Mechanical Properties and Sulfate Freeze–Thaw Resistance of Calcium Carbonate Whisker-Reinforced Iron Ore Tailings Concrete

Abstract

1. Introduction

2. Experimental Details

2.1. Raw Materials

2.1.1. Cement and Natural Aggregates

2.1.2. Iron Ore Tailings Aggregate

2.1.3. Calcium Carbonate Whiskers

2.2. Mix Proportions

2.3. Test Methods

2.3.1. Mechanical Performance

2.3.2. Accelerated Sulfate F-T Cycle

2.3.3. Non-Destructive Pore Testing by NMR

2.3.4. SEM for Morphology Analysis

3. Results and Discussion

3.1. Mechanical Properties

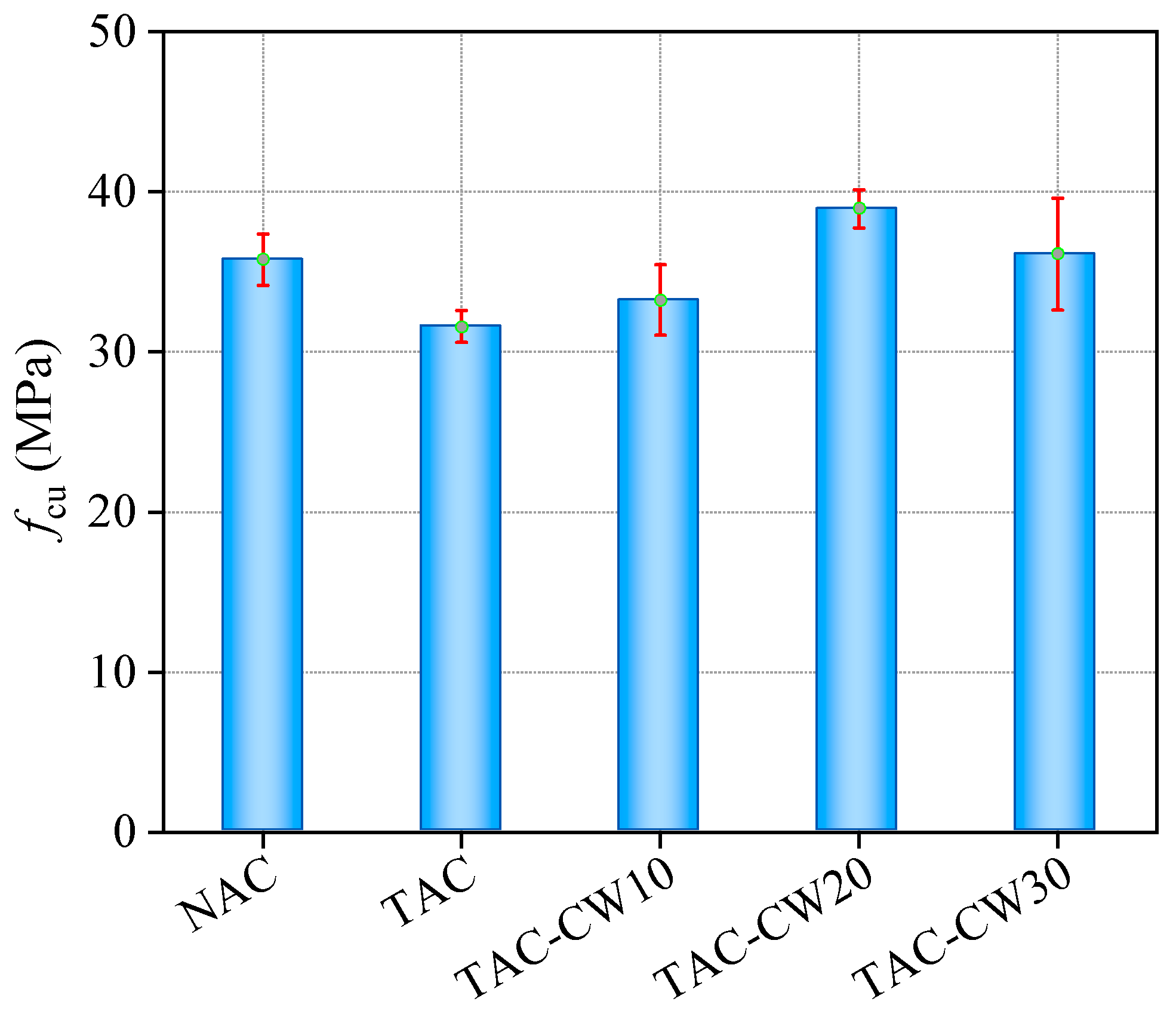

3.1.1. Compressive Strength

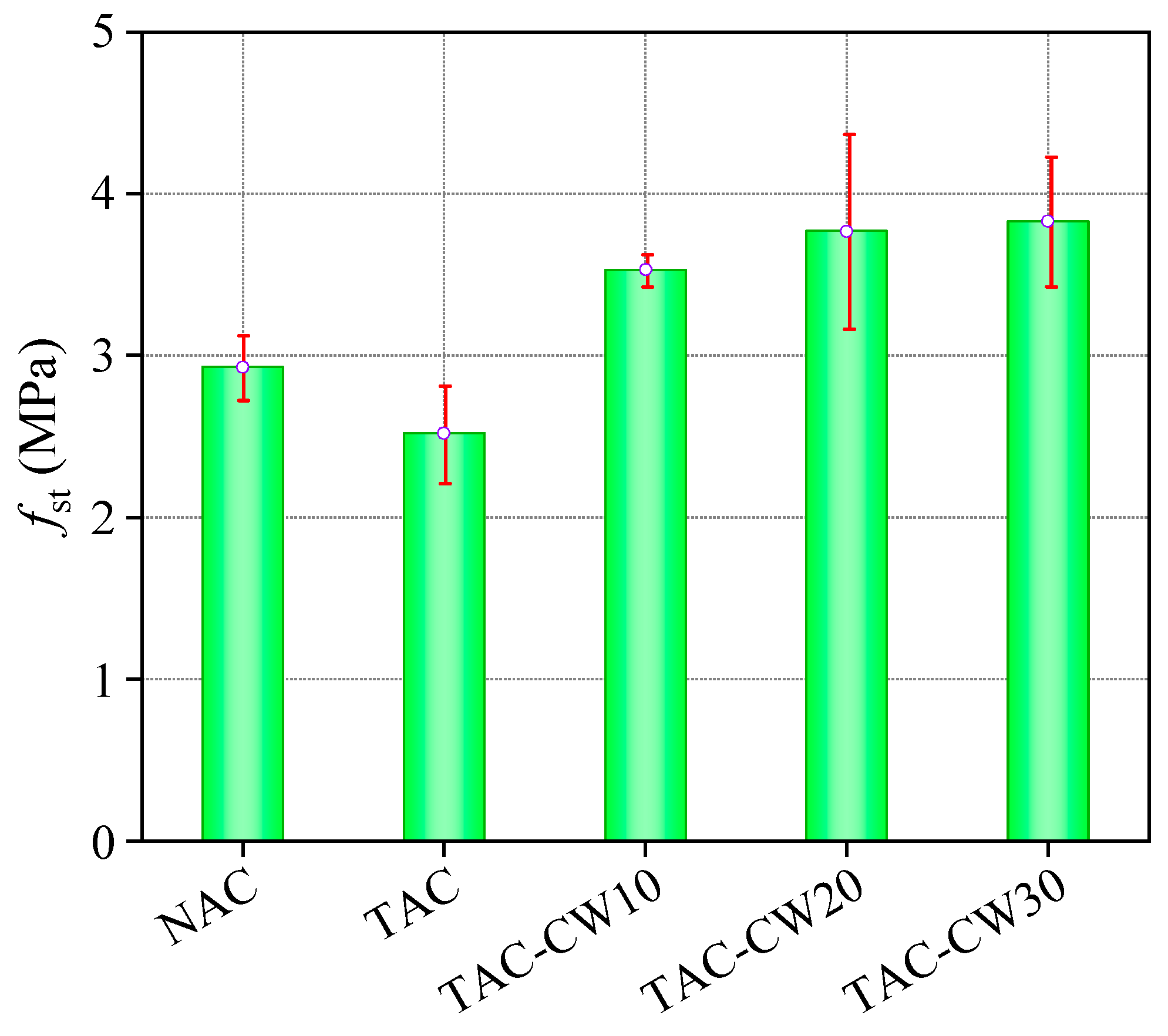

