Abstract

As construction projects become increasingly complex, modular integrated construction (MiC) has emerged as a pivotal solution, driving integrated development in complex projects. However, the reliance on prefabricated modules underscores the crucial role of supply chain management (SCM) in MiC, necessitating strategic planning and operational control. This study aimed to use bibliometric analysis to map the SCM knowledge domain within MiC. Through the use of keywords related to “supply chain” and “MiC”, 196 relevant papers were extracted from the Web of Science database. These papers were subjected to co-citation analysis, keyword co-occurrence analysis, and time span analysis to elucidate the historical evolution, multidisciplinary domains, and future directions in planning and control within SCM-MiC. The research identified two milestones in SCM-MiC’s historical trajectory, enhancing our understanding of its foundations. Moreover, 11 clusters were identified, illustrating the multidisciplinary nature of SCM-MiC. Dividing the literature into seven stages of the supply chain, the research outlined four research directions aligned with project complexity and technological development, highlighting current hotspots and gaps of the strategic planning and control. These directions bridge the construction management and information technology domains, guiding future SCM-MiC research within complex project management.

1. Introduction

The construction industry is currently experiencing significant evolution, fueled by the integration of pioneering methodologies aimed at addressing the escalating complexity and requirements of contemporary construction projects. Within this context, modular integrated construction (MiC) has emerged as an innovative construction methodology, attracting increasing interest for its potential to revolutionize conventional building practices [1]. MiC resembles prefabricated construction, in which a considerable part of the construction work is carried out offsite in a controlled factory setting and then transported to the building site for assembly [2]. This approach has been increasingly recognized for its potential to fundamentally change how projects are conceptualized, procured, designed, constructed, and managed [3]. The transition towards MiC reflects a broader shift in the construction sector towards more integrated and efficient processes, aligning closely with the principles of industrialization and sustainability [4].

However, the shift to MiC also imposes new demands on the planning and control mechanisms within the construction industry. Specifically, it underscores the crucial role of supply chain management (SCM) in the successful implementation of MiC strategies [5]. The prefabrication of modules at offsite facilities means that construction is no longer a predominantly site-based activity but is rather one that is spread across multiple locations and phases, integrating suppliers, manufacturers, and assembly processes seamlessly and efficiently [6]. Effective SCM is pivotal in maximizing the efficiency of MiC projects, as it addresses the complexities of logistics and management of materials, which are crucial for timely project execution and controlling costs. Therefore, a key factor that profoundly affects the success of MiC projects is the management of supply chains [3].

Existing research has recognized that the integral role of SCM within MiC (SCM-MiC) necessitates a thorough examination of how traditional supply chain strategies adapt to the modular construction environment [3,7]. Despite the burgeoning interest and increasing volume of literature on MiC, a significant gap persists: a comprehensive scholarly review that integrates these diverse insights into a unified framework is notably absent. Most current studies have focused on specific elements of SCM-MiC, such as logistical challenges or technological integration, failing to provide a holistic perspective on how these elements are interconnected and collectively influence overall delivery of the project [3,7]. This approach often results in an incomplete understanding of the evolution of the research, the existing gaps, and the broader implications of the topic. Therefore, the research question is as follows. What are the key trends, pivotal research contributions, and existing gaps in the field of supply chain management within modular integrated construction from a perspective of supply chain lifecycle?

To overcome the labor-intensive and potentially biased challenges inherent in traditional manual review methods [8], the use of bibliometric analysis has been proposed as an effective alternative [9]. Bibliometric techniques offer a quantitative approach to systematically identify the bibliographic relationships within a large volume of literature [10]. Tools such as Citespace and VOSviewer are instrumental in this regard, enabling researchers to visualize the knowledge network accurately and comprehensively [11,12]. These tools have the advantage of minimizing subjective interpretation by providing objective, data-driven insights into the literature’s structure [13]. By using bibliometric analysis, researchers can achieve a more nuanced and interconnected view of the SCM-MiC field, facilitating a deeper understanding of its foundational and emerging themes.

In this research, we undertook a detailed bibliometric analysis to dissect the landscape of SCM in every step of the supply chain from design to demolition within MiC. The research aimed to reveal the evolving trends, seminal research, and notable gaps within the existing research in SCM-MiC, suggesting directions for future research. The article is structured as follows. First, the research background is described. The second part describes the development of the research methodology based on the perspectives of bibliometric analysis. On this basis, the filtered papers were all analyzed. Finally, the discussion and conclusion are presented.

2. Research Background

2.1. Modular Integrated Construction in Complex Projects

Traditional complex construction projects often encounter issues such as inefficiencies, cost overruns, and delays [14,15,16]. For instance, empirical studies have indicated that the average cost overrun for the development of infrastructure across Asian nations has surpassed 25% [17], while a survey of 130 public projects revealed that 106 projects (81.5%) experienced delays averaging over 289 days [18]. Modular integrated construction (MiC) is increasingly recognized for its innovation in construction, offering substantial improvements over traditional construction techniques [3]. MiC involves the prefabrication of building modules at an offsite location, which are then transported to the construction site for assembly. These modules can include structural elements, architectural finishes, and mechanical, electrical, and plumbing systems that are pre-installed in controlled factory settings [19]. Unlike the traditional approach, which depends heavily on on-site assembly, MiC involves the offsite prefabrication of standardized modules that are later assembled at the construction site [20]. This method effectively addresses many challenges of the construction industry in hospital construction during pandemics [16], construction of high-rise buildings [21], and so forth.

Numerous studies have highlighted the efficiency of MiC, primarily through reduced construction time. Gibb and Isack [22] provided evidence that MiC could cut projects’ overall timelines by up to 50% due to the parallel progression of site work and production of the modules. Deep et al. [23] also noted significant time savings as being a critical factor in a project’s delivery and crucial for complex projects where delays are costly. MiC facilitates enhanced quality control, as the components are manufactured in a controlled environment, reducing the variability seen in traditional construction methods [24]. Additionally, MiC demonstrates potential environmental benefits, including reduced waste and lower carbon emissions, emphasizing the sustainable nature of offsite construction practices [25]. While the initial costs can be higher due to the need for specialized designs and transportation, the project’s overall costs may be reduced through decreased on-site labor, less waste, and a shorter project duration [26].

Despite its advantages, MiC faces challenges, particularly in logistical complexities and integration with traditional construction methods [8,27]. Transporting large prefabricated modules can present significant logistical challenges, especially in urban areas with restricted site access [28]. The complexity increases with the size and design intricacies of the modules. Integrating MiC with traditional construction methods poses challenges, especially in terms of coordination and management of the interface between modular and non-modular components [29]. These challenges of integration are heightened in complex projects that may require bespoke solutions. Regulatory frameworks often lag behind innovations in construction methods, presenting a barrier to the adoption of MiC. The lack of standardized codes specific to modular construction can hinder its implementation [30]. Moreover, market acceptance remains variable, influenced by conservatism in the industry and the novelty of the approach.

2.2. Supply Chain Management in Modular Integrated Construction

MiC offers significant benefits but encounters challenges that could limit its widespread adoption [31]. These challenges include the high initial investment costs, issues with scalability, regulatory obstacles, and the stakeholders’ resistance [32]. Addressing these challenges effectively requires a comprehensive approach to supply chain management for modular integrated construction (SCM-MiC), which encompasses procurement, transportation, inventory management, and coordination among stakeholders, ensuring efficient flows of materials, components, and information [33]. Initially developed in manufacturing, SCM now encompasses procurement, transportation, and inventory management, and has proved essential for increasing productivity [34], minimizing waste [35], and creating value within construction projects [36]. The supply chain of construction is defined as the sequence of stages that the resources of construction (materials, equipment, and personnel) pass through in their entirety, from the points of supply to the construction site [37].

Critical to the effectiveness of SCM in construction are integration and collaboration among stakeholders [38]. The success of SCM in construction hinges on the stakeholders’ integration and collaboration. The sector’s supply chains necessitate immediate sharing of data and strong communication for effective coordination. Such cooperation, rooted in solid stakeholder relationships, markedly improves a project’s outcomes by reducing lead times [39], shortening delivery periods [40], and enhancing efficiency [41]. Effective SCM-MiC is essential for overcoming obstacles, as it facilitates the on-time delivery of modules [42], optimizes inventory levels [43], minimizes transportation costs [44], etc. Moreover, leveraging technological innovations such as robotic automation and digital tools can greatly enhance the framework of SCM-MiC. Implementing sustainable SCM practices can also contribute to the environmental sustainability of MiC projects over the long term [15,45].

However, the existing research has identified specific SCM-related challenges within MiC projects. Poor management of MiC-SCM stands out as a significant barrier hindering the broader adoption of MiC [46]. This deficiency in management stems from ineffective planning of the supply chain that fails to integrate the stages of MiC-SCM [47], as well as from a lack of collaboration, trust, and real-time sharing of information among the stakeholders of MiC-SCM [48]. Consequently, this results in a weakly integrated, unresponsive, and suboptimal supply chain that undermines the advantages of MiC. These challenges are pivotal to the effective execution of MiC. For instance, transporting the modular components from the factories to the construction sites is often hindered by logistical issues such as traffic congestion and inadequate infrastructure, affecting the project’s timelines and efficiency [49]. Effective coordination of delivery schedules and optimization of transportation routes are vital to circumvent these obstacles [42]. Moreover, achieving successful stakeholder collaboration requires detailed management and robust communication strategies [50]. Despite the recognized advantages of MiC and its logistic and SCM challenges, there is an evident need for further investigation in this area. Future research should aim to develop strategies that address the transportation challenges, improve coordination of the supply chain, and tailor MiC approaches to accommodate specific site conditions.

2.3. The Utilization of Bibliometric Analysis

Several reviews have utilized bibliometric analysis to conduct literature reviews within the field of MiC. For instance, Li et al. [51] conducted a bibliometric review focusing on the management issues in prefabricated construction, analyzing 100 articles. Similarly, Jin et al. [52] conducted a more extensive bibliometric analysis, examining 349 articles to decipher the interconnections among the keywords, as well as the collaborative networks among the research sources, scholars, and nations. Additionally, Han et al. [53] executed a bibliometric evaluation of 131 articles, engaging in qualitative discussions to delineate the prevailing trends and gaps within the SCM-MiC research area.

However, many reviews have often addressed the logistics and supply chain aspects of MiC projects in a fragmented manner. They may have narrowly focused on one aspect or concentrated excessively on specific topics such as such as policies [54], environmental and economic performance [55], stakeholders [56], and critical factors [57], losing sight of the broader context and failing to provide a comprehensive overview of the field. This fragmented approach has hindered the development of a coherent understanding of MiC and its associated challenges of supply chain management. Therefore, despite their contributions, these reviews fall short of providing insights into the distinct operational problems at each stage of the supply chain and how these challenges have been resolved. There remains a lack of in-depth systematic analysis of the modeling approaches and problem formulations across the stages of SCM-MiC, spanning design, manufacturing, procurement, transportation, inventory, and installation. Addressing these gaps would contribute to a more comprehensive understanding of SCM-MiC and guide future research in the field. In essence, bibliometric analysis offers a robust methodology for synthesizing and analyzing vast amounts of literature, providing valuable insights into the landscape of research into complex project management. By mapping out citation networks; identifying the key authors, institutions, and research themes; and uncovering emerging trends, bibliometric analysis serves as a powerful tool for understanding the evolution and current state of the field.

3. Research Methodology

3.1. Method of Bibliometric Analysis

Advancements in information technology and scientific visualization have established bibliometrics as essential for researchers studying trends in academic literature. This approach examines bibliographic data to reveal complex scholarly relationships. For example, co-citation analysis groups scientific articles based on their citations’ connections and thematic similarities, revealing the main research communities and foundational studies [58]. Keyword co-occurrence analysis highlights the dominant research topics and methods, offering insights into current and emerging scholarly discussions [59]. Timespan analysis tracks the evolution of research themes, marking critical developments in academic discourse [60].

