Optimizing the Support System of a Shallow Buried Tunnel under Unsymmetrical Pressure

Abstract

1. Introduction

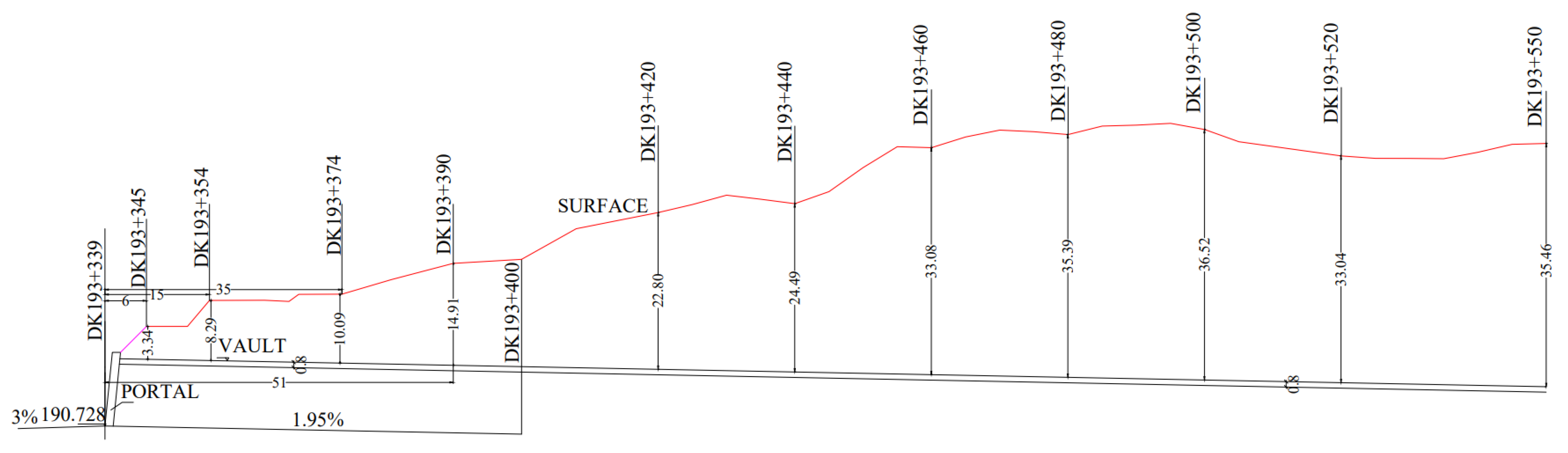

2. Overview of the Tunnel’s Entrance Section

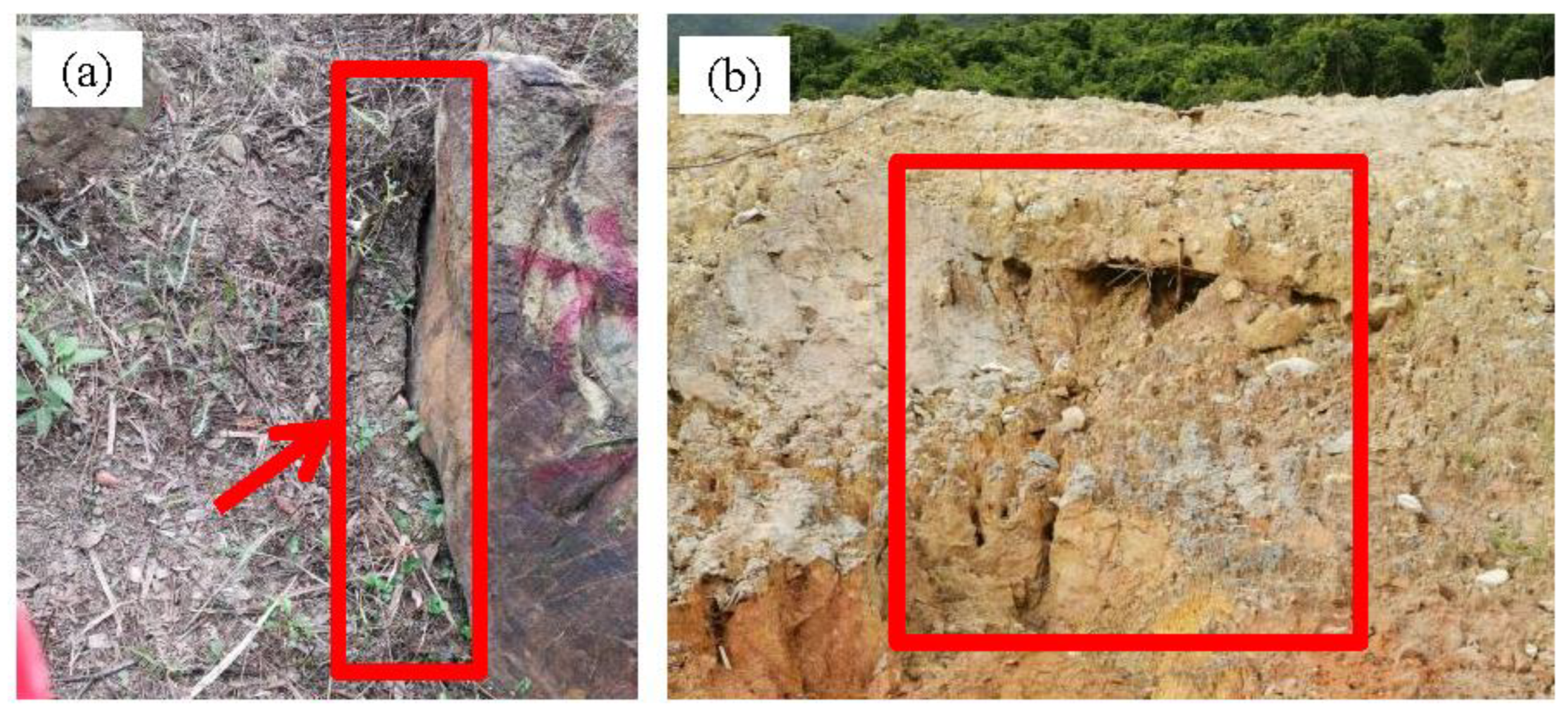

2.1. Geological and Geotechnical Conditions

2.2. Tunnel Entrance Conditions

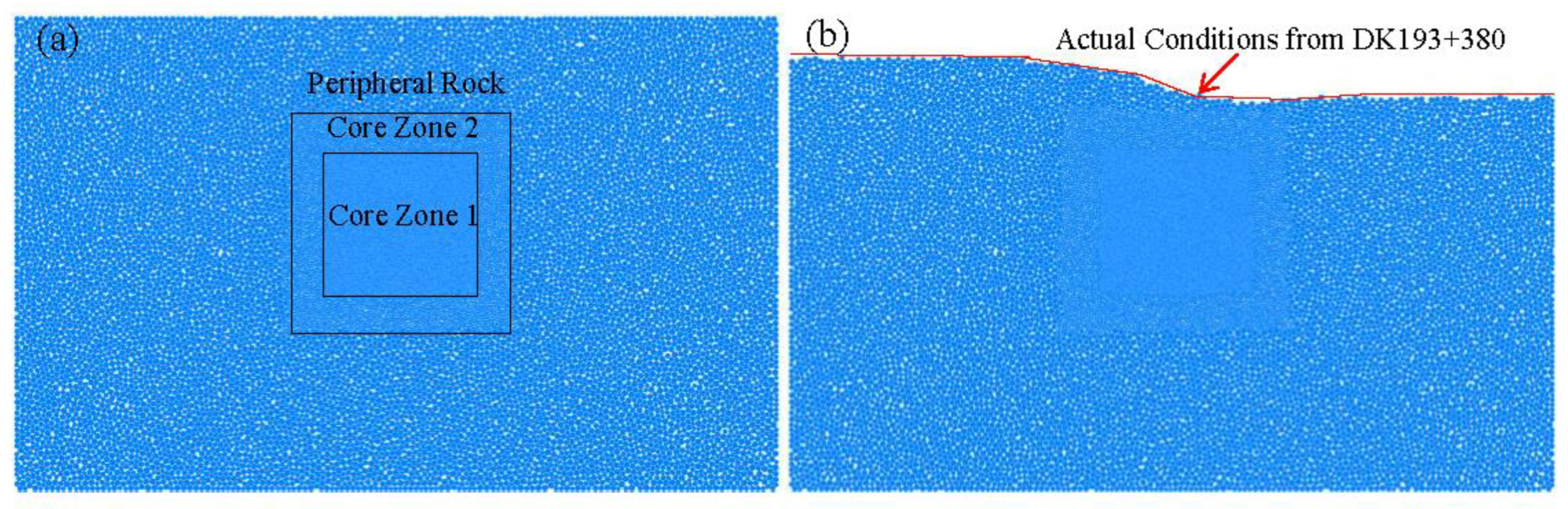

3. Numerical Simulation

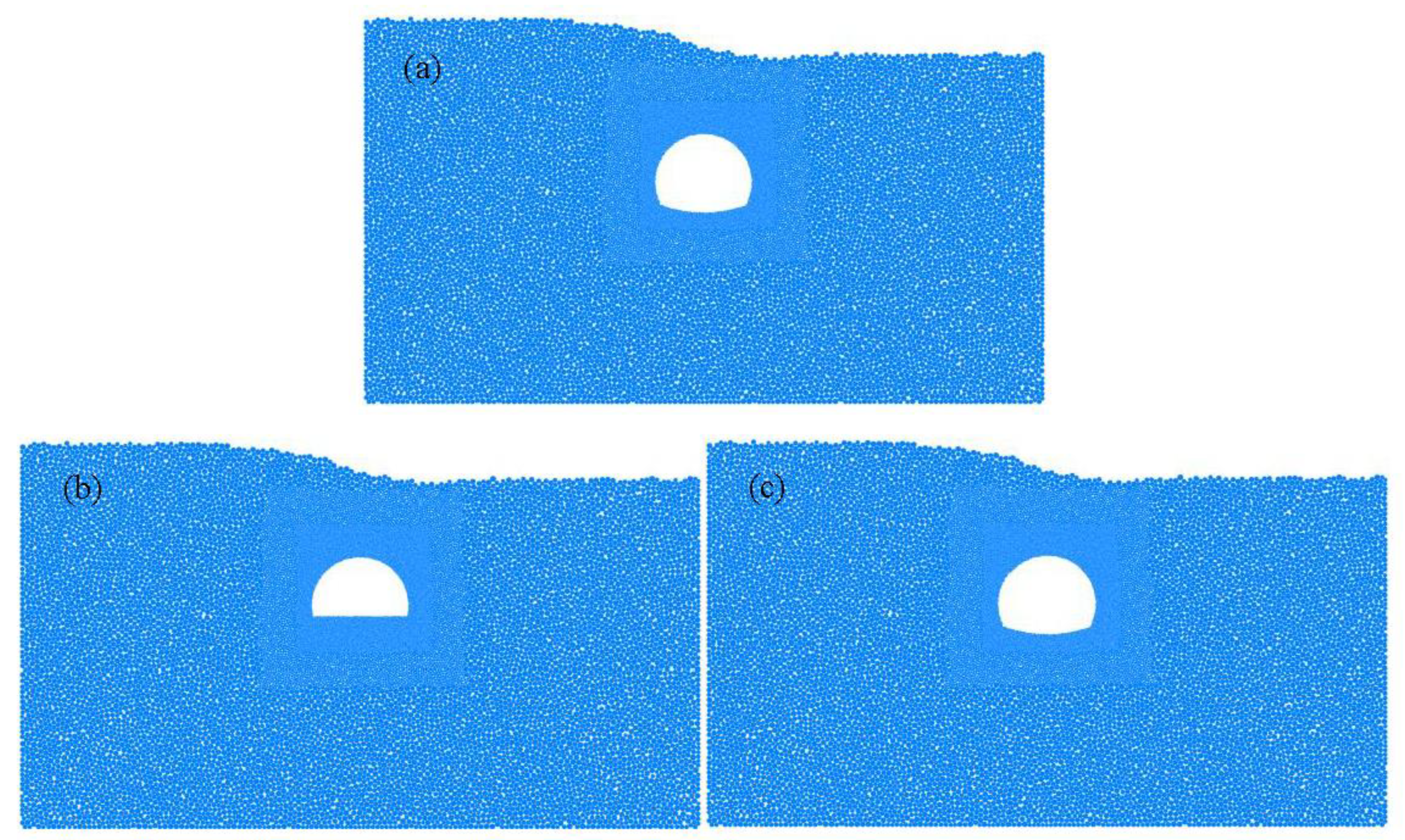

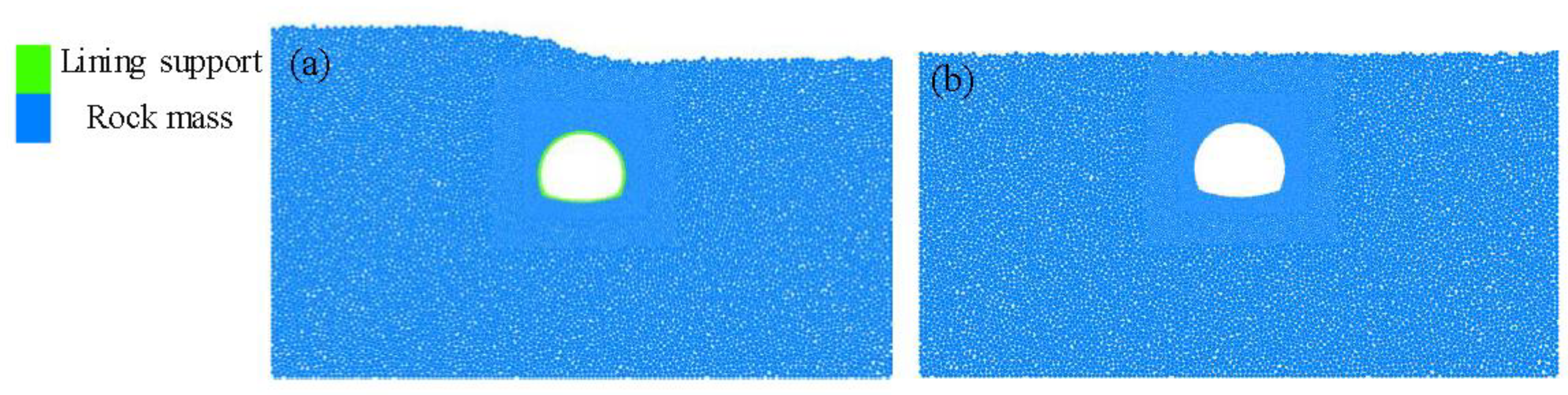

3.1. Establishment of the Numerical Model

3.2. Modelling Schemes

3.3. Simulation Results

3.3.1. Deformation Characteristics of the Surrounding Rock

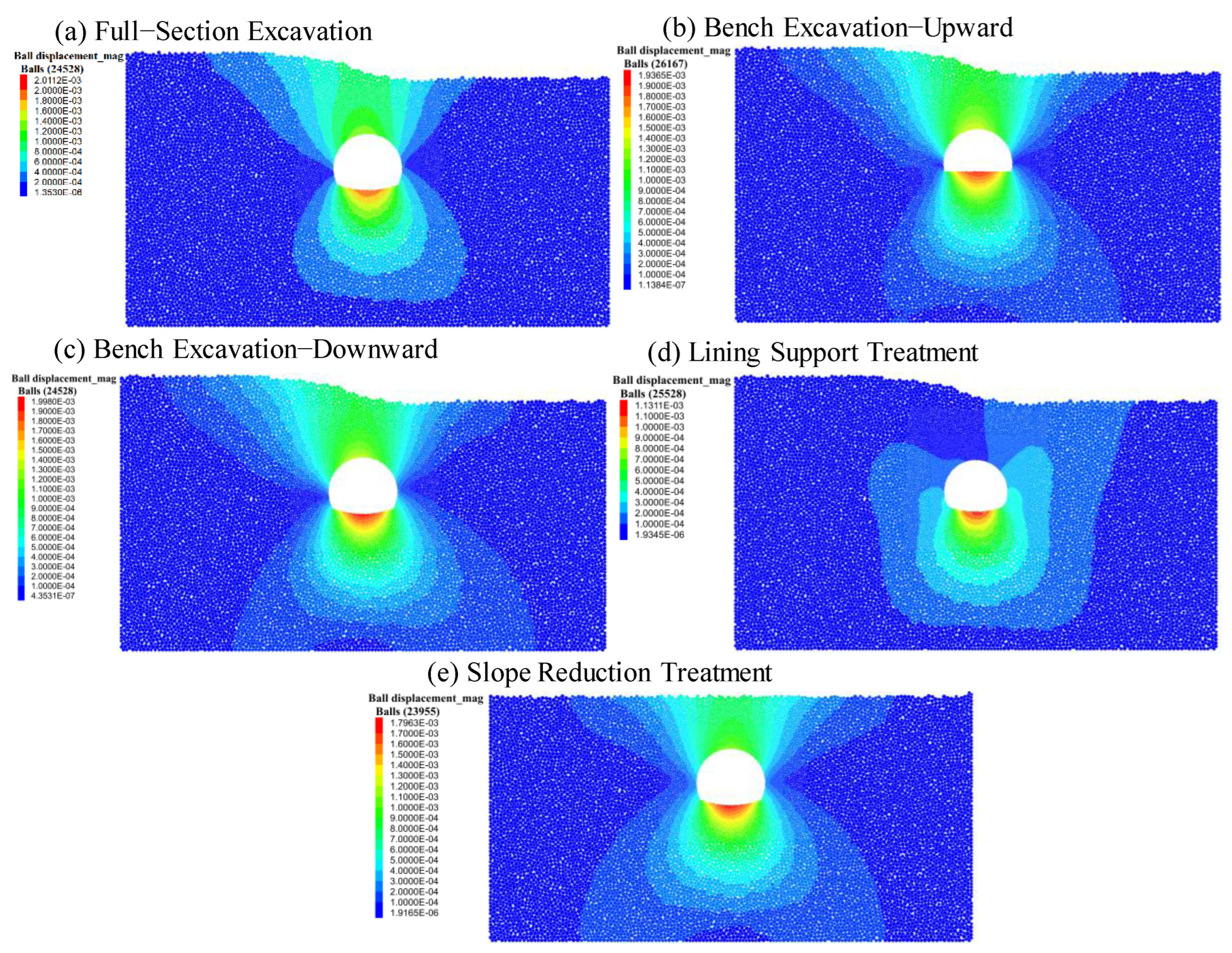

- (1)

- For both the full-section excavation model and bench excavation model, the deformation is most prominent at the arch. The maximum deformation values of the tunnel under full-section excavation and bench excavation are 2.01 mm and 1.99 mm, respectively, occurring at the bottom of the tunnel, while the deformation at side walls is relatively small. The total deformation around the tunnel caused by bench excavation is slightly smaller than that caused by full-section excavation;

- (2)

- The surrounding rock deformation caused by bench excavation has a wider range than that caused by full-section excavation, especially at the arch of the tunnel. This reflects the influence of frequent disturbance from bench construction on the stability of surrounding rock, where the range of unloading deformation of the surrounding rock is exacerbated;

- (3)

- Lining support treatment and slope reduction treatment can significantly reduce the overall deformation in the surrounding rock. The maximum deformation values of the tunnel under lining support treatment and slope reduction treatment have reduced to 1.13 mm and 1.80 mm, respectively. It should be noted that the lining support can greatly reduce the deformation in the rock mass above the arch;

- (4)

- Due to the influence of unsymmetrical pressure, the deformation of rock mass on the upper left side of the tunnel is larger than that on the upper right side. Especially after lining support treatment, the deformation of the rock mass on the left upper side of the tunnel is well controlled.

