Optimizing the Return Vent Height for Improved Performance in Stratified Air Distribution Systems

Abstract

1. Introduction

2. Research Setting and Methodology

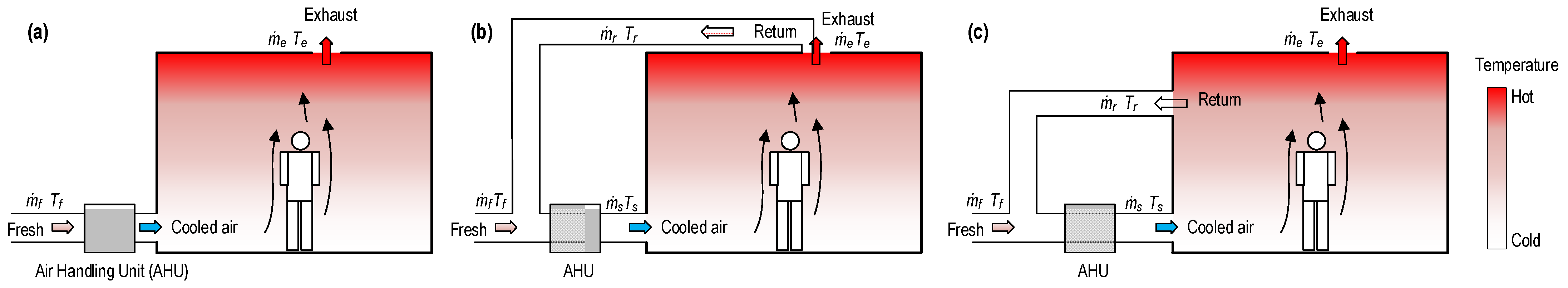

2.1. The Theoretical Analysis

2.2. Study Object (Modeled Room)

2.3. The Numerical Model

2.3.1. The Governing Equations

2.3.2. Boundary Conditions

