Structural Behavior of Precast Monolithic Composite Beams with ECC Prefabricated Shells

Abstract

1. Introduction

2. Materials and Methods

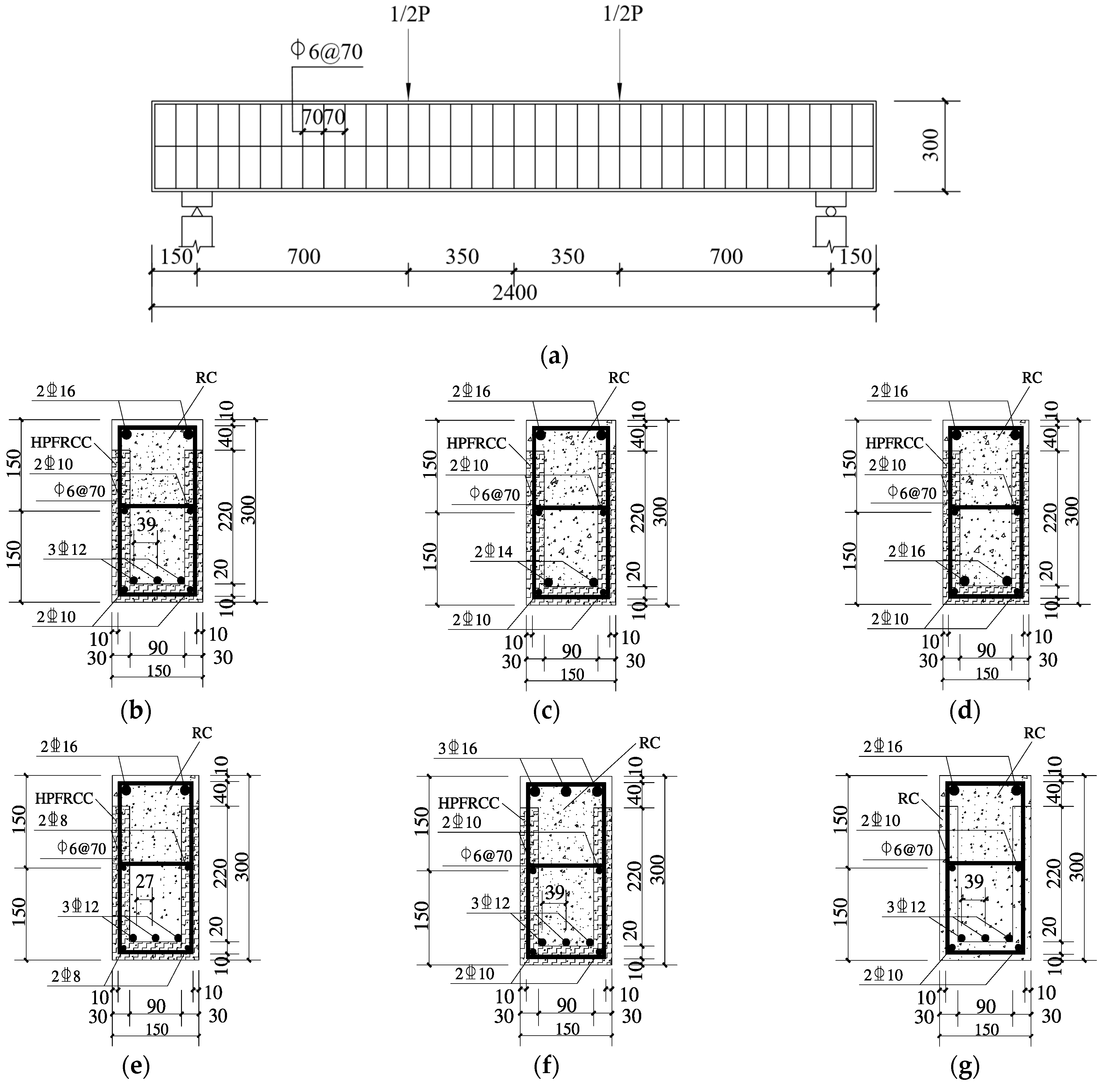

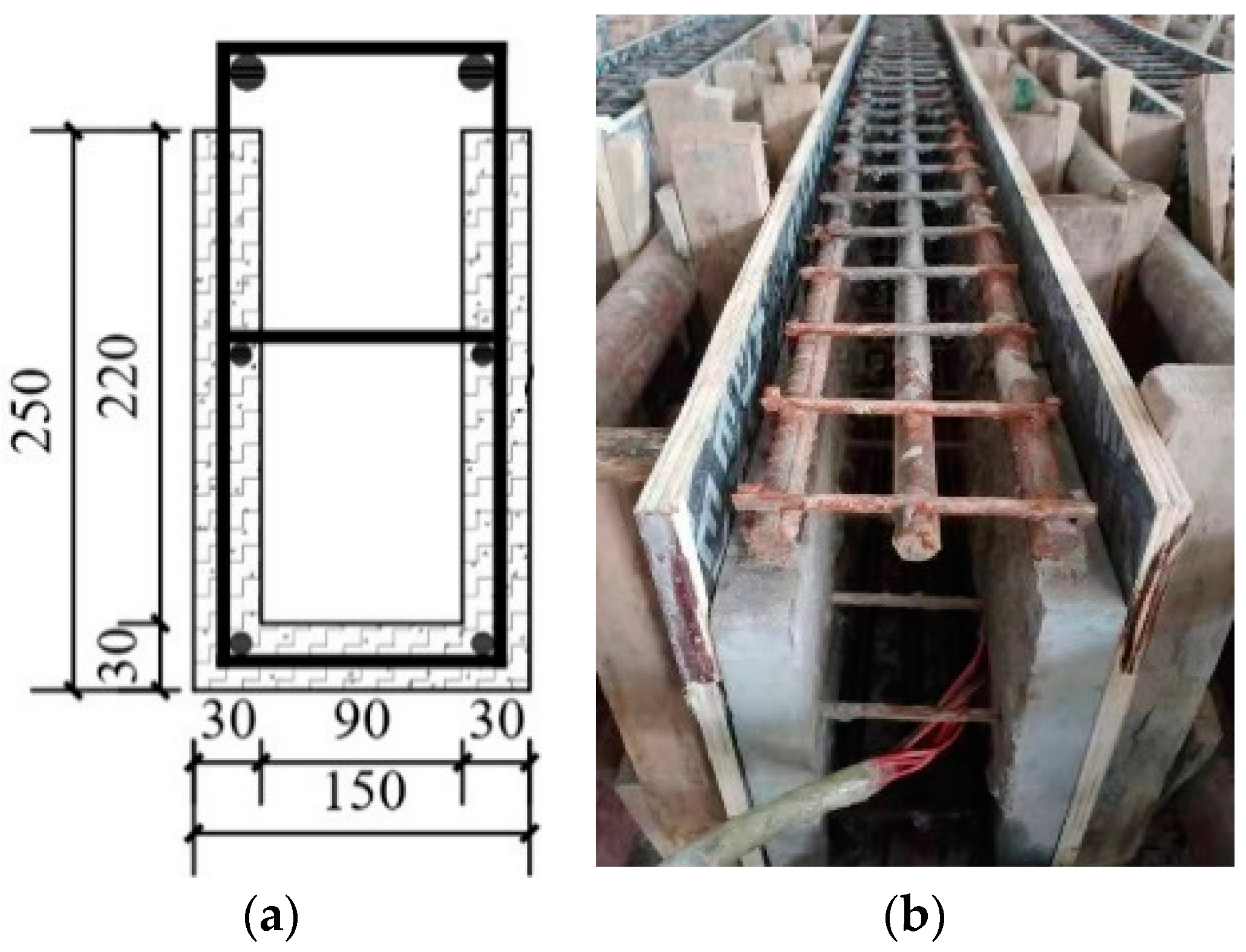

2.1. Specimen Design

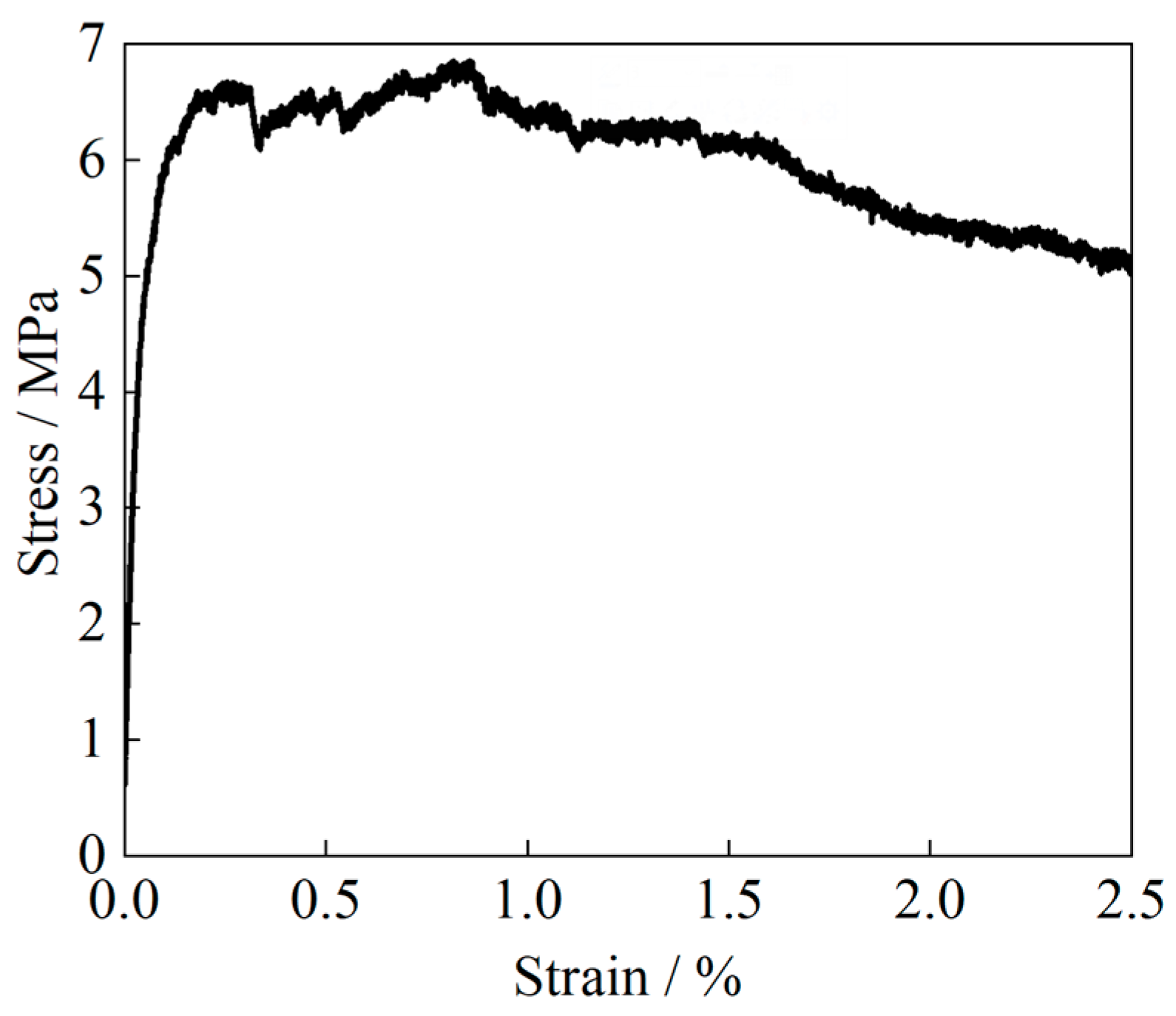

2.2. Mechanical Properties of Materials

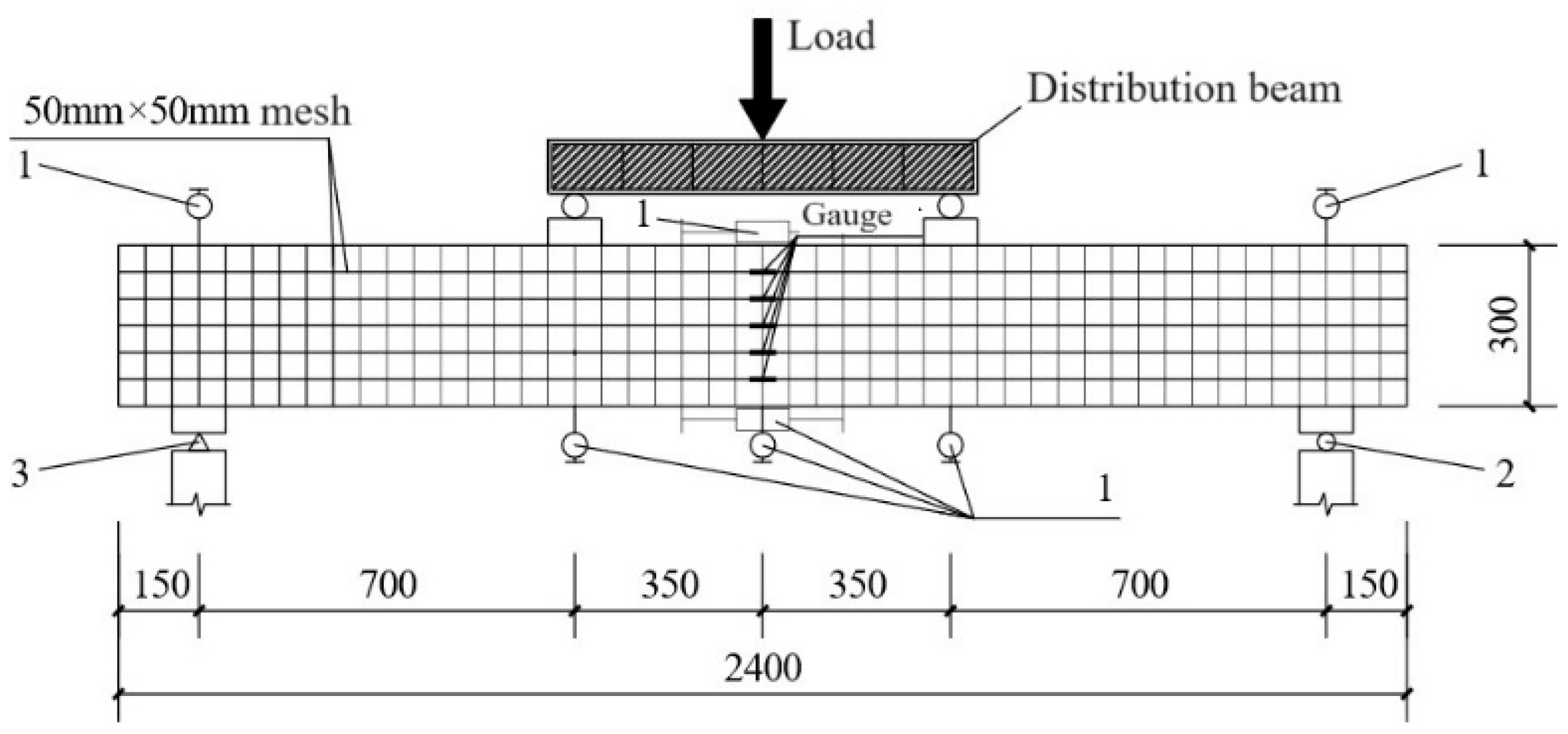

2.3. Test Setup and Instrument

3. Results and Analysis

3.1. Failure Description

3.2. Crack Width Analysis

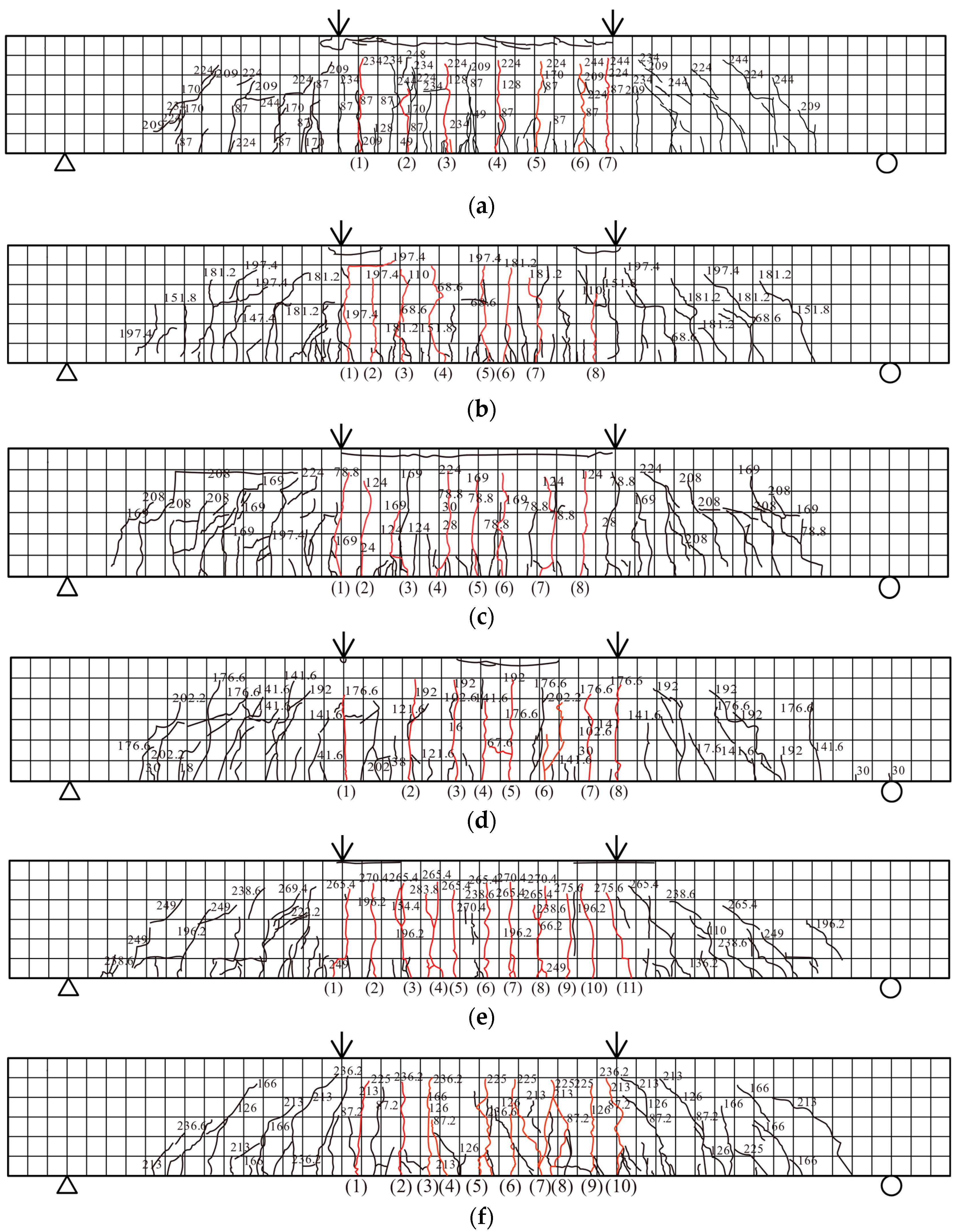

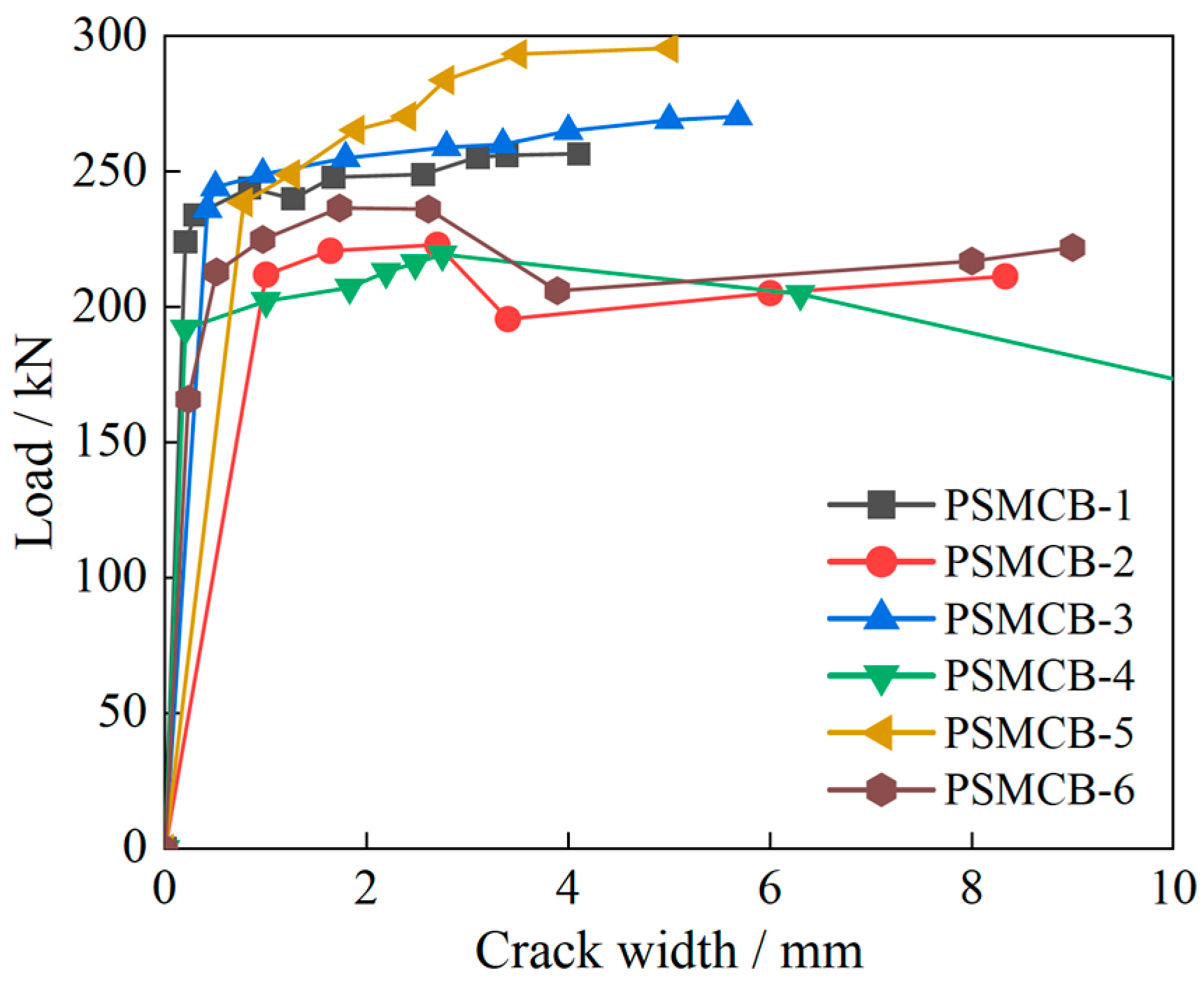

- In the process of testing the RC composite beam (PSMCB-6), after the first appearance of cracks, the original cracks extended and developed rapidly, although there were still new cracks. Few new cracks appeared after the beam yielded. The crack