A Study on the Factors Influencing High Backfill Slope Reinforced with Anti-Slide Piles under Static Load Based on Numerical Simulation

Abstract

1. Introduction

2. Engineering Overview and Test Point Selection

2.1. Project Overview

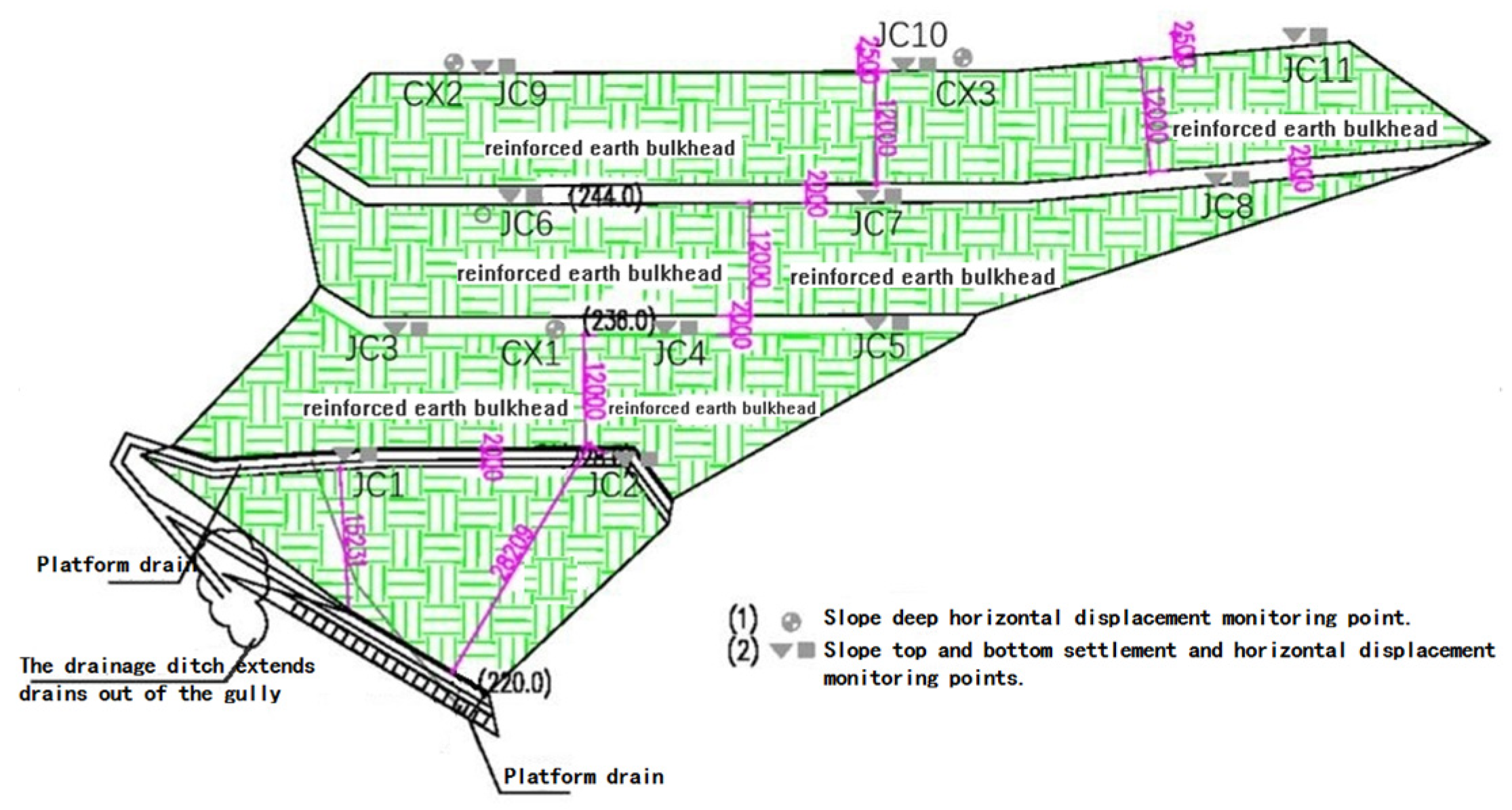

2.2. Selection of Test Points