2.4. Ventilation Performance Indices

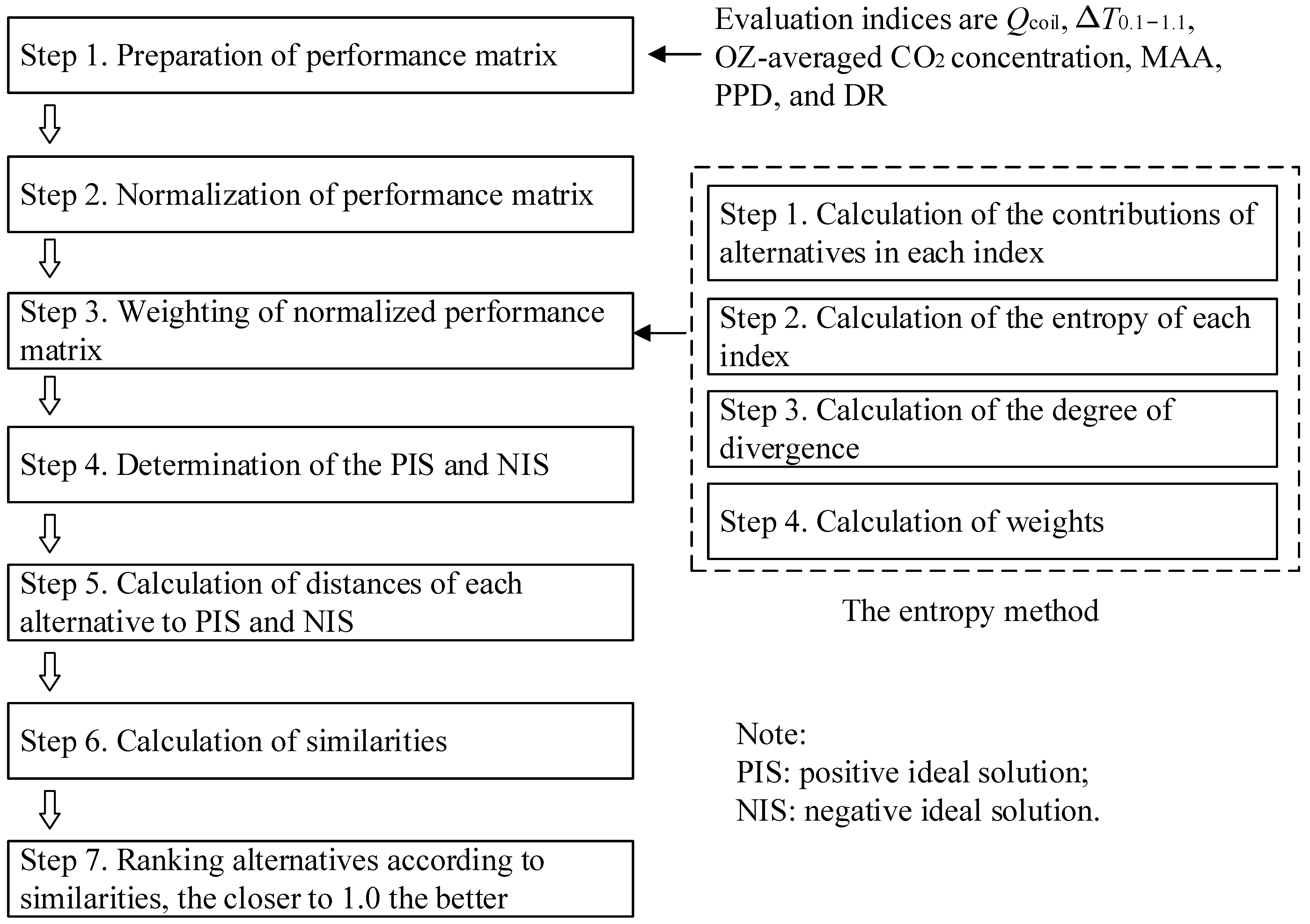

2.5. Optimization Algorithm: Entropy-Based TOPSIS

3. Validation of Numerical Model and Grid Independence Testing

3.1. Numerical Model Validation

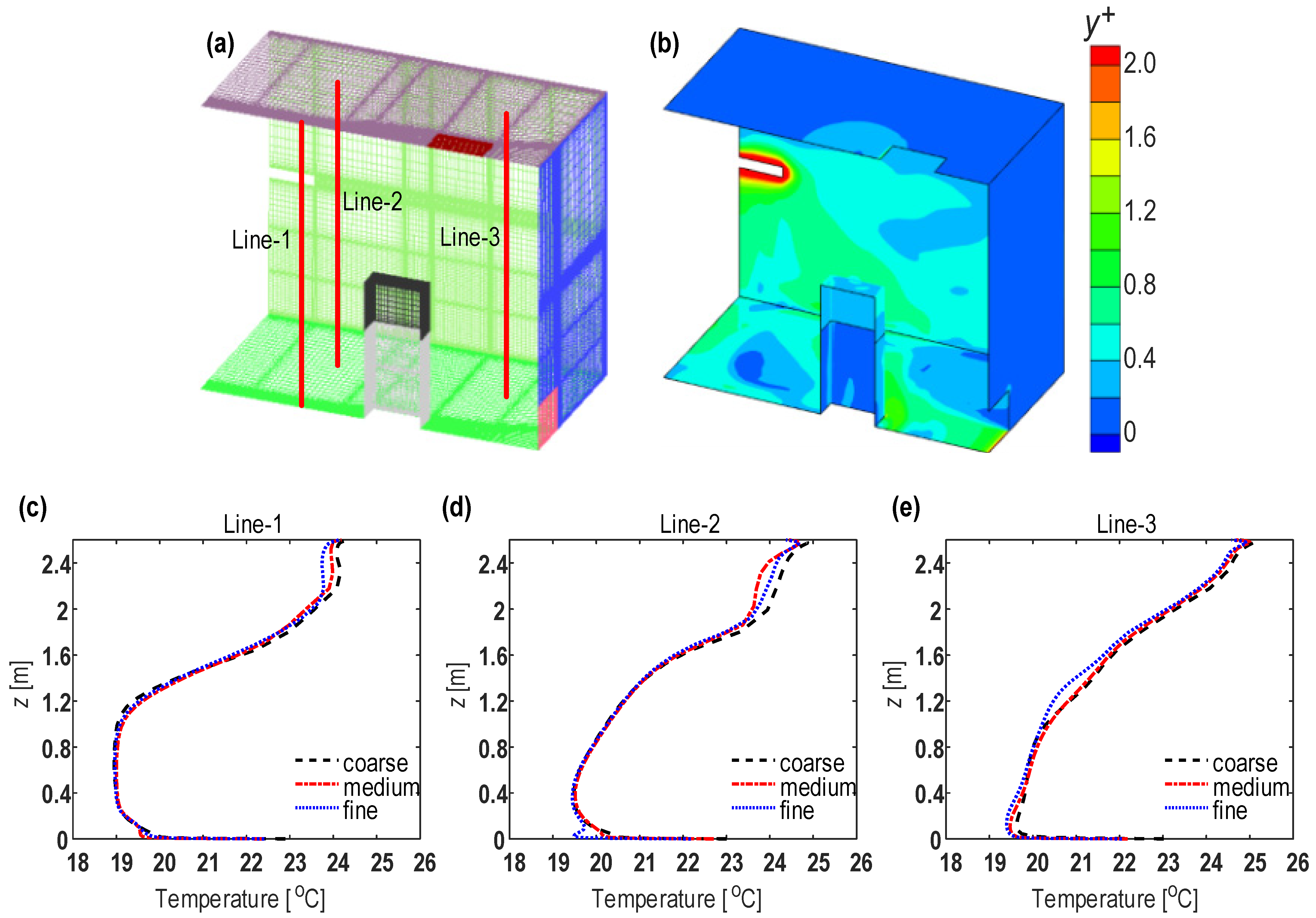

3.2. Grid Independence Testing

4. Results and Discussion

4.1. Optimizing H with Fixed Ts

4.1.1. Temperature Fields

