Abstract

Due to the industrialization of the construction sector, enterprises that manufacture prefabricated components are developing rapidly. Because the production capacity of each enterprise varies immensely, the upstream enterprises are unable to match the component manufacturing enterprises that are suitable for the supply target. With respect to the product capacity, scientific and accurate evaluations are crucial. The authors preliminarily determined factors that impact the production capacity of components and considered a literature review and the inspection results of component manufacturing enterprises. By performing a thorough investigation and analysis, they constructed the index system for evaluating the production capacity of enterprises that manufacture prefabricated components, and each index was interpreted. To determine the weight of the evaluation index, an analytic hierarchy process was utilized; furthermore, the characteristics of each grade were described, and a fuzzy comprehensive evaluation model was built. Moreover, to empirically analyze the built model, the authors selected a construction company and analyzed 127 questionnaires filled in by employees at all the organizational levels related to PCT production and to 34 evaluation results of experts from standard quota research institutions in various provinces. The results of the two methods revealed the following: This enterprise level is the “Reinforcement level” (level 3). The evaluation results are consistent with the empirical results of the model established herein, which verifies its feasibility.

1. Introduction

In recent years, sustainable development has become a global imperative [1]. More than 130 countries and regions have recently proposed the “zero carbon” or “carbon neutral” climate goal, and in September 2020, China officially proposed a goal aimed at achieving carbon peak by 2030 and carbon neutrality by 2060 [2]. Due to the increasingly strained resources that characterize the environmental scenario, the construction mode of construction projects and the development mode of the construction industry are accelerating the transformation of the sector [3]. Prefabricated construction (PC), which is a crucial method for achieving green development, has become prevalent worldwide [4], and the prefabricated component (PCT) is the main PC component [5]. Its development directly determines the development of prefabricated buildings and subsequently affects the achievement of sustainable development goals. Based on the investigation that considers the development of prefabricated components (PCs) in China, which was conducted by the Department of Standard Quota of Ministry of Housing and Urban–Rural Development, PRC, in 2021 (No. 33 of the Letter of Construction Bureau of the Individuals’ Republic of China (2021)), by the end of 2020, there were approximately 1170 prefabricated component manufacturing enterprises (PCMEs) in China, and with respect to different PCMEs, the price of PCTs varies considerably [6]. Undoubtedly, the difference in production capacity (PCP) is one of the factors that leads to the price variation [7]. Simultaneously, due to the immense difference in the PCP of each PCME, upstream enterprises cannot match the PCME that is suitable for the supply target [8]. Therefore, PC has encountered resistance in the national promotion process, which has affected the transformation of China’s construction industry and is ultimately not conducive to the achievement of sustainable development goals. Therefore, researchers should scientifically and accurately evaluate the PCP of each PCME.

The existing studies on the production stage of PCTs mainly focus on factors such as production scheduling optimization, production informatization, and production cost. Some scholars have analyzed the production scheduling model and considered all the parties that comprise the supply chain; furthermore, they have utilized the following calculation methods: the multi-objective hybrid symbiotic search algorithm [9], the multi-objective genetic algorithm model [10], the productivity utilization variance minimization model [11], the ant colony optimization algorithm hybrid optimization model that considers continuity and discretization [12], the dynamic decision support framework that is based on a genetic algorithm and a multi-agent system [13], and the MO-CGJaya/D algorithm [14]. Moreover, some scholars have focused on the informatization of the production stage. To enhance the manufacturing technology, the PCT construction process is analyzed and optimized, and the optimization entails combining lean construction and related theories with technologies such as building information modeling technology (BIM), a genetic algorithm, and Revit secondary development [15]; thus, the lean production and installation of PCTs is achieved. To monitor and manage the prefabrication process and enhance the automation of production equipment [16], we utilized the BIM-based PCT production stage energy consumption analysis method [17,18] and the RFID–BIM method [19]; furthermore, with respect to the production line, the aforementioned methods facilitated effective information management [20,21]. Regarding cost, some scholars have theoretically analyzed the PC project cost composition [22] and have considered the design, production, transportation, and installation costs [23]. This study accounts for the cost difference between prefabricated buildings (i.e., PC-based buildings) and traditional cast-in situ buildings [24]. To establish production cost analysis models, the study evaluates the factors that influence the PC cost [25], performs hierarchical division, and analyzes the key factors that control the PC cost [26], and the following methods are utilized: a hybrid genetic algorithm [27], an enhanced neural network algorithm [23], game theory–cloud theory [28], system dynamics [29], and time-driven activity-based costing [30]. Thus, the study offers targeted PCT cost-control countermeasures and proposals. Moreover, scholars have conducted research on the price-forecasting mode [31].

The research on PCP evaluation mainly considers the establishment of an evaluation index system and an evaluation method and usually focuses on the PCP evaluation that affects other industries or other aspects of the construction industry. The existing research on the establishment of an evaluation index system introduces numerous methods: literature surveys [32], field investigations, expert consultation [33], the anti-interpretive structural model method [34], and a word frequency analysis that is based on CiteSpace visualization software (5.7.R4, 2019) [35]. Thus, the research preliminarily determines factors such as the indicators, factor analysis, cluster analysis [36], principal component analysis [37], and system dynamics [38]. Furthermore, to analyze the mutual influence and logical relationship between the factors, determine the key factors, and establish an evaluation index system, the system introduces other influencing factors. The evaluation models pertaining to enterprises and industries have been continually analyzed. The analytic hierarchy process (AHP) emerged in the early 1970s [39], and in 1981, the good–bad solution example, ideal solution, and ideal point methods were proposed [40]. To determine index weights, some scholars proposed the structural equation modelling structural equation [41]; to enhance the objectivity and comprehensiveness of evaluation [42], some scholars selected the entropy method; and to solve the problem pertaining to repeated weighting, others selected the principal component analysis method [43]. Evaluation models include the fuzzy comprehensive evaluation method [41], the grey correlation analysis method [44], neural networks [45], topological networks [46], the data enveloping analysis method, the entropy method, and the extended multi-criteria compromise solution sorting method [47]. Furthermore, some scholars combine the existing qualitative and quantitative evaluation methods, such as the TOPSIS method [48], the AHP, and the interval hook intuitionistic fuzzy set; thus, an optimized qualitative and quantitative hybrid evaluation model is proposed. Moreover, some scholars propose a comprehensive evaluation method that is based on nonlinear optimization [49].

In summary, although there have been an increasing number of local and international studies that analyze PCTs, with respect to PCMEs, the contemporary studies remain limited. By analyzing the PCT production stage and that of the evaluation-related literature, we observed that most of the previous studies that consider the PCT production stage focus on the whole supply chain, and there are quite a few researchers who focus on only PCMEs. Moreover, the research is limited to the calculation of the scheduling capability, and a limited number of studies that focus on the PCP exist. Currently, research on the informatization that characterizes the production stage basically considers the enhancement of manufacturing technologies, and with respect to the utilization of information technology as a method for enhancing PCP, more in-depth research is required. The existing research on the production cost trend basically considers the cost research pertaining to the whole lifecycle, and there is no specific research that considers the production-stage cost; furthermore, because the research analyzes only part of the factors that affect the cost, it is incomprehensive. Although the establishment of an evaluation index system and that of an evaluation model has yielded immense research achievements that have affected the local and international industry, with respect to other industries or other aspects of the construction industry, the existing models are basically PCP evaluation methods. It can be observed that the research pertaining to how the PCP of PCMEs can be evaluated is potentially beneficial.

It is apparent that the existing production stage research provides a reference for the selection of PCP factors that influence PCMEs. The existing evaluation-related research provides theoretical support for the utilized evaluation model; however, the following questions should be answered: What are all the factors that affect PCP? How does each factor affect the PCP? How can the PCP be comprehensively evaluated? How can we determine the current PCME rank?

To answer these questions, we consider the current PC development state and the overall requirement pertaining to the scientific and accurate evaluation of the PCMEs; herein, we analyze each link that should be considered in the evaluation of the PCMEs. To identify the factors that affect the PCP, we performed a literature review and combined the published results with the interview results pertaining to the PCME. To classify the PCME and establish a set of PCP methods for evaluating the enterprises, the PCP evaluation index, which entailed the investigation and analysis of the factors that affect the PCP, was developed, and the PCP evaluation model was built. The model guides the evaluation of the PCME, and by facilitating continuous improvement and optimization, it enables the enterprise to understand its own development stage in a timely manner, accurately detect production bottlenecks, and enhance its production efficiency and competitiveness. The PCP analysis that this evaluation method utilizes can provide a certain reference for PCMEs; thus, they can develop production plans. Furthermore, because the study enables upstream enterprises to select suitable suppliers, it can positively enhance the performance of the enterprises. Finally, this study can enable enterprises to comprehend the level of PC development in a timely manner, activate the PCT market, guide the industry’s scientific development, and facilitate the PC development.

