Assessment of Intelligent Unmanned Maintenance Construction for Asphalt Pavement Based on Fuzzy Comprehensive Evaluation and Analytical Hierarchy Process

Abstract

:1. Introduction

2. Project Overview

2.1. Study Area

2.2. Intelligent Unmanned Maintenance Technology

2.3. Performance Tests

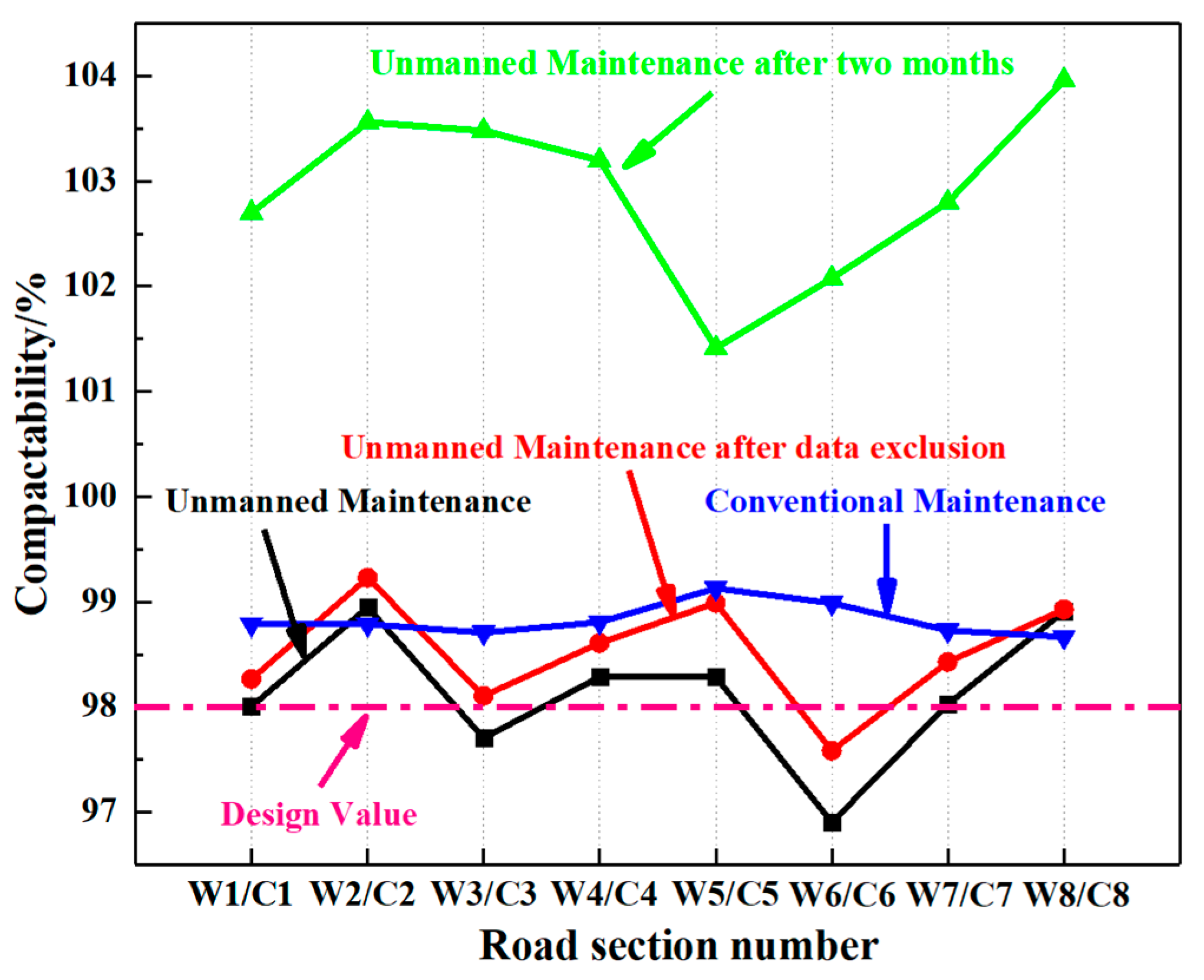

2.3.1. Compactability

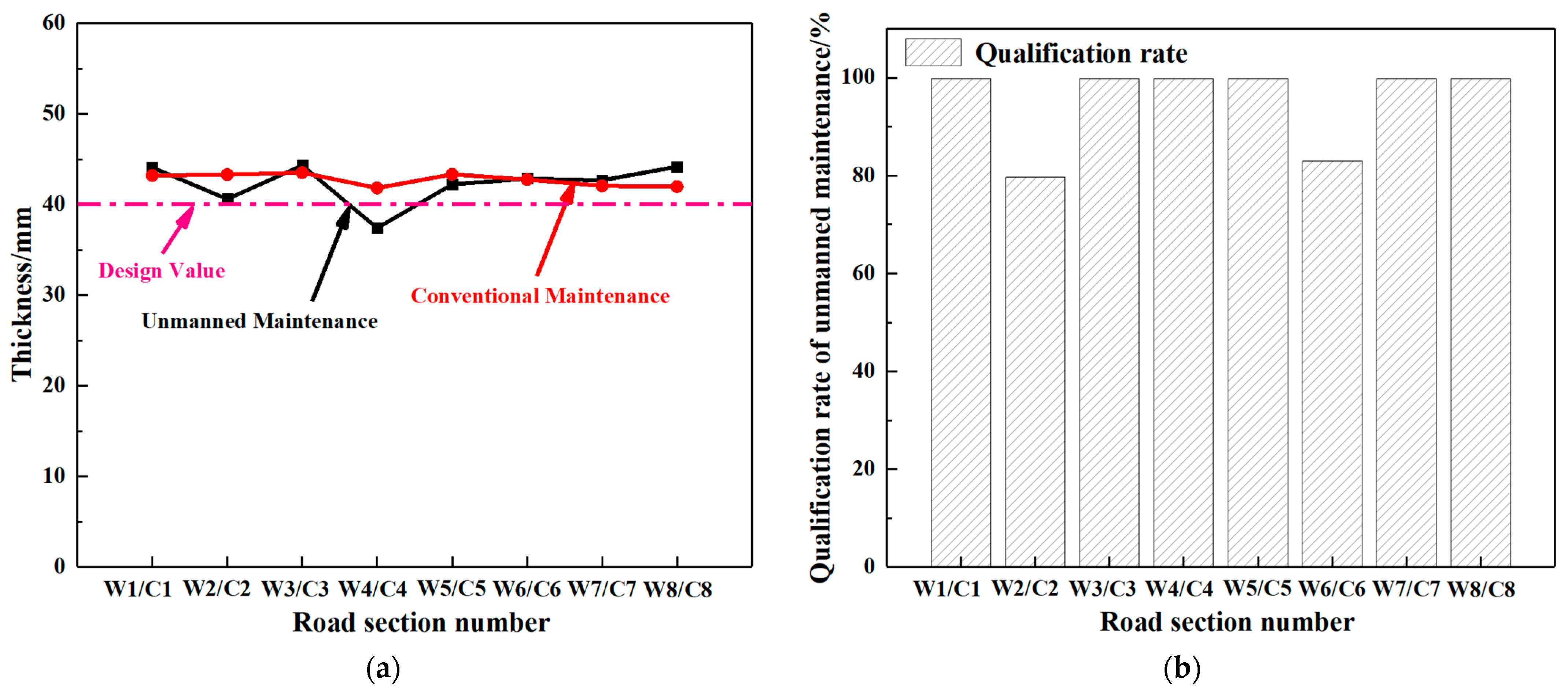

2.3.2. Thickness

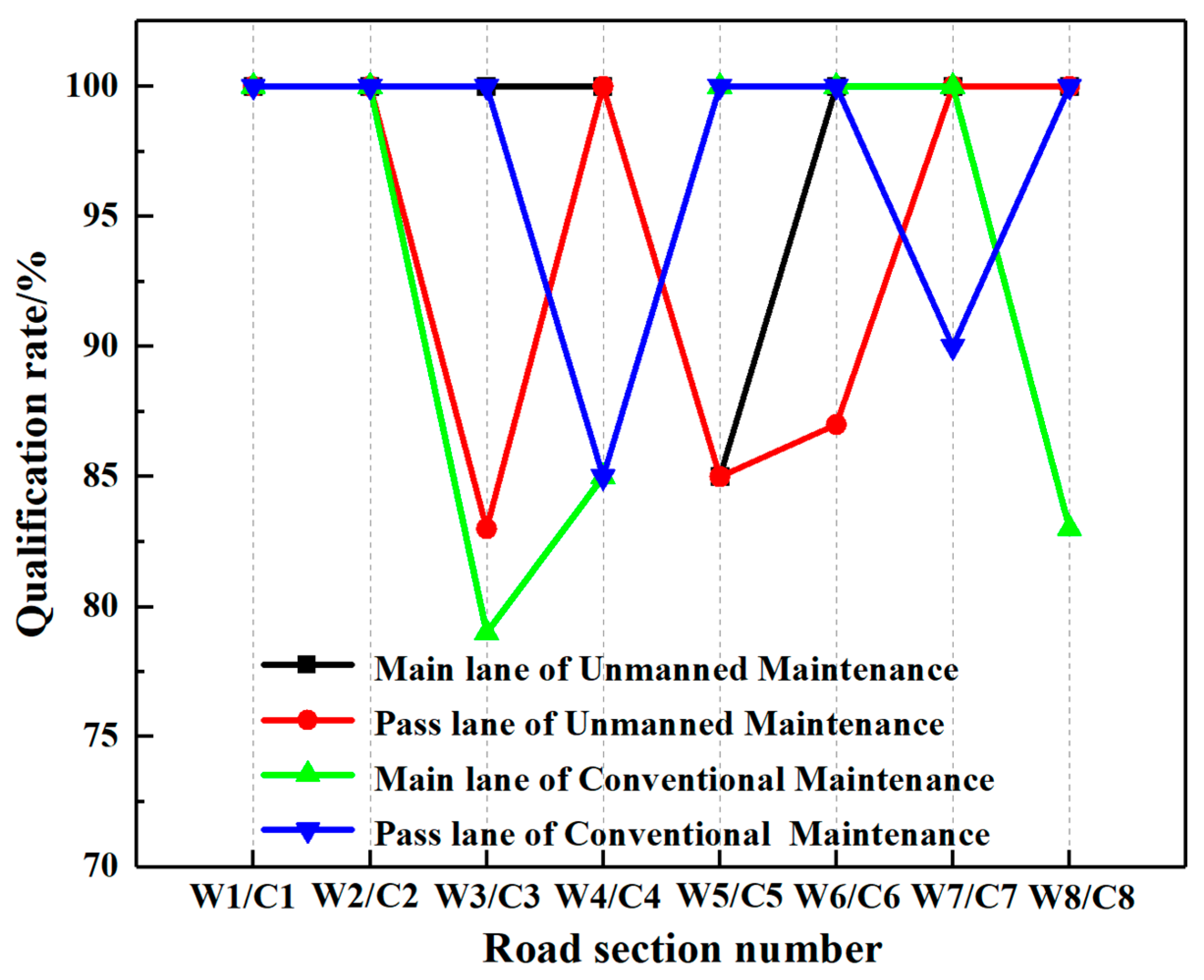

2.3.3. Surface Smoothness

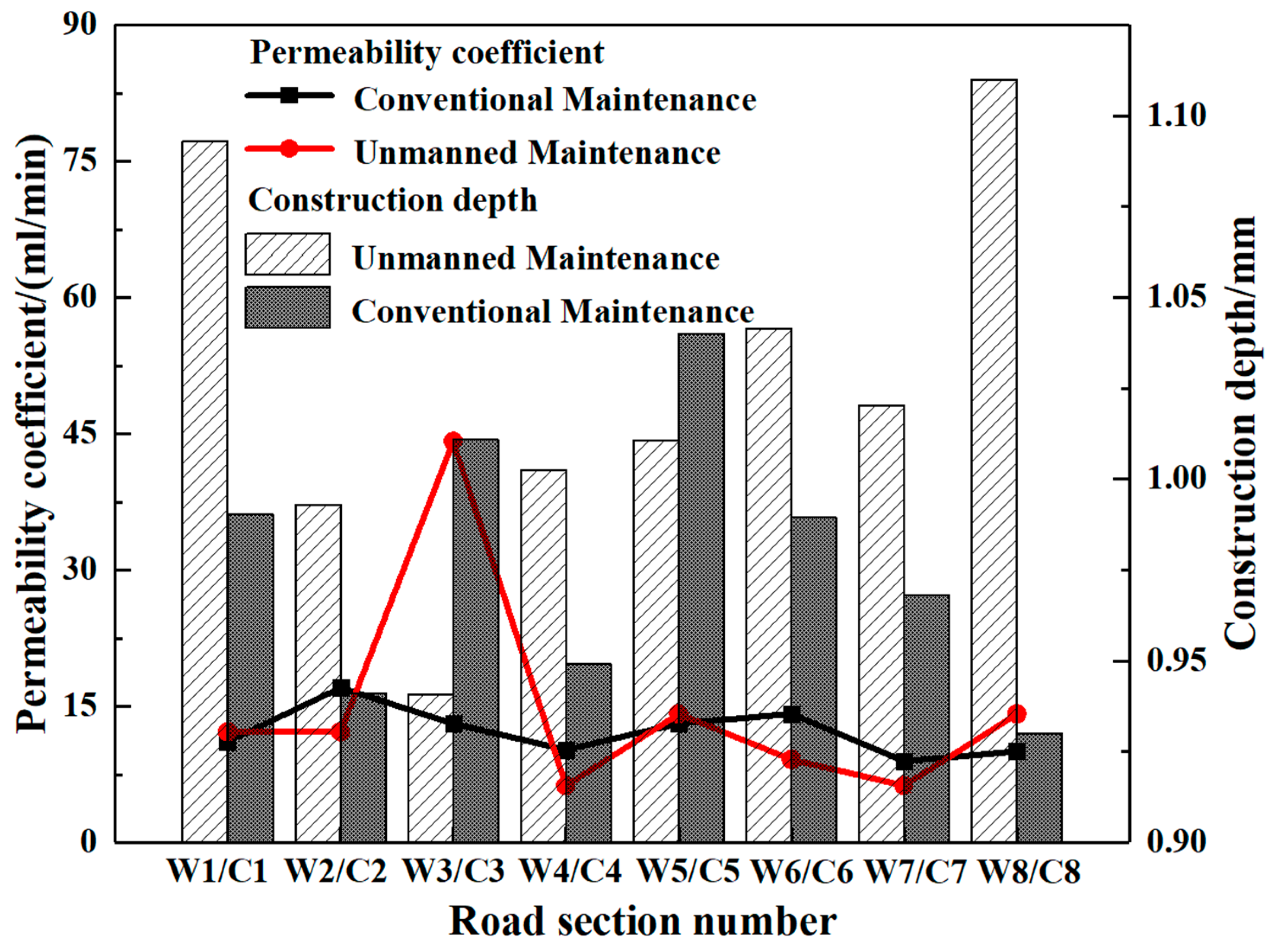

2.3.4. Permeability Coefficient and Constructure Depth

