Enhancement of Flexural Strength in Fiber–Cement Composites through Modification of Sisal Fiber with Natural Rubber Latex and Expanded Perlite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

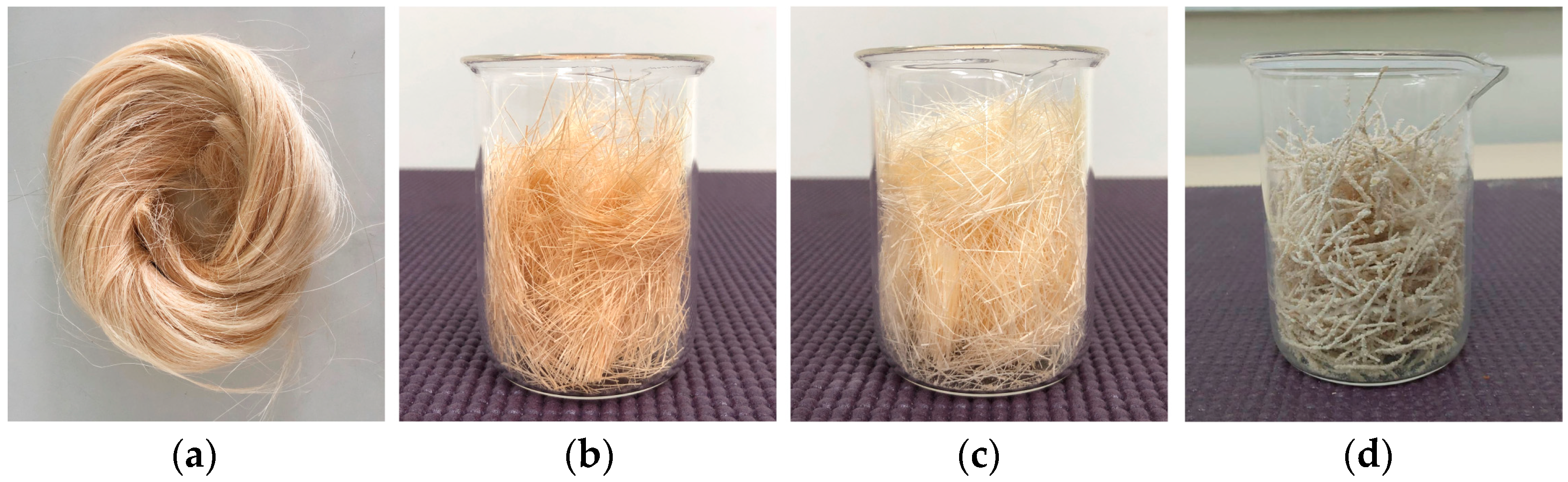

2.2. Preparation of Sisal Fibers

2.3. Preparation of Sisal Fiber–Cement Specimens

2.4. Characterization Methods

2.4.1. Microscopic Study

2.4.2. Physical Properties

2.4.3. Mechanical Properties

3. Results and Discussion

3.1. Microstructure Analysis and Water Absorption of Sisal Fibers

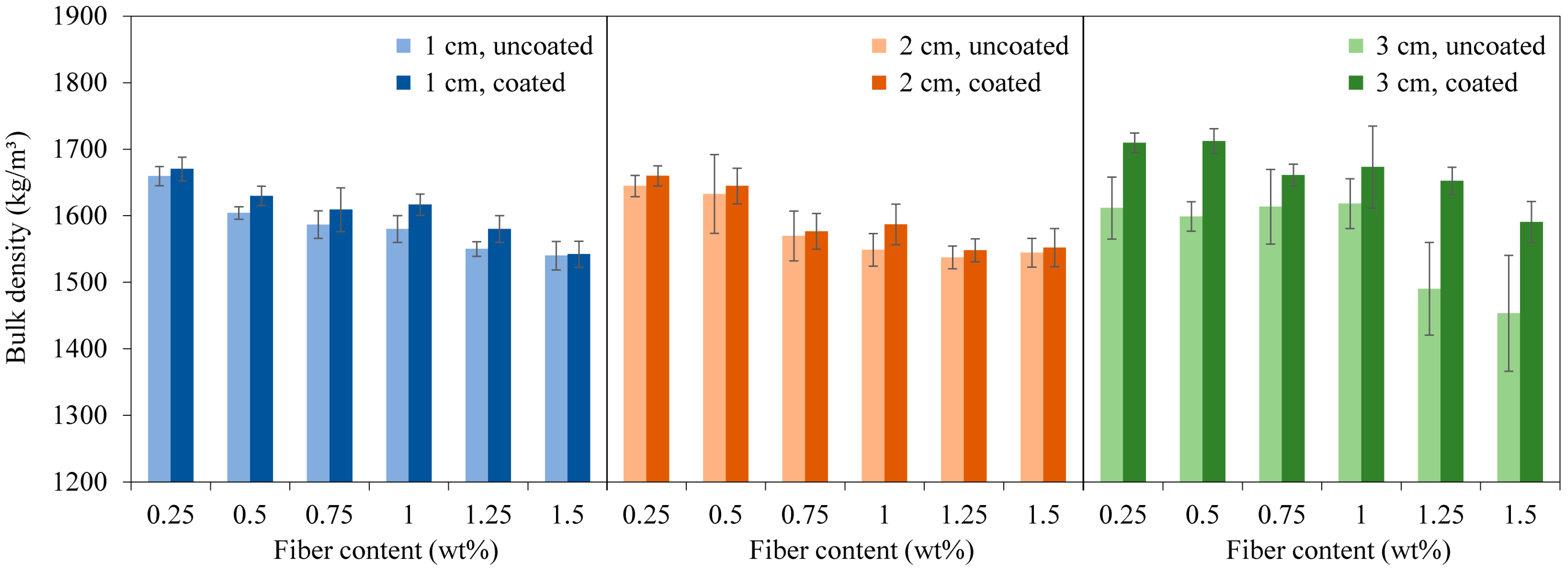

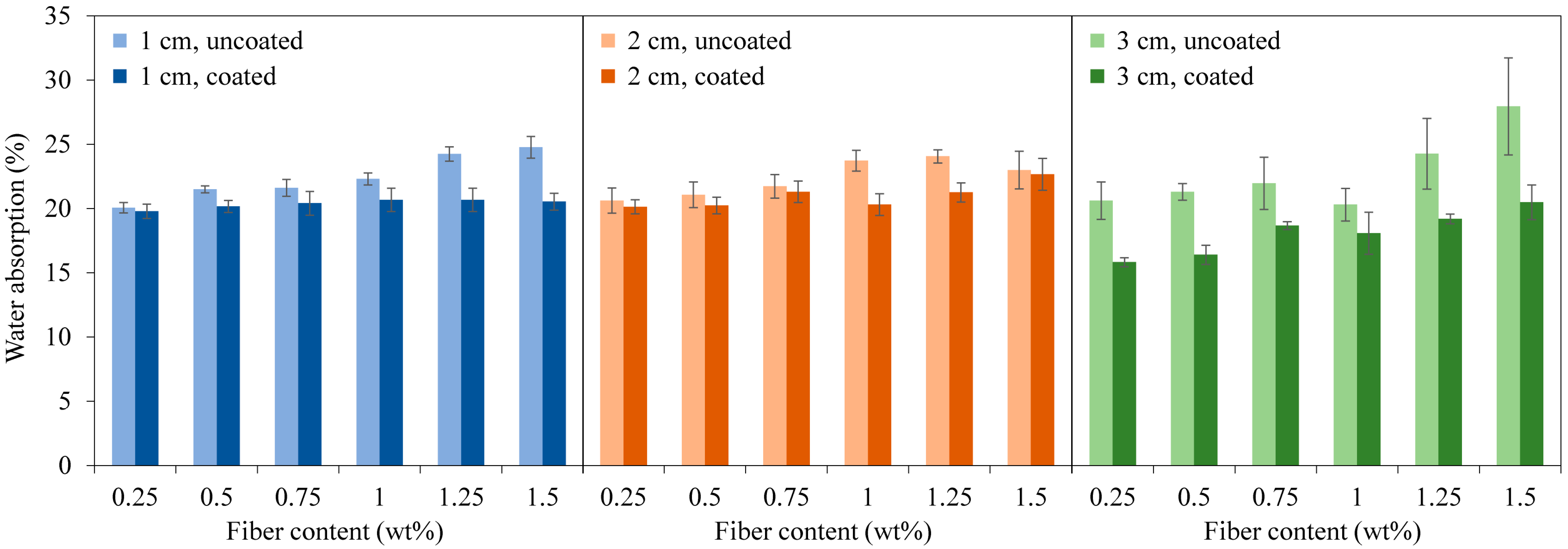

3.2. Physical Properties of Sisal Fiber Cement Composites

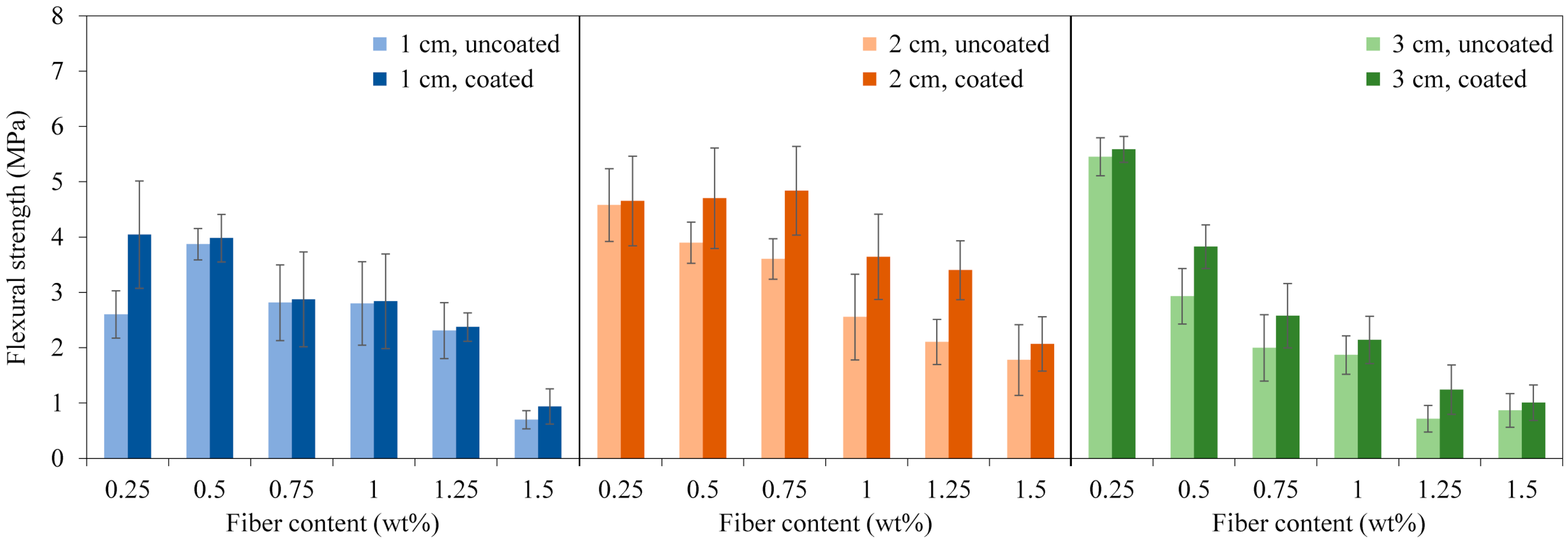

3.3. Flexural Strength of Sisal Fiber–Cement Composites

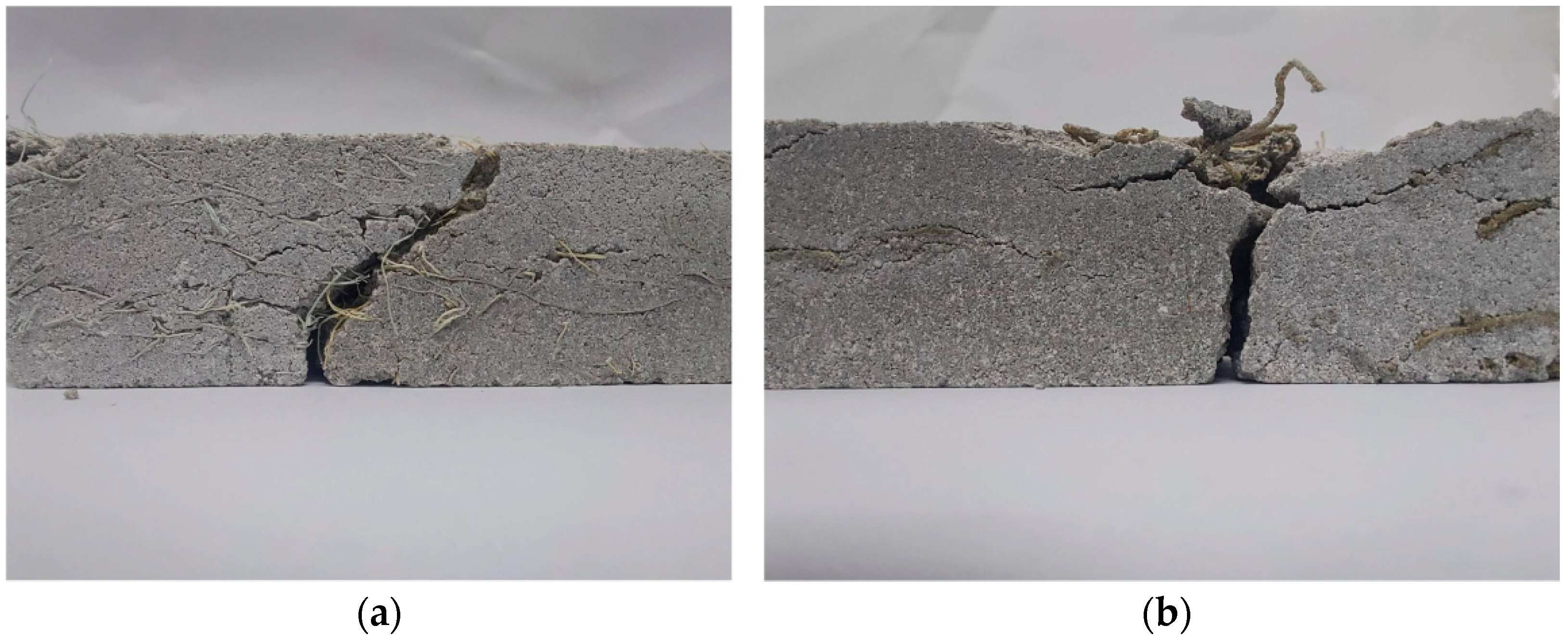

3.4. Microstructure Analysis of Sisal Fiber–Cement Composites

4. Conclusions