3. Model Establishment

4. Finite Element Results Analysis

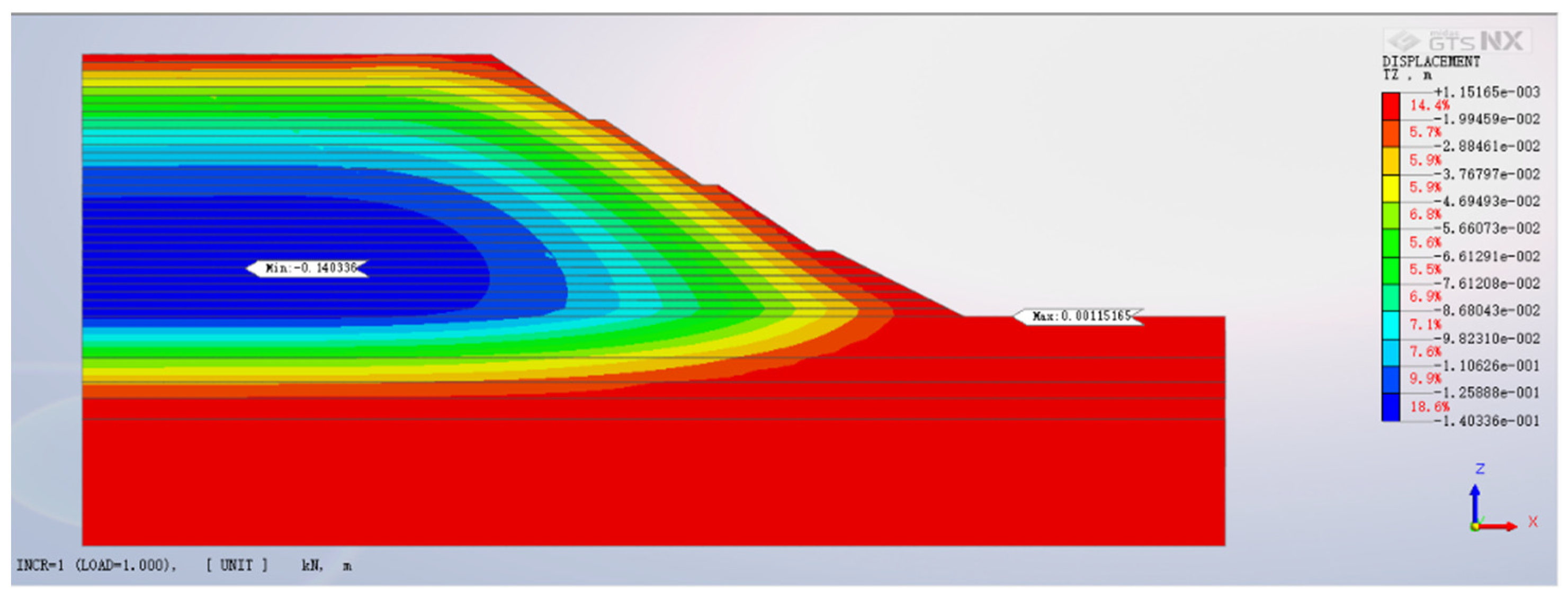

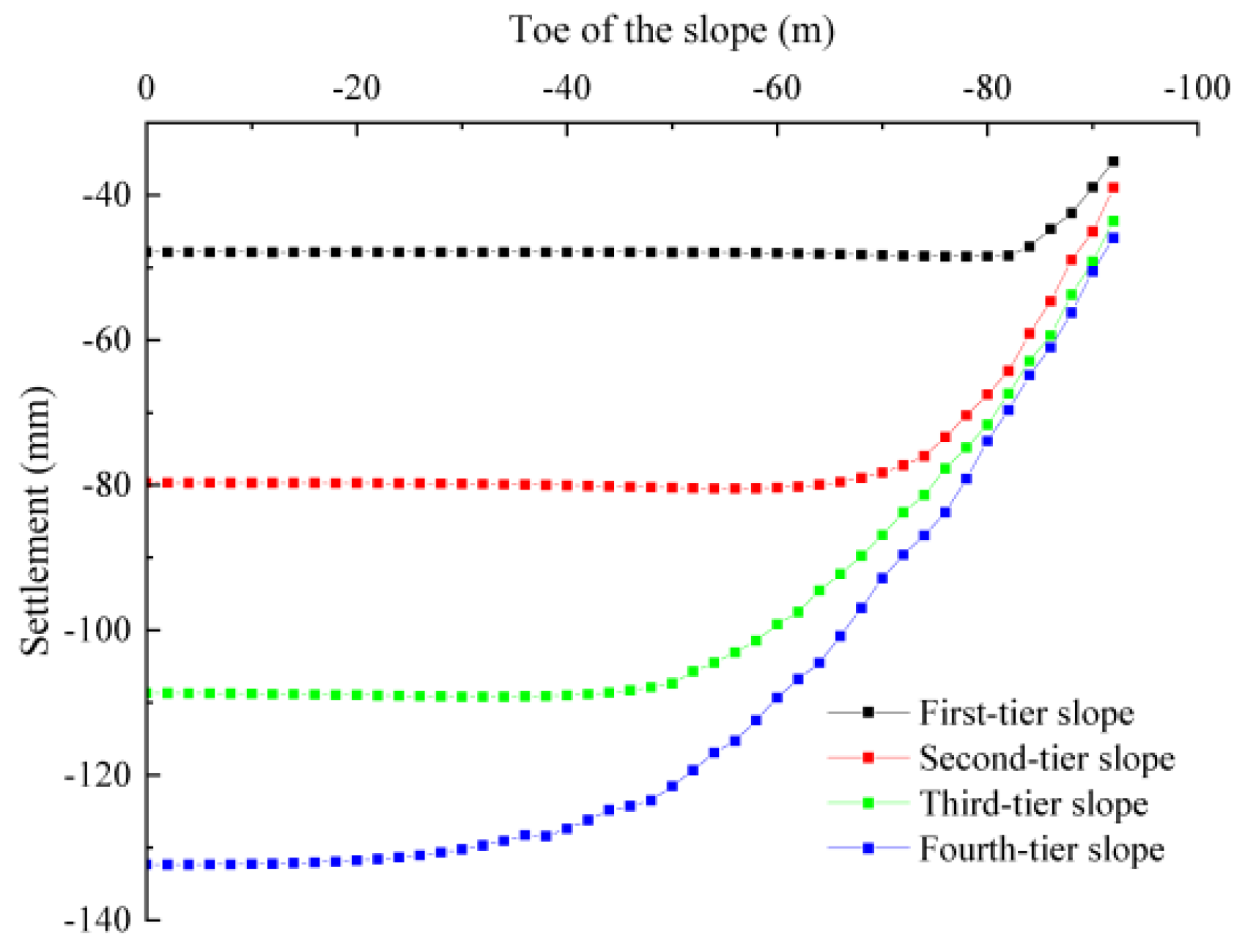

4.1. Slope Vertical Displacement Analysis

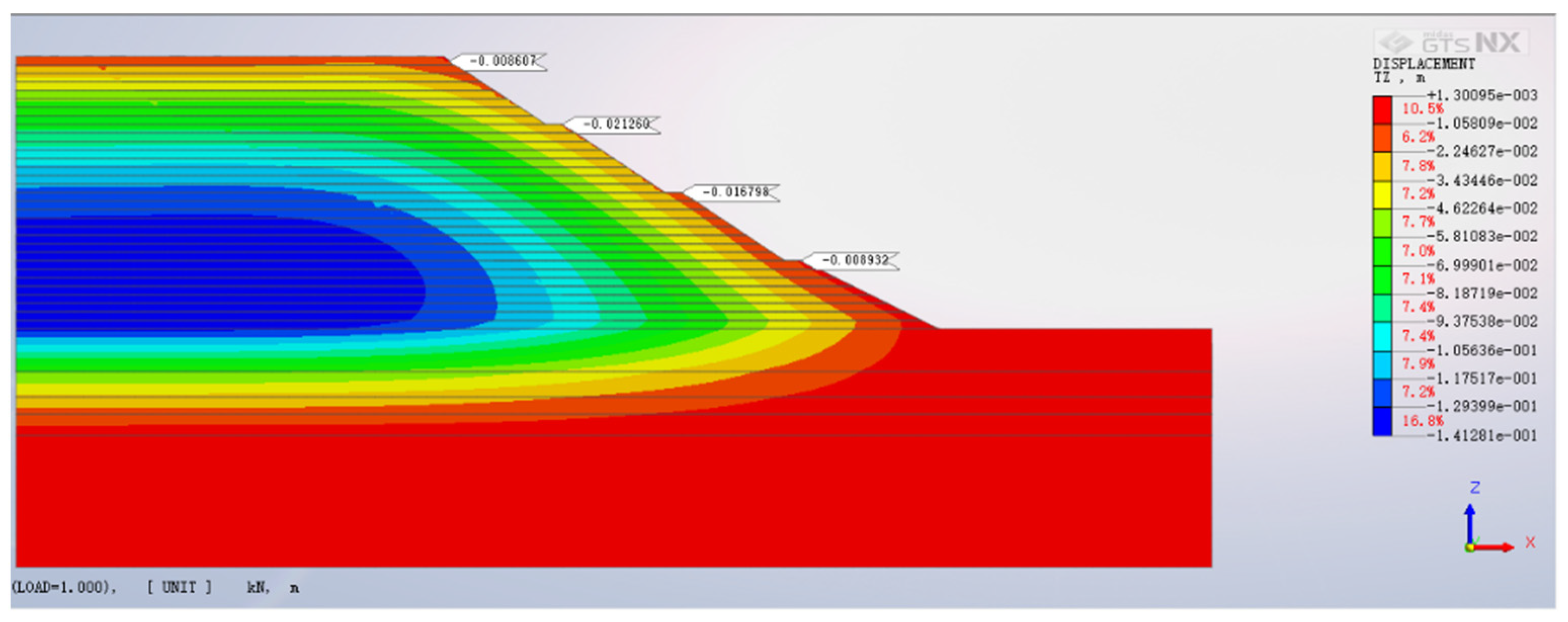

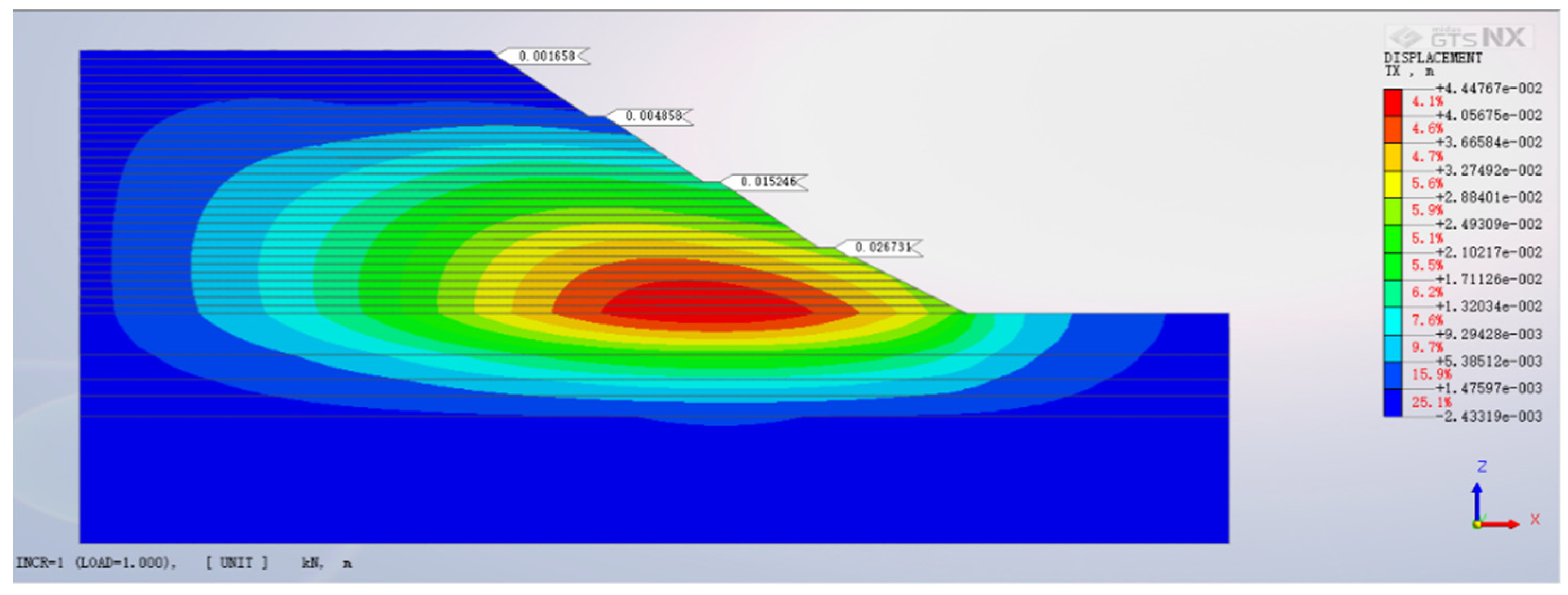

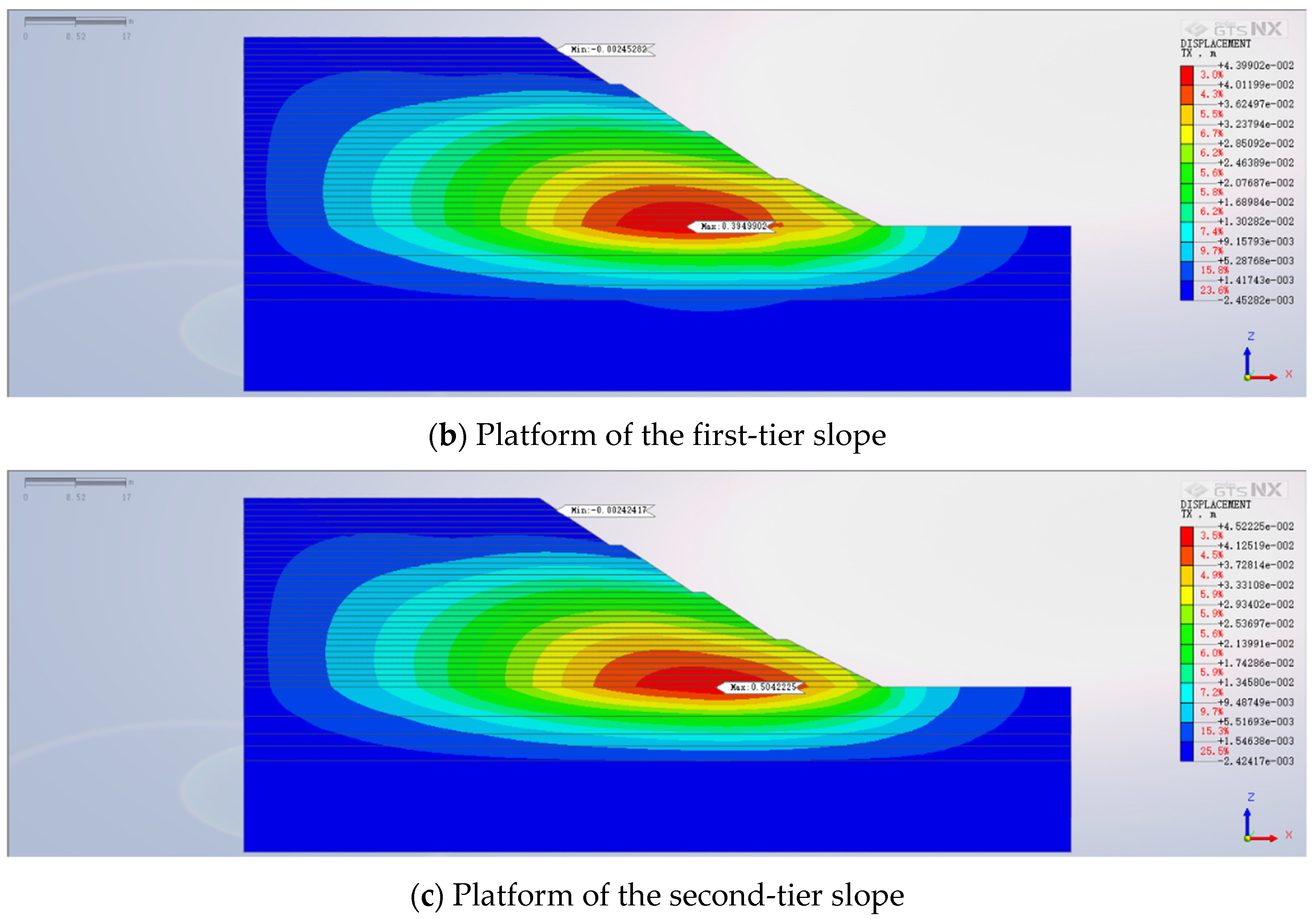