3.1.2. Splitting Tensile Strength

3.2. Sulfate F-T Cyclic Resistance

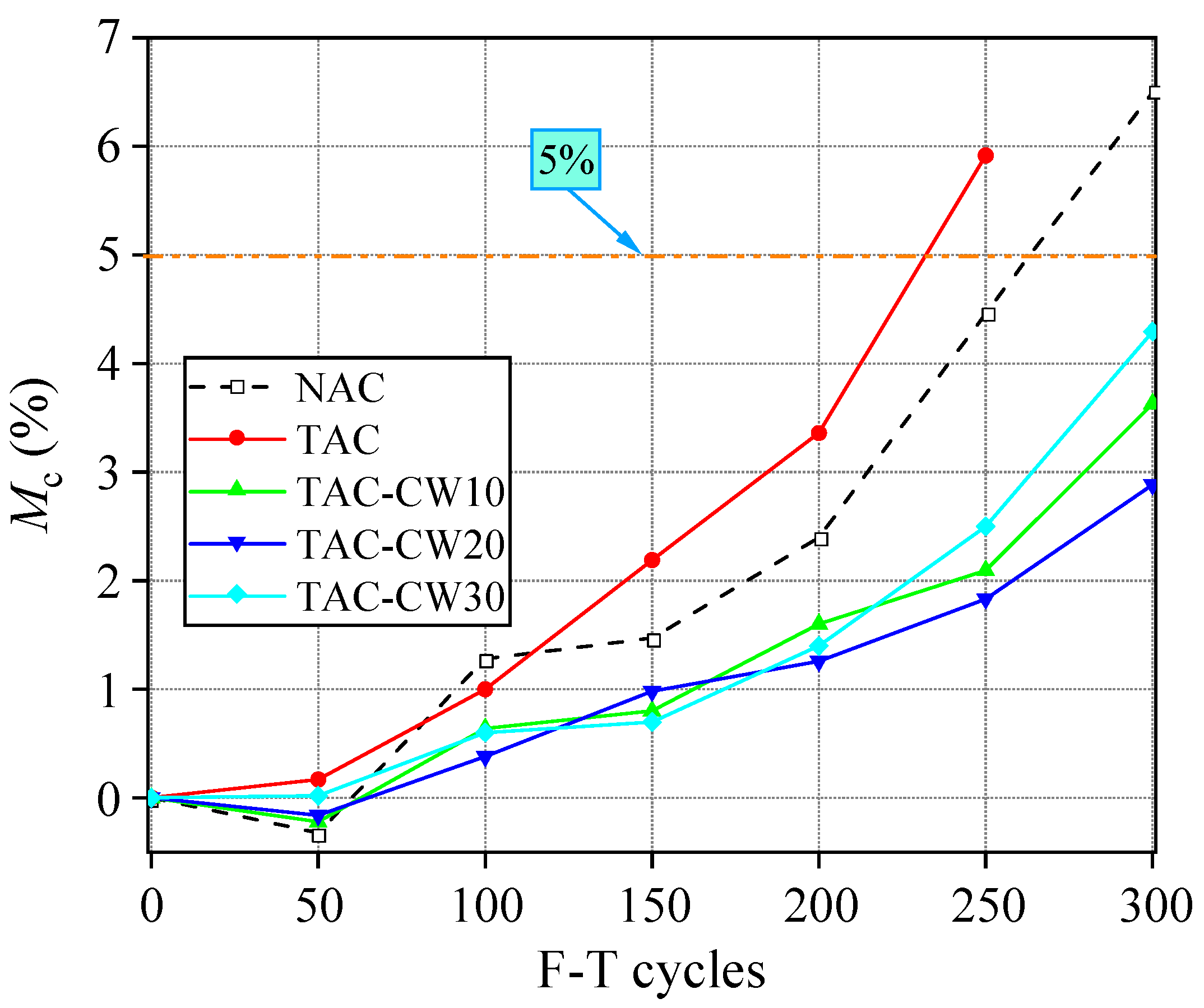

3.2.1. Mass Loss

3.2.2. RDEM

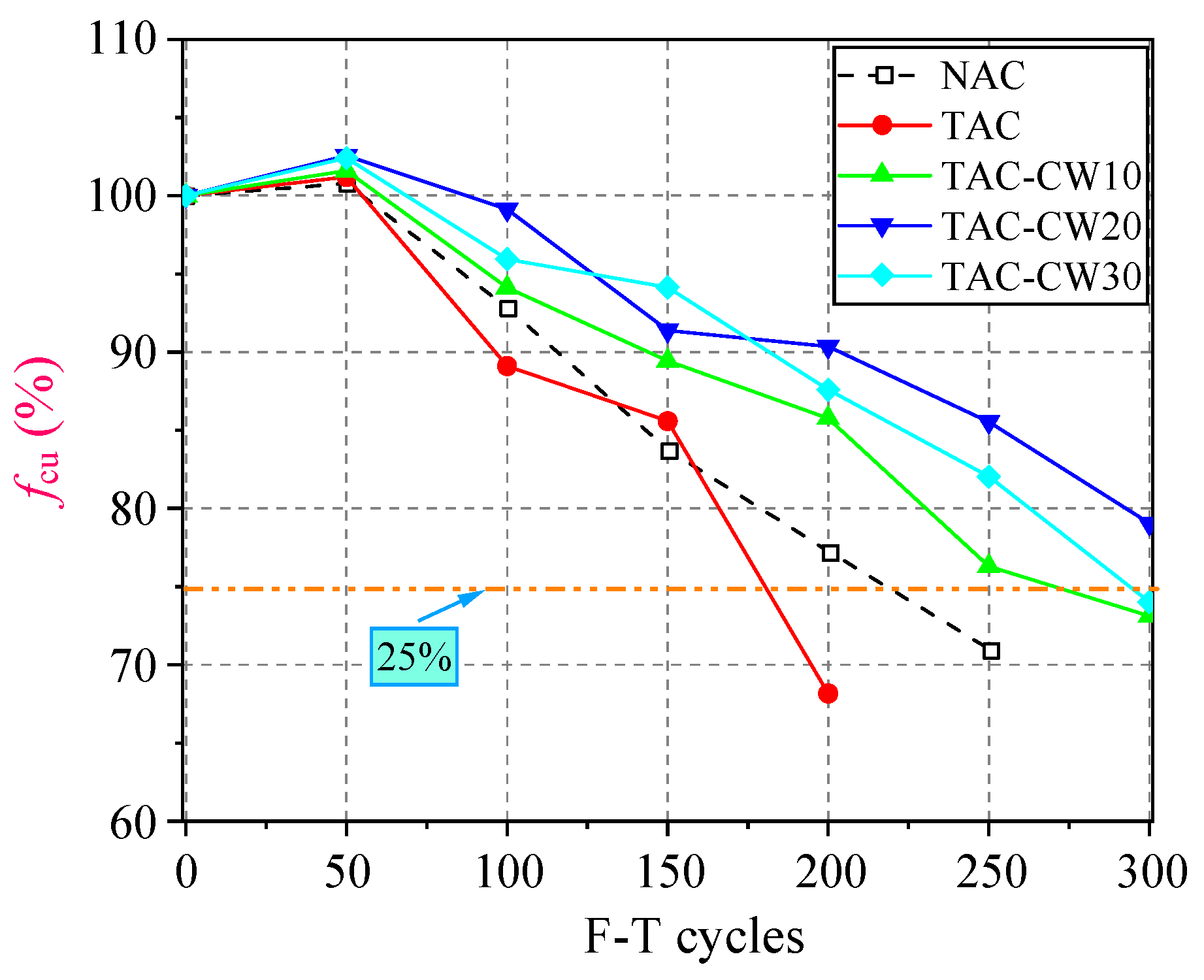

3.2.3. Relative Compressive Strength

3.3. Pore Characterization from NMR

3.3.1. T2 Spectral Fluid Distribution

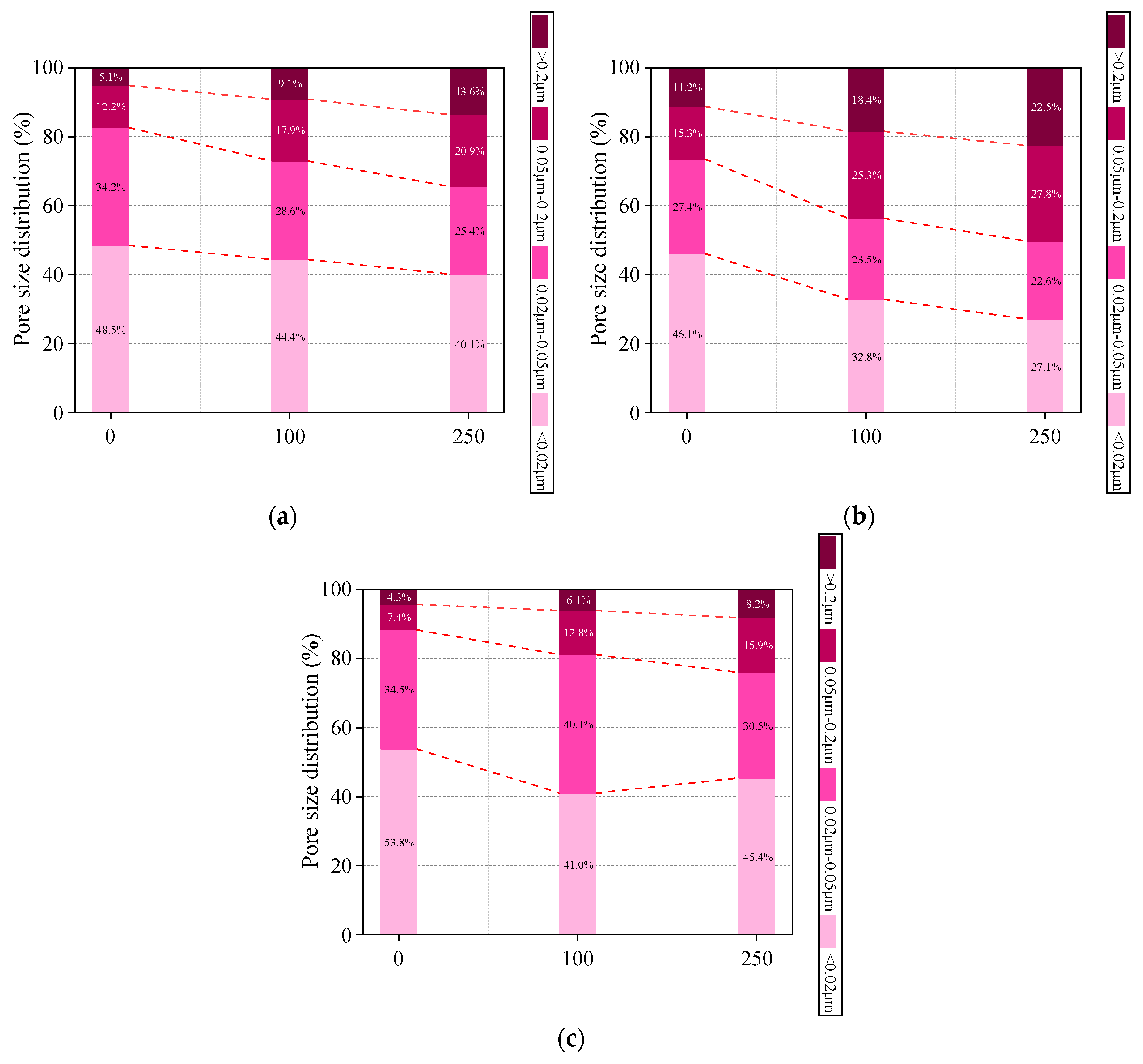

3.3.2. Pore Size Distribution

3.3.3. Porosity

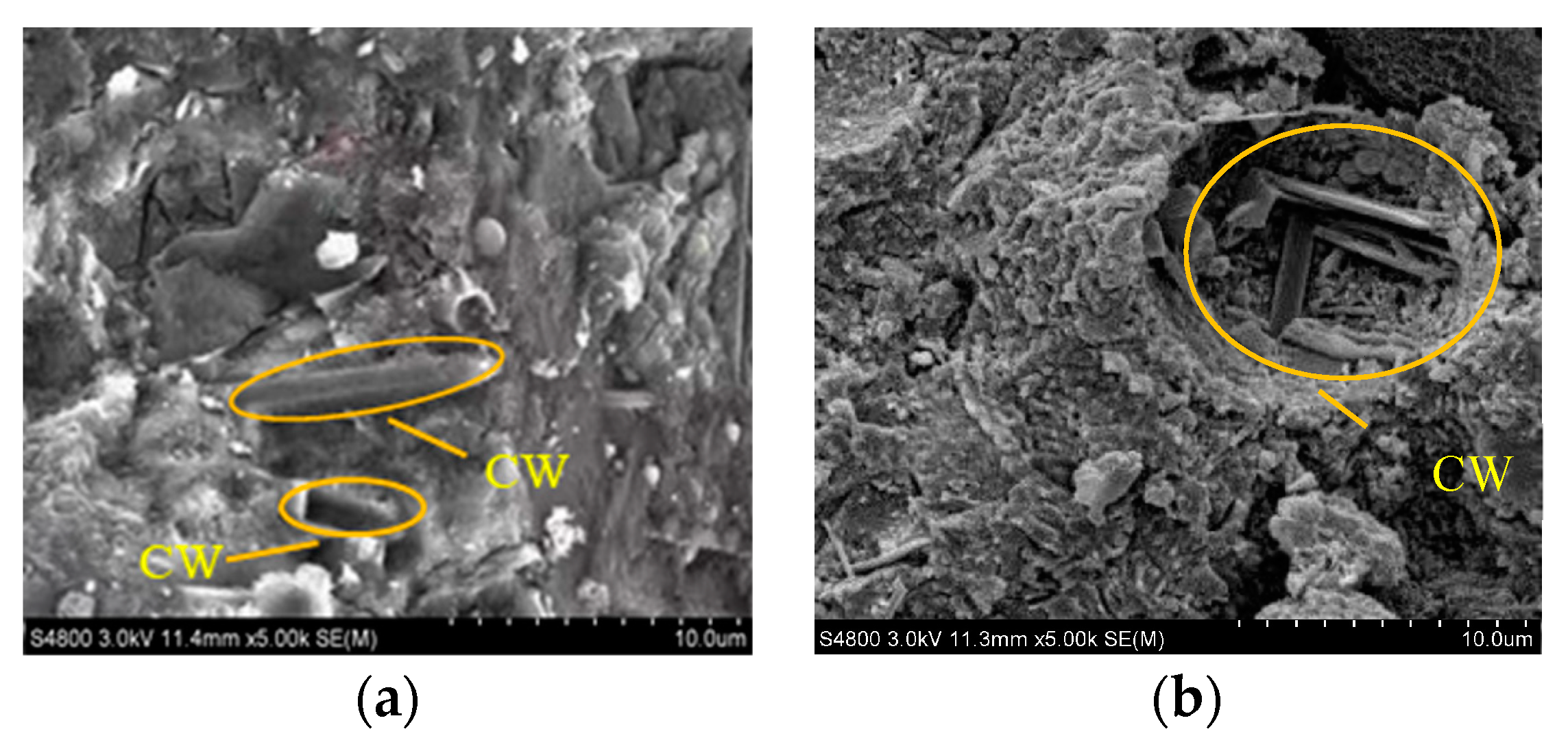

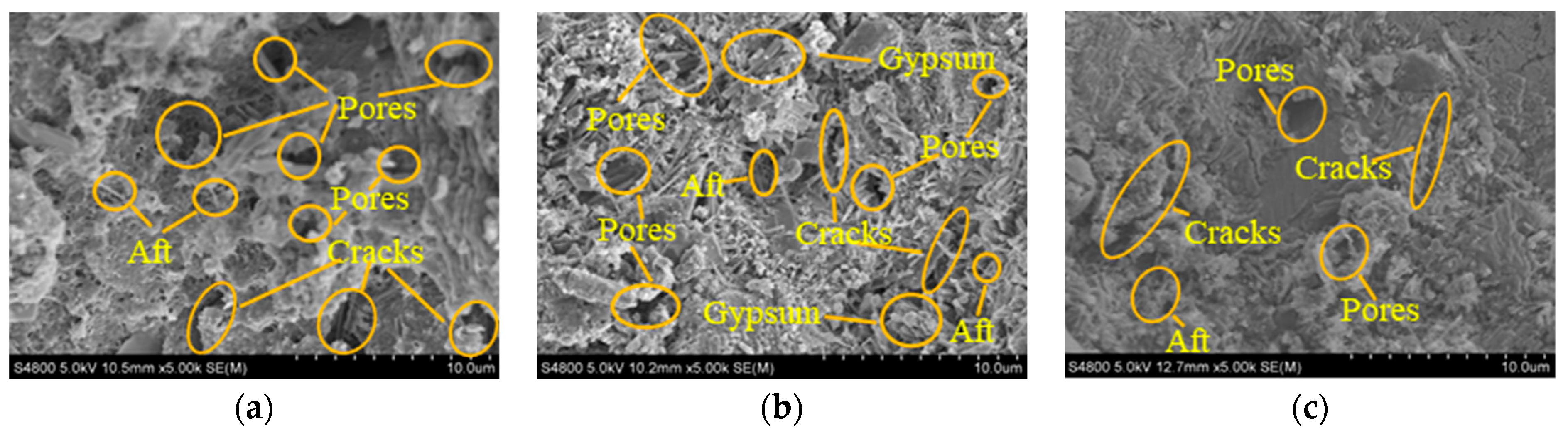

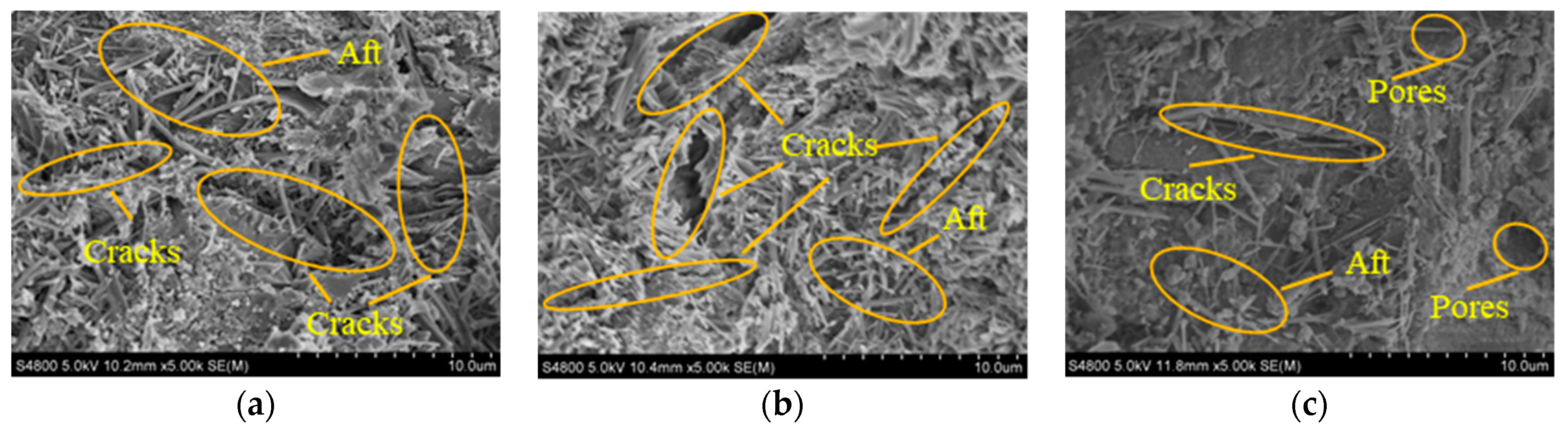

3.4. Micromorphology from SEM

4. Conclusions

- (1)

- When IOTA completely replaced NA, both the fcu and fst of TAC decreased. Upon adding 10–30% CWs to TAC, the