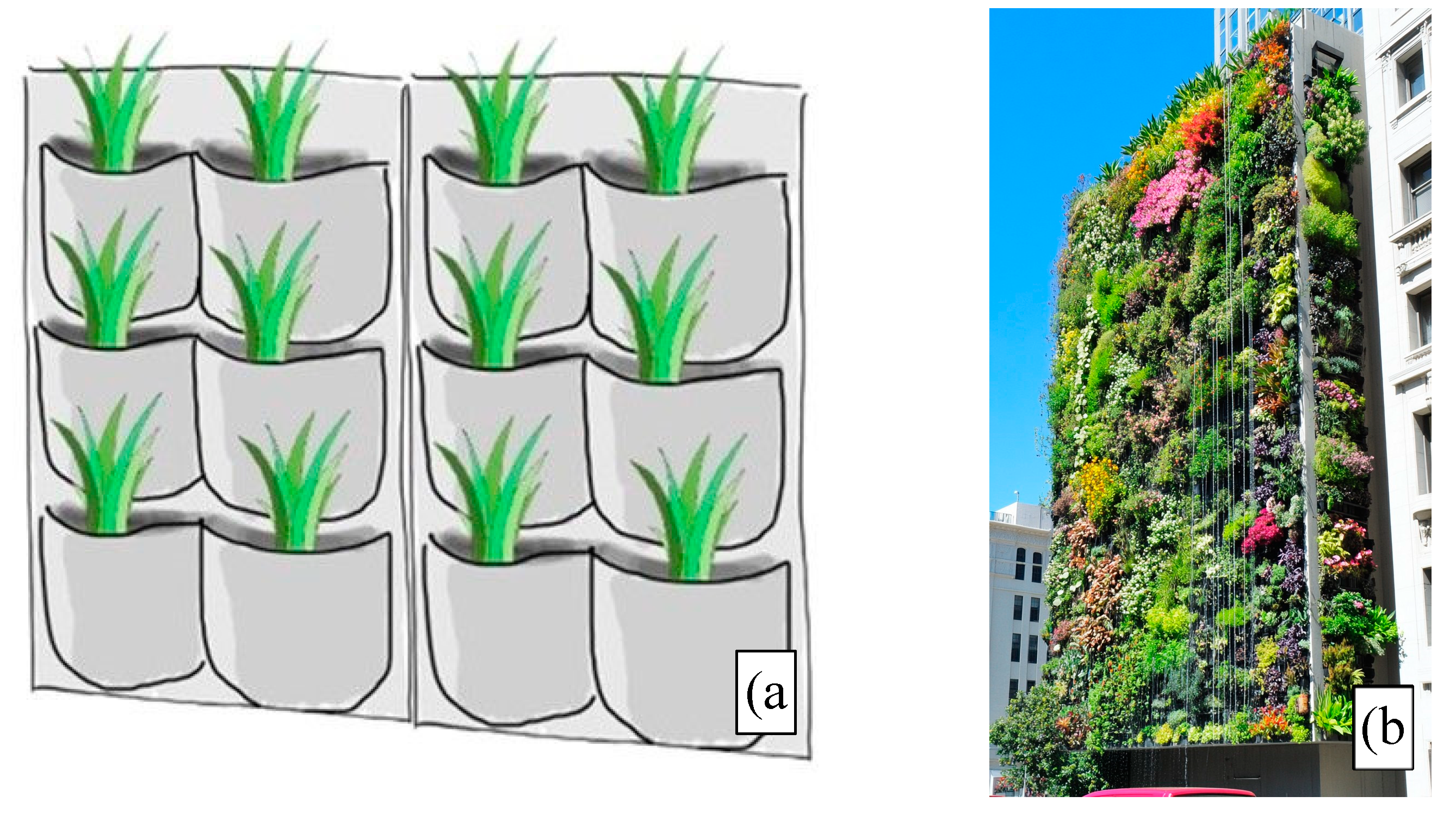

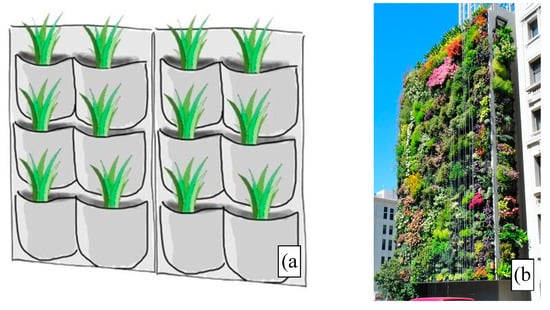

A suitable implementation of a living plant system integrated with the building envelope is represented by living walls (LWs), made of light support structures that do not interfere with the building static to allow plants to grow even without being rooted into the ground [8]. Plants can be pre-cultivated and subsequently implemented in the LW, providing varied designs and more options [8,9]. LWs are suitable for the retrofitting of existing buildings, especially in the presence of continuous opaque facades, maintaining low installation costs. There are two main types of LWs: continuous and modular systems [8,9,10,11]. The continuous LW system (Figure 1a) is composed of two layers of synthetic fabric. The external layer, usually made of felt or plastic sheets, consists of a pocket-shaped container that is filled with a planting medium and is used to favour the plants rooting. The internal layer is a waterproof membrane to preserve building facades from water and high moisture. The layers are supported by a framework directly fixed to the building wall. The modular systems (Figure 1b) are composed of containers in different shapes and sizes and hold the growing media to support the vegetable species. They can be in the form of framed or planter boxes, planter tiles, bags, vessels or trays. The water and nutrients are distributed to the plants through the growing media at different levels along the wall by gravity [8].

Figure 1.

Examples of continuous (a) and modular (b) [12] LW.

Both types improve the thermal performance of the building envelope, mainly due to the absorption of latent heat due to evapotranspiration, shading effects, reflection and the absorption of solar energy for photosynthesis and preventing the outdoor warm air from penetrating the green layer [13]. In light of this, LW systems implemented on a district level could represent a viable solution to reduce the heat island effect, a typical issue affecting the urban environments in the Mediterranean area. Nevertheless, further investigations on LWs are required because energy performance and environmental impact are difficult to generalize, depending on the system layout and the materials employed for the implementation. Recently, in Ref. [14], the impacts of the carbon fixation pathways on the CO2 removal rate through the implementation of LWs were experimentally investigated, measuring a limitation of the fresh air demand ranging between 13.9 and 38.5% with a corresponding energy saving of 28.2%. In Ref. [15], a novel modular system was conceived to reduce embodied carbon and enhance plant performances in terms of hydrological features by employing recycled materials and high water-holding substrates. The investigation carried out in Ref. [16] focused on the thermal characterization of a modular system measuring 85% in the limitation of the effective solar absorptivity when compared with the bare wall. Regarding the performance in terms of PM (particular matter) capture, Ref. [17] states that SLA (Specific Leaf Area) is the main parameter affecting the performances, after a study involving 11 different vegetable species.