4.2. Slope Horizontal Displacement Analysis

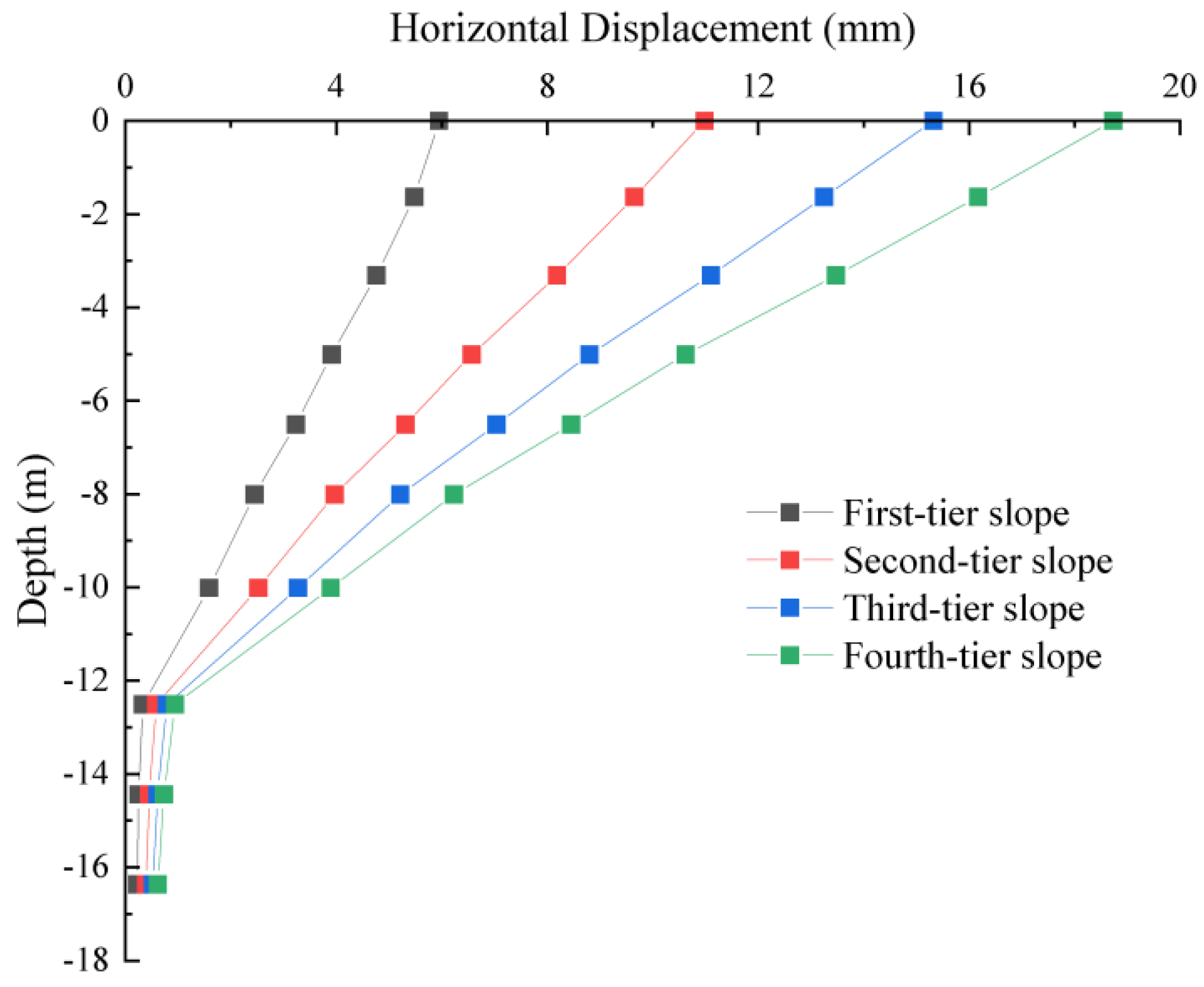

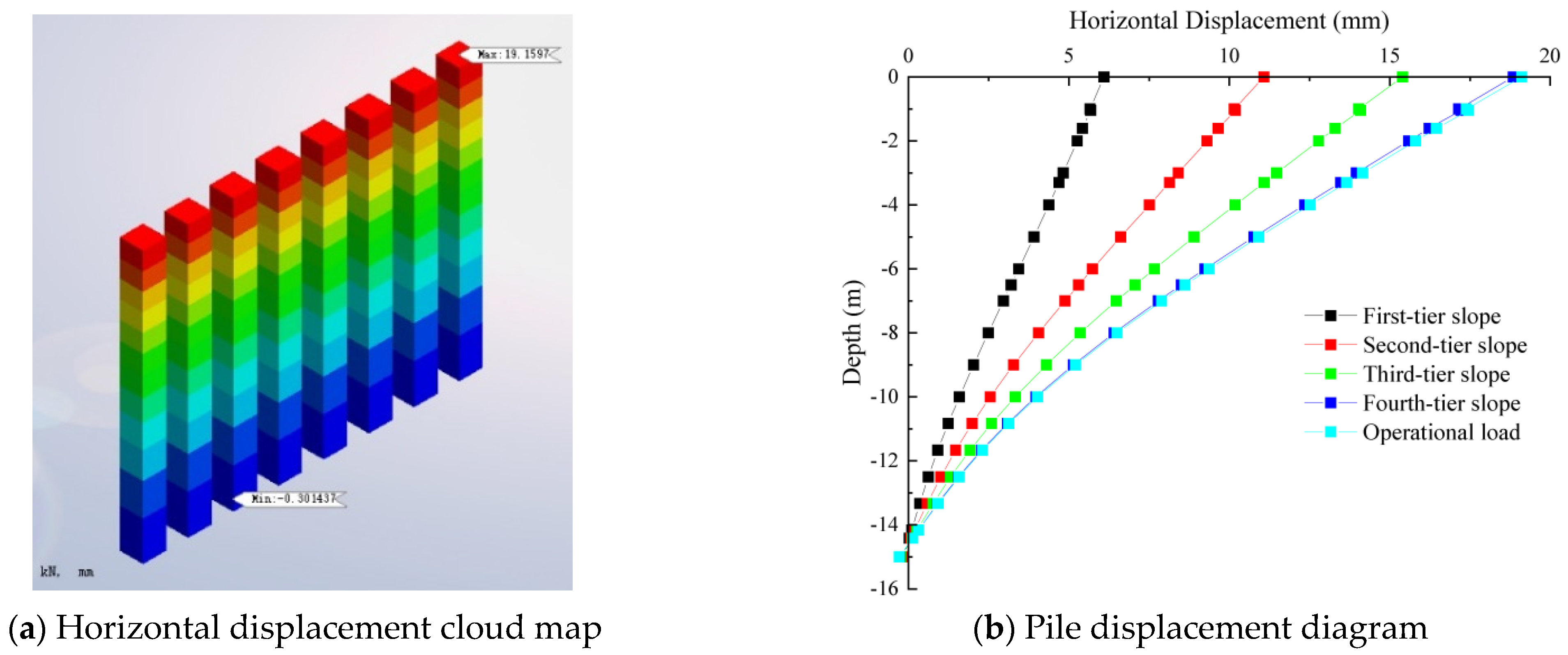

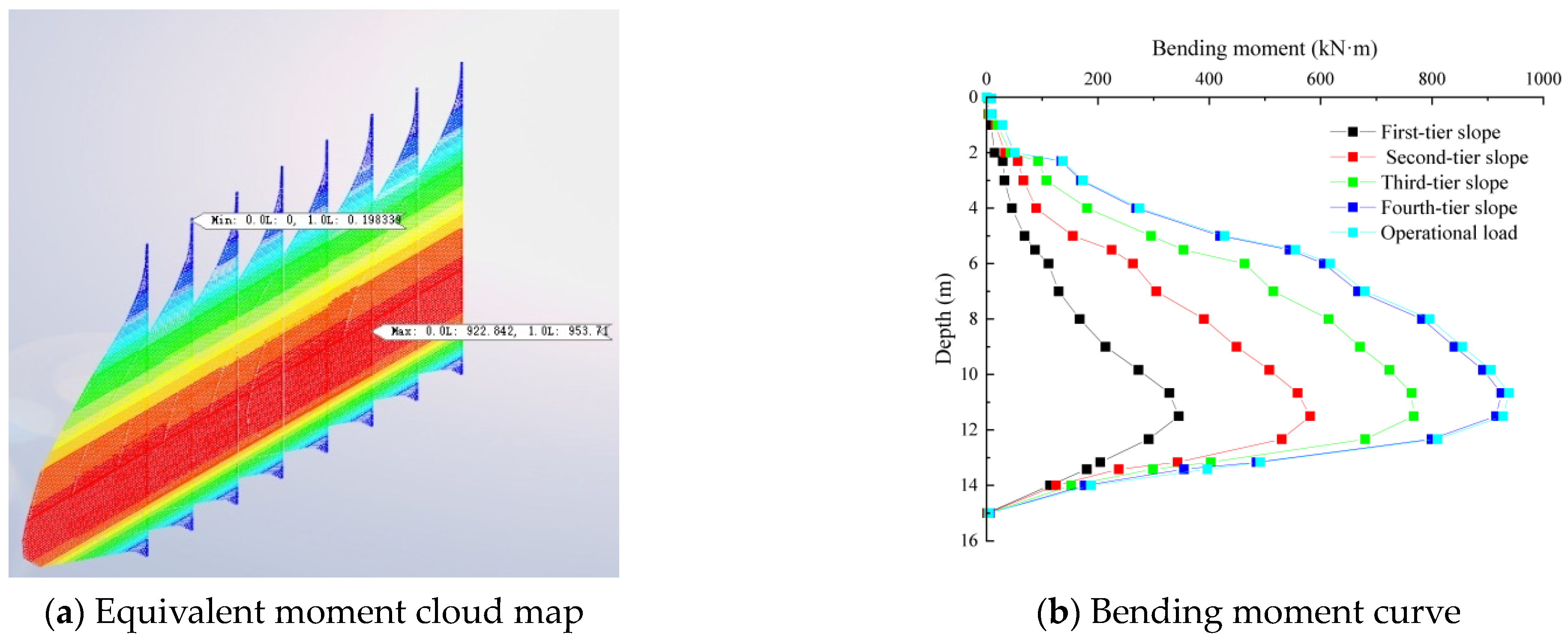

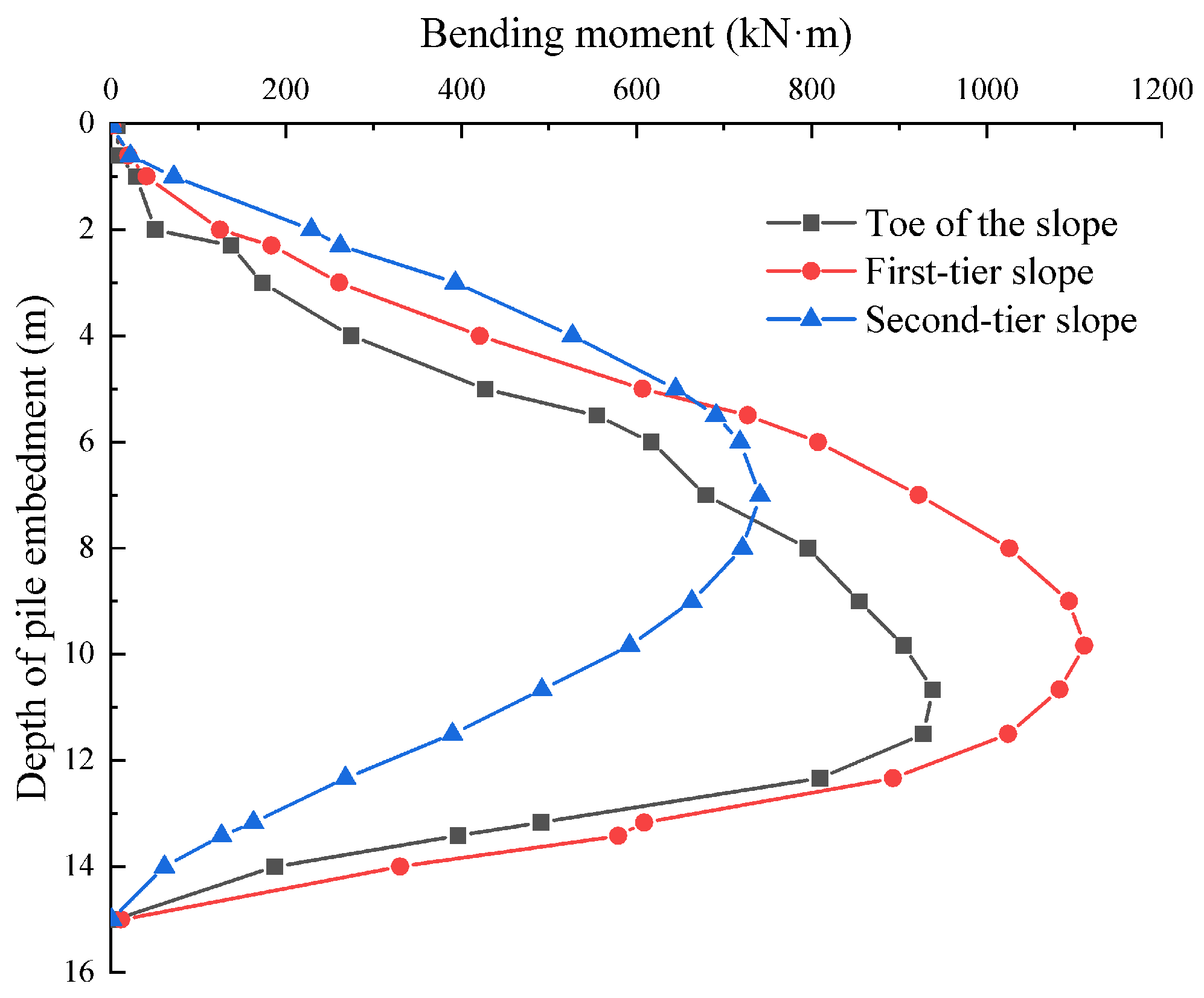

4.3. Analysis of Lateral Displacement and Bending Moment of Anti-Sliding Piles