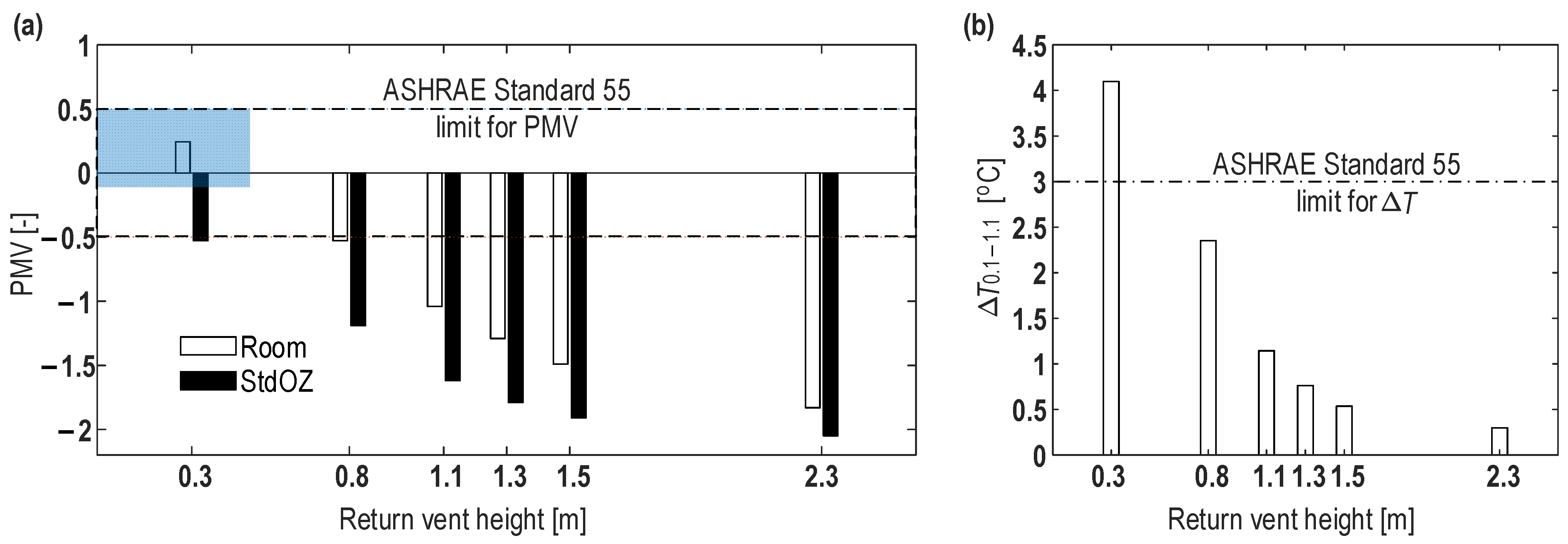

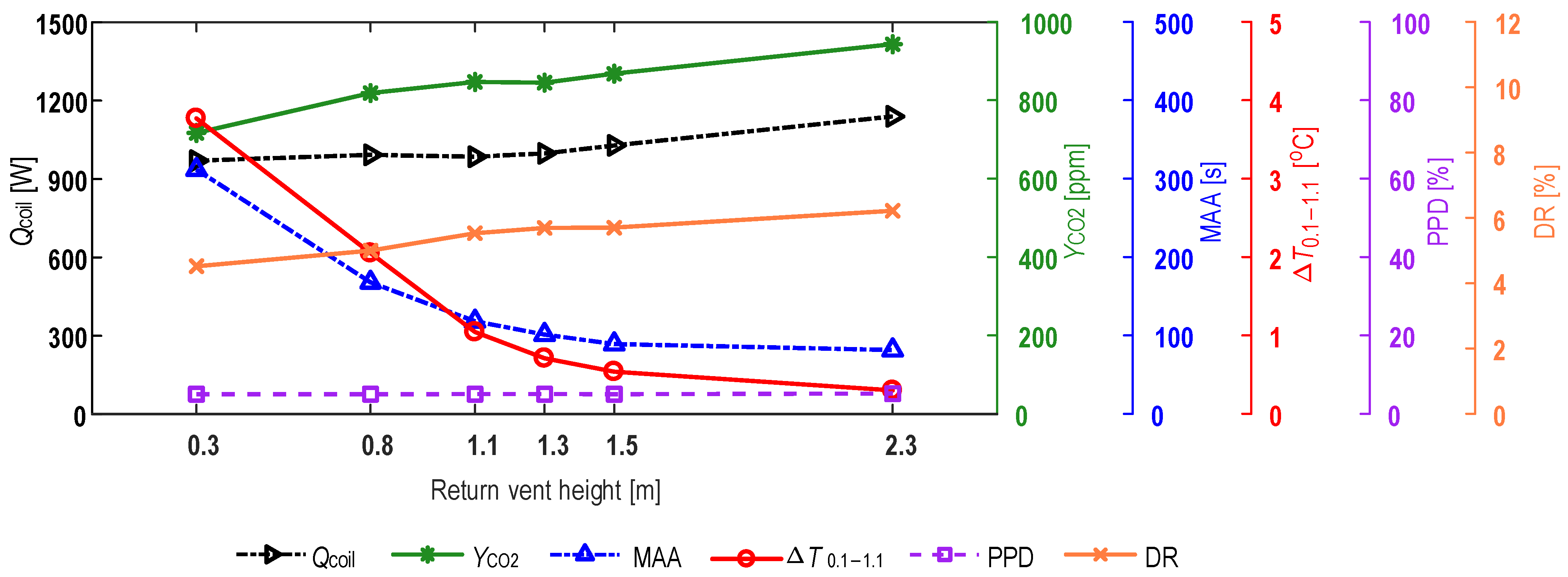

4.1.2. Thermal Comfort Comparison

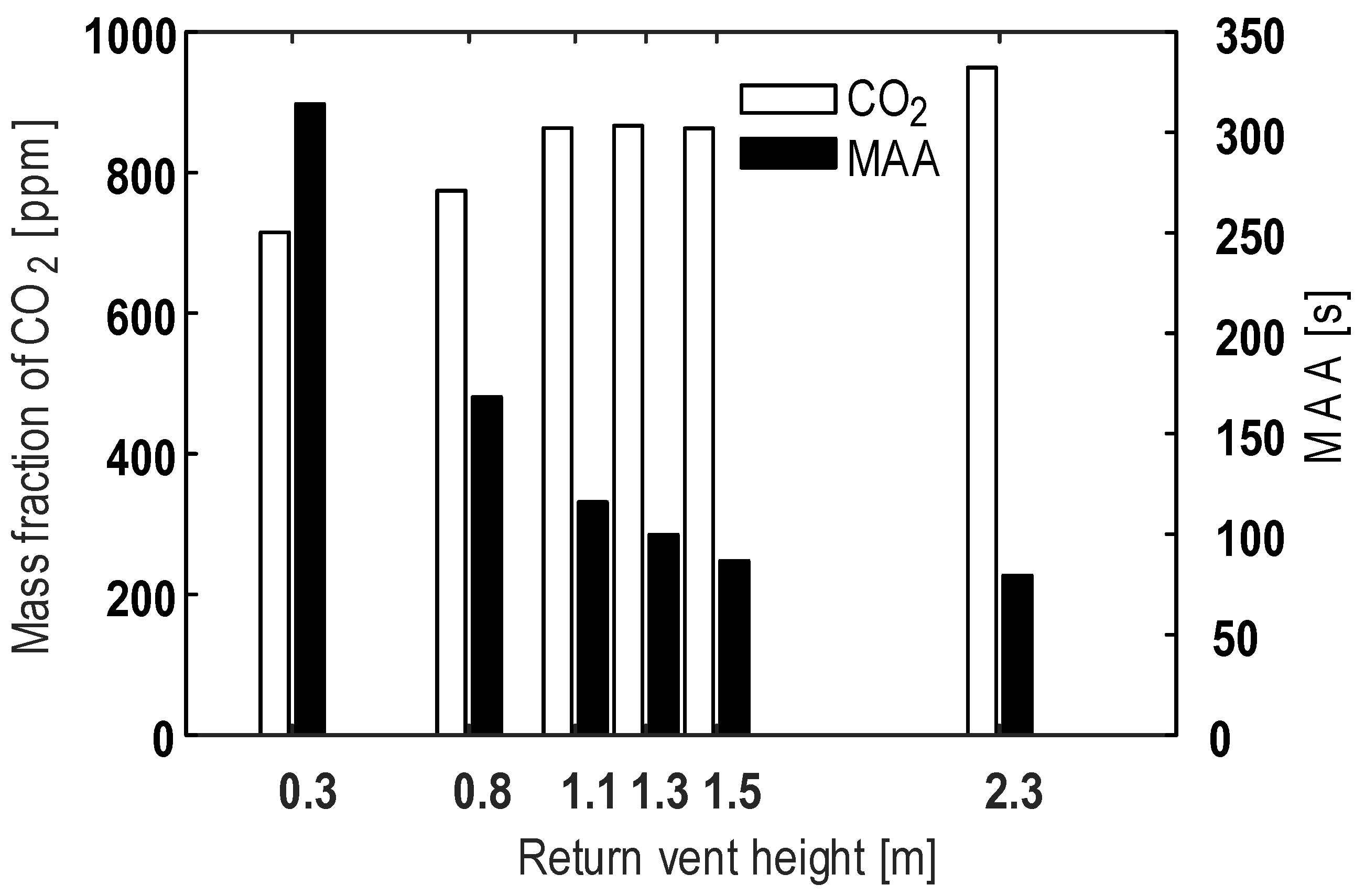

4.1.3. Comparison of IAQ Performance

4.1.4. The Optimal H

4.2. Optimization Subject to Thermoneutrality Requirement

4.2.1. Achieving Thermoneutrality via Adjusting Ts

4.2.2. Optimal H Given the Requirement That |PMV| Is Less Than 0.5

4.3. Limitations

5. Conclusions

- (a)

- A theoretical analysis demonstrated that the amount of energy saved when using a lower vent is smaller than the cost of the vertical temperature gradient for all STRAD systems.

- (b)

- When Ts is 18 °C, the PMV is under −0.5 in most cases except when the H is 0.3 m; that is, the studied enclosure (an office room) is overcooled. The TOPSIS method suggested 1.5–2.3 m as the optimal range.

- (c)

- When Ts is adjusted to achieve a thermal neutral environment, the suggested optimal H is 2.3 m. In this case, the benefits on the MAA and ΔT0.1–1.1 are so large that the costs in terms of the Qcoil value, concentration of CO2, and DR can be ignored.