fcu and fst of TAC-CW20, incorporating 20% CWs, increased by 23.26% and 49.6% compared to TAC and were higher than those of NAC, demonstrating that incorporating 20% CWs in the TAC had a beneficial effect.

- (2)

- The F-T damage of concrete initially increases and subsequently decreases during F-T cycles in Na2SO4 solution. When the CWs were added to TAC, TAC-CW20 showed the best frost resistance compared to the other groups of specimens undergoing 300 F-T cycles.

- (3)

- NMR results showed that concrete’s internal pore size and porosity gradually increase with increasing numbers of F-T cycles. After different F-T cycles, TAC-CW20 had a lower porosity and a larger number of harmful pores than NAC. The incorporation of 20% CWs is beneficial for the development of internal pore structure in TAC.

- (4)

- Based on the results of SEM, as the number of F-T cycles increased, the formation of corrosion products in concrete increased the number of pores and cracks. After 250 F-T cycles, TAC-CW20 showed a relatively denser interior with fewer erosion products than NAC. This further confirms that the inclusion of 20% CWs could enhance the performance of TAC.

- (5)

- The macroscopic and microscopic results indicated that incorporating 20% CWs into TAC in producing concrete led to superior performance, including mechanical properties, frost resistance, pore structure, and microstructure, compared to ordinary concrete.