Tools such as Citespace, Citnet, Bibexcel, Sci2, and VantagePoint are crucial for conducting bibliometric analyses [61]. These tools help researchers visualize and statistically analyze the knowledge landscape. We chose Citespace (Version 6.1.R6, Manufactured by Chaomei Chen, Philadelphia, PA, USA) for several reasons: it offers comprehensive visualization capabilities and it excels in dynamic analysis for tracking the evolution of research topics [62]. Additionally, it integrates seamlessly with major bibliographic database such as Web of Science, ensuring efficient data retrieval. In construction management, bibliometric methods have proven effective in synthesizing and exploring extensive research landscapes [63,64].

3.2. Data Collection

3.2.1. The Database

This research leveraged the Web of Science (WoS) database for collecting high-quality bibliometric data. Recognized for its inclusion of over 12,000 reputable and influential academic journals, WoS aggregates content from the Science Citation Index (SCI) and the Social Science Citation Index (SSCI), offering a broad spectrum of high-quality data necessary for the scope and depth of bibliometric analysis envisioned in this study [12]. Its established use in previous studies highlights its effectiveness in providing detailed bibliographic records for statistical analysis [9]. The study specifically targeted peer-reviewed articles and reviews for their acknowledged academic rigor. This approach aligned with the methodologies of prior reviews by Xue et al. [63] and Derakhshan et al. [65], ensuring a focus on literature with recognized scholarly integrity.

3.2.2. The Search Terms

The search terms utilized in this study were structured in two components to comprehensively capture literature that was relevant to logistics, supply chain, and modular integrated construction. The first component included terms such as “logistics” and “supply chain”, drawn from previous review studies, to ensure coverage of the relevant literature in these domains. The second component comprised project-related vocabulary, expanded to encompass various terms associated with modular construction, as detailed earlier in Section 2.2. A preliminary search was conducted for articles published between 2000 and 2022 to capture relevant literature over a significant timeframe.

The building and construction industry uses various alternative terms to describe concepts related to prefabrication. These terms, such as “industrialized buildings”, “offsite construction”, and “modular building”, were included in the search strategy to ensure comprehensive coverage of the relevant literature. The formulation for retrieval of the literature was established as follows: (“logistics” OR “supply chain”) AND (“modular integrated construction” OR “modular construction” OR “prefabricated building” OR “prefabricated construction” OR “prefabricated prefinished volumetric construction” OR “industrialized building” OR “industrialized construction” OR “offsite building” OR “offsite construction” OR “precast construction” OR “precast building”). The initial search yielded 271 articles.

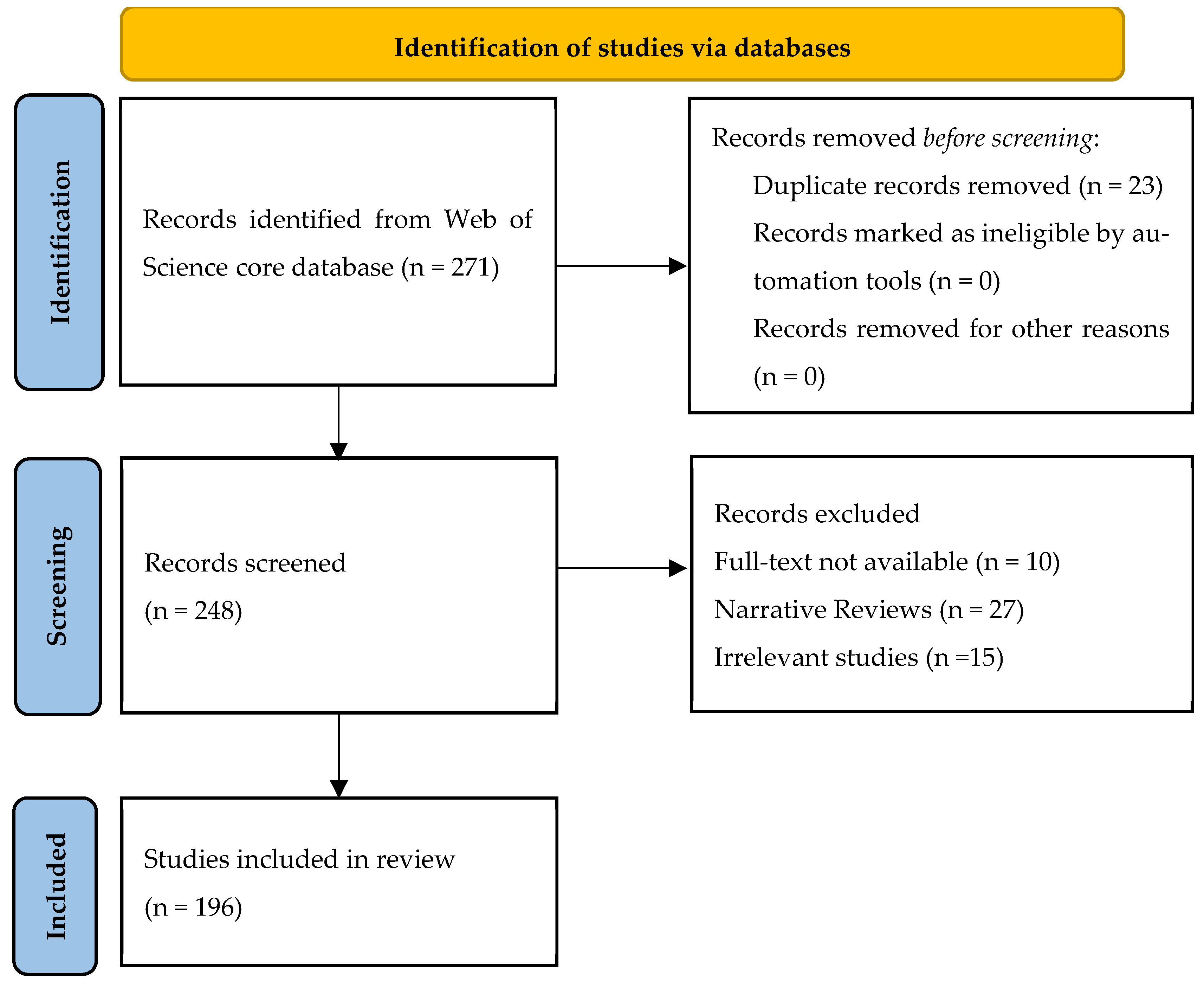

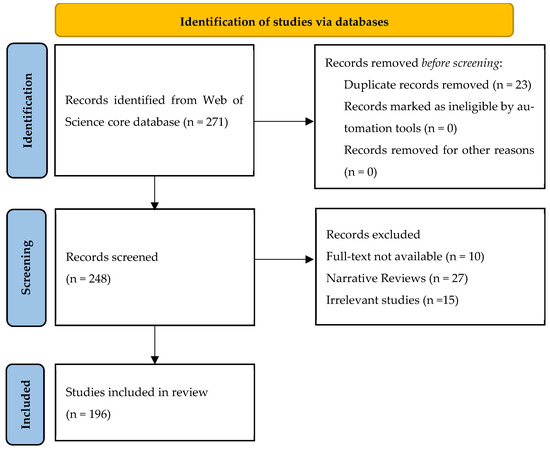

The WoS core database, renowned for its credibility, served as the primary source for collecting the relevant literature. Review articles and other irrelevant publications were filtered out according to predetermined criteria. Only articles exclusively linked to the WoS core were retained after this process. Next, publications lacking specific keywords in their titles or abstracts were excluded, followed by a manual review of the titles and abstracts to remove less relevant literature swiftly. The remaining records were then organized for subsequent bibliometric analysis. As a result, 196 articles were deemed eligible for further analysis in the subsequent phase. The diagram of the PRISMA process is shown in Figure 1.

Figure 1.

Diagram of the PRISMA process.

3.2.3. Bibliometric Records

Each bibliographic record contains the metadata of a published article, including the authors’ names, the articles’ titles, abstracts, keywords, volume numbers, DOI references, and all references cited within the articles.

3.3. Data Analysis

3.3.1. Co-Citation Analysis

Document co-citation analysis involves tracking articles that are often cited together, signaling shared research interests [66]. This method connects articles in a co-citation network, treating each as a node. The connections or links between nodes reveal the relationships and group articles into clusters, identifying distinct knowledge domains and specific research topics. Visualizing these networks helps elucidate the structure of the knowledge domains and the interconnectedness of articles.

3.3.2. Keyword Co-Occurrence Analysis

Co-occurrence analysis determines the prevalence of specific keywords within the dataset, indicating their relevance in the research area [13]. This analysis reveals the core concepts and themes within the research domain, showing what topics are the most frequently explored [67]. By identifying these patterns, researchers can discern the primary focus areas and conceptual underpinnings of the literature.

3.3.3. Time-Span Citation Analysis

Time-span citation analysis identifies pivotal articles across different periods, reflecting the evolution of a research topic [63]. It involves counting citations to highlight frequently cited works within specific timeframes. Tracking these citations over time reveals shifts in influential articles, indicating how research trends and seminal works have developed, thus offering insights into the dynamic nature of the research domains.

