Tensile Mechanical and Stress-Strain Behavior of Recycling Polypropylene Fiber Recycled Coarse Aggregate Concrete

Abstract

1. Introduction

2. Experimental Scheme

2.1. Experimental Material

2.2. Proportioning of RCA Concrete

2.3. Specimen Preparation

2.4. Test Methods

2.4.1. Cleavage Tensile Strength Test

2.4.2. Axial Tensile Strength Test

3. Results and Discussion

3.1. Cleavage Tensile Strength

The Influence of RCA Replacement Rate

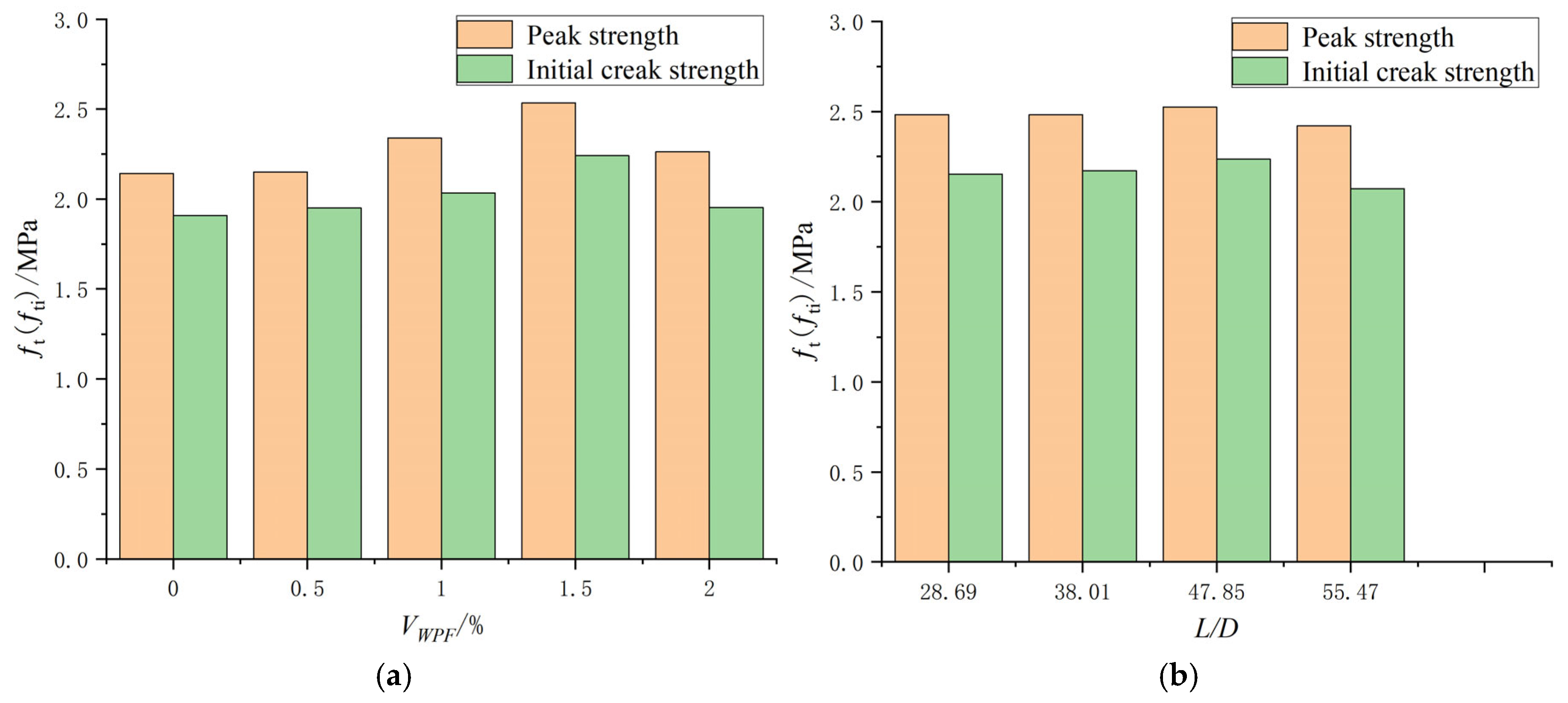

3.2. Axial Tensile Test Strength

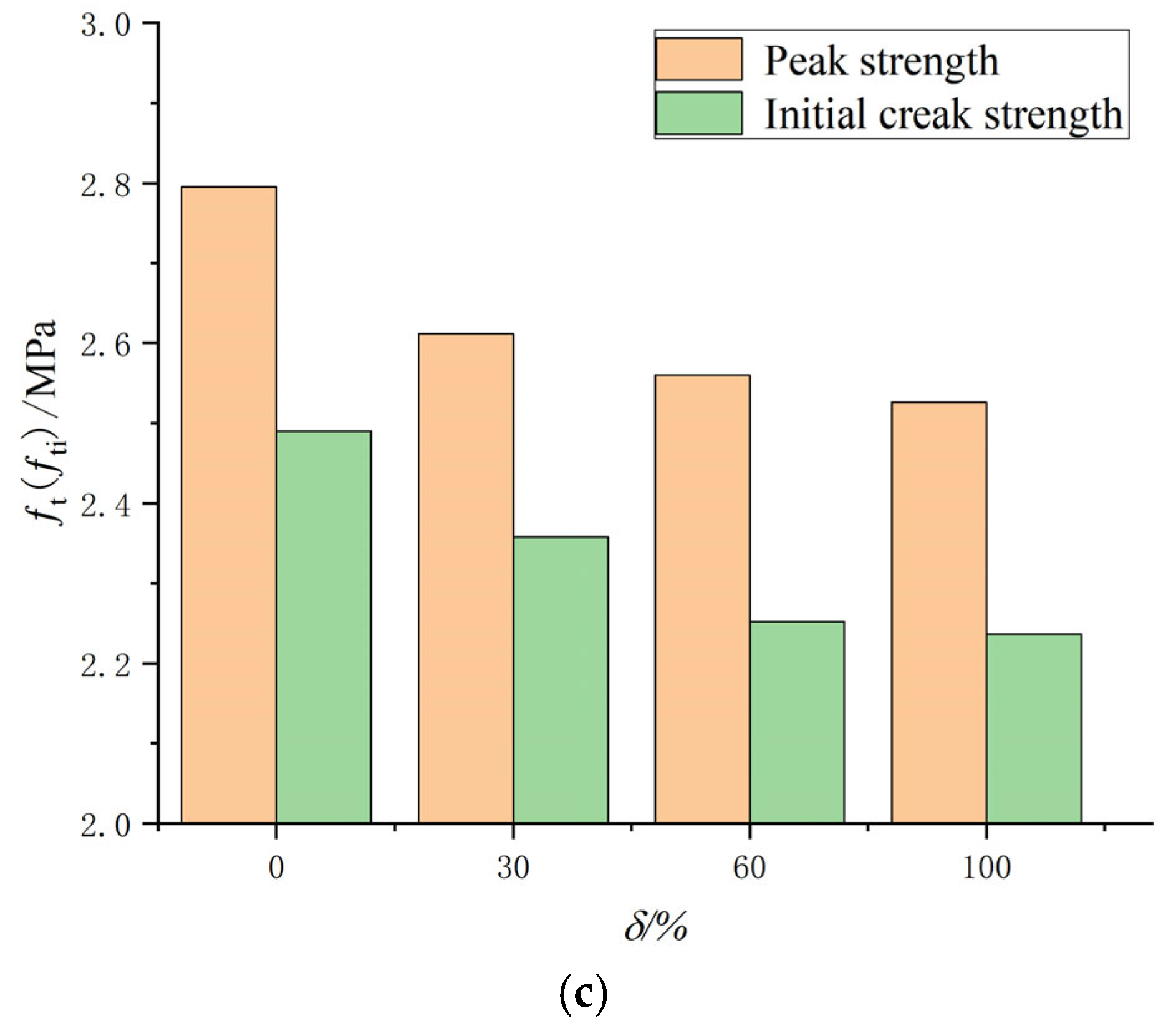

