A Linear Optimization for Slope Leveling of Ground-Mounted Centralized Photovoltaic Sites

Abstract

1. Introduction

2. Problem Description

3. A Linear Programming Model

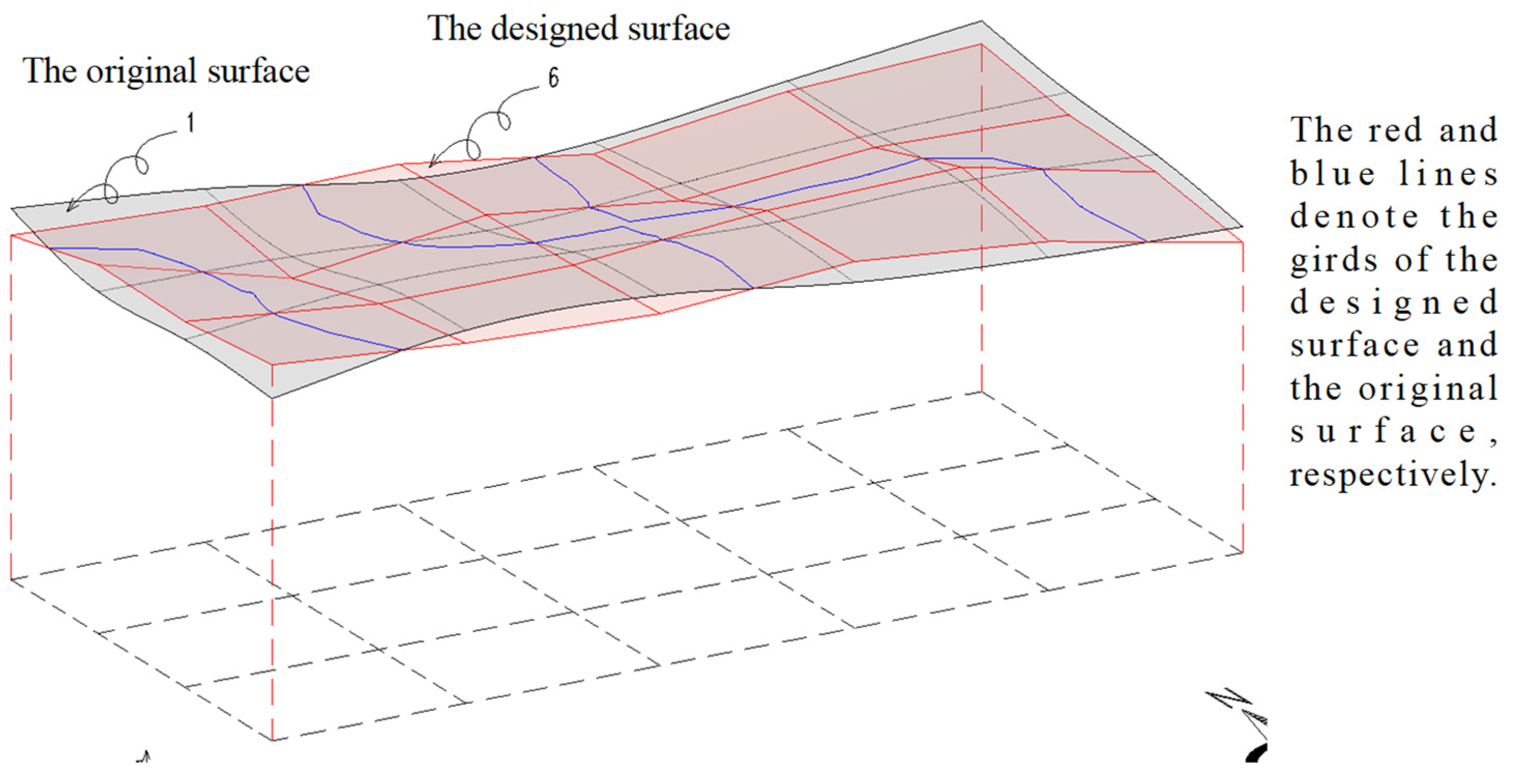