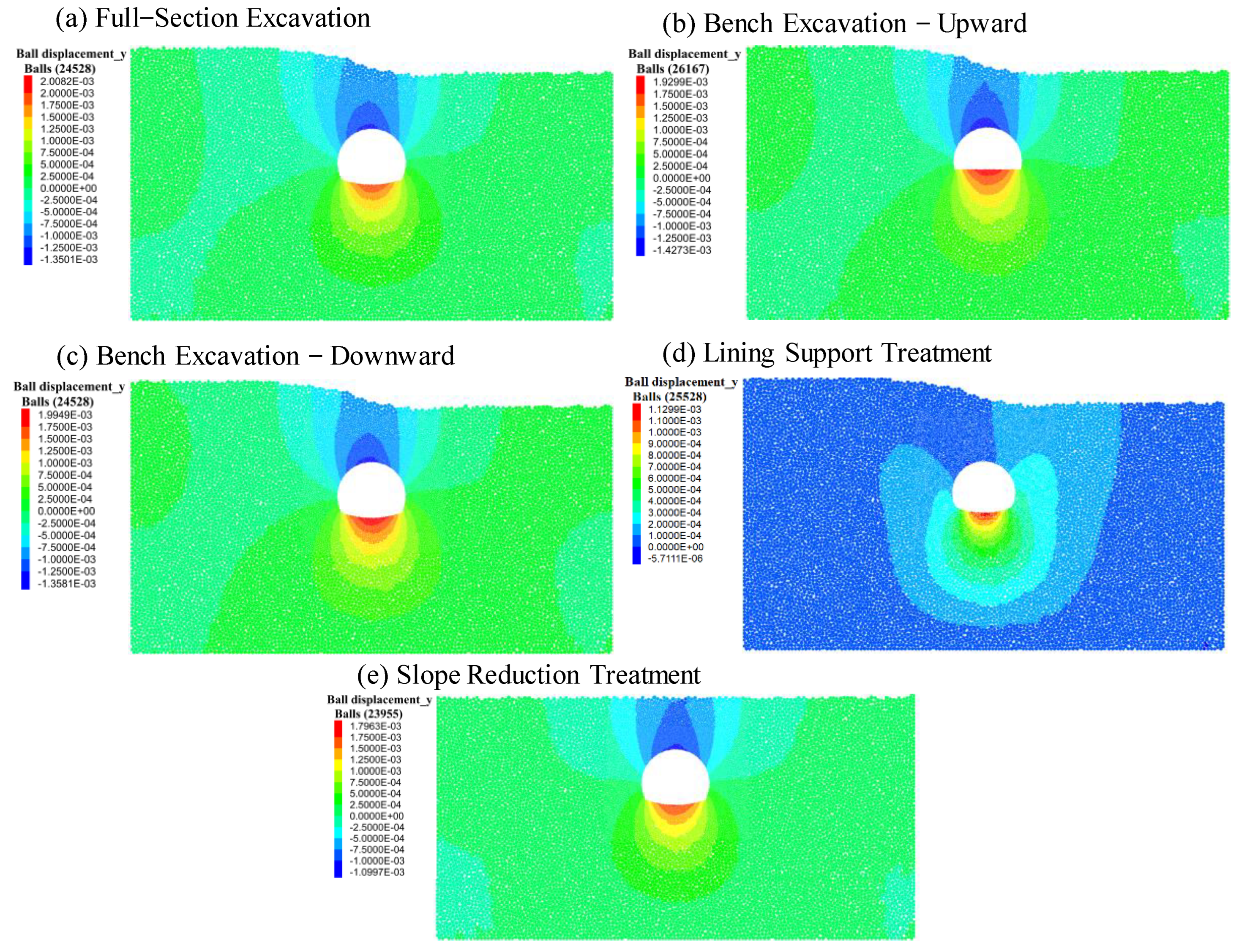

- (1)

- After tunnel excavation, the crown settlement and uplift of the inverted arch occur, with the absolute value of the maximum uplift displacement greater than that of the crown settlement. No significant difference can be found in the maximum vertical displacement between the full-section and bench excavation: the maximum crown settlement at the crown is 1.35 mm for both methods, while the maximum uplift displacement at the inverted arch is 2.01 mm and 2.00 mm, respectively;

- (2)

- Lining support treatment and slope reduction treatment significantly reduce the vertical deformation of the surrounding rock. The maximum settlement at the top of the crown is 0.00057 mm and 1.10 mm for the lining support treatment and slope reduction treatment, respectively, and the maximum uplift at the inverted arch is 1.13 mm and 1.80 mm, respectively;

- (3)

- Under lining support treatment and slope reduction treatment, the maximum settlement of the tunnel surrounding rock is 0.4% and 81.5% of that under full-section excavation, respectively; the maximum uplift of the tunnel surrounding rock is 56.2% and 89.5% of that under full-section excavation, respectively. Therefore, it can be observed that lining support treatment has a better effect in suppressing the vertical deformation of the surrounding rock.

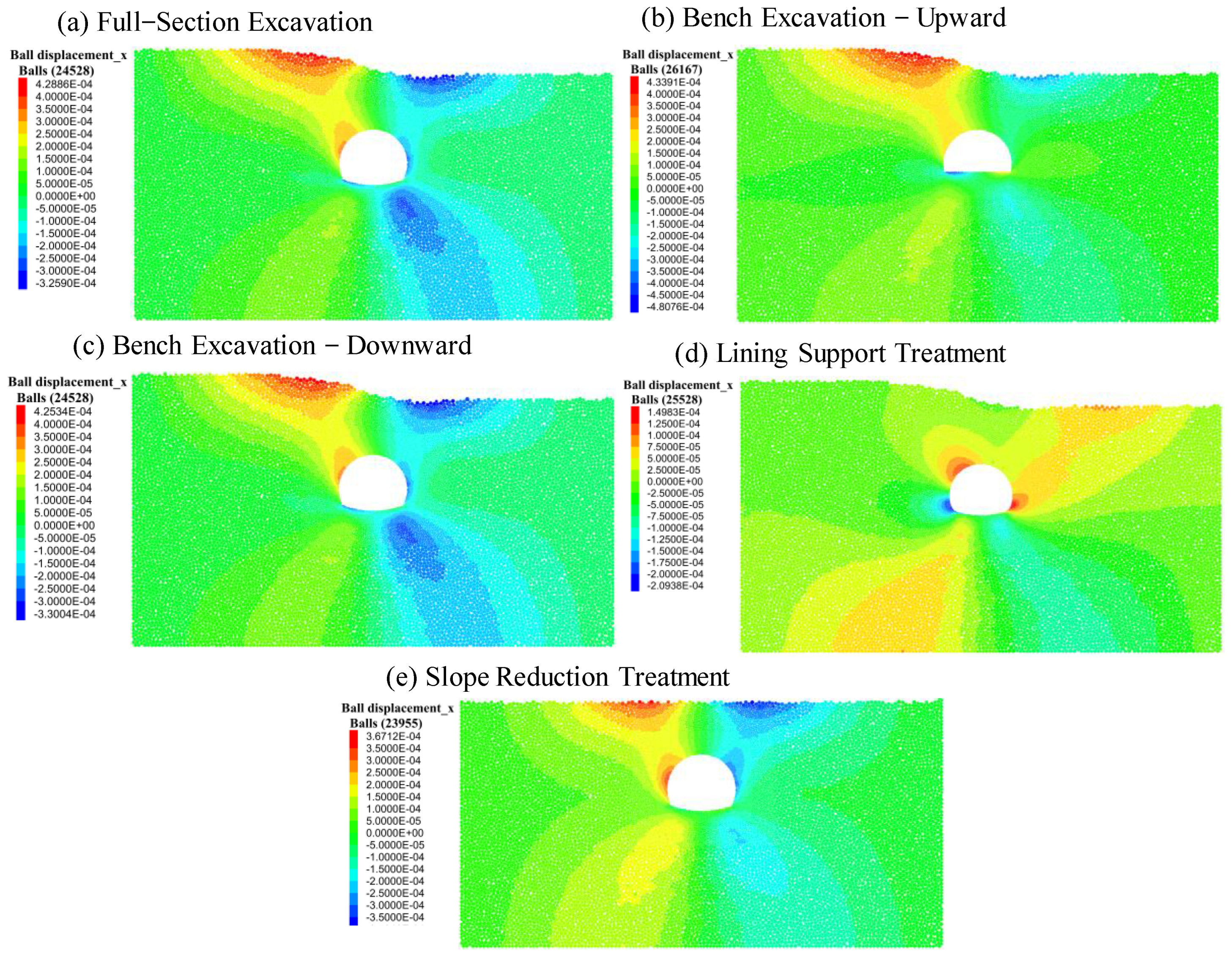

- (1)