2.3.5. Performance Comparison of Unmanned Maintenance between Daytime and Nighttime

3. Fuzzy Comprehensive Evaluation of Intelligent Unmanned Maintenance Technology

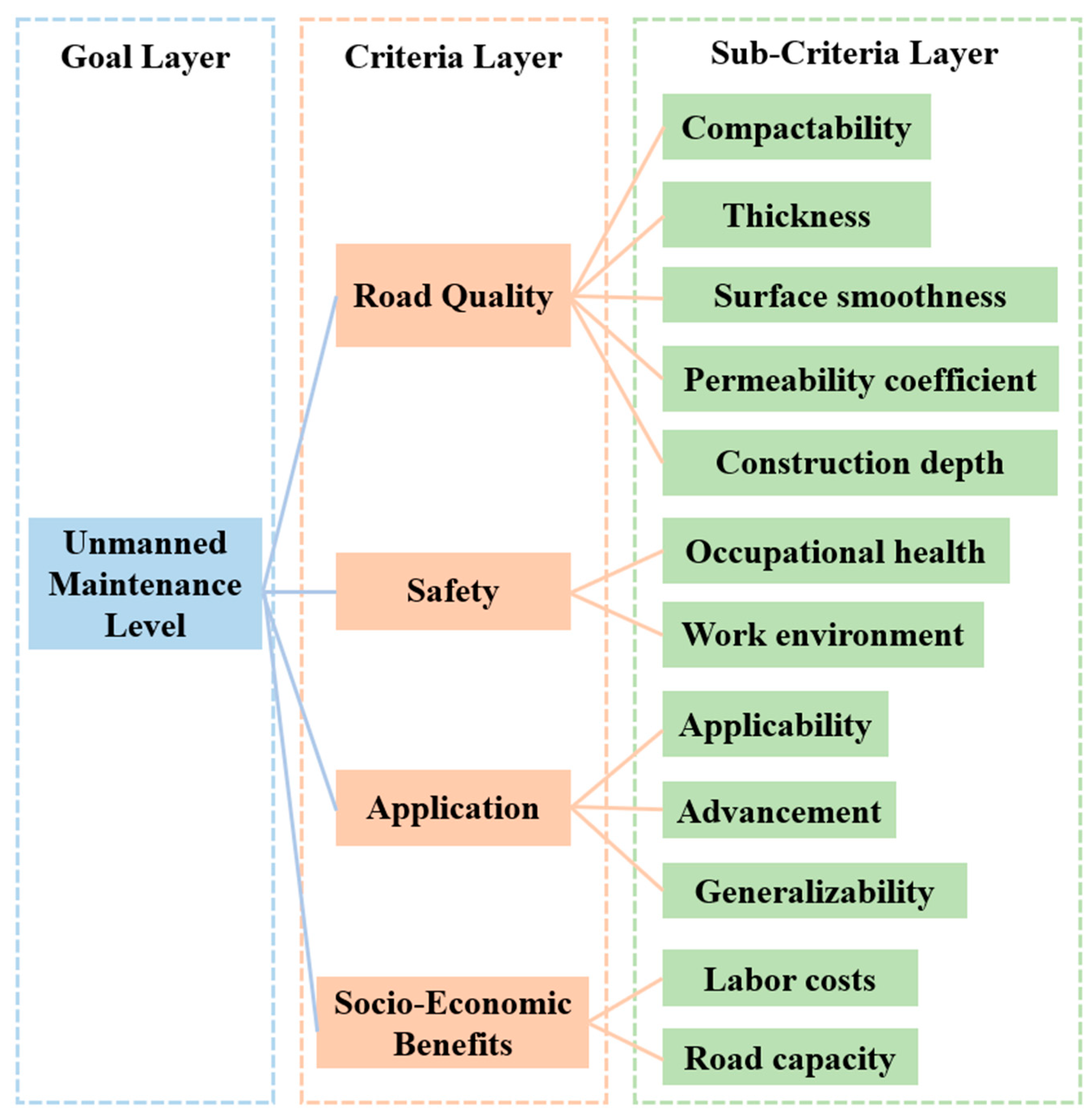

3.1. Establish Evaluation Index System

3.2. Evaluation Method

3.2.1. Fuzzy Comprehensive Evaluation

3.2.2. Analytic Hierarchy Process

- (1)

- Establishing hierarchical structure model: This step is used to construct a hierarchical organizational model for the evaluation of the application effectiveness of intelligent unmanned maintenance technology, as shown in Figure 5.