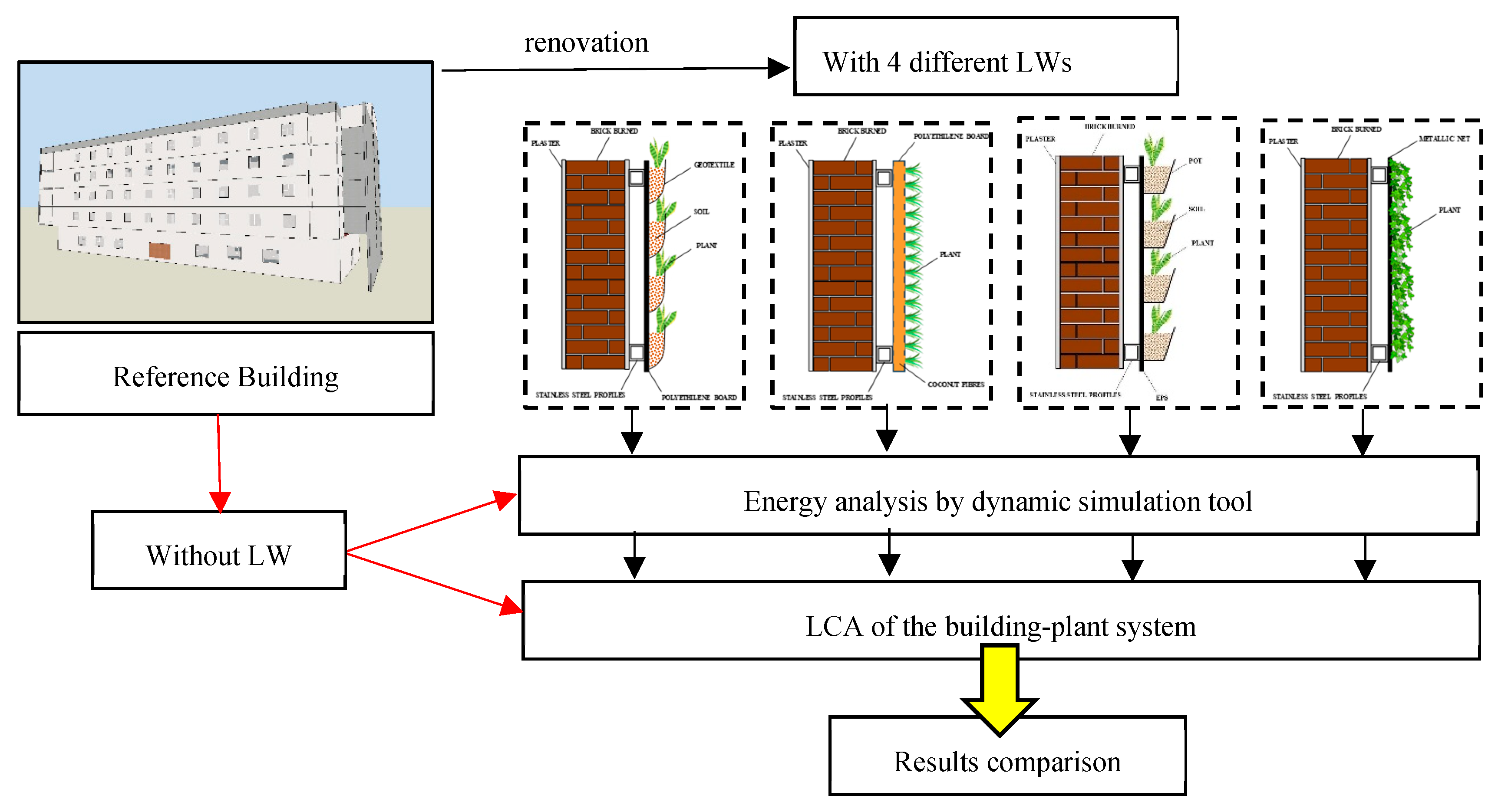

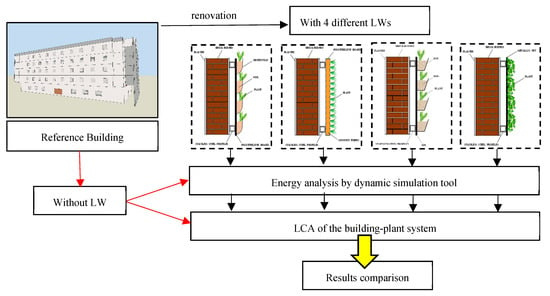

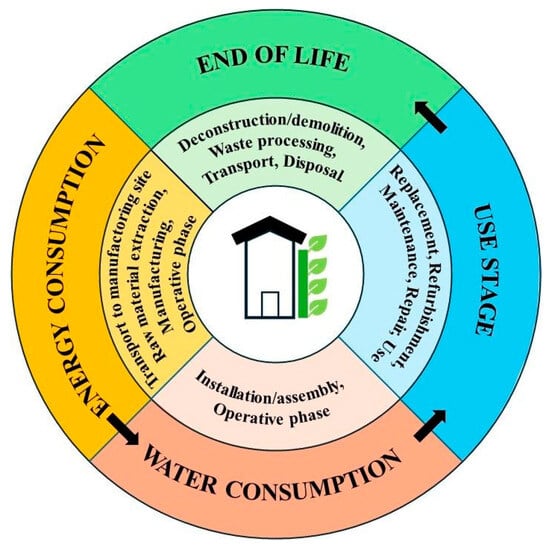

In recent years other investigations have analyzed different materials and shapes targeted to maximize environmental benefits. The focus of these studies was mainly the evaluation of the materials sustainability for the LW implementation influencing the inhabitant’s well-being, energy, water consumption and interaction between the buildings’ conditions with the site factors. In order to better consider this relationship, the LCA of the whole-building LW system is strictly required, considering the embodied impacts of all the elements. Since this aspect is still missing in the relevant literature, this study evaluates the environmental performance of four different LW solutions, focusing on the buildings’ sustainability through a combination of energy analyses and system LCA. In particular, the work is planned to follow the scheme depicted in Figure 2. Starting from a reference real building, the LWs were first analyzed in terms of energy performances by determining heating and cooling demands in the specific site. Subsequently, the association of the LCA results, for which a basic flow diagram is depicted in Figure 3, has allowed for obtainment of a more exhaustive framework of the building’s environmental impact. To quantitatively measure the enhancement achievable in terms of building sustainability, the results were compared with those provided by the reference building without LW, which was set as the benchmark.

Figure 2.

Workflow diagram describing the investigation methodology.

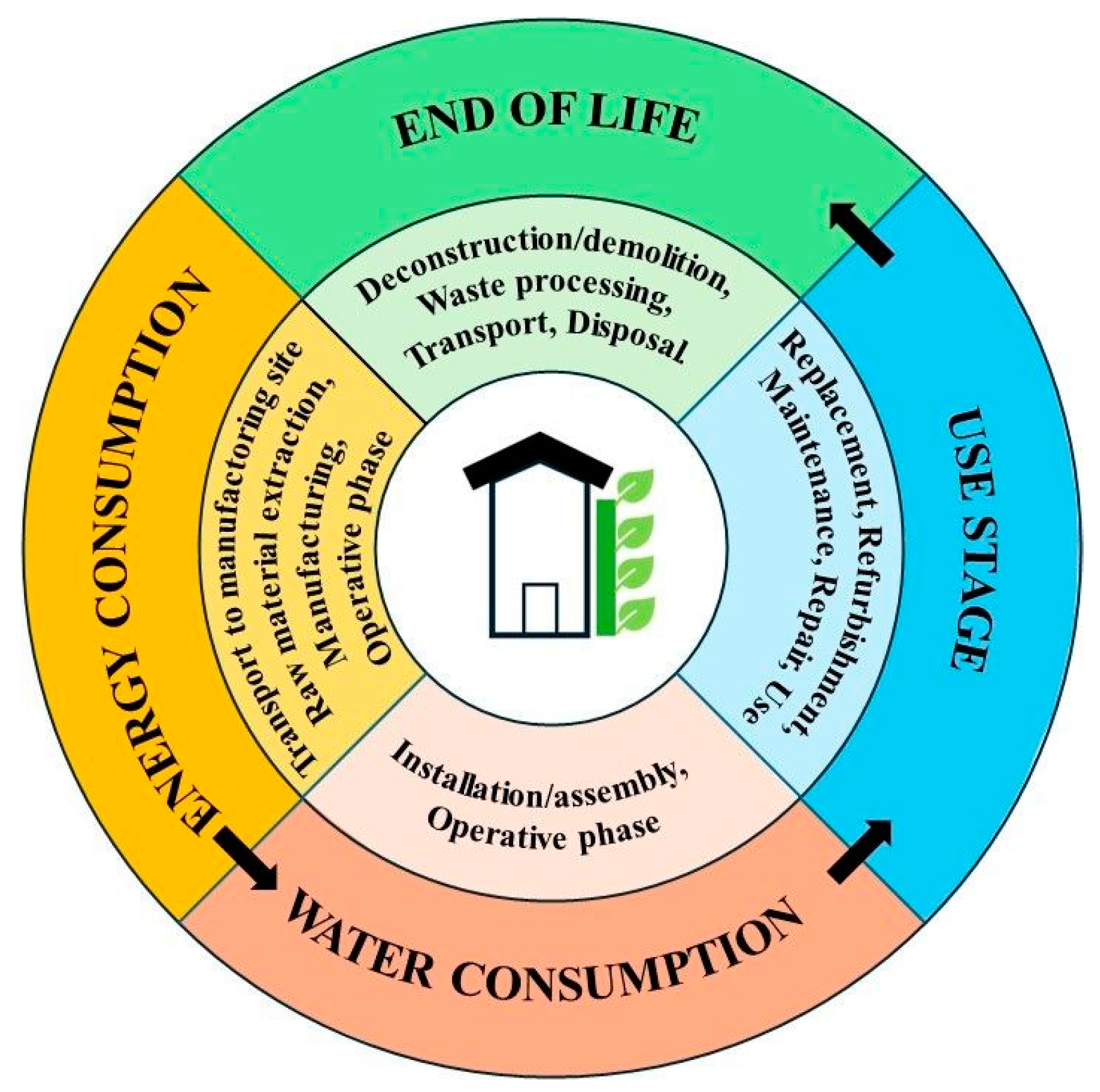

Figure 3.

Flow diagram of LCA assessment methodology.

LCA considered not only the life cycle of materials but also the resources used during the use of the building.

2. Materials and Methods

The sustainable performance of the different LW solutions was determined by implementing a specific methodology in two phases. In the first, the yearly energy building consumptions were analyzed to evaluate the LW effects by simulations carried out in a suitable software tool. In the second phase, the LCA evaluated the environmental impacts of the whole built system during the life cycle [18]. The reference building without LW is the benchmark to measure the effects related to the implementation of the bio-active elements on the building façades.