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CWs | Calcium carbonate whiskers |

| F-T | Freeze–thaw |

| IOTA | Iron ore tailings as crushed stone aggregate |

| NA | Natural crushed stone aggregate |

| NAC | Normal concrete |

| NMR | Nuclear magnetic resonance |

| RDEM | Relative dynamic elastic modulus |

| RS | River sand |

| SEM | Scanning electron microscopy |

| TAC | Iron ore tailings concrete |

| TAC-CW | Calcium carbonate whisker-reinforced iron ore tailings concrete |

| fcu | Compressive strength |

| fst | Splitting tensile strength |

| Mc | Mass loss |

References

- Zhang, L.; Xu, M.; Chen, H.; Li, Y.; Chen, S. Globalization, green economy and environmental challenges: State of the art review for practical implications. Front. Environ. Sci. 2022, 10, 870271. [Google Scholar] [CrossRef]

- Al-Shetwi, A.Q. Sustainable development of renewable energy integrated power sector: Trends, environmental impacts, and recent challenges. Sci. Total Environ. 2022, 822, 153645. [Google Scholar] [CrossRef] [PubMed]

- Cuce, P.M.; Cuce, E.; Alvur, E. Internal or external thermal superinsulation towards low/zero carbon buildings? A critical report. Gazi Mühendislik Bilimleri Dergisi 2024, 9, 435–442. [Google Scholar]