width expanded rapidly until the concrete at the top of the composite beam was crushed and damaged. However, the ECC composite beam specimen (PSMCB-1) was different. With increasing load, microcracks continued to appear during the test. Even after the composite beam yielded, new cracks continued to appear steadily. The crack width grew relatively slowly until the appearance of the main crack. For the RC composite beam (PSMCB-6), the crack width developed when the load was 166.0 kN. For the ECC prefabricated composite beam (PSMCB-1), cracks began to develop when the load was 209.0 kN. The ECC composite beams exhibited a better crack control capacity. This is mainly due to the characteristics of the ECC material, with microcracking and pseudo-strain hardening. The difference in the tensile hardening characteristics of ECC lies in the designed effect of fiber bridging on its load bearing capacity and energy absorption capacity. After cracking in ECC materials, unlike with the brittle cracking of concrete and other materials, the ECC does not lose its strength and has good crack width control.

- For the ECC composite beams PSMCB-4, PSMCB-2, PSMCB-1, and PSMCB-3, the reinforcement ratios were 1.07%, 1.13%, 1.21%, and 1.36%, respectively. The corresponding loads at which the cracks began to develop were 192 kN, 197.4 kN, 209 kN, and 224 kN, respectively. When the test stopped, the maximum crack widths were 13 mm, 9.0 mm, 4.1 mm, and 3.8 mm, respectively. Under the same load, the crack width decreased sequentially.

3.3. Bearing Capacity and Deformability