2. Methods

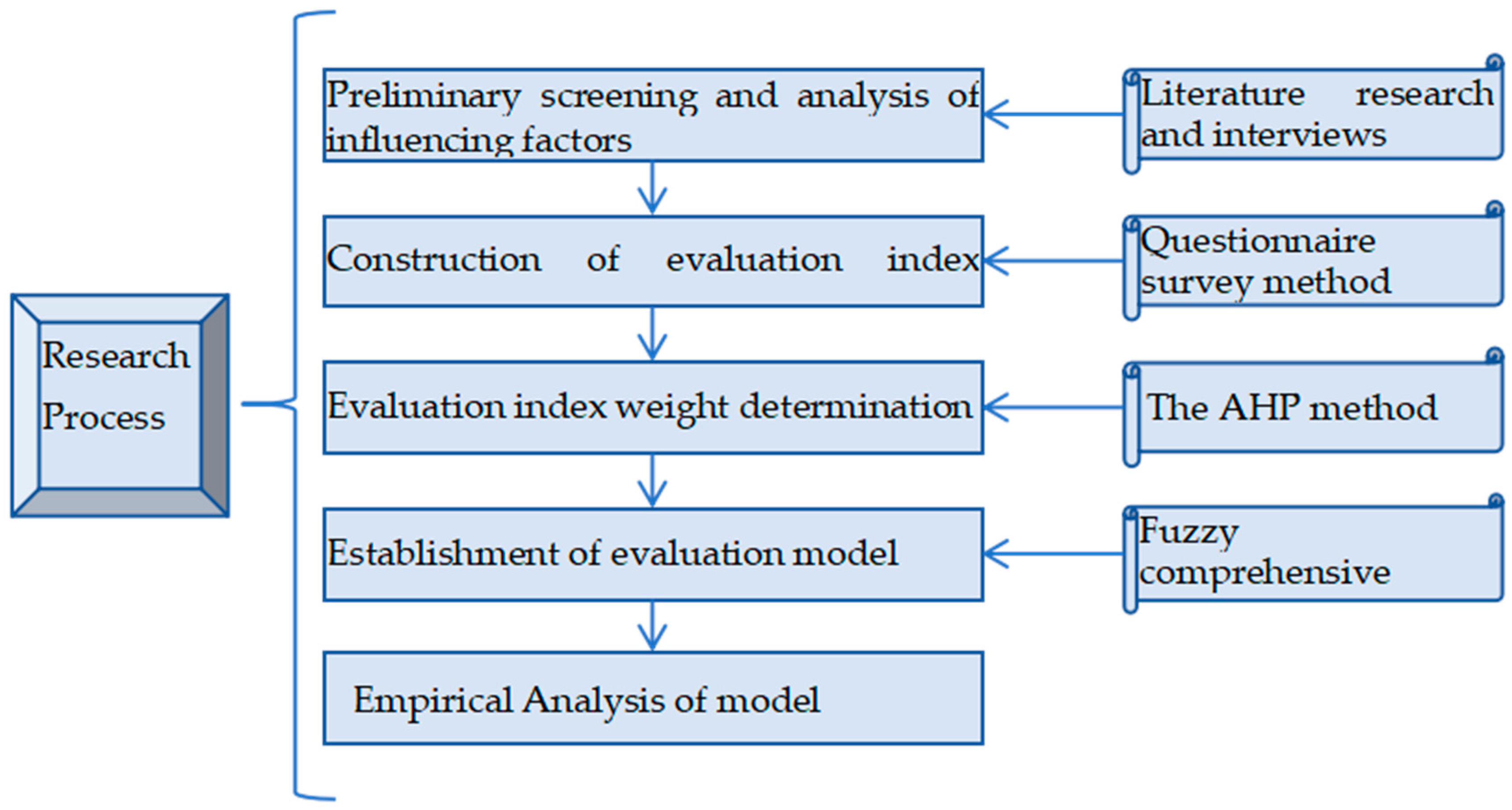

This study utilizes a variety of research methods. Figure 1 depicts the specific process pertaining to the evaluation of the PCP, and it focuses on PCME.

Figure 1.

Research flowchart.

2.1. Preliminary Determination of Indicators

We review academic literature, corporate reports, industry guidelines, and government documents from 2020 to 2023 to gather records of factors that may impact the PCP and preliminarily eliminate and merge words with the same meaning. Combined with the PCME interview results and the participation of production personnel and management personnel, the validity of the remaining factors was checked; finally, 33 factors that impact the PCP were selected [50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77].

The sources from which the influencing factors were derived include the following:

- (1)

- Academic literature: monographs, journals, research papers, and dissertations. To systematically search the relevant database, some keywords such as “prefabricated building”, “prefabricated component”, “production capacity”, and “index system” are utilized.

- (2)

- Enterprise and industry reports: PC-related research reports that are issued by enterprises or organizations, such as the China Prefabricated Building Development Report.

- (3)

- Industry guidelines: relevant technical guidelines and manuals that are issued by organizations such as the China Real Estate Research Society, the China Civil Engineering Society, the Housing Industry Development and Technology Committee, the Engineering Management Association, and the Building Industrialization Association. One such document is the “Prefabricated Construction Technical Manual (Concrete Structure Volume Production Part)”.

- (4)

- Government documents and standards: relevant statistical data, conference reports, technical standards, norms, and procedures that are issued by provincial housing and urban–rural development departments and provincial construction project cost management stations. One such document is the “Production of precast concrete components of prefabricated buildings standardized Management Regulations”.

2.2. Index Optimization Screening

The questionnaire method is more detailed, complete, and easy to control than the interview method. It can obtain more samples in a shorter time and exhibits higher efficiency. Additionally, because the questionnaire survey has a wider scope, researchers can select many samples. Moreover, the main advantage of the questionnaire method is standardization; its results are easily quantifiable. Finally, its cost is also quite low. Therefore, this study adopts the questionnaire method to investigate the importance of each influencing factor. Based on soliciting the opinions of experts, the preliminary design and optimization of the questionnaire are performed. The pilot test was performed in Jiangsu Province, China, and the reliability test was passed; thus, the final draft, which is illustrated in Appendix A, was formed. After feeding the final draft into the standardized survey system of the Ministry of Housing and Urban–Rural Development of China, we sent a questionnaire (i.e., system-derived outcome document that was provided by the standardization team of the Ministry of Housing) to PCMEs, government-related institutions, universities, and other research institutions across the country. Experts, scholars, managers, technicians, workers, and other relevant personnel were invited to fill in the questionnaire. The statistics indicate that 1492 valid questionnaires were recovered, and the collected questionnaires were processed as follows:

First, the number of individuals corresponding to each level of importance in each indicator is counted; subsequently, the importance is quantified. Consequently, the following values should be assigned as per expert advice: most = 100, more = 80, general = 60, and minimum = 40.

Second, to screen the influencing factors, the importance index is introduced.

Importance index = (∑number of individuals selected × importance value) ÷ total number of samples.

Finally, the importance index pertaining to each influence factor is calculated, and it is screened based on expert opinions.

2.3. Index Optimization Screening

Herein, a questionnaire survey and an expert interview were utilized to screen indicators and to establish an evaluation index system. The index system is divided into the following three levels: (1) the target level, which represents the index system that is adopted to achieve the final evaluation purpose; (2) the category level (i.e., the first-level indicator), which represents the different classification of evaluation indicators; and (3) the factor level (i.e., the second-level indicators), which represents the specific indicators in each category.

2.4. Index Weight Determination

After analyzing various methods and combining their respective characteristics, this study considerably enhances the AHP; thus, it determines the weight of the indicators. The specific process is as follows [78]:

- (1)

- Specify the basis for the assignment

By comparing their importance, this study assigns values to two elements (Table 1).

Table 1.

Assignment basis.

- (2)

- Design score table

Table 2 indicates the scoring table of the first-level indicators, and because the scoring table of the second-level indicators is similar to that of the first-level indicators, it is not depicted:

Table 2.

Scoring table.

Key:

- (1)

- X denotes the score pertaining to the importance of P1 compared with that of P2;

- (2)

- Z1 denotes the sum of the scores that are listed in Row P1;

- (3)

- The scenario in which P1 is more important than P2, P2 is more important than P3, and P3 is more important than P1 should be avoided.

- (3)

- Score by experts

To determine the weight of indicators and ensure the diversity of views, this study adopts various methods such as investigation, literature statistics, and recommendation investigation. From different departments such as enterprises, universities, and governments, the researchers selected professional and technical personnel and management personnel who have been working in PCMEs for more than 8 years as well as scholars who have possess the most academic achievements regarding PCP and PCT from 2016 to 2023. Meanwhile, personnel who have presided over PC and PCT topics several times in the past five years are also selected from the Ministry of Housing and Urban-Rural Development, China. This study invited 6 experts related to this research field (Table 3), and 5 experts finally responded.

Table 3.

Expert composition table.

- (4)

- Calculation and processing

The calculation process is as follows:

- (1)

- Constructing the judgment matrix

The integral of the index is obtained by processing the questionnaire data that were obtained from the experts, and to construct Judgment Matrix B, the pairwise ratio is processed as follows:

where Pij denotes the relative importance of pi, which is measured against pj. For example, p12 denotes the relative importance of p1, which is measured against p2, p12 = Z1/Z2.

- (2)

- Calculate according to Matrix B:

- (3)

- Calculate the n roots of , is :

- (4)

- Computational feature vector: :

denotes the weight of index i.

- (5)

- Calculate the eigenvalues of Matrix B:

- (6)

- Consistency test

To avoid contradictions pertaining to the importance of each factor, a consistency test, which considered the results, was conducted, and the following formula was utilized:

where n denotes the order of Matrix B.