- Cuce, E.; Cuce, P.M.; Wood, C.; Gillott, M.; Riffat, S. Experimental Investigation of Internal Aerogel Insulation Towards Low/Zero Carbon Buildings: A Comprehensive Thermal Analysis for a UK Building. Sustain. Clean Build. 2024, 1, 1–22. [Google Scholar]

- Akram, M.W.; Hasannuzaman, M.; Cuce, E.; Cuce, P.M. Global technological advancement and challenges of glazed window, facade system and vertical greenery-based energy savings in buildings: A comprehensive review. Energy Built Environ. 2023, 4, 206–226. [Google Scholar] [CrossRef]

- Ahmed, A.; Ge, T.; Peng, J.; Yan, W.C.; Tee, B.T.; You, S. Assessment of the renewable energy generation towards net-zero energy buildings: A review. Energy Build. 2022, 256, 111755. [Google Scholar] [CrossRef]

- Li, L.; Lin, J.; Wu, N.; Xie, S.; Meng, C.; Zheng, Y.; Wang, X.; Zhao, Y. Review and outlook on the international renewable energy development. Energy Built Environ. 2022, 3, 139–157. [Google Scholar] [CrossRef]

- Bertoldi, P.; Economidou, M.; Palermo, V.; Boza-Kiss, B.; Todeschi, V. How to finance energy renovation of residential buildings: Review of current and emerging financing instruments in the EU. Wiley Interdiscip. Rev. Energy Environ. 2021, 10, e384. [Google Scholar] [CrossRef]

- Tsemekidi Tzeiranaki, S.; Bertoldi, P.; Diluiso, F.; Castellazzi, L.; Economidou, M.; Labanca, N.; Serrenho, T.R.; Zangheri, P. Analysis of the EU residential energy consumption: Trends and determinants. Energies 2019, 12, 1065. [Google Scholar] [CrossRef]

- Drewniok, M.P.; Dunant, C.F.; Allwood, J.M.; Ibell, T.; Hawkins, W. Modelling the embodied carbon cost of UK domestic building construction: Today to 2050. Ecol. Econ. 2023, 205, 107725. [Google Scholar] [CrossRef]

- Rashad, M.; Khordehgah, N.; Żabnieńska-Góra, A.; Ahmad, L.; Jouhara, H. The utilisation of useful ambient energy in residential dwellings to improve thermal comfort and reduce energy consumption. Int. J. Thermofluids 2021, 9, 100059. [Google Scholar] [CrossRef]

- Cuce, P.M. Thermal performance assessment of a novel liquid desiccant-based evaporative cooling system: An experimental investigation. Energy Build. 2017, 138, 88–95. [Google Scholar] [CrossRef]

- Chen, Q.; Ja, M.K.; Burhan, M.; Akhtar, F.H.; Shahzad, M.W.; Ybyraiymkul, D.; Ng, K.C. A hybrid indirect evaporative cooling-mechanical vapor compression process for energy-efficient air conditioning. Energy Convers. Manag. 2021, 248, 114798. [Google Scholar] [CrossRef]

- Chang, C.K.; Yih, T.Y.; Othman, Z.B. Performance Assessment of Green Filtration System with Evaporative Cooling to Improve Indoor Air Quality (IAQ). Int. J. Environ. Sci. Dev. 2022, 13, 1–7. [Google Scholar]

- Zhou, C.; Hu, Y.; Zhang, L.; Fang, J.; Xi, Y.; Hu, J.; Li, Y.; Liu, L.; Zhao, Y.; Yang, L.; et al. Investigation of heat transfer characteristics of deflected elliptical-tube heat exchanger in closed-circuit cooling towers. Appl. Therm. Eng. 2024, 236, 121860. [Google Scholar] [CrossRef]

- Lai, L.; Wang, X.; Kefayati, G.; Hu, E. Evaporative cooling integrated with solid desiccant systems: A review. Energies 2021, 14, 5982. [Google Scholar] [CrossRef]

- Blanco-Marigorta, A.M.; Tejero-Gonzalez, A.; Rey-Hernandez, J.M.; Gomez, E.V.; Gaggioli, R. Exergy analysis of two indirect evaporative cooling experimental prototypes. Alex. Eng. J. 2022, 61, 4359–4369. [Google Scholar] [CrossRef]

- Mohammed, R.H.; El-Morsi, M.; Abdelaziz, O. Indirect evaporative cooling for buildings: A comprehensive patents review. J. Build. Eng. 2022, 50, 104158. [Google Scholar] [CrossRef]

- Shi, W.; Min, Y.; Ma, X.; Chen, Y.; Yang, H. Performance evaluation of a novel plate-type porous indirect evaporative cooling system: An experimental study. J. Build. Eng. 2022, 48, 103898. [Google Scholar] [CrossRef]

- Sun, T.; Tang, T.; Yang, C.; Yan, W.; Cui, X.; Chu, J. Cooling performance and optimization of a tubular indirect evaporative cooler based on response surface methodology. Energy Build. 2023, 285, 112880. [Google Scholar] [CrossRef]

- Putra, N.; Sofia, E.; Gunawan, B.A. Evaluation of indirect evaporative cooling performance integrated with finned heat pipe and luffa cylindrica fiber as cooling/wet media. J. Adv. Res. Exp. Fluid Mech. Heat Transf. 2021, 3, 16–25. [Google Scholar]