- The rock mass converges toward the inside of the tunnel after excavation, where the maximum displacement is found at the crown shoulder of the tunnel for both full-section and bench excavation methods. Additionally, the absolute value of displacement at the left shoulder exceeds that at the right shoulder, as a result of the unsymmetrical pressure. After full-section and bench excavation, the maximum displacement at the left shoulder is 0.429 mm and 0.434 mm, respectively, and the maximum displacement at the right shoulder is 0.326 mm and 0.330 mm, respectively. The difference in maximum horizontal displacement between the two excavation methods is insignificant;

- (2)

- Lining support treatment and slope reduction treatment can significantly suppress the deformation in the X-direction of the surrounding rock. After full-section and bench excavation, the maximum displacement at the left shoulder is 0.150 mm and 0.367 mm, respectively, and the maximum displacement at the right shoulder is 0.209 mm and 0.350 mm, respectively;

- (3)

- Under lining support treatment and slope reduction treatment, the maximum convergence at the right shoulder of the tunnel surrounding rock is 64.1% and 107.3% of that under full-section excavation, respectively. The maximum convergence at the left shoulder of the tunnel surrounding rock is 40.0% and 85.5% of that under full-section excavation, respectively. It is evident that compared to the slope reduction treatment, lining support treatment demonstrates superior capability in suppressing the deformation of the surrounding rock in the X-direction;

- (4)

- Due to the influence of unsymmetrical pressure, the maximum displacement of rock mass in the X direction on the left side of the ground after full-section excavation and bench excavation is larger than that on the right side. Lining support treatment significantly reduces the difference in the maximum displacement of ground rock mass, while slope reduction treatment makes the displacement nephogram basically a symmetrical distribution.

3.3.2. Stress Characteristics of the Surrounding Rock

- (1)

- The vertical stress levels at the top and bottom of the tunnel are reduced by excavations. Specifically, the vertical stress at the top decreases by 14.0% and 14.3% for full-section excavation and bench excavation respectively, and at the bottom, it decreases by 21.8% for both excavation methods. Correspondingly, the vertical stress levels at the left and right sidewalls increase to 187.0% and 186.5% of the pre-excavation levels for the left sidewall, and 178.7% and 178.1% for the right sidewall. The vertical stress levels at the crown remain relatively unchanged. This indicates that the redistributed vertical stress caused by excavation mainly concentrates on the tunnel sidewalls;

- (2)

- The vertical stress at the top of the tunnel increases by 100.7% and 127.6%, respectively, after lining support and slope reduction treatments compared to pre-excavation levels. Correspondingly, the vertical stress at the bottom decreases by 48.2% and 20.6%, respectively. After slope reduction treatment, the vertical stress on both left and right sidewalls increases, respectively, to 166.9% and 150.5% of the pre-excavation levels. However, after lining support treatment, the vertical stress on both left and right sidewalls decreases to 84.2% and 82.1% of the pre-excavation levels, respectively;

- (3)

- Both the lining support and slope reduction treatments have effectively caused redistribution of vertical stress around the surrounding rock, resulting in a more uniform distribution and, thus, enhancing the overall stability of the tunnel. According to the obtained data, lining support treatment is more effective than slope reduction treatment.

- (1)

- A notable increase in horizontal stress levels at the top and bottom of the tunnel has been recorded after excavation. Compared to pre-excavation levels, the horizontal stress at the top increases by 14.0% and 14.3%, respectively, for the full-section excavation and bench excavation, while at the bottom, the increase is 21.8% for both excavation methods. Correspondingly, there is a significant decrease in horizontal stress along the left and right sidewalls of the tunnel, with reductions of 53.0% and 52.7% on the left side, and 56.3% and 56.0% on the right side, respectively, for the full-section excavation and bench excavation. The horizontal stress at the crown remains relatively unchanged. This indicates that the excavation has caused the concentration of horizontal stress in the surrounding rock mass at the top and bottom of the tunnel;

- (2)

- Following lining support treatment, the horizontal stress decreases to 58.8% at the top and increases to 108.6% at the bottom of the tunnel, compared to full-section excavation. After slope reduction treatment, the horizontal stress decreases to 98.8% at the top, while the horizontal stress at the bottom remains unchanged. Additionally, there is an increase in horizontal stress along the left and right sidewalls of the tunnel after lining support treatment, with increases to 258.7% and 239.8%, respectively. However, after slope reduction treatment, there is a decrease in horizontal stress along the left and right sidewalls, with reductions to 86.0% and 90.6%, respectively;

- (3)

- Both lining support treatment and slope reduction treatment effectively result in the favorable redistribution of horizontal stress in the surrounding rock mass, with lining support treatment exhibiting better results than slope reduction treatment.

4. Optimization of the Reinforcement

4.1. Optimization Approaches for Reinforcement

- (1)

- Based on the numerical simulation results, the bench excavation approach, rather than full-section excavation, was chosen for tunnel excavation. Field exploration revealed a more pronounced fissure development, higher levels of rock fragmentation, and poorer rock strength than initially anticipated; consequently, the double-bench excavation method employed in the numerical simulation was further refined into a three-bench excavation method;

- (2)

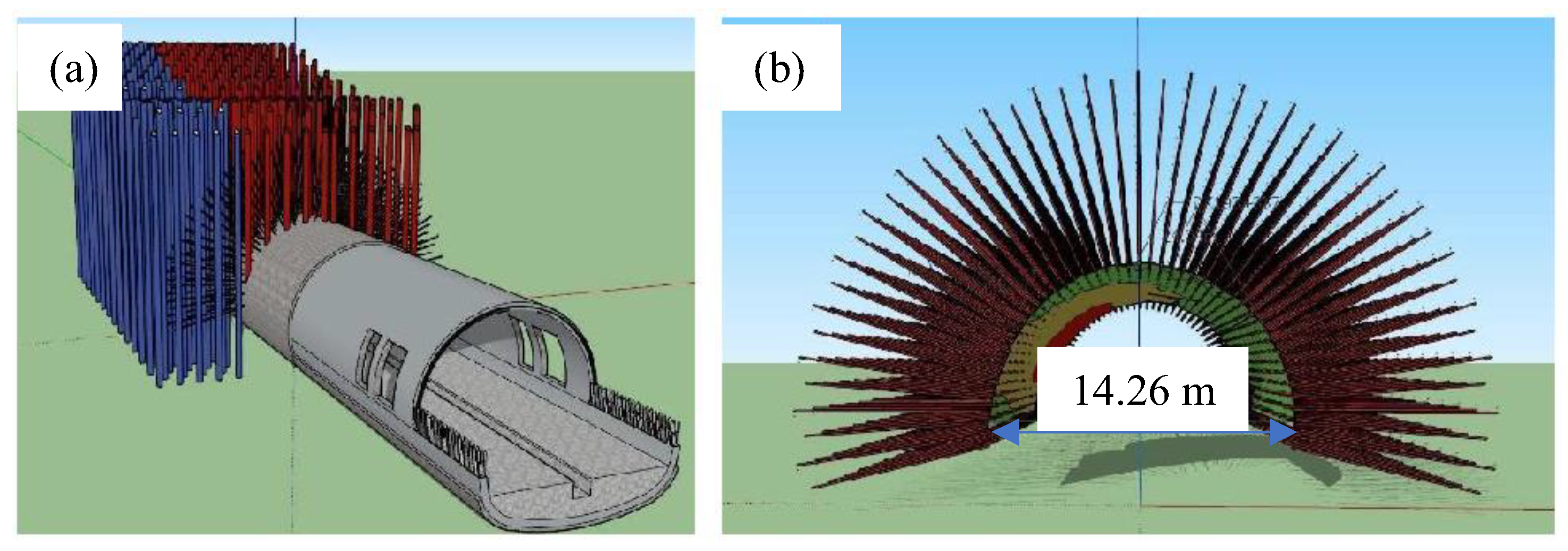

- Carrying out the lining support treatment: This involved employing backfilling with crushed stones to counteract the pressure. During the secondary lining, we monitored the displacement of the mountain body at the entrance and carried out temporary internal support; the surface was reinforced by sleeve valve grouting (Figure 13a), while conduct radial dual-pipe grouting was used inside the tunnel to reinforce the weak foundations (Figure 13b). In addition, a Φ89-hole long pipe shed and a Φ42 advanced small pipe (type II) were used to implement advanced support and replace arches in intrusion sections.

