Compressive and Bonding Performance of GFRP-Reinforced Concrete Columns

Abstract

:1. Introduction

2. Literature Review

2.1. Properties of Steel and GFRP Rebars

2.2. Structural Behavior of Concrete Columns Reinforced with Steel and GFRP Bars

2.3. Bond Behavior of Steel and GFRP Rebars in Concrete

3. Materials and Methods

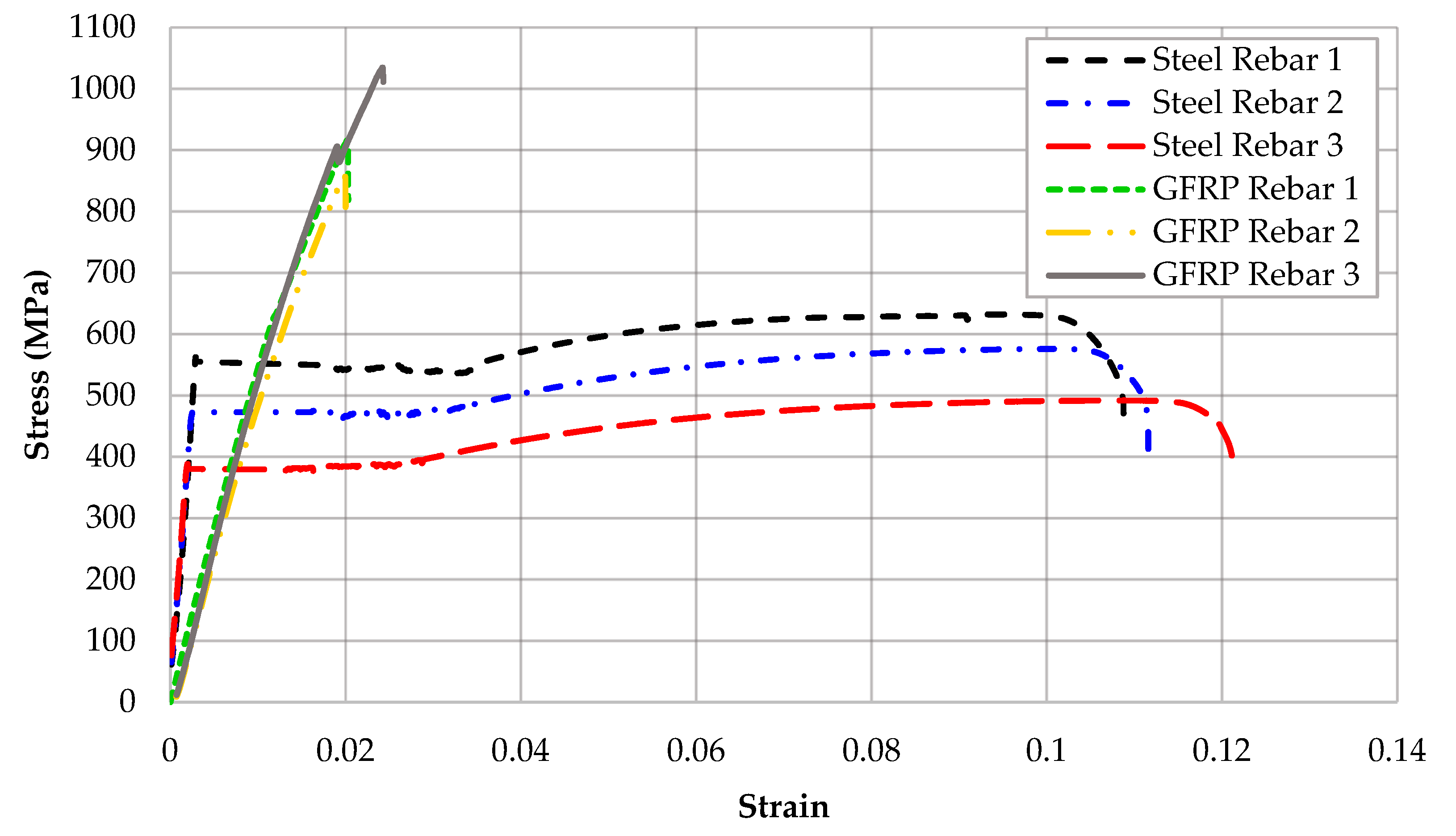

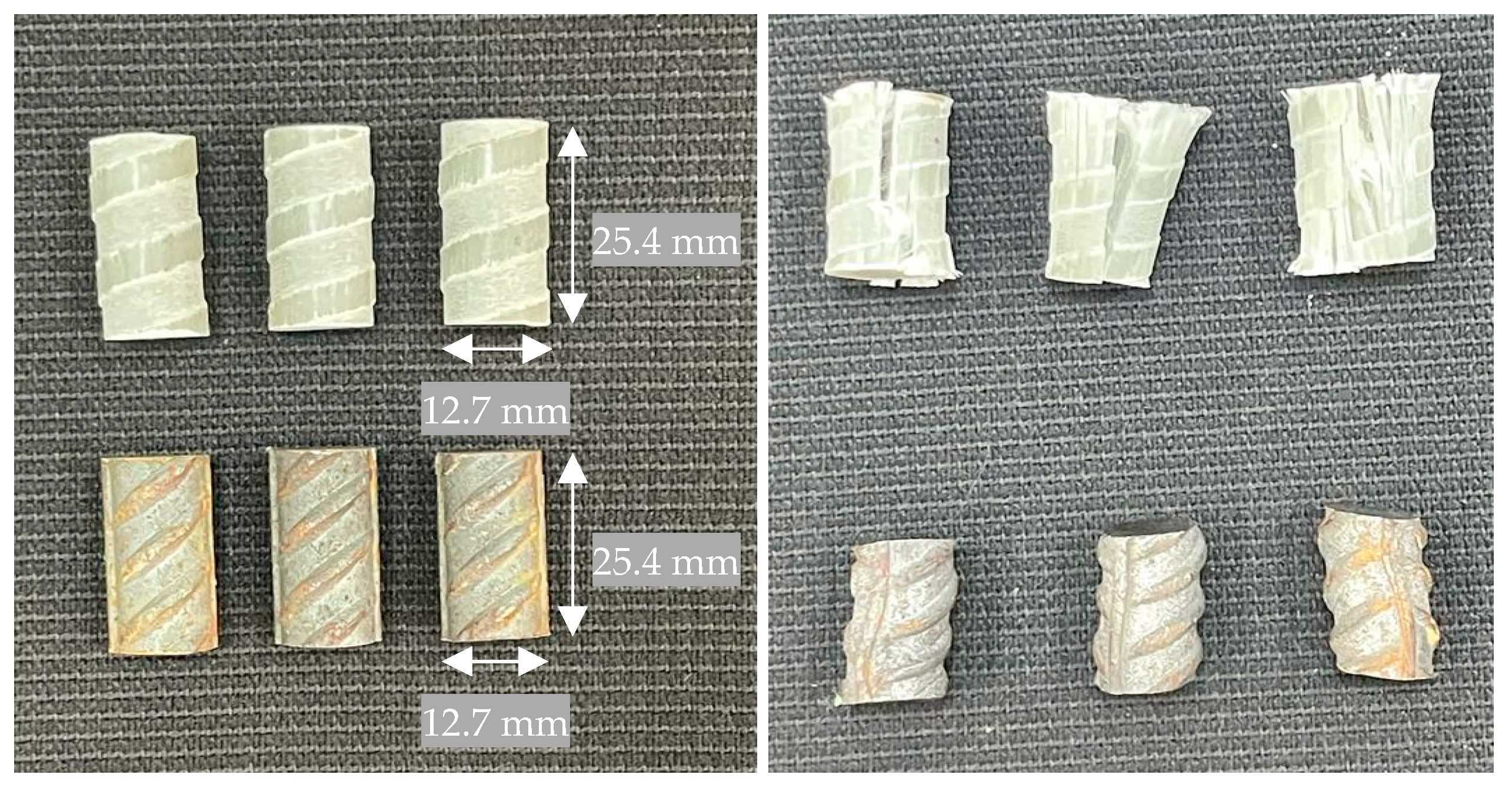

3.1. Tension Tests of Reinforcing Bars

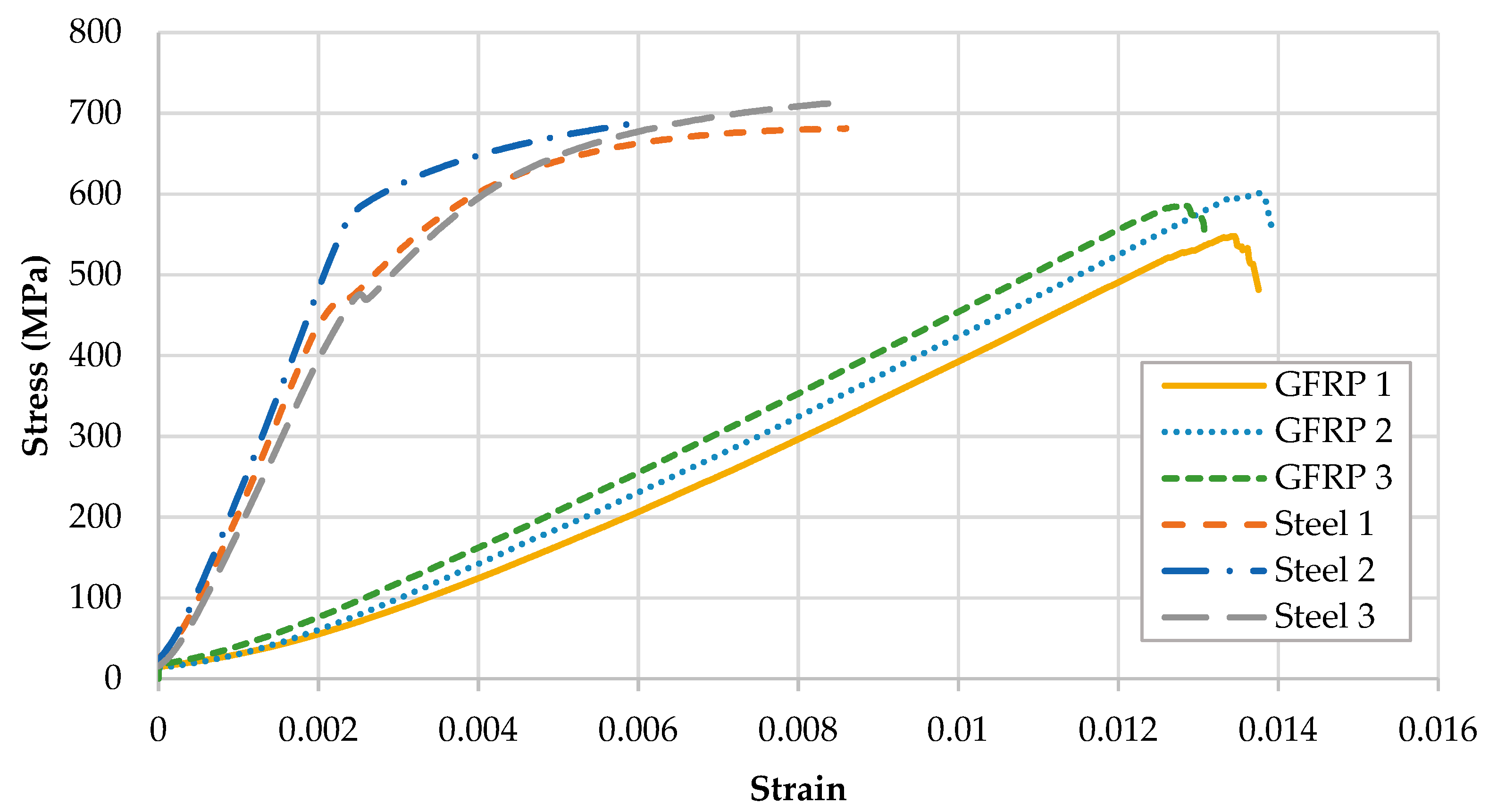

3.2. Compression Tests of Reinforcing Bars

3.3. Compression and Splitting Tensile Tests of Concrete Cylinders

