Abstract

Carbon emissions present a pressing challenge to the traditional construction industry, urging a fundamental shift towards more sustainable practices and materials. Recent advances in sensors, data fusion techniques, and artificial intelligence have enabled integrated digital technologies (e.g., digital twins) as a promising trend to achieve emission reduction and net-zero. While digital twins in the construction sector have shown rapid growth in recent years, most applications focus on the improvement of productivity, safety and management. There is a lack of critical review and discussion of state-of-the-art digital twins to improve sustainability in this sector, particularly in reducing carbon emissions. This paper reviews the existing research where digital twins have been directly used to enhance sustainability throughout the entire life cycle of a building (including design, construction, operation and maintenance, renovation, and demolition). Additionally, we introduce a conceptual framework for this industry, which involves the elements of the entire digital twin implementation process, and discuss the challenges faced during deployment, along with potential research opportunities. A proof-of-concept example is also presented to demonstrate the validity of the proposed conceptual framework and potential of digital twins for enhanced sustainability. This study aims to inspire more forward-thinking research and innovation to fully exploit digital twin technologies and transform the traditional construction industry into a more sustainable sector.

1. Introduction

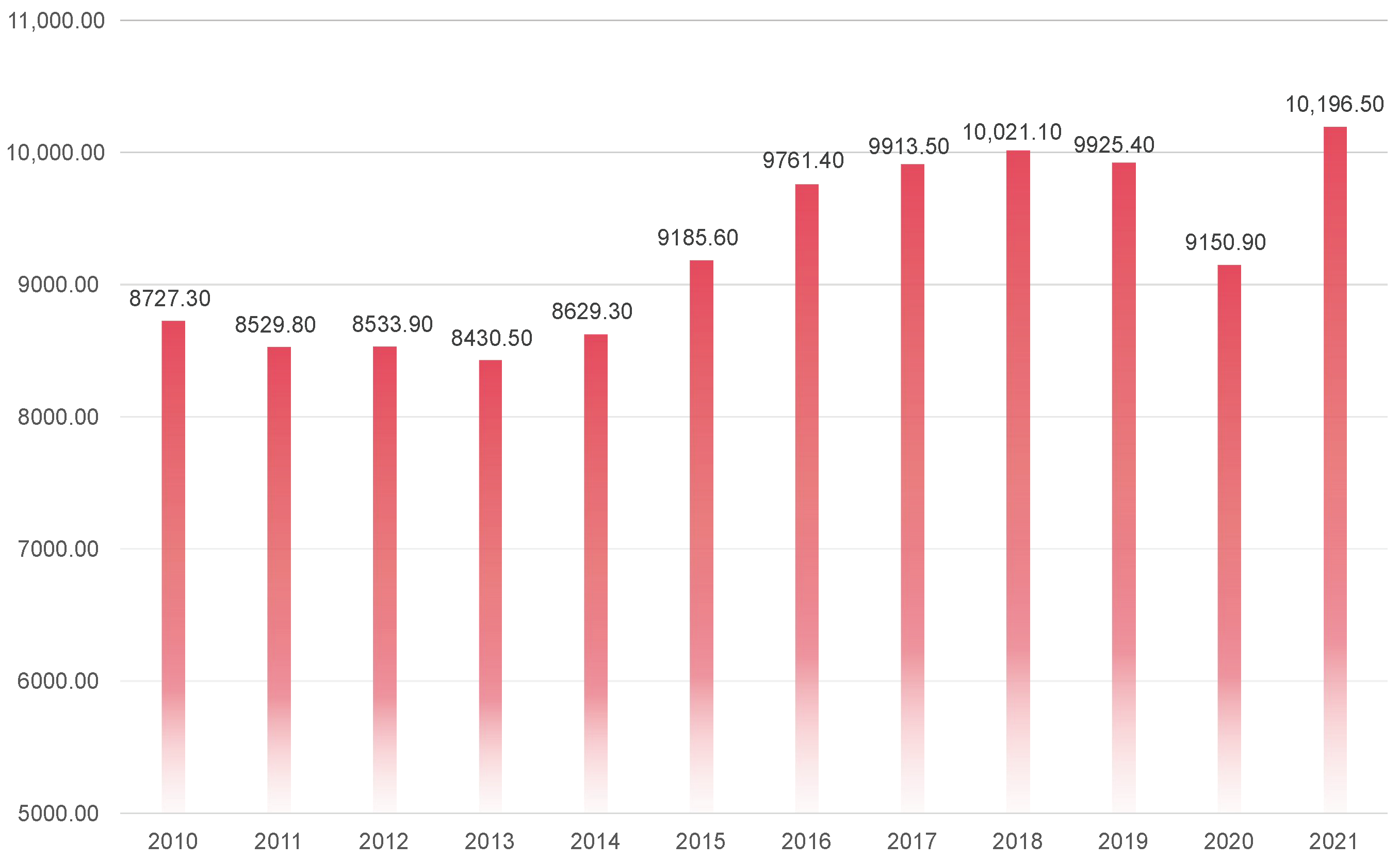

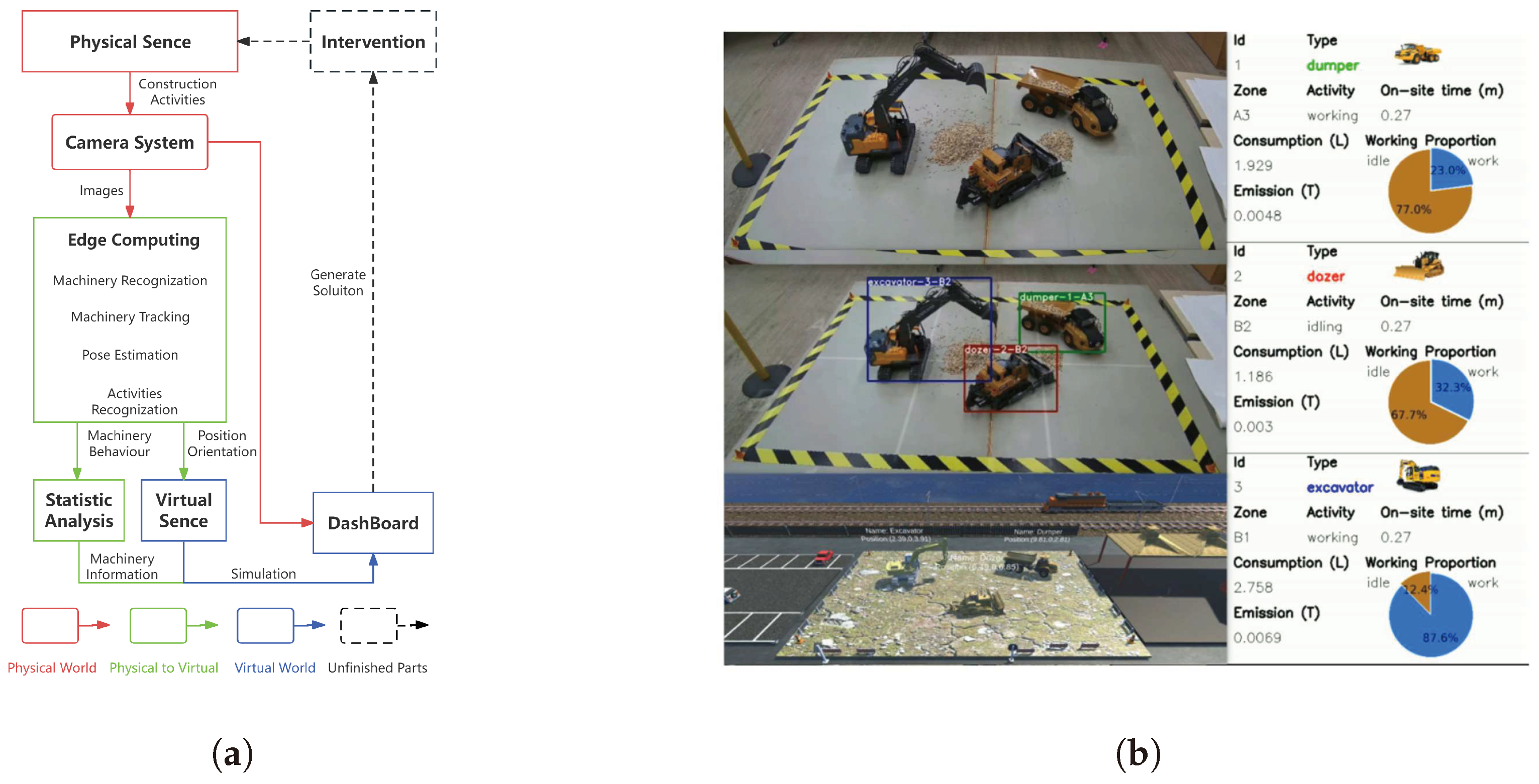

1.1. Sustainability in the Construction Sector

The construction industry is one of the important pillar industries of the global economy, and its development and prosperity play a key role in economic growth and advancement of urbanization [1]. However, the high energy consumption and high carbon emissions brought by this industry have become one of the most significant environmental challenges that the world is facing [2]. The construction industry consumes considerable energy and resources throughout a building’s life cycle and emits substantial greenhouse gases (GHG), especially carbon dioxide (CO2), which contributes significantly to global climate change [3]. According to the International Energy Agency (IEA), the world’s largest energy consumer, the construction industry accounts for approximately 40% of total energy consumption and is responsible for about 36% of total global GHG emissions [4]. Taking the UK as an example, according to a report released by the British government in September 2022, around 40% of UK carbon emissions are linked to the built environment [5]. This includes emissions associated with heating buildings, the energy they consume for operations, and the functioning of the transport infrastructure. Figure 1 shows the increasing trend of GHG emissions from the UK construction industry over the past decade [6]. In 2019 and 2020, there was a reduction due to the pause in many production activities caused by the COVID-19 virus. However, emissions resumed their growth in 2021, reaching a new high in nearly a decade.

Figure 1.

GHG emissions from the construction industry in the UK from 2010 to 2021 (in 1000 metric tons of carbon dioxide equivalent).

Amid rising concerns over climate change, global environmental protection gains increasing focus [7]. Governments and international bodies set emissions targets, with the Paris Agreement committing to keep global temperature rise below 2 °C, aiming for 1.5 °C [8]. In order to achieve these goals, the construction industry, as one of the important sources of carbon emissions, has been entrusted with an overwhelming responsibility. The continuous advancement of science and technology provides new opportunities to solve environmental problems [9]. Digital technology, as an emerging part, provides new possibilities and opportunities for carbon emission reduction in the construction industry. The rapid development of digital technologies, such as the Internet of Things (IoT), artificial intelligence (AI), cloud and edge computing, and blockchain, has brought opportunities for the digital transformation of the construction industry [10,11]. Among them, digital twins, as a subversive innovative technology, are regarded as one of the key and most promising technologies to achieve carbon emission reduction in the construction industry [12].