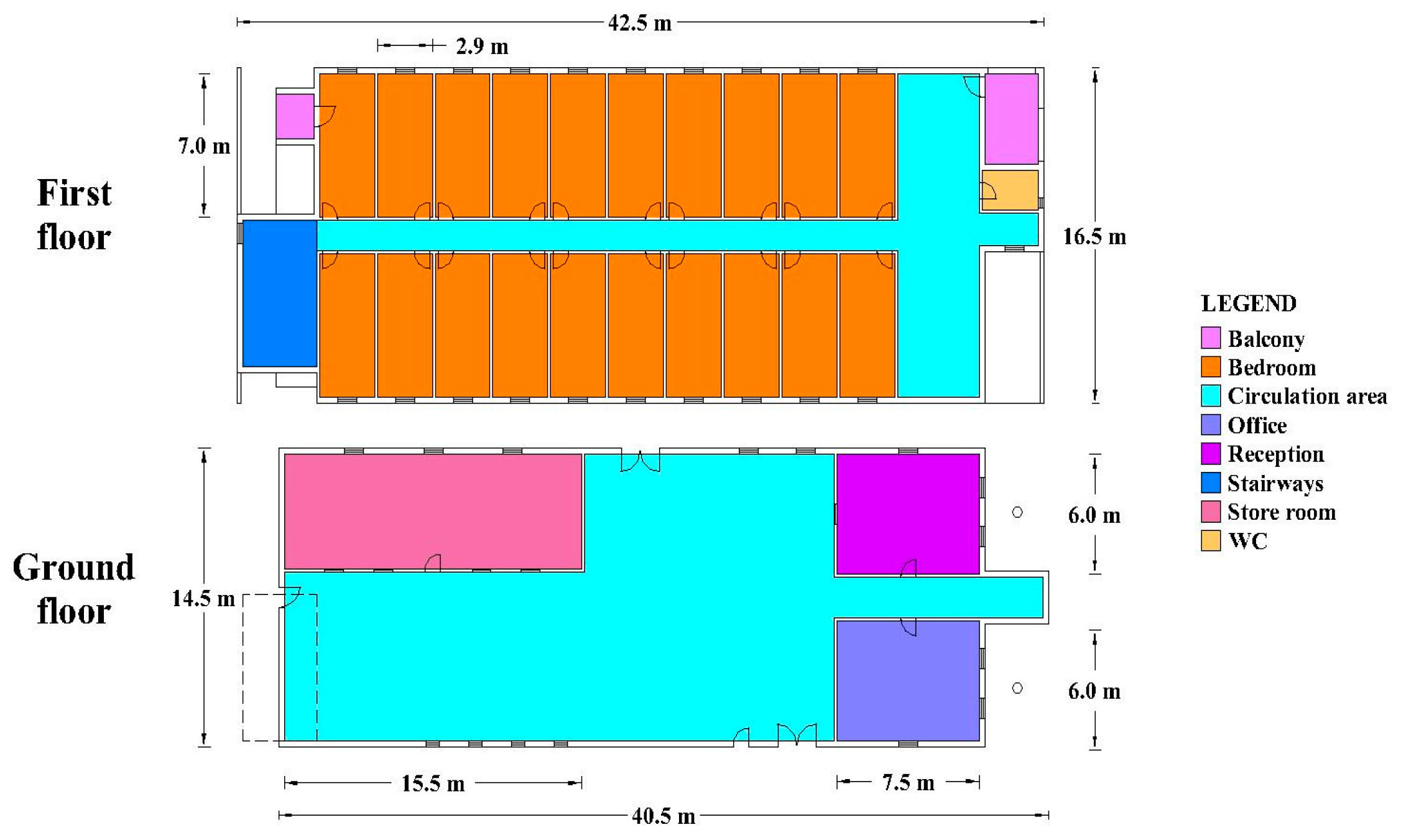

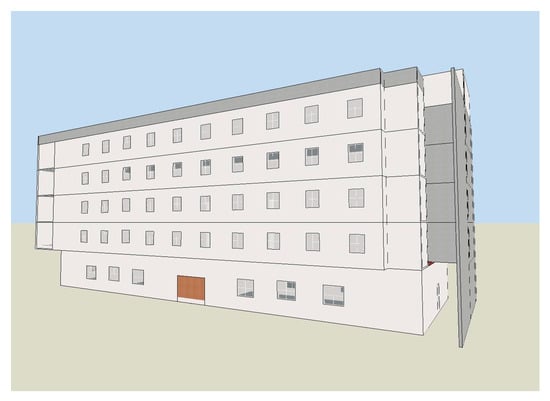

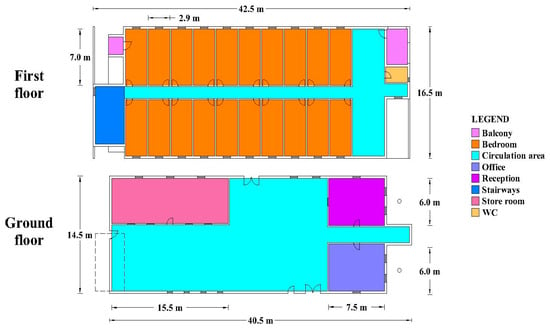

These evaluations were carried out by referring to the case study depicted in Figure 4, representing an under-construction university four-floor housing project made of a steel concrete load-bearing structure. The building is located in Reggio Calabria (38°07′21.4″ N 15°39′45.2″ E), belonging to the Csa zone following Koppen classification, and geometrically modelled by the .idf file generated in the DesignBuilder (DB) environment shown in Figure 5. The building will host a student accommodation equipped with hall and service areas on the ground floor and 20 student bedrooms for each floor above ground, following the scheme of Figure 6.

Figure 4.

Load-bearing structures of the university housing representing the case study.

Figure 5.

Geometrical model of the university housing for the energy analyses.

Figure 6.

Floor layout of the university housing chosen as case study.