- (3)

- Treatment for the uplift of the inverted arch: A static cone penetration test was performed on the inverted arch at the bottom of the tunnel to determine the bearing capacity and ensure the stability of the closed-loop initial support system. Temporary vertical support was set before the excavation of the lower bench, with additional foot anchors added to each steel frame on the left side. After the backfill on the excavation face, advanced grouting reinforcement needed to be carried out at the arch foot on the left and right sides of the upper bench;

- (4)

- Treatment for surface settlement: Mortar injection was carried out to stabilize the surface from possible voids (Figure 14). Underground grouting technology was utilized to fill the voids so the compactness of the strata was improved and settlement was reduced. The slope was reinforced around the tunnel to prevent settlement caused by geological disasters such as landslides.

4.2. Evaluation of the Reinforcement Effects

5. Conclusions

- (1)

- Numerical simulation results show that the total deformation caused by the bench excavation method is slightly smaller than that caused by full-face excavation but the deformation range is more significant, especially in the surrounding rock deformation at the tunnel arch. Due to the influence of unsymmetrical pressure, the deformation of rock mass on the upper left side of the tunnel is larger than that on the upper right side. Both lining support and slope reduction treatments can effectively control the deformation of surrounding rock in the tunnel; however, in terms of controlling rock deformation and improving stress distribution, the lining support treatment demonstrates superior effectiveness;

- (2)

- The stress detection results of numerical simulation show that the vertical stress mainly concentrates in the sidewall area while the horizontal stress is mainly concentrated in the top and bottom. The lining support treatment increases the vertical stress at the top and decreases the vertical stress at the bottom, whereas the slope reduction treatment has the opposite effect. Additionally, the lining support treatment has a more significant impact on the vertical stress of the left and right sidewalls;

- (3)

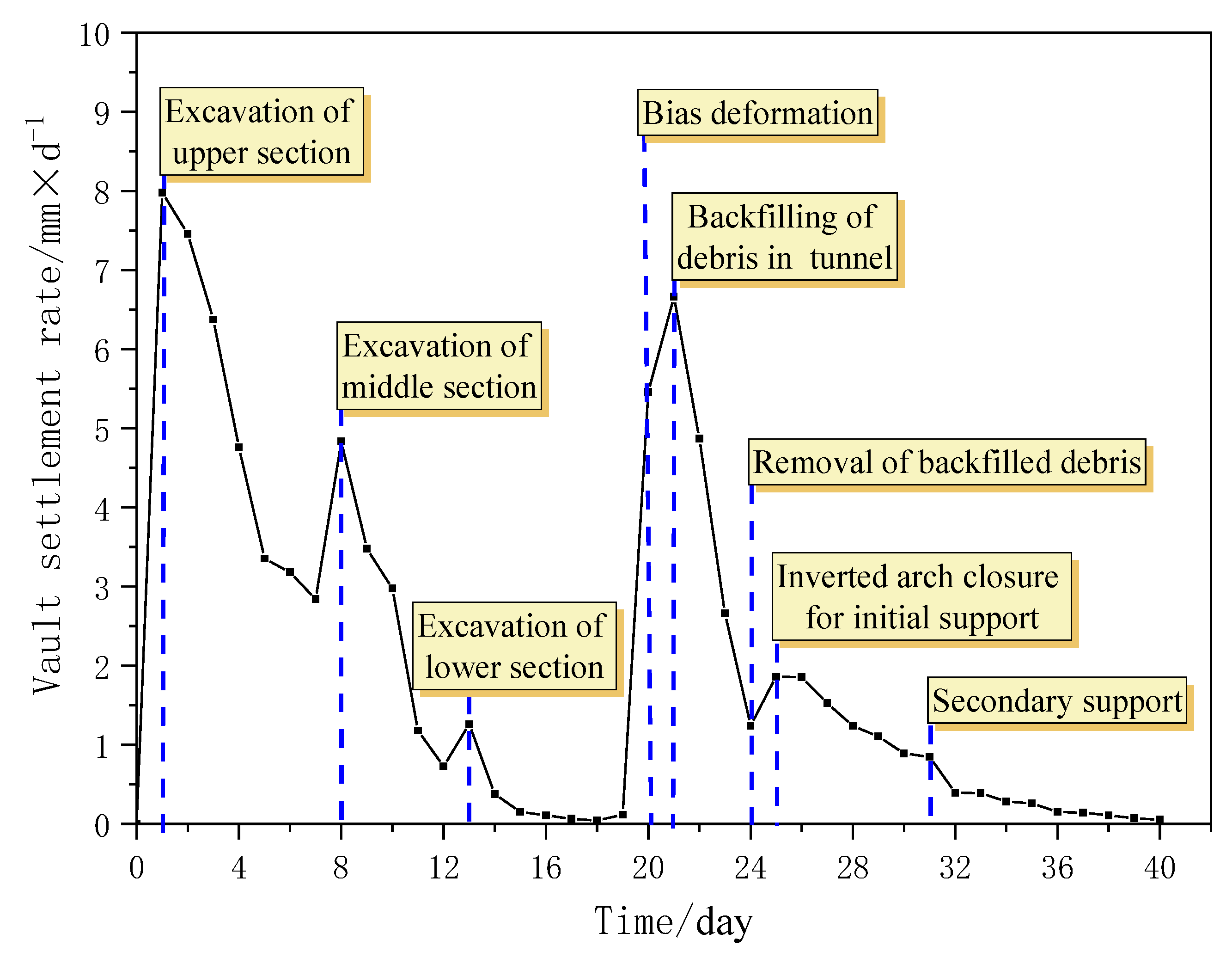

- Based on numerical simulation results, various optimization measures were adopted on site, including bench excavation, crushed-stone backfilling for compression resistance, advanced grouting reinforcement, and grouting. The on site monitoring results indicate that after the bench excavation, the surrounding convergence and vault settlement values increased sharply, with a sudden change in rate. After implementing the optimized reinforcement measures, the deformation rate decreased, and unsymmetrical deformation accounted for 40.12% and 38.63% of the final convergence values. This validates the effectiveness of the unsymmetrical control method proposed in this study.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wen, Y.B.; Huang, F.; Gao, X.Y. Analysis of surrounding rock stability in large-section, small-clearance, terrain-biased tunnels. Railw. Constr. 2017, 07, 77–80. [Google Scholar]