- Before cracking, the specimens were in an elastic stage. The load–deflection curves showed a linear change with an increase in load. The initial stiffness of specimen PSMCB-6 was larger than those of specimens PSMCB-1~PSMCB-5. When cracks appeared, the stiffness of the specimens decreased. There was no obvious turning point in the curves of the ECC prefabricated shell composite beams. However, there was a noticeable reduction in the stiffness of specimen PSMCB-6. The stiffness of specimen PSMCB-1 gradually became greater than that of specimen PSMCB-6 when the mid-span displacement reached 2.6 mm. The differences between the curves of ECC composite beams (PSMCB-1, PSMCB-2, PSMCB-3, PSMCB-4) with different longitudinal reinforcement ratios were small.Figure 8. Load–deflection curves of composite beams: (a) load–deflection curve; (b) elastic segment curves.Figure 8. Load–deflection curves of composite beams: (a) load–deflection curve; (b) elastic segment curves.

- The beams were in the plastic failure stage when the reinforcement bars yielded. Most of the concrete withdrew from the work. The deformation increased rapidly after yielding. The slope of the curves gradually decreased and tended to be horizontal. The stiffness of the composite beams also gradually reduced. The curve slope of specimen PSMCB-1 was still greater than that of specimen PSMCB-6. Thus, the stiffness of the ECC composite beam (PSMCB-1) was also larger than that of the RC composite beam (PSMCB-6), and the stiffness gap gradually increased. For the specimens with different reinforcement ratios, the higher the reinforcement ratio, the slower the specimen’s stiffness decreased.