- (2)

- Constructing judgment matrix: This step involves constructing the judgment matrices to obtain the relative importance of different evaluation indicators. For each pair of evaluation indicators to be compared, a scale is used to express the relative importance between them. Five basic scales (1, 3, 5, 7, and 9) of absolute numbers can be used, representing equal importance, moderate importance, strong importance, very strong importance, and extreme importance, respectively. The numbers between these scales (2, 4, 6, and 8) express intermediate importance. This method decomposes the evaluation objectives into multiple levels, assessing the relative importance of different factors within each level of the objectives. This study establishes a judgment matrix by inviting experts to quantitatively score the importance of each indicator.

- (3)

- Calculate the maximum eigenvector () and corresponding eigenvector (): These parameters can be calculated by Equation (7) [28]:where n is the order of the judgment matrix.

- (4)

- Consistency ratio check. In this step, the consistency index (CI) and consistency ratio (CR) are calculated to conduct a consistency check on the judgment matrix, aiming to enhance the reliability of the AHP, as shown in Equations (8) and (9) [26].where RI is a random consistency index. Generally, if the CR is less than an accepted threshold (typically 0.1), the judgment matrix is considered consistent; otherwise, a reevaluation of the relative importance of pairwise comparisons is necessary.

4. Results and Discussion

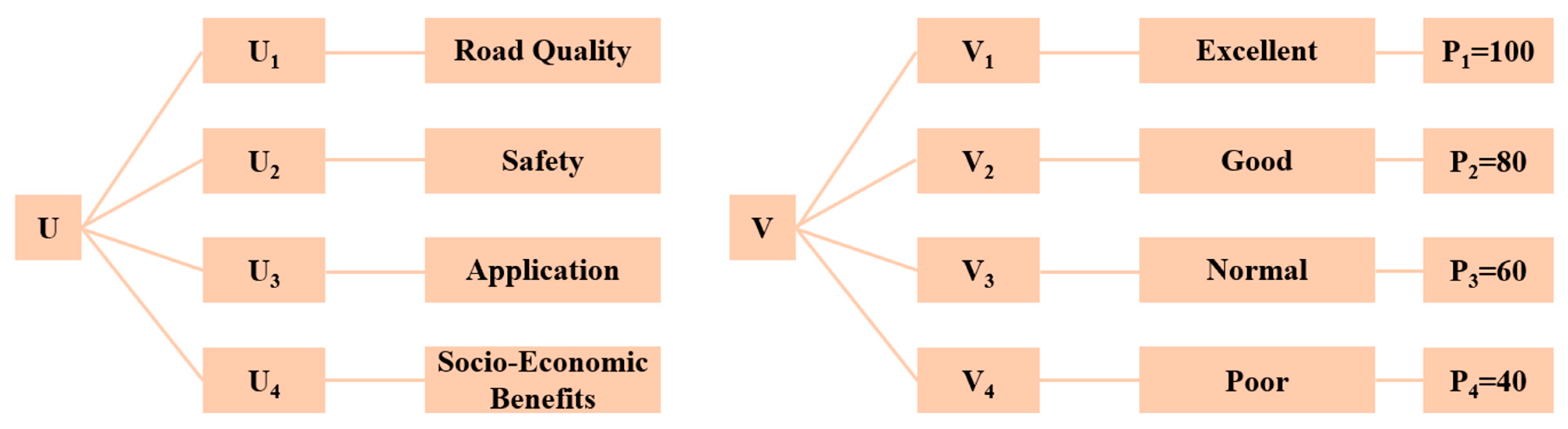

4.1. Determination of Evaluation Factors Set and Evaluation Grade Set

4.2. AHP for Weight Determination

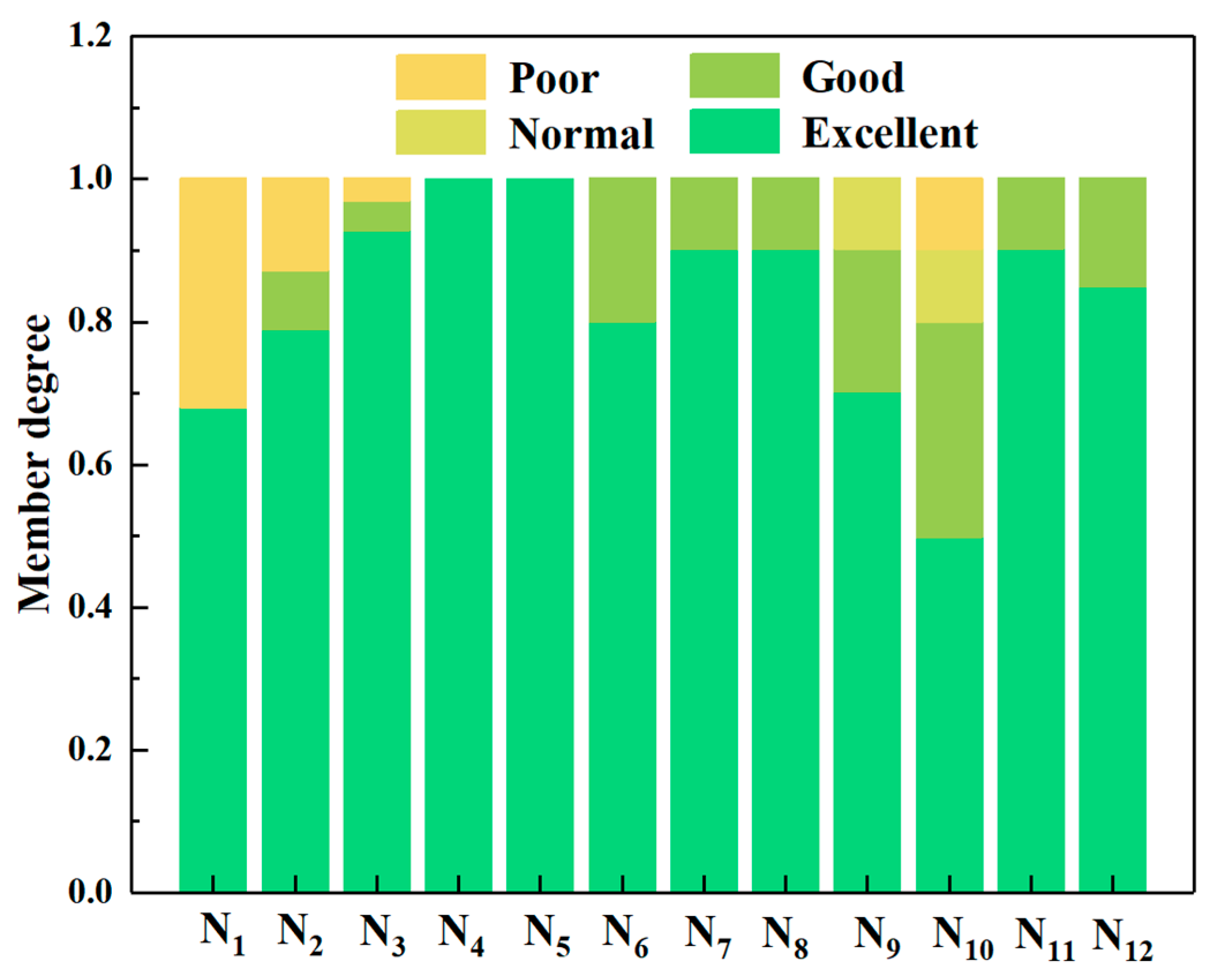

4.3. Fuzzy Comprehensive Evaluation

5. Conclusions

- (1)

- The road quality of the unmanned maintenance method is inferior to traditional manual maintenance methods, especially in terms of the compactability and surface smoothness at the starting and ending points of the maintenance section, which need improvement. However, the quality of the unmanned maintenance method still meets specification requirements.

- (2)

- The weight set of the four types of criteria layer evaluation indicators suggests that the importance of the evaluation indicators follows the order of road quality (U1) > safety (U2) > application (U3) > socio-economic benefits (U4). Consequently, stringent requirements must be placed on the implementation process of the target project, with continual monitoring of road quality.