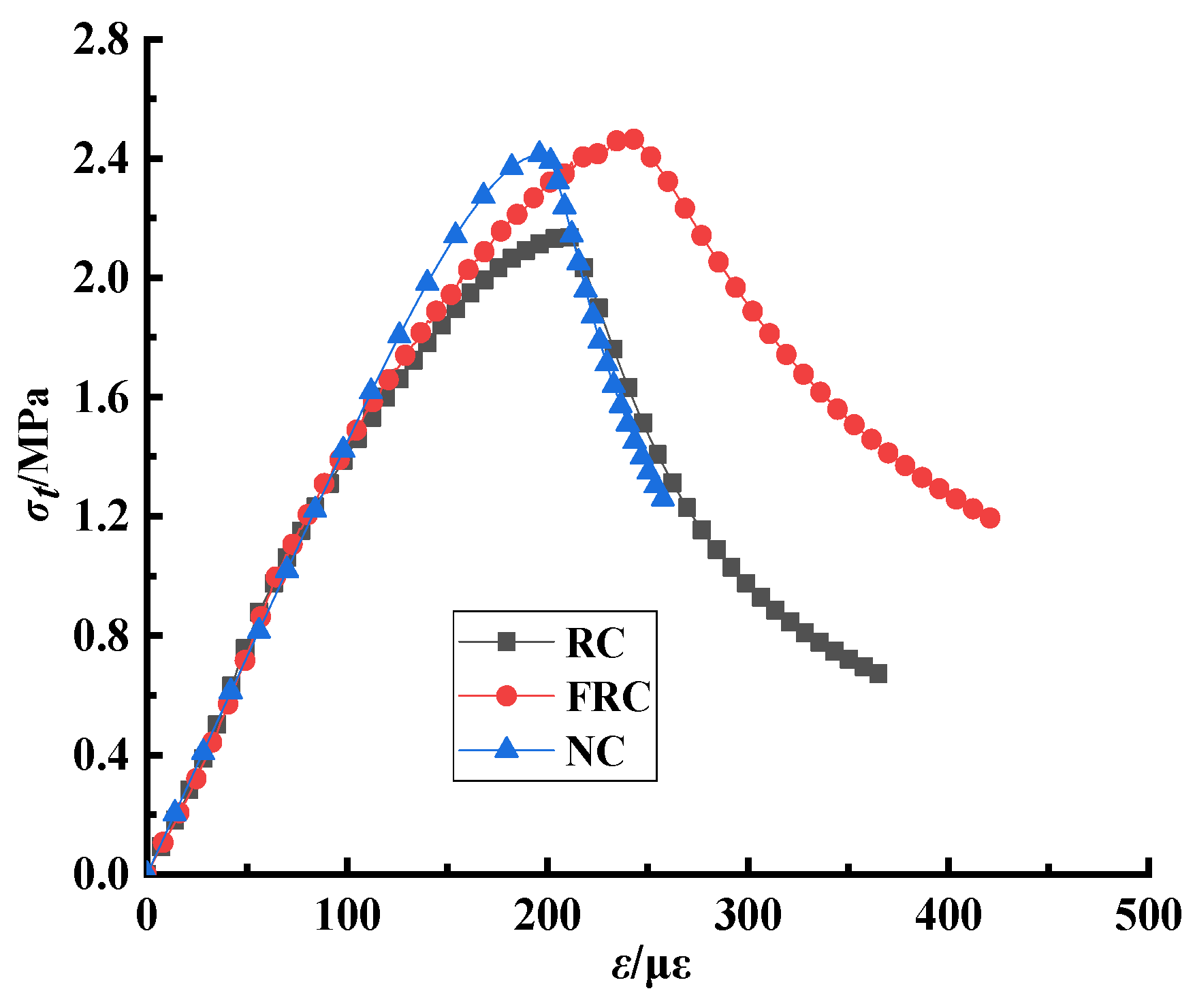

3.3. Axial Tensile Initial Crack Strain and Peak Strain

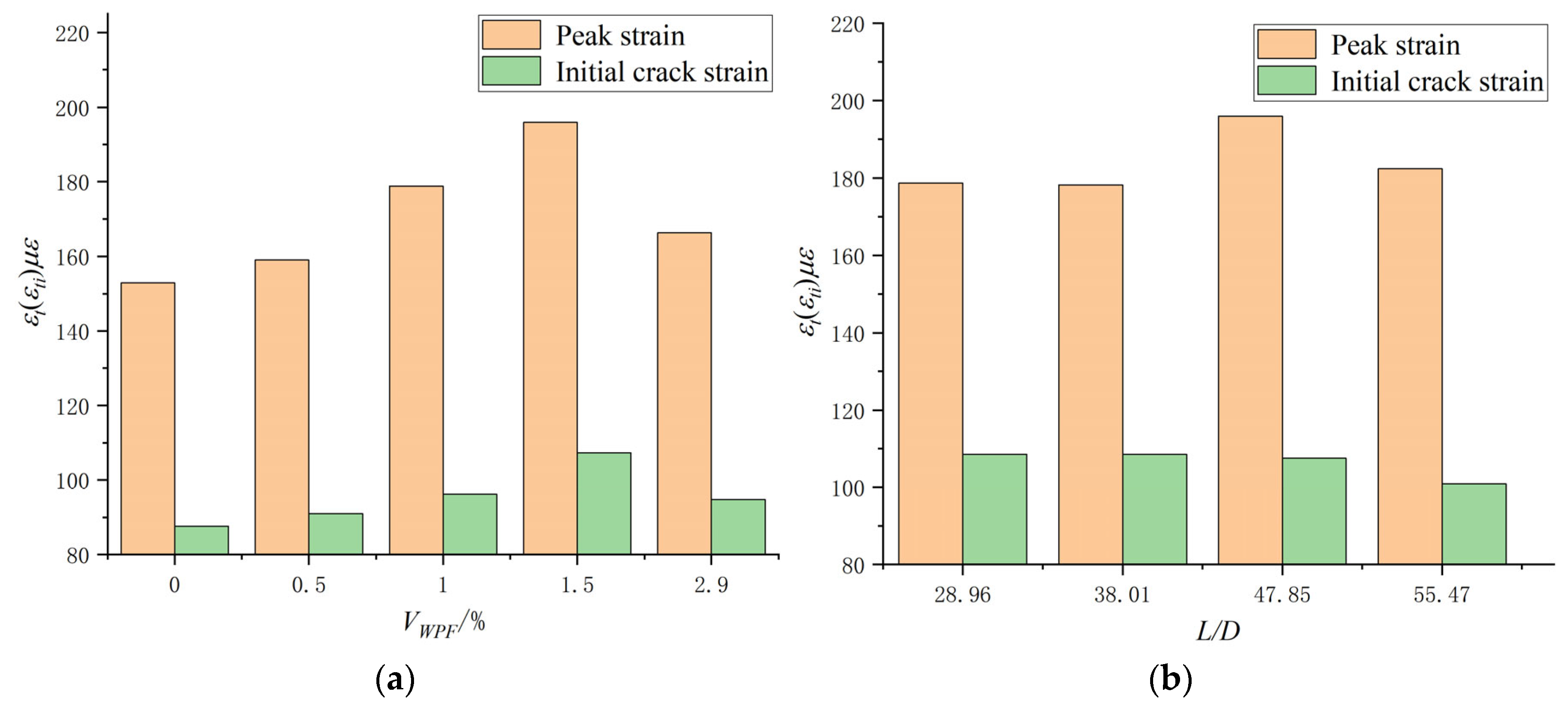

3.4. Analysis of the Stress-Strain Relationship

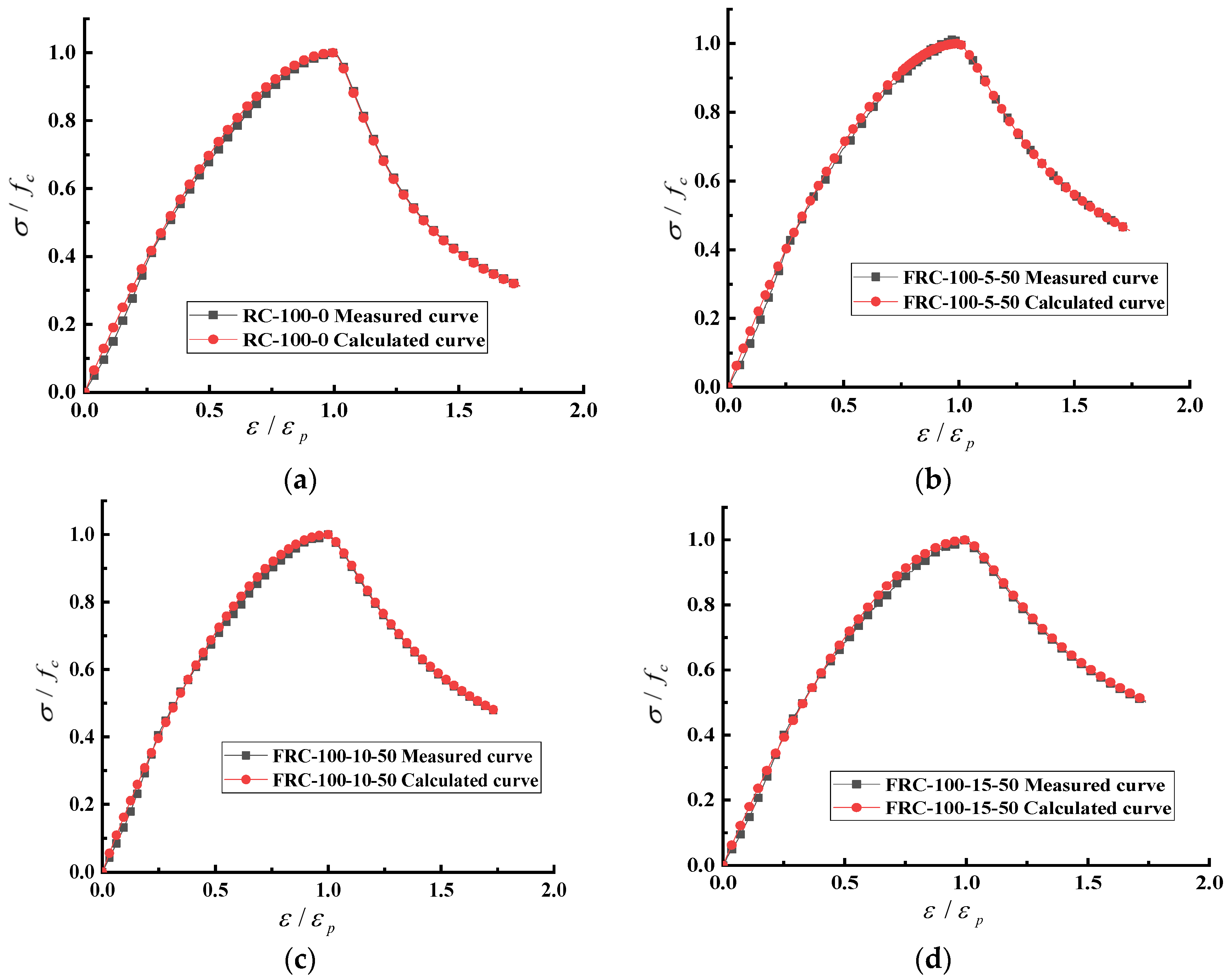

3.5. Stress-Strain Constitutive Models

3.5.1. Axial Tensile Stress-Strain Constitutive Model of NC

3.5.2. Axial Tensile Stress-Strain Constitutive Model of FRC

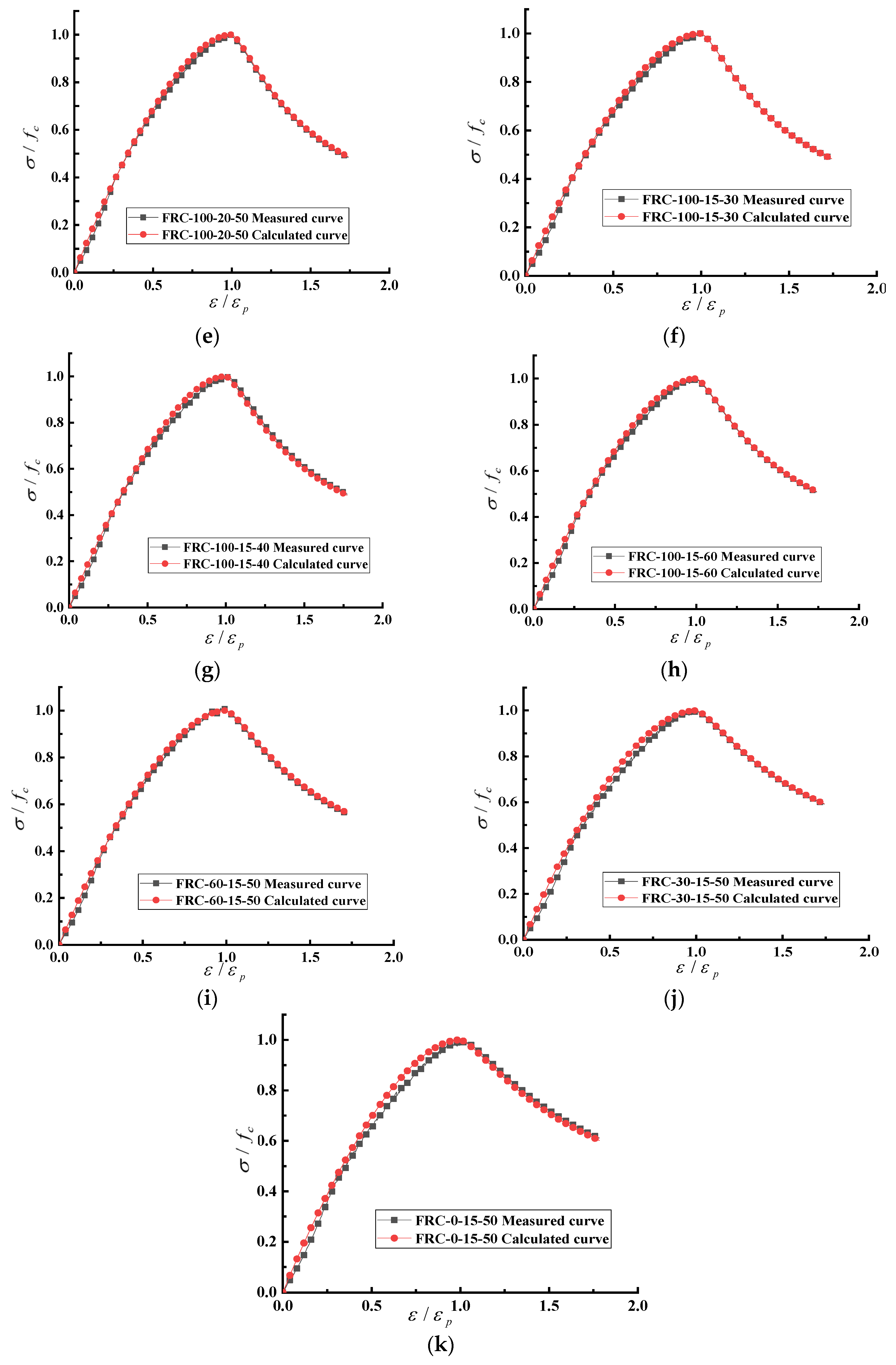

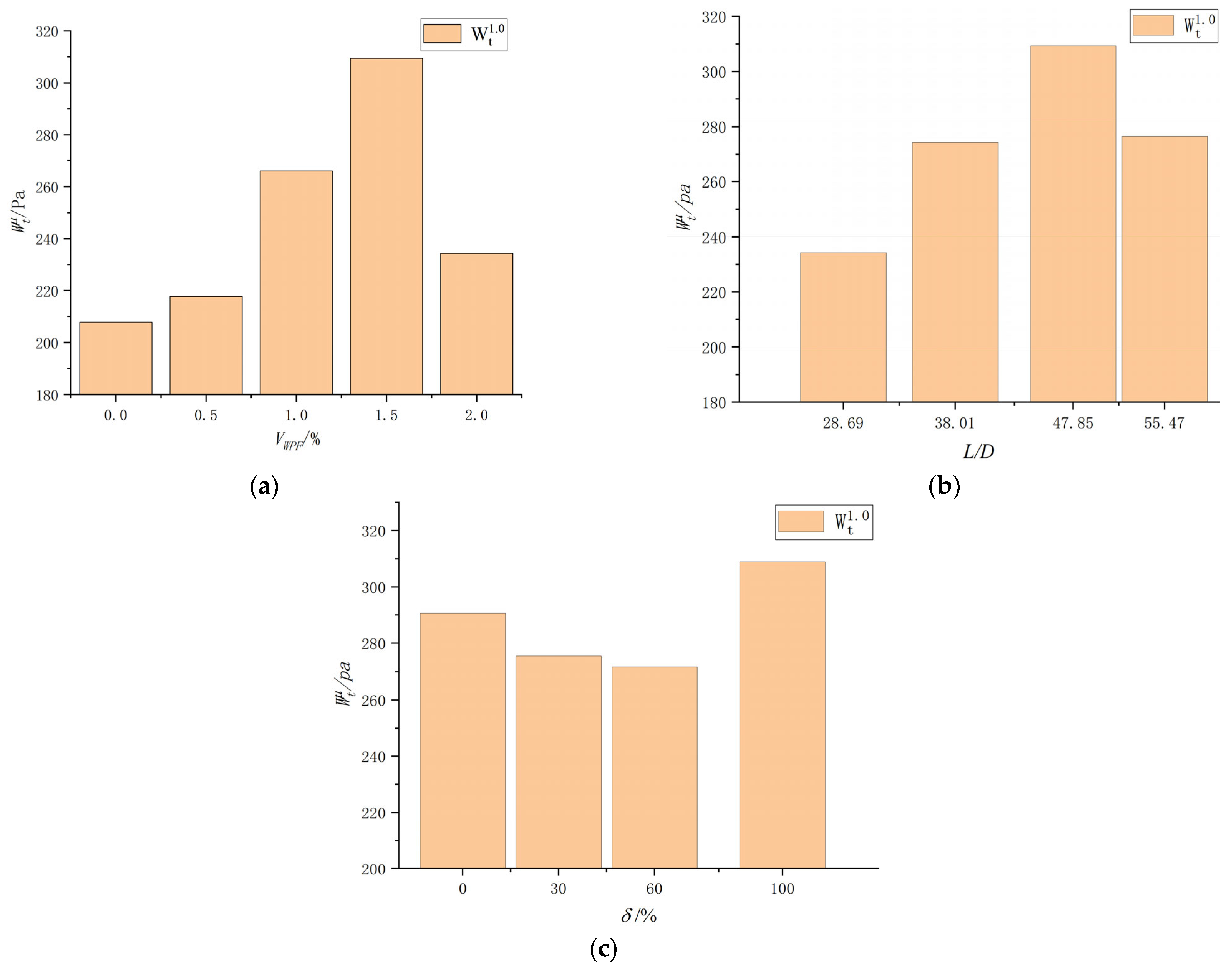

3.6. Tensile Toughness

4. Conclusions

- (1)