1.2. Digital Twins for Enhanced Sustainability

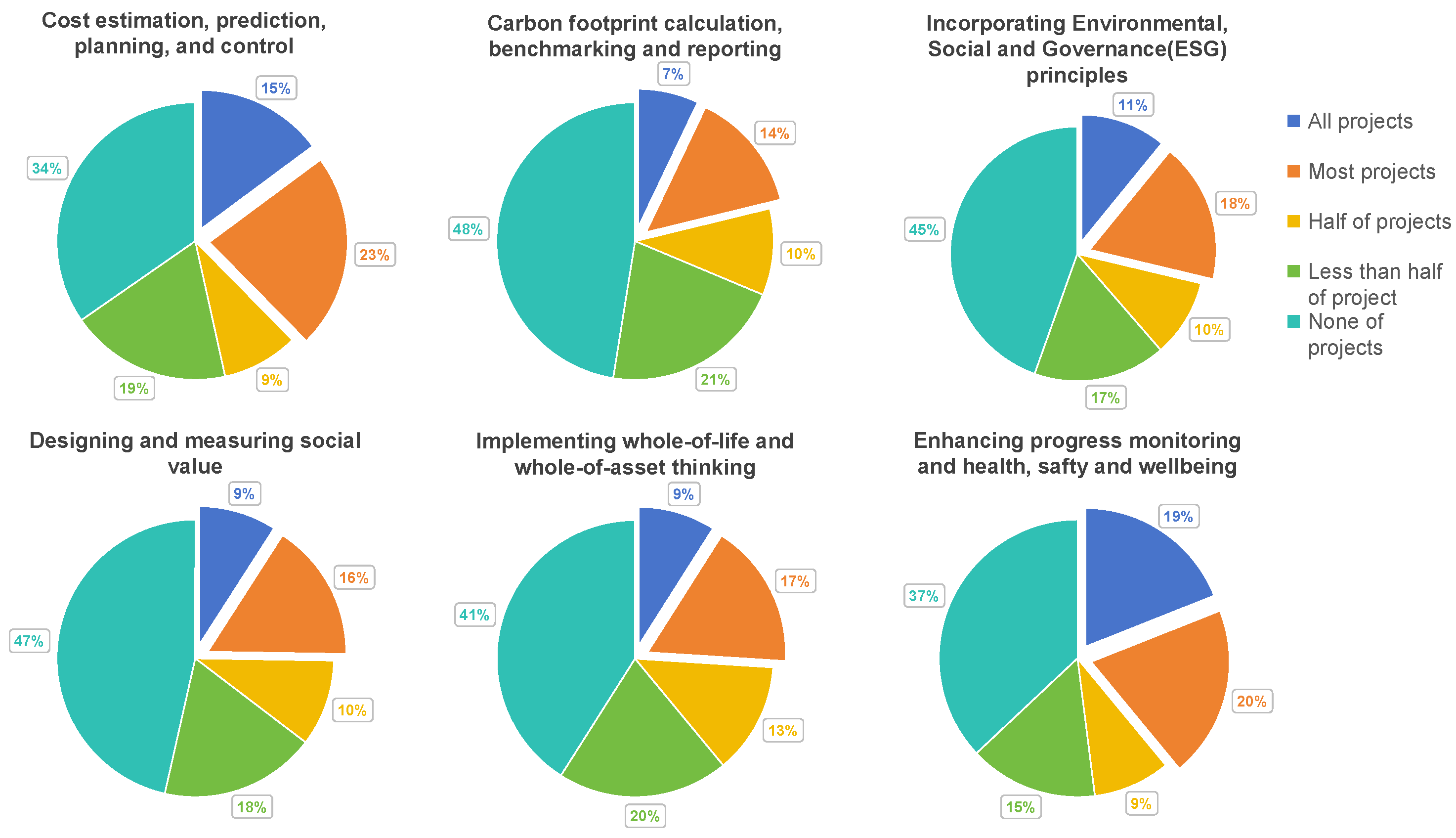

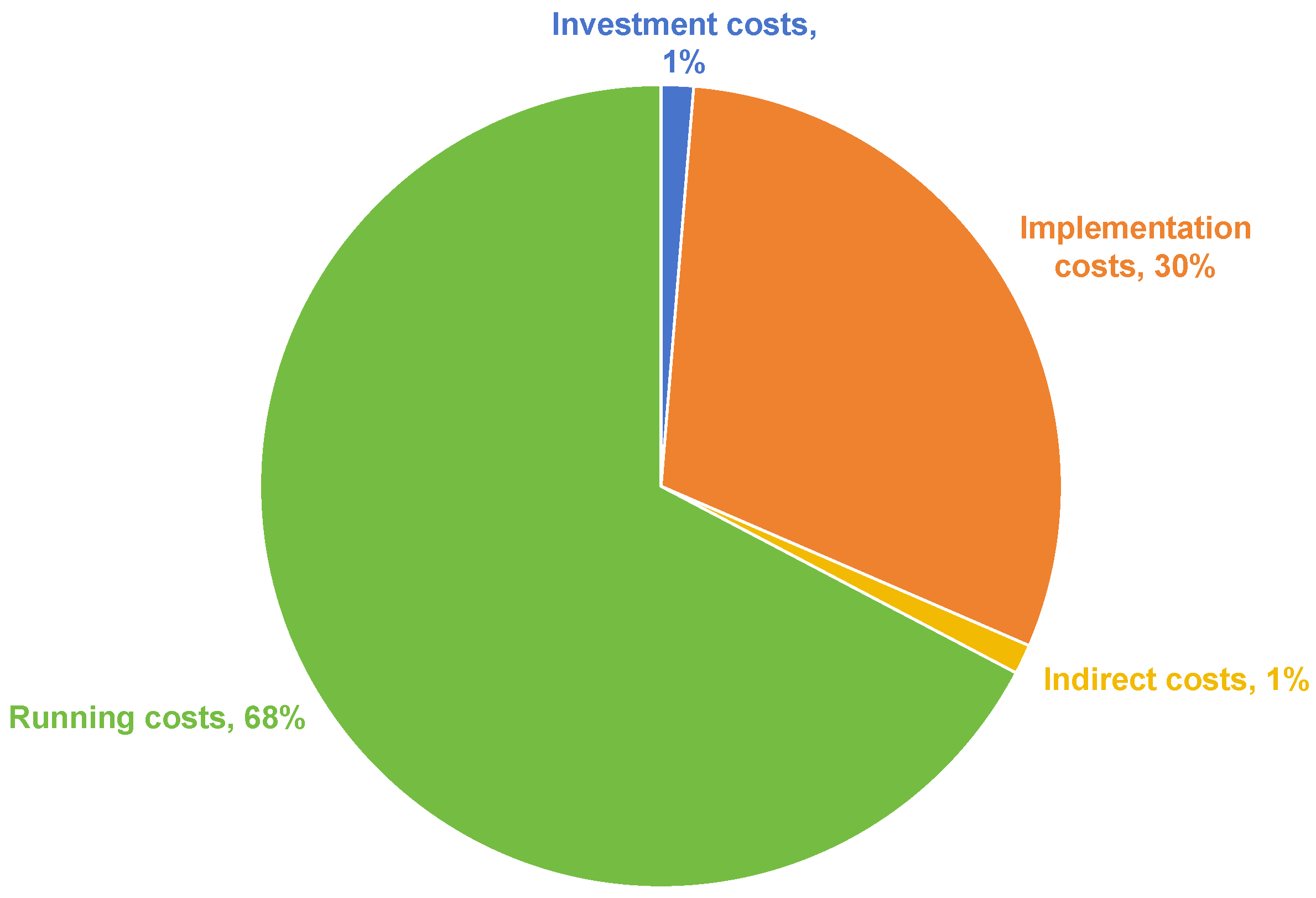

Digital twins technology creates a digital version of a physical object or system, linking real-world data with the virtual model. This allows for the real-time monitoring, simulation, prediction, and analysis of the system or object. This approach has been used in different sectors to enhance efficiency, productivity, and decision-making processes [13]. In manufacturing, digital twins optimize production by predicting maintenance needs and streamlining operations [14]. In healthcare, they facilitate hospital management and patient care by simulating medical procedures and predicting patient responses to treatments [15]. For urban planning, digital twins assist in the development of smarter cities through efficient infrastructure planning and traffic management [16]. From an academic perspective, the result of the literature review shows that the most prominent applications of digital twins in the construction industry are in facility management and operation, integration with Building Information Modeling (BIM) for predictive maintenance and resource efficiency, construction site management and monitoring, worker training and safety, and structural integrity assessment [17]. From the perspective of practical application cases in the industrial sector, Figure 2 shows research from Royal Institution of Chartered Surveyors (RICS) in 2023 [18], indicating the main application directions in the construction industry involving BIM or digital twins. The statistical results indicate that the current level of digitalization in sustainable direction is the lowest. This technology can span the entire life cycle of buildings, from design, construction, operation and maintenance, and renovation, to demolition [19]. Through adopting digital twins, stakeholders and engineers can fully understand the state and behavior of buildings, optimize the use of energy and resources, and reduce carbon emissions [12,20]. In the architectural design stage, digital twins can simulate the energy consumption of different design schemes to choose the most energy-efficient and environmentally friendly option [21]. During the construction process, digital twins can monitor the construction status of the building in real-time, identify problems promptly and make necessary adjustments, optimize construction efficiency, and reduce resource wastage [22]. In the operation and maintenance phase of buildings, digital twins can help operators, in real-time, to monitor energy consumption and the equipment operating status, discover and solve problems on time, and optimize energy utilization efficiency [23]. The renovation and demolition stages involve the assessment of recyclable materials, where digital twin systems can help construction teams better analyze recycling needs to achieve material savings.

Figure 2.

Consistent use of processes and practices driven by BIM or digital twins [18] (note: values may not add up to 100% because of rounding).

Digital twins can undoubtedly better assist the construction industry in achieving sustainable goals [24]. Some researchers already tried to combine specific digital technologies with digital twins; meanwhile, a lot of studies have already revealed that the advancements that digital twins can bring to sustainable development are substantial. A case study of a global Consumer Packaged Goods (CPGs) brand demonstrated how digital twins can support sustainability goals, such as reducing the overall carbon footprint by as much as 20% [25]. This involves simulating new product designs, packaging alternatives, or manufacturing configurations to minimize energy consumption, water usage, and waste. The study highlighted that digital twins could reduce greenhouse gas emissions and the carbon footprint of buildings by up to 50%, alongside cost savings of up to 35% [26]. Other benefits include facilitating a shift to a circular economy, the real-time tracking of the carbon footprint, optimizing logistics to reduce emissions, and enhancing water conservation.

Currently, the construction industry aims to achieve sustainability through technologies such as BIM, green building materials, solar technology, and intelligent building management [27]. BIM is a kind of technology focusing on information management during the design and construction phases, aiding in efficient collaboration and decision-making by project teams, but usually does not involve real-time data analysis of the building during its operational phase [28]. For digital twins, it can provide a real-time, dynamically updated model of a building, capable of simulating and monitoring the building’s actual performance, including energy consumption and structural health [29]. So, digital twins can continuously monitor and be self-optimized on top of BIM, maintaining efficient and sustainable operations throughout the building’s life cycle. Comparing with green building materials, digital twin technology enhances the effectiveness of green building materials by optimizing material selection and use, achieving a higher level of sustainability. Additionally, it can enhance the functionality of smart building technologies, allowing for more detailed energy management and maintenance strategies through in-depth analysis and simulation.

