Degradation Effect of Moisture on Mechanical Properties of Kevlar/PVB Composites with TiO2 Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Samples

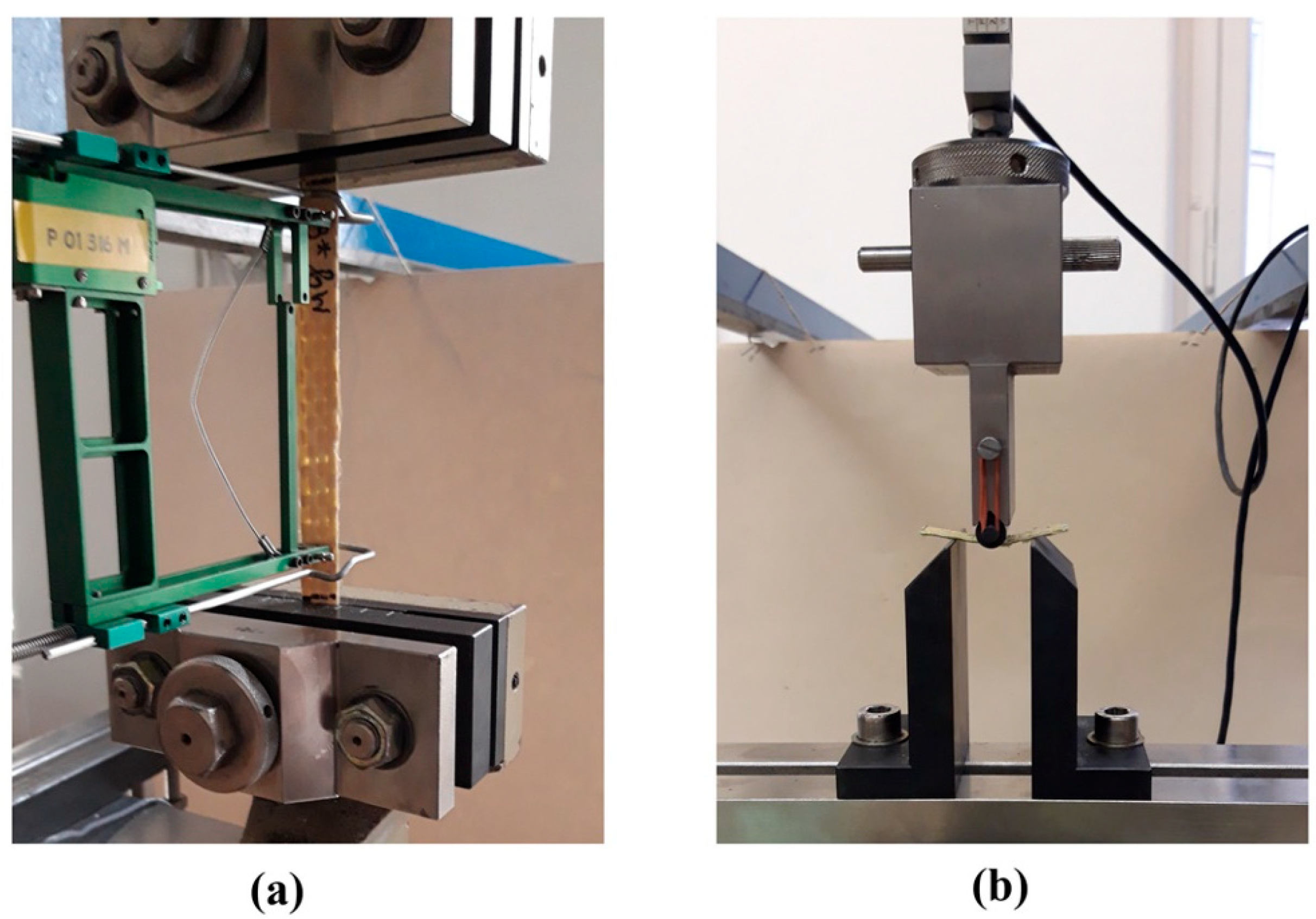

2.3. Characterization

2.4. Numerical Modelling

3. Results and Discussion