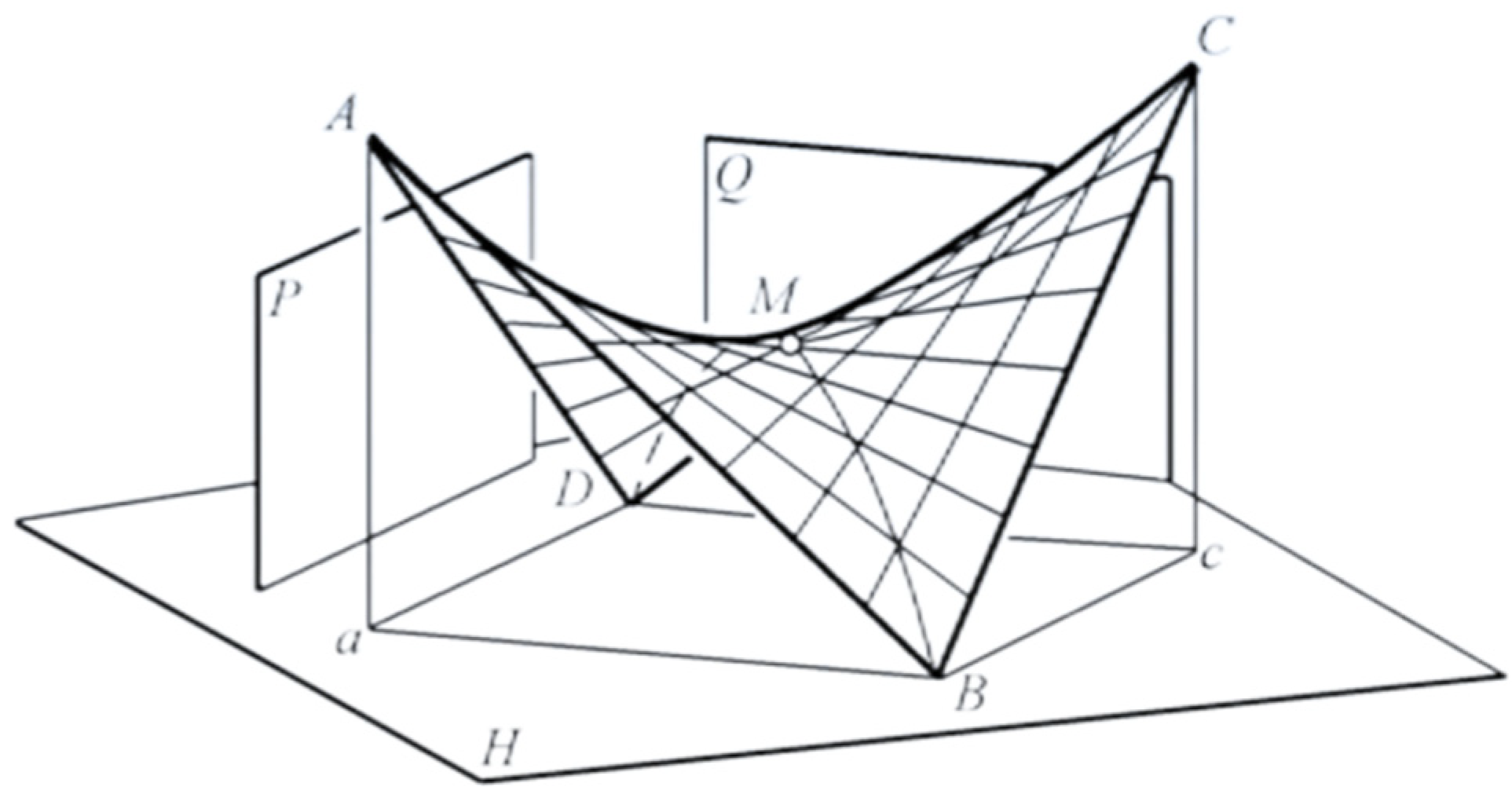

3.1. The Designed Surface

3.2. The Linear Transformation

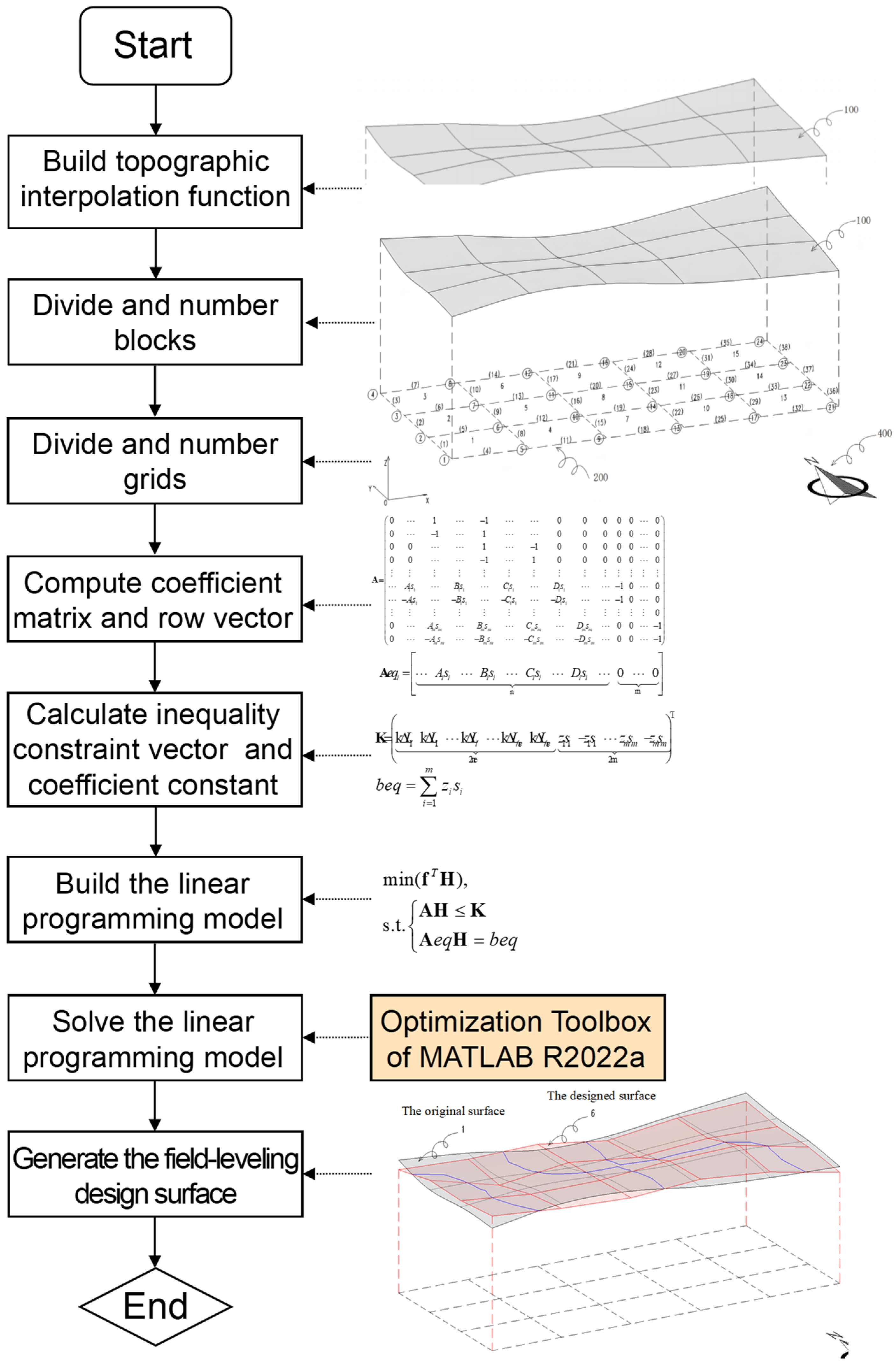

3.3. Calculation Steps

- (1)