When CI approximates 0, the results become consistent. To facilitate the analysis, RI is introduced. The size of RI is depicted in Table 4.

Table 4.

RI values.

To test whether the judgment matrix can be accepted, CR is utilized, and the following formula is applied:

As per the regulations [79] pertaining to the AHP, CR > 0.1, and B is not consistent.

- (7)

- Calculate the average weight of the indicators

Based on the preceding steps, the index weights corresponding to the scoring results of the five experts are calculated, and the average value is the final weight value of each index.

2.5. Comprehensive Evaluation Method

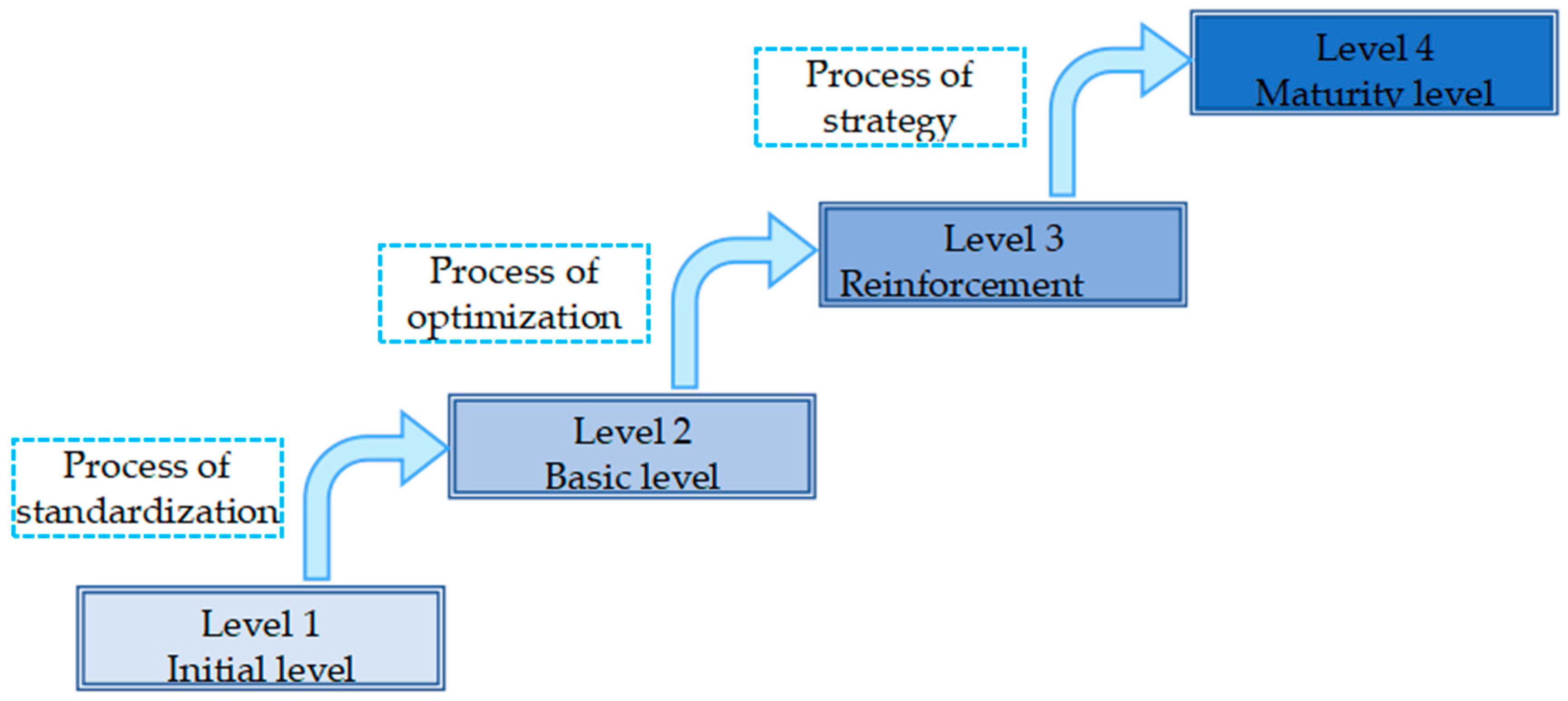

Based on the PCP characteristics pertaining to PCMEs [80], this study constructs a four-level PCP model, which is depicted in Figure 2.

Figure 2.

Production capacity level model of component manufacturing enterprises.

The PCP of PCMEs generally follows four phases, namely (1) the initial level, (2) the basic level, (3) the reinforcement level, and (4) the maturity level, and the description pertaining to each stage is depicted in Table 5.

Table 5.

Production–enterprise component-production capacity by grade.

By summarizing previous studies, this study summarizes some commonly utilized evaluation methods and performs a simple analysis, as illustrated in Table 6.

Table 6.

Comparison of evaluation methods.

The PCP of PCME is affected by many factors; some of the selected evaluation indicators are quantitative, and some are qualitative. Moreover, there is a correlation between these indicators. To evaluate these qualitative indicators fully and accurately, they should be converted into quantitative values for mathematical analysis and comparison. The fuzzy comprehensive evaluation method, which can effectively transform qualitative evaluation into a quantitative value is characterized by clear and systematic results, can more optimally solve fuzzy and difficult to quantify problems and is suitable for solving various non-deterministic problems [81,82,83,84,85,86,87]. The collaborative AHP and fuzzy comprehensive evaluation can enrich their advantages.

Therefore, to overcome the subjectivity of indicators, obtain the final evaluation results, obtain the optimal decision, and ensure the integrity, accuracy, and scientificity of PCME-related PCP evaluation, the fuzzy comprehensive evaluation method is utilized to evaluate the PCP of PCME in the end, and the process is as follows [88].

- (1)

- The construction of factor set U and evaluation set VEvaluation objective: PCP Grade B of the PCME

- (1)

- Establish factor set U

First-level indicators:B = {P1,P2,P3,P4,P5,P6,P7}Secondary indicators:P1 = {Q1,Q2,Q3,Q4,Q5}P2 = {Q6,Q7,Q8,Q9,Q10,Q11}P3 = {Q12,Q13,Q14,Q15,Q16}P4 = {Q17,Q18,Q19}P5 = {Q20,Q21}P6 = {Q22,Q23,Q24,Q25}P7 = {Q26,Q27,Q28,Q29}- (2)

- Establish evaluation set V

- (2)

- Construct the fuzzy evaluation matrix

The fuzzy evaluation matrix is represented by the following expression:

where Vij denotes Index i, the percentage of individuals who stated that the PCP grade of the PCME is Grade j. Therefore, the following formula is obtained: .

- (3)

- Fuzzy comprehensive evaluation

The evaluation vector corresponding to each first-level index is expressed as follows:

. Using the same calculation, we obtain the formulas for B2–B7.

The evaluation matrix of first-level indicators is expressed as follows:

Subsequently, the PCP final evaluation vector of the PCME should be expressed as follows:

Finally, the PCP level is the level that is represented by , and the expression pertaining to is expressed as follows:

3. Research Results

3.1. Index Screening Analysis

After statistically analyzing the 1492 collected questionnaires, the results are depicted in Table 7.

Table 7.

Statistical results pertaining to the importance of the factors influencing the production capacity of components related to production enterprises.

If “Perfection of internal incentive mechanism” is considered as an example, the preceding table indicates the following: 982 individuals think that the importance of this influencing factor is “most”, 216 think that it is “more”, 205 think that it is “general”, and 89 think that it is “minimum”. After processing as per the steps outline in Section 2.2, its importance index is expressed as follows:

Importance index = (∑number of individuals selected × importance value) ÷ total number of samples = (982 × 100 + 216 × 80 + 216 × 60 + 205 × 40)/1492 = 88.03

After all the data were processed, the quantization results are listed (Table 8).

Table 8.

Importance index of the factors affecting the production capacity of manufacturing enterprises.

With respect to the importance index of the PCP influencing factors, this study (in compliance with expert advice) eliminated the importance index that represents scores that are below 80 and finally screened out the main 29 influencing PCP factors.

3.2. Index System

In the preceding section, 33 impact factors were screened (as per expert opinions), and 29 PCP indicators were obtained. Table 9 illustrates the specific composition of the indicator system.

Table 9.

Evaluation index system of the component production capacity of manufacturing enterprises.

3.3. Indicator Weight Value

With respect to the preceding steps, the final results are depicted in Table 10; the results consider the scores pertaining to the five experts and are applied to the weights of the seven first-level indicators, namely, organizational management level P1, personnel level P2, machinery and equipment level P3, materials and materials level P4, product quality level P5, technical capability level P6, and production environment P7.

Table 10.

Eigenvalues and eigenvectors of five experts’ judgment matrix for first-level indicators.

The calculation results indicate that the five weight evaluation matrices are consistent. Therefore, the weights of the seven first-level indicators can be calculated as follows:

To calculate the weights of other indicators, we followed the preceding steps. Table 11 depicts the weights of all the PCP indicators.

Table 11.

Weight values of production–enterprise component–production capacity evaluation indicators.