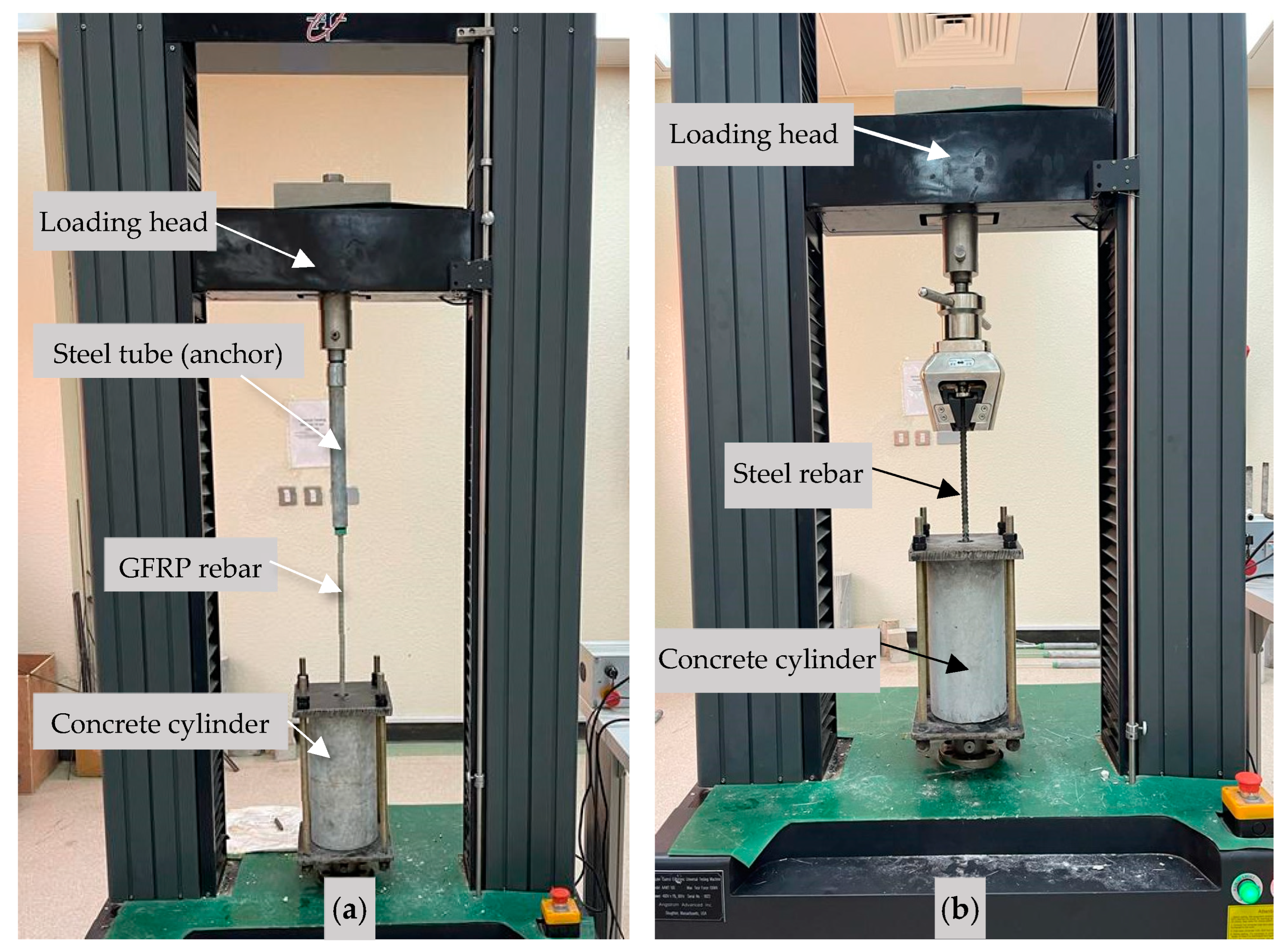

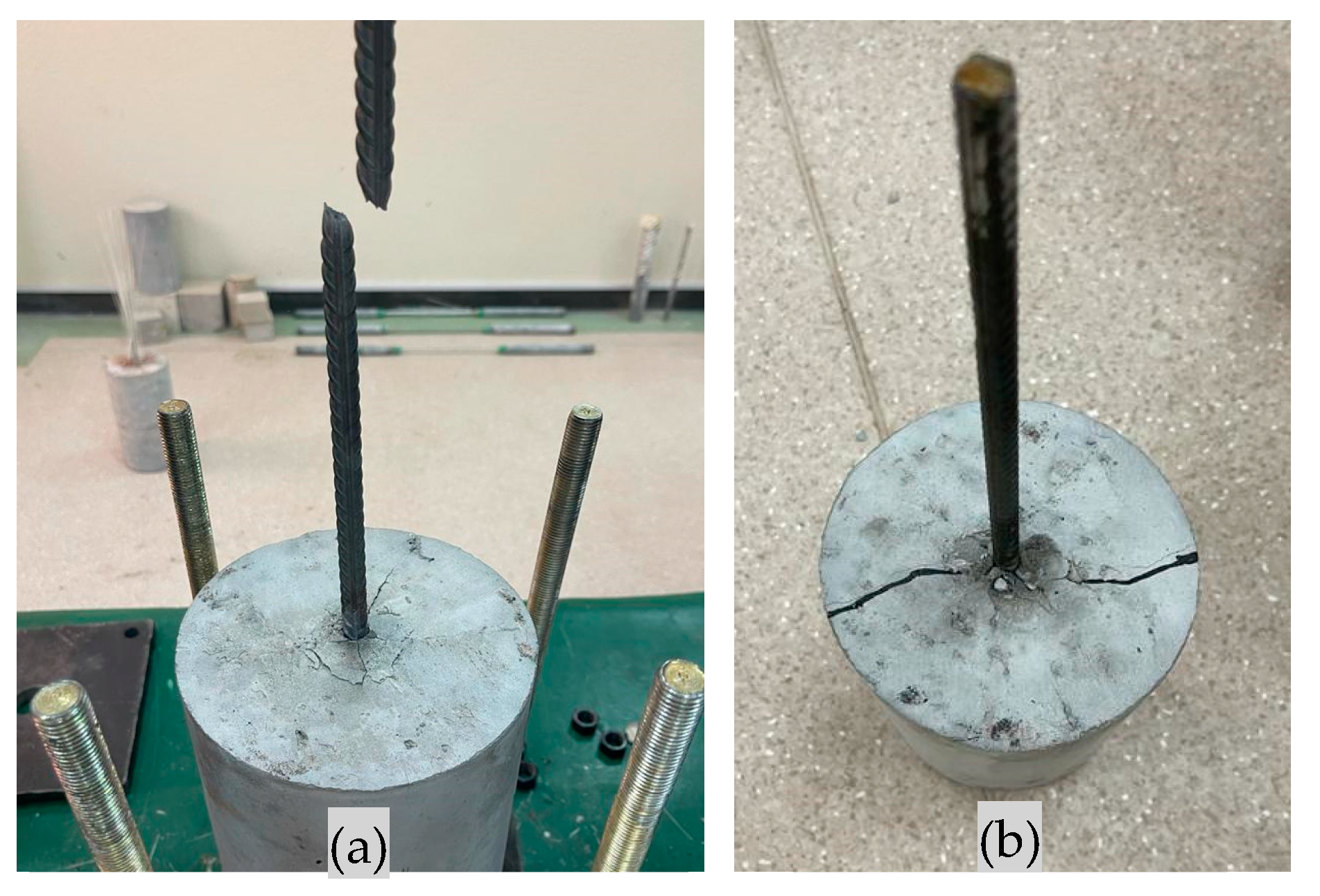

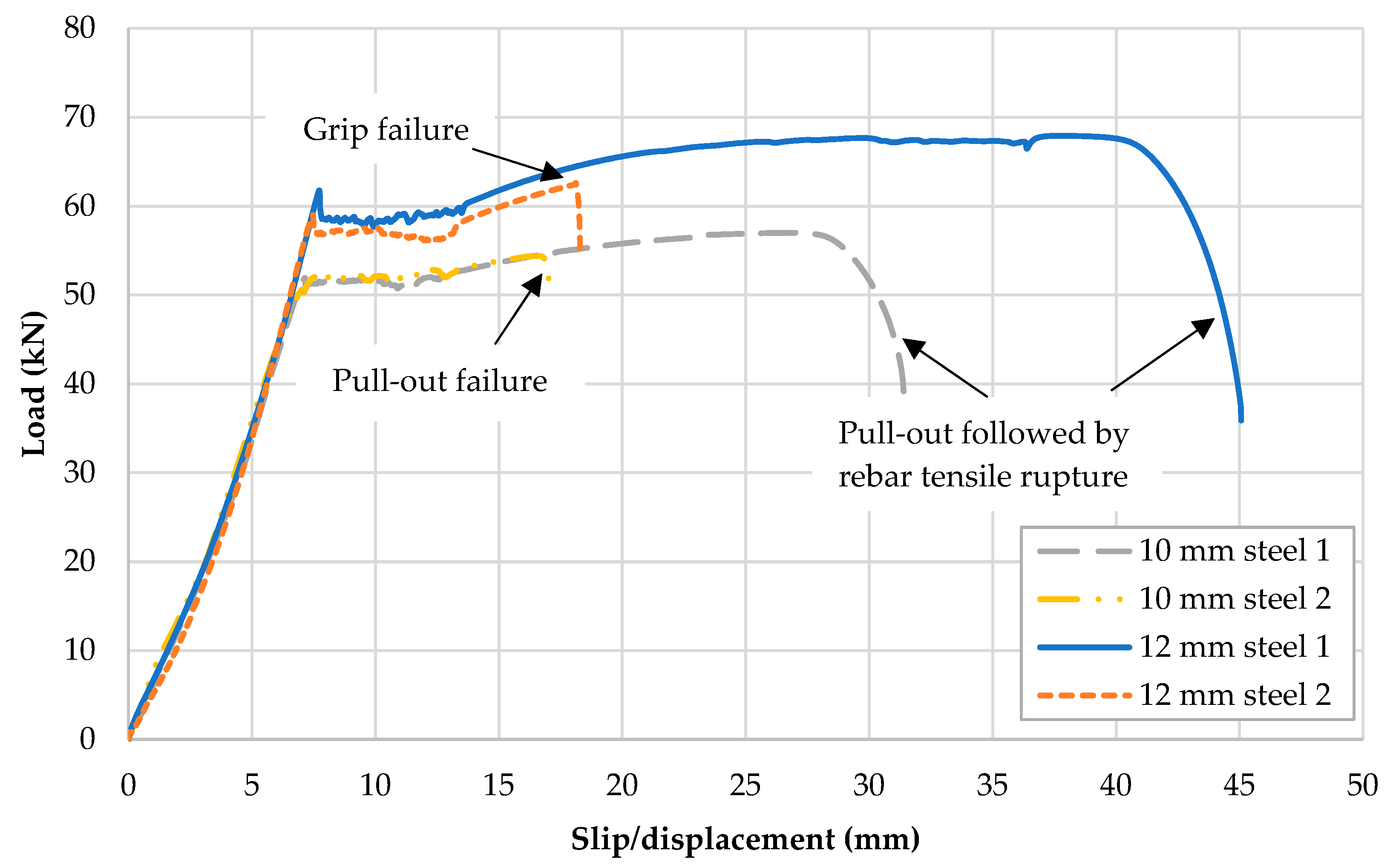

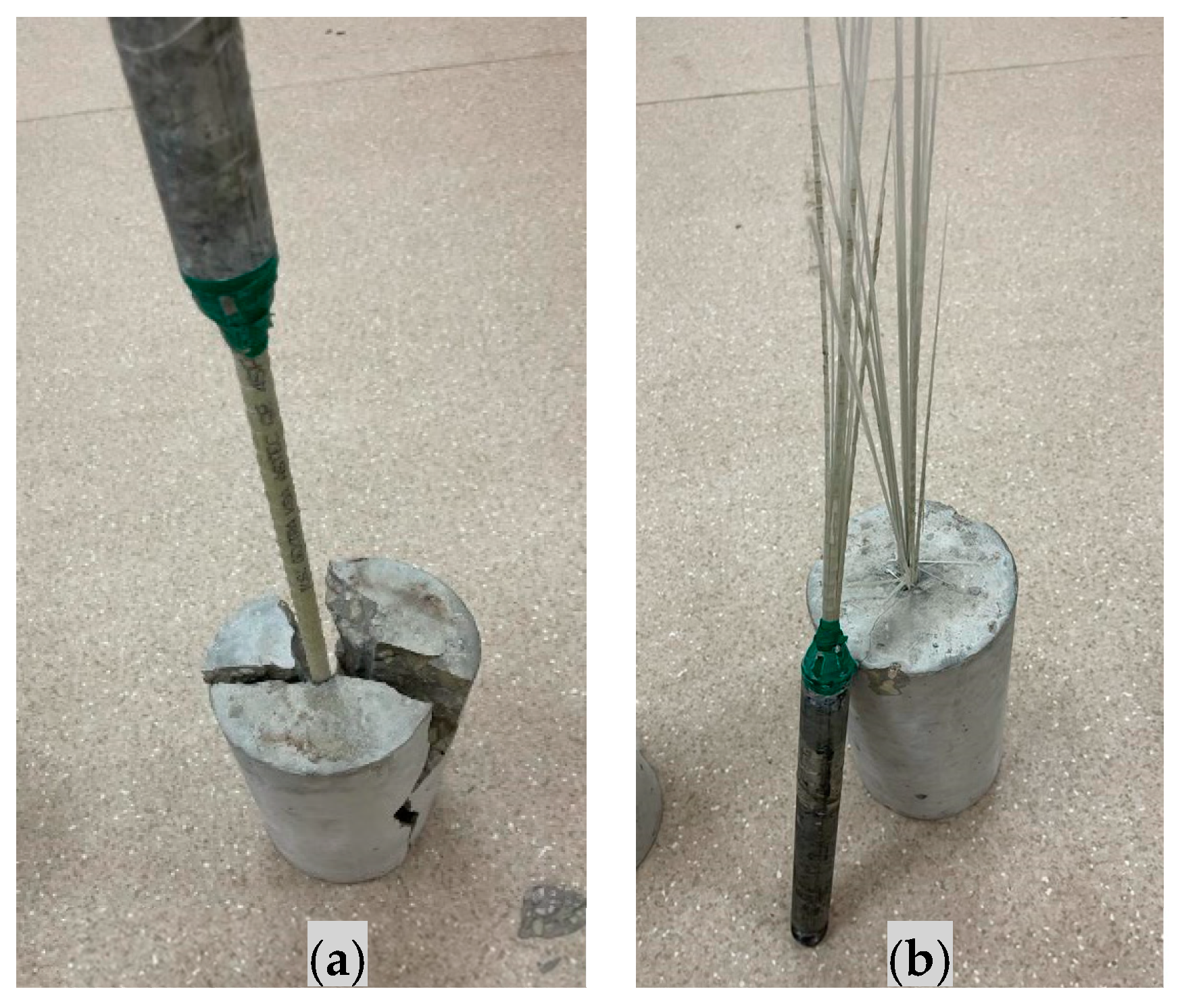

3.4. Bond Behavior Tests of Reinforcing Bars

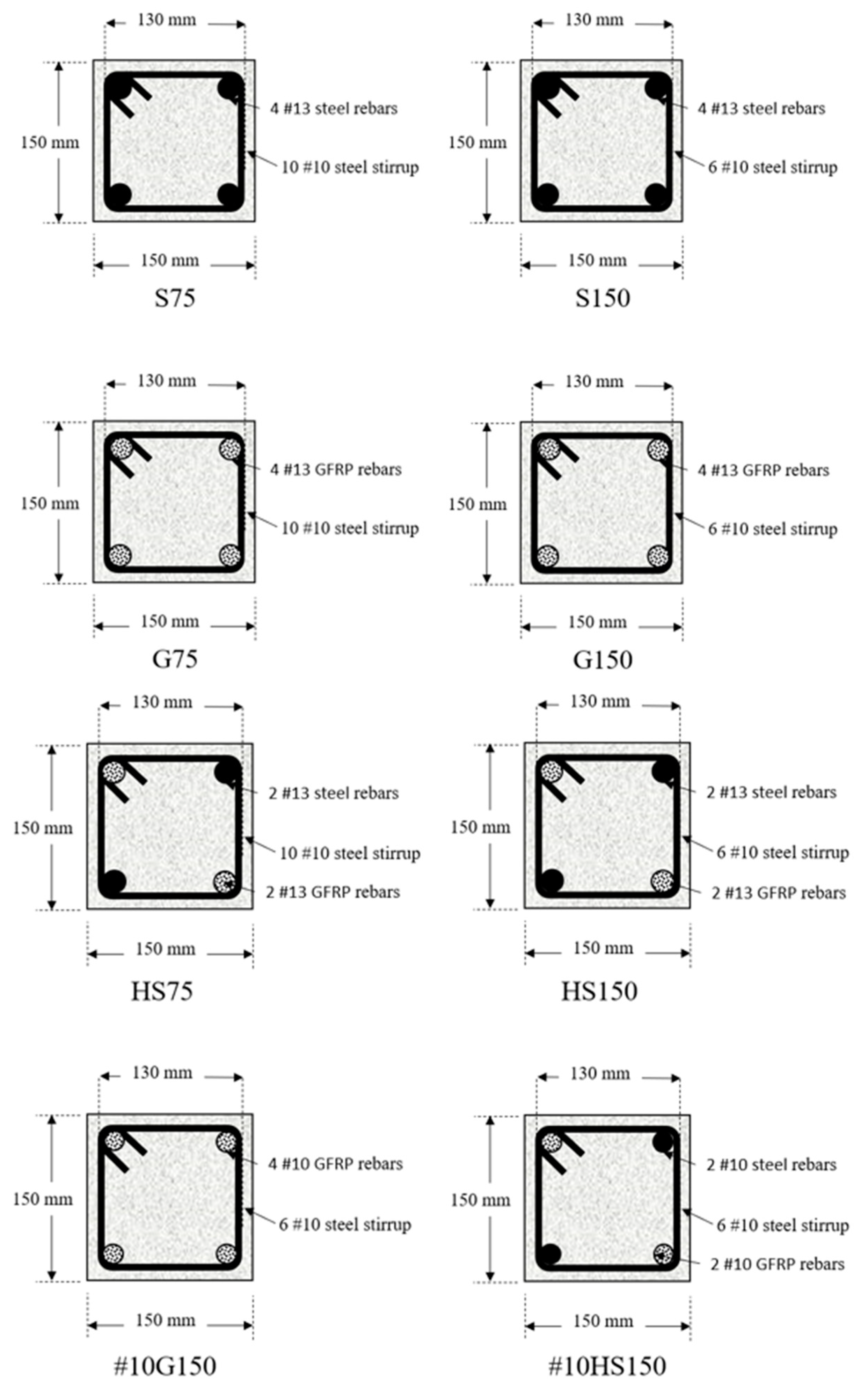

3.5. Structural Testing of Reinforced Concrete Columns

4. Experimental Results and Discussion

4.1. Tension Test Results of Reinforcing Bars

4.2. Compression Test Results of Reinforcing Bars

4.3. Compression and Splitting Tensile Tests Results of Concrete Cylinders

4.4. Bond Behavior Tests Results of Reinforcing Bars

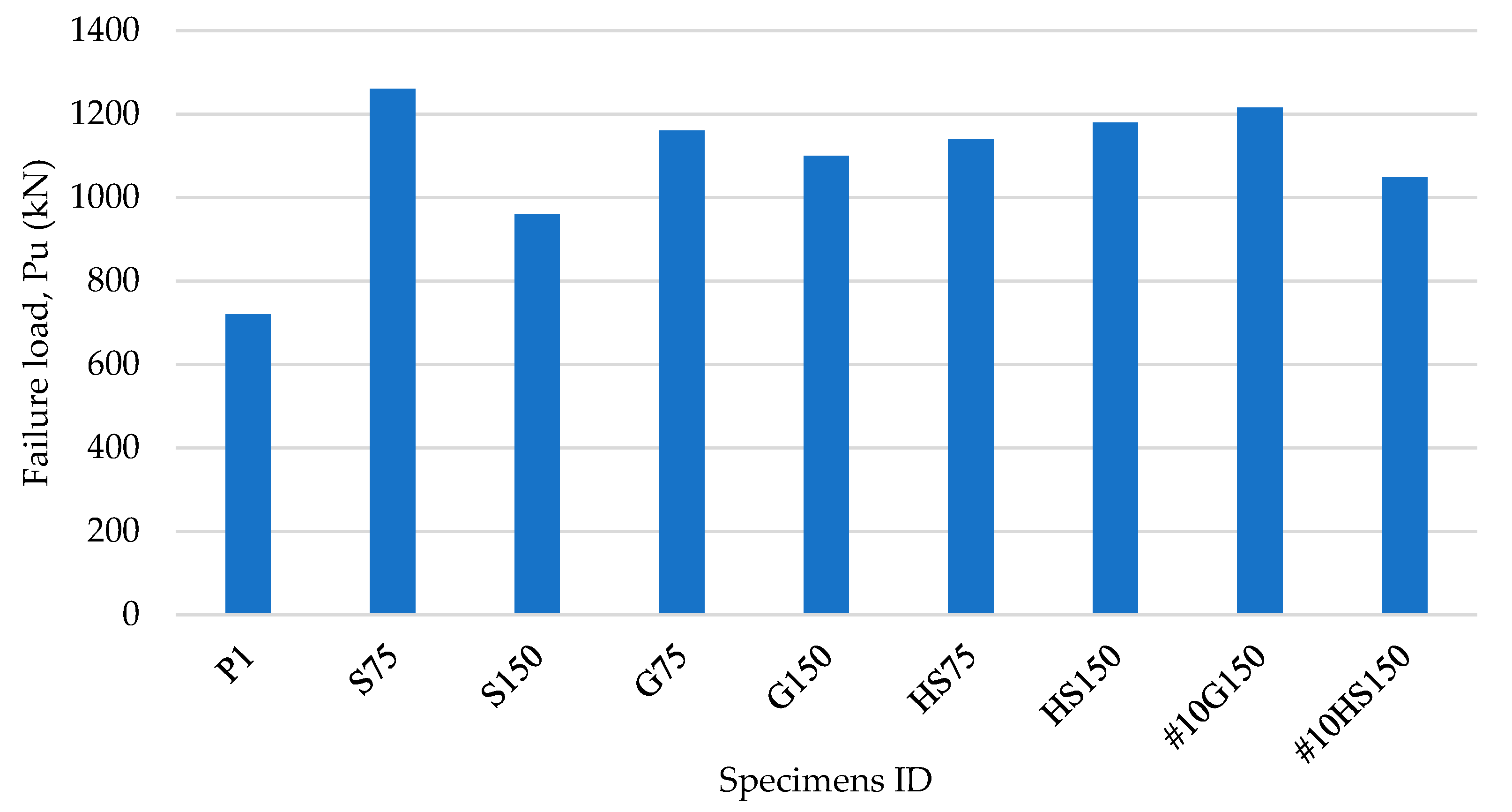