Digital twins in the construction industry stand out from existing sustainability-enhancing technologies due to their unique benefits in cost reduction, efficiency improvement, and scalability. By enabling predictive maintenance and life cycle management, digital twins significantly lower repair costs and extend the lifespan of building materials, optimizing resource usage and minimizing waste [30]. Real-time data analysis and enhanced collaboration further boost project management efficiency, ensuring projects are completed on time and within budget [31]. Additionally, their modular design and integration capability with other technologies like BIM, IoT sensors, and AI allow for adaptation to projects of varying sizes and complexities, facilitating seamless technological expansion [32]. This comprehensive approach not only incorporates existing sustainability technologies but also enhances their capabilities through real-time data analysis, predictive modeling, and improved collaboration, making digital twins a powerful tool for promoting sustainability in construction projects.

1.3. The Aim of This Study

Although many studies have conducted literature reviews on digital twins for the construction industry, very limited ones are specifically focused on energy conservation and emission reduction. By bridging this gap, the main contributions of this paper are listed in the following:

- A first review of state-of-the-art research and applications on digital twins in terms of their contributions to different stages in the entire life cycle of buildings. Different from the existing review papers, this work focuses on how digital twins can reduce energy consumption and carbon emissions.

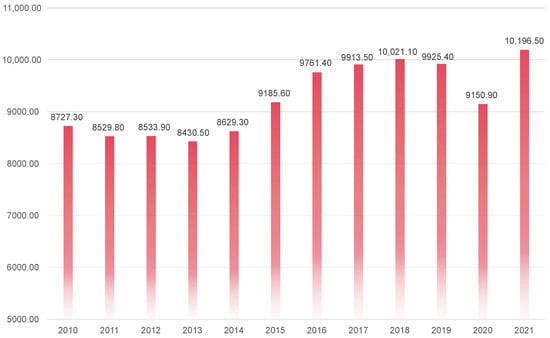

- A conceptual framework for the full-process implementation of digital twins was proposed. (a) Preparation phase: identify the physical elements and construct the cyber elements. (b) Implementation phase: all activities about data, such as collection, storage, integration, processing, and analysis. (c) Operation phase: deploy the solution and offer visualization for different purposes, then intervene in reality. Meanwhile, following this framework, a proof-of-concept demo in monitoring and visualizing fuel consumption and carbon emissions of construction machinery has been reported.

- Identification of the challenges and future opportunities when implementing digital twins in the construction industry, which span from complexities of data collection/fusion, optimization of the physical and digital entities, the construction of transparent and responsible artificial intelligence and cost issue.

2. State of the Art

This study employed a comprehensive and systematic approach to review the literature, primarily utilizing two major databases: Scopus and Google Scholar. The search was designed to capture the evolving landscape of digital twins in the construction industry, with a particular focus on sustainability and environmental considerations. The initial search criteria were defined around the keywords “digital twin” and “construction industry”. To refine the search and ensure relevance to the study’s objectives, advanced search parameters were introduced, incorporating additional keywords such as “sustainability”, “energy”, “green”, and “emission”. This strategy was aimed at identifying publications that not only discuss digital twins in a construction context but also their impact on or contributions to sustainable practices, energy efficiency, and emission reductions within this industry.

The time span for the literature search was mainly set from 2010 to the present, recognizing the significant advancements in digital twin technology and its application in constructions over the last decade. This period was chosen to encompass the maturation of digital twin concepts from their early stages to their current state-of-the-art implementations, allowing for a thorough examination of their development, challenges, and potential for future innovations in reducing the environmental footprint of construction activities.

Since the introduction of digital twins by NASA [33], significant breakthroughs have been achieved in the last decade, particularly in the aerospace industry [34], resulting in a high maturity level for related applications [35]. The construction industry has indeed begun integrating digital twins, but instances of actual implementations are either limited to the concept stage, or the integrated systems lack comprehensiveness [36].

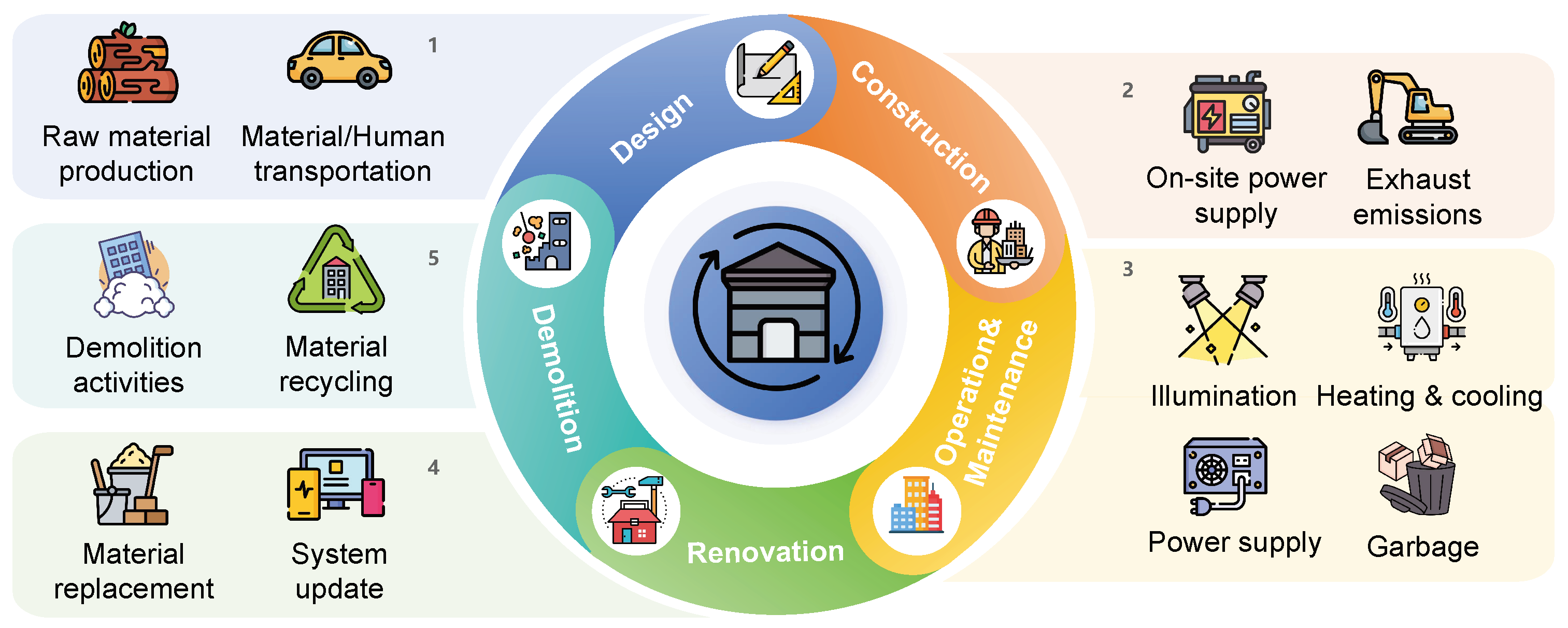

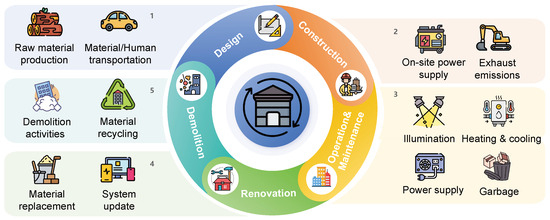

Before delving into the details, it is crucial to have a clear understanding of the different life cycle stages of a building and to identify the sources of carbon emissions at each stage [37]. In the life cycle of construction industries, there are five stages—design, construction, operation and maintenance, renovation, and demolition—as illustrated in Figure 3. The operation and maintenance phase, which includes energy usage for heating, cooling, and other functions, contributes the majority of emissions, estimated at over 80%. The construction phase, encompassing material production and building activities, accounts for a significant but smaller portion, about 10–15%. The demolition stage, involving the dismantling and disposal of building materials, contributes a relatively small fraction, estimated to be around 2% [38]. The sources of emissions include but are not limited to, the production and transportation of raw materials, energy consumption of on-site equipment (such as gasoline, electricity, and water resources), and the heating and electricity supply during operation and maintenance [39]. Based on the report released by World Green Building Council [40], for the building sector, which contributes 39% of global emissions, 28% of emissions are derived from the operation and maintenance phase, including cooling, heating, and power supply. The remaining 11% comes from the use of materials and building activities. Figure 3 maps different sources of carbon emissions in each stage, which shows the most significant carbon contributors of buildings and supports the discussions below.

Figure 3.

The typical life cycle of a building with associated main sources of carbon emissions at each stage.

In the current literature, there are presently only a few applications directly associating digital twins with sustainability. Table 1 summarizes the papers that simultaneously involve digital twins and sustainability. These papers directly incorporate and implement the concept of digital twins into the knowledge framework and application development. From the perspective of the technical layer, they employed emerging digital technologies related to digital twins, such as artificial intelligence, the Internet of Things, Cyber–Physical Systems, etc. From the perspective of the purpose layer, they focused on using digital twins systems to address carbon emission issues in construction. From the perspective of the application layer, they integrated different concepts in their respective application scenarios, such as Smart Maintenance, Life Cycle Sustainability Assessment, Resilient Management, etc. By combining digital twins with existing monitoring or management systems, they are aimed at better serving the goals of sustainability enhancement.

Table 1.

State of the art of digital twins for sustainability in the construction sector.

2.1. Construction Phase

Construction site activities involve a variety of carbon emission sources, ranking second in the entire life cycle of a building, following closely behind the operation and maintenance phase. The construction process involves materials, construction vehicles, lighting equipment, heating and power supply systems and a series of equipment that generate carbon emissions [56]. These carbon emissions originate from a wide range of sources, offering substantial room for reduction.

In the aspect of improving the sustainability of building materials, Hao et al. [57], Li et al. [58], and Liu et al. [59,60] proposed methods leveraging BIM (Building Information Modeling), blockchain, and CPSs (Cyber–Physical Systems) for quantifying the carbon emission reduction in prefabricated buildings, providing an important knowledge base for the circular economy and sustainable building development, assisting with the optimization of material deployment and allocation before the official start of a project. Building on this foundation, Wang et al. [43] introduced a method that combines 3D concrete printing technology with digital twins to shorten the construction time and enhance design flexibility, while also achieving environmental sustainability. Following on this, Mêda et al. [45] took a different technological route by incorporating mobile LiDAR (Light Detection and Ranging) technology and enhancing waste audits, achieving not only digital transformation but also sustainable development in construction projects, particularly through material savings.