- After the reinforcement bars yielded, the loads were not greatly increased. The displacement constantly increased, and the neutralization axis was constantly moving upward. The stiffness decrease for specimen PSMCB-1 was smaller than that for specimen PSMCB-6.

3.4. Moment–Curvature Analysis

3.5. Reinforcement Strain Analysis

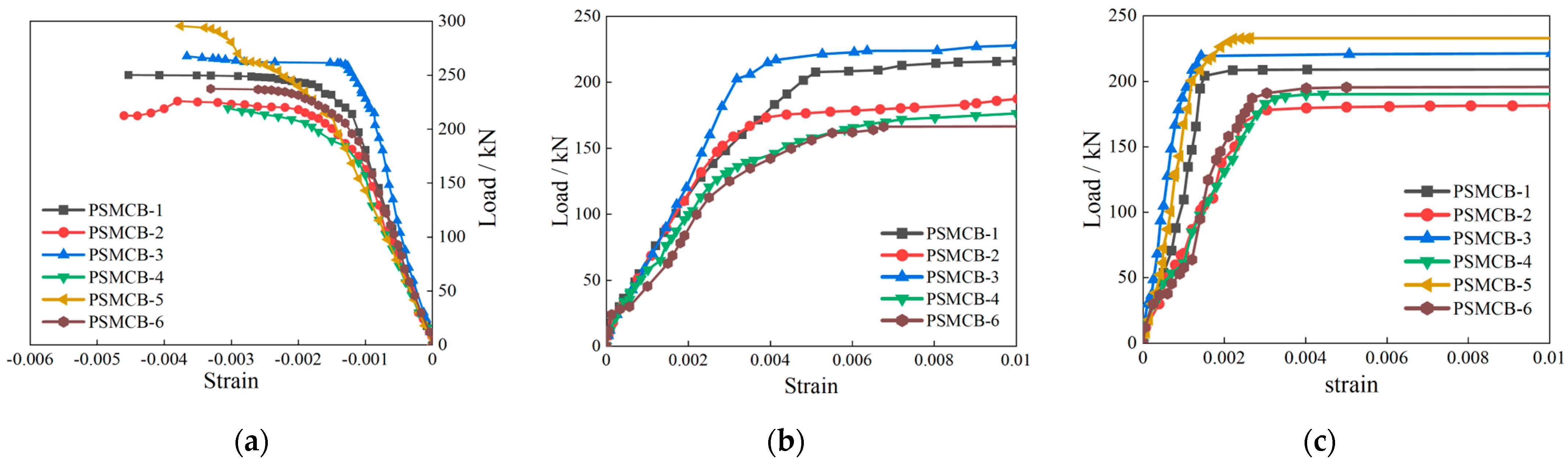

- For specimens PSMCB-1 and PSMCB-6, with different materials in their prefabricated shells, the reinforcement strain was small in the early stage, and the composite beams’ load–reinforcement strain curves were almost the same. For the RC composite beam (PSMCB-6), when the cracks appeared, the concrete in the crack section directly withdrew from the work, and the reinforcement stress increased suddenly. Thus, there was a sharp increase in the reinforcement strain. For specimen PSMCB-1, the reinforcement bar strain continued to grow without abrupt changes due to the presence of the ECC material. Compared with that of specimen PSMCB-6, the curve slope of the ECC composite beam PSMCB-1 was relatively larger, and the bending bearing capacity was also higher. The load–reinforcement strain curve tended to be smoother more slowly. Under the same load level, the reinforcement strain of specimen PSMCB-1 was relatively smaller among the two composite beams PSMCB-1 and PSMCB-6. In Figure 10b, when the load reached 83.8 kN, the reinforcement bar strain in the prefabricated shell of specimen PSMCB-6 was about 0.002, which was close to yielding, while the strain of specimen PSMCB-1 was only 0.0013. When the reinforcement bar strain of specimen PSMCB-1 reached 0.002, the corresponding load was 114.2 kN. In Figure 10c, when the load reached 146.2 kN, the reinforcement bar strain in the post-poured concrete of specimen PSMCB-6 was about 0.002, while the strain of specimen PSMCB-1 was about 0.0012. When the reinforcement bar strain of specimen PSMCB-1 reached 0.002, the corresponding load reached 207.3 kN. For the reinforcement bars under compression, as shown in Figure 10a, when the reinforcement bar strain reached −0.002, the corresponding load of PSMCB-1 was 243.6 kN, and the corresponding load of PSMCB-6 was 228.4 kN. In Figure 10b, the curves of the reinforcement bars in the prefabricated shells of specimens PSMCB-4 and PSMCB-6 were similar, although the amount of reinforcement in the beam PSMCB-4 was less than that in the beam PSMCB-6. This was mainly because the ECC material underwent multi-crack steady-state propagation under direct tension, showing tensile hardening characteristics. Using ECC material in the prefabricated shell could effectively delay not only the yielding of the longitudinal reinforcement bars but also the yielding of the reinforcement bars in the post-poured concrete. The overall mechanical performance of the beam was improved.