- (3)

- Regarding socio-economic benefits, labor costs hold considerable weight, underscoring the significant advantage of unmanned construction in reducing labor costs compared to traditional manual maintenance construction methods.

- (4)

- Both safety and socio-economic benefits exhibit membership degrees exceeding 0.8, attaining the excellent grade (V1). Furthermore, road quality attains a membership degree of 0.785 in the excellent grade (V1), the lowest among the four indicators. Additionally, the proportion of road quality classified as poor is relatively high, emphasizing the necessity for further refinement and enhancement.

- (5)

- The membership degree of unmanned maintenance technology in the excellent grade is the highest, reaching 0.805, and the quantified value for the overall evaluation of the application effectiveness of unmanned maintenance technology is 92.10. This means that the final comprehensive evaluation result of unmanned maintenance technology is rated as excellent.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mujtaba, H.; Khalid, U.; ur Rehman, Z.; Farooq, K. Recycling of reclaimed subbase materials in flexible pavement design. Road Mater. Pavement Des. 2021, 23, 2713–2732. [Google Scholar] [CrossRef]

- Ijaz, N.; Ye, W.; Rehman, Z.U.; Ijaz, Z.; Junaid, M.F. New binary paper/wood industry waste blend for solidification/stabilisation of problematic soil subgrade: Macro-micro study. Road Mater. Pavement Des. 2023, 24, 1215–1232. [Google Scholar] [CrossRef]

- Fu, C.; Liu, K.; Liu, Q.; Xu, P.; Dai, D.; Tong, J. Exploring directional energy conversion behavior of electromagnetic-based multifunctional asphalt pavement. Energy 2023, 268, 126573. [Google Scholar] [CrossRef]

- Wu, W.; Cavalli, M.C. Differing perspectives on the use of high-content SBS polymer-modified bitumen. Constr. Build. Mater. 2024, 411, 134433. [Google Scholar] [CrossRef]

- Qureshi, W.S.; Power, D.; Ullah, I.; Mulry, B.; Feighan, K.; McKeever, S.; O’Sullivan, D. Deep learning framework for intelligent pavement condition rating: A direct classification approach for regional and local roads. Autom. Constr. 2023, 153, 104945. [Google Scholar] [CrossRef]