In the aspect of enhancing construction process management, Jiang et al. [23] introduced an intelligent modular integrated construction system enhanced with digital twin technology (DT-SMiCS). This system employs robotic demonstrations and cloud services to implement a redesigned on-site assembly process, enhancing building efficiency and sustainability through real-time data integration and remote control. Hussein et al. [61,62] along with Abdelmageed et al. [63] have contributed to the establishment and enhancement of simulation models, covering the future directions, benefits, and challenges, providing a comprehensive understanding of the application and impact of digital technologies in construction management. Franciosi et al. [44] explored how to effectively use digital twin technology to improve the sustainable performance of production activities and established a conceptual model outlining the key characteristics and framework for the application of these technologies in sustainable production. Moreover, Metallidou et al. [46] proposed a method to reduce industrial carbon emissions using the Industrial Internet of Things and digital twin technology, aiming to optimize manufacturing decisions and improve energy efficiency in industrial operations. Yang et al. [31] contributed to urban development by summarizing research on integrating digital twins with eco-friendly intelligent buildings. Similarly, Çetin et al. [64] investigated the implementation of circular economy concepts throughout the construction process. These studies collectively underscore the power of digital twins technology in enhancing construction and urban planning for sustainable development, directly aligning with the initial focus on improving construction process management through digital innovation.

In the aspect of optimizing on-site construction machinery (initial efforts in this domain by Jassim et al. [65,66]), Arocho et al. [67] laid the groundwork by quantifying construction emissions and developing mitigation strategies. Their methodologies leveraged neural networks and productivity-based estimation tools, setting a precedent for combining data-driven approaches with construction operations. Building on these foundational studies, Hajji et al. [68] further refined the estimation of construction emissions, emphasizing the role of accurate, AI-enhanced tools in developing effective mitigation strategies. In subsequent research in this direction, Zhang et al. [69] introduced a novel approach for recognizing construction equipment actions, integrating convolutional neural networks (CNNs) with long short-term memory (LSTM) networks. This method not only advanced the precision of monitoring but also opened new avenues for understanding and improving the sustainability of construction practices through more nuanced and dynamic data analysis. Furthermore, Wang et al. [70] proposed a novel framework based on heterogeneous graph convolutional networks and mechanical keypoints region-based convolutional neural network (RCNN), which effectively classifies earthwork activities in images containing multiple excavators and cooperative machinery. It demonstrates the potential applications of site monitoring in the management of earthwork productivity, as well as energy saving and emission reduction.

2.2. Operation and Maintenance Phase

During the entire life cycle of a building, the operation and maintenance phase typically generates the highest proportion of carbon emissions compared to other phases, leading to significant research value in monitoring and managing GHG. Its persistence and complexity lead to higher carbon emissions at this stage, attracting numerous researchers to contribute to this field. Meanwhile, buildings in this phase inherently involve substantial cost and risk management. Leveraging digital technology, some advanced concepts and methods can be more seamlessly integrated with digital twins, thereby promoting the sustainability of buildings.

The works of Zhao et al. [71], Kaewunruen et al. [72], Banfi et al. [73], and Agostinelli et al. [74] have been instrumental in visualizing and assessing Net-Zero Energy Building (NZEB) solutions. Their work confirms the potential of digital twins in enhancing the energy efficiency of buildings, pointing toward a sustainable architectural future. Following this thread, Arsiwala et al. [47] discussed the use of digital twin technology, combined with the IoT, BIM, and AI to monitor and control the carbon dioxide emissions of building assets, aiming for net-zero emissions. This approach aims to achieve net-zero emissions, showcasing a practical application of digital twins in mitigating environmental impact. Osunsanmi et al. [48] proposed a conceptual framework for Smart Maintenance (SM) based on digital twins, supporting the autonomous maintenance of infrastructure within the building environment, with a focus on optimizing energy-saving strategies. It represents a shift towards more autonomous, technology-driven maintenance practices that align with sustainability goals.

Adding another dimension to the discourse, studies by Yan et al. [75], Johannes et al. [76] and Ismail et al. [77] provide in-depth discussions from the aspects of architectural design, technical dimensions, and system integration. These works contribute to a comprehensive understanding of how various elements of building operation can be optimized for sustainability through digital twins, respectively. Studies in the domain of Cyber–Physical–Social System (CPSS) by Zhang et al. [50], Zeng et al. [51], and Zhou et al. [52] conducted systematic reviews to determine the development direction and bottlenecks of this field, paving the way for integrated solutions that consider technical, social, and environmental aspects. Additionally, combined with digital twins, Keskin and Mengüç [49] introduced a CPSS that reduces energy waste through innovative ventilation systems, exemplifying the potential of integrating digital twins with energy-saving innovations. Lastly, the potential for resilience management in green buildings as demonstrated by Achour et al. [78] and Rosa et al. [79] alongside Rotilio et al.’s [53] approach to leveraging digital twins for post-disaster reconstruction and routine management highlight the broader applications of digital technologies in ensuring sustainability. Waraga et al.’s [54] framework, which integrates digital twin technology with AI to predict energy demand accurately, reveals the potential of these technologies in achieving effective energy management and sustainable development.

These studies articulate a vision of a sustainable future for the building sector, marked by the innovative use of digital twins to monitor, manage, and reduce carbon emissions while enhancing energy efficiency and resilience.

2.3. Design, Renovation and Demolition Phases

These stages are often not considered critical for energy saving and emission reduction since they are typically not directly associated with carbon emissions. However, some scholars have still made significant contributions in these stages. For the design phase, Carvalho [80] proposed a BIM-based framework for optimizing Building Sustainability Assessment (BSA) methods, demonstrating the significant potential of BIM in directly and indirectly assessing the most sustainable building standards. Therefore, the technical contributions from the design phase involve greater standardization and systematization of data. Additionally, the quality and precision of data are relatively improved, laying the foundation for data collection, statistics, and analysis in subsequent phases.

During the renovation phase, Tang et al. [55] proposed the use of Vertical Greenery Systems (VGSs). They applied digital twins to simulate the construction methods and irrigation of VGS, enabling the visualization of the VGS construction process in old commercial and residential buildings. This approach helps in identifying the optimal energy-saving solutions. In the renovation and demolition phases, few people have discussed these two phases separately. Considering the long life cycle of buildings and the relatively late development of digital twins, there are few papers in this direction. Meanwhile, because carbon emissions in these phases are lower compared to other stages, the significance to sustainability is reduced, leading to a lack of digital twin applications. Additionally, the universality of construction site activities is notable. Considering that some structures do not generate, or only produce minimal carbon emissions once built (such as bridges, warehouses, etc.), research on carbon emissions in construction site activities can more effectively cover the vast majority of projects in the construction industry.

Overall, the current application of digital twins in the direction of energy saving and emission reduction is still limited. Although numerous studies highlighted the potential for sustainable development, researchers often overlook this field, investing more attention towards monitoring, managing and improving work efficiency and safety. This also means that the construction industry has not effectively combined sustainability with advanced digital technologies and continues to rely on traditional methods for energy conservation and emission reduction. The fundamental reason is the lack of a complete digital twin system in the construction industry, so it is impossible to integrate various functional parts. There are many factors that affect sustainability, such as increasing production efficiency and optimizing management policies, which can also reduce carbon emissions to a certain extent. When it is not possible to focus on the development of sustainable strategies due to some practical issues, integrating other objectives can also enhance the sustainability goals of the project. Therefore, a composite and comprehensive strategy can become a driver for sustainability.

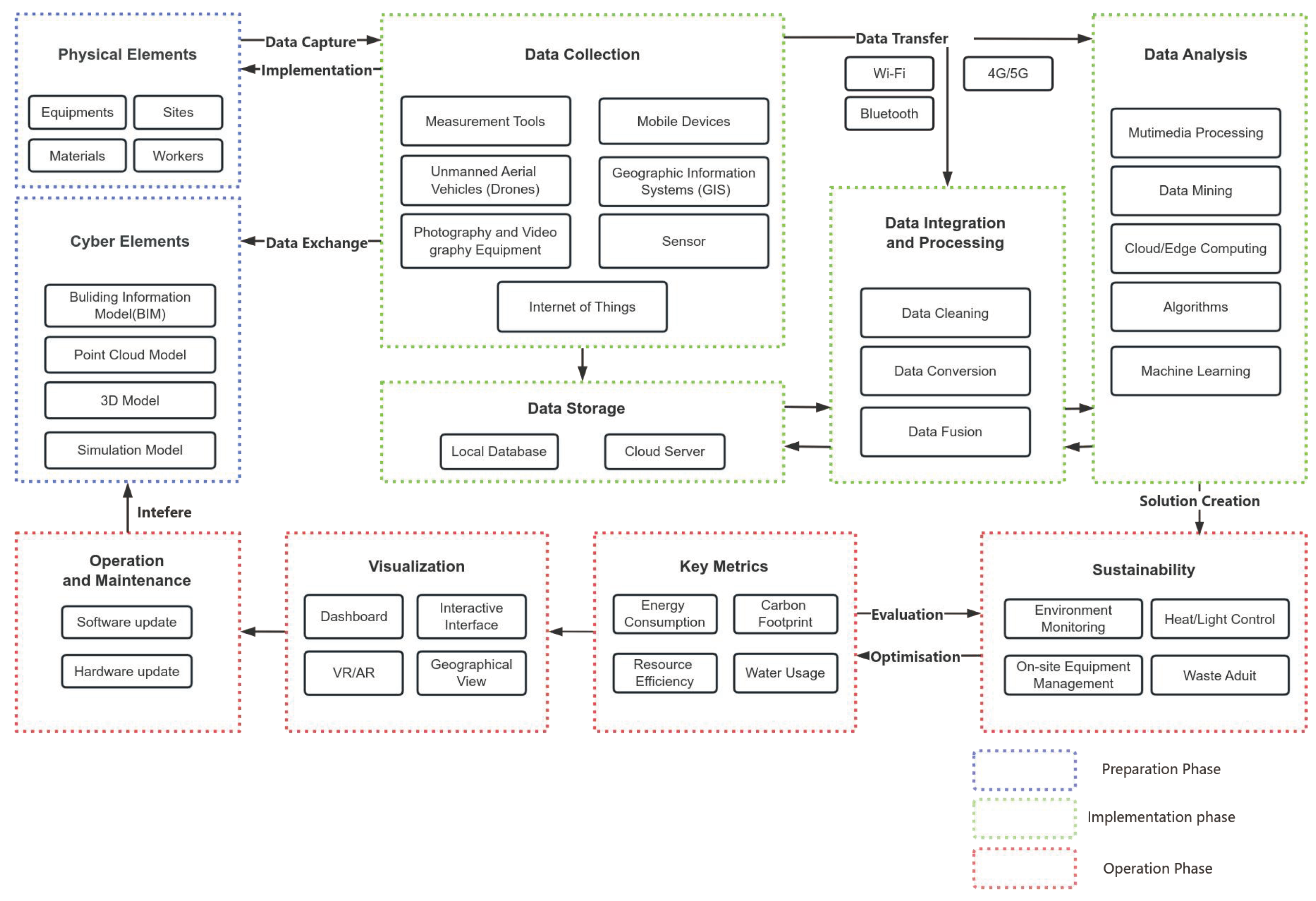

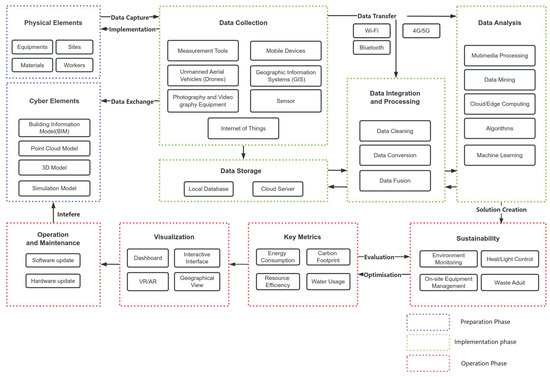

3. Framework and Proof-of-Concept Demo

We introduce a conceptual digital twins framework, which is aimed at helping scholars better understand the specific implementation process of digital twins, while pointing out the key elements in projects with sustainability as the main goal. Figure 4 displays this framework for the construction industry, starting from the preparation phase, which encompasses the physical elements in construction and their corresponding cyber elements, forming the foundation of digital twins. The implementation phase involves data collection, storage, integration, and data processing and data analysis, representing the most crucial component of the digital twin system. The operational phase covers the issues the system aims to resolve, the visual interactive interface, and the maintenance of the entire system. Each of these stages corresponds to different intricate digital technologies.