- For the ECC composite beams (PSMCB-1, PSMCB-2, PSMCB-3, PSMCB-4) with different longitudinal reinforcement ratios, the difference in the reinforcement strain curves of each test beam was very small in the elastic stage. Before the reinforcement bars yielded, as the reinforcement ratio of the longitudinal reinforcement bars increased, the slope of the load versus longitudinal reinforcement bar strain curves for the ECC composite beams was larger under the same load. Correspondingly, the strain on the reinforcement was smaller. In Figure 10c, when the load reached 137.8 kN, the reinforcement bar strain of specimen PSMCB-2 reached 0.002. At the same time, the reinforcement bar strain values of PSMCB-1 and PSMCB-3 were 0.0011 and 0.0006, respectively. When the reinforcement bar strain of PSMCB-1 and PSMCB-3 was 0.002, the load of the two composite beams reached about 207.3 kN and 219.5 kN. When the longitudinal reinforcement yielded, the longitudinal reinforcement bar strain of the composite beams with a lower reinforcement ratio increased dramatically.

- For the ECC composite beam PSMCB-5, there was no obvious difference as compared to the load–strain curves of the other beams in the early stage. When cracks appeared in the specimen, the reinforcement strain gradually increased since the concrete in the crack section no longer worked with the reinforcement bars. Then, the slope of the reinforcement bar strain curve for specimen PSMCB-5 decreased. When the reinforcement in the tension region yielded, the curve slope of specimen PSMCB-5 was slightly larger. When cracks appeared, due to the fiber bridging in the tension region, the neutralization position was lower under the same level load, and the compression height of the section increased.

3.6. Plane Section Assumption

4. Conclusions

- Compared with the RC prefabricated shell composite beam, specimen PSMCB-1 with an ECC prefabricated shell showed a higher bearing capacity and lower damage degree. The yield load of specimen PSMCB-1 increased by 5.6%, and the corresponding deflection was 0.08 mm larger than that of the beam PSMCB-6. The ultimate load increased by 8.1%. When the tests stopped, the maximum crack width of specimen PSMCB-1 was 4.1 mm, while the maximum crack width of specimen PSMCB-6 reached 9.0 mm.

- For composite beams, an ECC prefabricated shell could effectively delay the yielding of longitudinal reinforcement. Under the same load, the reinforcement strain of specimen PSMCB-1 with an ECC prefabricated shell was smaller than that of the RC composite beam PSMCB-6. The load of the ECC composite beam was significantly higher than that of RC composite beam when the reinforcement bars were under the same strain.

- The ECC precast monolithic composite beams showed good bearing capacity, integrity, and deformability. Compared with those of specimen PSMCB-1, the longitudinal reinforcement ratio of beam PSMCB-2 was 0.08% lower, the yield load was reduced by 20.4%, and the ultimate load was reduced by 13.5%. The longitudinal reinforcement ratio of beam PSMCB-3 was 0.15% higher than that of beam PSMCB-1; the yield load of specimen PSMCB-3 increased by 6.5%, and the ultimate load increased by 13.5%. Until the end of loading, the bearing capacity of specimens PSMCB-1 and PSMCB-3 did not decrease.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, T.; Guan, K.; Pan, J.; Liang, X. The effect of ECC materials on seismic performance of beam-column subassemblies with slabs. Buildings 2023, 13, 1942. [Google Scholar] [CrossRef]

- Lu, T.; Zhou, H.; Liang, X.W. Research on the mechanical properties of the joint of the beam-column subassembly. Structures 2022, 35, 873–881. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, G.; Shen, Z.; Gao, Y.; Zhou, H.; Wang, Z. A comprehensive study on the effect of reinforcing methods on the flexural behavior of Concrete-RUHTCC composite beams. Eng. Struct. 2023, 292, 116524. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Isa, M.N.; Baluch, M.H.; Rahman, M.K. Flexural behavior of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete. Constr. Build. Mater. 2017, 134, 279–296. [Google Scholar] [CrossRef]

- Bahraq, A.A.; Al-Osta, M.A.; Ahmad, S.; Al-Zahrani, M.M.; Al-Dulaijan, S.O.; Kalimur Rahman, M. Experimental and numerical investigation of shear behavior of RC beams strengthened by ultra-high performance concrete. Int. J. Concr. Struct. Mater. 2019, 13, 6. [Google Scholar] [CrossRef]

- Zhang, X.F.; Xu, S.L.; Li, H.D. Theoretical analysis of flexural performance of plain concrete composite beams strengthened with ultrahigh toughness cementitious composite. China Civ. Eng. J. 2010, 43, 51–62. [Google Scholar] [CrossRef]

- Xu, S.L.; Wang, N.; Li, Q.H. Experimental study on the flexural performance of concrete beam strengthened with ultra high toughness cementitious composites. China Civ. Eng. J. 2010, 43, 17–22. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Z.; Xie, T.; Yang, J. Flexural behavior and cost effectiveness of layered UHPC-NC composite beams. Eng. Struct. 2022, 273, 115060. [Google Scholar] [CrossRef]

- Nguyen, D.-L.; Thai, D.-K.; Nguyen, H.T.T.; Nguyen, T.-Q.; Le-Trung, K. Responses of composite beams with high-performance fiber-reinforced concrete. Constr. Build. Mater. 2021, 270, 121814. [Google Scholar] [CrossRef]

- Liang, X.W.; Wang, P.; Xu, M.X. Flexural behavior and capacity analysis of RC beams with permanent UHPC formwork. Eng. Mech. 2019, 36, 95–107. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, X.; Wang, Y.; Zhai, T. Experimental and theoretical investigations on the flexural behavior of RC slabs with steel-PVA hybrid fiber reinforced cementitious composite (HFRCC) permanent formwork. Case Stud. Constr. Mater. 2022, 17, e01432. [Google Scholar] [CrossRef]