- Zhao, X.; Liu, S.; Riffat, S.B. Comparative study of heat and mass exchanging materials for indirect evaporative cooling systems. Build. Environ. 2008, 43, 1902–1911. [Google Scholar] [CrossRef]

- Xu, P.; Ma, X.; Zhao, X.; Fancey, K.S. Experimental investigation on performance of fabrics for indirect evaporative cooling applications. Build. Environ. 2016, 110, 104–114. [Google Scholar] [CrossRef]

- Maclaine-Cross, I.L.; Banks, P.J. A general theory of wet surface heat exchangers and its application to regenerative evaporative cooling. J. Heat Transf. 1981, 103, 579–585. [Google Scholar] [CrossRef]

- Kettleborough, C.F.; Hsieh, C.S. The thermal performance of the wet surface plastic plate heat exchanger used as an indirect evaporative cooler. J. Heat Transf. 1983, 105, 366–373. [Google Scholar] [CrossRef]

- Kettleborough, C.F.; Waugaman, D.G.; Johnson, M. The thermal performance of the cross-flow three-dimensional flat plate indirect evaporative cooler. J. Energy Resour. Technol. 1992, 114, 181–186. [Google Scholar] [CrossRef]

- Wassel, A.T.; Mills, A.F. Design methodology for a counter-current falling film evaporative condenser. J. Heat Transf. 1987, 109, 784–787. [Google Scholar] [CrossRef]

- Hsu, S.T.; Lavan, Z.; Worek, W.M. Optimization of wet surface heat exchanger. Energy 1989, 14, 757–770. [Google Scholar] [CrossRef]

- Erens, P.J.; Dreyer, A.A. Modelling of indirect evaporative air coolers. Int. J. Heat Mass Transf. 1993, 36, 17–26. [Google Scholar] [CrossRef]

- Tsay, Y.L. Analysis of heat and mass transfer in a countercurrent-flow wet surface heat exchanger. Int. J. Heat Fluid Flow 1994, 15, 149–156. [Google Scholar] [CrossRef]

- Guo, X.C.; Zhao, T.S. A parametric study of an indirect evaporative air cooler. Int. Commun. Heat Mass Transf. 1998, 25, 217–226. [Google Scholar] [CrossRef]

- Halasz, B. A general mathematical model of evaporative cooling devices. Rev. Générale Therm. 1998, 37, 245–255. [Google Scholar] [CrossRef]

- Riffat, S.B.; Zhu, J. Mathematical model of indirect evaporative cooler using porous ceramic and heat pipe. Appl. Therm. Eng. 2004, 24, 457–470. [Google Scholar] [CrossRef]

- Adam, A.; Han, D.; He, W.; Amidpour, M.; Zhong, H. Numerical investigation of the heat and mass transfer process within a cross-flow indirect evaporative cooling system for hot and humid climates. J. Build. Eng. 2022, 45, 103499. [Google Scholar] [CrossRef]

| Component | NA | IOTA |

|---|---|---|

| SiO2 | 88.21 | 70.26 |

| Al2O3 | 9.02 | 6.42 |

| Fe2O3 | 6.44 | 13.75 |

| MgO | 0.14 | 2.85 |

| CaO | 0.32 | 4.21 |

| SO3 | 0.02 | 0.24 |

| Na2O | 0.16 | 1.22 |

| Loss | 0.006 | 0.014 |

| Length (μm) | Diameter (μm) | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) |  | |

| CWs | 20–30 | 0.5–1.0 | 2.8 | 3000–6000 | 410–710 |

| No. | C (kg/m3) | RS (kg/m3) | IOTA (kg/m3) | NA (kg/m3) | W (kg/m3) | CWs (%) | Slump (mm) |

|---|---|---|---|---|---|---|---|

| NAC | 545 | 617 | 1085 | 0 | 217 | 0 | 135 |

| TAC | 545 | 617 | 0 | 1085 | 217 | 0 | 110 |

| TAC-CW1 | 545 | 617 | 1085 | 0 | 217 | 10 | 85 |

| TAC-CW3 | 545 | 617 | 1085 | 0 | 217 | 20 | 85 |

| TAC-CW5 | 545 | 617 | 1085 | 0 | 217 | 30 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Gao, Y.; Liu, K. Mechanical Properties and Sulfate Freeze–Thaw Resistance of Calcium Carbonate Whisker-Reinforced Iron Ore Tailings Concrete. Buildings 2024, 14, 1004. https://doi.org/10.3390/buildings14041004

Wang S, Gao Y, Liu K. Mechanical Properties and Sulfate Freeze–Thaw Resistance of Calcium Carbonate Whisker-Reinforced Iron Ore Tailings Concrete. Buildings. 2024; 14(4):1004. https://doi.org/10.3390/buildings14041004

Chicago/Turabian StyleWang, Shufang, Yangyang Gao, and Kangning Liu. 2024. "Mechanical Properties and Sulfate Freeze–Thaw Resistance of Calcium Carbonate Whisker-Reinforced Iron Ore Tailings Concrete" Buildings 14, no. 4: 1004. https://doi.org/10.3390/buildings14041004

APA StyleWang, S., Gao, Y., & Liu, K. (2024). Mechanical Properties and Sulfate Freeze–Thaw Resistance of Calcium Carbonate Whisker-Reinforced Iron Ore Tailings Concrete. Buildings, 14(4), 1004. https://doi.org/10.3390/buildings14041004