- SEM analysis revealed the morphological changes in sisal fibers before and after alkali treatment and coating. The alkali treatment resulted in a slight reduction in fiber diameter, and the subsequent coating demonstrated a smooth layer of natural rubber latex and homogeneously anchoring expanded perlite.

- The bulk density of sisal fiber–cement composites decreased with increasing fiber content and length. Using coated sisal fibers resulted in a higher density than uncoated ones, attributed to improved adhesion and reduced porosity.

- The water absorption of the sisal fiber–cement composites increased with sisal fiber content, but this increase was less pronounced for coated sisal fibers. The coating of natural rubber latex prevented sisal fiber from absorbing water, and expanded perlite played a crucial role in reducing the void between the fiber and cement matrix.

- The flexural strength of sisal fiber–cement composites using coated sisal fibers consistently exhibited higher flexural strength compared to those using uncoated fibers. Flexural strength varied with fiber content and length, with the highest value of 5.58 MPa observed in a composite comprising 3 cm coated fiber composites with 0.25 wt% fiber content.

- The microstructure analysis revealed that coated sisal fibers displayed a perfectly bonded interface, free of voids, implying effective bonding with the cement matrix. The morphology of pulled-out fiber reveals the rough surface of coated fiber, with a significant presence of adhering cement matrix fragments, indicates a stronger bond. These results emphasize the positive impact of coating on the mechanical performance of the sisal fiber–cement composites.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.P.; Selvakumar, K.K.; Jyothi, M.S.; Jyothilakshmi, R.; Kumar, S. Development of Sustainable Alternative Materials for the Construction of Green Buildings Using Agricultural Residues: A Review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar]

- Hamada, H.M.; Shi, J.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T.; Kaplan, G. Application of Natural Fibres in Cement Concrete: A Critical Review. Mater. Today. Commun. 2023, 35, 105833. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-Based Natural Fibre Reinforced Cement Composites: A Review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural Fiber-Reinforced Mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Ren, G.; Yao, B.; Huang, H.; Gao, X. Influence of Sisal Fibers on the Mechanical Performance of Ultra-High Performance Concretes. Constr. Build. Mater. 2021, 286, 122958. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Impact Strength of a Few Natural Fibre Reinforced Cement Mortar Slabs: A Comparative Study. Cem. Concr. Compos. 2005, 27, 547–553. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Brazilian Waste Fibres as Reinforcement for Cement-Based Composites. Cem. Concr. Compos. 2000, 22, 379–384. [Google Scholar] [CrossRef]