- Qin, F.; Wei, X.; Lu, Y.; Zhang, Z.; Di, J.; Yin, Z. Flexural behaviour of high strength engineered cementitious composites (ECC)-reinforced concrete composite beams. Case Stud. Constr. Mater. 2023, 18, e02002. [Google Scholar] [CrossRef]

- Qiao, Z.; Pan, Z.; Xue, W.; Meng, S. Experimental study on flexural behavior of ECC/RC composite beams with U-shaped ECC permanent formwork. Front. Struct. Civ. Eng. 2019, 13, 1271–1287. [Google Scholar] [CrossRef]

- Zhang, R.; Hu, P.; Zheng, X.; Cai, L.; Guo, R.; Wei, D. Shear behavior of RC slender beams without stirrups by using precast U-shaped ECC permanent formwork. Constr. Build. Mater. 2020, 260, 120430. [Google Scholar] [CrossRef]

- Zhang, P.; Xu, F.; Liu, Y.; Sheikh, S.A. Shear behaviour of composite beams with permanent UHPC formwork and high-strength steel rebar. Constr. Build. Mater. 2022, 352, 128951. [Google Scholar] [CrossRef]

- Abbas, Y.M.; Khan, M.I. Behavioral response of reinforced concrete beams with ultra-ductile fiber-reinforced cementitious composite layers-Experiments, models and reinforcement limits. J. Build. Eng. 2023, 77, 114004. [Google Scholar] [CrossRef]

- Hu, Z.; Zhou, Y.; Hu, B.; Huang, X.; Guo, M. Local use of ECC to simultaneously enhance the shear strength and deformability of RC beams. Constr. Build. Mater. 2022, 353, 129085. [Google Scholar] [CrossRef]

- Zanuy, C.; Gonzalo, S.D. Ulzurrun, Manfred Curbach. Experimental determination of sectional forces in impact tests: Application to composite RC-HPFRCC beams. Eng. Struct. 2022, 256, 114004. [Google Scholar] [CrossRef]

| Number | Material of the Shell | Longitudinal Bars in Shell/HRB400 | Longitudinal Bars in Post-Cast Concrete/HRB400 | Longitudinal Reinforcement Ratio/% | Stirrups /HPB300 | |

|---|---|---|---|---|---|---|

| Lower | Upper | |||||

| PSMCB-1 | ECC | 4–10 | 3–12 | 2–16 | 1.21 | 6@70 |

| PSMCB-2 | ECC | 4–10 | 2–14 | 2–16 | 1.13 | |

| PSMCB-3 | ECC | 4–10 | 2–16 | 2–16 | 1.36 | |

| PSMCB-4 | ECC | 4–8 | 3–12 | 2–16 | 1.07 | |

| PSMCB-5 | ECC | 4–10 | 3–12 | 3–16 | 1.46 | |

| PSMCB-6 | RC | 4–10 | 3–12 | 2–16 | 1.21 | |

| Cement | Fly Ash | Water | Sand | Fiber |

|---|---|---|---|---|

| 569 | 696 | 405 | 455 | 26 |

| Grade | Diameter (mm) | fy (MPa) | fu (MPa) | Es/GPa |

|---|---|---|---|---|

| HPB300 | 6 | 355 | 506 | 210 |

| 8 | 410 | 512 | ||

| HRB400 | 10 | 425 | 626 | 200 |

| 12 | 465 | 642 | ||

| 14 | 442 | 614 | ||

| 16 | 532 | 698 |

| Number | Cracking Load/kN | Yielding Load/kN | Yielding Deflection/mm | Ultimate Load/kN |

|---|---|---|---|---|

| PSMCB-1 | 18.0 | 219.2 | 11.30 | 256.6 |

| PSMCB-2 | 18.0 | 174.5 | 8.27 | 226.0 |

| PSMCB-3 | 12.0 | 233.4 | 13.14 | 267.6 |

| PSMCB-4 | 16.0 | 178.5 | 10.62 | 219.4 |

| PSMCB-5 | 18.0 | 239.8 | 14.34 | 295.6 |

| PSMCB-6 | 28.0 | 207.6 | 11.22 | 237.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, T.; Li, Z.; Pan, J.; Guan, K. Structural Behavior of Precast Monolithic Composite Beams with ECC Prefabricated Shells. Buildings 2024, 14, 1024. https://doi.org/10.3390/buildings14041024

Lu T, Li Z, Pan J, Guan K. Structural Behavior of Precast Monolithic Composite Beams with ECC Prefabricated Shells. Buildings. 2024; 14(4):1024. https://doi.org/10.3390/buildings14041024

Chicago/Turabian StyleLu, Tingting, Zhilong Li, Jiaojiao Pan, and Kai Guan. 2024. "Structural Behavior of Precast Monolithic Composite Beams with ECC Prefabricated Shells" Buildings 14, no. 4: 1024. https://doi.org/10.3390/buildings14041024

APA StyleLu, T., Li, Z., Pan, J., & Guan, K. (2024). Structural Behavior of Precast Monolithic Composite Beams with ECC Prefabricated Shells. Buildings, 14(4), 1024. https://doi.org/10.3390/buildings14041024