- The axial tensile strength first increased and then decreased with the increase in fiber volume content, and was largest when the fiber volume content was 1.5%. Its strength increased by 18.22% compared with recycled concrete, and the change trend of axial tensile strength with fiber length-diameter ratio was roughly increased first and then decreased with the increase in length-diameter ratio, but the change range was not large, and its lifting rate relative to recycled concrete was between 5.61–18.22%. The change trend of axial tensile strength with the substitution rate of RCA is that it decreases with the increase in substitution rate, and the substitution rate decreases by 9.64% when the substitution rate is 100% compared with 0%.

- (2)

- The peak strain first increased and then decreased with the increase in fiber volume content, and the fiber volume content was largest when the fiber volume content was 1.5%, which was 28.19% higher than that of recycled concrete. The peak strain increased first and then decreased with the increase in the fiber length-diameter ratio, and the maximum was 47.85. The peak strain increased with the increase in the substitution rate of RCA, and the peak strain at 30%, 60% and 100% was 100.44%, 102.45% and 118.09% at 0%, respectively.

- (3)

- The equivalent tensile toughness index of RPF recycled concrete first increased and then decreased with the increase in fiber volume content, and the volume content was the best when the volume content was 1.5%. With the increase in the fiber aspect ratio, the tensile toughness index first decreased and then increased, and the substitution of natural aggregate by RCA may enhance the energy dissipation capacity of RPF recycled concrete.