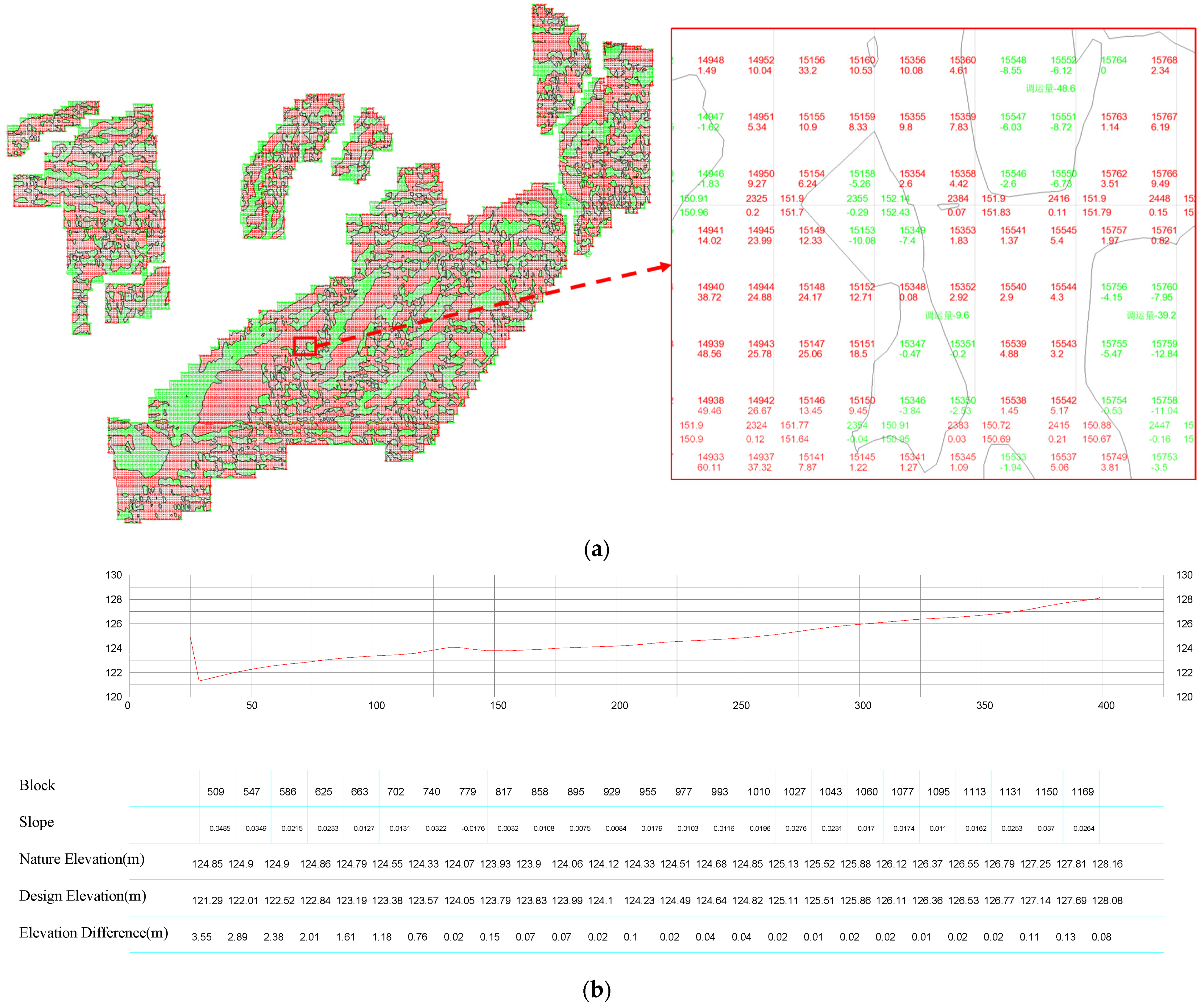

- Building a topographic two-dimensional interpolation function. Based on the original topographic elevation point data, the topographic two-dimensional interpolation function is generated to calculate the ground elevations of the given plane coordinates.

- (2)