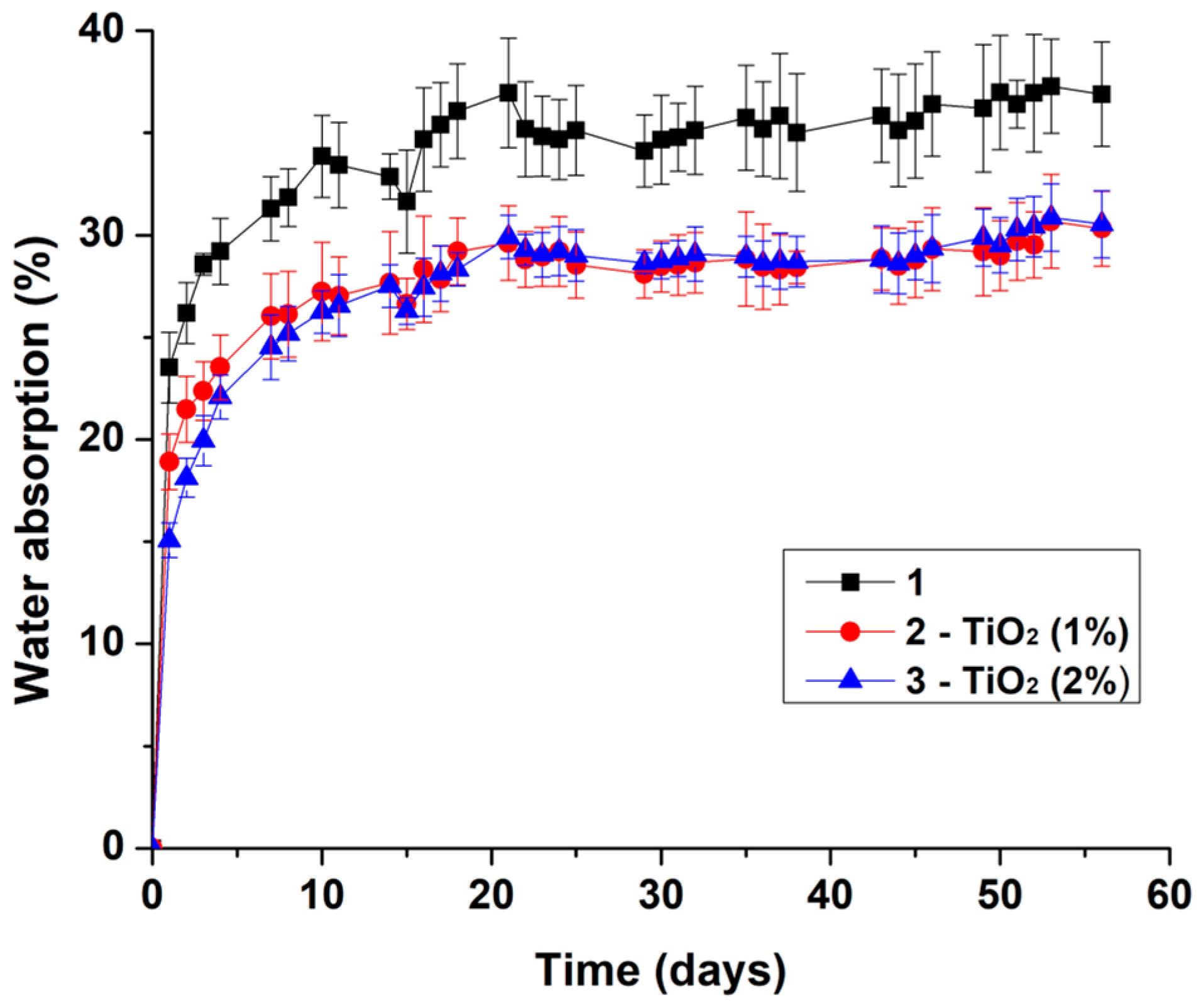

3.1. Water Absorption Results

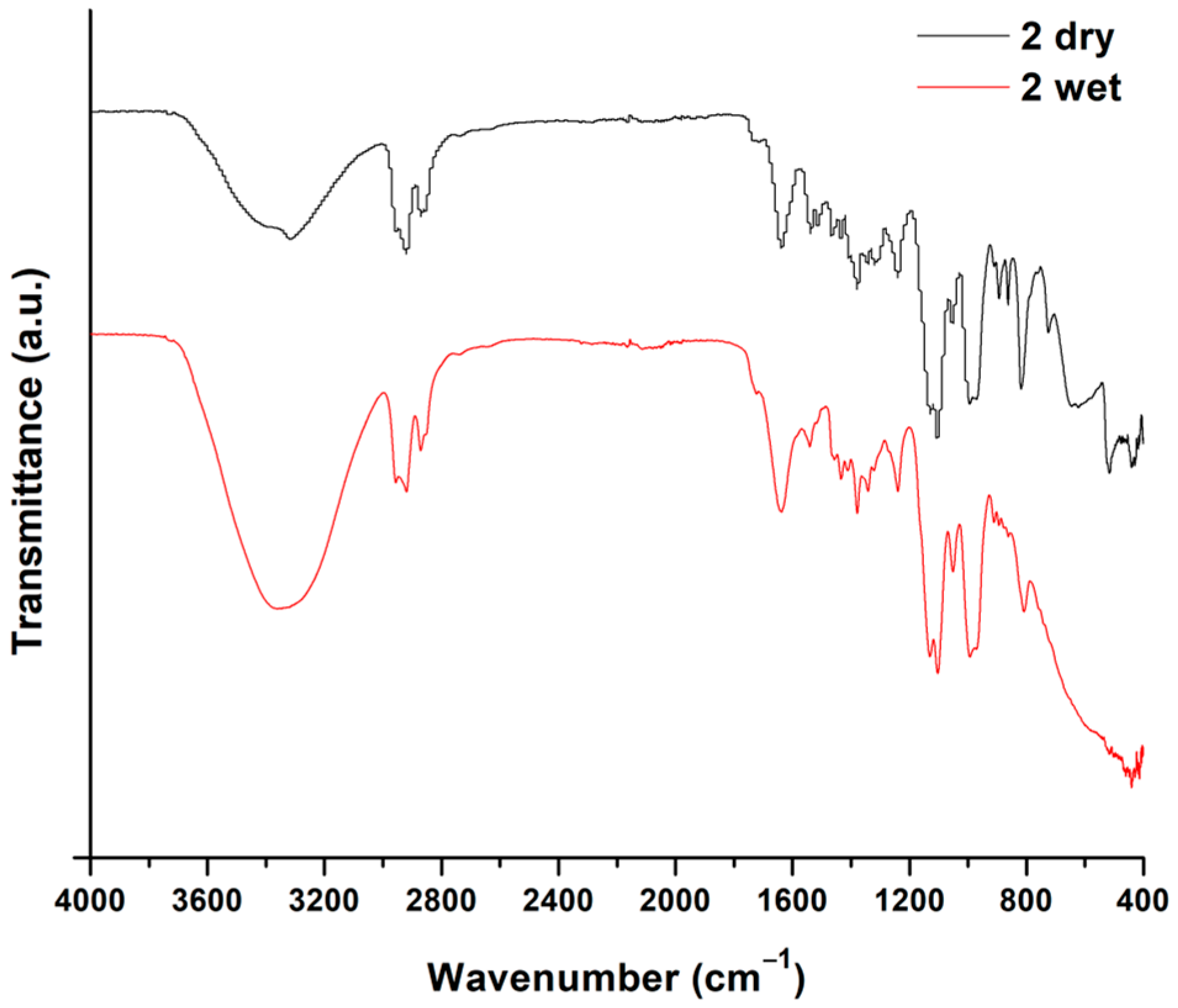

3.2. FTIR Analysis

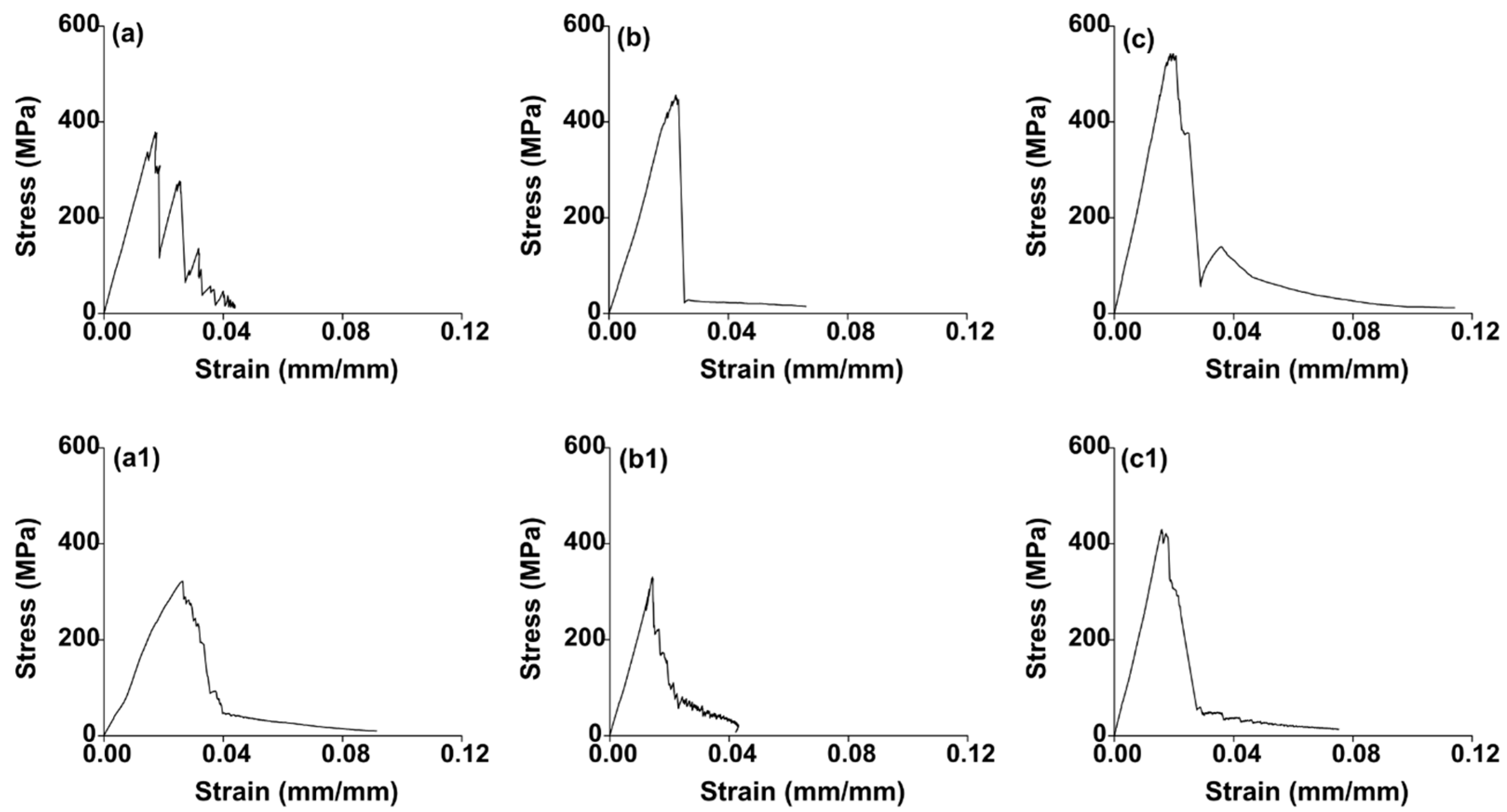