- (4)

- The constitutive model of the tensile rising section of the RPF recycled concrete is proposed, which is consistent with the actual rising section of the stress-strain curve.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Notation

| Concrete tensile strain | |

| Concrete tensile stress | |

| Peak tensile stress in concrete | |

| Peak tensile strain of concrete | |

| evolution parameter of concrete uniaxial tensile damage | |

| Parameter values for the falling section of the uniaxially tensile stressed concrete strain curve | |

| Peak tensile strains in concrete corresponding to representative values of uniaxial tensile strength | |

| Equivalent tensile toughness index of concrete () | |

| Vertical deformation scale of axial tensile test block () | |

| Equivalent tensile strength of concrete () | |

| The area under the load-deformation curve when the vertical deformation is () | |

| The longitudinal deformation when the load is reduced to a multiple of the ultimate load u () | |

| Pressure area of axial compression test block () |

References

- Mejia-Ballesteros, J.E.; Rodier, L.; Filomeno, R.; Savastano, H., Jr.; Fiorelli, J.; Rojas, M.F. Influence of the fiber treatment and matrix modification on the durability of eucalyptus fiber reinforced composites. Cem. Concr. Compos. 2021, 124, 104280. [Google Scholar] [CrossRef]

- Ferriz-Papi, J.A.; Weekes, E.; Whitehead, N.; Lee, A. A cost-effective recycled aggregates classification procedure for construction and demolition waste evaluation. Constr. Build. Mater. 2022, 324, 126642. [Google Scholar] [CrossRef]

- Frazão, C.; Díaz, B.; Barros, J.; Bogas, J.A.; Toptan, F. An experimental study on the corrosion susceptibility of Recycled Steel Fiber Reinforced Concrete. Cem. Concr. Compos. 2019, 96, 138–153. [Google Scholar] [CrossRef]

- Tran, D.L.; Mouret, M.; Cassagnabère, F.; Phung, Q.T. Effects of intrinsic granular porosity and mineral admixtures on durability and transport properties of recycled aggregate concretes. Mater. Today Commun. 2022, 33, 104709. [Google Scholar] [CrossRef]

- Wu, H.; Wang, C.; Ma, Z. Drying shrinkage, mechanical and transport properties of sustainable mortar with both recycled aggregate and powder from concrete waste. J. Build. Eng. 2022, 49, 104048. [Google Scholar] [CrossRef]

- Yang, Z.C.; Han, L.H.; Hou, C. Performance of recycled aggregate concrete-filled steel tubular columns under combined compression and shear load. Eng. Struct. 2022, 253, 113771. [Google Scholar] [CrossRef]

- El-Hawary, M.; Al-Sulily, A. Internal curing of recycled aggregates concrete. J. Clean. Prod. 2020, 275, 122911. [Google Scholar] [CrossRef]

- Resende, D.M.; de Carvalho, J.M.F.; Paiva, B.O.; Gonçalves, G.d.R.; Costa, L.C.B.; Peixoto, R.A.F. Sustainable Structural Lightweight Concrete with Recycled Polyethylene Terephthalate Waste Aggregate. Buildings 2024, 14, 609. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Qiu, Z.; Zhang, Y. Experimental research on compressive properties of recycling polypropylene (PP) fiber recycled coarse aggregate concrete. J. Build. Eng. 2023, 76, 107403. [Google Scholar] [CrossRef]

- Li, Z.; Shen, A.; Zeng, G.; Chen, Z.; Guo, Y. Research progress on properties of basalt fiber-reinforced cement concrete. Mater. Today Commun. 2022, 33, 104824. [Google Scholar] [CrossRef]

- Aslani, F.; Hou, L.; Nejadi, S.; Sun, J.; Abbasi, S. Experimental analysis of fiber-reinforced recycled aggregate self-compacting concrete using waste recycled concrete aggregates, polypropylene, and steel fibers. Struct. Concr. 2019, 20, 1670–1683. [Google Scholar] [CrossRef]

- Bagherzadeh, R.; Sadeghi, A.H.; Latifi, M. Utilizing polypropylene fibers to improve physical and mechanical properties of concrete. Text. Res. J. 2012, 82, 88–96. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Axial stress-strain behavior of macro-synthetic fiber reinforced recycled aggregate concrete. Cem. Concr. Compos. 2019, 97, 341–356. [Google Scholar] [CrossRef]

- Hanumesh, B.M.; Harish, B.A.; Venkata Ramana, N. Influence of polypropylene fibers on recycled aggregate concrete. Mater. Today Proc. 2018, 5, 1147–1155. [Google Scholar] [CrossRef]

- Hunashikatti, G.M.; Pradhan, S.; Bara, S.V. Partially hydrated recycled aggregate concrete: A systematic approach towards sustainable development. Constr. Build. Mater. 2018, 186, 537–549. [Google Scholar] [CrossRef]

- Ye, P.; Chen, Z.; Su, W. Mechanical properties of fully recycled coarse aggregate concrete with polypropylene fiber. Case Stud. Constr. Mater. 2022, 17, e01352. [Google Scholar] [CrossRef]

- Das, S.; Sinah, P.; Negi, V.S. Strength and durability properties of polypropylene fiber reinforced recycled coarse aggregate concrete. Indian Concr. J. 2018, 94, 62–69. [Google Scholar]

- Nam, J.; Kim, G.; Yoo, J.; Choe, G.; Kim, H.; Choi, H.; Kim, Y. Effectiveness of fiber reinforcement on the mechanical properties and shrinkage cracking of recycled fine aggregate concrete. Materials 2016, 9, 131. [Google Scholar] [CrossRef] [PubMed]

- Mudadu, A.; Tiberti, G.; Germano, F.; Plizzari, G.A.; Morbi, A. The effect of fiber orientation on the post-cracking behavior of steel fiber reinforced concrete under bending and uniaxial tensile tests. Cem. Concr. Compos. 2018, 93, 274–288. [Google Scholar] [CrossRef]

- Xiao, J.; Poon, C.S.; Zhao, Y.; Wang, Y.; Ye, T.; Duan, Z.; Peng, L. Fundamental behavior of recycled aggregate concrete—Overview II: Durability and enhancement. Mag. Concr. Res. 2022, 74, 1011–1026. [Google Scholar] [CrossRef]