4.5. Compression Tests Results of Concrete Columns

5. Conclusions

- Bond behavior of GFRP showed an excellent bond response as compared to steel rebars and can be assumed to have similar or superior bond properties than steel when embedded in concrete. This finding suggests that GFRP bars can effectively transfer loads between the concrete and the reinforcement, potentially leading to improved overall column performance.

- Concrete columns reinforced with GFRP resulted in a comparable compressive capacity to those reinforced with steel rebars. In certain cases, the capacity of columns reinforced with GFRP yielded higher values than those reinforced with steel. Contrary to the current design practice, GFRP contributes significantly to the compressive capacity of concrete columns.

- Closely spaced ties in column significantly enhanced the compressive load capacity compared to wider tie spacing, demonstrating the critical role of tie spacing in optimizing column performance. This finding is further supported by the minimal reduction in capacity (5–7%) observed in GFRP-reinforced columns with wider tie spacing compared to steel-reinforced columns. This highlights the effectiveness of GFRP bars in contributing to the compressive strength of concrete columns even with less confining tie spacing.

- The failure modes observed in both steel and GFRP-reinforced columns were predominantly concrete crushing and bar buckling, consistent with the analytical models used for capacity prediction.

- While the brittle behavior of GFRP bars is a concern in concrete members, it has a minimal impact on compressive strength. This is because the failure mode for both steel and GFRP-reinforced columns under compression is primarily governed by concrete crushing and bar buckling, not the brittleness of the reinforcing material.