4. Results

4.1. Results of Data Collection

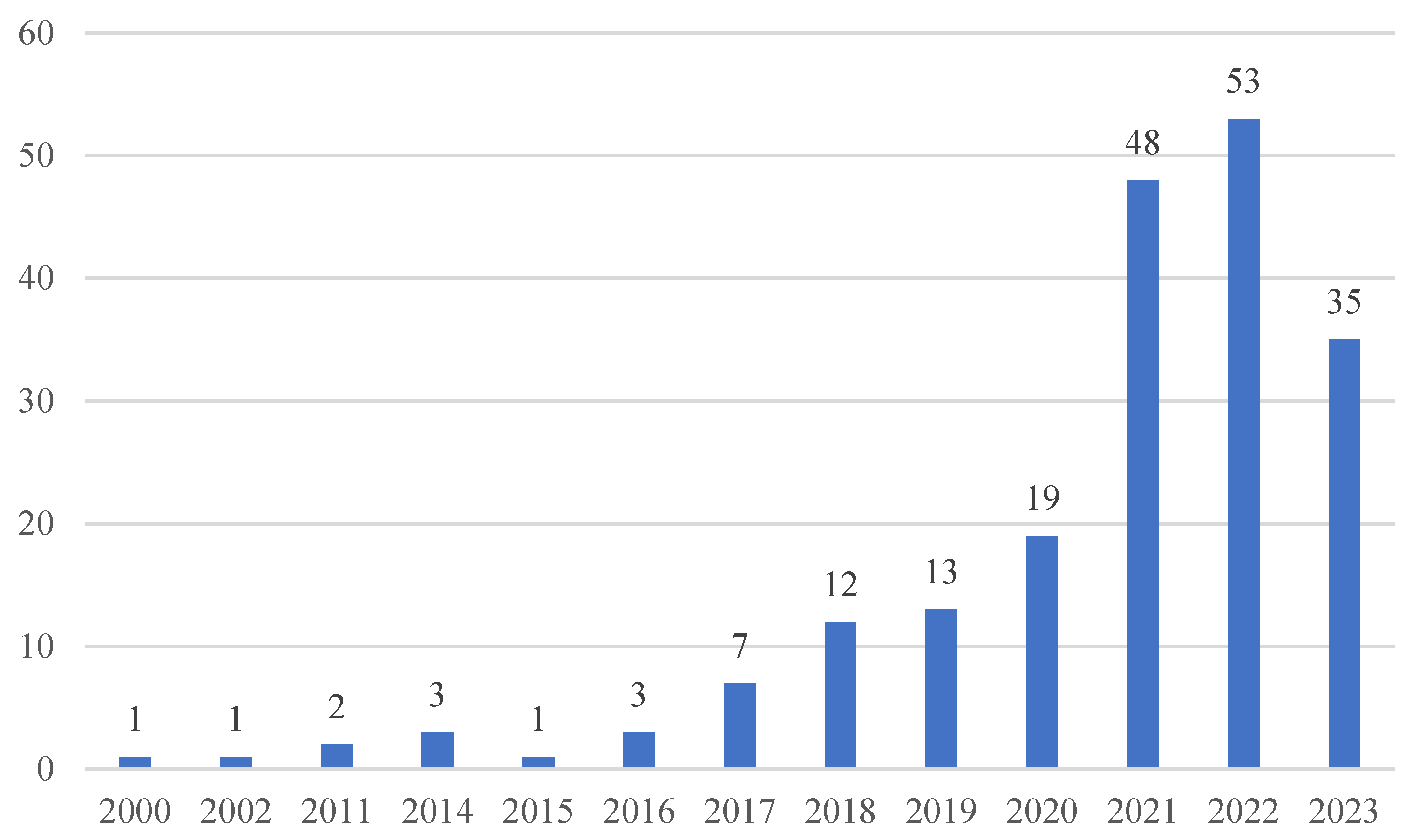

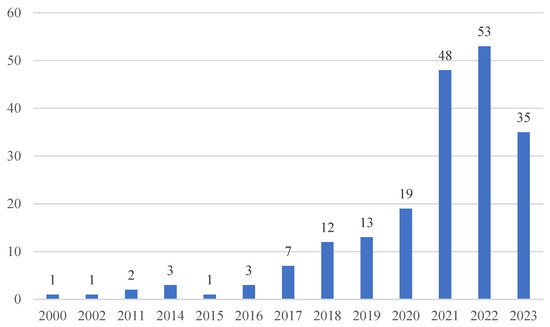

The literature review conducted on research into logistics and supply chain management within the construction industry, particularly modular integrated construction (MiC), yielded valuable insights into the developmental trends of the related research. Figure 2 illustrates the progression of SCM-MiC research from 2000 to 2023, based on data obtained from the sample in this study. In general, the quantity of published articles demonstrated a pattern of gradual then accelerated expansion. Consequently, the timeframe of publication for the studies can be divided into three distinct phases: an initial stage, a phase of fluctuating growth, and a phase of rapid development.

Figure 2.

Year of publication.

- (1)

- Initial stage (2000–2010): Before 2010, there was a relatively modest number of published articles. Much of the literature on MiC comprised policy recommendations for program and project management, with limited academic exploration of supply chain management in MiC.

- (2)

- Fluctuating growth phase (2011–2020): During this period, there was a gradual increase in the number of publications. As construction standards evolved and international competition intensified, MiC began to have greater significance. Many researchers recognized the need to integrate supply chain activities to optimize MiC activities.

- (3)

- Rapid development phase (2021–present): The number of published articles experienced rapid growth, peaking in 2022. Compared with 2021, the volume of literature in 2022 surged by over 150%, indicating a growing emphasis on the study of SCM-MiC worldwide.

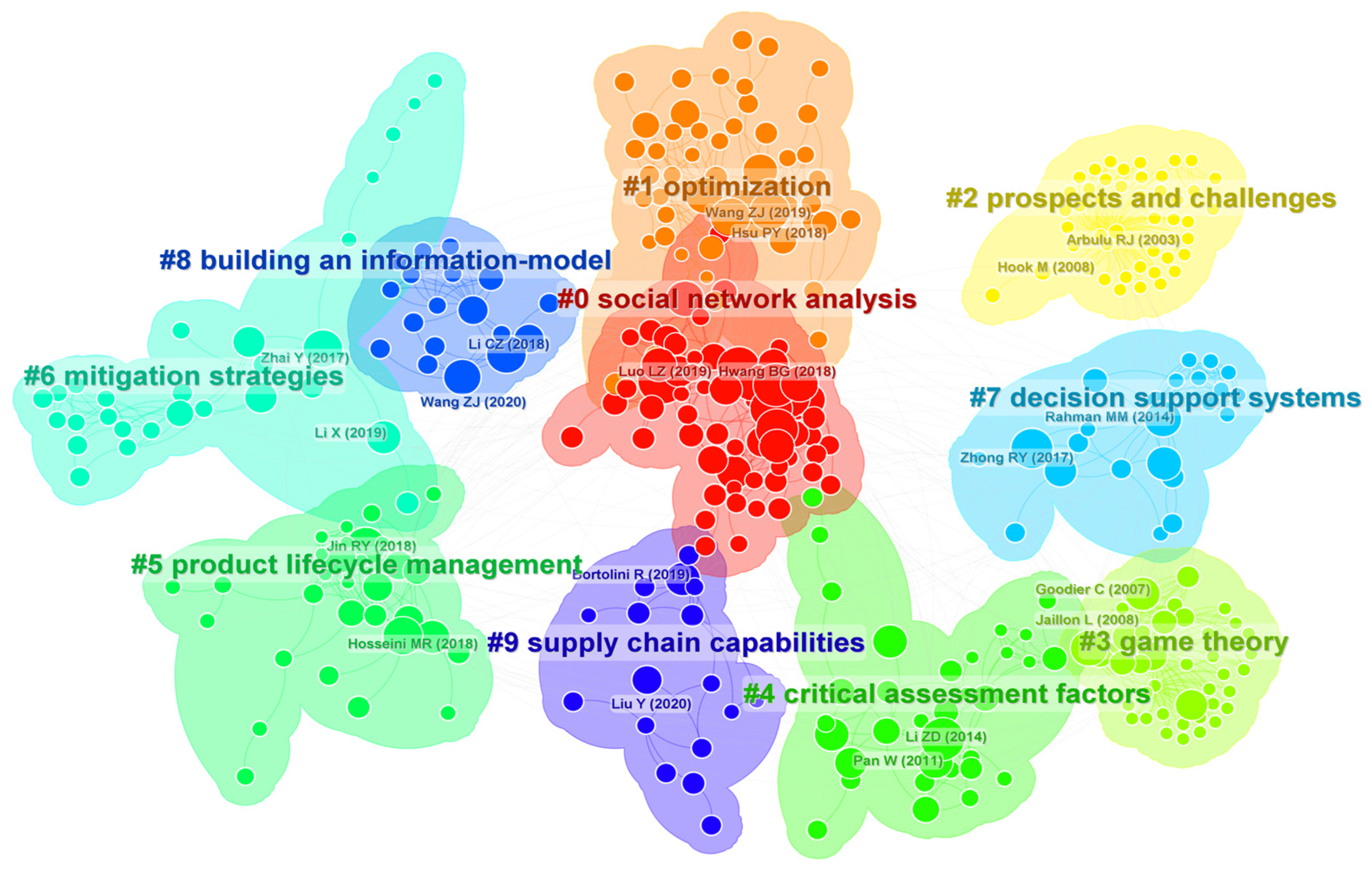

4.2. Knowledge Domains

The provided text explains how the literature’s co-citation network was organized into clusters based on the interconnections between the nodes. These clusters were then labeled using a statistical technique called the LLR (log-likelihood ratio) test. This method is a statistical technique utilized in the analysis of co-citation networks to determine the significance of words or terms associated with clusters [58]. A higher LLR value indicates that the observed frequency of a term within a cluster is significantly different from what would be expected by chance alone, suggesting that the term is meaningful or characteristic of that cluster [68]. By applying the LLR method, clusters in co-citation networks can be labeled with terms that are statistically significant and representative of the content within each cluster.

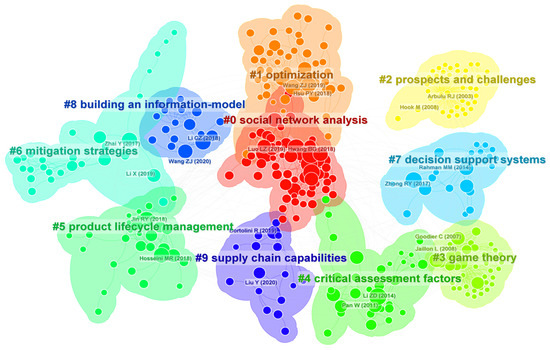

Here, we discuss the outcomes of clustering analysis conducted in the field of logistics in modular integrated construction (MiC). Table 1 presents a comprehensive list of 10 significant clusters, each containing at least five group members. Notably, the silhouette value for each cluster exceeded 0.7, indicating the reliability of the results for further interpretation.

Table 1.

Top-ranked clusters.

The results highlighted the most substantial cluster, focusing on stakeholders (Cluster 0), which included 49 publications. This emphasizes the importance of collaboration within logistics in construction, with social network analysis being the most prevalent method studied. Additionally, the results revealed other significant clusters such as Cluster 3, focusing on game theory and supply chain management, and Cluster 2, which included theoretical studies on prospects and challenges of the process of logistics. Furthermore, clusters such as Cluster 4 (factors of critical assessment) and Cluster 9 (the supply chain’s capability) address challenges that may arise in the process of logistics, highlighting the importance of management within logistics in MiC (Figure 3).

Figure 3.

Clusters of knowledge domains within the related research. Luo L.Z. (2019) [50]; Hwang B.G. (2018) [69]; Hsu P.Y. (2018) [70]; Wang Z.J. (2019) [71]; Arbulu R.J. (2003) [72]; Hook M. (2008) [73]; Jaillon L. (2008) [74]; Goodier C (2007) [75]; Li Z.D. (2014) [76]; Pan W. (2011) [77]; Jin R.Y. (2018) [52]; Hosseini M.R. (2018) [78]; Zhai Y. (2017) [39]; Li X. (2019) [79]; Rahman M.M. (2014) [80]; Zhong R.Y. (2017) [81]; Li C.Z. (2018) [82]; Wang Z.J. (2020) [48]; Bortolini R. (2019) [83]; Liu Y. (2020) [84].

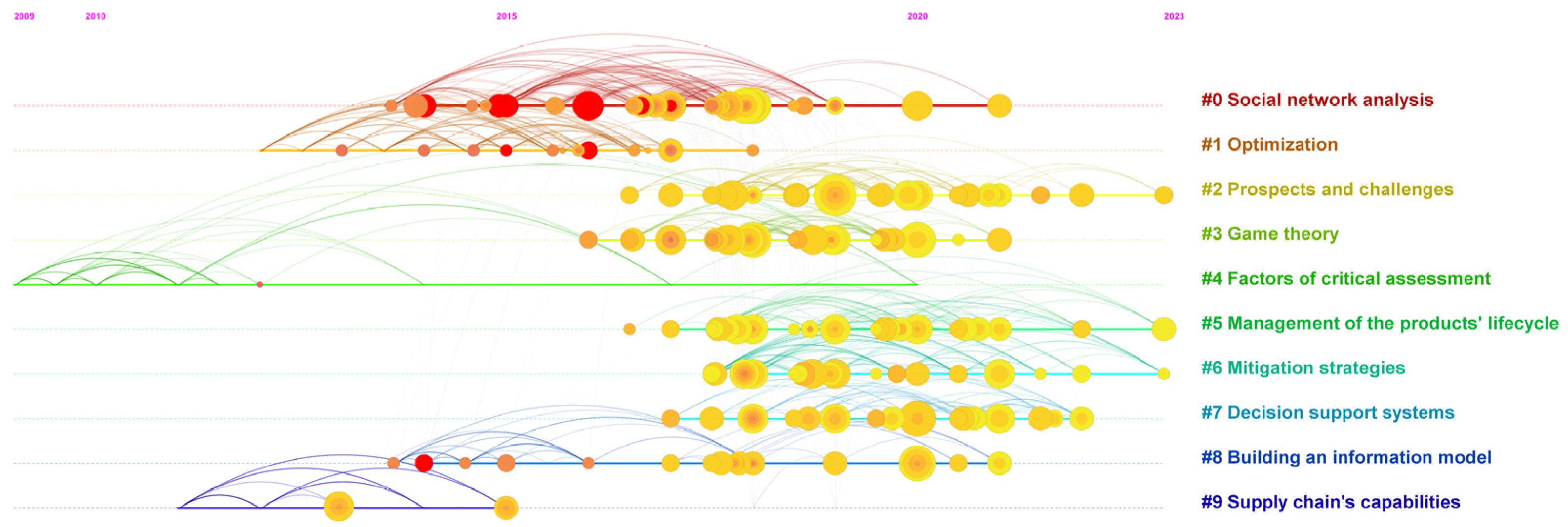

4.3. Knowledge Evolution

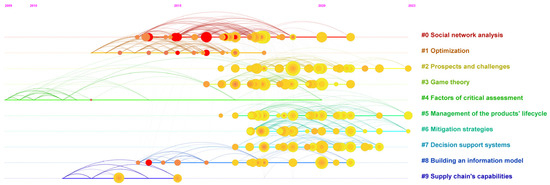

Here, we present the results of the time-span analysis, depicted in Figure 4, which revealed a distinct division of the evolution of knowledge into two stages on the basis of the timeline. In the initial stage, predating 2015, research and scholarly contributions regarding logistics in modular integrated construction (MiC) were emerging but limited. Attention and investigation in this field were relatively modest, with fewer publications and scholarly discussions dedicated to logistics-specific issues within the context of construction.