4. Empirical Analysis

To verify the rationality and feasibility of the constructed model, this study selects Zhongnan Construction Group Co., Ltd. (Haimen, Jiangsu Province, China), and using the fuzzy evaluation method and the steps that are introduced in Section 2.5, we evaluate the enterprise’s PCP grade.

4.1. Enterprise Research

First, a questionnaire (Appendix B) was designed, and with respect to Zhongnan Construction Group Co., Ltd., staff pertaining to all the organizational levels that were associated with PCT production were invited to fill the questionnaire.

The following observation is noteworthy: in the process of distributing the questionnaire, we found that some employees had resistance to filling in the questionnaire. Considering that this would affect the comprehensiveness of the questionnaire, the research group invited relevant government leaders and senior executives to participate in the mobilization meeting. The questionnaire was reissued after the meeting. To solve this problem, we visited the workshop to redistribute the questionnaire. In this survey, we found that the reasons for the low questionnaire recovery rate were as follows: low literacy level, no understanding of the words, no understanding of the meaning of the indicator, and an exceedingly busy work schedule. Therefore, we utilized in situ face-to-face interviews to record their thoughts in the questionnaire.

4.2. Statistical Analysis

For this survey, 127 valid questionnaires were collected. After analysis, we still found that part of the final questionnaire was not available. For example, all the indicators in some questionnaires were selected at the same level. After eliminating 23 invalid questionnaires, the statistical processing of all valid results was completed, and Table 12 was obtained.

Table 12.

Membership of secondary evaluation indicators.

The significance of each value that is mentioned in the preceding table refers to the proportion of all the participants who propose that Zhongnan Construction Group Co., Ltd., has attained this level, and the investigation of certain indexes is considered. As indicated in the preceding table, the corresponding membership degree of Q19 is , which indicates that when examining the quality level of raw materials and collaboration materials, 60% of the transferred personnel indicated that the quality level pertaining to the raw materials and collaboration materials that are produced by Zhongnan Construction Group Co., Ltd., is Basic (Level 2), 30% indicated that the quality level is Reinforcement (Level 3), and 10% indicated that the materials matched the Maturity (Level 4).

- (1)

- With respect to the PCME, the evaluation vectors of each PCP index level were calculated as per Formula (9), where is expressed as follows:

Similarly, the values of , , , , , and are calculated.

- (2)

- Subsequently, to calculate the corresponding PCP evaluation vector C, we substituted the preceding calculation results into Formula (11):

- (3)

- As per Formula (12), we calculated .

Finally, it can be noted that the PCP grade of the PCME is 0.444, which indicates that the PCP of Zhongnan Construction Group Co., Ltd., corresponds to the Reinforcement level (level 3).

4.3. Model Evaluation

To evaluate the rationality of the results, this study invited the standard quota research institutions pertaining to each province; thus, the study evaluated the PCP grade based on the evaluation standards of the provinces in which the PCME was located. A total of 34 evaluation results were received, and the evaluation feedback from each institution was counted (Table 13).

Table 13.

Statistical table of the number of grades.

As indicated in Table 13, the most prevalent grade is the Reinforcement level (level 3).

The preceding evaluation results are consistent with the empirical results of the model developed herein, which indicates that the model is rational and feasible.

5. Discussion

This study aims to identify and verify the potential factors that affect the PCP of PCMEs and to develop a method for evaluating the PCP. The main influencing factors that exhibit relative independence were noted, and the PCP model was established. The study addresses the shortage of academic research on the PCP evaluation of PCME, and the proposed model can support PCME decision making and guidance for supplier selection. Using the following discussion, the study aims to enhance the practicality of the research results.

Regarding the preceding study, the researcher selected 33 influencing factors (i.e., factors pertaining to the effect of PCP on PCME); this selection considered the results that were published in the existing literature and interviews, and the results were briefly discussed. Consequently, we observed that “reasonableness of working-face distribution” and “reasonable layout of functional areas” are not mutually independent, and because the former influencing factor was included in the latter, the former should be eliminated. By contrast, when “mechanical equipment utilization level” and “mechanical equipment deployment level”, which are similar in meaning, are simultaneously utilized for evaluation, they are repeated. Moreover, because the deployment level is not only the utilization level and timeliness relative to production, the former should be eliminated. When the “employee’s understanding of component knowledge and production processes” is compared with “operator training and education level”, the former factor should entail what the latter refers to (in regard to training), and it exhibits a wider scope; therefore, the former cannot be retained. With respect to the “proficiency of production and operation personnel” and “skill level of production personnel”, the latter factor refers to skill levels that include not only proficiency but also other aspects such as lean production; therefore, the former should also be eliminated. Regarding the preceding study, based on the expert advice, the researcher excluded influential factors that exhibited a <80 importance index (i.e., four influential factors): the reasonableness of the working face distribution, mechanical equipment utilization level, employee’s understanding of component knowledge and production processes, and proficiency of production and operation personnel. For the aforementioned influential factors, which should be eliminated, it can be observed that it is appropriate for experts to propose the elimination of influential factors that exhibit a <80 importance index.

With respect to the final weights of all levels of indicators, it can be noted that the highest weight value pertaining to the first-level indicators is “product quality level”. Therefore, for the evaluation process of the PCP, researchers should focus on the quality of the PC components that are produced. This finding coheres with the study that was conducted by Song (2021) [89,90]. The weight calculation results of the secondary indexes that characterize the product quality level indicated that the weight values of “product pass rate” and “precision of product” are similar. With respect to the survey, we noted that 67.2% of employees who work in construction companies propose that compared with the pass rate, the return rate exerts an immense impact on quality. Through the investigation and analysis of this unique phenomenon, it is noted that due to the policy requirements of local governments, some PCMEs may focus on quality inspections; however, with respect to daily production, they may engage in dishonest practices. Thus, the quality of products is reduced. Therefore, Tao (2013) [91] proposes that the product return rate should be added to the evaluation index system. However, this study indicates that this index mainly applies to the product delivery stage rather than the production stage and that the return rate determines whether the project progress is delayed, whether the transportation cost is wasted, and whether the future contract documents is characterized by disputes. Tao’s study is based on the performance of the whole project, whereas this study focuses on only the PCT production stage; therefore, the return rate is not selected as an index. Instead, to evaluate the PCP, “precision of product” is utilized.

Furthermore, with respect to “level of personnel”, if we consider the secondary indexes, the weights pertaining to “reasonable on-site personnel allocation” and “skill level of production personnel” are the largest, and they are approximate. Skill level refers to the quantity of products that are simultaneously produced by workers during the production phase and also refers to the quality of the same product, which directly indicates the PCP of the PCME. The preceding observation was also mentioned in He Jiapo’s study [92]. The rationality level of on-site personnel allocation includes whether the composition of the personnel and the teams that were configured in each process of the production site matches the production demand. When the composition is quite high, the production is slow, and the resources are wasted. By contrast, when the production is quite low, the requisite production level is not attained. It can be observed that because this index affects the other indicators, it is immensely crucial, which coheres with the research that was conducted by Jiang (2014) [93].

For the secondary indexes that correspond to “enterprise organization management level”, “reasonable degree of decomposition of production organization” exhibits the largest weight. Furthermore, Ahmed [94] noted that an effective organizational structure can enhance development. However, for some evaluations, only the cost and quality of products are considered in the establishment of indicators, whereas the role of the enterprise management level is ignored. Because this study confirmed the perspectives of Ahmed et al., the index system was established, and this index was selected. Moreover, subsequent expert opinions also confirm this notion.

It should be noted that this study discusses only the production and processing capacity of a single enterprise. Contrastingly, Xu Xianhao [95] and other scholars propose that under the complex and dynamic market environment, the PCP is no longer limited to the production and processing capacity of a single enterprise; however, it considers the flexible management ability of the entire supply chain system and the response ability pertaining to the personalized demands of customers. Therefore, with respect to the aforementioned scholars, the PCP evaluation indicators are added; thus, the cooperation between enterprises can be enhanced, and the customer needs pertaining to indicators such as technological innovation, product structure optimization design, cooperation between enterprises, and supply chain management can be quickly addressed. This difference accounts for the difference in the subjects’ PCP.

With respect this study’s limitations, only Chinese experts were invited to establish the evaluation index system and to determine the index weights. Therefore, some studies that are cited herein may not be applicable to other countries and regions.

Simultaneously, by performing a statistical analysis of the data that were obtained using this method, the differences pertaining to the development of PC in different countries and regions can be reflected, and using a longitudinal comparison, which considers the evaluation data pertaining to different periods, the social production level that characterizes different periods can be measured. This study can indirectly enable researchers to understand the development of PC in real time and to further promote its development.

6. Conclusions

6.1. Main Conclusions and Innovations

In recent years, many PCMEs have emerged in China. However, with regard to PCP evaluation, a reliable evaluation tool is lacking. To meet the PCP evaluation requirements, and to provide a crucial reference for PCT production and technical progress, researchers should compile the PCP evaluation model. This study utilizes the PCP of PCMEs as the research object, and to clarify the factors that should be considered during the establishment of the evaluation model, it utilizes a variety of methods and theories. The main conclusions and innovations of this study are as follows:

- (1)

- Establish an index system to evaluate the ability of the PCME. First, through literature reviews and site visits, 33 PCP influencing factors were preliminarily determined. Subsequently, after performing an investigation and obtaining expert advice, the PCP evaluation index system was constructed, and it included seven first-level indexes, namely “enterprise organization management level”, “level of personnel”, “mechanical equipment level”, “materials and supplies”, “product quality level”, “level of technical competence”, and “production environment”. Because four influencing factors were eliminated, this index system comprised 29 secondary indexes.