- While GFRP bars offer advantages like high tensile strength and corrosion resistance, they present limitations compared to steel. These include a more brittle failure mode with minimal plastic deformation, lower stiffness leading to potentially larger deflections, and the need for special design considerations in seismic regions to ensure adequate anchorage due to bond behavior. Additionally, further research is necessary to fully understand the behavior of GFRP bars under dynamic tension, particularly crucial for applications in earthquake-prone areas.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mallick, P.K. Fiber-Reinforced Composites; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar] [CrossRef]

- Wu, W.-P. Thermomechanical Properties of Fiber-Reinforced Plastic (FRP) Bars; West Virginia University: Morgantown, WV, USA, 1991. [Google Scholar]

- Deitz, D.H.; Harik, I.E.; Gesund, H. Physical Properties of Glass Fiber Reinforced Polymer Rebars in Compression. J. Compos. Constr. 2003, 7, 363–366. [Google Scholar] [CrossRef]

- Chaallal, O.; Benmokrane, B. Physical and mechanical performance of an innovative glass-fiber-reinforced plastic rod for concrete and grouted anchorages. Can. J. Civ. Eng. 1993, 20, 254–268. [Google Scholar] [CrossRef]

- ACI 318; Building Code Requirements for Structural Concrete. American Concrete Institute. ACI Committee: Indianapolis, IN, USA, 2014.

- Saudi Concrete Structures Code SBC 304-CR Code Requirements; The Saudi Building Code National Committee (SBCNC): Riyadh, Saudi Arabia, 2018.

- AASHTO. AASHTO LRFD Bridge Design Specifications, 8th ed.; AASHTO: Washington, DC, USA, 2017. [Google Scholar]

- A615/A 615M-04a; Standard Specification for Deformed and Plain Carbon Steel Bars for Concrete Reinforcement. 2012. Available online: www.astm.org (accessed on 8 April 2024).

- A706/A706M−13; Standard Specification for Low-Alloy Steel Deformed and Plain Bars for Concrete Reinforcement. 2013. Available online: https://doi.org/10.1520/A0706_A0706M-13 (accessed on 8 April 2024).

- Gomes, A.; Appleton, J. Nonlinear cyclic stress-strain relationship of reinforcing bars including buckling. Eng. Struct. 1997, 19, 822–826. [Google Scholar] [CrossRef]

- Dodd, L.L.; Restrepo-Posada, J.I. Model for Predicting Cyclic Behavior of Reinforcing Steel. J. Struct. Eng. 1995, 121, 433–445. [Google Scholar] [CrossRef]

- Djavanroodi, F.; Salman, A. Variability of Mechanical Properties and Weight for Reinforcing Bar Produced in Saudi Arabia. IOP Conf. Ser. Mater. Sci. Eng. Inst. Phys. Publ. 2017, 230, 012002. [Google Scholar] [CrossRef]

- Paulay, T.; Priestley, M.J.N. Seismic Design of Reinforced Concrete and Masonry Buildings; Wiley & Sons: New York, NY, USA, 1992. [Google Scholar]

- Priestley, M.J.N.; Calvi, G.M.; Kowalsky, M.J. Displacement-Based Seismic Design of Structures; IUSS Press: Pavia, Italy, 2007. [Google Scholar]

- AlAjarmeh, O.S.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P. Axial performance of hollow concrete columns reinforced with GFRP composite bars with different reinforcement ratios. Compos. Struct. 2019, 213, 153–164. [Google Scholar] [CrossRef]

- El-Nemr, A.; Ahmed, E.A.; Benmokrane, B. Flexural Behavior and Serviceability of Normal- and High-Strength Concrete Beams Reinforced with Glass Fiber-Reinforced Polymer Bars. ACI Struct. J. 2013, 110, 1077–1088. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P. Behavior of concentrically loaded geopolymer-concrete circular columns reinforced longitudinally and transversely with GFRP bars. Eng. Struct. 2016, 117, 422–436. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P.; Nguyen, T.Q. Shear behaviour of geopolymer-concrete beams transversely reinforced with continuous rectangular GFRP composite spirals. Compos. Struct. 2018, 187, 454–465. [Google Scholar] [CrossRef]

- BBenmokrane; Nazair, C.; Seynave, X.; Manalo, A. Comparison between ASTM D7205 and CSA S806 Tensile-Testing Methods for Glass Fiber–Reinforced Polymer Bars. J. Compos. Constr. 2017, 21, 04017038. [Google Scholar] [CrossRef]

- Benmokrane, B.; Manalo, A.; Bouhet, J.-C.; Mohamed, K.; Robert, M. Effects of Diameter on the Durability of Glass Fiber–Reinforced Polymer Bars Conditioned in Alkaline Solution. J. Compos. Constr. 2017, 21, 04017040. [Google Scholar] [CrossRef]

- Benmokrane, B.; Ali, A.H.; Mohamed, H.M.; ElSafty, A.; Manalo, A. Laboratory assessment and durability performance of vinyl-ester, polyester, and epoxy glass-FRP bars for concrete structures. Compos. B Eng. 2017, 114, 163–174. [Google Scholar] [CrossRef]

- Nazair, C.; Benmokrane, B.; Loranger, M.-A.; Robert, M.; Manalo, A. A comparative study of the thermophysical and mechanical properties of the glass fiber reinforced polymer bars with different cure ratios. J. Compos. Mater. 2018, 52, 4105–4116. [Google Scholar] [CrossRef]

- Maranan, G.; Manalo, A.; Karunasena, K.; Benmokrane, B. Bond Stress-Slip Behavior: Case of GFRP Bars in Geopolymer Concrete. J. Mater. Civ. Eng. 2015, 27, 04014116. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Karunasena, W.; Benmokrane, B. Pullout behaviour of GFRP bars with anchor head in geopolymer concrete. Compos. Struct. 2015, 132, 1113–1121. [Google Scholar] [CrossRef]

- Benmokrane, B.; Nazair, C.; Loranger, M.-A.; Manalo, A. Field Durability Study of Vinyl-Ester–Based GFRP Rebars in Concrete Bridge Barriers. J. Bridge Eng. 2018, 23, 04018094. [Google Scholar] [CrossRef]

- Wijayawardane, I.S.K.; Mutsuyoshi, H.; Nguyen, H.; Manalo, A. Flexural behaviour of glass fibre-reinforced polymer and ultra-high-strength fibre-reinforced concrete composite beams subjected to elevated temperature. Adv. Struct. Eng. 2017, 20, 1357–1374. [Google Scholar] [CrossRef]

- Davalos, J.F.; Chen, Y.; Ray, I. Long-term durability prediction models for GFRP bars in concrete environment. J. Compos. Mater. 2012, 46, 1899–1914. [Google Scholar] [CrossRef]

- Robert, M.; Benmokrane, B. Behavior of GFRP Reinforcing Bars Subjected to Extreme Temperatures. J. Compos. Constr. 2010, 14, 353–360. [Google Scholar] [CrossRef]

- Brahim, B.; Mohamed, H.M.; Allan, M.; Patrice, C. Evaluation of Physical and Durability Characteristics of New Headed Glass Fiber–Reinforced Polymer Bars for Concrete Structures. J. Compos. Constr. 2017, 21, 04016081. [Google Scholar] [CrossRef]

- CSA S807:19; Specification for Fibre-Reinforced Polymers. CSA Group: Toronto, ON, Canada, 2019.