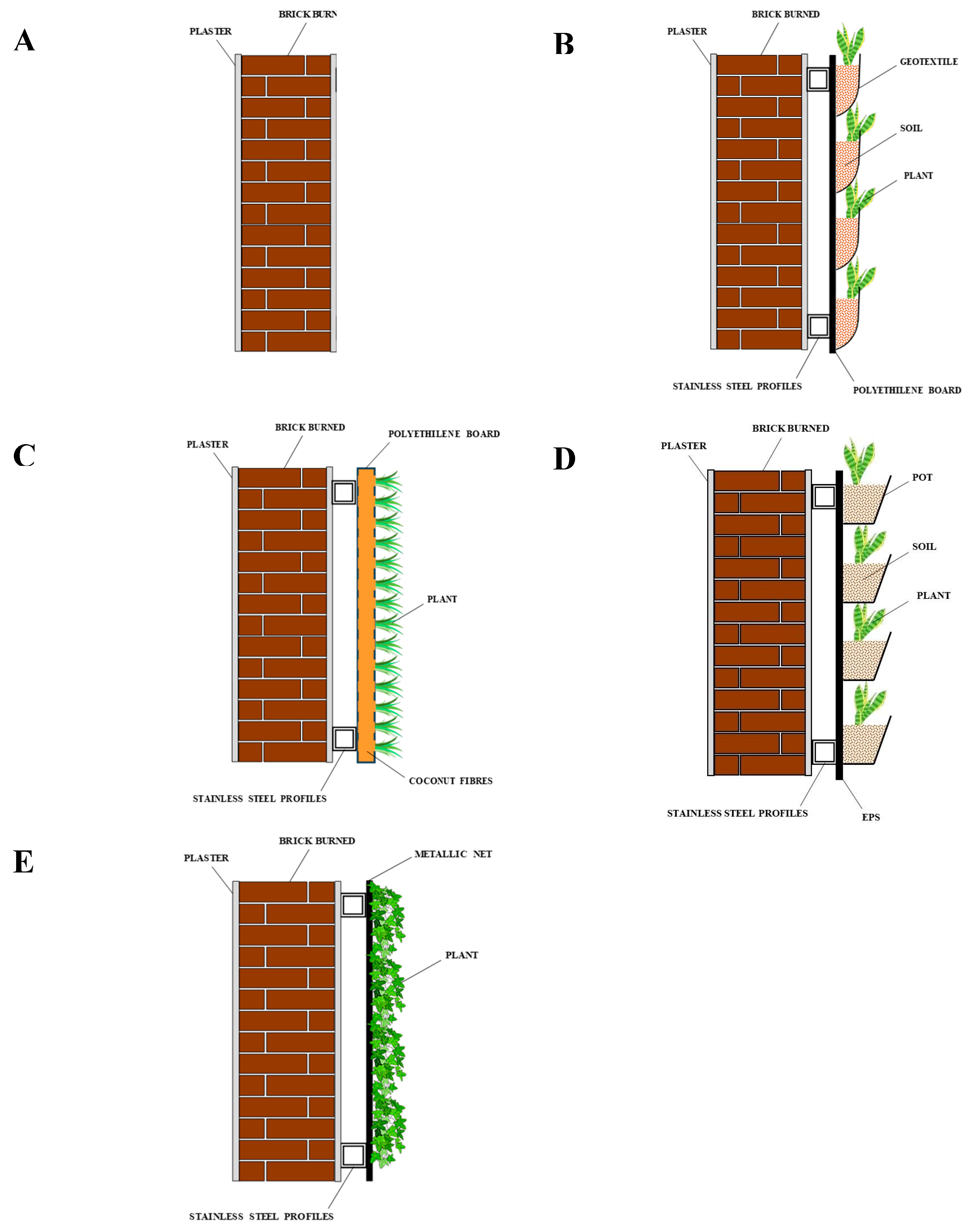

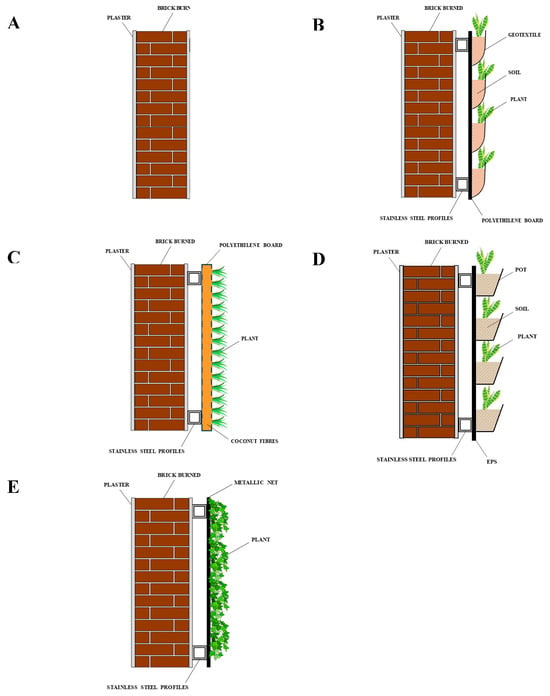

The simulations allowed for determining the energy performance of the reference building in the current state [9], assuming external walls made of traditional brick following the sketch plan of Figure 7A, and the energy performances, assuming the installation of four different LW solutions illustrated in Figure 7B–E. A deep review was conducted in the pertinent literature to find papers describing the LW technical solutions which not only allow for promoting the growth of plants in the Mediterranean habitat, but also the employment of sustainable materials. The first solution contemplates a continuous system made of a 25 mm container module of recycled polyethylene board and a geotextile felt layer in the form of pockets to contain the growing media [19]. The system is fixed to the external wall through aluminium rails, as depicted in Figure 7B. The second solution considers the modular LW depicted in Figure 7C made of 600 × 400 × 80 mm squared modules of recycled polyethylene filled with a substrate of coconut fibres to enhance the water-holding capacity [16]. The third analyzed LW constitutes standard planters with side or rear irrigation system following the scheme depicted in Figure 7D. Planters were made of polypropylene with a depth of 0.20 m and height of 0.15 m to contain a substrate of expanded clay suitable for specific plants [20]. The vertical distance between every two lines of horizontal planters is 15 cm. The planters are installed on the exterior surface, featuring an expanded polystyrene insulation (EPS) layer and 1 cm thick waterproof layer to protect the wall from humidity, which are fixed by employing suitable metal rails. The last analyzed LW is another continuous system made of a metallic structure and covered with Hedera helix plant, whose sketch is shown in Figure 7E. The rails hold and distance the metallic net, forming an air gap between the facade and the plants. All the considered LW types cover a vertical wall surface of 1832 m2. The water was distributed using capillary pipes [21], whereas a recirculation water system was foreseen to save irrigation water.

Figure 7.

Schematic diagrams of the investigated LW systems: (A) bare brick wall (without LW); (B) brick wall with geotextile layer forming pockets; (C) brick wall with module filled with coconut fibres substrate; (D) brick wall with planters made in polypropylene; (E) brick wall with continuous metal (aluminium) rails for clinging plants like ivy.

2.1. Energy Analysis

The DB software version 6.1 is tightly integrated with the EnergyPlus v.8.9 engine, providing advanced dynamic thermal simulation [22,23]. This analysis allows for evaluating the energy demand required to maintain indoor air temperature within the well-being range for each LW solution [24] using hourly weather data of Reggio Calabria provided by the International Weather for Energy Calculation [25].

For this purpose, five different models have been built to evaluate and compare the energy consumption of the considered LW solutions with the benchmark.

The energy modelling procedure was articulated in three phases:

- Definition of the plan of the building regarding the thermal zone for activity in every space;

- Setting of the thermo-physical characteristics of the materials and definition of the boundary conditions for the building envelope and for the LWs;

- Implementation of an HVAC and other energy devices compliant with the building’s air-conditioning;

HVAC uses an electric air–water heat pump system to maintain indoor air temperature in the winter range of 16–20 °C and in the summer range of 22–25 °C specifically for bedrooms. Intervals of 17–20 °C for heating and 20–23 °C for cooling were considered for the hall and the service areas. A continuous heat pump was considered, operating for 24 h every day, following the Italian standards for the analysis of energy performance in buildings [26]. The windowed surfaces feature a double-glazing system with the panes being 6 mm thick and filled with 13 mm of still air. Other scheduled values were automatically set by the software for each activity area. The lighting and the domestic hot water (DHW) systems were implemented without focusing on energy consumptions, so that only the HVAC system is the main source of absorbed power. The reference building was modelled considering external wall made of reinforced concrete and bricks, representing a common solution for the considered area. The steady-state features of the LW systems are listed in Table 1.

Table 1.

Steady-state thermal parameters for the analyzed wall solutions.

Regarding modular solutions B, C and D, simulations were carried out by exploiting the Double Skin Façade (DSFM) model available in DB, representing the most useful tool able to simulate a LW system that forms an air cavity with the envelope [16,27]. Specifically, for solution E, simulations were conducted using the Baffle Model (BM) that allows for modelling the effects connected with the presence of naturally ventilated rainscreens and the solar shading on exterior surfaces hosting a continuous system [20]. Nevertheless, an evident weakness of these models is represented by the neglection of the main plants’ effects on the local microclimate, such as evapotranspiration and the accurate radiative analysis due to the modification of the solar absorptivity and thermal emissivity. These effects cannot be modelled by EnergyPlus v.8.9. affecting the results accuracy of the final calculation. Alternatively, the use of the Penman–Monteith equation for evapotranspiration calculation [28], involving some correction coefficients for each individual specie, would provide greater uncertainty because the variables iteratively influence the same correction coefficient value. These approximations can be considered advantageous for the determination of energy consumption; furthermore, the adoption of simplified analysis methods limit the computational effort [29]. Indeed, it is significant to consider that, in this work, the aim of the energy analysis is not the accurate calculation of the LW energy performances, but rather the comparison among the annual energies required to achieve an efficient temperature control for users’ well-being in the different scenarios [30].

2.2. Life Cycle Analysis

In the second step of the methodology, the cradle to the grave approach is used to carry out the Life Cycle Analysis of the whole-building LW system using the One click LCA tool v.1.06.24 [31]. It is a web platform for performing the Life Cycle Assessment based on the Environmental Product Declarations (EPDs), following ISO 14044 [32] and EN 15804 standards [33]. The software considers the impact of different materials, from the production and construction phases until the end of life. It is worth noting the possibility of integration between the DB energy software and OneClick LCA; this functionality is able to transfer the energy model developed by DB to One Click LCA for the material modelling, limiting errors in the input data setting and saving input time.

OneClick LCA has a large database of building materials, and it can be expanded and updated with data supplied by manufacturers. In this study, only for few components, the materials environmental data were obtained by analogy to similar elements. An important goal in the future will be to expand the existing database with the more widespread LWs available on the market.

The LCA was conducted to evaluate the effects of the proposed solutions on seven impact categories: global warming, acidification, eutrophication, ozone depletion potential, formation of ozone in the lower atmosphere, total use of primary energy and biogenic carbon storage [34]. Again, LCA analysis was performed to compare the four LWs solutions with the benchmark. The environmental impact was evaluated by selecting building materials based on EPDs considering the type of transportation and the distances from manufacturers and building site. According to the Eurocode, the Required Service Life (ReqSL) was set to 50 years. The LCA did not consider vegetal species and water reuse but the materials for components in the different technical solutions (felt, plastic, steel net), the growing media (soil) and the irrigation water (see Table 2). For this aim, the calculation of the annual water consumption is quite difficult because it depends on growing media properties, plant support, climatic conditions, selected species, orientation, exposure to incident solar radiation, vegetative period, irrigation methods (e.g., drip or percolation), light exposure, plant density and rainfall [35]. Consequently, to further simplify the model, water consumption values were approximated but not neglected. Indeed, in these systems vegetation, watering is compulsory; therefore, water consumption is one of the main factors that affect sustainability. Since the selected species depend on the LW solution, the water consumption for each analyzed system was estimated from previous studies and reported in Table 3. The listed values have been found by conducting a deep literature review and must be considered as a mean value due to the different test conditions. It can be noticed that for the plants adopted in solution C, Table 3 reports an annual water consumption of 2006 m3·year−1, corresponding to a higher water saving of about 64% compared to solution D, which, in contrast, offers the highest consumption. Finally, the LCA was implemented by considering a combination between drip and percolation irrigation techniques.