Figure 4.

Timeline of research domains.

However, the second stage, spanning from 2016 to the present, witnessed significant growth and development in the knowledge base concerning logistics in MiC. Researchers and industry practitioners increasingly recognized the significance of logistics in project delivery, supply chain management, and handling of materials. Consequently, there was a surge in the number of publications, research studies, and academic contributions during this period.

Furthermore, the results highlighted a shift in the focus of research between the two stages. In the first stage, there was more emphasis on the technical methods of logistics in MiC, whereas in the second stage, the focus of research shifted towards the capability and resilience of the supply chain. This change underscores the evolution of priorities and interests within the domain of research, suggesting that relevant research in this field will continue to gain attention.

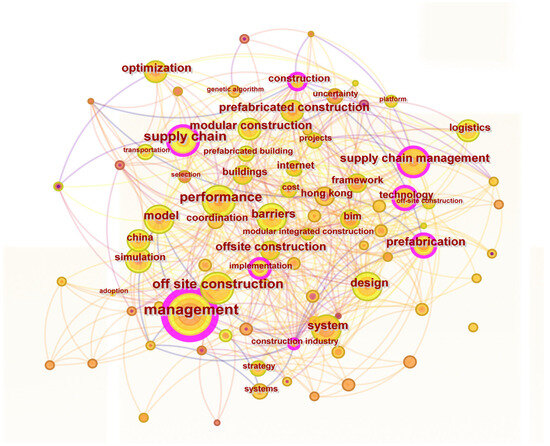

4.4. Knowledge Frontiers

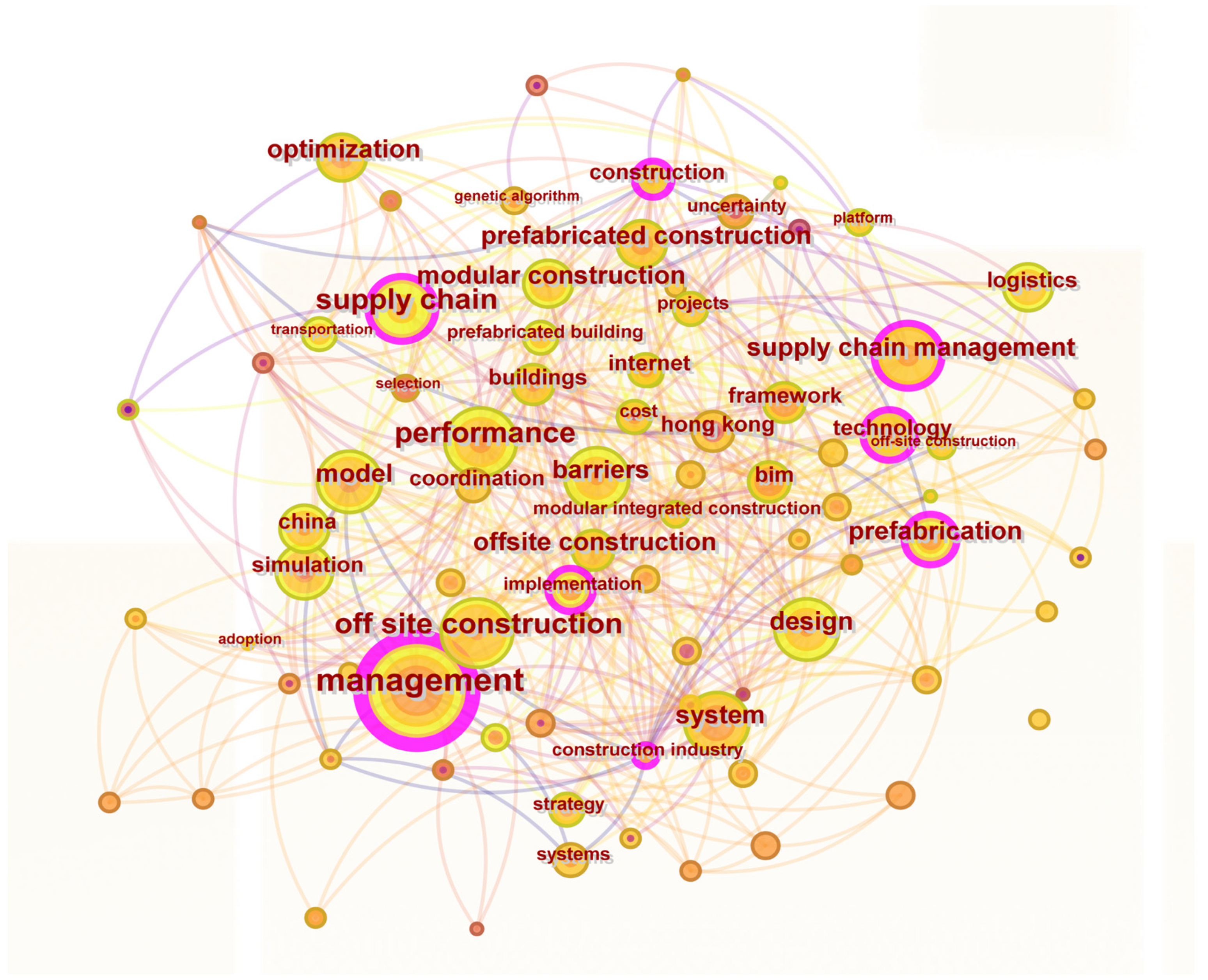

This section provides a summary of the findings derived from the keyword co-occurrence analysis spanning from 2010 to 2023, which is visually represented in Figure 5. In this analysis, the most frequently occurring keywords are depicted with larger characters, revealing three primary research aspects. First, the research delves into supply chain management, decision-making processes, blockchain technology, management of demolition waste, and optimization of the supply chain. Second, it focuses on research targets such as prefabricated buildings, modular construction, and offsite construction methodologies. Third, it explores research methods including model research, social network analysis, and case studies.

Figure 5.

Network of keywords’ co-occurrence.

Additionally, the results revealed recent strong citation bursts depicted in Figure 5, indicating emerging trends in research into supply chains and logistics within MiC. These trends encompass the integration of artificial intelligence and machine learning techniques, the adoption of building-model technology for enhanced traceability, the process of reverse logistics, and exploration of the principles of the circular economy in construction supply chains. The literature review underscored the importance of future research endeavors centered on evaluating the practical implementation of these innovations and assessing their impact on the supply chain’s performance within the context of MiC.

5. Discussion and Implications

5.1. Milestones in the Development of SCM-MiC

The chronological markers identified through the timespan analysis, as depicted in Figure 4, serve as crucial indicators of the progress made in SCM-MiC projects. Initially, the focus of research was on fundamental principles and methodologies of supply chain management [85,86]. This foundational work established the basic framework for understanding and managing supply chains in modular integrated construction (MiC). Over time, there has been a clear progression towards the application of advanced technologies and theories across various sub-domains, such as digitalization, automation, and sustainable practices [4,8]. This trend showed the evolution of SCM-MiC from the exploration of basic theories to the integration of multidisciplinary fields within the construction industry. The adoption of technologies such as building information modeling (BIM) and the internet of things (IoT) has been particularly noteworthy, marking significant milestones in enhancing efficiency and collaboration in SCM-MiC projects [87,88]. These chronological markers not only highlight the key developments in SCM-MiC but also reflect the dynamic nature of this field, driven by continuous innovation and interdisciplinary integration.

5.1.1. Birth Stage: Concept and Method of SCM-MiC

The birth stage of SCM-MiC marked the initial forays into fundamental applications and methodologies within the field. During this phase, researchers focused on exploring the potential of leveraging the supply chain to optimize the efficiency of construction, although their understanding of SCM in modular building processes was still developing. A significant milestone during this period is the work of Doran and Giannakis [86], titled “An examination of a modular supply chain: a construction sector perspective”. This seminal article delved into modular practices and principles within the construction sector’s supply chain, aiming to elucidate the alignment between supply chain practices and principles of modular construction.

Additionally, research during this stage delved into the overarching prospects and challenges inherent in SCM-MiC, such as the supply chain’s transparency [89], deeper explorations of the challenges [90], and analyses of the major barriers [91]. Moreover, this stage witnessed an exploration of management methodologies and emerging technologies in supply-chain-related research, aiming to enhance the efficiency of construction. Projects focused on management of the projects’ lifecycle (Cluster 5) and building an information model (Cluster 8) aligned closely with the temporal aspects of the timespan analysis. For instance, the study by O’Connor et al. [92] provided insights into the characteristics and benefits of modular projects with standard designs, while the research by Arashpour et al. [93] optimized decision-making processes in offsite construction networks, ultimately aiming to eliminate schedule delays and increase efficiency in modular construction practices. Arashpour et al. [94] built an autonomous production tracking method to eliminate schedule delays and the increased costs of deficiencies in offsite construction.

5.1.2. Development Stage: The Application of Technology and the Focus of SCM-MiC

After the year 2015, the landscape of research within SCM-MiC experienced a significant expansion, marking the onset of a growth phase. This period was characterized by a concerted effort to address the complex challenges posed by the multifaceted aspects of supply chain dynamics within the MiC domain. While previous research predominantly focused on the risks encountered during the construction stage of MiC projects, a comprehensive assessment revealed that schedule-related risks permeated modular integrated construction across the entire supply chain. Hsu et al. [8] highlighted this observation, emphasizing that risks manifested at every stage, from design and manufacturing to logistics and on-site assembly. In response to this understanding, Li et al. [95] delved into stakeholder-related risks, exploring their intricate cause-and-effect relationships. Their work aimed to uncover the network of potential risk factors associated with stakeholders, which significantly impact the complex framework of MiC projects. This perspective was further supported by Luo et al. [50], who meticulously identified and analyzed these risk factors, underscoring their pivotal role within the MiC landscape. Similarly, the contribution of Arshad and Zayed [7] offered valuable insights into the challenges arising from the complex supply chain and the sensitive logistical processes inherent in MiC projects.

Following the exploration of the supply chain’s risks within the context of the MiC approach, researchers shifted their focus towards examining the supply chain’s resilience, vulnerability, and capability, which represent critical dimensions contributing significantly to the robustness and effectiveness of SCM-MiC [96,97]. In light of the complex risks inherent in MiC projects, there was an increasing emphasis on the supply chain’s resilience, which involves equipping supply chains with the ability to anticipate, withstand, and recover from disruptions such as manufacturing delays, transportation issues, or unforeseen design changes [98,99]. In addition to the supply chain’s resilience, assessments of vulnerability played a vital role. Researchers analyzed potential weak points in MiC supply chains that were susceptible to disruptions such as material shortages, breakdowns of transportation, or regulatory shifts to develop strategies to mitigate these vulnerabilities [100]. Furthermore, the supply chain’s capability, referring to the inherent ability of a supply chain to efficiently deliver products or services, garnered attention from researchers. They sought to identify factors that enhance the supply chain’s capabilities, including accurate predictions of demand, streamlined stakeholder coordination, and optimized inventory management strategies [40].