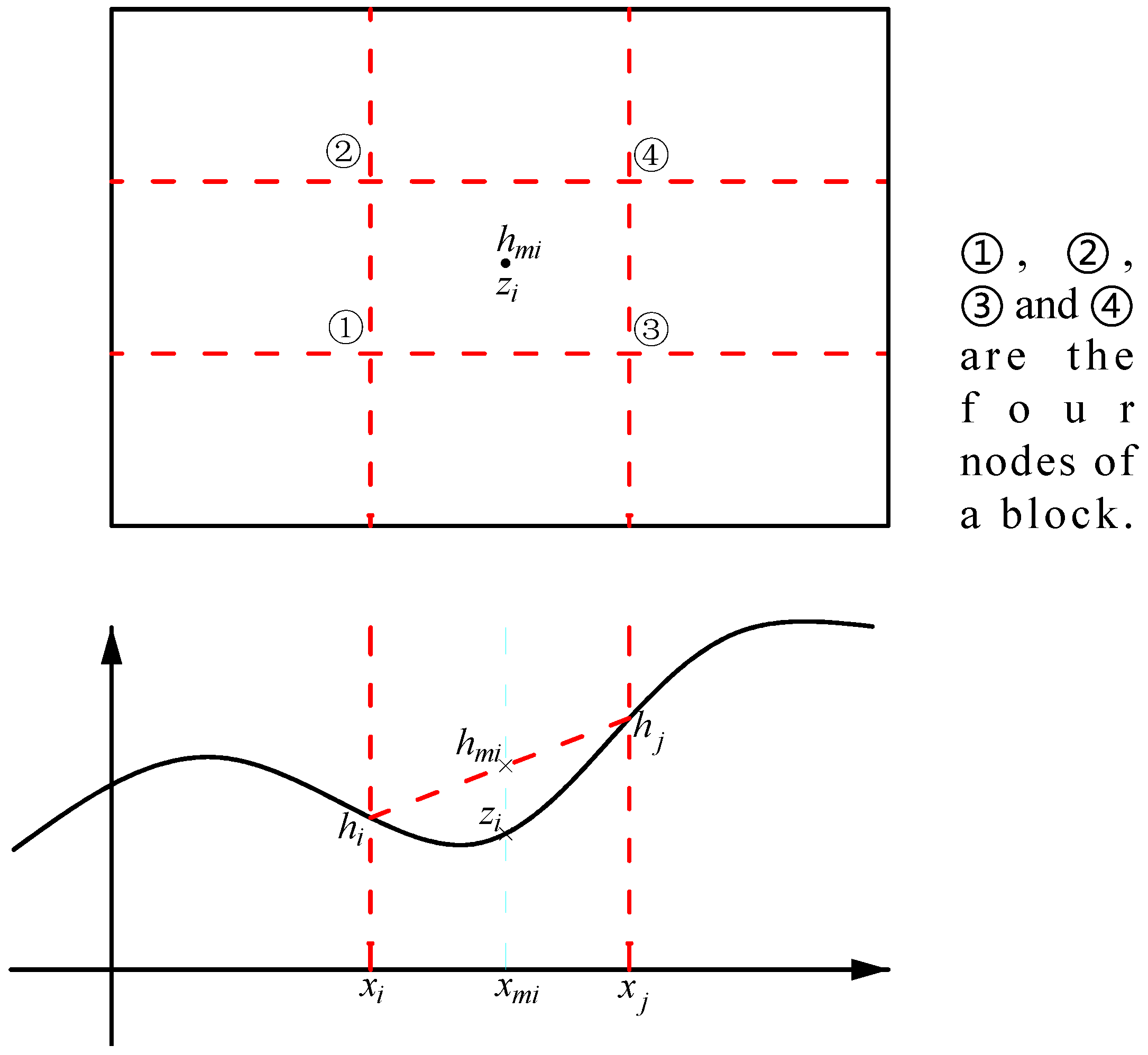

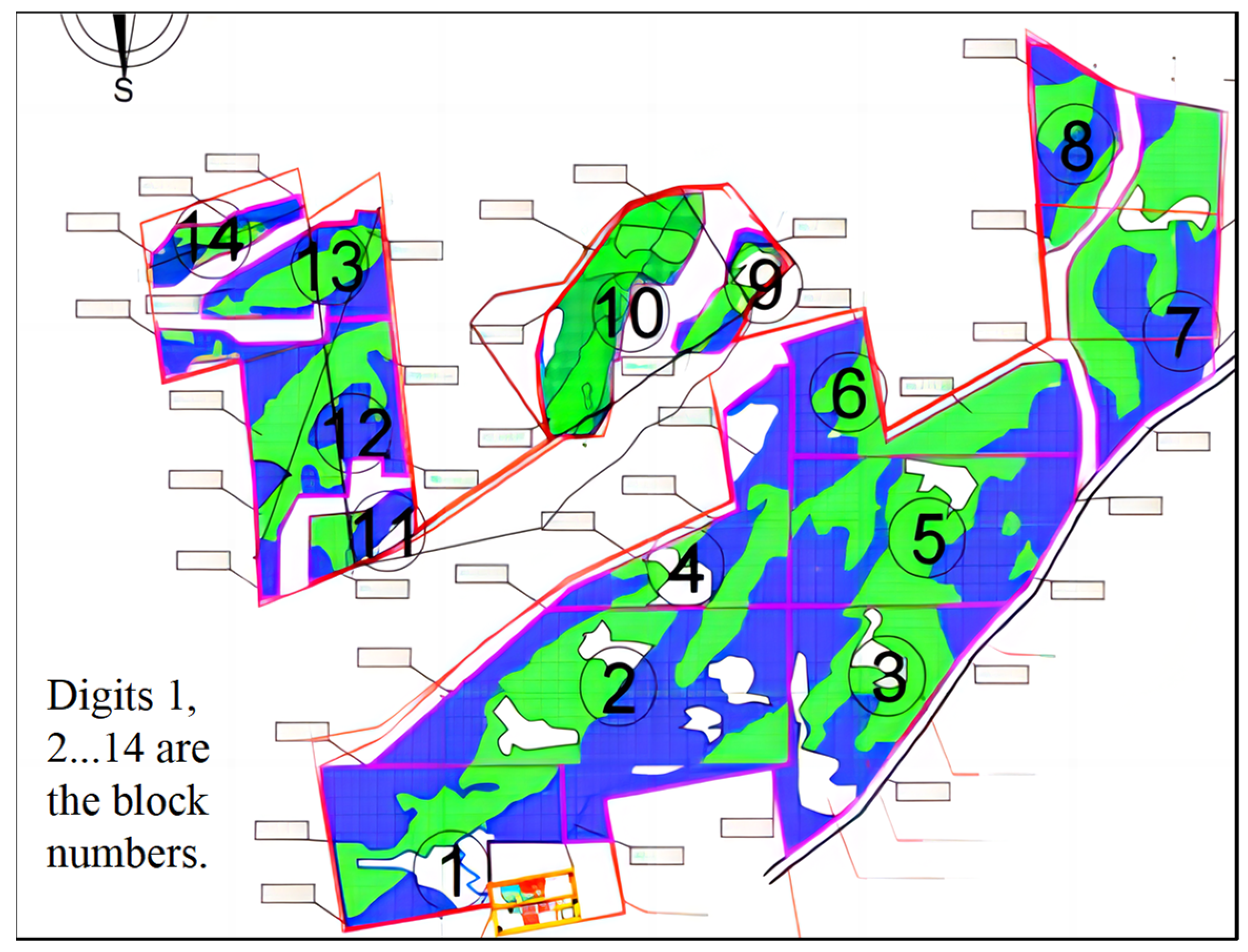

- Dividing the PV site into blocks and numbering blocks.