- Quintaliani, C.; Merli, F.; Fiorini, C.V.; Corradi, M.; Speranzini, E.; Buratti, C. Vegetal Fiber Additives in Mortars: Experimental Characterization of Thermal and Acoustic Properties. Sustainability 2022, 14, 1260. [Google Scholar] [CrossRef]

- Asim, M.; Uddin, G.M.; Jamshaid, H.; Raza, A.; Tahir, Z.U.R.; Hussain, U.; Satti, A.N.; Hayat, N.; Arafat, S.M. Comparative Experimental Investigation of Natural Fibers Reinforced Light Weight Concrete as Thermally Efficient Building Materials. J. Build. Eng. 2020, 31, 101411. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, W.; Zhang, S.; Hou, J. Performance Study of Lightweight Insulating Mortar Reinforced with Straw Fiber. Materials 2023, 16, 2266. [Google Scholar] [CrossRef] [PubMed]

- Laverde, V.; Marin, A.; Benjumea, J.M.; Rincón Ortiz, M. Use of Vegetable Fibers as Reinforcements in Cement-Matrix Composite Materials: A Review. Constr. Build. Mater. 2022, 340, 127729. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical Properties Evaluation of Sisal Fibre Reinforced Polymer Composites: A Review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Chandrasekaran, R.G.; Ramakrishna, G. Experimental Investigation on Mechanical Properties of Economical Local Natural Fibre Reinforced Cement Mortar. Mater. Today Proc. 2021, 46, 7633–7638. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of Alkali-Sensitive Sisal and Coconut Fibres in Cement Mortar Composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation Mechanisms of Natural Fiber in the Matrix of Cement Composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Silva, F.D.A.; Lima, P.R.L.; Toledo Filho, R.D. Effect of Fiber Treatments on the Sisal Fiber Properties and Fiber–Matrix Bond in Cement Based Systems. Constr. Build. Mater. 2015, 101, 730–740. [Google Scholar] [CrossRef]

- Veigas, M.G.; Najimi, M.; Shafei, B. Cementitious Composites Made with Natural Fibers: Investigation of Uncoated and Coated Sisal Fibers. Case Stud. Constr. Mater. 2022, 16, e00788. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic Fiber Reinforced Cement-Based Composites: A Review of Recent Research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Ghavami, K.; England, G.L.; Scrivener, K. Development of Vegetable Fibre–Mortar Composites of Improved Durability. Cem. Concr. Compos. 2003, 25, 185–196. [Google Scholar] [CrossRef]

- De Gutiérrez, R.M.; Díaz, L.N.; Delvasto, S. Effect of Pozzolans on the Performance of Fiber-Reinforced Mortars. Cem. Concr. Compos. 2005, 27, 593–598. [Google Scholar] [CrossRef]

- Mohr, B.J.; Biernacki, J.J.; Kurtis, K.E. Supplementary Cementitious Materials for Mitigating Degradation of Kraft Pulp Fiber-Cement Composites. Cem. Concr. Res. 2007, 37, 1531–1543. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; de Andrade Silva, F.; Fairbairn, E.M.R.; Filho, J.d.A.M. Durability of Compression Molded Sisal Fiber Reinforced Mortar Laminates. Constr. Build. Mater. 2009, 23, 2409–2420. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Filho, R.D.T.; Filho, J.d.A.M.; Fairbairn, E.d.M.R. Physical and Mechanical Properties of Durable Sisal Fiber–Cement Composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar] [CrossRef]

- Filho, J.D.A.M.; Silva, F.D.A.; Toledo Filho, R.D. Degradation Kinetics and Aging Mechanisms on Sisal Fiber Cement Composite Systems. Cem. Concr. Compos. 2013, 40, 30–39. [Google Scholar] [CrossRef]

- Yu, L.H.; Ou, H.; Lee, L.L. Investigation on Pozzolanic Effect of Perlite Powder in Concrete. Cem. Concr. Res. 2003, 33, 73–76. [Google Scholar] [CrossRef]

- Erdem, T.K.; Meral, Ç.; Tokyay, M.; Erdoǧan, T.Y. Use of Perlite as a Pozzolanic Addition in Producing Blended Cements. Cem. Concr. Compos. 2007, 29, 13–21. [Google Scholar] [CrossRef]