The prevailing themes of this research direction, which included optimization, simulation, scheduling, and decision-making, collectively underscored the commitment to enhancing the efficiency, effectiveness, and overall performance of projects within the subject’s domain. Researchers incorporated diverse approaches such as social network analysis (SNA), fuzzy logic techniques, and game theory, among others. SNA highlights stakeholder-associated risks, interactions, and challenges, aiming to provide a structured framework for effectively managing these risks within MiC projects [101,102]. Additionally, researchers leveraged fuzzy logic approaches to discern a comprehensive array of the critical factors [90,103,104]. Moreover, game theory is widely utilized in optimization and simulation scenarios for modeling strategic decision-making among interdependent participants [53,105,106]. In this context, the research methodology centers around the identification and examination of these pivotal factors, constituting a holistic approach to understanding and enhancing the performance of the supply chain within the realm of MiC projects.

5.2. Major Knowledge Domains of SCM-MiC

The co-citation analysis identified three key dimensions within SCM-MiC: strategies, topics, and challenges. SCM strategies encompass methodologies such as social network analysis, game theory, and decision support systems, which are crucial for understanding the stakeholders’ interactions and navigating complex decision-making processes. In today’s global and risk-prone supply chains, these strategies facilitate agile responses to disruptions [107,108]. Additionally, focusing on the refinement of processes, leveraging information models, and coordinating the stages of the products’ lifecycle underscore the new demands on the planning and control mechanisms of SCM. Integration of technological advancements such as AI and big data analytics is imperative for optimizing supply chains [109,110]. Addressing the challenges of SCM involves grasping the industry’s trends, overcoming obstacles, and aligning SCM-MiC initiatives with organizational goals through the factors of critical assessment.

5.2.1. Directions of Supply Chain Management

In the evolving landscape of SCM-MiC, the importance of sophisticated planning and control mechanisms cannot be overstated. These complexities are reflected in the analytical methodologies, which are distributed across four significant clusters, highlighting critical areas such as optimization, management of the products’ lifecycle, modeling information, and enhancement of the supply chain’s capability. However, uncertainties and risk factors inherent in any link can significantly impact the overall operation of the supply chain [111]. Analytical methodologies in SCM-MiC, represented by four clusters, underscore the importance of improvements in the supply chain [112,113].

Firstly, optimization (Cluster 2 in Table 1) of MiC projects is crucial. Optimization of the supply chain aims to streamline the processes to achieve the best possible outcomes, balancing cost, speed, quality, and sustainability. Utilizing data analysis, mathematical modeling, and advanced algorithms, optimization techniques enhance forecasts of demand, management of the inventory, scheduling production, routing transportation, and resource allocation [32,83,114].

Secondly, management of the products’ lifecycle (Cluster 5 in Table 1) plays a significant role. Studying the lifecycle of the production system provides valuable insights and benefits for organizations involved in manufacturing and business operations. In supply chain management, the lifecycle of the production system ensures that products are designed with considerations for manufacturability, sustainability, and end of life [115]. By facilitating collaboration and information-sharing, it reduces the time to market, minimizes defects in the products, and enhances the supply chain’s overall efficiency [116,117].

Thirdly, establishing a comprehensive information model (Cluster 8 in Table 1) is critical for effective supply chain management. A robust information model provides transparency in the supply chain, enabling better decision-making, faster resolution of issues, and improved collaboration among stakeholders [32,83]. And finally, the supply chain’s capability, introduced in Section 5.1.2, is a vital area of research. Enhancing the supply chain’s capabilities involves investment in technology, talent, and processes to meet customers’ demands and strategic objectives. A resilient and agile supply chain with strong capabilities can navigate disruptions, seize opportunities, and consistently deliver value to customers.

5.2.2. Methods of Supply Chain Management

In the realm of SCM-MiC, the evolving landscape demands a profound re-evaluation of the planning and control mechanisms to navigate the intricacies of the stakeholders’ dynamics, strategic decision-making, and optimization of the supply chain. Among these, social network analysis (Cluster 0 in Table 1) stands out as a major knowledge domain. Recognizing stakeholders’ participation as a critical driving force stimulating the demand for SCM-MiC studies (as stated in Section 5.1), numerous discussions have focused on effectively managing a project’s stakeholders [50,101]. Given that construction projects often attract significant public attention due to their use of public funds and profound social impact, it is imperative to identify the stakeholders’ concerns clearly to detect the key challenges and associated risks of the stakeholders [63,114].

In addition to social network analysis, game theory (Cluster 3 in Table 1) has emerged as another frequently utilized simulation method. Game theory has proven invaluable for identifying suitable suppliers of various modular components and facilitating contract negotiations that align the goals of different suppliers, contractors, and stakeholders [32]. Moreover, the social equation model (SEM) has also been used to demonstrate that integrating different aspects of the supply chain positively impacts the operational performance, thereby improving the financial performance of the companies involved in the process of integration [118].

In advanced MiC, making robust supply decisions is vital. As the construction industry becomes more industrialized and digital, a decision support system (Clusters 7 in Table 1) utilizing ontology and multiagent methods is recommended for SCM-MiC. Through mathematical analysis and evaluations of real projects, this approach enhances decision-making in the manufacturing of prefabricated product [119,120].

5.2.3. Topics of Supply Chain Management

Supply chain management in modular integrated construction presents several unique challenges due to the combination of the attributes of manufacturing and construction, involving the offsite manufacturing of building components and their subsequent on-site assembly. These challenges span every aspect of the supply chain, with numerous studies discussing potential solutions. The overarching goal is to find effective strategies for addressing the challenges related to capability, resilience, vulnerability, and efficiency.

Identifying critical factors (Cluster 4 in Table 1) is paramount, including the optimization of scheduling, decision-making, and transportation [119,121,122]. Additionally, one study modeled the dynamic impact of the supply chains’ vulnerabilities and capabilities on the supply chains [98]. Wang et al. [123] systematically analyzed risks to the supply chain and calculated the risks’ balance point, concluding that risks can persist in the supply chain for extended periods.

Delving into the prospects and challenges (Cluster 2 in Table 1), delays in the schedule of construction have emerged as a fundamental challenge. These delays can stem from various factors and have far-reaching consequences for all stakeholders involved [8,124]. Additionally, accurately predicting the lead times for the manufacturing and transportation of modular components poses a challenge, given the coordination required among various processes and the potential disruptions impacting delivery schedules [20]. While modular construction offers potential cost savings, effectively managing the costs across the supply chain necessitates meticulous monitoring and control, especially considering potential variations in the costs of materials and the efficiency of production [125]. Implementing circular economy principles, such as reusing and recycling materials, within the supply chain of modular integrated construction can be complex. Designing components with future repurposing or recycling in mind can challenge the traditional thinking of a linear supply chain [126]. Moreover, concrete operational challenges persist. Adapting modular components to specific on-site conditions can be operationally challenging. Ensuring a seamless fit with the existing infrastructure and making the necessary adjustments efficiently are essential for smooth assembly [127].

5.3. Trends in the Supply Chain Management in MiC

Utilizing co-occurrence network analysis from 2011 to 2023 as a foundational framework, this study delved into the focal points at the cutting edge of SCM-MiC, as illustrated in Figure 5. The forthcoming changes in SCM-MiC align with the lifecycle processes and new technologies commonly found in modern construction projects. We compiled the essential co-occurrence keywords into a two-dimensional classification matrix, distinguishing between the SCM-MiC process and the main research domains of SCM-MiC summarized above. By leveraging such analytical tools, researchers and practitioners can pinpoint the vital intersections between emerging technologies and the lifecycle processes of complex construction projects.

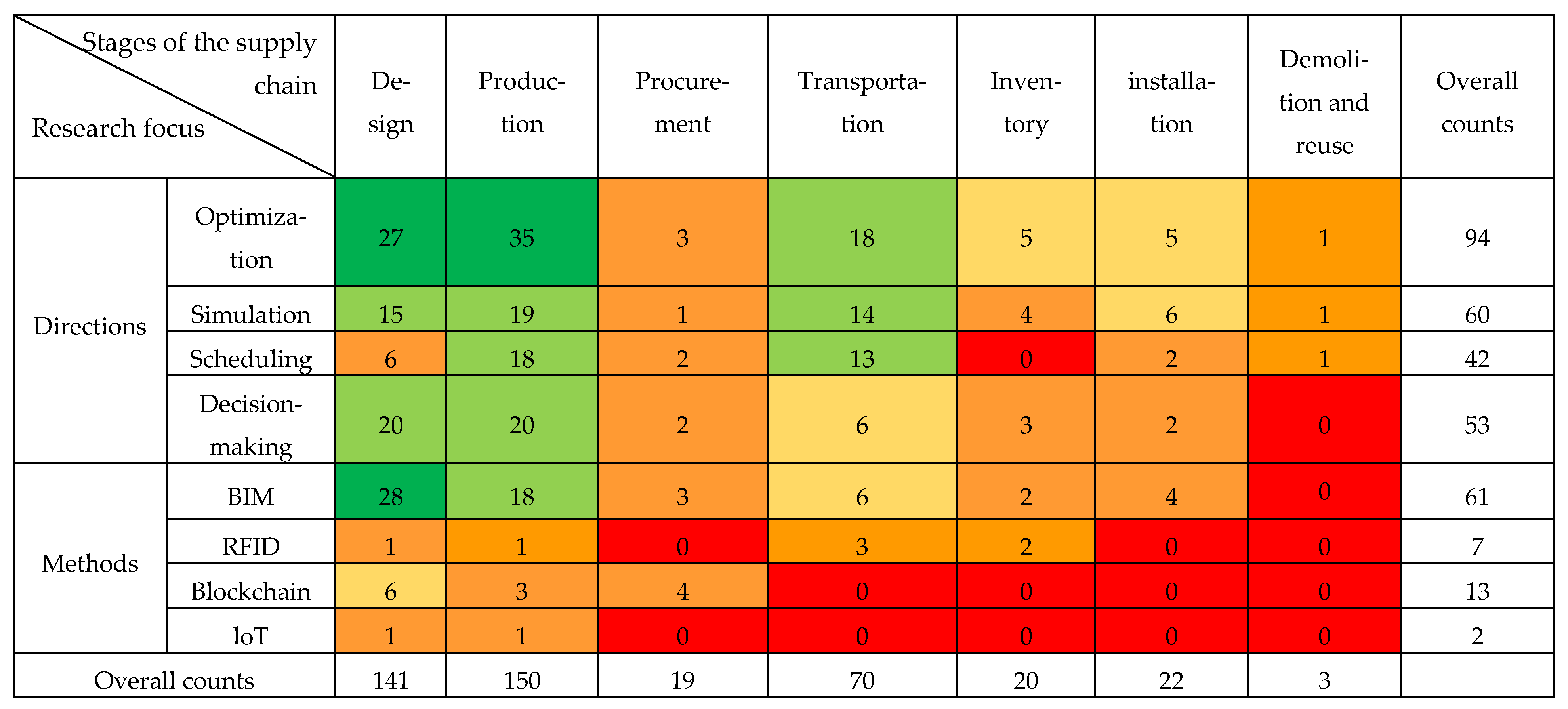

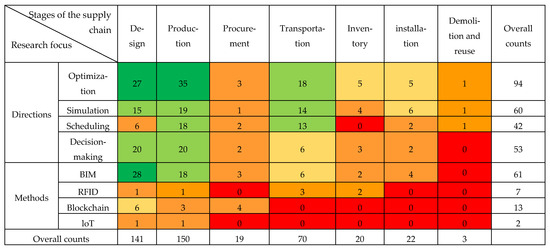

Regarding the lifecycle of construction processes, Figure 6 depicts the distribution of studies concerning the stages of construction and their research emphases. The stages of the supply chain encompass the overarching stages of the supply chains’ research, design, production, procurement, transportation, inventory, installation, and demolition. Predominant research directions center around optimization, simulation, scheduling, and decision-making. These investigations are often underpinned by specific methods, including building information modeling (BIM), artificial intelligence (AI), blockchain, the internet of things (IoT), and radio frequency identification (RFID). A color map is utilized to better visualize these matrices. Each graph is supplemented with a two-dimensional polynomial trend line to demonstrate the accumulation of knowledge in each of these research areas. Therefore, these figures provide an overview of mainstream research on the modeling of SCM-MiC and can guide researchers in identifying areas that need further study.