3.3. Tensile Test Results

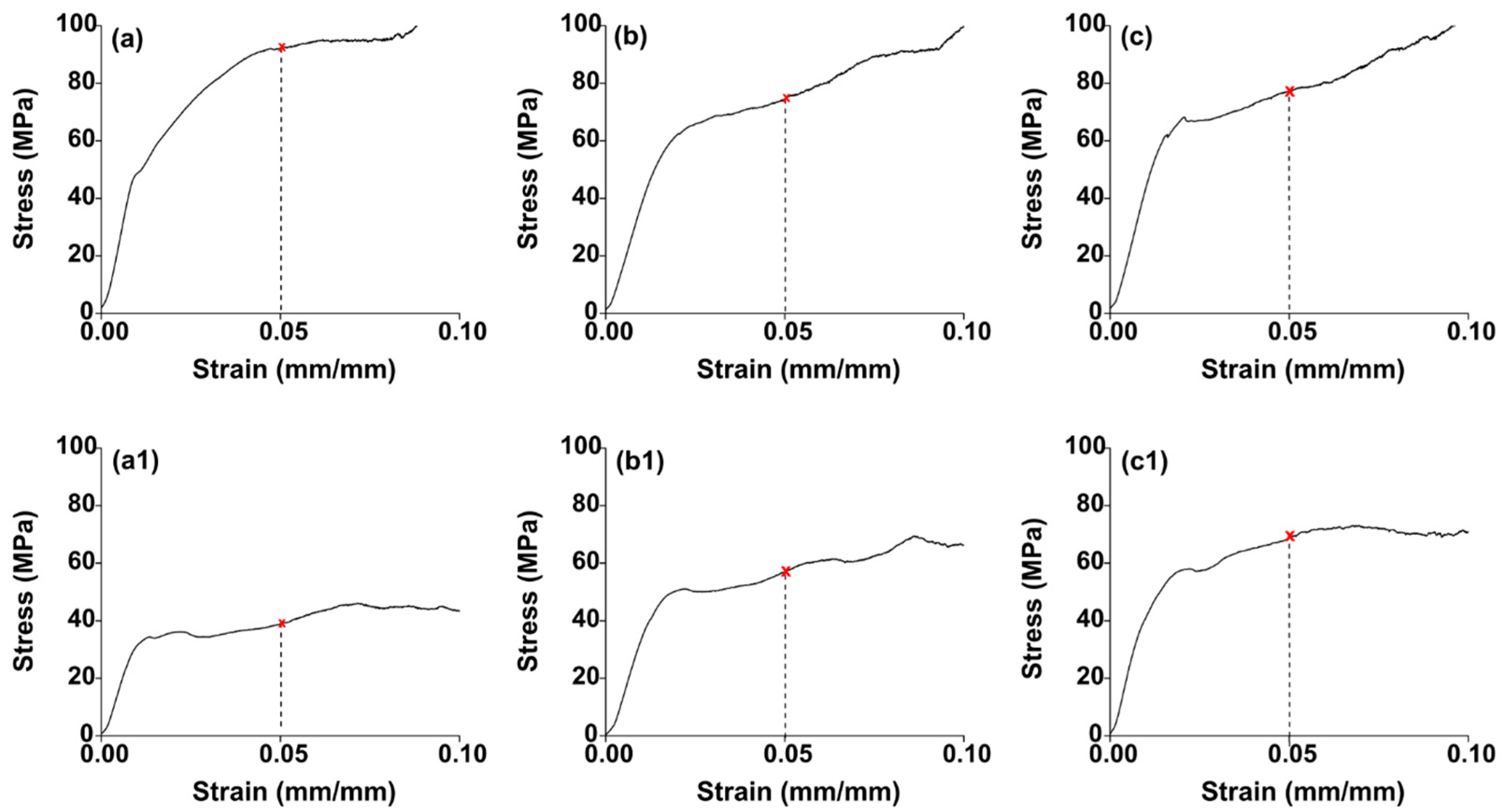

3.4. Bending Test Results

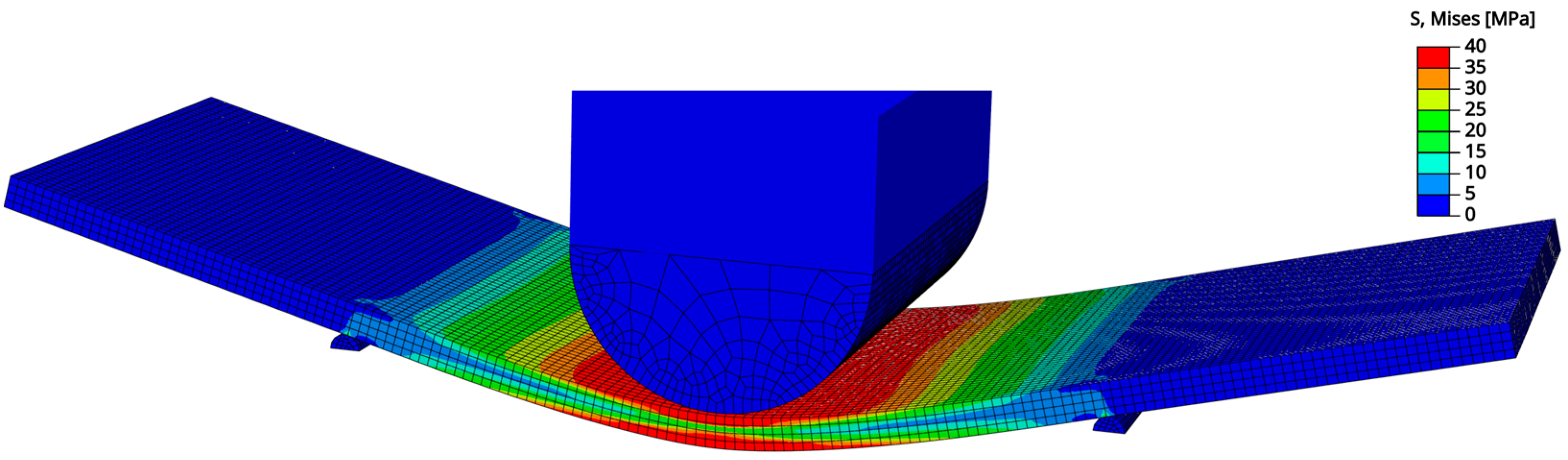

3.5. Numerical Modelling

4. Conclusions

- -

- The addition of TiO2 nanoparticles improved the tensile properties of Kevlar/PVB composites;