- Wang, X.; Wu, D.; Geng, Q.; Hou, D.; Wang, M.; Li, L.; Wang, P.; Chen, D.; Sun, Z. Characterization of Sustainable Ultra-High Performance Concrete (UHPC) Including Expanded Perlite. Constr. Build. Mater. 2021, 303, 124245. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The Hornification of Vegetable Fibers to Improve the Durability of Cement Mortar Composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- do Amaral, L.M.; de Souza Rodrigues, C.; Poggiali, F.S.J. Hornification on Vegetable Fibers to Improve Fiber-Cement Composites: A Critical Review. J. Build. Eng. 2022, 48, 103947. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Lima, P.R.L.; Silva, F.A.; Toledo Filho, R.D. Effect of Sisal Fiber Hornification on the Fiber-Matrix Bonding Characteristics and Bending Behavior of Cement Based Composites. Key Eng. Mater. 2014, 600, 421–432. [Google Scholar] [CrossRef]

- Santos, R.D.J.; Lima, P.R.L. Effect of Treatment of Sisal Fiber on Morphology, Mechanical Properties and Fiber-Cement Bond Strength. Key Eng. Mater. 2015, 634, 410–420. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical Treatments on Plant-Based Natural Fibre Reinforced Polymer Composites: An Overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Experimental Study of Physical, Chemical and Mechanical Properties of Enset and Sisal Fibers. Polym. Test. 2022, 106, 107453. [Google Scholar] [CrossRef]

- Sedan, D.; Pagnoux, C.; Smith, A.; Chotard, T. Mechanical Properties of Hemp Fibre Reinforced Cement: Influence of the Fibre/Matrix Interaction. J. Eur. Ceram. Soc. 2008, 28, 183–192. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Wang, X. Flexural Characteristics of Coir Fiber Reinforced Cementitious Composites. Fibers Polym. 2006, 7, 286–294. [Google Scholar] [CrossRef]

- Rocha Ferreira, S.; Rodrigues Sena Neto, A.; de Andrade Silva, F.; Gomes de Souza, F.; Dias Toledo Filho, R. The Influence of Carboxylated Styrene Butadiene Rubber Coating on the Mechanical Performance of Vegetable Fibers and on Their Interface with a Cement Matrix. Constr. Build. Mater. 2020, 262, 120770. [Google Scholar] [CrossRef]

- da Silva, E.J.; Marques, M.L.; Velasco, F.G.; Fornari Junior, C.; Luzardo, F.M.; Tashima, M.M. A New Treatment for Coconut Fibers to Improve the Properties of Cement-Based Composites—Combined Effect of Natural Latex/Pozzolanic Materials. Sustain. Mater. Technol. 2017, 12, 44–51. [Google Scholar] [CrossRef]

- ASTM C1186; Standard Specification for Flat Fiber-Cement Sheets. ASTM International: West Conshohocken, PA, USA, 2022.

- Patthanavarit, J.; Kitiwan, M.; Keawprak, N.; Tunthawiroon, P. Effect of Expanded Perlite on Physical and Mechanical Properties of Cement Mortar. In Proceedings of the 7th International Conference on Engineering, Applied Sciences and Technology (ICEAST2021), Bangkok, Thailand, 1–3 April 2021. [Google Scholar]

- Thomas, B.C.; Jose, Y.S. A Study on Characteristics of Sisal Fiber and Its Performance in Fiber Reinforced Concrete. Mater. Today Proc. 2022, 51, 1238–1242. [Google Scholar] [CrossRef]

- de Klerk, M.D.; Kayondo, M.; Moelich, G.M.; de Villiers, W.I.; Combrinck, R.; Boshoff, W.P. Durability of Chemically Modified Sisal Fibre in Cement-Based Composites. Constr. Build. Mater. 2020, 241, 117835. [Google Scholar] [CrossRef]

- Okeola, A.A.; Abuodha, S.O.; Mwero, J. Experimental Investigation of the Physical and Mechanical Properties of Sisal Fiber-Reinforced Concrete. Fibers 2018, 6, 53. [Google Scholar] [CrossRef]

- Gereziher Atsbha, T.; Zhutovsky, S. The Effect of External Curing Methods on the Development of Mechanical and Durability-Related Properties of Normal-Strength Concrete. Constr. Build. Mater. 2022, 324, 126706. [Google Scholar] [CrossRef]

- Rahimi, M.Z.; Zhao, R.; Sadozai, S.; Zhu, F.; Ji, N.; Xu, L. Research on the Influence of Curing Strategies on the Compressive Strength and Hardening Behaviour of Concrete Prepared with Ordinary Portland Cement. Case Stud. Constr. Mater. 2023, 18, e02045. [Google Scholar] [CrossRef]

- ASTM C20; Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C1185; Standard Test Methods for Sampling and Testing Non-Asbestos Fiber-Cement Flat Sheet, Roofing and Siding Shingles, and Clapboards. ASTM International: West Conshohocken, PA, USA, 2016.