- (d)

- The optimal case under thermoneutral conditions is preferable with respect to the IAQ, reduced energy consumption, and thermal comfort, compared with those of the optimal H ranging from 1.5 m to 2.3 m at a Ts of 18 °C with a fixed supply temperature. A near-ceiling H is suggested.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, G.; Chen, B.; Lai, D.; Chen, Q. An improved displacement ventilation system for a machining plant. Atmos. Environ. 2020, 228, 117419. [Google Scholar] [CrossRef]

- Qin, C.; Zhou, W.-R.; Fang, H.-Q.; Lu, W.-Z.; Lee, E.W. Optimization of return vent height for stratified air distribution system with impinging jet supply satisfying threshold of |PMV| < 0.5. J. Clean. Prod. 2022, 359, 132033. [Google Scholar]

- Hu, J.; Kang, Y.; Yu, J.; Zhong, K. Numerical study on thermal stratification for impinging jet ventilation system in office buildings. Build. Environ. 2021, 196, 107798. [Google Scholar] [CrossRef]

- Fan, Y.; Li, X.; Yan, Y.; Tu, J. Overall performance evaluation of underfloor air distribution system with different heights of return vents. Energy Build. 2017, 147, 176–187. [Google Scholar] [CrossRef]

- Johnson, R.; Burroughs, C. Reducing Airborne Particulates Using Displacement Ventilation. ASHRAE J. 2022, 64, 38–48. [Google Scholar]

- Yang, R.; Ng, C.S.; Chong, K.L.; Verzicco, R.; Lohse, D. Do increased flow rates in displacement ventilation always lead to better results? J. Fluid Mech. 2022, 932, A3. [Google Scholar] [CrossRef]

- Liu, S.; Koupriyanov, M.; Paskaruk, D.; Fediuk, G.; Chen, Q. Investigation of airborne particle exposure in an office with mixing and displacement ventilation. Sustain. Cities Soc. 2022, 79, 103718. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Yang, J.; Du, Z.; Peng, J. Investigations on the energy efficiency of stratified air distribution systems with different diffuser layouts. Sustainability 2016, 8, 732. [Google Scholar] [CrossRef]

- Cheng, Y.; Niu, J.; Gao, N. Stratified air distribution systems in a large lecture theatre: A numerical method to optimize thermal comfort and maximize energy saving. Energy Build. 2012, 55, 515–525. [Google Scholar] [CrossRef]

- Heidarinejad, G.; Fathollahzadeh, M.H.; Pasdarshahri, H. Effects of return air vent height on energy consumption, thermal comfort conditions and indoor air quality in an under floor air distribution system. Energy Build. 2015, 97, 155–161. [Google Scholar] [CrossRef]

- Fathollahzadeh, M.H.; Heidarinejad, G.; Pasdarshahri, H. Prediction of thermal comfort, IAQ, and energy consumption in a dense occupancy environment with the under floor air distribution system. Build. Environ. 2015, 90, 96–104. [Google Scholar] [CrossRef]

- ASHRAE55; ANSI/ASHRAE Standard 55–2023. Thermal Environmental Conditions for Human Occupancy: Atlanta, GA, USA, 2023.

- ISO7730; Ergonomics of the Thermal Environment, Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organization for Standardization: Geneva, Switzerland, 2005.

- Shokrollahi, S.; Hadavi, M.; Heidarinejad, G.; Pasdarshahri, H. Multi-objective optimization of underfloor air distribution (UFAD) systems performance in a densely occupied environment: A combination of numerical simulation and Taguchi algorithm. J. Build. Eng. 2020, 32, 101495. [Google Scholar] [CrossRef]

- Heidarinejad, G.; Shokrollahi, S.; Pasdarshahri, H. An investigation of thermal comfort, IAQ, and energy saving in UFAD systems using a combination of Taguchi optimization algorithm and CFD. Adv. Build. Energy Res. 2021, 15, 799–817. [Google Scholar] [CrossRef]

- Ye, X.; Kang, Y.; Yan, Z.; Chen, B.; Zhong, K. Optimization study of return vent height for an impinging jet ventilation system with exhaust/return-split configuration by TOPSIS method. Build. Environ. 2020, 177, 106858. [Google Scholar] [CrossRef]