- Win, T.T.; Jongvivatsakul, P.; Jirawattanasomkul, T.; Prasittisopin, L.; Likitlersuang, S. Use of polypropylene fibers extracted from recycled surgical face masks in cement mortar. Constr. Build. Mater. 2023, 391, 131845. [Google Scholar] [CrossRef]

- Al-Quraishi, H.; Abdulkhudhur, R.; Abdulazeez, A. Shear Strength Behavior of Fiber Reinforced Recycled Aggregate Concrete Beams. Int. Rev. Civ. Eng. 2021, 12, 4183. [Google Scholar] [CrossRef]

- McGinnis, M.J.; Davis, M.; de la Rosa, A.; Weldon, B.D.; Kurama, Y.C. Quantified sustainability of recycled concrete aggregates. Mag. Concr. Res. 2017, 69, 1203–1211. [Google Scholar] [CrossRef]

- Carneiro, J.A.; Lima, P.R.L.; Leite, M.B.; Toledo Filho, R.D. Compressive stress–strain behavior of steel fiber reinforced-recycled aggregate concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Dinh, N.H.; Park, S.H.; Choi, K.K. Effect of dispersed micro-fibers on tensile behavior of uncoated carbon textile-reinforced cementitious mortar after high-temperature exposure. Cem. Concr. Compos. 2021, 118, 103949. [Google Scholar] [CrossRef]

- Feng, Z.; Shen, D.; Luo, Y.; Huang, Q.; Liu, Z.; Jiang, G. Effect of polypropylene fiber on early-age properties and stress relaxation of ultra-high-performance concrete under different degrees of restraint. J. Build. Eng. 2023, 68, 106035. [Google Scholar] [CrossRef]

- Vijayan, V.; Jayakesh, K.; Anand, K.B. Mechanical properties of recycled aggregates concrete with sisal fiber and silica fume. Mater. Today Proc. 2022, 65, 1887–1894. [Google Scholar] [CrossRef]

- JGJ/T 443-2018; Technical Standard for Recycled Concrete Structure. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2018.

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2011.

- Magdalena, P.M.; Kaszynska, M. Mechanical performance and environmental assessment of sustainable concrete reinforced with recycled end-of-life tyre fibers. Materials 2021, 14, 1–20. [Google Scholar]

- Ahmadi, M.; Farzin, S.; Hassani, A.; Motamedi, M. Mechanical properties of the concrete containing recycled fibers and aggregates. Constr. Build. Mater. 2017, 144, 392–398. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomia, T.; Takahashia, H. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 78, 79–93. [Google Scholar] [CrossRef]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Tolêdo Filho, R.D. Tensile behavior of flax textile reinforced lime-mortar: Influence of reinforcement amount and textile impregnation. Cem. Concr. Compos. 2021, 119, 103984. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Tam, V.W.; Wattage, H.; Le, K.N.; Butera, A.; Soomro, M. Hybrid methods to improve microstructure of recycled concrete and brick aggregate for high-grade concrete production. Mag. Concr. Res. 2022, 75, 17–31. [Google Scholar] [CrossRef]

- Li, L.; Ruan, S.; Zeng, L. Mechanical properties and constitutive equations of concrete containing a low volume of tire rubber particles. Constr. Build. Mater. 2014, 70, 291–308. [Google Scholar] [CrossRef]

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2016.

- GB/T 50081-2019; Standard for Test Method of Mechanical Properties on Ordinary Concrete. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2019.

- BS EN 12350-2-2009; Testing Fresh Concrete-Slump-Test. Comité Européen de Normalisation: Brussels, Belgium, 2009.

- BS EN 12390-3-2009; Testing Hardened Concrete-Compressive Strength of Test Specimens. Comité Européen de Normalisation: Brussels, Belgium, 2009.

- BS EN 12390-5-2009; Testing Hardened Concrete-Flexural Strength of Test Specimens. Comité Européen de Normalisation: Brussels, Belgium, 2009.

- BS EN 12390-6-2009; Testing Hardened Concrete-Tensile Cleavage Strength of Test Specimens. Comité Européen de Normalisation: Brussels, Belgium, 2009.

- BS EN 12390-13-2013; Testing Hardened Concrete-Determination of Secant Modulus of Elasticity in Compression. Comité Européen de Normalisation: Brussels, Belgium, 2013.

- Guo, Z.; Zhang, X.; Zhang, D. Experimental study on the stress-strain curve of concrete. J. Build. Struct. 1982, 1–12. [Google Scholar]

- Guo, Z.; Nan, J.; Shi, X. Temperature stress coupled constitutive relationship of concrete. J. Tsinghua Univ. (Nat. Sci. Ed.) 1997, 89–92. [Google Scholar] [CrossRef]

- Han, R.; Zhao, S.; Qu, F. Experimental study on the tensile performance of steel fiber reinforced concrete. J. Civ. Eng. 2006, 63–67. [Google Scholar]

- Yang, M.; Huang, C. Experimental study on the axial tensile performance of steel fiber high-strength concrete. J. Civ. Eng. 2006, 55–61. [Google Scholar]

| Mineral Component of P.O 42.5 (%) | |||||

|---|---|---|---|---|---|

| C3S | C2S | C3A | C4AF | CaSO4 | Other |

| 58.72 | 18.54 | 6.91 | 9.03 | 3.16 | 3.64 |

| Chemical component of P.O 42.5 (%) | |||||

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 |

| 21.76 | 5.15 | 2.93 | 66.59 | 1.21 | 2.36 |

| Material | Size (mm) | Performance Density (kg·m−3) | Water Absorption Rate (%) | Crush Index (%) | Stacking Density (kg·m−3) | Mud Content (%) |

|---|---|---|---|---|---|---|

| RCA | 5–20 | 2353 | 2.68–3.05 | 12.7 | 1457 | 3.55 |

| Material | Peak Load (N) | Peak Strain | Peak Stress (MPa) | Elasticity Modulus (GPa) |