Figure 4.

Systematic flow of implementing digital twin system process and its key elements in the construction industry.

In projects where sustainability is the main objective, this universal conceptual framework can help end-users better deploy digital twin systems. In the preparation phase, digital models of equipment that generate carbon emissions are designed in advance, such as construction machinery, and heating and power supply equipment, essentially creating virtual models of relevant physical equipment based on the specific content of the project [36]. This step aids in gaining a clear overall understanding of the emissions-generating equipment before the construction, renovation, or demolition of the project, while also preparing for subsequent visual interactive processes.

During the deployment phase, the main focus is on data-related operations. Since the project’s main goal is sustainability, the primary target of data collection should be carbon emissions, carbon footprint, and status of the related emissions-generating equipment. Different types of sensors or monitoring devices are installed on various equipment, producing emissions to collect related data [81]. For example, gas sensors or thermal imaging devices can be used to count and monitor carbon emission concentrations, position sensors to collect the movement trajectories or positions of construction machinery, and devices to monitor the areas and times of buildings’ heating and power supply [82]. The collected data are usually stored in the cloud, and most cloud systems have advanced data pre-processing capabilities, which can help categorize, clean, transform, and integrate various types of data. Especially when facing different types of sensors and data, categorization is needed to support subsequent sustainable strategy generation [23]. In terms of data analysis, edge computing can process and feedback emission data information in real-time, and the system can generate basic optimization measures based on IoT-based data transmission. At the same time, optimization algorithms and machine learning technologies play a key role in this phase by analyzing historical and real-time data, predicting future trends, identifying inefficient areas, and proposing strategies to reduce carbon emissions [70]. In this way, the dynamic management of carbon emissions can be achieved, rather than just static recording and reporting. By deploying advanced control systems and automation technologies, the operating status of equipment can be automatically adjusted based on real-time or historical data and prediction models to optimize energy use efficiency, thereby reducing carbon emissions. For example, smart scheduling systems [83] can ensure that construction machinery and equipment operate at optimal times, reducing idle time, and smart building management systems [29] can automatically adjust heating and power supply demands based on the actual usage of buildings.

During the operation phase, the visualization platform is an important link. By combining virtual models, raw or pre-processed data, and IoT transmission, important carbon emission information can be intuitively displayed, helping end-users understand the overall status [84]. Moreover, visualization platforms make the understanding of complex data and models more intuitive and easier to comprehend, thereby improving the efficiency and effectiveness of decision-making. Using these platforms, project managers and other stakeholders can easily monitor carbon emission hotspots and assess the potential effects of different emission reduction measures. They can also integrate simulation and scenario analysis functions. This means that end-users can test different operational strategies in a virtual environment and assess their specific impact on carbon emissions without having to implement these strategies in the real world [85]. This “risk-free” testing environment is an ideal place to assess the impact of new technologies or process changes on sustainability goals, helping to drive innovation and optimize the project’s sustainability performance.

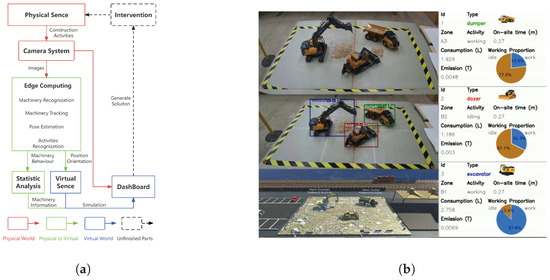

Figure 5 shows a demo of a digital shadow built by our team, simulating the collaborative work among construction machinery during the construction phase with its implication to sustainability, based on the proposed conceptual framework. Figure 5a shows the work flow of the whole system. This implementation includes data collection using cameras, 3D virtual model construction, AI-based data analysis, data transfer, and visualization in the overall process of digital twins. We collected visual data from an in-house construction site at a fixed position. Machinery recognition and tracking, pose detection and 3D coordinate calculation were carried out by machine learning algorithms deployed in edge computing devices [70]. Then, the extracted data were transmitted in real-time to a virtual scene created by Unity to achieve synchronization between reality and virtuality as illustrated in Figure 5b. Acting as a digital shadow (no feedback to reality yet), this system has successfully demonstrated the capability of monitoring carbon emissions and fuel consumption based on on-site activities, thereby formulating and implementing long-term energy-saving strategies in future. This demo validates the feasibility of certain aspects within the conceptual framework proposed in this paper, and, as a “semi-finished” digital twin, it aims to inspire other scholars with research ideas and directions for future development.

Figure 5.

A proof-of-concept digital shadow demo for construction machinery monitoring for sustainability. (a) The work flow of the whole system, where the solid line parts represent the completed sections of the digital shadow, while the dashed lines illustrate the uncompleted parts to enable a digital twin. (b) A snapshot of the dashboard of the digital shadow, where the left side shows the physical scene, machinery activities and corresponding mirroring in the virtual scene (from top to bottom), and the right side displays the implication of fuel consumption and emission estimation based on machinery activities.

4. Challenges and Opportunities

Despite the sparkle works at different stages in the entire construction life cycle, developing and implementing comprehensive digital twin systems in construction industries remains very limited, not to mention the establishment of standards or guidelines for energy saving and emission reduction. This is due to the challenges of industry practices, technical barriers, cost factors, etc., which are detailed below.

Before delving into specific discussions on the challenges and opportunities, it is important to understand the deployment process of digital twins, which involves various elements, technologies, and methods.

4.1. Complexity in Data Collection and Fusion

Real-time data collection/processing demands the extensive integration of sensors, processors, networks, and other devices [86]. Beyond potential compatibility issues among sensors produced by different manufacturers, integrating multi-modal data is a challenge. Sensor types encompass those for temperature [87], sound [88], and optics [89], based on different purposes. To overcome the challenges, Adaptive Middleware Solutions, similar to those used in the healthcare industry for integrating data from diverse medical devices and systems, can be employed [90]. These solutions facilitate the transformation and mapping of data formats, protocols, and standards from diverse sources, enabling cross-platform data integration, such as integrating and sharing sensor data with BIM model data on a unified platform [91].

The massive amount of industrial data generated from different sensors or data collection devices will face challenges in terms of storage. Qi et al. [92] highlighted the inability of traditional databases to manage the growing heterogeneity and volume of digital twin data originating from various sources. One of the potential solutions in this field is Federated Data Storage [93], which can manage data heterogeneity and volume efficiently by allowing different databases to retain their autonomy while operating under a unified schema.

Unique on-site conditions (like structural vibrations or extreme weather conditions) might affect the accuracy and stability of sensors [94]. The quality, integrity, and precision of data remain a persistent challenge since any inaccuracies could distort the digital twin model. Inspired by the aerospace industry, employing Advanced Calibration Techniques, where sensors undergo rigorous testing under simulated extreme conditions, can improve sensor accuracy and stability. This type of test usually requires a laboratory under normal circumstances, and its testing and subsequent improvement costs are relatively high. Apart from hardware, improving the software’s adaptation to extreme weather can also better calibrate data. Ashraf et al. [95] demonstrated the YOLOx model’s superior performance in detecting vehicles under adverse weather conditions, providing assistance in the model selection under special conditions.

Issues related to network bandwidth and security are also vital, especially in projects involving remote monitoring or multiple locations. Ensuring network [96] and data security requires considerations beyond just communication safety and data encryption during transit but also data storage and access security. Blockchain technology [97] might be utilized for ensuring data integrity and immutability, similar to its use in supply chain management for secure, transparent transactions.

Lastly, utilizing these data effectively necessitates advanced analytic tools and algorithms, along with expertise to interpret and apply these data, making the choice, training, and deployment of machine learning models crucial. For instance, employing deep learning networks to predict a building’s energy consumption [98,99] and operational states requires ensuring the accuracy, robustness, and real-time response of algorithms. Also, the design of machine learning-based algorithms should incorporate ethical and legal perspectives, which is necessary to achieve a trustworthy way to minimize human uncertainty.

4.2. Responsible AI

It is well accepted that AI is a key technique for building powerful digital twins systems. As AI increasingly enters the construction industry, building a trustworthy AI has become a challenge [100]. Firstly, AI systems are often seen as ’black boxes’, with decision-making processes lacking transparency. In the field of construction, design and construction decisions need to be explainable and verifiable, especially when simulating and predicting through digital twins [101]. It is crucial to consider the impact of these decisions, as they involve important factors, such as the lifespan of the building, safety, and energy efficiency. Therefore, explaining the operating modes and principles of the entire system to gain the trust and acceptance of stakeholders is a potential issue for AI. Moreover, the construction industry is limited to strict norms and standards (e.g., earthquake safety standards, energy efficiency and sustainability standards, and cultural and historical preservation standards) that vary by region or country [102]. Concurrently, considering the complexity of the construction industry as mentioned earlier, AI systems are required to comply with these diverse norms and adapt to the highly dynamic construction environment and projects to ensure compliance [103]. However, currently, the maturity level of existing digital twin systems is relatively low. They are usually focused on solving different specific problems, and industry standards are not in place yet, making it difficult to integrate with specific standards in various regions.

4.3. Real-Time System Updating

Projects in the construction industry vary significantly, with each having its uniqueness. The primary technical challenge is how to establish and update virtual models (e.g., digital twins, Building Information Modeling) in real-time [104,105]. It is challenging to find general designs or products in construction, making the replication and updating of digital twin systems more complicated. This means that every new project requires building and implementing a specific digital twin from scratch, evidently raising the cost and complexity.

Techniques such as point cloud [106] or 3D scanning technologies [107] can be used to capture the actual on-site conditions, and then compare and adjust them against the physical model (such as specific equipment and machinery, dynamically changing environment and construction progress). Concurrently, the constructed 3D model must accurately reflect the state of the actual construction [108]. The quality and accuracy of data are crucial for accurate predictions and analysis. This phase tests the project team’s ability to produce high-quality model constructions and real-time imaging, necessitating that initial design plans be preserved and organized to best integrate with 3D modeling services for the digital twin system. Moreover, for older buildings wishing to adopt the digital twin framework, original design data might be unavailable or outdated, requiring prompt corrections and modifications [109].