- (3)

- Dividing blocks into grids and numbering grids.

- (4)

- Computing the coefficient matrix and row vector, namely and .

- (5)

- Calculating the inequality constraint vector K and the coefficient constant .

- (6)

- Building the linear programming model as presented in Equation (18).

- (7)

- Solving the linear programming model. Using the optimization toolbox of MATLAB R2022a, the linear programming model in Equation (18) can be solved and optimum solution H can be obtained.

- (8)

- Generating the design surface of PV sites by connecting design elevations of each adjacent grid.

4. Results and Discussions

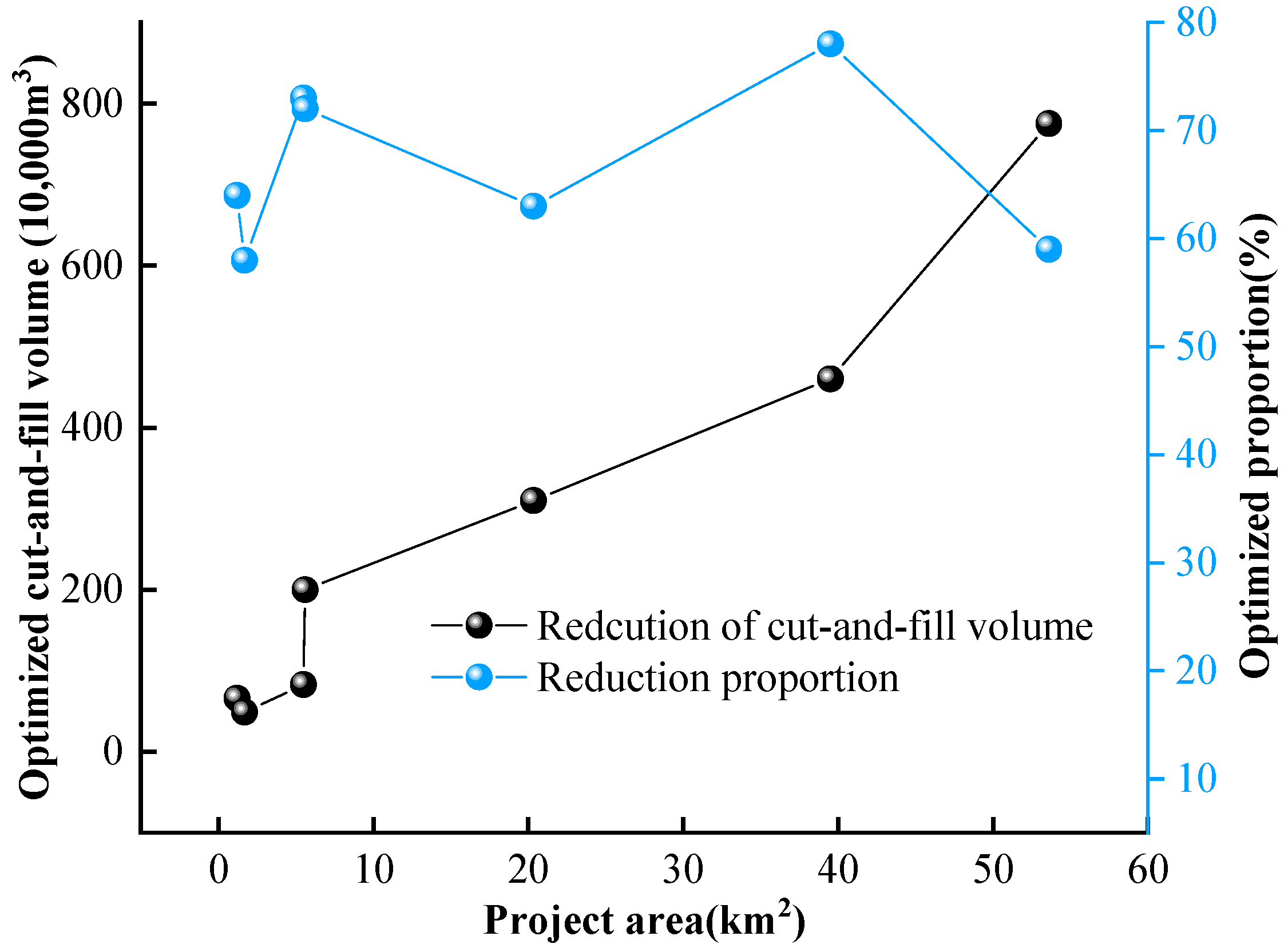

4.1. Comparison of Our Linear Optimization Methodology and the Segmented Plane Method

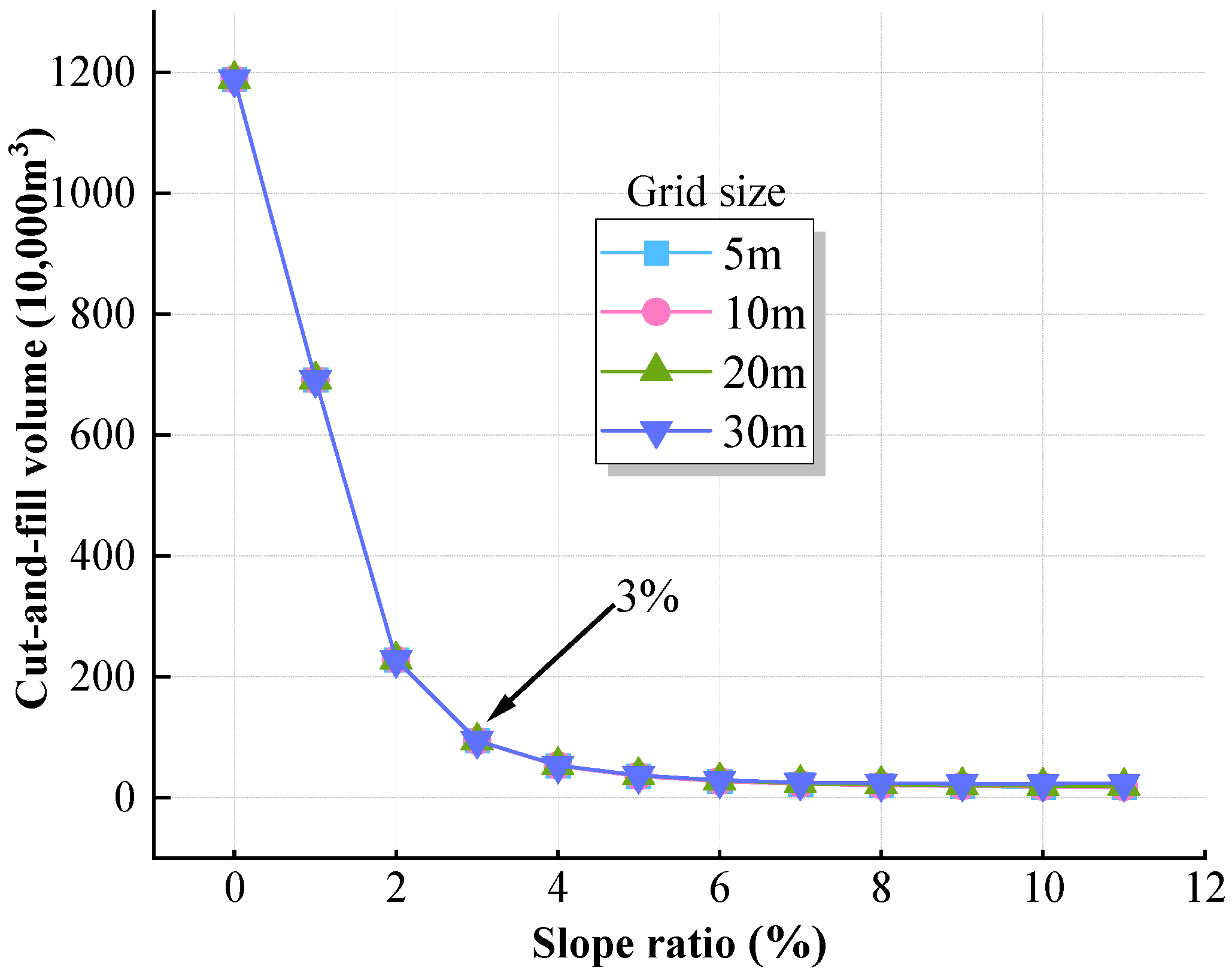

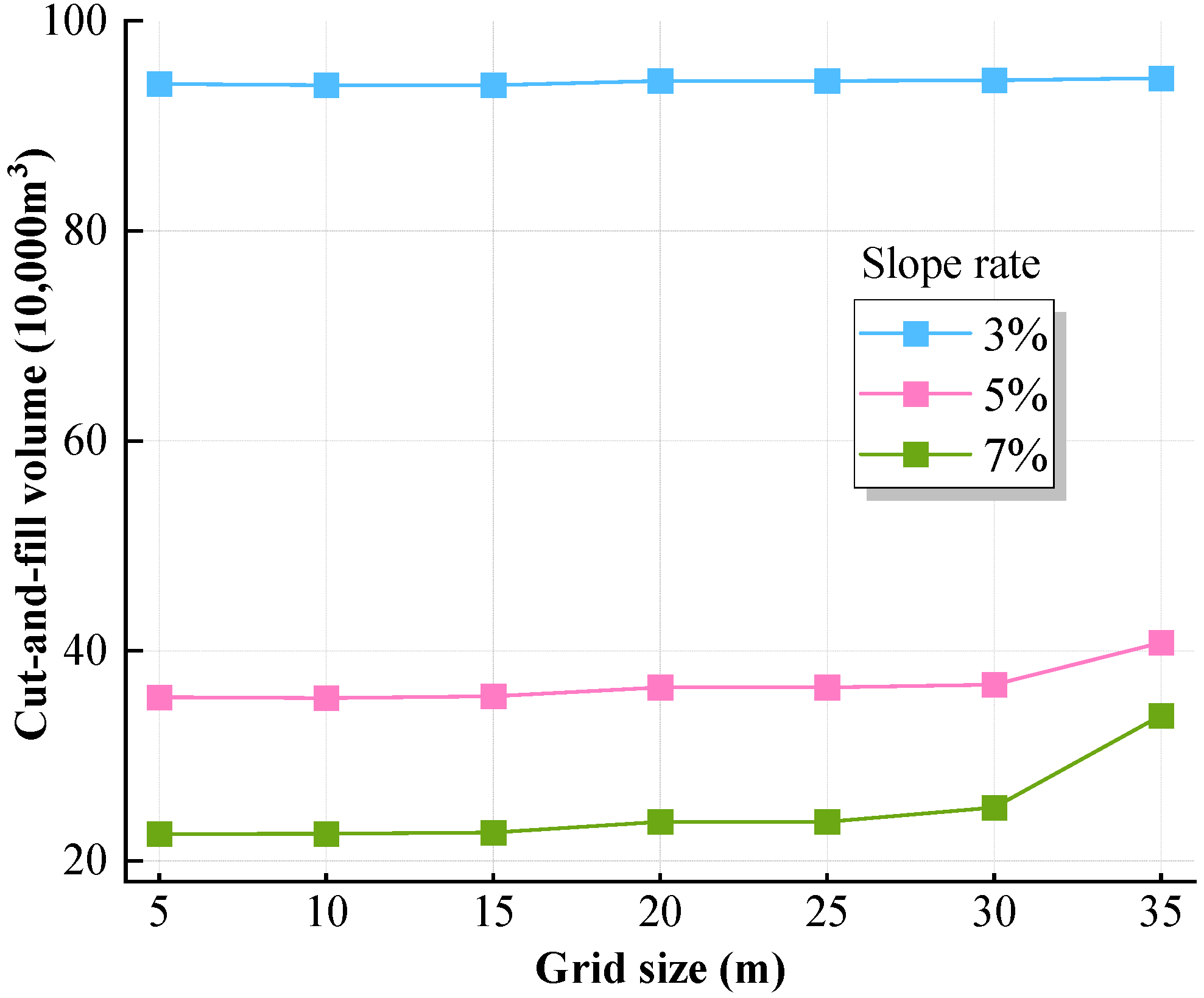