- Zhu, D.W. Study on Spatiotemporal Effects and Optimal Support Timing in Excavation of Terrain-Biased Soft Rock Tunnels; Chongqing University: Chongqing, China, 2012. [Google Scholar]

- Mu, M.C.; Huang, Z.Y. New construction technologies for shallowly buried tunnels in mixed rock strata. West. Transp. Technol. 2024, 1, 177–179. [Google Scholar]

- Wang, S.H.; Mei, Y.C.; Liu, Q.W. Research and application of active support mechanisms in shallowly buried large-span rock tunnels. China Railw. Sci. 2024, 45, 131–141. [Google Scholar]

- Chen, X. Construction mechanics characteristics and support optimization design of super large-section shallowly buried tunnels in red bed areas. Transp. World 2024, 1, 238–240. [Google Scholar]

- Sui, J.Y. Study on the mechanical characteristics of shallow buried tunnel excavation method in large-section loess strata. Eng. Mach. Maint. 2024, 1, 114–116. [Google Scholar]

- Cai, Y.C.; Wang, Q.; Zhang, Q. Analysis of slope stability in shallowly buried terrain-biased tunnels. J. Hebei Eng. Univ. 2022, 39, 56–64. [Google Scholar]

- Zhang, Z.L.; Liu, Y.J.; Guo, N.R. Analysis of surrounding rock deformation in large-span shallowly buried terrain-biased tunnels. Radio Eng. 2019, 3, 241–246. [Google Scholar]

- Wang, F. Analysis of portal landslide stability and its treatment methods in shallowly buried terrain-biased tunnels. Anhui Archit. 2019, 26, 107–113. [Google Scholar]

- Zhang, D.H. Construction technology for high-speed railway tunnels in shallowly buried, Terrain-Biased. Weak Surrounding Rock. Heilongjiang Transp. Sci. Technol. 2017, 40, 122–123+126. [Google Scholar]

- Hu, Z.; Shen, J.; Wang, Y.; Guo, T.; Liu, Z.; Gao, X. Cracking characteristics and mechanism of entrance section in asymmetrically-load tunnel with bedded rock mass: A case study of a highway tunnel in southwest China. Eng Fail Anal 2021, 122, 105221. [Google Scholar] [CrossRef]

- Hashash, Y.M.; Hook, J.J.; Schmidt, B.; John, I.; Yao, C. Seismic design and analysis of underground structures. Tunn. Undergr. Space Technol. 2001, 16, 247–293. [Google Scholar] [CrossRef]

- Xu, Q.W.; Cheng, P.P.; Su, P.S. Research on the mechanical characteristics of tunnel entrance construction in shallowly buried terrain-biased tunnels. J. Undergr. Space Eng. 2017, 13, 1311–1318+1380. [Google Scholar]

- Liang, Y.R. Research on the construction mechanical characteristics and control techniques of the entrance section of shallowly buried terrain-biased tunnels. China Highw. 2017, 17, 110–111. [Google Scholar]

- Li, Y.B. Construction technology for shallowly buried terrain-biased cut-and-cover tunnels in highway tunnel engineering. Eng. Technol. Res. 2021, 6, 96–97. [Google Scholar]

- Zhou, C.; Jin, W.; Ma, B. Research on drilling and blasting design and support system at the entrance of shallowly buried terrain-biased tunnels. Shanxi Archit. 2024, 50, 158–161. [Google Scholar]

- Daraei, A.; Sherwani, A.F.H.; Faraj, R.H.; Kalhor, Q.; Zare, S.; Mahmoodzadeh, A. Optimization of the outlet portal of Heybat Sultan twin tunnels based on the value engineering methodology. SN Appl. Sci. 2019, 1, 270. [Google Scholar] [CrossRef]

- Can, A.; Baskose, Y.; Gokceoglu, C. Stability assessments of a triple-tunnel portal with numerical analysis (south of Turkey). Geotech. Res. 2022, 9, 116–128. [Google Scholar] [CrossRef]

- Daraei, A.; Zare, S. A new multi-graph approach for selecting the sequential excavation method of civil tunnels. Tunn. Undergr. Space Technol. 2019, 91, 102999. [Google Scholar] [CrossRef]

- Lv, G.R.; Sui, B.; Wang, Y.J. Numerical simulation and stability analysis of excavation in shallowly buried terrain-biased tunnels. J. Shandong Univ. 2013, 43, 68–73. [Google Scholar]

- Li, W.J. Study on the Stability of Shallowly Buried Terrain-Biased Tunnels in Weak Surrounding Rock; Dalian University of Transportation: Liaoning, China, 2013. [Google Scholar]

- Liu, C.; Yang, H.; Jiang, X.; Shi, H. Shaking table test and numerical simulation for acceleration response laws of shallow-buried biased double-arch tunnel. J. Vibroeng. 2019, 21, 1188–1200. [Google Scholar] [CrossRef]

- Zhang, L.M.; Chao, W.W.; Liu, Z.Y.; Cong, Y.; Wang, Z.Q. Crack propagation characteristics during progressive failure of circular tunnels and the early warning thereof based on multi-sensor data fusion. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 172. [Google Scholar] [CrossRef]

- Zhang, L.M.; Zhang, D.; Wang, Z.Q.; Cong, Y.; Wang, X.S. Constructing a three-dimensional creep model for rocks and soils based on memory-dependent derivatives: A theoretical and experimental study. Comput. Geotech. 2023, 159, 105366. [Google Scholar] [CrossRef]

- Bi, Z.G.; Li, X.Z.; Wang, K. Study on the disturbance space effect of construction in shallowly buried terrain-biased tunnels with small clearance. J. Henan Univ. Urban Constr. 2023, 32, 1–8. [Google Scholar]

- Qiu, F.Y.; Qin, L.; Li, G.D. Analysis of surrounding rock stress characteristics in shallowly buried karst tunnels with terrain bias. North. Transp. 2024, 2, 52–55. [Google Scholar]

- Xiao, J.Z.; Dai, F.C.; Wei, Y.Q.; Min, H.; Xu, C.; Tu, X.B.; Wang, M.L. Cracking mechanism of secondary lining for a shallow and asymmetrically-loaded tunnel in loose deposits. Tunn. Undergr. Space Technol. 2014, 43, 232–240. [Google Scholar] [CrossRef]

- Ma, H.L. Study on the influence of construction methods on shallowly buried, terrain-biased, Small Clearance Tunnels. Sci. Technol. Innov. 2023, 2, 149–154. [Google Scholar]

- Mao, Z.; An, N.; Li, R.; Xu, L.; Wu, H. Analysis of treatment effects on shallowly buried bias slope sections of tunnels based on fuzzy comprehensive evaluation. Geotech Geol Eng. 2020, 38, 4463–4477. [Google Scholar] [CrossRef]

- Miao, Q.C.; Nuo, C.; Zheng, W.F. Mechanism and remediation measures for large deformation of the entrance section of shallowly buried terrain-biased tunnels in fine sandstone mudstone. Hydropower Energy Sci. 2023, 41, 133–137. [Google Scholar]