- (2)

- The PCP evaluation model was established. First, to determine the weight of each evaluation index, the AHP method is utilized; subsequently, the PCP grades pertaining to “initial level”, “basic level”, “reinforcement level “and “maturity level “are applied. Finally, to construct the PCP model for evaluating the PCME, fuzzy comprehensive evaluation is utilized.

- (3)

- With respect to the model constructed herein, an empirical analysis was performed, and it was observed that the constructed model was rational and feasible. First, we conducted a survey that considered Zhongnan Construction Group Co., Ltd. Based on the data that were obtained from the survey, the PCP evaluation model was utilized for calculation and analysis; furthermore, we noted that the company’s PCP grade matched the reinforcement level. Subsequently, to facilitate PCP grade evaluation, standard quota research institutions pertaining to each province were invited. As per the statistical evaluation results, 18 institutions indicated that the enterprise exhibited the reinforcement level, which was the most prevalent PCP grade. The evaluation results are consistent with the model’s empirical results; thus, the constructed model is rational and feasible.

In summary, the main contributions of this study are as follows:

Theoretically, this study considers all the possible factors that affect production; forms a set of index systems; and develops an evaluation model, which considers the shortage of related academic research on PCP evaluation for PCMEs and enriches the database pertaining to PC research results.

With respect to practical application, the proposed model can facilitate the decision making of PCMEs. Based on the evaluation data, the enterprise managers can identify the difficulties that are encountered in the current development phase, identify the key aspects that should be enhanced, and formulate appropriate mitigation measures. Simultaneously, this model can also provide guidance for the selection of suppliers. Upstream enterprises can utilize this model to evaluate the PCP level of the available suppliers who serve the current market, and they can select the PCME that corresponds to the supply target. Moreover, it contributes to the development of PC.

6.2. Limitations and Further Recommendations

Although the author has performed a systematic and scientific study, some limitations persist, and many aspects still require further analysis:

- (1)

- This study utilizes the opinions of experts who are involved in the determination of relevant indicators and relevant weights; thus, it exhibits subjectivity, which may affect its scientific nature. More objective methods should be adopted in future research; alternatively, the influence of sample subjectivity on the scientific results should be reduced by expanding the number of experts and ensuring their diversity.

- (2)

- In regard to the empirical analysis, the staff that represent all the levels pertaining to PCT production were invited to fill the questionnaire; we assumed that the employees who work for the enterprise comprehend its state. However, due to the employees’ personal feelings towards the enterprise, the results may not be objective; thus, the final results are affected. In future studies, it may be possible to avoid the aforementioned problems by utilizing a more confidential approach or by inviting non-company employees who have no conflicts of interest to perform the evaluation.

- (3)

- Although this study determines the factors that influence the PCP of PCMEs, due to the level of progress that the society exhibits, the production technology and management mode is likely to change; thus, the developed PCP evaluation index system is imperfect. Therefore, researchers should consider how they can build an enriched and optimized system, which may necessitate the reestablishment of the indicator system by the addition, removal, and combination of indicators.

- (4)

- Although this study has built a PCP model method that can evaluate the production level of PCMEs, it has not performed an in-depth analysis of the consequential work, which entails investigating the following issues: the methods of determining the main factors that affect the current production capacity level; the methods that can optimize the different factors; and the methods of optimizing the model. Therefore, researchers should further explore methods of analyzing the development factors that should be enhanced (as per the evaluation results), formulate enterprise development strategies, and continue to explore the construction of a comprehensive and rational PCP optimization model.

We aim to promote the development of PC. However, due to the limited scope of this research, some aspects of the analysis provided herein will be explored in future studies.

Author Contributions

L.C. formulated this research topic, conducted the literature review, performed the theoretical framework model, and wrote the original draft; W.C. supplemented the research framework and improved the content; and Y.S. supervised the research direction, contributed to data collection, and participated in the data analysis. Z.Z. was responsible for data statistics and collation and analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partly supported by the National key Research and development Program of China (Project No.: 2021YFF0602002). This study was supported by the Ministry of Housing and the Urban-Rural Construction of the Individuals’ Republic of China.

Data Availability Statement

Data generated or analyzed during the study are available from the corresponding author by request.

Acknowledgments

The authors are grateful to the individuals who helped undertake the research and enhance this article. Special thanks to Li Xinrui from the School of Software, Taiyuan University of Technology, she is responsible for a lot of data analysis in this paper. We believe that her contribution is very great, and without her participation, the paper cannot be completed smoothly. We thank the survey participants for taking the time to complete the interviews.We would also like to thank the editors and reviewers for their insightful comments on this research.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Questionnaire of Factors Affecting Production Capacity of Enterprises.

Table A1.

Questionnaire of Factors Affecting Production Capacity of Enterprises.

| Dear Sir/Madam, Hello! Thank you for filling out this questionnaire. This questionnaire is aimed at providing a basis for the production capacity evaluation of prefabricated precast manufacturing enterprises, completing the compilation of the production capacity evaluation model of prefabricated precast manufacturing enterprises, and promoting the development of prefabricated buildings. The questionnaire has no adverse purpose and only provides data support for the study. Therefore, please take the time to fill in the questionnaire. Thanks again for your participation and support! If you are interested or have different opinions, please contact us at 249504991@qq.com. Thanks! Best wishes! | |||||||

| 1. Your occupation/organization: | |||||||

| ◯ Research institutes/universities | ◯ Construction units | ◯ design units | |||||

| ◯ Prefabricated component Manufacturer | ◯ Government Department | ◯ Supervision Unit | ◯ Others | ||||

| 2. The nature of your work in the unit: | |||||||

| ◯ Senior management | ◯ Middle management | ◯ Technical personnel | ◯ Administrative personnel | ◯ Others | |||

| 3. Your years of service: | |||||||

| ◯ 5 years or less | ◯ 5–10 years | ◯ 10–15 years | ◯ 15–20 years | ◯ More than 20 years | |||

| 4. In your opinion, the impact of the following factors on the production capacity of the manufacturer is (please tick √ after the corresponding options). | |||||||

| number | Factor of influence | Degree of importance | |||||

| most | more | general | minimum | ||||

| 1 | Perfection of internal incentive mechanism | ||||||

| 2 | Management system (e.g., inspection and measurement) soundness | ||||||

| 3 | Reasonable degree of decomposition of production organization | ||||||

| 4 | Level of coordination and communication between departments | ||||||

| 5 | Operator training and education level | ||||||

| 6 | The advanced level of production machinery | ||||||

| 7 | The number of production machines | ||||||

| 8 | Mechanical-equipment-utilization level | ||||||

| 9 | The complete degree of production machinery | ||||||

| 10 | Application of machinery to field conditions | ||||||

| 11 | Mechanical-equipment-deployment level | ||||||

| 12 | The degree of completeness of process procedures | ||||||

| 13 | Feasibility of production plan and technical measures | ||||||

| 14 | Whether the technology research and development center are established or not | ||||||

| 15 | Enterprise technical level accumulation degree | ||||||

| 16 | The level of leadership, organization, and control of management personnel | ||||||

| 17 | Reasonable on-site personnel allocation | ||||||

| 18 | Employee’s understanding of component knowledge and production process | ||||||

| 19 | Employee awareness of component quality | ||||||

| 20 | Skill level of production personnel | ||||||

| 21 | Proficiency of production and operation personnel | ||||||

| 22 | Team cooperation level | ||||||

| 23 | The labor enthusiasm of production and operation personnel | ||||||

| 24 | Operating site-environment comfort | ||||||

| 25 | Reasonable layout of functional areas | ||||||

| 26 | Production preparation is sufficient | ||||||

| 27 | Reasonableness of working-face distribution | ||||||

| 28 | Power-supply level | ||||||

| 29 | Product-pass rate | ||||||

| 30 | Precision of product | ||||||

| 31 | Reasonable placement of materials | ||||||

| 32 | Procurement and supply level of materials and materials | ||||||

| 33 | Quality level of raw materials and collaboration materials | ||||||

| If you have any further questions about this study, please feel free to comment below: The questionnaire has been completed. Thank you very much for your cooperation and assistance. | |||||||

Appendix B

Table A2.

Questionnaire for evaluating the production capacity of PC components.

Table A2.