|---|---|---|---|---|

| RPF | 881 | 0.066 | 164.59 | 2.49 |

| Group | Proportioning of RCA Concrete (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Cement | Sand | Water | RCA | Crushed Stones | RPF | Additional Water | Slump (mm) | |

| RC-100-0 | 590 | 704.48 | 295 | 810.53 | 0 | 0 | 23.26 | 48 |

| FRC-100-5-50 | 590 | 704.48 | 295 | 810.53 | 0 | 3.74 | 23.26 | 47 |

| FRC-100-10-50 | 590 | 704.48 | 295 | 810.53 | 0 | 7.48 | 23.26 | 45 |

| FRC-100-15-50 | 590 | 704.48 | 295 | 810.53 | 0 | 11.22 | 23.26 | 44 |

| FRC-100-20-50 | 590 | 704.48 | 295 | 810.53 | 0 | 14.96 | 23.26 | 43 |

| FRC-100-15-30 | 590 | 704.48 | 295 | 810.53 | 0 | 11.22 | 23.26 | 44 |

| FRC-100-15-40 | 590 | 704.48 | 295 | 810.53 | 0 | 11.22 | 23.26 | 44 |

| FRC-100-15-60 | 590 | 704.48 | 295 | 810.53 | 0 | 11.22 | 23.26 | 44 |

| FRC-60-15-50 | 590 | 704.48 | 295 | 486.32 | 324.21 | 11.22 | 13.96 | 46 |

| FRC-30-15-50 | 590 | 704.48 | 295 | 243.16 | 567.37 | 11.22 | 6.98 | 47 |

| FNC-0-15-50 | 590 | 704.48 | 295 | 0 | 810.53 | 11.22 | 0 | 48 |

| Group | Cleavage Tensile Strength | Axial Tensile | |||

|---|---|---|---|---|---|

| (MPa) | Peak Strength (MPa) | Initial Crack Strength (MPa) | Initial Crack Strain (με) | Peak Strain (με) | |

| RC-100-0 | 2.46 | 2.14 | 1.14 | 87.65 | 152.98 |

| FRC-100-5-50 | 2.55 | 2.15 | 1.17 | 91.15 | 158.97 |

| FRC-100-10-50 | 2.69 | 2.34 | 1.22 | 96.10 | 178.93 |

| FRC-100-15-50 | 2.98 | 2.53 | 1.30 | 107.65 | 196.10 |

| FRC-100-20-50 | 2.61 | 2.26 | 1.17 | 94.88 | 166.52 |

| FRC-100-15-30 | 2.87 | 2.49 | 1.34 | 109.02 | 178.85 |

| FRC-100-15-40 | 2.91 | 2.49 | 1.31 | 108.87 | 178.20 |

| FRC-100-15-60 | 2.79 | 2.43 | 1.25 | 101.11 | 182.22 |

| FRC-60-15-50 | 2.99 | 2.56 | 1.35 | 108.65 | 170.12 |

| FRC-30-15-50 | 3.11 | 2.62 | 1.42 | 109.52 | 166.78 |

| FNC-0-15-50 | 3.23 | 2.80 | 1.50 | 111.86 | 166.05 |

| Group | Parameters | |

|---|---|---|

| RC-100-0 | 1.742 | 5.883 |

| FRC-100-5-50 | 1.788 | 3.214 |

| FRC-100-10-50 | 1.780 | 2.947 |

| FRC-100-15-50 | 1.733 | 2.645 |

| FRC-100-20-50 | 1.670 | 2.844 |

| FRC-100-15-30 | 1.681 | 2.876 |

| FRC-100-15-40 | 1.646 | 2.731 |

| FRC-100-15-60 | 1.693 | 2.597 |

| FRC-60-15-50 | 1.691 | 2.140 |

| FRC-30-15-50 | 1.760 | 1.844 |

| FNC-0-15-50 | 1.714 | 1.682 |

| Group | (Pa) | Gain Ratio |

|---|---|---|

| RC-100-0 | 207.6905 | 100.00% |

| FRC-100-5-50 | 217.9078 | 104.92% |

| FRC-100-10-50 | 266.6963 | 128.41% |

| FRC-100-15-50 | 309.6578 | 149.10% |

| FRC-100-20-50 | 234.8848 | 113.09% |

| FRC-100-15-30 | 234.8848 | 113.09% |

| FRC-100-15-40 | 274.8961 | 132.36% |

| FRC-100-15-60 | 276.7001 | 133.23% |

| FRC-60-15-50 | 272.0142 | 130.97% |

| FRC-30-15-50 | 276.1605 | 132.97% |

| FNC-0-15-50 | 291.8175 | 140.51% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Liang, J.; Li, Y.; Hou, W. Tensile Mechanical and Stress-Strain Behavior of Recycling Polypropylene Fiber Recycled Coarse Aggregate Concrete. Buildings 2024, 14, 1116. https://doi.org/10.3390/buildings14041116

Wang J, Liang J, Li Y, Hou W. Tensile Mechanical and Stress-Strain Behavior of Recycling Polypropylene Fiber Recycled Coarse Aggregate Concrete. Buildings. 2024; 14(4):1116. https://doi.org/10.3390/buildings14041116

Chicago/Turabian StyleWang, Jianchao, Jiahe Liang, Yucheng Li, and Wei Hou. 2024. "Tensile Mechanical and Stress-Strain Behavior of Recycling Polypropylene Fiber Recycled Coarse Aggregate Concrete" Buildings 14, no. 4: 1116. https://doi.org/10.3390/buildings14041116

APA StyleWang, J., Liang, J., Li, Y., & Hou, W. (2024). Tensile Mechanical and Stress-Strain Behavior of Recycling Polypropylene Fiber Recycled Coarse Aggregate Concrete. Buildings, 14(4), 1116. https://doi.org/10.3390/buildings14041116