Figure 6.

Research trends and 2D classification matrix of SCM-MiC based on stages of the supply chain and solution methods. Note: Red color indicates there are 0 relevant papers; orange color indicates 1–4 relevant papers; yellow color indicates 5–9 relevant papers; light green color indicates 10–20 relevant papers; deep green color indicates more than 20 relevant papers.

5.3.1. Specific Research into the Stages of SCM-MiC

According to Figure 6, it is evident that the directions of SCM-MiC, including optimization, simulation, scheduling, and decision-making, are closely related to the field of project planning and control. These terms are commonly used to enhance processes, make efficient decisions, and optimize various aspects of systems. However, the distribution of the stages of research stages appears to be uneven, with earlier steps exhibiting higher article counts.

Examining the supply chain process depicted in Figure 6, prior researchers have primarily focused on addressing challenges at the stages of design (104 studies involved in total), production (115 studies involved in total), and transportation (60 studies involved in total). Design choices made during the initial phases of MiC projects significantly influence the effectiveness of the subsequent stages of the supply chain. Consequently, fostering close collaboration among design teams across diverse disciplines becomes imperative [20]. Furthermore, the research trend aimed to simplify uncertainties in the process of production related to goals and methods, to resolve conflicts between different industries on-site, and to address interdependencies among the supply chain’s members [128]. Moreover, the intricate logistics of transporting materials and equipment procured from the suppliers to designated construction sites necessitate meticulous planning to optimize route selection, modes of transportation, and scheduling [122].

The number of research articles focusing on procurement (15 studies involved in total), inventory management (16 studies involved in total), installation procedures (19 studies involved in total), and demolition strategies (3 studies involved in total) is relatively limited. Effective procurement strategies demand a thorough evaluation of the critical factors such as quality, cost, availability, and lead times [129]. Establishing collaborative partnerships with suppliers is crucial to ensure reliable sources and negotiate favorable terms [130]. Efficient inventory management is essential for the seamless functioning of the supply chain, ensuring timely access to the necessary materials and preventing disruptions caused by shortages or excess inventory [70]. Technological advancements play a vital role in enhancing the precision of inventory management, with specialized software tailored to the construction industry and real-time tracking systems improving the efficacy of oversight [131]. Addressing the complexities of installing large components and promoting streamlined collaboration in lean construction requires a focus on installation methodologies and the integration of information technology solutions [83]. Additionally, as modular integrated buildings continue to develop, attention to the management of demolition becomes imperative, considering the entire lifecycle of the building. Scholars are increasingly exploring demolition strategies and the reuse of components for specific buildings, highlighting the importance of sustainability in construction practices [132]. As research in SCM-MiC progresses, addressing the lacunae in these understudied areas will be crucial for advancing the field’s understanding and enhancing its practical applications.

5.3.2. Improvements in the Directions of SCM-MiC

In terms of the research directions, planning and optimization of the control of complex projects has received the most attention from previous researchers in SCM-MiC, followed by simulation, decision-making, and scheduling. This trend reflects a concerted effort to enhance the operations and management of the supply chain’s processes within the context of modular integrated construction. This indicates a sustained interest and recognition of the importance of optimizing the supply chain’s processes, simulating various scenarios, making informed decisions, and scheduling activities efficiently to overcome the challenges and complexities inherent in MiC projects.

In the realm of SCM-MiC, research into optimization is directed towards identifying optimal decisions and strategies across various aspects such as resource constraints, supply arrangements, and resource allocation. Researchers have used mathematical models, algorithms, and computational tools to optimize factors such as the cost, time, resource utilization, and quality, with the overarching goal of minimizing waste, maximizing resource utilization, and enhancing the overall performance of the supply chain. In recent years, there has been a notable emphasis on optimizing the processes of fitting and decision-making. Traditionally, managing the dimensional and geometric variability in MiC involved trial and error approaches and standardized tolerance values, which often led to the risk of reworking [46]. However, the adoption of decision-making and optimization approaches in SCM-MiC has introduced considerations of uncertainty [119]. For instance, techniques such as fuzzy set theory and the analytic hierarchy process (AHP) have been utilized to capture uncertainty effectively [133]. Moreover, uncertainty analysis, aimed at supporting optimization efforts, has been facilitated by various methods such as multi-attribute utility theory [134], media richness theory [135], discrete event simulation experiments [6], and cloud models [136]. The integration of uncertainty analysis has substantially enriched the field of SCM-MiC, highlighting the importance of addressing uncertainties in decision-making and the processes of optimization.

Based on the outcomes derived from numerical simulation, a set of managerial implications has been formulated to drive the advancement of MiC. These recommendations encompass strategies for widespread awareness, obligatory enforcement, enhanced integration of the industrial chain, and more robust guidance for the factories making the components [137]. To address environmental concerns, innovative scheduling methods for on-time production of precast components have been produced, leveraging integrated simulation–optimization algorithms, with the differential evolution–simulation approach standing out for effectively minimizing total weighted earliness and tardiness [138,139]. Numerous methods have been used to simulate scenarios of supply chain management in modular integrated construction, including approaches such as game theory and genetic algorithms. Effective coordination and timing of operations throughout the supply chain of offsite construction are crucial for project success. An orderly framework is presented to manage the supply chain, covering strategic planning, master planning and scheduling, and detailed planning and scheduling [140]. Additionally, a distinct approach involving integrated scheduling of offsite logistics for high-rise modular building projects has been suggested. This approach effectively addresses project-specific constraints and uncertainties, enhancing the project’s overall efficiency and performance [47].

5.3.3. Generalization of Research Methods in SCM-MiC

The most frequent solution methods used to solve the planning and control problems of the different stages of the SCM-MiC are BIM, blockchain, the IoT, and RFID. During ongoing technological progress, BIM plays a crucial role in navigating complex issues within MiC projects [83]. Functioning as an information exchange and dissemination platform among MiC projects, building information modeling (BIM) presents a novel avenue for the accurate and instantaneous collection of stakeholders’ information. A promising avenue is its integration with internet of things (IoT) technology [15,141]. In instances such as MiC projects, the combination of BIM models with RFID labels has been used to share stakeholders’ information, leading to enhanced schedule performance [142,143].

Additionally, the integration of blockchain technology holds promise for enhancing transparency, traceability, and trust within construction supply chains. Mechanisms such as smart contracts and secure data sharing streamline contractual procedures and mitigate conflicts, thereby promoting operational efficiency [48].

Looking forward to the Industrial Revolution 4.0, there is an expectation of the emergence of more advanced integrated information tools that will bolster SCM-MiC’s capacity to address sustainability, complexity, and uncertainty in construction projects [144]. In the current research landscape, there is a notable trend towards exploring and adopting advanced digital solutions to enhance efficiency, collaboration, and decision-making throughout the process of construction. Artificial intelligence (AI) stands out as a powerful tool with diverse capabilities, although its utilization in the construction field remains relatively limited compared with other sectors. AI holds significant potential, particularly in complex construction projects such as MiC, where it can accurately predict events, risks, and costs during the planning stage, leading to improved project outcomes and streamlined processes [145]. There is ample opportunity for further research into the applications of AI in SCM-MiC to unlock its full potential for driving innovation.

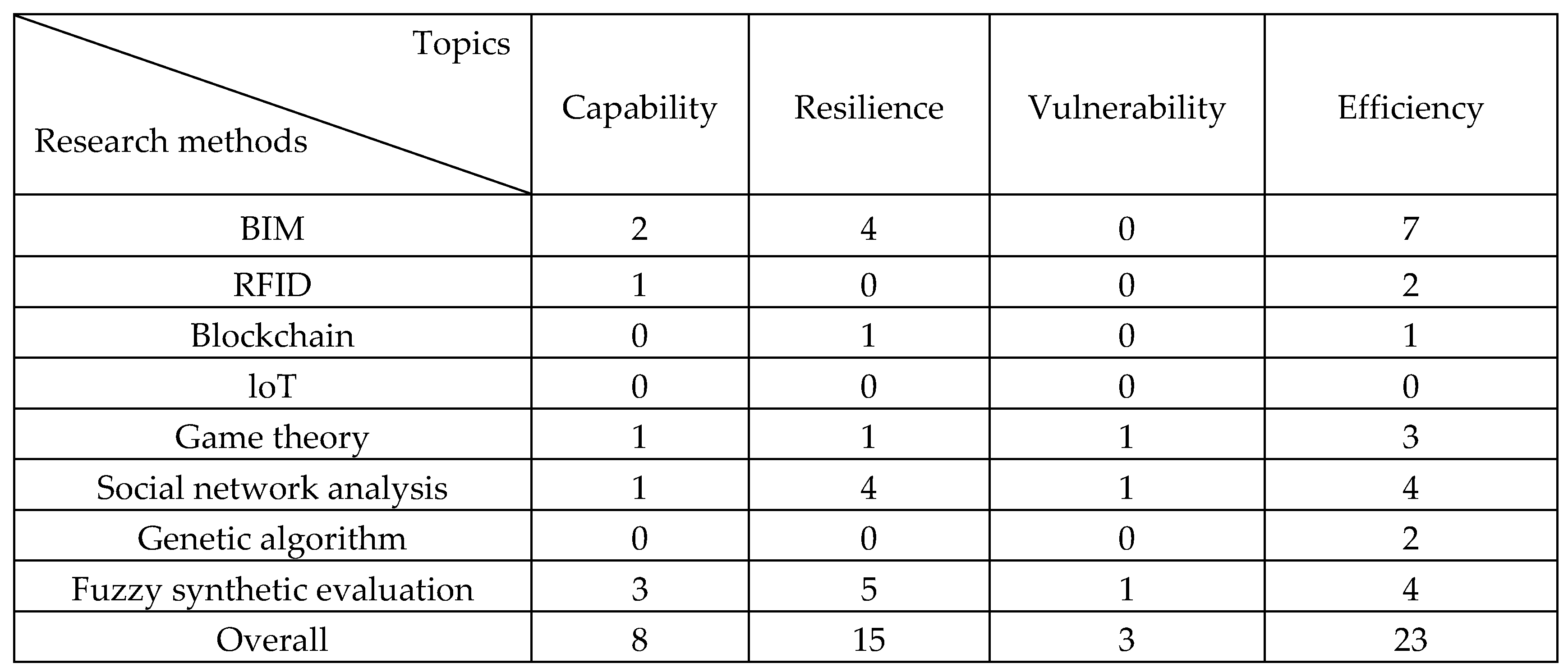

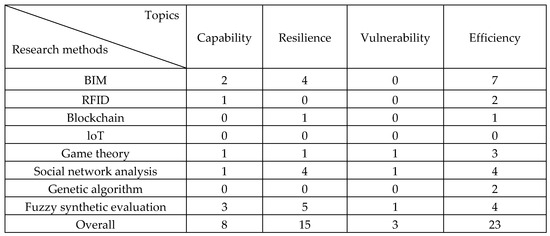

5.3.4. Research on Supply Chain Systems in MiC

After delving into the risks that supply chains face in the context of complex MiC projects, researchers have shifted their focus to explore four critical aspects: the supply chain’s resilience, the supply chain’s vulnerability, the supply chain’s capability, and the supply chain’s efficiency [146,147,148]. This line of research has predominantly focused on analyzing the entire system within SCM-MiC, aiming to understand its intricate workings and interactions (Figure 7).

Figure 7.

Quantitative analysis of research methods within supply chains’ systems in MiC.