5. Analysis of Factors Affecting High Backfilled Slope Reinforced by Anti-Sliding Piles

5.1. Influence of Anti-Sliding Pile Length on High Backfilled Slope

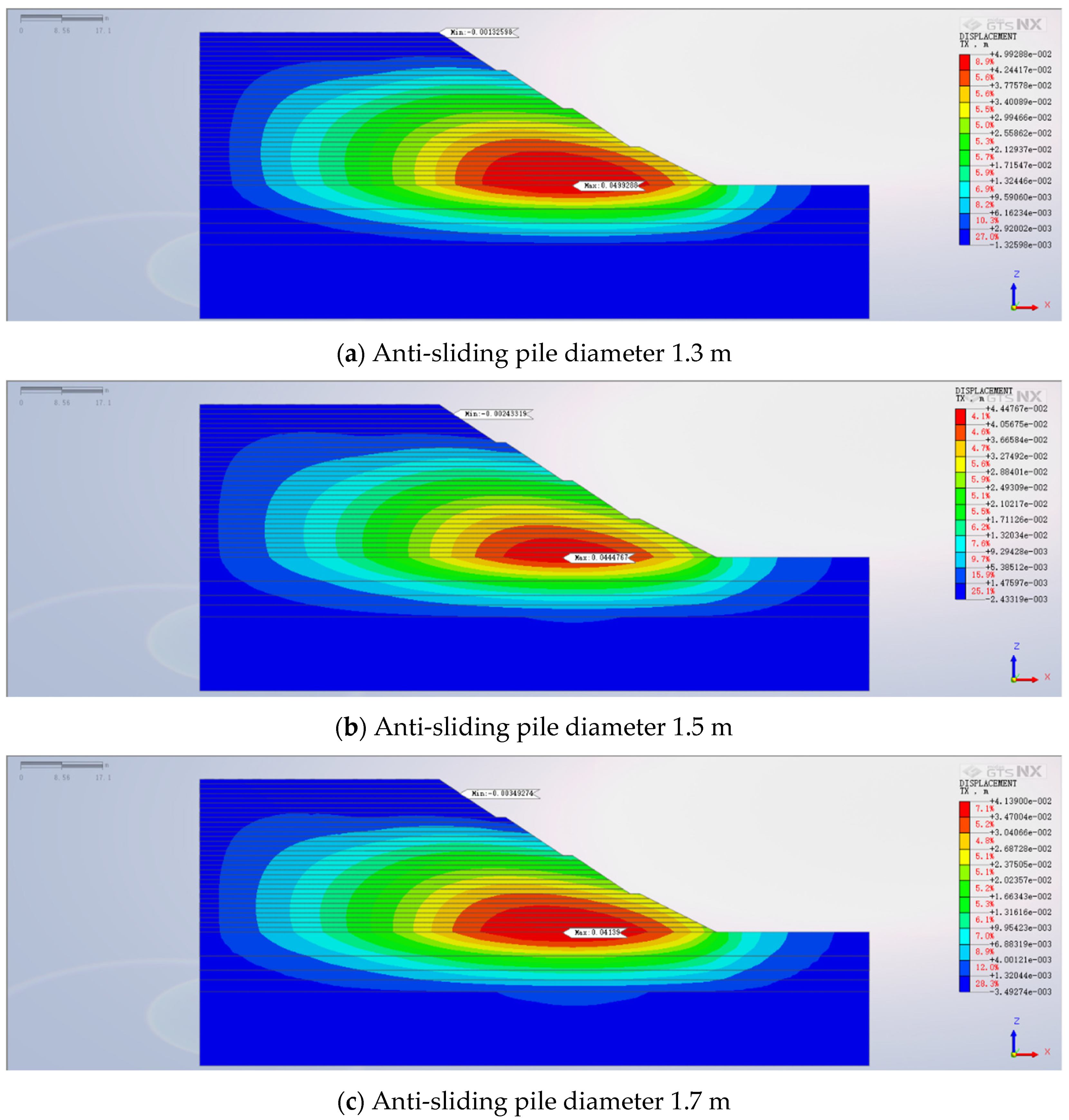

5.2. Impact of Pile Diameter on High Backfill Slope Reinforced with Anti-slide Piles