- Xue, F.; Zhang, M. Stability of the excavation face on a shield tunnel crossing beneath an existing tunnel. Geotech Res. 2020, 7, 96–102. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Q.; Zhu, J.; Zhu, Z. Stability of the excavation surface of a submarine shield tunnel considering the fluid-solid coupling effect and the equivalent layer. J. Mar. Sci. Eng. 2023, 11, 1667. [Google Scholar] [CrossRef]

- Zamora, H.Y.; Durand, F.A.; Pacheco, D.A. Three-dimensional analysis of excavation face stability of shallow tunnels. Tunn. Undergr. Space Technol. 2019, 92, 103062. [Google Scholar] [CrossRef]

- Dai, X.Y.; Wang, G.B.; Ye, M.; Zhang, Y.Q. Safety evaluation of crossing tunnel engineering: A case study. Appl. Sci. 2023, 13, 9459. [Google Scholar] [CrossRef]

- Guan, C.; Peng, H.; Wang, B. Study on stability of excavation surface of shield tunnel in clay layer. Transp. Res. Rec. J. Transp. Res. Board 2023, 2677, 675–693. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Chen, F.F.; Li, N.; He, M.C. Influence of fault on the surrounding rock stability for a mining tunnel: Distance and tectonic stress. Adv. Civ. Eng. 2017, 61, 2054938. [Google Scholar] [CrossRef]

- Xu, J.M.; Zheng, L.R.; Song, G.Y.; Zhang, D.W.; Sheil, B.; Marshall, A.M. Effects of embedded walls on tunnelling-induced sandy ground displacements: A numerical investigation. Geotechnique 2024, 1–14. [Google Scholar] [CrossRef]

- Xu, J.M.; Gui, J.S.; Sheil, B. A numerical investigation of the role of basements on tunnel-frame interaction in sandy soil. Comput Geotech. 2024, 169, 106197. [Google Scholar] [CrossRef]

- Gao, W.X.; Sun, W.L.; Zhou, W.X. Numerical simulation and monitoring analysis of excavation for shallowly buried terrain-biased tunnels. Constr. Tech. 2011, 40, 48–50. [Google Scholar]

- Mehrabi, R.; Baziar, M.H.; Nabizadeh, A.; Hung, W.Y. Discrete-element modelling of underground tunnel response to reverse fault rupture in sand. Proc. Inst. Civ. Eng.-Geotech. Eng. 2023, 176, 356–368. [Google Scholar] [CrossRef]

- Kielbassa, S.; Duddeck, H. Stress-strain fields at the tunnelling face-Three-dimensional analysis for two-dimensional technical approach. Rock Mech. Rock Eng. 1991, 24, 115–132. [Google Scholar] [CrossRef]

- Sterpi, D. An analysis of geotechnical problems involving strain softening effects. Int. J. Numer. Anal. Methods Geomech. 1999, 23, 142–145. [Google Scholar] [CrossRef]

- Chu, B.L.; Hsu, S.C.; Chang, Y.L.; Lin, S.Y. Mechanical behavior of a twin-tunnel in multi-layered formation. Tunn. Undergr. Space Technol. 2007, 22, 351–362. [Google Scholar] [CrossRef]

- Gao, G.; Meguid, M.A. On the role of joint roughness on the micromechanics of rock fracturing process: A numerical study. Acta Geotech. 2021, 17, 2799–2824. [Google Scholar] [CrossRef]

| Epoch Cause | Geotechnical Designation | φ (°) | c (kPa) | Comprehensive Coefficient of Internal Friction | Compression Modulus Es (MPa) | Saturated Compressive Strength (Mpa) | Basic Bearing Capacity σ0 (kPa) | Grade of Geotechnical Engineering |

|---|---|---|---|---|---|---|---|---|

| Q4ml | Hand fill | I | ||||||

| Q4al + pl | Silty clay | 35 | 0.3 | 0.3 | 12 | 180 | III | |

| J2 + 3gjd | Dacite porphyry | 35 | 45 | 0.3 | 15 | 250 | III | |

| J2 + 3gjd | Dacite porphyry | 45 | 0.5 | 500 | IV | |||

| J2 + 3gjd | Dacite porphyry | 55 | 0.6 | 800 | V | |||

| γy3 | Granite | 35 | 45 | 0.3 | 15 | 250 | III | |

| γy3 | Granite | 45 | 0.5 | 500 | IV | |||

| γy3 | Granite | 55 | 0.6 | 30.7 | 800 | V |

| ° | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.45 | 0.3 | 2700 | 2.1 | 1.5 | 2.1 | 1.5 | 45 | 1.2 | 3.2 |

| Pre-Excavation | Full-Section Excavation | Stepwise Excavation | Lining Support Treatment | Slope Reduction Treatment | |

|---|---|---|---|---|---|

| 1 | 0.293 | 0.041 | 0.042 | 0.295 | 0.374 |

| 2 | 0.699 | 0.148 | 0.148 | 0.337 | 0.144 |

| 3 | 0.468 | 0.875 | 0.873 | 0.394 | 0.781 |

| 4 | 0.521 | 0.931 | 0.928 | 0.428 | 0.784 |

| 5 | 0.351 | 0.34 | 0.34 | 0.373 | 0.307 |

| 6 | 0.344 | 0.383 | 0.383 | 0.418 | 0.31 |

| 7 | 0.585 | 0.849 | 0.846 | 0.737 | 0.706 |

| 8 | 0.606 | 0.783 | 0.781 | 0.761 | 0.735 |

| Pre-Excavation | Full-Section Excavation | Stepwise Excavation | Lining Support Treatment | Slope Reduction Treatment | |

|---|---|---|---|---|---|

| 1 | 0.22 | 0.345 | 0.346 | 0.203 | 0.341 |

| 2 | 0.348 | 0.326 | 0.327 | 0.354 | 0.326 |

| 3 | 0.283 | 0.15 | 0.149 | 0.388 | 0.129 |

| 4 | 0.339 | 0.191 | 0.19 | 0.458 | 0.173 |

| 5 | 0.275 | 0.255 | 0.256 | 0.195 | 0.278 |

| 6 | 0.251 | 0.292 | 0.292 | 0.186 | 0.24 |

| 7 | 0.314 | 0.42 | 0.421 | 0.338 | 0.374 |

| 8 | 0.323 | 0.327 | 0.328 | 0.308 | 0.336 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Liu, K.; Li, X.; Yan, Z. Optimizing the Support System of a Shallow Buried Tunnel under Unsymmetrical Pressure. Buildings 2024, 14, 1825. https://doi.org/10.3390/buildings14061825

Liu Y, Liu K, Li X, Yan Z. Optimizing the Support System of a Shallow Buried Tunnel under Unsymmetrical Pressure. Buildings. 2024; 14(6):1825. https://doi.org/10.3390/buildings14061825

Chicago/Turabian StyleLiu, Yongsheng, Kewei Liu, Xiang Li, and Zhaoxi Yan. 2024. "Optimizing the Support System of a Shallow Buried Tunnel under Unsymmetrical Pressure" Buildings 14, no. 6: 1825. https://doi.org/10.3390/buildings14061825

APA StyleLiu, Y., Liu, K., Li, X., & Yan, Z. (2024). Optimizing the Support System of a Shallow Buried Tunnel under Unsymmetrical Pressure. Buildings, 14(6), 1825. https://doi.org/10.3390/buildings14061825