Table 2.

Environmental parameters of the materials utilized for the considered LWs.

Table 3.

Annual water consumption for each LW system in order of the plant species adopted.

3. Results and Discussion

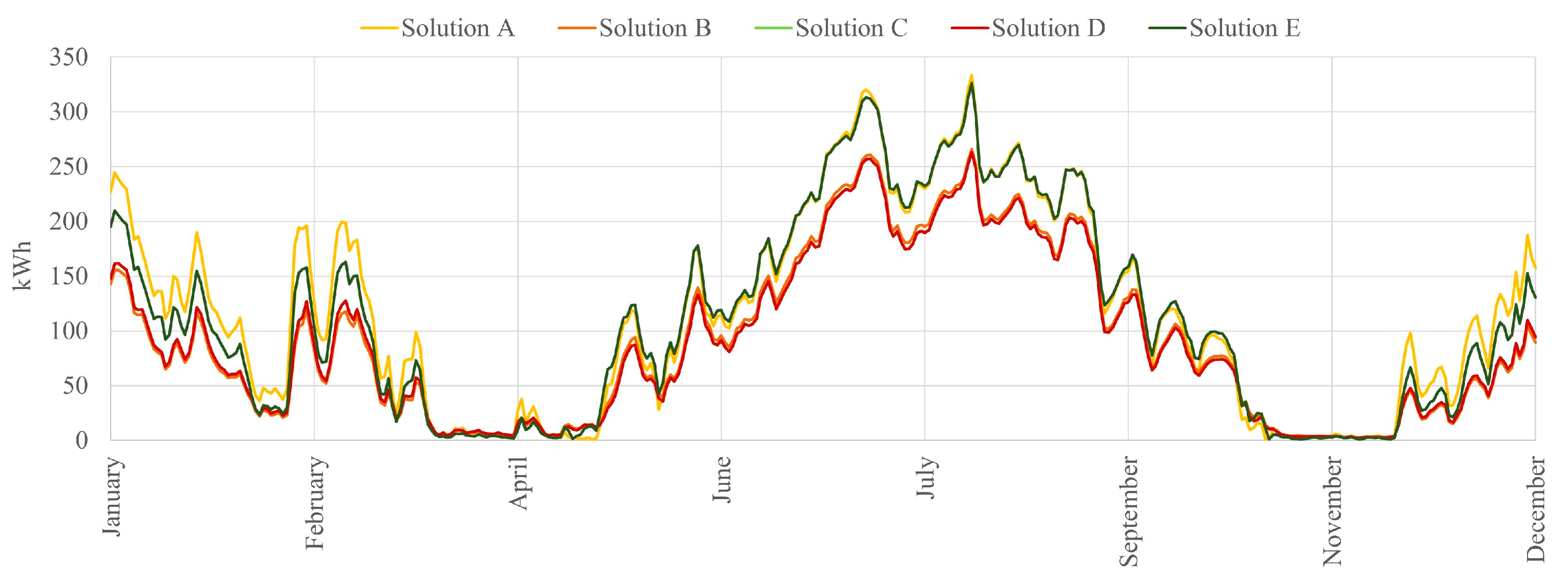

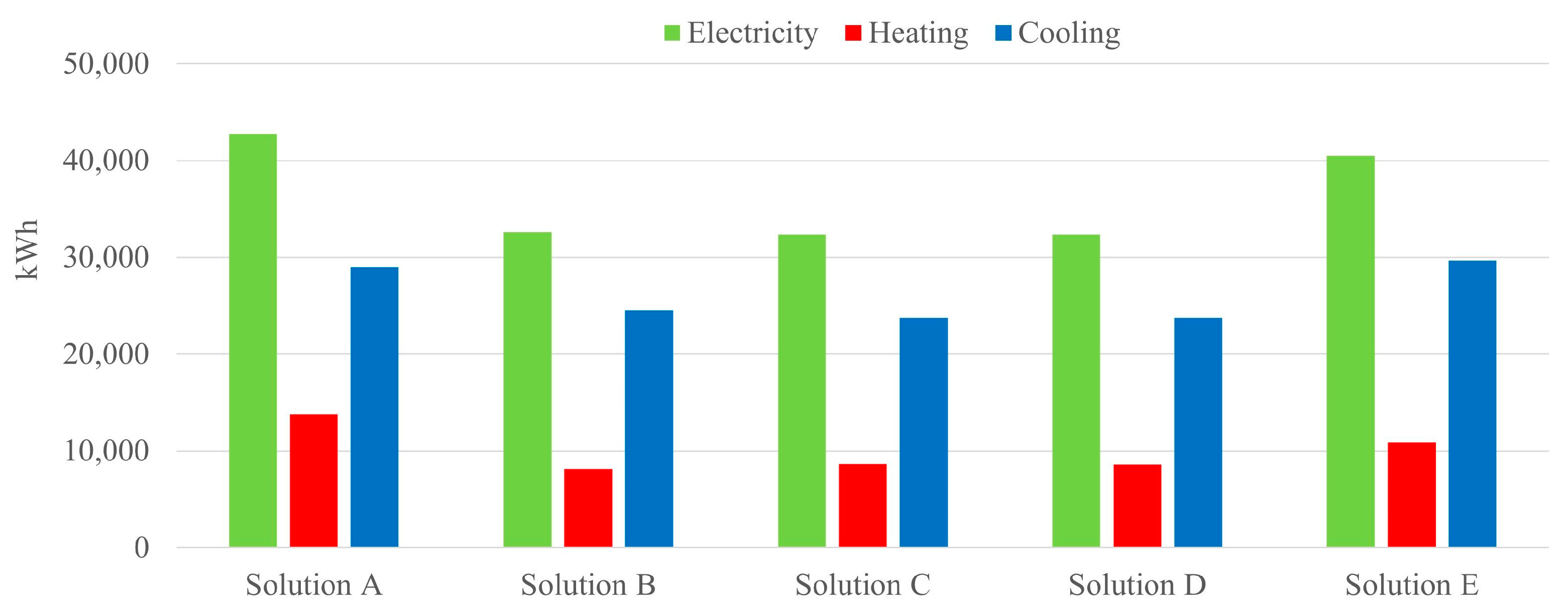

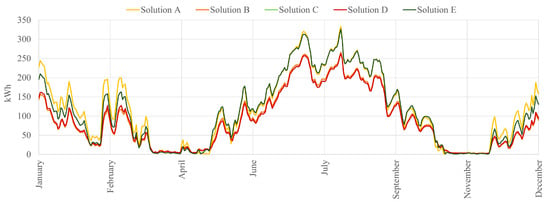

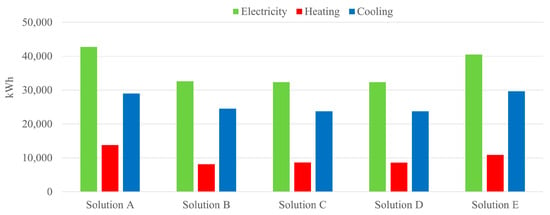

The energy analysis highlights the benefits achievable in terms of energy savings and the control of the indoor air temperature within the well-being range using LWs (Figure 8). Solution B shows the best performance in the winter, allowing for the minimization of the heating demand (8125 kWh), corresponding to a saving of 40% more than the benchmark value. On the contrary, solution D offers the best performance in the summer, with a cooling demand of 23,737 kWh, corresponding to a saving of 18% more than the benchmark value.

Figure 8.

Energy consumption by the HVAC for different wall living solutions.

Nevertheless, from Figure 9, it can be observed that, at an annual level (green bar), the best solution is represented by solution C, offering the best compromise between winter and summer, with a total energy consumption of 32,352 kWh and energy saving of 24% more than the benchmark annual demand, slightly better than solutions B and D. It is true that the energy consumptions vary between the different LWs, with solutions B, C and D showing slight differences. This is due mainly to the simplified energy model, as confirmed by the experimental results that show that evapotranspiration significantly increases the combined convection and radiation heat transfer coefficient, reducing façade overheating and limiting cooling demand [39].

Figure 9.

HVAC annual energy consumption for heating and cooling with different living wall solutions.

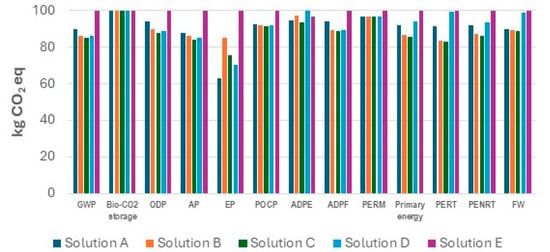

For each LW solution, the annual energy consumption was also introduced in the sustainability assessment models. The LCA was carried out about the level EN 15804 +A1 [33], including results in the following categories:

- Global warming (kg CO2e) (GWP);

- Biogenic carbon storage (kg CO2e-bio) (BIO-CO2 storage);

- Ozone depletion (ODP);

- Acidification (AP);

- Eutrophication (EP);

- Formation of ozone in lower atmosphere (POCP);

- Abiotic depletion potential (ADP-elements) for non-fossil resources (ADPE);

- Abiotic depletion potential (ADP-fossil fuels) for fossil resources (ADPF);

- Use of renewable primary resources as raw materials (PERM);

- Total use of renewable primary energy (Primary Energy);

- Total use of non-renewable primary energy (PERT);

- Use of net freshwater (PERNT).