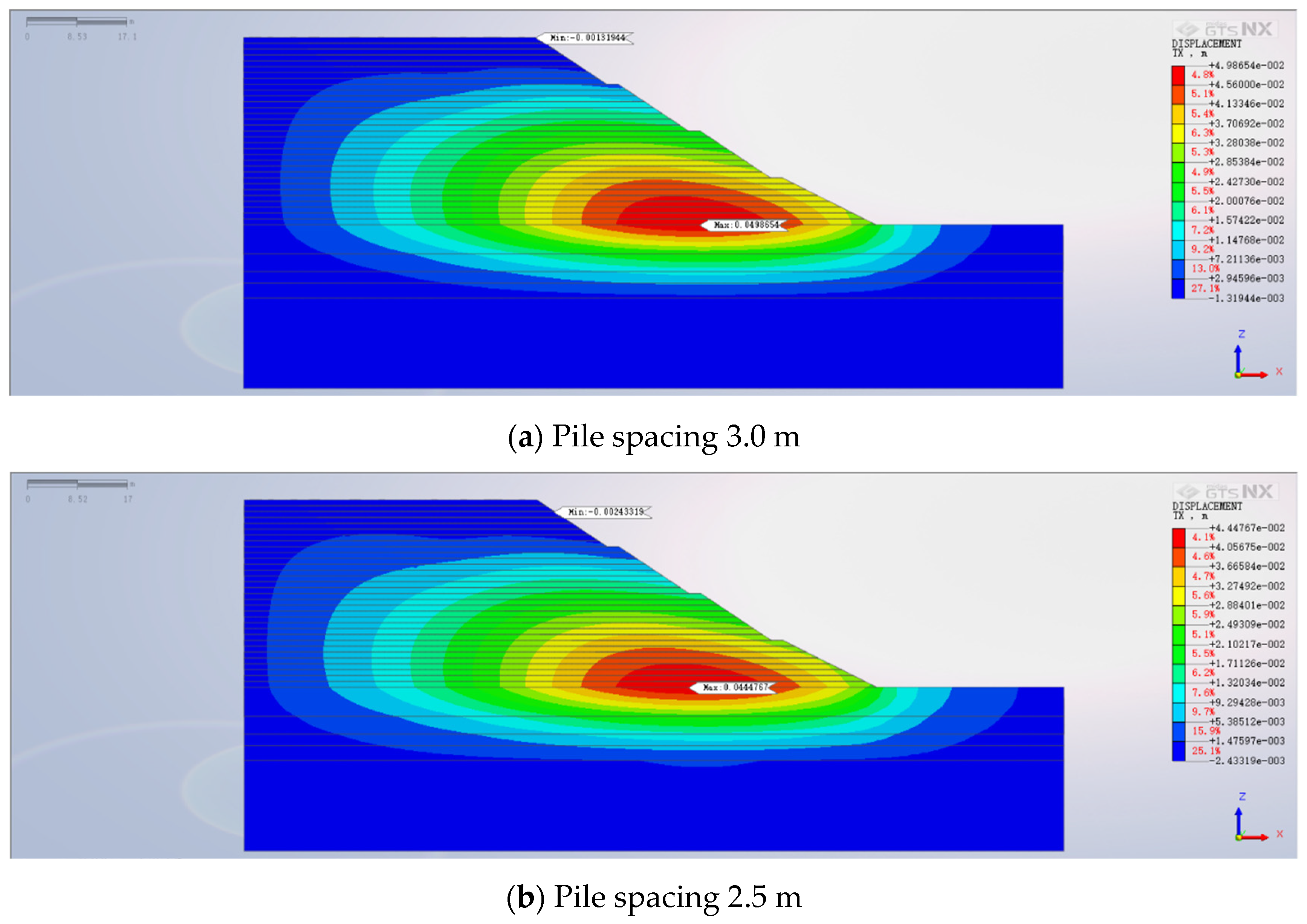

5.3. Impact of Pile Spacing on High Backfill Slope Reinforced with Anti-Slide Piles

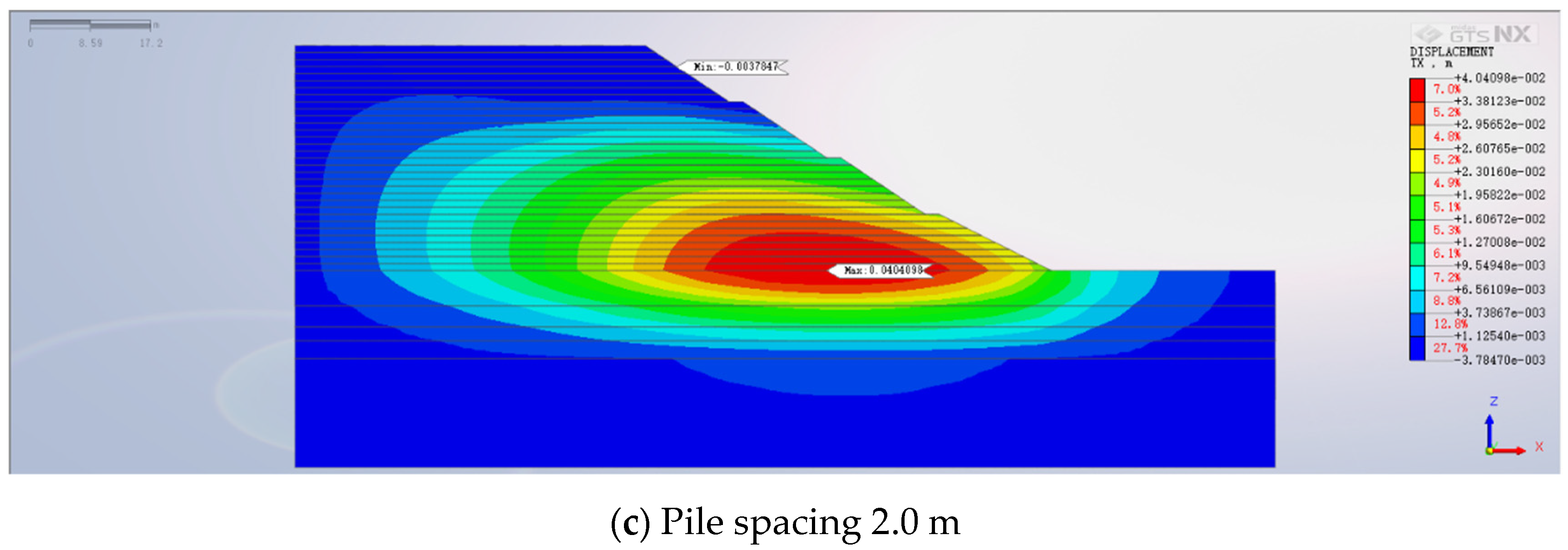

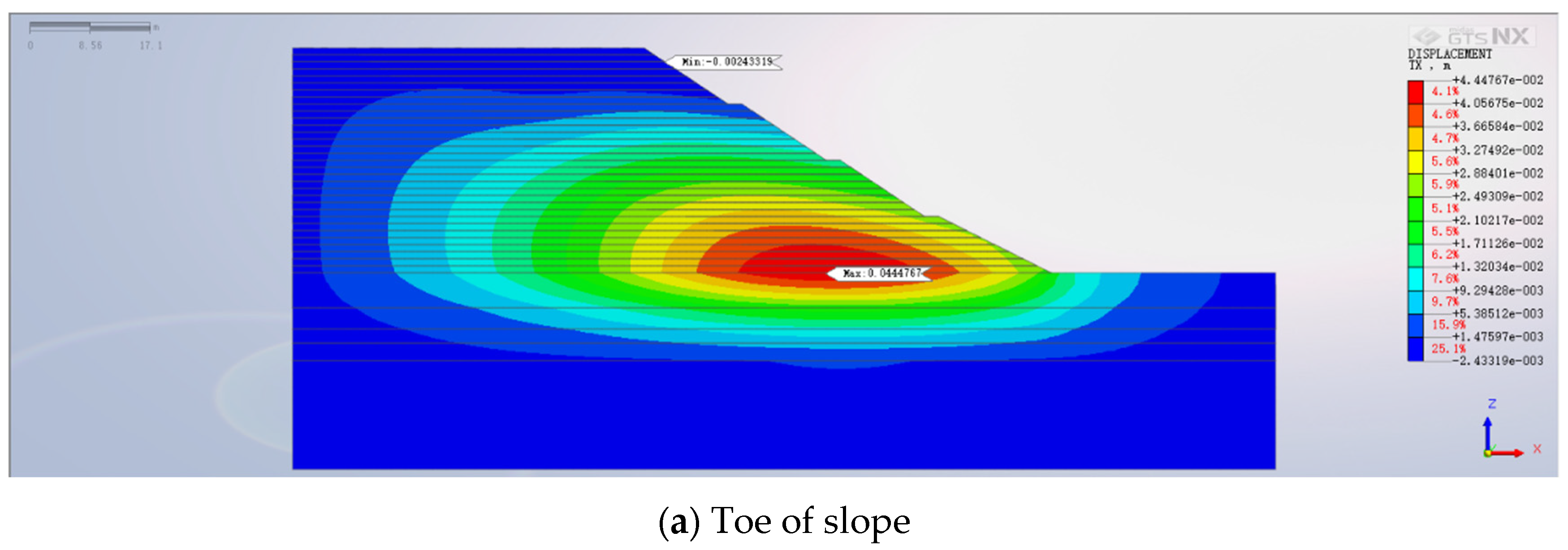

5.4. Influence of Anti-Slide Pile Position on High Backfill Slope

6. Conclusions

- (1)

- Vertical settlement prevails as the predominant form of displacement in high backfilled slopes, with the zenith of settlement not aligning with the slope crest but instead adjacent to the summits of the second and third tiers. As backfill height escalates, vertical settlement mounts, albeit at a decelerating pace.