Recently, generative AIs (e.g., large language models—LLMs) have been integrated into the building and updating of digital twins for drug delivery [110], wireless communications [111], 3D model reconstruction [112], etc. Leveraging the advantages of fast multi-modal data processing, LLM shows great potential to achieve system real-time updating. However, there are still unsolved questions on how to design case-specific prompts for, for example, suggesting eco-friendly materials, optimizing building parameters, or proposing innovative technologies [37,113], in response to real-time environmental changes.

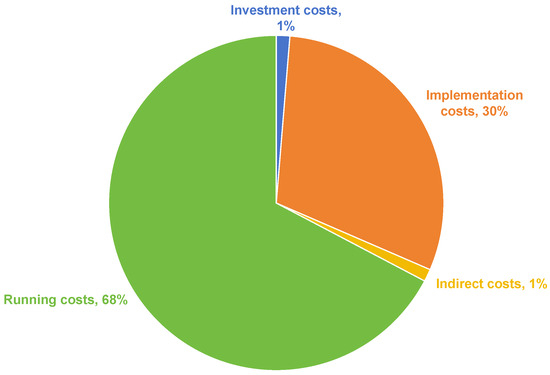

4.4. Cost Factors

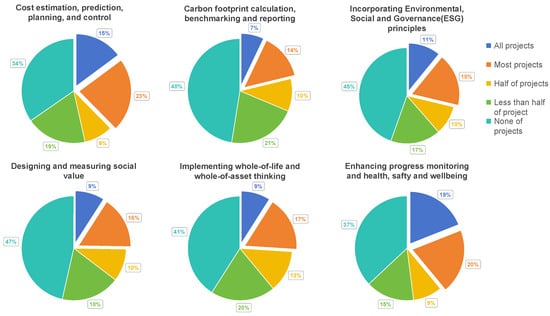

The cost of implementing digital twins varies at different stages in the whole life cycle. Oettl et al. [114] designed a method to predict these costs, considering the company’s current digital level and past digital achievements to achieve more accurate predictions, verified through a case study. Although there are significant differences between different projects and varying levels of digitalization, it can still provide some insights. Figure 6 displays the predicted results of a manufacturing company setting up a product system material flow [114], indicating that the running costs in digital twin systems are the highest, while the implementation cost is the second highest.

Figure 6.

Estimated cost of building digital twin systems for an industry use case.

The high cost of implementing digital twins in the construction field manifests itself in many aspects. First, the initial investment cost is extremely high: creating a digital twin requires significant investment in hardware, software, data collection, processing, and storage equipment [115]. For example, to build a high-quality digital twin system, it is usually necessary to purchase and maintain high-performance servers, cloud storage space, and data processing capabilities to ensure the real-time and accurate transmission and analysis of data [116]. Certainly, the expense involved in operating a high-performance graphics processing unit (GPU), which is essential for running machine learning algorithms, can range from $1000 to $10,000 [117]. Secondly, the labor cost is equally substantial: engineers, data scientists, IT experts, and other related personnel with professional skills need to be hired to develop, operate, and maintain digital twin systems [118,119]. At the same time, these professionals often require continuous training and learning to keep up with rapid changes and upgrades in technology. Third, the costs of data collection cannot be ignored: in order to accurately simulate various situations of physical buildings, many sensors and monitoring equipment must be installed and ensure their stable operation under various environmental conditions, which also requires a large amount of investment [105]. Fourth, a large amount of investment is also required in data security and privacy protection (network security protection, backup and recovery, etc.) [120]. In addition, the selection and development of software platforms, the purchase and ongoing payment of cloud services [121], frequent and rapid technology updates, as well as technical difficulties and unforeseen problems that may be encountered during the implementation process will all bring additional expenses [122] and delay risk. Table 2 shows the common digital twin-related software and their costs, we can clearly see that for medium-sized or smaller enterprises, the cost of deploying all the software is very high.

Table 2.

Some common digital twin-related software and their costs [117].

When discussing the high cost of digital twins, one has to consider the construction industry’s low-profit margins, usually between 2% and 5% [123]. On one hand, practitioners within this sector might hesitate to invest significant resources (money, time, and manpower) into digital twin systems given these slim profit margins. On the other hand, digital twins could potentially act as a breakthrough to drive an increase in profit margins. However, according to the Digitalization in Construction report released by the Royal Institution of Chartered Surveyors (RICS) in 2023 [18], practitioners are trying to improve, but progress is slow, and the overall attitude tends to be negative. Therefore, how to reduce the implementation cost of digital twins becomes a key point of future research. Currently, very few researchers have discussed this issue. For the future direction, researchers should carry out some extensive cost–benefit analyses or construct cost models, which can encompass factors influencing the cost of digital twins, essential pre-adoption considerations, and guidelines for implementing digital twins in construction projects.

Due to the high cost of research, development, and implementation of digital twins, small- and medium-sized enterprises (SMEs) may find it difficult to effectively utilize this technology to meet their own needs [124]. Despite these challenges, by adopting a strategic approach, SMEs can still leverage digital twin technology. These enterprises can start with small-scale projects to gradually familiarize themselves and expand the application scope of the digital twin technology, while seeking partnerships with technology providers, universities, or companies that have adopted digital twin technology to gain access to technical resources and expertise, and alleviate financial burdens through cost-sharing [125]. Moreover, SMEs can consider using open-source platforms and cost-effective digital twin solutions, focusing on application areas that can deliver immediate value, such as project management, real-time monitoring, and maintenance planning. By demonstrating rapid returns and tangible benefits, SMEs can provide economic justification for broader implementation efforts [126]. By following these methods, SMEs can not only enhance their competitiveness in the construction industry but also improve project efficiency, sustainability, and quality, then make full use of limited resources to meet needs.

4.5. Data Privacy and Security

Digital twins involve creating highly accurate digital replicas of physical assets, necessitating the collection of sensitive data, including material usage, structural details, and personal information, thereby raising concerns over privacy [127]. Moreover, the interconnected nature of digital twins makes them susceptible to cyber attacks, with unauthorized access potentially leading to theft of proprietary information, data tampering, or ransomware attacks [128]. The protection of intellectual property becomes a concern as well, with the proprietary designs and technologies within a digital twin facing the risk of theft. Additionally, the global nature of the construction industry means that digital twins must adhere to various national and regional data protection laws and regulations, such as GDPR in Europe or CCPA in USA, posing challenges for ensuring compliance [129].

To mitigate these risks, a series of measures is recommended, and it includes the following:

- Implementing robust cyber security measures, including data encryption [130], regular security audits [101], and blockchain [131] for data integrity.

- Adopting data minimization and anonymization techniques to collect only the necessary data for the digital twin and further reduce privacy risks through anonymization.

- Applying digital rights management (DRM) and other technologies to protect intellectual property, ensuring that proprietary designs and technologies within the digital twin are not misappropriated [47].

- Developing a strict compliance framework to adhere to international data protection laws and regulations, with regular audits and updates for compliance.

- Introducing ethical guidelines and standards to raise awareness among all participants about the importance of data privacy, security, and ethical considerations.

- Establishing a comprehensive incident response plan to swiftly address data breaches or cyber attacks, mitigate damage, and communicate transparently with affected parties [132].

Through all these measures, the construction industry can alleviate security risks to a certain extent.

4.6. Future Research Opportunities

To advance digital twin technology in the construction sector, breakthroughs in key technological areas such as data collection and integration [91], advanced modeling and simulation [43], as well as augmented reality (AR) [133] and virtual reality (VR) [134] are essential. Efficient data collection technologies enable the real-time gathering of data on the built environment and its performance, which forms the foundation for creating comprehensive digital twin models. Additionally, leveraging advanced computational methods such as Finite Element Analysis (FEA) [135] and Computational Fluid Dynamics (CFD) [136] can enhance the accuracy and predictive capabilities of models. The application of AR and VR technologies allows engineers and decision makers to interact with models in unprecedented ways through immersive visualization tools, further improving the efficiency of design, planning, and complex analyses.

Research in AI and machine learning is equally crucial for optimizing and expanding digital twin technologies [137]. AI can automate the processing and analysis of vast amounts of data, identifying performance indicators and potential issues. Machine learning models’ capabilities for predictive maintenance and fault detection can anticipate equipment failures and performance declines by analyzing historical and real-time data [138]. Furthermore, the application of AI technologies in optimizing architectural design and operational strategies not only increases energy efficiency and reduces costs but also enhances the end-user experience. As these technologies continue to develop and integrate, the application of digital twins in the construction field will become more widespread and effective.

5. Conclusions

This paper provided a thorough review of the existing digital twin research and applications for sustainability in the construction industry. A conceptual framework of digital twins deployment is proposed to support the discussion of challenges and opportunities. It is revealed and demonstrated that digital twins have the potential to improve the sustainable development capabilities of project engineering, but their implementation faces challenges from industry norms (complexity, tradition, and uniqueness), technical barriers, and cost factors.

Despite the great potential of digital twins in the construction industry, we also mentioned issues related to technical or cost barriers, as well as non-technical issues that need further exploration. Since the digital twins technology is still in its infancy in this industry, the absence of standardized practices and specifications adds difficulty to its promotion and application [139]. Currently, some industry alliances and standard organizations have started to promote the standardization of digital twin technology. For instance, Digital Twin Consortium (DTC) [140] is dedicated to developing best practices, reference architectures, and standards for digital twin technology. Meanwhile, there are ongoing efforts to develop international standards for digital twins, including work by the International Organization for Standardization (ISO) [139] and ASTM International [141]. Furthermore, within Industry 4.0, aimed at the digital transformation of manufacturing, several global smart city initiatives are working towards standardizing digital twin technologies to fulfill their broader goals of enhancing manufacturing efficiency, urban planning, management, and sustainability efforts [142].

A major issue highlighted in many industry interviews [119] is that the investment in digital twins does not seem to yield proportional returns. On one hand, professionals prefer investing their time and money in methods that boost production efficiency, their highest priority being to increase profit margins. On the other hand, they still rely on traditional, non-technical methods for sustainable development, which are effective to some extent while also reducing costs for energy conservation and emission reduction. As digital twins and related technologies evolve, along with the unavoidable trend of digitalization, the construction industry is expected to increasingly depend on digital technologies for sustainable growth. Future research might mainly focus on developing and deploying cost-effective digital twin technologies to meet the real-world needs of these professionals.

It is also important to note the complexity involved in carbon emission sources and the many factors that affect emissions, making it challenging to set up a digital twin-based carbon emission monitoring system covering the entire life cycle. Research in other areas, like improving production efficiency [134,143] and management [30,144], could also positively impact carbon emission reduction. Although energy conservation and emission reduction were not the primary objectives in these studies, the experimental results of some research indeed have had a positive impact on low-carbon environmental protection. In other words, these studies inadvertently achieved optimization in energy saving and emission reduction. Therefore, functional expansion based on existing technologies can be considered one of the future development directions. By utilizing relevant management or productivity technologies, their impact on low-carbon initiatives can be assessed and further developed. Given the existing technological achievements, costs can be saved to a certain extent, making stakeholders more likely to invest in and develop these technologies.