- Zhao, L.; Zhu, S.; Wu, H.; Liang, H.; Liu, C.; Liu, W.; Zhou, W.; Song, Y. The Improved Resistance against the Degradation of Sisal Fibers under the Environment of Cement Hydration by Surface Coating of Graphene Oxide (GO) Based Membranes. Constr. Build. Mater. 2021, 305, 124694. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Suntijitto, A. Properties of Natural Fiber Cement Materials Containing Coconut Coir and Oil Palm Fibers for Residential Building Applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- ASTM C1530/C1530M; Standard Specification for Non-Asbestos Fiber-Cement Roofing Shakes, Shingles, and Slates with Designed Varying Profiles and Thicknesses. ASTM International: West Conshohocken, PA, USA, 2019.

- Hou, Y.; Yang, K.; Yin, S.; Chen, X.; Zhang, L. Experimental Study on Mechanical Properties, Microstructure and Ratio Parameter Optimization of Mixed Fiber-Reinforced Rubber Cemented Coarse Aggregate Backfill. Constr. Build. Mater. 2023, 409, 134105. [Google Scholar] [CrossRef]

| Materials | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | Na2O | TiO2 | P2O5 | SiO3 |

|---|---|---|---|---|---|---|---|---|---|---|

| Portland cement | 66.2 | 17.8 | 4.13 | 3.20 | 2.95 | 0.55 | 0.37 | - | - | 3.67 |

| Expanded perlite | 1.42 | 74.2 | 13.3 | 1.70 | 0.37 | 6.27 | 1.72 | 0.29 | 0.58 | 0.25 |

| Physical Properties | Portland Cement | Expanded Perlite |

|---|---|---|

| Bulk density (g/cm3) | 3.15 | 0.191 |

| Specific surface area (m2/g) | 0.3359 | 72.99 |

| Particle geometry | Quasi-sphere | Irregular |

| Color | Grey | White |

| Physical Properties | Composition (wt%) [11] | ||

|---|---|---|---|

| Shape | Straight | Cellulose | 60–78 |

| Color | Creamy white | Hemicellulose | 10–14 |

| Density | 1.59 g/cm3 | Lignin | 2–14 |

| Water absorption | 67.5% | Wax | 1–2 |

| Properties | Specification |

|---|---|

| Form | Liquid |

| Color | Milky white |

| pH value | 8–9 |

| Total solid content | 60.9% |

| Dry rubber content | 57.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thepruttana, S.; Patthanavarit, J.; Hankoy, M.; Kitiwan, M.; Keawprak, N.; Tunthawiroon, P. Enhancement of Flexural Strength in Fiber–Cement Composites through Modification of Sisal Fiber with Natural Rubber Latex and Expanded Perlite. Buildings 2024, 14, 1067. https://doi.org/10.3390/buildings14041067

Thepruttana S, Patthanavarit J, Hankoy M, Kitiwan M, Keawprak N, Tunthawiroon P. Enhancement of Flexural Strength in Fiber–Cement Composites through Modification of Sisal Fiber with Natural Rubber Latex and Expanded Perlite. Buildings. 2024; 14(4):1067. https://doi.org/10.3390/buildings14041067

Chicago/Turabian StyleThepruttana, Siriwan, Jira Patthanavarit, Montree Hankoy, Mettaya Kitiwan, Nittaya Keawprak, and Phacharaphon Tunthawiroon. 2024. "Enhancement of Flexural Strength in Fiber–Cement Composites through Modification of Sisal Fiber with Natural Rubber Latex and Expanded Perlite" Buildings 14, no. 4: 1067. https://doi.org/10.3390/buildings14041067

APA StyleThepruttana, S., Patthanavarit, J., Hankoy, M., Kitiwan, M., Keawprak, N., & Tunthawiroon, P. (2024). Enhancement of Flexural Strength in Fiber–Cement Composites through Modification of Sisal Fiber with Natural Rubber Latex and Expanded Perlite. Buildings, 14(4), 1067. https://doi.org/10.3390/buildings14041067