- (2)

- The horizontal slope displacement is subject to both backfill height and the characteristics of anti-slide piles. Augmenting the backfill height induces horizontal displacement escalation, albeit with diminishing rates. The apex horizontal displacement is situated at the first tier’s crest. Furthermore, as the backfill height amplifies, the horizontal displacement at the crest diminishes progressively. This observed pattern from finite element calculations aligns with the displacement trend observed at the crest via field monitoring.

- (3)

- Alterations in anti-slide pile parameters wield a more substantial influence on the horizontal displacement of the backfilled slope. As pile length and diameter expand, horizontal displacement systematically recedes. However, after penetrating the weathered rock layer, the effect of pile length on horizontal displacement dwindles. Furthermore, reducing pile spacing yields reduced horizontal displacement, although the pace of reduction decelerates progressively.

- (4)

- The arrangement of anti-slide piles profoundly impacts both horizontal displacement and bending moments within the slope. Placing piles on the second-tier platform diminishes reinforcement efficacy due to inadequate embedding in the rock layer, resulting in the most substantial horizontal displacement. Pile placement at the slope toe embeds them in the weathered rock layer, yet their proximity to the region of maximum displacement hinders full effectiveness. Conversely, situating piles on the first-tier platform effectively curbs lateral soil movement, yielding minor horizontal displacement and optimum reinforcement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bai, B.; Nie, Q.; Zhang, Y.; Wang, X.; Hu, W. Cotransport of heavy metals and SiO2 particles at different temperatures by seepage. J. Hydrol. 2021, 597, 125771. [Google Scholar] [CrossRef]

- Bai, B.; Rao, D.; Chang, T.; Guo, Z. A nonlinear attachment-detachment model with adsorption hysteresis for suspension-colloidal transport in porous media. J. Hydrol. 2019, 578, 124080. [Google Scholar] [CrossRef]

- Bai, B.; Zhou, R.; Cai, G.; Hu, W.; Yang, G. Coupled thermo-hydro-mechanical mechanism in view of the soil particle rearrangement of granular thermodynamics. Comput. Geotech. 2021, 137, 104272. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, W.; Zhao, J.; Li, L.; Liu, F.; Guo, Y.; Zhang, B. Addition of alkaline solutions and fibers for the reinforcement of kaolinite-containing granite residual soil. Appl. Clay Sci. 2022, 228, 106644. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, W.; Li, Z.; Zhao, J.; Luo, Q.; Chen, W.; Chen, T. Sustainability of the polymer SH reinforced recycled granite residual soil: Properties, physicochemical mechanism, and applications. J. Soils Sediments 2023, 23, 246–262. [Google Scholar] [CrossRef]

- Cui, C.; Liang, Z.; Xu, C.; Xin, Y.; Wang, B. Analytical solution for horizontal vibration of end-bearing single pile in radially heterogeneous saturated soil. Appl. Math. Model. 2023, 116, 65–83. [Google Scholar] [CrossRef]

- Meng, K.; Cui, C.; Liang, Z.; Li, H.; Pei, H. A new approach for longitudinal vibration of a large-diameter floating pipe pile in visco-elastic soil considering the three-dimensional wave effects. Comput. Geotech. 2020, 128, 103840. [Google Scholar] [CrossRef]

- Wei, L.; Chen, C.; Yang, C. Study on Constitutive Relation and Permeable Coefficient Tensor of Rocks under Tensile Stress Loading with Micromechanics. Key Eng. Mater. 2006, 324–325, 899–902. [Google Scholar] [CrossRef]

- Yang, G.; Zhong, Z.; Zhang, Y.; Fu, X. Optimal design of anchor cables for slope reinforcement based on stress and displacement fields. J. Rock Mech. Geotech. Eng. 2015, 7, 411–420. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, J.; Du, Y.; Gao, Y.; Li, J. A laboratory and field-monitoring experiment on the ability of anti-slide piles to prevent buckling failures in bedding slopes. Environ. Earth Sci. 2021, 80, 44. [Google Scholar] [CrossRef]

- Qu, L.-M.; Ding, X.-M.; Wu, C.-R.; Long, Y.-H.; Yang, J.-C. Effects of topography on dynamic responses of single piles under vertical cyclic loading. J. Mt. Sci. 2020, 17, 230–243. [Google Scholar] [CrossRef]

- Xiao, J.; Long, X.; Qu, W.; Li, L.; Jiang, H.; Zhong, Z. Influence of sulfuric acid corrosion on concrete stress–strain relationship under uniaxial compression. Measurement 2022, 187, 110318. [Google Scholar] [CrossRef]

- Que, X.; Zhu, Z.; Niu, Z.; Zhu, S.; Wang, L. A modified three-dimensional Hoek–Brown criterion for intact rocks and jointed rock masses. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 7. [Google Scholar] [CrossRef]

- Li, X.Z.; Jiang, H.; Pan, Q.J.; Zhao, L.H. Characterizing model uncertainty of upper-bound limit analysis on slopes using 3D rotational failure mechanism. Rock Mech. Bull. 2023, 2, 100026. [Google Scholar] [CrossRef]

- Lefebvre, G.; Duncan James, M.; Wilson Edward, L. Closure to “Three-Dimensional Finite Element Analyses of Dams”. J. Geotech. Eng. Div. 1974, 100, 1164. [Google Scholar] [CrossRef]

- Yang, X.-L.; Wei, J.-J. Analytical approach for stability of 3D two-stage slope in non-uniform and unsaturated soils. Eng. Geol. 2021, 292, 106243. [Google Scholar] [CrossRef]

- Rathod, D.; Muthukkumaran, K.; Thallak, S. Analysis of laterally loaded group of piles located on sloping ground. Int. J. Geotech. Eng. 2018, 14, 580–588. [Google Scholar] [CrossRef]

- Griffiths, D.; Marquez, R. Three-dimensional slope stability analysis by elasto-plastic finite elements. Géotechnique 2007, 57, 537–546. [Google Scholar] [CrossRef]

- Bushira, K.M.; Gebregiorgis, Y.B.; Verma, R.K.; Sheng, Z. Cut soil slope stability analysis along National Highway at Wozeka–Gidole Road, Ethiopia. Model. Earth Syst. Environ. 2018, 4, 591–600. [Google Scholar] [CrossRef]

- Zheng, Y.; Tang, X.; Shangyi, Z.; Deng, C.; Wenjie, L. Strength reduction and step-loading finite element approaches in geotechnical engineering. J. Rock Mech. Geotech. Eng. 2010, 2010, 21–30. [Google Scholar] [CrossRef]

- Zhao, L.; Shao, L.; Mao, J.; Mu, K.; Li, T. A fracture model for the deformable spheropolygon-based discrete element method. Granul. Matter 2022, 24, 50. [Google Scholar] [CrossRef]

- Shao, L.; Mao, J.; Zhao, L.; Li, T. A three-dimensional deformable spheropolyhedral-based discrete element method for simulation of the whole fracture process. Eng. Fract. Mech. 2022, 263, 108290. [Google Scholar] [CrossRef]

- Hong, Y.; Shao, Z.; Shi, G.; Nie, X. Comparison of GIM and SRM calculated slope safety factor based on three-dimensional limit analysis method. J. Hohai Univ. (Nat. Sci.) 2022, 50, 112–120. [Google Scholar]

- Hao, M.; Da, H.; Lin, S. Numerical simulation of s-shaped failure evolution of anti-dip slope based on statistics of broken length and layer thickness. J. Eng. Geol. 2020, 28, 1160. [Google Scholar] [CrossRef]

- Gao, G.-Y.; Song, J.; Yang, J. Identifying boundary between near field and far field in ground vibration caused by surface loading. J. Cent. South Univ. 2014, 21, 3284–3294. [Google Scholar] [CrossRef]

- Yuan, B.; Li, Z.; Chen, Y.; Ni, H.; Zhao, Z.; Chen, W.; Zhao, J. Mechanical and microstructural properties of recycling granite residual soil reinforced with glass fiber and liquid-modified polyvinyl alcohol polymer. Chemosphere 2022, 286, 131652. [Google Scholar] [CrossRef]

- Que, X.; Zhu, Z.; He, Y.; Niu, Z.; Huang, H. Strength and deformation characteristics of irregular columnar jointed rock mass: A combined experimental and theoretical study. J. Rock Mech. Geotech. Eng. 2023, 15, 429–441. [Google Scholar] [CrossRef]