The most prominent area of research revolves around enhancing the supply chain’s efficiency. The methodologies that have been used are diverse, with BIM being extensively utilized to amplify productivity, refine efficiency, and optimize effectiveness [149]. Additionally, there has been a growing tendency to enhance stakeholders’ relationships and pinpoint the essential factors for boosting the efficiency of SCM-MiC [150,151].

The supply chain’s capability and resilience have been less important research topics in research into the supply chain’s system. Recognizing the intricate risks embedded in MiC projects, considerable attention is being placed on enhancing the supply chain’s resilience. This entails preparing supply chains to anticipate, endure, and recover from disruptions such as delays in manufacturing, transportation glitches, or sudden design modifications. Furthermore, researchers are delving into the concept of the supply chain’s capability, which pertains to its inherent capacity to efficiently provide products or services. The objective here is to uncover factors that enhance the capabilities of supply chains. This encompasses areas such as accurate predictions of demand, seamless coordination among stakeholders, and optimized management of the inventory.

Building upon an understanding of the supply chain’s risks, the assessment of vulnerability has emerged as a crucial step. Researchers have turned to finding the underlying components of vulnerabilities and developing a model to explore the correlational impacts of vulnerabilities [40,104,151]. More researchers are conducting analyses to identify potential weak points within MiC supply chains that are susceptible to disturbances such as shortages of materials, breakdowns in transportation, or shifts in regulations [100].

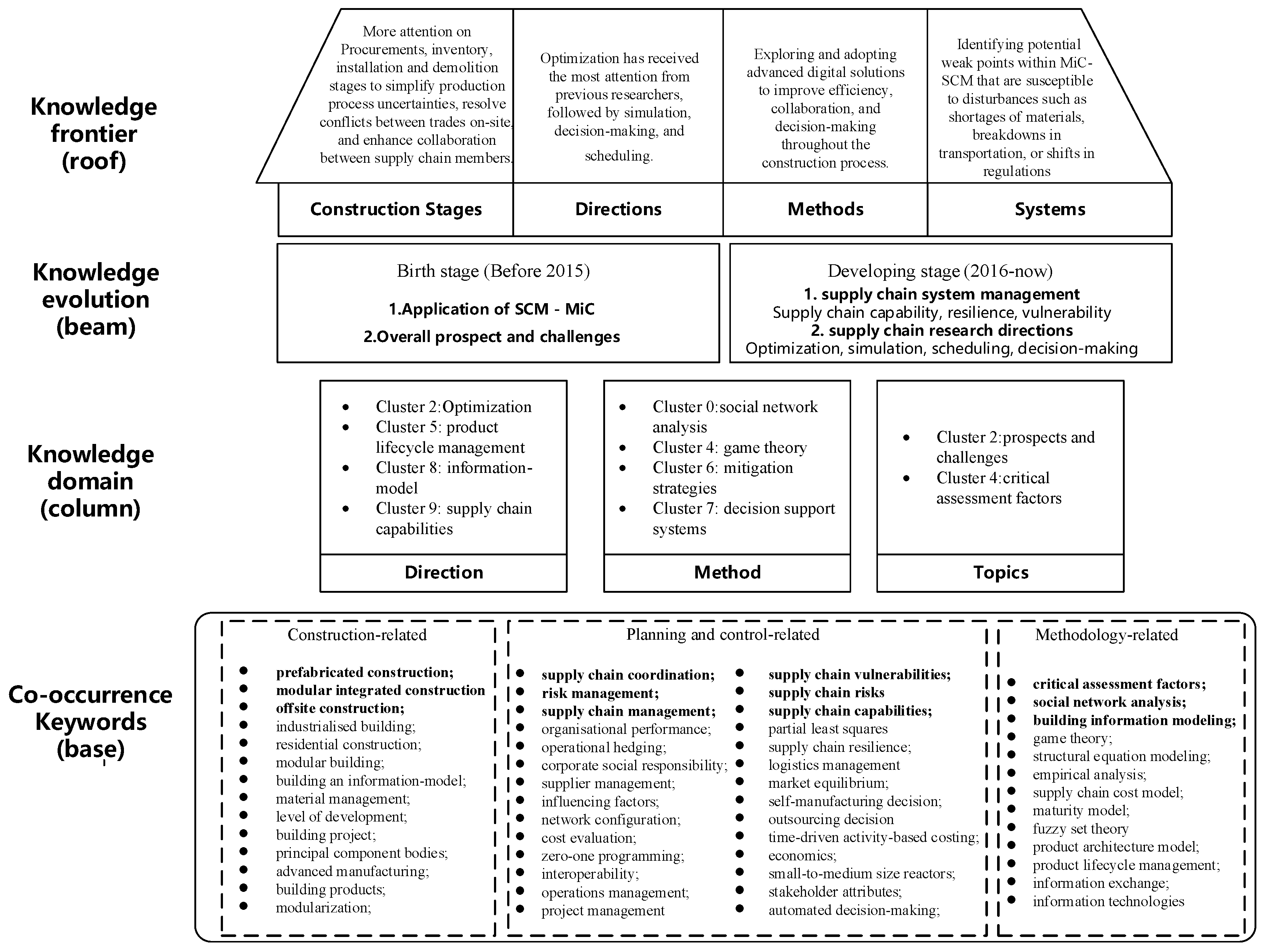

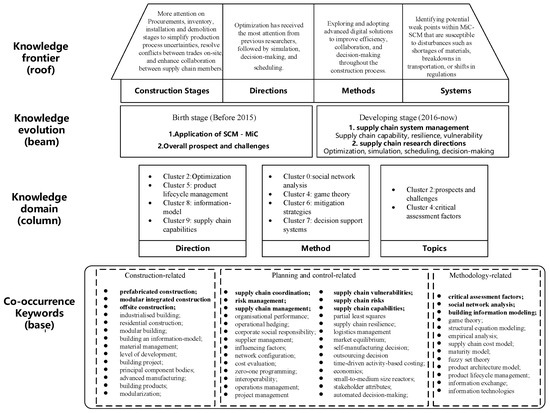

5.4. A Knowledge Map of Supply Chain Management in MiC

The depiction of the knowledge landscape within SCM-MiC, illustrated in Figure 8, resembles a residential model, representing its foundational, structural, and visionary components. The base represents the historical evolution of knowledge of SCM-MiC, providing insights into its classical underpinnings through pivotal milestones. These milestones serve as reference points for scholars, offering a deeper understanding of the field’s trajectory over time.

Figure 8.

“Housing model” of the knowledge map of SCM-MiC.

The base part of the graphic is composed of co-occurring keywords, which are mainly categorized as related to construction, planning and control, and methodology. The keywords in bold are the most frequent ones in each category. Anchored upon this foundation are three key aspects, forming 10 distinct clusters that shape the knowledge domain. These clusters act as foundational pillars, representing the multidisciplinary nature of SCM-MiC research and its correlation with contemporary stakeholder studies. This structural analogy provides scholars with a novel perspective on the existing research landscape within SCM-MiC, facilitating a comprehensive understanding of its multidimensional aspects.

Positioned atop this structure is the roof, symbolizing the trajectory of the knowledge frontiers across four dimensions: stages of construction, directions, methods, and systems. This visionary path outlines four synchronized research directions aligned with the complexities of construction-related project management and the evolution of construction-related information technology. These proposed research directions serve as bridges connecting stakeholder studies, construction-related project management, and domains of information technology, guiding future research endeavors in SCM-MiC.

6. Conclusions

The increasing complexity of construction projects has driven the development of MiC. The requirement for more refined MiC has made supply chain management progressively more topical. Our research used a bibliometric analysis method to delve into the evolution and frontiers of SCM-MiC research. First, we extracted data from the Web of Science (WoS) database due to its comprehensive coverage of the relevant literature. Following this, we utilized advanced bibliometric analysis tools to map and visualize the structure of knowledge within the SCM-MiC domain. In total, 196 articles centered around SCM-MiC concerns were extracted. Systematic analysis of the bibliographic records enabled the structured extraction of the evolution of knowledge, the scope of the domain, and insights into the frontier within the realm of MiC. Through a comprehensive analysis spanning multiple dimensions, including historical evolution, exploration of the domain, perspectives of the frontier, and knowledge mapping, we have gained valuable insights into the past, present, and future trajectories of SCM-MiC.

The study’s results indicated that the development of SCM-MiC can be traced through two pivotal milestones, marking significant advancements and challenges faced along the way. From the early stages of exploration to the integration of emerging technologies, researchers have diligently paved the path for understanding and optimizing the SCM-MiC domain. The 10 clusters were categorized into three critical dimensions within the knowledge domain: strategies, topics, and challenges. Looking towards the research frontier, the integration of construction-related information technology, including BIM and IoT, promises to revolutionize SCM-MiC, enhancing efficiency, collaboration, and decision-making throughout the process of construction. The metaphorical “house” of SCM-MiC, constructed upon the foundation of historical evolution, offers a comprehensive tableau capturing the past, present, and prospective dimensions of the field.

This research makes a distinctive theoretical and practical contribution to the field of SCM-MiC. The knowledge map presented in this study systematically traces the evolution, domains, and frontiers of SCM-MiC, shedding light on historical milestones and their impact on the knowledge system. By identifying key research areas within the latest knowledge frontier, the study has demonstrated how SCM-MiC research has expanded into a multidisciplinary field encompassing stakeholder research, construction-related project management, and information technology. These insights can inform practitioners and policymakers about the emerging trends and areas of focus within the industry, guiding decision-making processes related to planning projects, resource allocation, and the adoption of technology. Additionally, by pinpointing hotspots and gaps in the current research landscape, the study offers valuable guidance for stakeholders involved in the management of complex projects, facilitating the development of strategies to enhance efficiency, mitigate the risks, and promote sustainable practices in construction projects.

Despite the comprehensive analysis conducted in this study, it is important to acknowledge certain limitations that may have influenced the findings and conclusions. Firstly, for software compatibility reasons, only the literature resources of the WoS database were used. Furthermore, the analysis focused on academic research and may not have incorporated insights from industry practitioners involved in MiC projects.

As we pivot towards the future of SCM-MiC, it is imperative to focus on the potential and challenges presented by cutting-edge technologies such as artificial intelligence, blockchain, and augmented reality. These innovations hold the promise of fundamentally transforming SCM-MiC by optimizing the supply chain’s processes, which, in turn, can significantly enhance decision-making capabilities and operational efficiencies in complex projects. Furthermore, the integration of the principles of sustainability into SCM-MiC practices is crucial. This aligns SCM-MiC with broader global environmental objectives, prioritizing resource efficiency and reductions in waste. Incorporating these principles requires meticulous planning and control mechanisms to manage the sustainable practices within complex projects effectively. Cross-sectoral and cross-regional collaboration is another critical area that can amplify the benefits of SCM-MiC. By bridging the gap between theoretical research and practical applications, and by fostering an environment of international standardization, SCM-MiC can achieve greater uniformity and predictability in its outcomes, which are essential for global scalability and efficiency. Lastly, there is a pressing need for a thorough exploration of risk management strategies within SCM-MiC. As global challenges such as climate change and geopolitical instability increase the supply chain’s vulnerabilities, enhancing resilience through robust risk management becomes paramount. This not only involves identifying the potential risks but also developing strategies to mitigate these risks proactively. Integrating risk management with strong planning and control processes in the context of managing complex projects is vital for preemptively addressing these challenges and ensuring the robustness of SCM-MiC initiatives.

Author Contributions

Conceptualization, Y.Z. and G.Q.S.; methodology, J.X.; software, Y.Z.; validation, Y.Z., G.Q.S. and J.X.; formal analysis, Y.Z.; investigation, Y.Z.; resources, G.Q.S.; data curation, J.X.; writing—original draft preparation, Y.Z.; writing—review and editing, G.Q.S. and J.X.; visualization, Y.Z.; supervision, J.X.; project administration, G.Q.S.; funding acquisition, G.Q.S. All authors have read and agreed to the published version of the manuscript.