Questionnaire for evaluating the production capacity of PC components.

| Dear Sir/Madam, Hello! Thank you for filling out this questionnaire. This questionnaire is aimed at providing a basis for the production capacity evaluation of prefabricated precast manufacturing enterprises, completing the compilation of the production capacity evaluation model of prefabricated precast manufacturing enterprises, and promoting the development of prefabricated buildings. This questionnaire has no adverse purpose and only provides data support for the study. Therefore, please take the time to fill in the questionnaire. Thanks again for your participation and support! If you are interested or have different opinions, please contact us at 249504991@qq.com. Thanks! Best wishes! | ||||

| 1.Your workplace: | ||||

| 2.Your department: | ||||

| 3.The nature of the work you undertake in this unit: | ||||

| ◯ Top management | ◯ Middle manager | ◯ Technical personnel | ◯ Administrative personnel | ◯ other |

| 4.Your years of service: | ||||

| ◯ ≤ 5 years | ◯ 5–10 years | ◯ 10–15 years | ◯ 15–20 years | ◯ >20 years |

| 5.In your opinion, the component production capacity level of your enterprise in the following aspects is (Please put an √ after the corresponding option). | ||||

| first-level index | second-level index | Production capacity grade of component manufacturing enterprise | ||

| Enterprise organization management level (P1) | Perfection of internal incentive mechanism (Q1) | Initial level: Not formed or formed but not executed ( ) Basic level: It’s a reasonable system but it’s just starting to work ( ) Reinforcement level: The system is exceedingly reasonable, feasible and relatively smooth ( ) Maturity level: The system is exceedingly reasonable, feasible and works well ( ) | ||

| Management system (e.g., inspection, measurement, etc.) soundness (Q2) | Initial level: No management system ( ) Basic level: Just meet normal production ( ) Reinforcement level: Sound management system ( ) Maturity level: The management system is quite sound and smoothly implemented ( ) | |||

| Reasonable degree of decomposition of production organization (Q3) | Initial level: The breakdown of production organization is not reasonable ( ) Basic level: The decomposition of production organization is unreasonable ( ) Reinforcement level: The decomposition of production organization is more reasonable ( ) Maturity level: Reasonable decomposition of production organization ( ) | |||

| Level of coordination and communication between departments (Q4) | Initial level: There is limited coordination and communication ( ) Basic level: Not much coordination and communication ( ) Reinforcement level: Frequent coordination and communication ( ) Maturity level: Long-term coordination and communication and the effect is obvious ( ) | |||

| Operator training and education level (Q5) | Initial level: Basically, no training ( ) Basic level: Trained several times ( ) Reinforcement level: Regular training ( ) Maturity level: Long-term training and the effect is apparent ( ) | |||

| Level of personnel (P2) | The level of leadership, organization, control, etc., of management personnel (Q6) | Initial level: Inability to effectively manage and organize production ( ) Basic level: General management ability, able to organize normal production ( ) Reinforcement level: Strong management ability and can effectively organize production ( ) Maturity level: A highly qualified management team that can effectively developand ( ) | ||

| Reasonable on-site personnel allocation (Q7) | Initial level: Personnel allocation is not reasonable, cannot ensure normal production ( ) Basic level: General staffing and low production efficiency ( ) Reinforcement level: More reasonable and efficient personnel allocation for production ( ) Maturity level: The personnel allocation is quite reasonable and can perform ( ) | |||

| Employee awareness of component quality (Q8) | Initial level: Employees have low awareness of component quality ( ) Basic level: Employees have general awareness of component quality ( ) Reinforcement level: Employees have strong awareness of component quality ( ) Maturity level: Employees have strong awareness of component quality ( ) | |||

| Skill level of production personnel (Q9) | Initial level: The technical level of the operators is poor ( ) Basic level: The technical level of the operators is average ( ) Reinforcement level: The technical level of the operators is high ( ) Maturity level: The technical level of the operators is quite high ( ) | |||

| Team cooperation level (Q10) | Initial level: Team coordination is poor ( ) Basic level: Team cooperation is not good ( ) Reinforcement level: Team cooperation is tacit ( ) Maturity level: The team cooperated quite well ( ) | |||

| The labor enthusiasm of production and operation personnel (Q11) | Initial level: Labor enthusiasm is not high ( ) Basic level: General enthusiasm for labor ( ) Reinforcement level: High enthusiasm for labor ( ) Maturity level: The labor enthusiasm is quite high ( ) | |||

| Mechanical equipment level (P3) | The advanced level of production machinery (Q12) | Initial level: Backward production machinery, cannot ensure normal production ( ) Basic level: The level of production machinery is normal, and can produce normally ( ) Reinforcement level: The level of production machinery is relatively advanced, which can smoothly conduct the production work ( ) Maturity level: The level of production machinery is quite advanced, which can perform the production work quickly and efficiently ( ) | ||

| The number of production machines (Q13) | Initial level: The number of production machinery is small, unable to produce normally ( ) Basic level: The number of production machinery is not large, and the production can be normal ( ) Reinforcement level: Sufficient production machinery, the production work is smooth ( ) Maturity level: The production machinery is quite sufficient and the production work is quite smooth ( ) | |||

| The complete degree of production machinery (Q14) | Initial level: Production machinery is not complete, cannot guarantee normal production ( ) Basic level: The production machinery is generally complete, and the production efficiency is not high ( ) Reinforcement level: More complete production machinery, more efficient production ( ) Maturity level: Production machinery is quite complete, and production components are barrier-free ( ) | |||

| Application of machinery to field conditions (Q15) | Initial level: Machinery is not suitable for field conditions ( ) Basic level: Machinery is generally suitable for field conditions ( ) Reinforcement level: The machinery can more optimally adapt to the site conditions ( ) Maturity level: The machinery is quite suitable for field conditions ( ) | |||

| Mechanical equipment deployment level (Q16) | Initial level: The deployment of mechanical equipment is confused ( ) Basic level: The allocation of mechanical equipment is basically normal ( ) Reinforcement level: Mechanical equipment deployment is timely ( ) Maturity level: Smooth deployment of mechanical equipment ( ) | |||

| Materials and supplies (P4) | Reasonable placement of materials (Q17) | Initial level: Improper placement of materials ( ) Basic level: The reasonable placement of materials is general ( ) Reinforcement level: The placement of materials is more reasonable ( ) Maturity level: The arrangement of materials is quite reasonable ( ) | ||

| Procurement and supply level of materials and materials (Q18) | Initial level: The procurement and supply level of materials and materials is low, which cannot guarantee normal production ( ) Basic level: The procurement and supply level of materials and materials is general, which can guarantee the basic production ( ) Reinforcement level: High level of procurement and supply of materials ( ) Maturity level: The procurement and supply level of materials is exceedingly high, which can ensure efficient production ( ) | |||

| Quality level of raw materials and collaboration materials (Q19) | Initial level: Poor quality of raw materials and collaboration materials ( ) Basic level: The quality of raw materials and collaborative components is average ( ) Reinforcement level: The quality of raw materials and collaborative components is more optimal ( ) Maturity level: The quality of raw materials and collaboration materials is excellent ( ) | |||

| Product quality level (P5) | Product pass rate (Q20) | Initial level: The qualified rate of the produced products is quite low ( ) Basic level: The qualified rate of the produced products is average ( ) Reinforcement level: Higher qualified rate of produced ( ) Maturity level: The production product qualified rate is quite high ( ) | ||

| Precision of product (Q21) | Initial level: The produced products are more crude ( ) Basic level: The precision of the products can meet the requirements ( ) Reinforcement level: High precision of the produced products ( ) Maturity level: The produced products are of high precision ( ) | |||

| Level of technical competence (P6) | The degree of completeness of process procedures (Q22) | Initial level: No process regulation ( ) Basic level: There are simple process procedures ( ) Reinforcement level: Relatively complete technological procedures ( ) Maturity level: Complete process regulation system ( ) | ||

| Feasibility of production plan and technical measures (Q23) | Initial level: Production plan and technical measures are not feasible ( ) Basic level: Production schemes and technical measures are partially feasible ( ) Reinforcement level: The production plan and technical measures are more feasible ( ) Maturity level: The production plan and technical measures are quite feasible ( ) | |||

| Enterprise technical level accumulation degree (Q24) | Initial level: No technology research and development center ( ) Basic level: The establishment of technology research and development center but investment is not robust ( ) Reinforcement level: Establish a technology research and development center and invest heavily ( ) Maturity level: Establish a technology research and development center with immense investment ( ) | |||

| Whether the technology research and development center are established or not (Q25) | Initial level: The ability to accumulate technical level is weak ( ) Basic level: Technical level accumulation ability is average ( ) Reinforcement level: A satisfactory ability to accumulate technical level ( ) Maturity level: Technical level accumulation ability is quite satisfactory ( ) | |||

| Production environment (P7) | Operating site environment comfort (Q26) | Initial level: The operation site is uncomfortable ( ) Basic level: The operation site environment is normal ( ) Reinforcement level: The site environment is comfortable ( ) Maturity level: The site environment is exceedingly comfortable ( ) | ||

| Reasonable layout of functional areas (Q27) | Initial level: The layout of functional areas is not reasonable ( ) Basic level: The layout of functional areas is general ( ) Reinforcement level: The layout of functional areas is reasonable ( ) Maturity level: The layout of functional areas is quite reasonable ( ) | |||

| Production preparation is sufficient (Q28) | Initial level: The production preparation is not sufficient ( ) Basic level: The production preparation is not quite sufficient ( ) Reinforcement level: Adequate preparation for production ( ) Maturity level: The production preparation is quite full ( ) | |||

| Power supply level (Q29) | Initial level: Power supply cannot achieve normal production ( ) Basic level: Power supply level is general and can support basic production ( ) Reinforcement level: The high power-supply level can meet the high production requirements ( ) Maturity level: The power-supply level is quite high to meet the needs of efficient production ( ) | |||

| If you have any further questions pertaining to this study, please feel free to comment below: The questionnaire has been completed. Thank you very much for your cooperation and assistance! | ||||