- Qin, C.; Fang, H.-Q.; Wu, S.-H.; Lu, W.-Z. Establishing multi-criteria optimization of return vent height for underfloor air distribution system. J. Build. Eng. 2022, 57, 104800. [Google Scholar] [CrossRef]

- Zhang, S.; Ai, Z.; Lin, Z. Novel demand-controlled optimization of constant-air-volume mechanical ventilation for indoor air quality, durability and energy saving. Appl. Energy 2021, 293, 116954. [Google Scholar] [CrossRef]

- Anand, P.; Sekhar, C.; Cheong, D.; Santamouris, M.; Kondepudi, S. Occupancy-based zone-level VAV system control implications on thermal comfort, ventilation, indoor air quality and building energy efficiency. Energy Build. 2019, 204, 109473. [Google Scholar] [CrossRef]

- Fisk, W.J.; De Almeida, A.T. Sensor-based demand-controlled ventilation: A review. Energy Build. 1998, 29, 35–45. [Google Scholar] [CrossRef]

- Alaidroos, A.; Almaimani, A.; Krarti, M.; Dahlan, A.; Maddah, R. Evaluation of the performance of demand control ventilation system for school buildings located in the hot climate of Saudi Arabia. Build. Simul. 2022, 15, 1067–1082. [Google Scholar] [CrossRef]

- Qin, C.; Wu, S.-H.; Fang, H.-Q.; Lu, W.-Z. The impacts of evaluation indices and normalization methods on E-TOPSIS optimization of return vent height for an impinging jet ventilation system. Build. Simul. 2022, 15, 2081–2095. [Google Scholar] [CrossRef]

- Lee, J.H.-W.; Chu, V.H. Turbulent Jets and Plumes: A Lagrangian Approach; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- Fan, Y.; Li, X.; Zheng, M.; Weng, R.; Tu, J. Numerical study on effects of air return height on performance of an underfloor air distribution system for heating and cooling. Energies 2020, 13, 1070. [Google Scholar] [CrossRef]

- Wan, M.; Chao, C. Numerical and experimental study of velocity and temperature characteristics in a ventilated enclosure with underfloor ventilation systems. Indoor Air 2005, 15, 342–355. [Google Scholar] [CrossRef]

- Kong, B.; Vigil, R.D. Simulation of photosynthetically active radiation distribution in algal photobioreactors using a multidimensional spectral radiation model. Bioresour. Technol. 2014, 158, 141–148. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Fluent Theory Guide; ANSYS Inc.: Athens, Greece, 2015. [Google Scholar]

- GB50736; China Architecture and Building Press, the People’s Republic of China National Standard GB 50736-2012, Design Code for Heating, Ventilation and Air Conditioning of Civil Buildings. China Academy of Building Research: Beijing, China, 2012. (In Chinese)

- ASHRAE62.1; ANSI/ASHRAE Standard 62.1-2010. Ventilation for Acceptable Indoor Air Quality: Atlanta, GA, USA, 2010.

- Qin, C.; Zhang, S.-Z.; Li, Z.-T.; Wen, C.-Y.; Lu, W.-Z. Transmission mitigation of COVID-19: Exhaled contaminants removal and energy saving in densely occupied space by impinging jet ventilation. Build. Environ. 2023, 232, 110066. [Google Scholar] [CrossRef]

- Fanger, P. Thermal environment—Human requirements. Environmentalist 1986, 6, 275–278. [Google Scholar] [CrossRef]

- Shannon, C.E. A mathematical theory of communication. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Park, J.H.; Park, I.Y.; Kwun, Y.C.; Tan, X. Extension of the TOPSIS method for decision making problems under interval-valued intuitionistic fuzzy environment. Appl. Math. Model. 2011, 35, 2544–2556. [Google Scholar] [CrossRef]

- Mao, N.; Song, M.; Deng, S. Application of TOPSIS method in evaluating the effects of supply vane angle of a task/ambient air conditioning system on energy utilization and thermal comfort. Appl. Energy 2016, 180, 536–545. [Google Scholar] [CrossRef]

- Li, Y.; Sandberg, M.; Fuchs, L. Effects of thermal radiation on airflow with displacement ventilation: An experimental investigation. Energy Build. 1993, 19, 263–274. [Google Scholar] [CrossRef]