- Elseicy, A.; Alonso-Díaz, A.; Solla, M.; Rasol, M.; Santos-Assunçao, S. Combined use of GPR and other NDTs for road pavement assessment: An Overview. Remote Sens. 2022, 14, 4336. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, Z.; Liu, H.; Zuo, J.; Ke, Y.; Philbin, S.P.; Zhou, Z.; Feng, Y.; Ni, Q. System framework for digital monitoring of the construction of asphalt concrete pavement based on IOT, BeiDou navigation system, and 5G technology. Buildings 2024, 411, 503. [Google Scholar] [CrossRef]

- Liang, J.; Guan, Z. Design of intelligent automatic leveling control system based on ultrasonic distance measuring technology. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Shandong, China, 18–21 August 2007; Volumes 1–6, pp. 1620–1624. [Google Scholar]

- Qi, Y.; Ma, W.; Zhang, J. Construction deviation control method of transverse super large inclined asphalt pavement. Arch. Civ. Eng. 2023, 69, 165–176. [Google Scholar]

- Chen, B.; Yu, X.; Dong, F.; Zheng, C.; Ding, G.; Wu, W. Compaction quality evaluation of asphalt pavement based on intelligent compaction technology. J. Constr. Eng. Manag. 2021, 147, 04021099. [Google Scholar] [CrossRef]

- Lu, L.; Dai, F.; Zaniewski, J.P. Automatic roller path tracking and mapping for pavement compaction using infrared thermography. Comput. Aided Civ. Infrastruct. Eng. 2021, 36, 1416–1434. [Google Scholar] [CrossRef]

- Dunston, P.S.; Monty, J. Practices for Seamless Transmission of Design Data from Design Phase to Construction Equipment Operation: A Synthesis Study, No. FHWA/IN/JTRP-2008/08. In Joint Transportation Research Program, Indiana Department of Transportation and Purdue University, Indiana. 2009. Available online: https://docs.lib.purdue.edu/cgi/viewcontent.cgi?article=2672&context=jtrp (accessed on 1 May 2009).

- Snyder, M. Stringless Paving, No. HWA-HIF-18-011, Federal Highway Administration, United States. 2019. Available online: https://www.fhwa.dot.gov/pavement/pubs/hif18011.pdf (accessed on 1 January 2019).

- Peyret, F.; Jurasz, J.; Carrel, A.; Zekri, E.; Gorham, B. The computer integrated road construction project. Autom. Constr. 2000, 9, 447–461. [Google Scholar] [CrossRef]

- Ye, W.; Wang, T.; Zhou, C. Application of millimeter 3D automatic paving system in highway engineering construction. In Proceedings of the 20th COTA International Conference of Transportation Professionals, Xi’an, China, 14–16 August 2020; pp. 1604–1615. [Google Scholar]

- Bian, Y.; Fang, X.; Yang, M.; Zhao, Z. Automatic rolling control for unmanned vibratory roller based on fuzzy algorithm. J. Tongji Univ. 2017, 45, 1830–1838. [Google Scholar]

- Xie, R. Research on intelligent construction technology of asphalt pavement complete equipment. Value Eng. 2021, 40, 129–131. [Google Scholar]

- Wang, J.; Yang, J.; Zhang, R.; Xie, W.; Wu, G. Research and practice of operating expressway maintenance based on unmanned automatic driving technology. In Proceedings of the CICTP 2023, Beijing, China, 14–17 June 2023; pp. 310–319. [Google Scholar]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. Research Institute of Highway Ministry of Transport: Beijing, China, 2004.

- JTG 3450-2019; Field Test Methods of Highway Subgrade and Pavement. China Communications Press: Beijing, China, 2019.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- JTG 5210-2018; Highway Performance Assessment Standards. Ministry of Transport of the People’s Republic of China: Beijing, China, 2018.

- JTG 5220-2020; Inspection and Evaluation Quality Standards for Highway Maintenance Engineering Section 1 Civil Engineering. Research Institute of Highway Ministry of Transport: Beijing, China, 2020.

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 9, 338–353. [Google Scholar] [CrossRef]

- Xu, X.; Yu, F.; Pedrycz, W.; Du, X. Multi-source fuzzy comprehensive evaluation. Appl. Soft Comput. 2023, 135, 110042. [Google Scholar] [CrossRef]

- Fu, C.; Liu, K.; Zhi, W.; Liu, P.; Oeser, M. Comprehensive evaluation of thermally conductive functional layer on snow-melting performance for electric heating bridge system. Cold Reg. Sci. Technol. 2023, 219, 104099. [Google Scholar] [CrossRef]