- -

- The immersion process lowered the tensile and bending strength;

- -

- The numerical simulation might provide more realistic values for the stress in the outer fibers at midpoint compared to the analytical formulae of the ASTM D 790-03 standard.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Seretis, G.V.; Kostazos, P.K.; Manolakos, D.E.; Provatidis, C.G. On the mechanical response of woven para-aramid protection fabrics. Compos. Part B Eng. 2015, 79, 67–73. [Google Scholar] [CrossRef]

- Obradović, V.; Simić, D.; Sejkot, P.; Machalická, K.V.; Vokáč, M. Moisture absorption characteristics and effects on mechanical properties of Kolon/epoxy composites. Curr. Appl. Phys. 2021, 26, 16–23. [Google Scholar] [CrossRef]

- Singh, T.J.; Samanta, S. Characterization of Kevlar fiber and its composites: A review. Mater. Today Proc. 2015, 2, 1381–1387. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, X.; Shen, J.; Gao, C.; Van der Bruggen, B. The potential of Kevlar aramid nanofiber composite membranes. J. Mater. Chem. A 2020, 8, 7548–7568. [Google Scholar] [CrossRef]

- Almaroof, A.; Ali, A.; Mannocci, F.; Deb, S. Semi-interpenetrating network composites reinforced with Kevlar fibers for dental post fabrication. Dent. Mater. J. 2019, 38, 511–521. [Google Scholar] [CrossRef] [PubMed]

- Obradović, V.; Simić, D.; Zrilić, M.; Stojanović, D.B.; Uskoković, P.S. Novel hybrid nanostructures of carbon nanotube/fullerene-like tungsten disulfide as reinforcement for aramid fabric composites. Fibers Polym. 2021, 22, 528–539. [Google Scholar] [CrossRef]

- Kumar, P.; Khan, N.; Kumar, D. Polyvinyl butyral (PVB), versetile template for designing nanocomposite/composite materials: A review. Green Chem. Technol. Lett. 2016, 2, 185–194. [Google Scholar] [CrossRef]

- Obradović, V.; Stojanović, D.B.; Jokić, B.; Zrilić, M.; Radojević, V.; Uskoković, P.S.; Aleksić, R. Nanomechanical and anti-stabbing properties of Kolon fabric composites reinforced with hybrid nanoparticles. Compos. Part B Eng. 2017, 108, 143–152. [Google Scholar] [CrossRef]

- Ismail, I.N.; Ishak, Z.A.M.; Jaafar, M.F.; Omar, S.; Zainal Abidin, M.F.; Ahmad Marzuki, H.F. Thermomechanical properties of toughened phenolic resol resin. Solid State Sci. Technol. 2009, 17, 155. [Google Scholar]

- Grębowski, K.; Wróbel, A. Architectural and Urban Planning Solutions for the Protection of Heritage Buildings in the Context of Terrorist Attacks: Following the Example of Passive Protection Systems. Buildings 2022, 12, 988. [Google Scholar] [CrossRef]

- Mowital—Your Global Partner for PVB. Available online: https://www.kuraray.eu/products-solutions/polyvinyl-butyral (accessed on 27 November 2023).

- Hooper, A.; Blackman, B.R.K.; Dear, J.P. The mechanical behaviour of poly (vinyl butyral) at different strain magnitudes and strain rates. J. Mater. Sci. 2012, 47, 3564. [Google Scholar] [CrossRef]

- Sánchez, M.; Campo, M.; Jiménez-Suárez, A.; Ureña, A. Effect of the carbon nanotube functionalization on flexural properties of multiscale carbon fiber/epoxy composites manufactured by VARIM. Compos. Part B Eng. 2013, 45, 1613–1619. [Google Scholar] [CrossRef]

- Mhadhbi, M.; Abderazzak, H.; Avar, B. Synthesis and Properties of Titanium Dioxide Nanoparticles; Intechopen: London, UK, 2023; Available online: https://www.intechopen.com/chapters/87015 (accessed on 10 January 2024).

- Siwińska-Stefańska, K.; Jesionowski, T. Advanced hybrid materials based on titanium dioxide for environmental and electrochemical applications. In Titanium Dioxide; IntechOpen: London, UK, 2017; Available online: https://www.intechopen.com/chapters/55832 (accessed on 10 January 2024).