- Gilani, S.; Montazeri, H.; Blocken, B. CFD simulation of stratified indoor environment in displacement ventilation: Validation and sensitivity analysis. Build. Environ. 2016, 95, 299–313. [Google Scholar] [CrossRef]

- Roache, P.J. Quantification of uncertainty in computational fluid dynamics. Annu. Rev. Fluid Mech. 1997, 29, 123–160. [Google Scholar] [CrossRef]

- Espinosa, F.D.; Glicksman, L.R. Determining thermal stratification in rooms with high supply momentum. Build. Environ. 2017, 112, 99–114. [Google Scholar] [CrossRef]

- Bhagat, R.K.; Wykes, M.D.; Dalziel, S.B.; Linden, P. Effects of ventilation on the indoor spread of COVID-19. J. Fluid Mech. 2020, 903, F1. [Google Scholar] [CrossRef]

- Zhong, K.; Yang, X.; Kang, Y. Effects of ventilation strategies and source locations on indoor particle deposition. Build. Environ. 2010, 45, 655–662. [Google Scholar] [CrossRef]

- Gao, N.; He, Q.; Niu, J. Numerical study of the lock-up phenomenon of human exhaled droplets under a displacement ventilated room. Build. Simul. 2012, 5, 51–60. [Google Scholar] [CrossRef]

| Wall Height [m] | Temperature [°C] |

|---|---|

| 0.08 | 22.4 |

| 0.73 | 23.4 |

| 1.39 | 24.0 |

| 2.04 | 24.5 |

| 2.68 | 24.4 |

| Line | 1 | 2 | 3 |

|---|---|---|---|

| GCIc,m * [%] | 0.1 | 0.7 | 0.2 |

| GCIm,f [%] | 0.1 | 0.2 | 0.2 |

| H [m] | 0.3 | 0.8 | 1.1 | 1.3 | 1.5 | 2.3 |

|---|---|---|---|---|---|---|

| Similarity | 0.1758 | 0.4806 | 0.7499 | 0.8065 | 0.8221 | 0.8242 |

| Ranking | 6 | 5 | 4 | 3 | 2 | 1 |

| H [m] | 0.3 | 0.8 | 1.1 | 1.3 | 1.5 | 2.3 |

|---|---|---|---|---|---|---|

| Similarity | 0.0028 | 0.5055 | 0.7889 | 0.8837 | 0.9328 | 0.9972 |

| Ranking | 6 | 5 | 4 | 3 | 2 | 1 |

| Optimal Cases | Average MAA [s] | Qcoil [W] | Average CO2 [ppm] | ΔT0.1–1.1 [°C] | DR [%] | PPD [%] |

|---|---|---|---|---|---|---|

| Ts = 18 °C, H = 1.5 m | 86.7 | 1264.5 | 863.1 | 0.54 | 9.5 | 72.7 |

| Ts = 18 °C, H = 2.3 m | 79.5 | 1393.7 | 949.5 | 0.30 | 10.3 | 78.8 |

| |PMV| < 0.5, H = 2.3 m | 81.4 | 1139.9 | 943.2 | 0.30 | 6.2 | 5.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, D.; Wu, S.; Zhang, N.; Qin, C. Optimizing the Return Vent Height for Improved Performance in Stratified Air Distribution Systems. Buildings 2024, 14, 1008. https://doi.org/10.3390/buildings14041008

Qiao D, Wu S, Zhang N, Qin C. Optimizing the Return Vent Height for Improved Performance in Stratified Air Distribution Systems. Buildings. 2024; 14(4):1008. https://doi.org/10.3390/buildings14041008

Chicago/Turabian StyleQiao, Danping, Shihai Wu, Nan Zhang, and Chao Qin. 2024. "Optimizing the Return Vent Height for Improved Performance in Stratified Air Distribution Systems" Buildings 14, no. 4: 1008. https://doi.org/10.3390/buildings14041008

APA StyleQiao, D., Wu, S., Zhang, N., & Qin, C. (2024). Optimizing the Return Vent Height for Improved Performance in Stratified Air Distribution Systems. Buildings, 14(4), 1008. https://doi.org/10.3390/buildings14041008