- Jing, H.; Yao, P.; Song, L.; Zhang, J.; Zhao, Y.; Zhang, Z. Analysis on optimization decision of pavement maintenance mode based on analytic hierarchy process. Dyna 2021, 96, 605–611. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, P.; Rochlani, M.; Falla, G.C.; Leischner, S.; Oeser, M. A fuzzy comprehensive evaluation method to select the optimal mineral filler for optimization of the performance of asphalt mastics. Constr. Build. Mater. 2021, 298, 123847. [Google Scholar] [CrossRef]

| Road Section Number | Direction | Starting Milepost | Ending Milepost | Length/km |

|---|---|---|---|---|

| W1 | Up | K445 + 050 | K445 + 444 | 0.394 |

| W2 | Down | K461 + 306 | K460 + 606 | 0.7 |

| W3 | Down | K460 + 460 | K459 + 760 | 0.7 |

| W4 | Down | K466 + 308 | K465 + 991 | 0.317 |

| W5 | Up | K431 + 803 | K432 + 503 | 0.7 |

| W6 | Up | K432 + 494 | K433 + 250 | 0.756 |

| W7 | Up | K475 + 244 | K475 + 977 | 0.733 |

| W8 | Down | K94 + 422 | K93 + 928 | 0.494 |

| Road Section Number | Direction | Starting Milepost | Ending Milepost | Length/km |

|---|---|---|---|---|

| C1 | Up | K415 + 282 | K415 + 975 | 0.693 |

| C2 | Up | K437 + 296 | K438 + 171 | 0.875 |

| C3 | Up | K443 + 622 | K445 + 031 | 1.409 |

| C4 | Up | K445 + 527 | K446 + 179 | 0.652 |

| C5 | Up | K474 + 619 | K475 + 241 | 0.622 |

| C6 | Down | K467 + 230 | K466 + 308 | 0.922 |

| C7 | Down | K463 + 136 | K462 + 046 | 1.09 |

| C8 | Down | K438 + 605 | K437 + 960 | 0.645 |

| Road Section Number | Main Lane | Pass Lane | ||

|---|---|---|---|---|

| IRI | RQI | IRI | RQI | |

| W1 | 1.35 | 94.13 | 1.11 | 94.93 |

| W2 | 1.23 | 94.53 | 1.39 | 93.98 |

| W3 | 1.13 | 94.86 | 1.42 | 93.85 |

| W4 | 1.30 | 94.31 | 1.39 | 93.96 |

| W5 | 1.31 | 94.25 | 1.47 | 93.66 |

| W6 | 1.19 | 94.68 | 1.40 | 93.93 |

| W7 | 0.98 | 95.32 | 1.12 | 94.90 |

| W8 | 1.40 | 93.93 | 1.13 | 94.87 |

| Type | Daytime | Nighttime | Standard Value |

|---|---|---|---|

| Compactability | 96.8 | 95.5 | / |

| Thickness | 41.7 | 43.3 | >40 mm |

| Smoothness | 94.5 | 94.6 | / |

| Permeability coefficient | 16.0 | 10.0 | <80 mL/min |

| Construction depth | 1.06 | 1.12 | >0.55 mm |

| Coefficient of variation for IRI | 0.07 | 0.12 | / |

| Criteria Layer Evaluation Indicators | Weight | Sub-Criteria Layer Evaluation Indicators | Weight |

|---|---|---|---|

| Road quality | 0.510 | Compactability (N1) | 0.485 |

| Thickness (N2) | 0.227 | ||

| Surface smoothness (N3) | 0.143 | ||

| Permeability coefficient (N4) | 0.089 | ||

| Construction depth (N5) | 0.057 | ||

| Safety | 0.330 | Occupational health (N6) | 0.25 |

| Workplace (N7) | 0.75 | ||

| Application | 0.100 | Applicability (N8) | 0.623 |

| Advancement (N9) | 0.239 | ||

| Generalizability (N10) | 0.137 | ||

| Socio-economic benefits | 0.059 | Labor costs (N11) | 0.667 |

| Road capacity (N12) | 0.333 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, G.; Shi, G.; Zhang, R.; Chen, J.; Wang, H.; Wang, J. Assessment of Intelligent Unmanned Maintenance Construction for Asphalt Pavement Based on Fuzzy Comprehensive Evaluation and Analytical Hierarchy Process. Buildings 2024, 14, 1112. https://doi.org/10.3390/buildings14041112

Hu G, Shi G, Zhang R, Chen J, Wang H, Wang J. Assessment of Intelligent Unmanned Maintenance Construction for Asphalt Pavement Based on Fuzzy Comprehensive Evaluation and Analytical Hierarchy Process. Buildings. 2024; 14(4):1112. https://doi.org/10.3390/buildings14041112

Chicago/Turabian StyleHu, Gensheng, Gongzuo Shi, Runhua Zhang, Jianfeng Chen, Haichang Wang, and Junzhe Wang. 2024. "Assessment of Intelligent Unmanned Maintenance Construction for Asphalt Pavement Based on Fuzzy Comprehensive Evaluation and Analytical Hierarchy Process" Buildings 14, no. 4: 1112. https://doi.org/10.3390/buildings14041112

APA StyleHu, G., Shi, G., Zhang, R., Chen, J., Wang, H., & Wang, J. (2024). Assessment of Intelligent Unmanned Maintenance Construction for Asphalt Pavement Based on Fuzzy Comprehensive Evaluation and Analytical Hierarchy Process. Buildings, 14(4), 1112. https://doi.org/10.3390/buildings14041112