- Que, X.; Zhu, Z.; Zhou, L.; Niu, Z.; Huang, H. Strength and Failure Characteristics of an Irregular Columnar Jointed Rock Mass Under Polyaxial Stress Conditions. Rock Mech. Rock Eng. 2022, 55, 7223–7242. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, L.; Ye, Y.; Cheng, Z.; Zhou, Z. Effects of different chloride salts on granite residual soil: Properties and water–soil chemical interaction mechanisms. J. Soils Sediments 2023, 23, 1844–1856. [Google Scholar] [CrossRef]

- Yuan, B.; Li, Z.; Zhao, Z.; Ni, H.; Su, Z.; Li, Z. Experimental study of displacement field of layered soils surrounding laterally loaded pile based on transparent soil. J. Soils Sediments 2021, 21, 3072–3083. [Google Scholar] [CrossRef]

- Yang, B.; Chen, Y.; Zhao, C.; Li, Z. Effect of geotextiles with different masses per unit area on water loss and cracking under bottom water loss soil conditions. Geotext. Geomembr. 2023, 52, 233–240. [Google Scholar] [CrossRef]

- Yuan, B.; Sun, M.; Xiong, L.; Luo, Q.; Pradhan, S.P.; Li, H. Investigation of 3D deformation of transparent soil around a laterally loaded pile based on a hydraulic gradient model test. J. Build. Eng. 2020, 28, 101024. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, L.; Sun, Y.; Cheng, Z.; Gong, W. Physical–mechanical properties and microstructure degradation of acid–alkali contaminated granite residual soil. Geomech. Energy Environ. 2023, 36, 100501. [Google Scholar] [CrossRef]

| Layer Depth (m) | Elastic Modulus E (Mpa) | Poisson’s Ratio ν | Unit Weight γ (kN/m3) | Initial Porosity n | Cohesion c (kPa) | Internal Friction Angle φ (°) | |

|---|---|---|---|---|---|---|---|

| Fill Soil | 1.2 | 50 | 0.3 | 18 | 0.5 | 26 | 37 |

| Residual Sandy Clay | 8.9 | 30 | 0.33 | 19.4 | 0.6 | 21 | 26 |

| Fully Weathered Sandstone | 2.4 | 300 | 0.3 | 21 | 0.5 | 44 | 28 |

| Sandy Soil-Like Highly Weathered Granite | 2.5 | 800 | 0.26 | 22.5 | 0.6 | 500 | 31 |

| Fragmented, Highly Weathered Granite | 3.1 | 1000 | 0.24 | 23 | 0.5 | 800 | 35 |

| Moderately Weathered Granite | 1 | 2000 | 0.23 | 24 | 0.5 | 1200 | 38 |

| Observation Date | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Observation Point | 2021.10.06~2021.10.25 | 2021.10.25~2021.11.12 | 2021.11.12~2021.12.16 | 2021.12.16~2021.12.26 | 2021.10.06~2021.12.26 | ||||

| Displacement (mm) | Change Rate (mm/d) | Displacement (mm) | Change Rate (mm/d) | Displacement (mm) | Change Rate (mm/d) | Displacement (mm) | Change Rate (mm/d) | Cumulative Displacement (mm) | |

| JC1 | +7.68 | +0.38 | +2.45 | +0.14 | +1.07 | +0.03 | +0.98 | +0.10 | +12.18 |

| JC2 | +6.48 | +0.32 | +2.04 | +0.11 | +1.64 | +0.05 | +1.23 | +0.12 | +11.39 |

| JC3 | / | / | +9.08 | +0.50 | +5.67 | +0.17 | +2.43 | +0.24 | +17.68 |

| JC4 | / | / | +8.48 | +0.47 | +6.49 | +0.19 | +2.06 | +0.21 | +17.03 |

| JC5 | / | / | +8.75 | +0.49 | +5.17 | +0.15 | +2.71 | +0.27 | +17.13 |

| JC6 | / | / | / | / | +14.48 | +0.43 | +4.21 | +0.42 | +18.69 |

| JC7 | / | / | / | / | +15.18 | +0.45 | +4.28 | +0.43 | +19.46 |

| JC8 | / | / | / | / | +11.45 | +0.34 | +4.32 | +0.43 | +15.77 |

| JC9 | / | / | / | / | / | / | +4.53 | +0.45 | +4.53 |

| JC10 | / | / | / | / | / | / | +3.33 | +0.33 | +3.33 |

| JC11 | / | / | / | / | / | / | +4.42 | +0.44 | +4.42 |

| Observation Date | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Observation Point | 2021.10.06~2021.10.25 | 2021.10.25~2021.11.12 | 2021.11.12~2021.12.16 | 2021.12.16~2021.12.26 | 2021.10.06~2021.12.26 | ||||

| Displacement (mm) | Change Rate (mm/d) | Displacement (mm) | Change Rate (mm/d) | Displacement (mm) | Change Rate (mm/d) | Displacement (mm) | Change Rate (mm/d) | Cumulative Displacement (mm) | |

| JC1 | +9.32 | +0.47 | +7.25 | +0.40 | +4.42 | +0.13 | +1.44 | +0.14 | +22.43 |

| JC2 | +8.46 | +0.42 | +6.04 | +0.34 | +3.66 | +0.11 | +1.01 | +0.10 | +19.17 |

| JC3 | / | / | +8.21 | +0.46 | +5.52 | +0.16 | +1.64 | +0.16 | +15.37 |

| JC4 | / | / | +8.45 | +0.47 | +6.76 | +0.20 | +1.12 | +0.11 | +16.33 |

| JC5 | / | / | +7.73 | +0.43 | +6.34 | +0.19 | +1.77 | +0.18 | +15.84 |

| JC6 | / | / | / | / | +7.48 | +0.22 | +1.53 | +0.15 | +9.01 |

| JC7 | / | / | / | / | +6.18 | +0.18 | +2.43 | +0.24 | +8.61 |

| JC8 | / | / | / | / | +6.45 | +0.19 | +2.22 | +0.22 | +8.67 |

| JC9 | / | / | / | / | / | / | +2.56 | +0.26 | +2.56 |

| JC10 | / | / | / | / | / | / | +1.58 | +0.16 | +1.58 |

| JC11 | / | / | / | / | / | / | +2.03 | +0.20 | +2.03 |

| Construction Stage | First-Level Backfill | Second-Level Backfill | Third-Level Backfill | Fourth-Level Backfill | Highway Vehicle Load |

|---|---|---|---|---|---|

| Pile Top Displacement (mm) | 6.12 | 11.08 | 15.41 | 18.89 | 19.16 |

| Pile Base Displacement (mm) | −0.15 | −0.20 | −0.25 | −0.29 | −0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, B.; Zhong, H.; Yang, K.; Yang, X.; Cai, C.; Xiao, J.; Liu, Y.; Yuan, B. A Study on the Factors Influencing High Backfill Slope Reinforced with Anti-Slide Piles under Static Load Based on Numerical Simulation. Buildings 2024, 14, 799. https://doi.org/10.3390/buildings14030799

Zhou B, Zhong H, Yang K, Yang X, Cai C, Xiao J, Liu Y, Yuan B. A Study on the Factors Influencing High Backfill Slope Reinforced with Anti-Slide Piles under Static Load Based on Numerical Simulation. Buildings. 2024; 14(3):799. https://doi.org/10.3390/buildings14030799

Chicago/Turabian StyleZhou, Baogui, Huabin Zhong, Kaipeng Yang, Xueqiang Yang, Chifeng Cai, Jie Xiao, Yongjian Liu, and Bingxiang Yuan. 2024. "A Study on the Factors Influencing High Backfill Slope Reinforced with Anti-Slide Piles under Static Load Based on Numerical Simulation" Buildings 14, no. 3: 799. https://doi.org/10.3390/buildings14030799

APA StyleZhou, B., Zhong, H., Yang, K., Yang, X., Cai, C., Xiao, J., Liu, Y., & Yuan, B. (2024). A Study on the Factors Influencing High Backfill Slope Reinforced with Anti-Slide Piles under Static Load Based on Numerical Simulation. Buildings, 14(3), 799. https://doi.org/10.3390/buildings14030799