The building components included in the level calculation were as follows: (FW)

- Foundations (substructure);

- Load-bearing structural frame;

- Non-load-bearing items;

- Façades;

- LWs (excluding vegetable species);

- Roof.

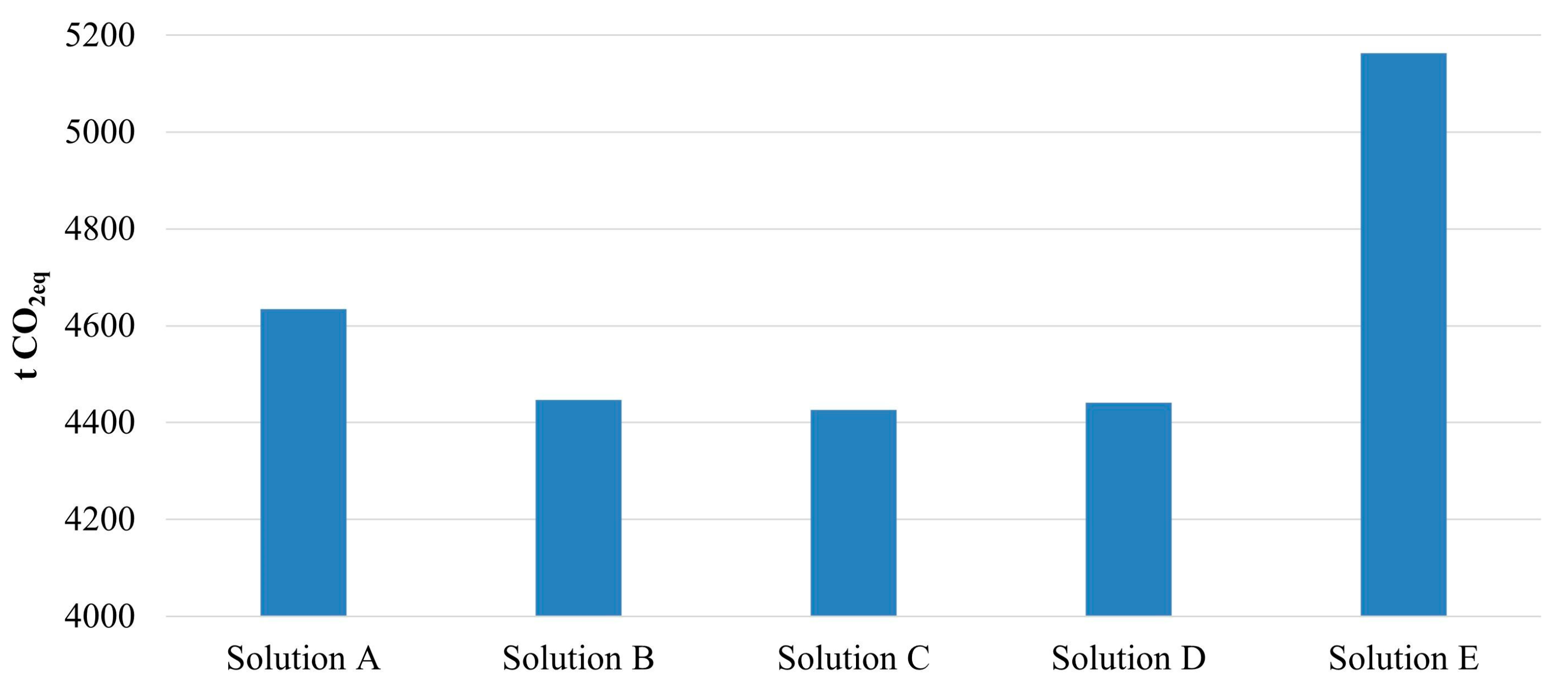

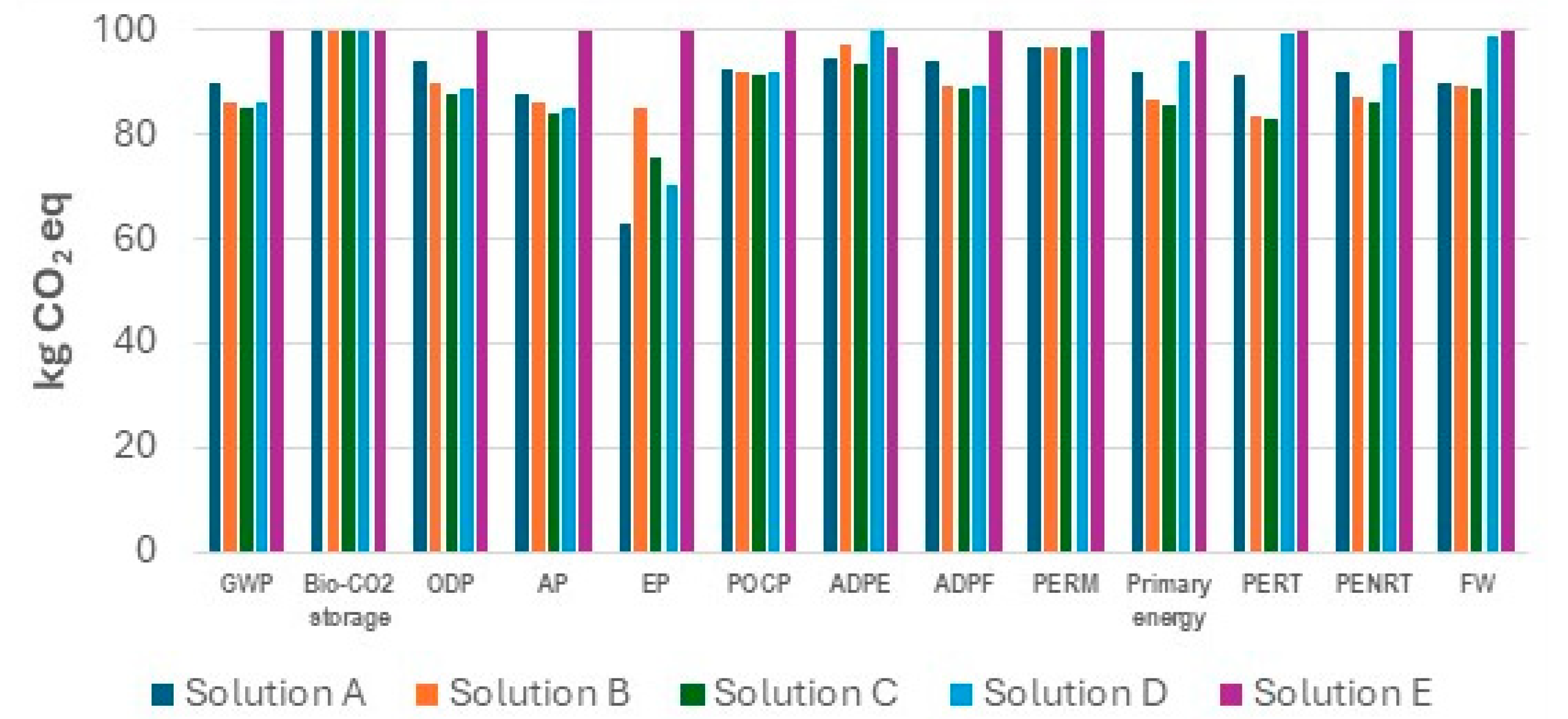

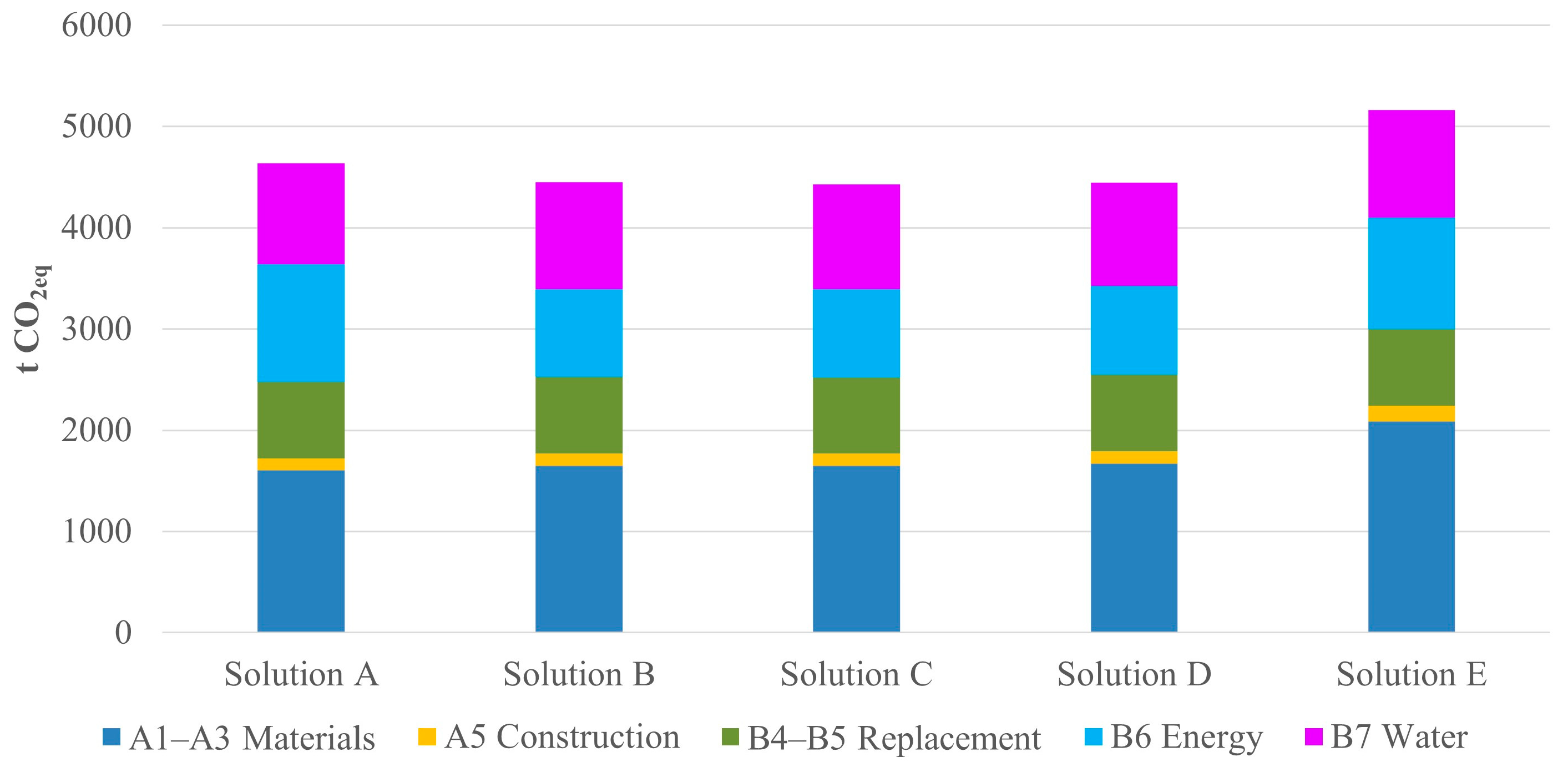

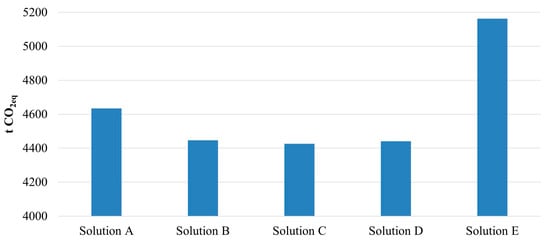

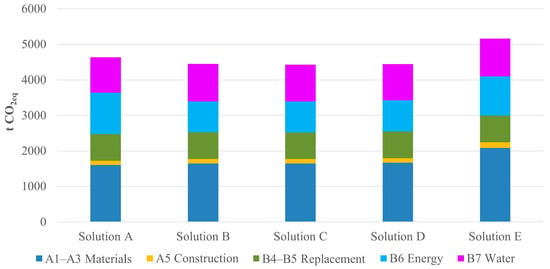

The comparison among the LCA of the different LW systems is shown in Figure 10, highlighting solution C as the LW that impacts the environment the least, with a global warming potential of 4.426·103 t of CO2eq. On the contrary, solution E produces the greatest global warming potential with a value of 5.163·103 t of CO2eq, which is worse than the benchmark, considering that its value is equal to 4.634·103 t of CO2eq.

Figure 10.

Total carbon dioxide equivalent emission for each wall solution.

The higher life cycle impact determined for all categories and calculated in accordance with EN 15804 [33] is shown in Figure 11. Solution C produces the best score for every category, excluding BIO-CO2 storage and EP, for which solution A offers better performances.

Figure 11.

Levels of life cycle assessment according to EN15804 [33] for all impact categories.

From Figure 12, it can be observed that the elements with the large environmental impacts are those that use more water and energy. Since LWs are closed systems, the results can be improved by introducing devices that promote the reuse of the excess water. The score can be further enhanced by incorporating systems that are able to use greywaters directly on-site, which can be made available from lightly polluted sources such as showers, hand basins and kitchen [40]. For all these reasons, the application of this in the Mediterranean area can become a sustainable solution, considering the issues related to the water scarcity affecting many areas in this geographic context. Figure 12 highlights also the major carbon dioxide equivalent emission, calculated in accordance with EN 15804 [33], due to the features of the materials adopted in solution E.

Figure 12.

Carbon dioxide equivalent emission calculated in accordance with EN 15804 [33] for each element and life cycle stage.

It is worth noting that that the impact of the materials in solution C is less than the other LWs. This is due to the use of agricultural waste products such as coconut fibres, which allow for the recycling of a waste material.

4. Conclusions

In this study, four different living wall (LW) configurations implemented in a reference building have been investigated in terms of environmental performances combining energy analysis and LCA. The considered systems belong to some technical solutions recommended for the Mediterranean region and suggested by the literature. Generally, an enhancement of the building energy performances was achieved, except for the solution made of a metallic structure covered with Hedera helix (solution E), which induces a high energy usage for cooling that outweighs the slight decrease in heating needs. Furthermore, the high environmental impact of the employed materials, combined with the large water quantity required for irrigation, makes this solution not compliant for locations with water scarcity such as the Mediterranean area, and it demonstrates the greatest global warming potential calculated by the LCA following the cradle to the grave approach.