References

- Yin, S.; Dong, T.; Li, B.Z.; Gao, S. Developing a Conceptual Partner Selection Framework: Digital Green Innovation Management of Prefabricated Construction Enterprises for Sustainable Urban Development. Buildings 2022, 12, 721. [Google Scholar] [CrossRef]

- Xu, J. Research on Green and Low-carbon Development Path of prefabricated Building Business of Construction Enterprises under Double Carbon Background. Value Eng. 2002, 41, 165–168. [Google Scholar]

- Cheng, Y.R.; Zheng, S.Q.; Liu, J.H. Analysis of Constraints on the development of prefabricated buildings. J. Shandong Jianzhu Univ. 2021, 11, 54–61. [Google Scholar]

- Xue, H. Study on Stakeholder Cooperation Mechanism of Prefabricated Construction Project under Construction Cost Orientation. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- Xu, Z.; Xie, Z.; Wang, X.R.; Niu, M. Automatic Classification and Coding of Prefabricated Components Using IFC and the Random Forest Algorithm. Buildings 2022, 12, 688. [Google Scholar] [CrossRef]

- Lu, Q.F.; Jin, W.W.; Zhang, J.; Sun, C.J. Present Situation and Countermeasures of the Development of Chinese Construction Industrialization. Chief Engineer Working Committee of China Civil Engineering Society. In Proceedings of the China Civil Engineering Society Chief Engineer Working Committee 2021 Annual Conference, Nanchang, China, 4–5 December 2021. [Google Scholar]

- Wang, H.Z. Study on Influencing Factors of Prefabricated Construction Cost under EPC General Contracting Mode Based on SEM. Master’s Thesis, Jiangxi University of Science and Technology, Ganzhou, China, 2022. [Google Scholar]

- Liu, K.N.; Su, Y.K.; Zhang, S.J. Optimization of the Supplier Selection Process in Prefabrication Using BIM. Buildings 2019, 9, 222. [Google Scholar] [CrossRef]

- Qin, X.; Fang, Z.H.; Zhang, Z.X. Multi-objective Production Scheduling Optimization of Prefabricated Components Considering Resource Constraints. Comput. Integr. Manuf. Syst. 2021, 27, 2248–2259. [Google Scholar]

- Du, J.; Dong, P.; Sugumaran, V. Dynamic Production Scheduling for Prefabricated Components Considering the Demand Fluctuation. Intell. Autom. Soft Comput. 2020, 26, 715–723. [Google Scholar] [CrossRef]

- Chen, X.B.; Yu, F.F.; Zhou, H.Y.; Li, Z.D.; Wu, K.J.; Qian, X.K. Mixed Production Line Optimization of Industrialized Building Based on Ant Colony Optimization Algorithm. Adv. Civ. Eng. 2022, 2022, 2411458. [Google Scholar] [CrossRef]

- Chang, C.G.; Han, M.Y. Production Scheduling Optimization of Prefabricated Building Components Based on DDE Algorithm. Math. Probl. Eng. 2021, 2021, 6672753. [Google Scholar] [CrossRef]

- Du, J.; Dong, P.; Sugumaran, V.; Castro-Lacouture, D. Dynamic decision support framework for production scheduling using a combined genetic algorithm and multiagent model. Expert Syst. 2021, 38, e12533. [Google Scholar] [CrossRef]

- Wang, H.P.; Zhao, D.Y.; Chen, M.K.; Li, Y. Research on Job Assignment Optimization of PC Component Mixed-Flow Production Based on MO-CGJaya/D Algorithm. Manag. Sci. China 2022, 3, 1–14. [Google Scholar]

- Zuo, J. Study on Lean Construction Process Optimization of Precast Concrete Components in Prefabricated Buildings. Master’s Thesis, Guilin University of Technology, Guilin, China, 2022. [Google Scholar]

- Zhong, H.; Meng, X.Y.; Sun, H.; Zhang, K.; Geng, R.; Li, D. Research on Data Generation Technology of BIM Component Concrete pouring Control. In Proceedings of the 2019 Chinese Automation Congress, Hangzhou, China, 22–24 November 2019; pp. 79–83. [Google Scholar]

- Ding, Z.K.; Liu, S.; Luo, L.W.; Liao, L.H. A building information modeling-based carbon emission measurement system for prefabricated residential buildings during the materialization phase. J. Clean. Prouction 2020, 264, 121728. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, S.Z.; Wang, E.D. Integration of BIM and Energy Consumption Modelling for Manufacturing Prefabricated Components: A Case Study in China. Adv. Civ. Eng. 2019, 2019, 1609523. [Google Scholar] [CrossRef]

- Qi, B.; Chen, K.; Costin, A. RFID and BIM-Enabled Prefabricated Component Management System in Prefabricated Housing Production. In Proceedings of the Construction Research Congress 2018: Construction Information Technology, New Orleans, LA, USA, 2–4 April 2018; pp. 591–601. [Google Scholar]

- Gao, Q.Y.; Gao, X.S. Research on Production Information Model of Prefabricated Components based on IFC Standard. Acta Graph. Sin. 2018, 39, 538–546. [Google Scholar]

- Yu, Y.P. Production Process Optimization and MES System Development of PC Components for Prefabricated Buildings. Master’s Thesis, Shandong Jianzhu University, Jinan, China, 2022. [Google Scholar]

- Fu, L.; Yong, J.; Wang, X.J. On Component-Based Industrialization Construction Costs Valuation. AER-Adv. Eng. Res. 2017, 118, 24–30. [Google Scholar]

- Lin, X.; Lu, Y.N. Research on Mathematical Model of Cost Budget in the Early Stage of Assembly Construction Project Based on Improved Neural Network Algorithm. Math. Probl. Eng. 2021, 10, 3674929. [Google Scholar] [CrossRef]

- Tang, J.L. Analysis of incremental cost in the whole construction process of prefabricated concrete buildings. Constr. Econ. 2022, 43, 156–160. [Google Scholar]

- Liu, C.; Liu, J.J.; Liu, F.J. Research on Influencing Factors and Control measures of Precast component cost based on AHP method. Proj. Manag. Technol. 2022, 20, 15–20. [Google Scholar]

- Li, N.; Liu, Z. Analysis of Influencing Factors of PC component cost based on ISM Model. Shanghai Energy Conserv. 2022, 2, 139–144. [Google Scholar]

- Chen, W.; Chen, A.Q.; Liu, J.; Deng, S.Y. Research on Production Cost Optimization of PC Exterior Wall Panel Based on Hybrid Genetic Algorithm. In Proceedings of the ICCREM 2021: Challenges of The Constructon Industry under The Pandmic, Beijing, China, 16–17 October 2021; pp. 687–693. [Google Scholar]

- Li, N.; Fan, Z.F. Impact Evaluation of Prefabricated Buildings Cost on Game Theory-Cloud Model. J. Math. 2022, 10, 3635009. [Google Scholar] [CrossRef]

- Ye, M.Z. Research on Influencing Factors of Prefabricated Construction Cost Based on System Dynamics. Master’s Thesis, Guangxi University, Nanning, China, 2022. [Google Scholar]

- Yu, H.A.; Shang, Z.F.; Liu, Q.W.; Wang, F.L. Research on Production cost accounting of Prefabricated components in Prefabricated Buildings based on TDABC. Build. Econ. 2021, 42, 35–39. [Google Scholar]

- Xu, J.W. Research on Prefabricated Component Pricing Model. Master’s Thesis, Dongbei University of Finance and Economics, Dalian, China, 2021. [Google Scholar]

- Xie, W.W.; Deng, B.C.; Yin, Y.L.; Lv, X.D.; Deng, Z.J. Critical Factors Influencing Cost Overrun in Construction Projects: A Fuzzy Synthetic Evaluation. Buildings 2022, 12, 2028. [Google Scholar] [CrossRef]

- Ji, F.R.; Shi, J.L.; Zhu, T.L.; Hu, X.C. Risk Assessment in the Industry Chain of Industrialized Construction: A Chinese Case Study. Buildings 2022, 12, 1688. [Google Scholar] [CrossRef]

- Wei, H.L.; Niu, C.L.; Liu, F.J.; Wu, X.R.; Qi, S.W. Analysis of Influence Factors on Cost of prefabricated building components based on DEMATEL-AISM Method. Archit. Econ. 2021, 42, 83–88. [Google Scholar]

- Shi, X.B.; Ren, J.; Liu, C.C. Construction of Evaluation index system for Prefabricated building component suppliers. Build. Econ. 2019, 40, 92–97. [Google Scholar]

- Han, S. Competitiveness Evaluations and Predictions of Logistics Enterprises Based on Supply Chains. In Basic & Clinical Pharmacology & Toxicology; Wiley: Hoboken, NJ, USA, 2020; p. 126. [Google Scholar]

- Marzouk, M.M.; Gaid, E.F. Assessing Egyptian construction projects performance using principalcomponent analysis. Int. J. Product. Perform. Manag. 2018, 67, 1727–1744. [Google Scholar] [CrossRef]

- Bo, D.H.; Kong, L.J.; Xu, X.F. Research on Production capacity of Manufacturing Enterprise Based on System Dynamics. J. Qingdao Univ. (Nat. Sci. Ed.) 2009, 22, 71–77. [Google Scholar]