- D7957/D7957M; 17 Standard Specification for Solid Round Glass Fiber Reinforced Polymer Bars for Concrete Reinforcement 1. ASTM: Conshohocken, PA, USA, 2017. [CrossRef]

- Taerwe, L. Non-Metallic (FRP) Reinforcement for Concrete Structures; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar] [CrossRef]

- Paramanantham, N.S. Investigation of the Behavior of Concrete Columns Reinforced with Fiber Reinforced Plastic Rebars. Master’s Thesis, Lamar University, Beaumont, TX, USA, 1993. [Google Scholar]

- Alsayed, S.H.; Al-Salloum, Y.A.; Almusallam, T.H.; Amjad, M.A. Concrete Columns Reinforced by Glass Fiber Reinforced Polymer Rods. In SP-188: 4th Intl Symposium—Fiber Reinforced Polymer Reinforcement for Reinforced Concrete Structures; American Concrete Institute: Indianapolis, IN, USA, 1999. [Google Scholar] [CrossRef]

- Lotfy, E. Behavior of reinforced concrete short columns with fiber reinforced polymers bars. Int. J. Civ. Struct. Eng. 2010, 1, 545–557. [Google Scholar]

- Tobbi, H.; Farghaly, A.S.; Benmokrane, B. Concrete Columns Reinforced Longitudinally and Transversally with Glass Fiber-Reinforced Polymer Bars. ACI Struct. J. 2012, 109, 551–558. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. Standard Specifications for Highway Bridges; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2002. [Google Scholar]

- ACI Committee 440. Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer FRP Bars; American Concrete Institute: Indianapolis, IN, USA, 2015. [Google Scholar]

- Commentary on CAN/CSA-S6-06. Canadian Highway Bridge Design Code. 2006. Available online: www.ShopCSA.ca (accessed on 8 April 2024).

- Isleem, H.F.; Tayeh, B.A.; Alaloul, W.S.; Musarat, M.A.; Raza, A. Artificial Neural Network (ANN) and Finite Element (FEM) Models for GFRP-Reinforced Concrete Columns under Axial Compression. Materials 2021, 14, 7172. [Google Scholar] [CrossRef] [PubMed]

- Karabinis, A.I.; Rousakis, T.C. Concrete confined by FRP material: A plasticity approach. Eng. Struct. 2002, 7, 923–932. Available online: https://www.infona.pl//resource/bwmeta1.element.elsevier-15d1e761-db73-3f01-b5d2-f85481f0f5a6 (accessed on 22 January 2023). [CrossRef]

- Xie, J.; Huang, L.; Guo, Y.; Li, Z.; Fang, C.; Li, L.; Wang, J. Experimental study on the compressive and flexural behaviour of recycled aggregate concrete modified with silica fume and fibres. Constr. Build. Mater. 2018, 178, 612–623. [Google Scholar] [CrossRef]

- Afifi, M.Z.; Mohamed, H.M.; Benmokrane, B. Axial Capacity of Circular Concrete Columns Reinforced with GFRP Bars and Spirals. J. Compos. Constr. 2014, 18, 04013017. [Google Scholar] [CrossRef]

- Mohamed, H.M.; Afifi, M.Z.; Benmokrane, B. Performance Evaluation of Concrete Columns Reinforced Longitudinally with FRP Bars and Confined with FRP Hoops and Spirals under Axial Load. J. Bridge Eng. 2014, 19, 04014020. [Google Scholar] [CrossRef]

- Tobbi, H.; Farghaly, A.S.; Benmokrane, B. Behavior of Concentrically Loaded Fiber-Reinforced Polymer Reinforced Concrete Columns with Varying Reinforcement Types and Ratios. ACI Struct. J. 2014, 111, 375–386. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N.S. Axial-Flexural Interactions of GFRP-CFFT Columns with and without Reinforcing GFRP Bars. J. Compos. Constr. 2017, 21, 04016109. [Google Scholar] [CrossRef]

- Baig, M.; Zain-Ul-Abideen; Munir, Q.; Ahmad, B. Bond Performance of Zinc Galvanized Rebars in Reinforced Concrete and their Effectiveness in Corrosion Prevention. Int. Res. J. Mod. Eng. Technol. Sci. 2022, 4. [Google Scholar] [CrossRef]

- Sólyom, S.; Balázs, G. Bond Strength of FRP Rebars. Concr. Struct. 2015, 16, 62–68. [Google Scholar]

- Fawaz, G.; Murcia-Delso, J. Bond behavior of iron-based shape memory alloy reinforcing bars embedded in concrete. Mater. Struct. 2020, 53, 114. [Google Scholar] [CrossRef]

- Amin, M.; Althoey, F.; Khan, K.; Faraz, M.; Qadir, M.; Alabdullah, A.; Ajwad, A.; Sarker, P.; Iqbal, M. Investigating the Bond Strength of FRP Rebars in Concrete under High Temperature Using Gene-Expression Programming Model. Polymers 2022, 14, 2992. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Li, M.; Alquraishi, A.S.S.; Sun, H. Experimental Study on the Novel Interface Bond Behavior between Fiber-Reinforced Concrete and Common Concrete through 3D-DIC. Adv. Mater. Sci. Eng. 2021, 2021, 1–21. [Google Scholar] [CrossRef]

- Vembu, P.R.S.; Ammasi, A.K. A Comprehensive Review on the Factors Affecting Bond Strength in Concrete. Buildings 2023, 13, 577. [Google Scholar] [CrossRef]

- Sólyom, S.; Balázs, G.L.; Sólyom -György, S.; Balázs, L. Bond Strength of FRP Rebars. 2015. Available online: https://www.researchgate.net/publication/308688068 (accessed on 8 April 2024).

- Wu, C.; Bai, Y.; Kwon, S. Improved bond behavior between GFRP rebar and concrete using calcium sulfoaluminate. Constr. Build. Mater. 2016, 113, 897–904. [Google Scholar] [CrossRef]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Development length of FRP straight rebars. Compos. B Eng. 2002, 33, 493–504. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Rahai, A.; Sebt, M.H. Bond behavior of steel and GFRP bars in self-compacting concrete. Constr. Build. Mater. 2014, 61, 230–240. [Google Scholar] [CrossRef]

- Okelo, R.; Yuan, R.L. Bond Strength of Fiber Reinforced Polymer Rebars in Normal Strength Concrete. J. Compos. Constr. 2005, 9, 203–213. [Google Scholar] [CrossRef]

- ASTM D7205/D7205M-06; Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars 1. ASTM International: West Conshohocken, PN, USA, 2016. [CrossRef]

- Mateenbar Limited, Mateenbar. 2023. Available online: https://mateenbar.com/products/mateenbar/ (accessed on 8 April 2024).

- ASTM E9-09; Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. ASTM International: West Conshohocken, PN, USA, 2009. [CrossRef]

- ASTM D695-15; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PN, USA, 2015. [CrossRef]

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PN, USA, 2021. [CrossRef]

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PN, USA, 2017. [CrossRef]

- ASTM C234; Standard Test Method for Bond Strength of Concrete Developed with Reinforcing Steel. ASTM International: West Conshohocken, PN, USA, 1991.