The other three LW solutions considered in this study (solutions B, C and D) confirmed their ability to enhance the building’s environmental impact providing slight differences in terms of energy savings and equivalent carbon dioxide emissions. These solutions were shown to be reliable in improving the well-being of the building’s occupants and make cities more sustainable and resilient. Furthermore, the employed user-friendly software demonstrated their validity in supporting the work of technicians and building designers for promoting the sustainability concept in the building sector, despite parameters such as plant evapotranspiration, shading effects and transient variations of the substrate humidity, which made the study quite difficult. Although different methods and mathematical algorithms were developed [41], a rigorous solution for this problem is not attainable by commercial tools, and future research in this direction could overcome this issue. Novel and sustainable LW configuration must be conceived to promote water saving, easy management and an easy integration into the envelope. The main weakness remains the feasible integration of such a system with windowed surfaces and gutters. However, considering the improvement that these solutions can bring to a single building, district and urban area, new regulations and/or financial support should be planned in the future to favour the spread of living plants integrated with buildings. Indeed, it has to be noticed that LWs represent a viable tool to solve diverse issues in different fields, improve aesthetics in aged buildings, contrast the city degradation, improve acoustic performance, reduce the flood risks and enhance the air quality inside the urban environments, all elements that contribute to an increase in the city’s livability. Finally, LWs can be easily proposed in hybrid configurations: assuming integrated PV panels, an increase in the power producibility can be observed by benefitting from the cooling effects produced by evapotranspiration, making the system more environmentally friendly.

Author Contributions

Conceptualization, F.B. and N.A.; methodology, G.D.C. and F.B.; software, G.D.C.; formal analysis, R.B. and N.A.; investigation, G.D.C., F.B. and R.B.; resources, F.B. and R.B.; data curation, G.D.C.; writing—original draft preparation, G.D.C., F.B. and R.B.; writing—review and editing, R.B. and N.A.; visualization, N.A.; supervision, F.B. All authors have read and agreed to the published version of the manuscript.

Funding

This study received support from the Italian Ministery for University and Research (M.U.R.) called “Progetti di Rilevante Interesse Nazionale (PRIN) 2022” (Project code P202257LNE, PNRR CUP Master H53D23008520001) within of the operations supported by the PNRR.

Data Availability Statement

Data are available upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- European Commission. Energy Performance of Buildings Directive Adopted to Bring down Energy Bills and Reduce Emissions. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_24_1965 (accessed on 30 June 2024).