Funding

The Research Grants Council of the Hong Kong Special Administrative Region, China (Project No. PolyU/RGC PolyU15225822).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abdelmageed, S.; Zayed, T. A study of literature in modular integrated construction-Critical review and future directions. J. Clean. Prod. 2020, 277, 124044. [Google Scholar] [CrossRef]

- Hussein, M.; Eltoukhy, A.E.; Karam, A.; Shaban, I.A.; Zayed, T. Modelling in off-site construction supply chain management: A review and future directions for sustainable modular integrated construction. J. Clean. Prod. 2021, 310, 127503. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Critical success factors for modular integrated construction projects: A review. Build. Res. Inf. 2020, 48, 763–784. [Google Scholar] [CrossRef]

- Nguyen, T.D.H.N.; Moon, H.; Ahn, Y. Critical review of trends in modular integrated construction research with a focus on sustainability. Sustainability 2022, 14, 12282. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Exploring the critical success determinants for supply chain management in modular integrated construction projects. Smart Sustain. Built Environ. 2023, 12, 258–276. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Lee, E.; Chan, R.; Hosseini, M.R. Analysis of interacting uncertainties in on-site and off-site activities: Implications for hybrid construction. Int. J. Proj. Manag. 2016, 34, 1393–1402. [Google Scholar] [CrossRef]

- Arshad, H.; Zayed, T. Critical influencing factors of supply chain management for modular integrated construction. Autom. Constr. 2022, 144, 104612. [Google Scholar] [CrossRef]

- Hsu, P.Y.; Aurisicchio, M.; Angeloudis, P. Risk-averse supply chain for modular construction projects. Autom. Constr. 2019, 106, 102898. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Merigó, J.M.; Yang, J.-B. A bibliometric analysis of operations research and management science. Omega 2017, 73, 37–48. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, S.; Tan, L.; Tan, Y.; Wang, Y.; Ye, Z.; Hou, C.; Xu, Y.; Liu, S.; Wang, G. Frontier and hot topics in electrochemiluminescence sensing technology based on CiteSpace bibliometric analysis. Biosens. Bioelectron. 2022, 201, 113932. [Google Scholar] [CrossRef]

- Wen, S.; Tang, H.; Ying, F.; Wu, G. Exploring the global research trends of supply chain management of construction projects based on a bibliometric analysis: Current status and future prospects. Buildings 2023, 13, 373. [Google Scholar] [CrossRef]

- Chen, C.; Hu, Z.; Liu, S.; Tseng, H. Emerging trends in regenerative medicine: A scientometric analysis in CiteSpace. Expert Opin. Biol. Ther. 2012, 12, 593–608. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Hwang, B.-G. Risks of modular integrated construction: A review and future research directions. Front. Eng. Manag. 2020, 7, 63–80. [Google Scholar] [CrossRef]

- Zhou, J.X.; Shen, G.Q.; Yoon, S.H.; Jin, X. Customization of on-site assembly services by integrating the internet of things and BIM technologies in modular integrated construction. Autom. Constr. 2021, 126, 103663. [Google Scholar] [CrossRef]

- Tsz Wai, C.; Wai Yi, P.; Ibrahim Olanrewaju, O.; Abdelmageed, S.; Hussein, M.; Tariq, S.; Zayed, T. A critical analysis of benefits and challenges of implementing modular integrated construction. Int. J. Constr. Manag. 2023, 23, 656–668. [Google Scholar] [CrossRef]

- Andrić, J.M.; Mahamadu, A.-M.; Wang, J.; Zou, P.X.; Zhong, R. The cost performance and causes of overruns in infrastructure development projects in Asia. J. Civ. Eng. Manag. 2019, 25, 203–214. [Google Scholar] [CrossRef]

- Al-Momani, A.H. Construction delay: A quantitative analysis. Int. J. Proj. Manag. 2000, 18, 51–59. [Google Scholar] [CrossRef]

- Lawson, M.; Ogden, R.; Goodier, C.I. Design in Modular Construction; CRC Press: Boca Raton, FL, USA, 2014; Volume 476. [Google Scholar]

- Hussein, M.; Zayed, T. Critical factors for successful implementation of just-in-time concept in modular integrated construction: A systematic review and meta-analysis. J. Clean. Prod. 2021, 284, 124716. [Google Scholar] [CrossRef]

- Pan, W.; Yang, Y.; Pan, M. Implementing modular integrated construction in high-rise high-density cities: Perspectives in Hong Kong. Build. Res. Inf. 2023, 51, 354–368. [Google Scholar] [CrossRef]

- Gibb, A.; Isack, F. Re-engineering through pre-assembly: Client expectations and drivers. Build. Res. Inf. Syst. Front. 2003, 31, 146–160. [Google Scholar] [CrossRef]

- Deep, S.; Banerjee, S.; Dixit, S.; Vatin, N.I. Critical factors influencing the performance of highway projects: An empirical evaluation. Buildings 2022, 12, 849. [Google Scholar] [CrossRef]

- Shin, J.; Choi, B.J.B. Design and implementation of quality information management system for modular construction factory. Buildings 2022, 12, 654. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Bertram, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular construction: From projects to products. McKinsey Co. Cap. Proj. Infrastruct. 2019, 1, 1–34. [Google Scholar]

- Tafazzoli, M.; Mousavi, E.; Kermanshachi, S. Opportunities and challenges of green-lean: An integrated system for sustainable construction. Sustainability 2020, 12, 4460. [Google Scholar] [CrossRef]

- Choi, J.O.; Chen, X.B.; Kim, T.W. Opportunities and challenges of modular methods in dense urban environment. Int. J. Constr. Manag. 2019, 19, 93–105. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Ivanova, M. Literature review on disruption recovery in the supply chain. Int. J. Prod. Res. 2017, 55, 6158–6174. [Google Scholar] [CrossRef]

- Thai, H.T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. In Structures; Elsevier: Amsterdam, The Netherlands, 2020; Volume 28, pp. 1265–1290. [Google Scholar]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Luo, L.; Jin, X.; Shen, G.Q.; Wang, Y.; Liang, X.; Li, X.; Li, C.Z. Supply chain management for prefabricated building projects in Hong Kong. J. Manag. Eng. 2020, 36, 05020001. [Google Scholar] [CrossRef]

- Shen, G.Q.; Xue, J. Managing stakeholder dynamics and complexity in mega infrastructure projects. Front. Eng. Manag. 2021, 8, 148–150. [Google Scholar] [CrossRef]

- Zhou, J.X.; Huang, L.; Shen, G.Q.; Wu, H.; Luo, L. Modeling stakeholder-associated productivity performance risks in modular integrated construction projects of Hong Kong: A social network analysis. J. Clean. Prod. 2023, 423, 138699. [Google Scholar] [CrossRef]

- Banihashemi, S.; Tabadkani, A.; Hosseini, M.R. Integration of parametric design into modular coordination: A construction waste reduction workflow. Autom. Constr. 2018, 88, 1–12. [Google Scholar] [CrossRef]

- Iacovidou, E.; Purnell, P.; Tsavdaridis, K.D.; Poologanathan, K. Digitally enabled modular construction for promoting modular components reuse: A UK view. J. Build. Eng. 2021, 42, 102820. [Google Scholar] [CrossRef]

- Irizarry, J.; Karan, E.P.; Jalaei, F. Integrating BIM and GIS to improve the visual monitoring of construction supply chain management. Autom. Constr. 2013, 31, 241–254. [Google Scholar] [CrossRef]

- Isatto, E.L.; Azambuja, M.; Formoso, C.T. The role of commitments in the management of construction make-to-order supply chains. J. Manag. Eng. 2015, 31, 04014053. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhong, R.Y.; Li, Z.; Huang, G. Production lead-time hedging and coordination in prefabricated construction supply chain management. Int. J. Prod. Res. 2017, 55, 3984–4002. [Google Scholar] [CrossRef]

- Ekanayake, E.; Shen, G.; Kumaraswamy, M.M. Critical capabilities of improving supply chain resilience in industrialized construction in Hong Kong. Eng. Constr. Archit. Manag. 2021, 28, 3236–3260. [Google Scholar] [CrossRef]

- RezaHoseini, A.; Noori, S.; Ghannadpour, S.F. Integrated scheduling of suppliers and multi-project activities for green construction supply chains under uncertainty. Autom. Constr. 2021, 122, 103485. [Google Scholar] [CrossRef]

- Li, J.; Han, Y.; Duan, P.; Han, Y.; Niu, B.; Li, C.; Zheng, Z.; Liu, Y. Meta-heuristic algorithm for solving vehicle routing problems with time windows and synchronized visit constraints in prefabricated systems. J. Clean. Prod. 2020, 250, 119464. [Google Scholar] [CrossRef]

- Yang, H.; Chung, J.K.H.; Chen, Y.; Pan, Y.; Mei, Z.; Sun, X. Ordering Strategy Analysis of Prefabricated Component Manufacturer in Construction Supply Chain. Math. Probl. Eng. 2018, 2018, 4062871. [Google Scholar] [CrossRef]

- Ahn, S.; Han, S.; Al-Hussein, M. Improvement of transportation cost estimation for prefabricated construction using geo-fence-based large-scale GPS data feature extraction and support vector regression. Adv. Eng. Inform. 2020, 43, 101012. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Guo, D.; Wu, W.; Zhong, R.Y.; Huang, G.Q. Digital twin-enabled smart modular integrated construction system for on-site assembly. Comput. Ind. 2022, 136, 103594. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Yang, Y.; Pan, M.; Pan, W. Integrated offsite logistics scheduling approach for high-rise modular building projects. J. Constr. Eng. 2022, 148, 04022032. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Autom. Constr. 2020, 111, 103063. [Google Scholar] [CrossRef]

- Vrijhoef, R.; Koskela, L. The four roles of supply chain management in construction. Eur. J. Purch. Supply Manag. 2000, 6, 169–178. [Google Scholar] [CrossRef]

- Luo, L.; Qiping Shen, G.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-associated supply chain risks and their interactions in a prefabricated building project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Han, Y.; Xu, X.; Zhao, Y.; Wang, X.; Chen, Z.; Liu, J. Impact of consumer preference on the decision-making of prefabricated building developers. J. Civ. Eng. Manag. 2022, 28, 166–176. [Google Scholar] [CrossRef]

- Luo, T.; Xue, X.; Wang, Y.; Xue, W.; Tan, Y. A systematic overview of prefabricated construction policies in China. J. Clean. Prod. 2021, 280, 124371. [Google Scholar] [CrossRef]

- Aghasizadeh, S.; Tabadkani, A.; Hajirasouli, A.; Banihashemi, S. Environmental and economic performance of prefabricated construction: A review. Environ. Impact Assess. Rev. 2022, 97, 106897. [Google Scholar] [CrossRef]

- Mok, K.Y.; Shen, G.Q.; Yang, J. Stakeholder management studies in mega construction projects: A review and future directions. Int. J. Proj. Manag. 2015, 33, 446–457. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P.; Mahmud, A.T. Critical risk factors in the application of modular integrated construction: A systematic review. Int. J. Constr. Manag. 2022, 22, 133–147. [Google Scholar] [CrossRef]

- Chen, C.; Ibekwe-SanJuan, F.; Hou, J. The structure and dynamics of cocitation clusters: A multiple-perspective cocitation analysis. J. Am. Soc. Inf. Sci. 2010, 61, 1386–1409. [Google Scholar] [CrossRef]

- Su, H.N.; Lee, P.C. Mapping knowledge structure by keyword co-occurrence: A first look at journal papers in Technology Foresight. Scientometrics 2010, 85, 65–79. [Google Scholar] [CrossRef]

- Abu, K. Visualizing the citation patterns of parasitology research in India: A study using CiteNet explorer. Int. J. Innov. Knowl. Concepts 2016, 2. [Google Scholar]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. Science mapping software tools: Review, analysis, and cooperative study among tools. J. Am. Soc. Inf. Sci. Technol. 2011, 62, 1382–1402. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace: A Practical Guide for Mapping Scientific Literature; Nova Science Publishers: Hauppauge, NY, USA, 2016. [Google Scholar]