- Saaty, T.L. A scaling method for priorities in hierarchical structures. J. Math. Psychol. 1977, 15, 234–281. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making; Springer: Berlin, Germany, 1981; pp. 58–191. [Google Scholar]

- Wang, M. Research on the Competitiveness Evaluation of Chinese Construction Enterprises. Master’s Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2022. [Google Scholar]

- Fu, L.L.; Mao, X.H.; Mao, X.B.; Cai, R.X. Evaluation of comprehensive grain production capacity in Zhejiang Province during 2013–2018. Acta Agric. Zhejiangensis 2021, 33, 1748–1758. [Google Scholar]

- Jiang, X.X.; Li, S.L. Research on the Selection of Components Manufacturers in prefabricated construction industry Chain. Constr. Econ. 2020, 41, 46–50. [Google Scholar]

- Bai, Y.T.; Lin, Q.W. Grey correlation analysis of agricultural resources Utilization and comprehensive grain production capacity: A case study of Hebei Province. China Agric. Resour. Reg. Plan. 2016, 37, 57–61. [Google Scholar]

- Aksoy, A.; Oztiirk, N. Supplier selection and performance evaluation in just-in-time production environments. Expert Syst.-Appl. 2011, 38, 6351–6359. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kim, J.J.; Lee, T.S. Topological Competiveness Based on Social Relationships in the Korean Construction-Management Industry. J. Constr. Eng. Manag. 2016, 142, 05016014. [Google Scholar] [CrossRef]

- Liang, W.Z.; Zhao, G.Y.; Hong, C.S. Performance assessment of circular economy for phosphoruschemical firms based on VIKOR-QUALIFLEX method. J. Clean. Prod. 2018, 196, 1365–1378. [Google Scholar] [CrossRef]

- Guo, H.Y. Research on Enterprise Production Capacity Evaluation Sharing System Based on Block Chain. Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2020. [Google Scholar]

- Gao, Q.; Li, Y.; Xu, Y.Q. Analysis on Influencing Factors of Construction industrialization Development. J. Eng. Manag. 2017, 31, 14–18. [Google Scholar]

- Prefabricated Building the 13th Five-Year Plan Development Research Group. Innovation and Development of Prefabricated Buildings; China Architecture and Building Press: Beijing, China, 2017. [Google Scholar]

- Hu, Y.P.; Xie, Z.Z.; Tong, M.D.; Zou, S.; Li, H.; Chen, X.Q. Research on the planning and location of prefabricated components production base for prefabricated buildings. Constr. Econ. 2018, 39, 22–25. [Google Scholar]

- Zhang, J.S.; Wang, C.C.; Liu, X.C. Production and Management of Precast Concrete Components for Prefabricated Buildings, 2nd ed.; China Architecture and Building Press: Beijing, China, 2022. [Google Scholar]

- Tan, G.W.; Jian, X.S. Production of Prefabricated Precast Concrete Building Components; Science Press: Beijing, China, 2021. [Google Scholar]

- Wu, Y.Q.; Lu, W.Q. Fabrication and Transportation of Prefabricated Concrete Member; Yellow River Water Conservancy Press: Zhengzhou, China, 2017. [Google Scholar]

- Hu, J.L.; Wang, F.R. Manufacturing Technology of Prefabricated Concrete Precast Member; Central South University Press: Changsha, China, 2020. [Google Scholar]

- Fang, S.L.; Feng, D.K. Production and Installation of Precast Components; China Architecture and Building Press: Beijing, China, 2020. [Google Scholar]

- Ye, H.W. Production Technical Guide of Precast Concrete Member; China Architecture and Building Press: Beijing, China, 2016. [Google Scholar]

- Science, Technology and Industrialization Development Center; Ministry of Housing and Urban-Rural Development/Housing Industrialization Promotion Center; Ministry of Housing and Urban-Rural Development. China Prefabricated Building Development Report (2017); China Architecture and Building Press: Beijing, China, 2017. [Google Scholar]

- Shenzhen Construction Industry Association/Shenzhen Housing and Construction Bureau. Development Report of Prefabricated Buildings in Shenzhen during the 13th Five-Year Plan; China Architecture and Building Press: Beijing, China, 2022. [Google Scholar]

- Jiangsu Provincial Department of Housing and Urban-Rural Development/Jiangsu Provincial Department of Housing and Urban-Rural Development Science and Technology Development Center. Prefabricated Building Development Report of Jiangsu Province (2018); China Architecture and Building Press: Beijing, China, 2019. [Google Scholar]

- Wang, J. Development Status and Thinking of Construction industrialization in China. Journal of Civil Engineering—2017 "Forum" Compilation; China Academy of Building Science: Beijing, China, 2017; pp. 25–47. [Google Scholar]

- Asia Pacific Institute of Construction Technology Information Co, Ltd. Lauguesi Application Development of Prefabricated Buildings Construction Technology Magazine. In Proceedings of the 2019 National Exchange Meeting on New Technology of Construction, Beijing, China, November 2019; pp. 85–86. [Google Scholar]

- Jiangsu Provincial Department of Housing and Urban-Rural Development. Prefabricated Building Technical Manual (Concrete Structure Volume Production Chapter); China Architecture and Building Press: Beijing, China, 2021. [Google Scholar]

- Jiangsu Provincial Department of Housing and Urban-Rural Development/Jiangsu Provincial Department of Housing and Urban-Rural Development Science and Technology Development Center. Prefabrication and Installation Technology of Prefabricated Concrete Building Components; Southeast University Press: Nanjing, China, 2021. [Google Scholar]

- TY01-01(01)-2016; Prefabricated Construction Engineering Consumption Quota. China Planning Press: Beijing, China, 2017.

- DBJ51/T088-2017; Sichuan Province Prefabricated Concrete Building Precast Component Production and Construction Information Technology Standard. Sichuan Provincial Department of Housing and Urban-Rural Development: Chengdu, China, 2018.

- T/BIAS 5-2019; Code for Fabrication and Inspection of Precast Concrete Components. Shenzhen Building Industrialization Association: Shenzhen, China, 2020.

- T/LESC 01-2021; Production Standardization of Precast Concrete Components for Prefabricated Buildings. Shandong Engineering Construction Standard Cost Association: Jinan, China, 2021.

- Mudiyanselage, S.E.; Nguyen, P.H.D.; Rajabi, M.S.; Akhavian, R. Automated workers’ ergonomic risk assessment in manual material handling using sEMG wearable sensors and machine learning. Electronice 2021, 10, 2558. [Google Scholar] [CrossRef]

- Schober, P.; Estiri, S.N.; Aygun, S.; Jalilvand, A.H.; Najafi, M.H.; Taheri Nejad, N. Stochastic Computing Design and Implementation of a Sound Source Localization System. IEEE J. Emerg. Sel. Top. Circuits Syst. 2023, 13, 3243604. [Google Scholar] [CrossRef]

- Estiri, S.N.; Jalilvand, A.H.; Naderi, S.; Najafi, M.H.; Fazeli, M. A Low-Cost Stochastic Computing-based Fuzzy Filtering for Image Noise Reduction. In Proceedings of the 2022 IEEE 13th International Conference on Green And Sustainable Computing (IGSC), Electrician Network, Pittsburgh, PA, USA, 24–25 October 2022. [Google Scholar]

- Rabiee, F.; Kajouyan, M.; Estiri, N.; Fluech, J.; Fazeli, M.; Patooghy, A. Enduring non-volatile L1 cache using low-retention-time STTRAM cells. In Proceedings of the 2020 IEEE Computer Society Annual Symposium on Vlsi (ISVLSI 2020), Electrician Network, Limassol, Cyprus, 6–8 July 2020. [Google Scholar]

- Ghasemi, M.; Rajabi, M.S.; Rezaeiashtiani, M.; Ourang, S. Automation of Multi-Tower Crane Location Optimization in Pre-Fabricated Construction Sites: An Application Programming Interface Approach. In Proceedings of the 2nd Joint Conference of the Construction Research Congress (CRC), Iowa State Univ, Des Moines, IA, USA, 26 April 2024. [Google Scholar]

- Ma, W.M.; Almasifar, N.; Amini, R.; Ourang, A.; Mahariq, I.; Alhoee, J. Crashworthiness evaluation and optimization of full polypropylene sandwich tubes under low-velocity impact based on machine learning algorithms. Structures 2024, 60, 105901. [Google Scholar] [CrossRef]

- Ourang, A.; Pilehvar, S.; Mortezaei, M.; Damircheli, R. Effect of aluminum doped iron oxide nanoparticles on magnetic properties of the polyacrylonitrile nanofibers. J. Polym. Eng. 2017, 37, 1515. [Google Scholar] [CrossRef]

- Shiva, O.; Armin, O. Optimizing Power Balance and Communication links in Microgrids: A Clustering Approach Using Particle Swarm Optimization. Asian J. Soc. Sci. Manag. Technol. 2023, 5, 6. [Google Scholar]

- Naderi, H.; Heydari, M.H.; Jalal, M.P. Risk Analysis in Implementing Building Energy Performance Projects: Hybrid DANP-VIKOR Model Analysis—A Case Study in Iran. Buildings 2023, 13, 2066. [Google Scholar] [CrossRef]