However, we must face a problem: the construction and operation of a digital twin system itself also generates carbon emissions, which may come from the installation and operation of equipment, as well as data collection, processing, and storage. Carbon emissions produced in these processes are extremely difficult to quantify. Therefore, comparing the carbon emissions of the system itself with the energy-saving benefits it brings is a critical issue. Currently, there are almost no papers that have explored this aspect.

Additionally, it is encouraging to see that some scholars have already made considerable contributions to reducing energy consumption and emissions through digital twin technology. The review section of this article primarily discusses technologies strongly related to digital twins. Although these technologies essentially only integrate digital twin technology rather than constructing a complete digital twin system, they can already be considered individual components within the larger framework of digital twin technology. There has been substantial research in building individual components of a digital twin system, and future work is likely to involve more comprehensive and cross-platform data integration to form a complete system for monitoring and optimizing carbon emissions.

Author Contributions

Conceptualization, Z.Z.; Formal analysis, Z.Z; Funding acquisition, Y.Z.; Investigation, Z.Z.; Methodology, Z.Z.; Project administration, Y.Z.; Supervision, S.C. and Y.Z.; Validation, Z.W., L.Y., S.W. and A.T.; Writing—original draft, Z.Z.; Writing—review & editing, Z.Z., Z.W., S.C., L.Y. and Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Royal Academy of Engineering Industrial Fellowship [grant IF2223B-110].

Data Availability Statement

No new data were created.

Conflicts of Interest

Author Arjun Thirunavukarasu was employed by the company BAM Nuttall. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Mohd Nawi, M.N.; Baluch, N.H.; Bahaudin, A.Y. Impact of fragmentation issue in construction industry: An overview. In Proceedings of the MATEC Web of Conferences, Agadir, Morocco, 19–21 May 2014; EDP Sciences: Les Ulis, France, 2014; Volume 15, p. 01009. [Google Scholar]

- Hussin, J.M.; Rahman, I.A.; Memon, A.H. The way forward in sustainable construction: Issues and challenges. Int. J. Adv. Appl. Sci. 2013, 2, 15–24. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Khan, M.A.; Khan, M.Z.; Zaman, K.; Naz, L. Global estimates of energy consumption and greenhouse gas emissions. Renew. Sustain. Energy Rev. 2014, 29, 336–344. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Abegaz, K.A. Embodied Energy and CO2 Emissions of Widely Used Building Materials: The Ethiopian Context. Buildings 2019, 9, 136. [Google Scholar] [CrossRef]

- Bernstein, D.J.; Lange, T. Post-quantum cryptography. Nature 2017, 549, 188–194. [Google Scholar] [CrossRef] [PubMed]

- Caney, S. Climate change. In The Routledge Handbook of Global Ethics; Routledge: London, UK, 2015; pp. 384–398. [Google Scholar]

- Rogelj, J.; Popp, A.; Calvin, K.V.; Luderer, G.; Emmerling, J.; Gernaat, D.; Fujimori, S.; Strefler, J.; Hasegawa, T.; Marangoni, G.; et al. Scenarios towards limiting global mean temperature increase below 1.5 C. Nat. Clim. Change 2018, 8, 325–332. [Google Scholar] [CrossRef]

- Hossain, M.A.; Nadeem, A. Towards digitizing the construction industry: State of the art of construction 4.0. In Proceedings of the ISEC, Jeddah, Saudi Arabia, 19–20 January 2019; Volume 10, pp. 1–6. [Google Scholar]

- Maraveas, C.; Bartzanas, T. Application of Internet of Things (IoT) for optimized greenhouse environments. AgriEngineering 2021, 3, 954–970. [Google Scholar] [CrossRef]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.D.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Omrany, H.; Al-Obaidi, K.M.; Husain, A.; Ghaffarianhoseini, A. Digital twins in the construction industry: A comprehensive review of current implementations, enabling technologies, and future directions. Sustainability 2023, 15, 10908. [Google Scholar] [CrossRef]

- Jiang, Y.; Yin, S.; Li, K.; Luo, H.; Kaynak, O. Industrial applications of digital twins. Philos. Trans. R. Soc. A 2021, 379, 20200360. [Google Scholar] [CrossRef] [PubMed]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. Ifac-PapersOnline 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Alazab, M.; Khan, L.U.; Koppu, S.; Ramu, S.P.; Iyapparaja, M.; Boobalan, P.; Baker, T.; Maddikunta, P.K.R.; Gadekallu, T.R.; Aljuhani, A. Digital twins for healthcare 4.0-recent advances, architecture, and open challenges. IEEE Consum. Electron. Mag. 2022, 12, 29–37. [Google Scholar] [CrossRef]

- Ketzler, B.; Naserentin, V.; Latino, F.; Zangelidis, C.; Thuvander, L.; Logg, A. Digital twins for cities: A state of the art review. Built Environ. 2020, 46, 547–573. [Google Scholar] [CrossRef]

- Ammar, A.; Nassereddine, H.; AbdulBaky, N.; AbouKansour, A.; Tannoury, J.; Urban, H.; Schranz, C. Digital twins in the construction industry: A perspective of practitioners and building authority. Front. Built Environ. 2022, 8, 834671. [Google Scholar] [CrossRef]

- Sawhney, A.; Andrew Knight, S.B. RICS Digitalisation in Construction Report 2023; RICS: London, UK, 2023. [Google Scholar]

- Yitmen, I.; Alizadehsalehi, S.; Akıner, İ.; Akıner, M.E. An adapted model of cognitive digital twins for building lifecycle management. Appl. Sci. 2021, 11, 4276. [Google Scholar] [CrossRef]

- Kineber, A.F.; Singh, A.K.; Fazeli, A.; Mohandes, S.R.; Cheung, C.; Arashpour, M.; Ejohwomu, O.; Zayed, T. Modelling the relationship between digital twins implementation barriers and sustainability pillars: Insights from building and construction sector. Sustain. Cities Soc. 2023, 99, 104930. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean practices using building information modeling (Bim) and digital twinning for sustainable construction. Sustainability 2020, 13, 161. [Google Scholar] [CrossRef]

- Shahzad, M.; Shafiq, M.T.; Douglas, D.; Kassem, M. Digital twins in built environments: An investigation of the characteristics, applications, and challenges. Buildings 2022, 12, 120. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Guo, D.; Wu, W.; Zhong, R.Y.; Huang, G.Q. Digital twin-enabled smart modular integrated construction system for on-site assembly. Comput. Ind. 2022, 136, 103594. [Google Scholar] [CrossRef]

- Tzachor, A.; Sabri, S.; Richards, C.E.; Rajabifard, A.; Acuto, M. Potential and limitations of digital twins to achieve the sustainable development goals. Nat. Sustain. 2022, 5, 822–829. [Google Scholar] [CrossRef]

- Taqi, M.; Mohsin, I.; Khan, I.H. A Study into Sustainable Ethical Business Practices of CPG (Consumer Packaged Goods) Companies. Int. J. Spec. Educ. 2022, 37, 5418. [Google Scholar]

- Rojek, I.; Mikołajewski, D.; Dostatni, E. Digital twins in product lifecycle for sustainability in manufacturing and maintenance. Appl. Sci. 2020, 11, 31. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Zhou, J. Enhancing environmental sustainability over building life cycles through green BIM: A review. Autom. Constr. 2015, 57, 156–165. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.; Kamat, V.R. From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry. J. Inf. Technol. Constr. 2021, 26, 58–83. [Google Scholar] [CrossRef]

- Petri, I.; Rezgui, Y.; Ghoroghi, A.; Alzahrani, A. Digital twins for performance management in the built environment. J. Ind. Inf. Integr. 2023, 33, 100445. [Google Scholar] [CrossRef]

- Yang, B.; Lv, Z.; Wang, F. Digital twins for intelligent green buildings. Buildings 2022, 12, 856. [Google Scholar] [CrossRef]

- Baghalzadeh Shishehgarkhaneh, M.; Keivani, A.; Moehler, R.C.; Jelodari, N.; Roshdi Laleh, S. Internet of Things (IoT), Building Information Modeling (BIM), and Digital Twin (DT) in construction industry: A review, bibliometric, and network analysis. Buildings 2022, 12, 1503. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Li, L.; Aslam, S.; Wileman, A.; Perinpanayagam, S. Digital twin in aerospace industry: A gentle introduction. IEEE Access 2021, 10, 9543–9562. [Google Scholar] [CrossRef]

- Phanden, R.K.; Sharma, P.; Dubey, A. A review on simulation in digital twin for aerospace, manufacturing and robotics. Mater. Today Proc. 2021, 38, 174–178. [Google Scholar]

- Zhang, J.; Cheng, J.C.; Chen, W.; Chen, K. Digital twins for construction sites: Concepts, LoD definition, and applications. J. Manag. Eng. 2022, 38, 04021094. [Google Scholar] [CrossRef]

- Zamfirescu-Pereira, J.; Wong, R.Y.; Hartmann, B.; Yang, Q. Why Johnny Can’t Prompt: How Non-AI Experts Try (and Fail) to Design LLM Prompts. In Proceedings of the 2023 CHI Conference on Human Factors in Computing Systems, New York, NY, USA, 23–28 April 2023. CHI ’23. [Google Scholar]

- Peng, C. Calculation of a building’s life cycle carbon emissions based on Ecotect and building information modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- Fan, H. A critical review and analysis of construction equipment emission factors. Procedia Eng. 2017, 196, 351–358. [Google Scholar] [CrossRef]

- World Green Building Council. Bringing Embodied Carbon Upfront; World Green Building Council: Toronto, ON, Canada, 2019. [Google Scholar]

- Boje, C.; Menacho, Á.J.H.; Marvuglia, A.; Benetto, E.; Kubicki, S.; Schaubroeck, T.; Gutiérrez, T.N. A framework using BIM and digital twins in facilitating LCSA for buildings. J. Build. Eng. 2023, 76, 107232. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Lian, Q. Digital twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Wang, Y.; Aslani, F.; Dyskin, A.; Pasternak, E. Digital Twin Applications in 3D Concrete Printing. Sustainability 2023, 15, 2124. [Google Scholar] [CrossRef]

- Franciosi, C.; Miranda, S.; Resende Veneroso, C.; Riemma, S. Exploring the Digital Twin implementation for sustainable production. In Proceedings of the Summer School Francesco Turco, Sanremo, Italy, 7–9 September 2022. [Google Scholar]

- Mêda, P.; Calvetti, D.; Sousa, H. Exploring the Potential of iPad-LiDAR Technology for Building Renovation Diagnosis: A Case Study. Buildings 2023, 13, 456. [Google Scholar] [CrossRef]

- Metallidou, C.; Psannis, K.; Vergados, D.; Dossis, M. Digital Twin and Industrial Internet of Things Architecture to Reduce Carbon Emissions. In Proceedings of the 2022 4th International Conference on Computer Communication and the Internet, ICCCI 2022, Chiba, Japan, 1–3 July 2022; pp. 185–189. [Google Scholar]

- Arsiwala, A.; Elghaish, F.; Zoher, M. Digital twin with Machine learning for predictive monitoring of CO2 equivalent from existing buildings. Energy Build. 2023, 284, 112851. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Okafor, C.C.; Aigbavboa, C.O. Critical success factors for implementing smart maintenance in the fourth industrial revolution era: A bibliometric analysis within the built environment. J. Facil. Manag. 2023. [Google Scholar] [CrossRef]