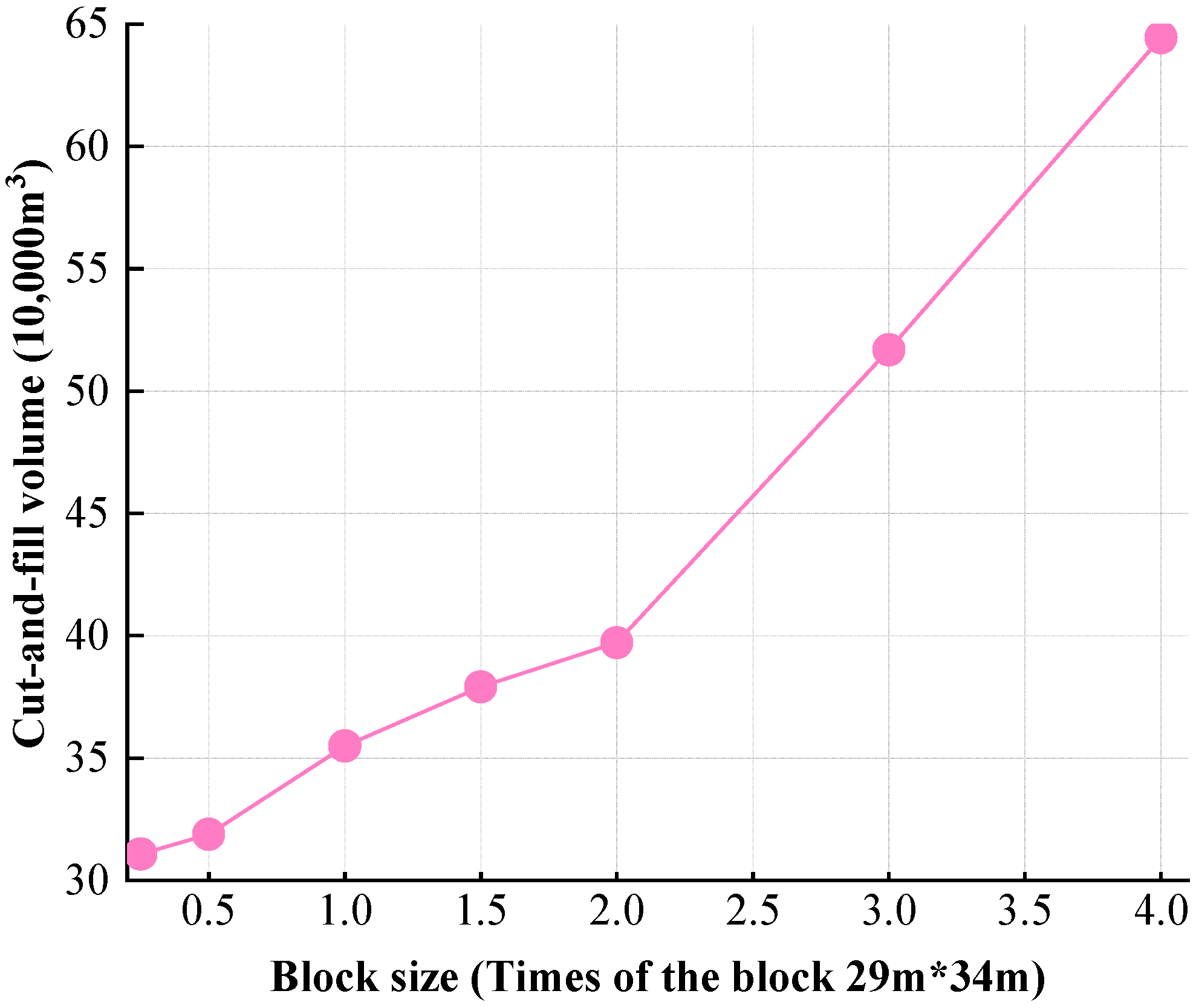

4.2. Parameter Analysis for the Linear Optimization Methodology

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Cut-and-fill volume of grid | |

| Area of grid | |

| Elevation of the midpoint of grid i in the fitted surface | |

| Elevation of the midpoint of grid i in the original surface | |

| Slope ratio limit | |

| Distance of two adjacent grid nodes and | |

| , , , | Elevations of the four nodes of block |

| , , , | Fitting coefficients |

| Fitting coefficient row vector of block | |

| Inequality constraint coefficient matrix | |

| Inequality constraint constant vector | |

| Global column vector of elevation | |

| Global column vector of the fitting coefficient | |

| Equality constraint coefficient vector | |

| Equality constraint constant |

References

- Thapar, V. A revisit to solar radiation estimations using sunshine duration: Analysis of the impact of these estimations on energy yield of a PV generating system. Energy Sources Part A 2019, 45, 1–25. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.J.; Wu, C.J.; Yang, B.H. The status and development of solar photovoltaic industry under the background of carbon neutrality. Energy Storage Sci. Technol. 2022, 11, 731–732. [Google Scholar]

- Lu, H.; Zhao, W. CFD prediction of dust pollution and impact on an isolated groundmounted solar photovoltaic system. Renew. Energy 2019, 131, 829–840. [Google Scholar] [CrossRef]

- Kulsoom, F.; Ahmad, F.M.; Hasmat, M.; Fausto, P.G.M. Experimental analysis of dust composition impact on Photovoltaic panel Performance: A case study. Sol. Energy 2024, 267, 112206. [Google Scholar] [CrossRef]