- Fetting, C. The European Green Deal; ESDN Office: Brussels, Belgium, 2020. [Google Scholar]

- Carpino, C.; Bruno, R.; Carpino, V.; Arcuri, N. Uncertainty and Sensitivity Analysis to Moderate the Risks of Energy Performance Contracts in Building Renovation: A Case Study on an Italian Social Housing District. J. Clean. Prod. 2022, 379, 134637. [Google Scholar] [CrossRef]

- Kaitouni, S.I.; Gargab, F.-Z.; Es-sakali, N.; Mghazli, M.O.; Mansouri, F.E.; Jamil, A.; Ahachad, M. Digital Workflow for Nearly Zero-Energy High-Rise Office Building Design Optimization at the District Scale in Mediterranean Context. Energy Built. Environ. 2024. [Google Scholar] [CrossRef]

- Bakkour, A.; Ouldboukhitine, S.E.; Biwole, P.; Amziane, S. A Review of Multi-Scale Hygrothermal Characteristics of Plant-Based Building Materials. Constr. Build. Mater. 2024, 412, 134850. [Google Scholar] [CrossRef]

- Leite, F.R.; Antunes, M.L.P. Green Roof Recent Designs to Runoff Control: A Review of Building Materials and Plant Species Used in Studies. Ecol. Eng. 2023, 189, 106924. [Google Scholar] [CrossRef]

- Kandel, S.; Frantzeskaki, N. Nature-Based Solutions and Buildings: A Review of the Literature and an Agenda for Renaturing Our Cities One Building at a Time. Nat.-Based Solut. 2024, 5, 100106. [Google Scholar] [CrossRef]

- Manso, M.; Castro-Gomes, J.P. Thermal Analysis of a New Modular System for Green Walls. J. Build. Eng. 2016, 7, 53–62. [Google Scholar] [CrossRef]

- Ottelé, M.; Perini, K. Comparative Experimental Approach to Investigate the Thermal Behaviour of Vertical Greened Façades of Buildings. Ecol. Eng. 2017, 108, 152–161. [Google Scholar] [CrossRef]

- El Menshawy, A.S.; Mohamed, A.F.; Fathy, N.M. A Comparative Study on Green Wall Construction Systems, Case Study: South Valley Campus of AASTMT. Case Stud. Constr. Mater. 2022, 16, e00808. [Google Scholar] [CrossRef]

- Carlucci, S.; Charalambous, M.; Tzortzi, J.N. Monitoring and Performance Evaluation of a Green Wall in a Semi-Arid Mediterranean Climate. J. Build. Eng. 2023, 77, 107421. [Google Scholar] [CrossRef]

- Stockcake. Available online: https://stockcake.com/i/urban-garden-facade_1228979_1136820 (accessed on 5 August 2024).

- Dede, O.H.; Mercan, N.; Ozer, H.; Dede, G.; Pekarchuk, O.; Mercan, B. Thermal Insulation Characteristics of Green Wall Systems Using Different Growing Media. Energy Build. 2021, 240, 110872. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, L.; Zhang, Y. Investigation of the Indoor CO2 Removal Efficiency and Fresh Air Energy Savings of Living Walls in Office Spaces. J. Build. Eng. 2024, 90, 109422. [Google Scholar] [CrossRef]

- Jimenez, M.S.; Cortesão, J.; Lenzholzer, S.; Walker, R. Plant Pixel: An Optimized Bio-Inspired Living Wall System. Dev. Built Environ. 2024, 18, 100438. [Google Scholar] [CrossRef]

- Azkorra-Larrinaga, Z.; Romero-Anton, N.; Martin-Escudero, K.; Lopez-Ruiz, G.; Giraldo-Soto, C. Comparative Summer Thermal Performance Analysis between Open Ventilated Facade and Modular Living Wall. Case Stud. Therm. Eng. 2024, 53, 103919. [Google Scholar] [CrossRef]

- Koch, K.; Wuyts, K.; Denys, S.; Samson, R. The Influence of Plant Species, Leaf Morphology, Height and Season on PM Capture Efficiency in Living Wall Systems. Sci. Total Environ. 2023, 905, 167808. [Google Scholar] [CrossRef] [PubMed]

- Chandrasekaran, V.; Dvarionienė, J. A Review of the Environmental Impact of Buildings with an Emphasis on Performance Assessment Tools and Their Incorporation of LCA. Adv. Civ. Eng. 2022, 2022, 9947920. [Google Scholar] [CrossRef]

- Ruiz-Valero, L.; Faxas-Guzmán, J.; Arranz, B.; Flores-Sasso, V.; Céspedes, L. Living Wall System for Improved Thermal Performance of Facades Located in Tropical Climate. Case Study in Dominican Republic. Build. Environ. 2022, 222, 109419. [Google Scholar] [CrossRef]

- Khabaz, A. Optimum Thermal Performance of Green Walls Systems and Design Requirements against Heat Transfer of Conventional External Walls of Low-Rise Concrete Buildings in Hot Regions. J. Build. Eng. 2023, 78, 107654. [Google Scholar] [CrossRef]

- Tudiwer, D.; Korjenic, A. The Effect of Living Wall Systems on the Thermal Resistance of the Façade. Energy Build. 2017, 135, 10–19. [Google Scholar] [CrossRef]

- Dahanayake, K.C.; Chow, C.L. Comparing Reduction of Building Cooling Load through Green Roofs and Green Walls by EnergyPlus Simulations. Build. Simul. 2018, 11, 421–434. [Google Scholar] [CrossRef]

- Barreca, F.; Praticò, P. Environmental Indoor Thermal Control of Extra Virgin Olive Oil Storage Room with Phase Change Materials. J. Agric. Eng. 2019, 50, 208–214. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P.; Rollo, A.; Barreca, F.; Arcuri, N. A Novel Bio-Architectural Temporary Housing Designed for the Mediterranean Area: Theoretical and Experimental Analysis. Energies 2022, 15, 3243. [Google Scholar] [CrossRef]

- Barreca, F. Sustainability in Food Production: A High-Efficiency Offshore Greenhouse. Agronomy 2024, 14, 518. [Google Scholar] [CrossRef]

- Ufficiale, G. Decreto Legislativo 192/2005. 2005. Available online: https://www.gazzettaufficiale.it/eli/id/2005/09/23/005G0219/sg (accessed on 15 May 2024).

- Fox, M.; Morewood, J.; Murphy, T.; Lunt, P.; Goodhew, S. Living Wall Systems for Improved Thermal Performance of Existing Buildings. Build. Environ. 2022, 207, 108491. [Google Scholar] [CrossRef]

- Tulip, S.S.; Siddik, M.S.; Islam, M.N.; Rahman, A.; Torabi Haghighi, A.; Mustafa, S.M.T. The Impact of Irrigation Return Flow on Seasonal Groundwater Recharge in Northwestern Bangladesh. Agric. Water Manag. 2022, 266, 107593. [Google Scholar] [CrossRef]

- Ceccarelli, M.; Barbaresi, A.; Menichetti, G.; Santolini, E.; Bovo, M.; Tassinari, P.; Barreca, F.; Torreggiani, D. Simulations in Agricultural Buildings: A Machine Learning Approach to Forecast Seasonal Energy Need. In Proceedings of the 2022 IEEE Workshop on Metrology for Agriculture and Forestry (MetroAgriFor), Perugia, Italy, 3–5 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 116–120. [Google Scholar]

- Freewan, A.A.; Jaradat, N.M.; Amaireh, I.A. Optimizing Shading and Thermal Performances of Vertical Green Wall on Buildings in a Hot Arid Region. Buildings 2022, 12, 216. [Google Scholar] [CrossRef]

- One Click LCA One Click LCA® LIFE CYCLE ASSESSMENT FOR BUILDINGS 2021, 32.

- UNI EN ISO 14044:2021; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Standard: Geneva, Switzerland, 2021.

- UNI EN 15804:2021; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. International Standard: Geneva, Switzerland, 2021.

- Petersen, E.H. BEAT 2002—An LCA Based Assessment Tool for the Building Industry. In Proceedings of the Sustainable Building Conference, Oslo, Norway, 23–25 September 2002. [Google Scholar]

- Pérez-Urrestarazu, L. Water Consumption of Felt-Based Outdoor Living Walls in Warm Climates. Urban For. Urban Green. 2021, 59, 127025. [Google Scholar] [CrossRef]

- UNI EN ISO 14025:2010; Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. International Standard: Geneva, Switzerland, 2010.

- Prodanovic, V.; Wang, A.; Deletic, A. Assessing Water Retention and Correlation to Climate Conditions of Five Plant Species in Greywater Treating Green Walls. Water Res. 2019, 167, 115092. [Google Scholar] [CrossRef]

- Stache, E.; Schilperoort, B.; Ottelé, M.; Jonkers, H.M. Comparative Analysis in Thermal Behaviour of Common Urban Building Materials and Vegetation and Consequences for Urban Heat Island Effect. Build. Environ. 2022, 213, 108489. [Google Scholar] [CrossRef]

- Azkorra-Larrinaga, Z.; Erkoreka-González, A.; Martín-Escudero, K.; Pérez-Iribarren, E.; Romero-Antón, N. Thermal Characterization of a Modular Living Wall for Improved Energy Performance in Buildings. Build. Environ. 2023, 234, 110102. [Google Scholar] [CrossRef]

- Lakho, F.H.; Vergote, J.; Ihsan-Ul-Haq Khan, H.; Depuydt, V.; Depreeuw, T.; Van Hulle, S.W.H.; Rousseau, D.P.L. Total Value Wall: Full Scale Demonstration of a Green Wall for Grey Water Treatment and Recycling. J. Environ. Manag. 2021, 298, 113489. [Google Scholar] [CrossRef]

- Yungstein, Y.; Helman, D. Cooling, CO2 Reduction, and Energy-Saving Benefits of a Green-Living Wall in an Actual Workplace. Build. Environ. 2023, 236, 110220. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).