- Nawaz, H.; Umar, M.; Maryam, R.; Nawaz, I.; Razzaq, H.; Malik, T.; Liu, X. Polymer Nanocomposites based on TiO2 as a reinforcing agent: An Overview. Adv. Eng. Mater. 2022, 24, 2200844. [Google Scholar] [CrossRef]

- Zamanian, M.; Sadrnia, H.; Khojastehpour, M.; Hosseini, F.; Thibault, J. Effect of TiO2 nanoparticles on barrier and mechanical properties of PVA films. J. Membr. Sci. Res. 2021, 7, 67–73. [Google Scholar]

- Amit, C.; Islam, M.S. Fabrication and characterization of TiO2-epoxy nanocomposites. Mater. Sci. Eng. A 2008, 487, 574–585. [Google Scholar]

- Doxsee JR, L.E.; Janssens, W.; Verpoest, I.; De Meester, P. Strength of aramid-epoxy composites during moisture absorption. J. Reinf. Plast. Comp. 1991, 10, 645–655. [Google Scholar] [CrossRef]

- Desloir, M.; Benoit, C.; Bendaoud, A.; Alcouffe, P.; Carrot, C. Plasticization of poly (vinyl butyral) by water: Glass transition temperature and mechanical properties. J. Appl. Polym. Sci. 2019, 136, 47230. [Google Scholar] [CrossRef]

- Botelho, E.C.; Silva, R.A.; Pardini, L.C.; Rezende, M.C. A review on the development and properties of continuous fiber/epoxy/aluminum hybrid composites for aircraft structures. Mater. Res. 2006, 9, 247–256. [Google Scholar] [CrossRef]

- ISO 62:2008; Plastics—Determination of Water Absorption. ISO (International Organization for Standardization): Geneva, Switzerland, 2008.

- Obradović, V.; Bajić, D.; Sejkot, P.; Fidanovski, B.; Machalická, K.V.; Vokáč, M. Effect of moisture absorption on the thermo-mechanical properties of carbon/epoxy composites with SiC reinforcement. Compos. Interfaces 2022, 29, 1309–1324. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM D790-03; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2003.

- Alamri, H.; Low, I.M. Effect of water absorption on the mechanical properties of nano-filler reinforced epoxy nanocomposites. Mater. Des. 2012, 42, 214–222. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Effect of water absorption on the mechanical properties of n-SiC filled recycled cellulose fibre reinforced epoxy eco-nanocomposites. Polym. Test. 2012, 31, 810–818. [Google Scholar] [CrossRef]

- Obradović, V.; Vuksanović, M.; Tomić, N.; Petrović, M.; Marinković, A.; Stojanović, D.; Radojević, V.; Heinemann, R.J.; Uskoković, P. Impact properties of Kolon/PVB fabrics reinforced with rice-husk silica particles. Mater. Lett. 2022, 324, 132668. [Google Scholar] [CrossRef]

- Ehrhart, B.; Valeske, B.; Ecault, R.; Boustie, M.; Berthe, L.; Bockenheimer, C. Extended NDT for the quality assessment of adhesive bonded CFRP structures. In Proceedings of the Smart Material, Structures & NDT in Aerospace Conference, Montreal, QC, Canada, 2 November 2011. [Google Scholar]

- Callister, W.D., Jr. Materials Science and Engineering: An Introduction, 7th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2007. [Google Scholar]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B-Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Wang, M.; Berry, C.; Braden, M.; Bonfield, W. Young’s and shear moduli of ceramic particle filled polyethylene. J. Mater. Sci. Mater. Med. 1998, 9, 621–624. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Al-Huniti, N. Critical review of the parameters affecting the effectiveness of moisture absorption treatments used for natural composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Akay, M.; Mun, S.K.; Stanley, A. Influence of moisture on the thermal and mechanical properties of autoclaved and oven-cured Kevlar-49/epoxy laminates. Compos. Sci. Technol. 1997, 57, 565–571. [Google Scholar] [CrossRef]

- Ahn, H.; Wee, J.H.; Kim, Y.M.; Yu, W.R.; Yeo, S.Y. Microstructure and Mechanical Properties of Polyacrylonitrile Precursor Fiber with Dry and Wet Drawing Process. Polymers 2021, 13, 1613. [Google Scholar] [CrossRef] [PubMed]

- Ogrodowska, K.; Łuszcz, K.; Garbacz, A.N. Hybridization and Temperature Impact on Shear Strength of Basalt Fiber-Reinforced Polymer Bars. Polymers 2021, 13, 2585. [Google Scholar] [CrossRef]