- Keskin, C.; Mengüç, M.P. An Adaptive Vent System for Localized and Customized Thermal Management in Buildings. J. Heat Transf. 2020, 142, 052903. Available online: http://arxiv.org/abs/https://asmedigitalcollection.asme.org/heattransfer/article-pdf/142/5/052903/6516449/ht_142_05_052903.pdf (accessed on 17 December 2023). [CrossRef]

- Zhang, J.J.; Wang, F.Y.; Wang, X.; Xiong, G.; Zhu, F.; Lv, Y.; Hou, J.; Han, S.; Yuan, Y.; Lu, Q.; et al. Cyber-physical-social systems: The state of the art and perspectives. IEEE Trans. Comput. Soc. Syst. 2018, 5, 829–840. [Google Scholar] [CrossRef]

- Zeng, J.; Yang, L.T.; Lin, M.; Ning, H.; Ma, J. A survey: Cyber-physical-social systems and their system-level design methodology. Future Gener. Comput. Syst. 2020, 105, 1028–1042. [Google Scholar] [CrossRef]

- Zhou, Y.; Yu, F.R.; Chen, J.; Kuo, Y. Cyber-physical-social systems: A state-of-the-art survey, challenges and opportunities. IEEE Commun. Surv. Tutor. 2019, 22, 389–425. [Google Scholar] [CrossRef]

- Rotilio, M.; Villa, V.; Corneli, A. Digital Twin for a resilient management of the built environment. In Proceedings of the 2023 IEEE International Workshop on Metrology for Living Environment, MetroLivEnv 2023—Proceedings, Milano, Italy, 29–31 May 2023; pp. 113–117. [Google Scholar]

- Waraga, O.A.; Talib, M.A.; Bettayeb, M.; Ghenai, C.; Nasir, Q. A Framework Application for Improving Energy Demand Forecasting Using Digital Twining. IET Conf. Proc. 2021, 2021, 95–105. [Google Scholar]

- Tang, Y.; Gao, F.; Wang, C.; Huang, M.M.; Wu, M.; Li, H.; Li, Z. Vertical Greenery System (VGS) Renovation for Sustainable Arcade-Housing: Building Energy Efficiency Analysis Based on Digital Twin. Sustainability 2023, 15, 2310. [Google Scholar] [CrossRef]

- Muleski, G.E.; Cowherd, C., Jr.; Kinsey, J.S. Particulate emissions from construction activities. J. Air Waste Manag. Assoc. 2005, 55, 772–783. [Google Scholar] [CrossRef] [PubMed]

- Hao, J.L.; Cheng, B.; Lu, W.; Xu, J.; Wang, J.; Bu, W.; Guo, Z. Carbon emission reduction in prefabrication construction during materialization stage: A BIM-based life-cycle assessment approach. Sci. Total Environ. 2020, 723, 137870. [Google Scholar] [CrossRef] [PubMed]

- Li, C.Z.; Chen, Z.; Xue, F.; Kong, X.T.R.; Xiao, B.; Lai, X.; Zhao, Y. A blockchain- and IoT-based smart product-service system for the sustainability of prefabricated housing construction. J. Clean. Prod. 2021, 286, 125391. [Google Scholar] [CrossRef]

- Liu, G.; Yang, H.; Fu, Y.; Mao, C.; Xu, P.; Hong, J.; Li, R. Cyber-physical system-based real-time monitoring and visualization of greenhouse gas emissions of prefabricated construction. J. Clean. Prod. 2020, 246, 119059. [Google Scholar] [CrossRef]

- Liu, G.; Chen, R.; Xu, P.; Fu, Y.; Mao, C.; Hong, J. Real-time carbon emission monitoring in prefabricated construction. Autom. Constr. 2020, 110, 102945. [Google Scholar] [CrossRef]

- Hussein, M.; Darko, A.; Eltoukhy, A.E.; Zayed, T. Sustainable logistics planning in modular integrated construction using multimethod simulation and Taguchi approach. J. Constr. Eng. Manag. 2022, 148, 04022022. [Google Scholar] [CrossRef]

- Tsz Wai, C.; Wai Yi, P.; Ibrahim Olanrewaju, O.; Abdelmageed, S.; Hussein, M.; Tariq, S.; Zayed, T. A critical analysis of benefits and challenges of implementing modular integrated construction. Int. J. Constr. Manag. 2023, 23, 656–668. [Google Scholar] [CrossRef]

- Abdelmageed, S.; Zayed, T. A study of literature in modular integrated construction-Critical review and future directions. J. Clean. Prod. 2020, 277, 124044. [Google Scholar] [CrossRef]

- Çetin, S.; Gruis, V.; Straub, A. Digitalization for a circular economy in the building industry: Multiple-case study of Dutch social housing organizations. Resour. Conserv. Recycl. Adv. 2022, 15, 200110. [Google Scholar] [CrossRef]

- Jassim, H.S.; Lu, W.; Olofsson, T. Predicting energy consumption and CO2 emissions of excavators in earthwork operations: An artificial neural network model. Sustainability 2017, 9, 1257. [Google Scholar] [CrossRef]

- Jassim, H.S.; Lu, W.; Olofsson, T. Quantification of energy consumption and carbon dioxide emissions during excavator operations. In Proceedings of the Workshop of the European Group for Intelligent Computing in Engineering, Lausanne, Switzerland, 10–13 June 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 431–453. [Google Scholar]

- Arocho, I.; Rasdorf, W.; Hummer, J. Methodology to forecast the emissions from construction equipment for a transportation construction project. In Proceedings of the Construction Research Congress 2014: Construction in a Global Network, Atlanta, GA, USA, 19–21 May 2014; pp. 554–563. [Google Scholar]

- Hajji, A.M.; Lewis, M.P. How to estimate green house gas (GHG) emissions from an excavator by using CAT’s performance chart. In Proceedings of the AIP Conference Proceedings, East Java, Indonesia, 8–9 August 2017; AIP Publishing: Melville, NY, USA, 2017; Volume 1887. [Google Scholar]

- Zhang, J.; Zi, L.; Hou, Y.; Wang, M.; Jiang, W.; Deng, D. A Deep Learning-Based Approach to Enable Action Recognition for Construction Equipment. Adv. Civ. Eng. 2020, 2020, 8812928. [Google Scholar] [CrossRef]

- Wang, S.; Yang, L.; Zhang, Z.; Zhao, Y. Keypoints-based Heterogeneous Graph Convolutional Networks for construction. Expert Syst. Appl. 2024, 237, 121525. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, H.; Wang, Q.; Wang, H. Digital-Twin-Based Evaluation of Nearly Zero-Energy Building for Existing Buildings Based on Scan-to-BIM. Adv. Civ. Eng. 2021, 2021, 6638897. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Rungskunroch, P.; Welsh, J. A Digital-Twin Evaluation of Net Zero Energy Building for Existing Buildings. Sustainability 2019, 11, 159. [Google Scholar] [CrossRef]

- Banfi, F.; Brumana, R.; Salvalai, G.; Previtali, M. Digital Twin and Cloud BIM-XR Platform Development: From Scan-to-BIM-to-DT Process to a 4D Multi-User Live App to Improve Building Comfort, Efficiency and Costs. Energies 2022, 15, 4497. [Google Scholar] [CrossRef]

- Agostinelli, S.; Cumo, F.; Guidi, G.; Tomazzoli, C. Cyber-Physical Systems Improving Building Energy Management: Digital Twin and Artificial Intelligence. Energies 2021, 14, 2338. [Google Scholar] [CrossRef]

- Yan, K.; Zhou, X.; Yang, B. Editorial: AI and IoT applications of smart buildings and smart environment design, construction and maintenance. Build. Environ. 2023, 229, 109968. [Google Scholar] [CrossRef]

- Johannes, K.; Theodorus Voordijk, J.; Marias Adriaanse, A.; Aranda-Mena, G. Identifying maturity dimensions for smart maintenance management of constructed assets: A multiple case study. J. Constr. Eng. Manag. 2021, 147, 05021007. [Google Scholar] [CrossRef]

- Ismail, Z.A. Maintenance management practices for green building projects: Towards hybrid BIM system. Smart Sustain. Built Environ. 2021, 10, 616–630. [Google Scholar] [CrossRef]

- Achour, N.; Pantzartzis, E.; Pascale, F.; Price, A.D. Integration of resilience and sustainability: From theory to application. Int. J. Disaster Resil. Built Environ. 2015, 6, 347–362. [Google Scholar] [CrossRef]

- Rosa, L.V.; França, J.E.; Haddad, A.N.; Carvalho, P.V. A resilience engineering approach for sustainable safety in green construction. J. Sustain. Dev. Energy Water Environ. Syst. 2017, 5, 480–495. [Google Scholar] [CrossRef]

- Carvalho, J.P.; Bragança, L.; Mateus, R. Optimising building sustainability assessment using BIM. Autom. Constr. 2019, 102, 170–182. [Google Scholar] [CrossRef]

- Segovia, M.; Garcia-Alfaro, J. Design, modeling and implementation of digital twins. Sensors 2022, 22, 5396. [Google Scholar] [CrossRef] [PubMed]

- Talmaki, S.A.; Kamat, V.R. Sensor acquisition and allocation for real-time monitoring of articulated construction equipment in digital twins. Sensors 2022, 22, 7635. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wu, Z. Model construction of planning and scheduling system based on digital twin. Int. J. Adv. Manuf. Technol. 2020, 109, 2189–2203. [Google Scholar] [CrossRef]

- Tuhaise, V.V.; Tah, J.H.M.; Abanda, F.H. Technologies for digital twin applications in construction. Autom. Constr. 2023, 152, 104931. [Google Scholar] [CrossRef]

- Al-Sehrawy, R.; Kumar, B. Digital twins in architecture, engineering, construction and operations. A brief review and analysis. In Proceedings of the 18th International Conference on Computing in Civil and Building Engineering: ICCCBE 2020, São Paulo, Brazil, 18–20 August 2020; Springer: Berlin/Heidelberg, Germany, 2021; pp. 924–939. [Google Scholar]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Shah, K.; Prabhakar, T.; Sarweshkumar, C.; Abhishek, S. Construction of a digital twin framework using free and open-source software programs. IEEE Internet Comput. 2021, 26, 50–59. [Google Scholar] [CrossRef]

- Babazadeh, N.; Teizer, J.; Bargstädt, H.J.; Melzner, J. Digital Twin for Control of Noise Emissions from Heavy Equipment on Construction Sites. In Proceedings of the CIB W099 & W123 Annual International Conference: Digital Transformation of Health and Safety in Construction, Porto, Portugal, 21–22 June 2023; pp. 211–221. [Google Scholar]

- Zou, R.; Liang, X.; Chen, Q.; Wang, M.; Zaghloul, M.A.; Lan, H.; Buric, M.P.; Ohodnicki, P.R.; Chorpening, B.; To, A.C.; et al. A digital twin approach to study additive manufacturing processing using embedded optical fiber sensors and numerical modeling. J. Light. Technol. 2020, 38, 6402–6411. [Google Scholar] [CrossRef]