- ASTM D7913/D7913M-14; Standard Test Method for Bond Strength of Fiber-Reinforced Polymer Matrix Composite Bars to Concrete by Pullout Testing. ASTM International: West Conshohocken, PN, USA, 2020. [CrossRef]

- Industrial Control Solutions Company (ICSC). Industrial Control Solutions Company (ICSC) a Manufacturer of Glass Fiber Reinforce Polymer (GFRP) Rebars in Saudi Arabia; Industrial Control Solutions Company (ICSC): Dammam, Saudi Arabia, 2023. [Google Scholar]

| Researcher/Stander | Proposed Models |

|---|---|

| CSA S806-12 [41] | |

| CSA S806-02 [42] | |

| Afifi et al. [43] | |

| Mohamed et al. [44] | |

| Tobbi et al. [45] | |

| Khan et al. [46] |

| Item Type | Item Description | Amount (kg/m3) | Quantity (%) | Specific Gravity |

|---|---|---|---|---|

| Cement | Cement Type I (OPC) | 320 | 13.53 | 3.15 |

| Water | Water (Raw) | 152 | 6.42 | 1.00 |

| Coarse Aggregate | 20 mm | 660 | 27.90 | 2.60 |

| Coarse Aggregate | 10 mm | 440 | 18.60 | 2.61 |

| Fine Aggregate | Dune red sand | 790 | 33.39 | 2.60 |

| Admixture | Master Pozzolith 333 | 2 | 0.10 | 1.22 |

| Admixture | Master Ease 3760 | 1.8 | 0.08 | 1.09 |

| Specimen ID | Longitudinal Reinforcement Size, Type | Transverse Reinforcement Spacing, mm | Transverse Reinforcement Size, Type |

|---|---|---|---|

| P1 | -- | -- | -- |

| S75 | 4 #13, Steel | 75 | 10 #10, Steel |

| S150 | 4 #13, Steel | 150 | 6 #10, Steel |

| G75 | 4 #13, GFRP | 75 | 10 #10, Steel |

| G150 | 4 #13, GFRP | 150 | 6 #10, Steel |

| HS75 | 2 #13, Steel 2 #13, GFRP | 75 | 10 #10, Steel |

| HS150 | 2 #13, Steel 2 #13, GFRP | 150 | 6 #10, Steel |

| #10G150 | 4 #10, GFRP | 150 | 6 #10, Steel |

| #10HS150 | 2 #10, Steel 2 #10, GFRP | 150 | 6 #10, Steel |

| Sample # | Yielding Load (kN) | Yielding Stress (MPa) | Tensile Load (kN) | Tensile Stress (MPa) |

|---|---|---|---|---|

| Steel 1 | 68.6 | 542 | 80.1 | 632 |

| Steel 2 | 59.3 | 468 | 73.0 | 576 |

| Steel 3 | 47.7 | 377 | 62.3 | 492 |

| Average | 58.5 | 462 | 71.8 | 567 |

| GFRP Sample | Load (kN) | Tensile Stress (MPa) | Failure Strain |

|---|---|---|---|

| GFRP 1 | 46.0 | 916 | 0.0189 |

| GFRP 2 | 43.1 | 944 | 0.0187 |

| GFRP 3 | 52.0 | 1034 | 0.0227 |

| Average | 47.1 | 965 | 0.0201 |

| Specimens | Load (kN) | Compressive Stress (MPa) |

|---|---|---|

| GFRP 1 | 69.4 | 548 |

| GFRP 2 | 76.1 | 601 |

| GFRP 3 | 74.4 | 587 |

| Average | 73.3 | 579 |

| Steel 1 | 59.1 | 467 (Yeilding) |

| Steel 2 | 73.3 | 578 (Yeilding) |

| Steel 3 | 59.7 | 471 (Yeilding) |

| Average | 64.0 | 505 (Yeilding) |

| Samples | Compressive Stress (MPa) | Splitting Tensile Strength (MPa) |

|---|---|---|

| Concrete cylinder 1 | 24.5 | 2.9 |

| Concrete cylinder 2 | 24.4 | 3.2 |

| Concrete cylinder 3 | 26.6 | 3.5 |

| Average | 25.2 | 3.2 |

| Rebar Specimens | Ultimate Load, kN | Ultimate Slip, mm | Failure Mode |

|---|---|---|---|

| 10 mm steel 1 | 56.9 | 31 | Pull-out followed by rebar tensile rupture |

| 10 mm steel 2 | 54.5 | 17 | Pull-out |

| 12.7 mm steel 1 | 67.9 | 45 | Pull-out followed by rebar tensile rupture |

| 12.7 mm steel 2 | 62.6 | 18 | Pull-out followed by grip failure |

| Bar Specimens | Ultimate Load, kN | Ultimate Slip, mm | Failure Mode |

|---|---|---|---|

| 12.7 mm GFRP 1 | 57.92 | 12 | Concrete cylinder failure and splitting into three pieces |

| 12.7 mm GFRP 2 | 61.84 | 12 | |

| 12.7 mm GFRP sand coated 1 | 66.34 | 12.5 | |

| 12.7 mm GFRP sand coated 2 | 62.95 | 13 | |

| Average | 62.26 | 12.375 | |

| 10 mm GFRP 1 | 56.9 | 13.62 | GFRP tensile rupture |

| 10 mm GFRP 2 | 52.4 | 15.79 | |

| Average | 54.65 | 14.7 |

| Specimen ID | Failure Load, Pu (kN) | Failure Mode |

|---|---|---|

| P1 | 720 | 1/Compressive concrete crushing (CC)/concrete spalling. |

| S75 | 1260 | |

| S150 | 960 | |

| G75 | 1160 | 1/Compressive concrete crushing (CC)/concrete spalling. 2/Crushing of GFRP longitudinal bar near loading location. 3/Transverse reinforcement tie rupture. |

| G150 | 1100 | 1/Compressive concrete crushing (CC)/concrete spalling. 2/Crushing of GFRP longitudinal bar near loading location. |

| HS75 | 1140 | 1/Compressive concrete crushing (CC)/concrete spalling. 2/Transverse reinforcement tie rupture. |

| HS150 | 1180 | 1/Compressive concrete crushing (CC)/concrete spalling. 2/Buckling of steel longitudinal bar. 3/Transverse reinforcement tie rupture. |

| #10G150 | 1215 | 1/Compressive concrete crushing (CC)/concrete spalling. 2/Crushing of all GFRP longitudinal bars. |

| #10HS150 | 1048 | 1/Compressive concrete crushing (CC)/concrete spalling. 2/Buckling of GFRP longitudinal bar. 3/Crushing of GFRP longitudinal bar. 4/Buckling of steel longitudinal rebar. |

| Column Compression Capacity (KN) | ||||||

|---|---|---|---|---|---|---|

| Specimen No. | CSA S806-12 [41] | Afifi et al. [43] | Mohamed et al. [44] | Tobbi et al. [45] | Khan et al. [46] | Experimental |

| G75 | 497 | 660 | 543 | 567 | 780 | 1160 |

| G150 | 497 | 660 | 543 | 567 | 780 | 1100 |

| HS75 | 598 | 674 | 616 | 628 | 734 | 1140 |

| HS150 | 598 | 674 | 616 | 628 | 734 | 1180 |

| #10G150 | 502 | 592 | 528 | 541 | 658 | 1215 |

| #10HS150 | 571 | 612 | 580 | 587 | 645 | 1048 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsuhaibani, E.; Alturki, M.; Alogla, S.M.; Alawad, O.; Alkharisi, M.K.; Bayoumi, E.; Aldukail, A. Compressive and Bonding Performance of GFRP-Reinforced Concrete Columns. Buildings 2024, 14, 1071. https://doi.org/10.3390/buildings14041071

Alsuhaibani E, Alturki M, Alogla SM, Alawad O, Alkharisi MK, Bayoumi E, Aldukail A. Compressive and Bonding Performance of GFRP-Reinforced Concrete Columns. Buildings. 2024; 14(4):1071. https://doi.org/10.3390/buildings14041071

Chicago/Turabian StyleAlsuhaibani, Eyad, Mansour Alturki, Saleh M. Alogla, Omar Alawad, Mohammed K. Alkharisi, Elsaid Bayoumi, and Ali Aldukail. 2024. "Compressive and Bonding Performance of GFRP-Reinforced Concrete Columns" Buildings 14, no. 4: 1071. https://doi.org/10.3390/buildings14041071