- Somaiah Chowdary, M.; Raghavendra, G.; Niranjan Kumar, M.S.R.; Ojha, S.; Om Prakash, M. A review on the degradation of properties under the influence of liquid medium of hybrid polymer composites. SN Appl. Sci. 2020, 2, 1708. [Google Scholar] [CrossRef]

- Rafiq, A.; Merah, N. Nanoclay enhancement of flexural properties and water uptake resistance of glass fiber-reinforced epoxy composites at different temperatures. J. Compos. Mater. 2019, 53, 143–154. [Google Scholar] [CrossRef]

- Tupý, M.; Měřínská, D.; Svoboda, P.; Kalendová, A.; Klásek, A.; Zvoníček, J. Effect of water and acid–base reactants on adhesive properties of various plasticized poly (vinyl butyral) sheets. J. Appl. Polym. Sci. 2013, 127, 3474–3484. [Google Scholar] [CrossRef]

- Hou, P.; Zhao, H.; Ma, Z.; Zhang, S.; Li, J.; Dong, X.; Sun, Y.; Zhu, Z. Influence of punch radius on elastic modulus of three-point bending tests. Adv. Mech. Eng. 2016, 8, 1–8. [Google Scholar] [CrossRef]

| Specimen | Tensile Strength | TEA | Tensile Modulus |

|---|---|---|---|

| (MPa) | (N/mm2) | (GPa) | |

| Kevlar/PVB—dry | 369.71 ± 30.00 | 7.70 ± 2.65 | 24.85 ± 4.42 |

| Kevlar/PVB—wet | 293.09 ± 15.34 | 7.80 ± 0.47 | 19.02 ± 2.51 |

| Kevlar/PVB/1% TiO2—dry | 423.80 ± 29.05 | 5.87 ± 1.53 | 23.15 ± 2.31 |

| Kevlar/PVB/1% TiO2—wet | 351.41 ± 21.41 | 5.12 ± 2.43 | 22.02 ± 1.11 |

| Kevlar/PVB/2% TiO2—dry | 516.84 ± 42.01 | 8.85 ± 2.99 | 30.90 ± 1.99 |

| Kevlar/PVB/2% TiO2—wet | 426.03 ± 20.45 | 6.51 ± 1.47 | 25.98 ± 2.48 |

| Specimen | Flexural Strength, 5% Strain | Flexural Modulus |

|---|---|---|

| (MPa) | (GPa) | |

| Kevlar/PVB—dry | 98.58 ± 4.99 | 5.61 ± 0.89 |

| Kevlar/PVB—wet | 38.02 ± 2.11 | 4.40 ± 0.62 |

| Kevlar/PVB/1% TiO2—dry | 72.76 ± 5.00 | 3.98 ± 0.20 |

| Kevlar/PVB/1% TiO2—wet | 45.62 ± 8.44 | 3.50 ± 1.29 |

| Kevlar/PVB/2% TiO2—dry | 71.45 ± 10.65 | 3.70 ± 1.13 |

| Kevlar/PVB/2% TiO2—wet | 54.96 ± 9.99 | 3.01 ± 1.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obradović, V.; Sejkot, P.; Zabloudil, A.; Machalická, K.V.; Vokáč, M. Degradation Effect of Moisture on Mechanical Properties of Kevlar/PVB Composites with TiO2 Nanoparticles. Buildings 2024, 14, 409. https://doi.org/10.3390/buildings14020409

Obradović V, Sejkot P, Zabloudil A, Machalická KV, Vokáč M. Degradation Effect of Moisture on Mechanical Properties of Kevlar/PVB Composites with TiO2 Nanoparticles. Buildings. 2024; 14(2):409. https://doi.org/10.3390/buildings14020409

Chicago/Turabian StyleObradović, Vera, Petr Sejkot, Adam Zabloudil, Klára V. Machalická, and Miroslav Vokáč. 2024. "Degradation Effect of Moisture on Mechanical Properties of Kevlar/PVB Composites with TiO2 Nanoparticles" Buildings 14, no. 2: 409. https://doi.org/10.3390/buildings14020409

APA StyleObradović, V., Sejkot, P., Zabloudil, A., Machalická, K. V., & Vokáč, M. (2024). Degradation Effect of Moisture on Mechanical Properties of Kevlar/PVB Composites with TiO2 Nanoparticles. Buildings, 14(2), 409. https://doi.org/10.3390/buildings14020409