- Bouraiou, M.; Hamouda, A.; Chaker, M.; Mostefaoui, S.; Lachtar, M.; Sadok, N.; Boutasseta, M.; Othmani, A.I. Analysis and evaluation of the impact of climatic conditions on the photovoltaic modules performance in the desert environment. Energy Conver. Manag. 2015, 106, 1345–1355. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Z.; Li, B.; Guan, J. The impact of photovoltaic projects on ecological corridors through the Least-Cost Path model. Glob. Ecol. Conserv. 2023, 42, e02381. [Google Scholar] [CrossRef]

- Song, C.C.; Guo, Z.L.; Liu, A.G.; Zhang, H.Y.; Liu, R.; Zhang, H.R. Application of photovoltaics on different types of land in China: Opportunities, status and challenges. Renew. Sustain. Energy Rev. 2024, 191, 114146. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Oztop, H.F. Efficient cooling system design by using different shaped nanoparticles and rotating cylinders in channel system for photovoltaic thermal management. Numer. Heat Transf. Part B Fundam. 2024, 1–24. [Google Scholar] [CrossRef]

- Abbassi, R.; Saidi, S.; Urooj, S.; Alhasnawi, B.N.; Alawad, M.A.; Premkumar, M. An accurate metaheuristic mountain gazelle optimizer for parameter estimation of single- and double-diode photovoltaic cell models. Mathematics 2023, 11, 4565. [Google Scholar] [CrossRef]

- Barbón, A.; Bayón-Cueli, C.; Bayón, L.; Carreira-Fontao, V. A methodology for an optimal design of ground-mounted photovoltaic power plants. Appl. Energy 2022, 314, 118881. [Google Scholar] [CrossRef]

- Sulaiman, S.I.; Rahman, T.K.A.; Musirin, I.; Shaari, S.; Sopian, K. An intelligent method for sizing optimization in grid-connected photovoltaic system. Sol. Energy 2012, 86, 2067–2082. [Google Scholar] [CrossRef]

- Saidi, S.; Abbassi, R.; Hassen, W.B.; Chebbi, S. Solar photovoltaic energy system-based shunt active filter for electrical energy quality improvement. Int. J. Simul. Process Model. 2016, 11, 119–126. [Google Scholar] [CrossRef]

- Charabi, Y.; Rhouma, M.B.H.; Gastli, A. Siting of PV power plants on inclined terrains. Int. J. Sust. Energy 2014, 35, 834–843. [Google Scholar] [CrossRef]

- Fast Software. Available online: https://www.fast.com.cn/ (accessed on 1 June 2024).

- Autodest Official. Available online: https://www.autodesk.com/asean/products/civil-3d/ (accessed on 1 June 2024).

- Jat, M.L.; Gathala, M.K.; Ladha, J.K.; Saharawat, Y.S.; Jat, A.S.; Kumar, V.; Sharma, S.K.; Kumar, V.; Gupta, R. Evaluation of precision land leveling and double zero-till systems in the rice–wheat rotation: Water use, productivity, profitability and soil physical properties. Soil Tillage Res. 2009, 105, 112–121. [Google Scholar] [CrossRef]

- Song, X.Y.; Yang, Y.R.; Li, Y.R. Optimization of site-leveling design of thermal power projects for trough solar energy in large desert area. Electr. Power Surv. Des. 2021, 7, 50–57. [Google Scholar] [CrossRef]

- Song, X.M. Comparison and selection of vertical layout plan for solar photovoltaic site. Electr. Power Surv. Des. 2021, 8, 63–67. [Google Scholar] [CrossRef]

- You, H.P.; Zhang, M.; Wang, T.T. Application of mathematical morphology in the terrain treatment of photovoltaic power stations. Acta Energ. Sol. Sin. 2015, 36, 2341–2346. [Google Scholar]

- Yang, X.D.; Sun, J. General layout and vertical design optimization of solar photovoltaic power station—20 MWp project of Jinshan Photovoltaic Power Field Phase I, Guyang County, Baotou, Datang. Sol. Energy 2012, 13, 37–41. [Google Scholar] [CrossRef]

- Fan, N. The calculation method of site leveling for solar power station in the desert area. Low Temp. Archit. Technol. 2020, 42, 147–149. [Google Scholar] [CrossRef]

- Hamid, R.V.; Mohammad, S.; Ali, S.T.; Mohammad, A.A.; Saeid, E.; Mahboubeh, A.K.; Maryam, M.B.; Kaveh, O.A. A Simple Method for Land Grading Computations and its Comparison with Genetic Algorithm (GA) Method. Int. J. Res. Stud. Agric. Sci. 2017, 3, 26–38. [Google Scholar] [CrossRef]

- Ebne, J.R. Weighted average method for land grading design. J. Irrig. Drain. Eng. 2004, 130, 239–247. [Google Scholar] [CrossRef]

- Hossein, S.S.; Faride, B.; Mahamad, M. Optimizing land leveling by applying warped surface. Int. J. Eng. Prod. Res. 2015, 26, 39–44. [Google Scholar] [CrossRef]

- Safa, N.H.; Ahmed, M.A. Land grading design by using nonlinear programming. J. Irrig. Drain. Eng. 1990, 116, 219–226. [Google Scholar] [CrossRef]

- Warren, H.; Yves, L.; Faisal, R. A mixed-integer linear programming model to optimize the vertical alignment considering blocks and side-slopes in road construction. Eur. J. Oper. Res. 2015, 241, 631–641. [Google Scholar] [CrossRef]

- Lin, C.Y.; Hazela, P. Genetic algorithms in structural optimization problems with discrete and integer design variables. Eng. Optim. 1992, 19, 309–327. [Google Scholar] [CrossRef]

- Huang, J.; Yuan, Y.; Cui, W.; Zhan, Y. An approach based on Decision Tree to agricultural land grading. In Proceedings of the 2010 International Conference On Computer Design and Applications, Qinhuangdao, China, 25–27 June 2010; pp. 246–249. [Google Scholar] [CrossRef]

- Xia, Y.; Liu, Y.; Hong, X.; Liu, D. Application of binary tree based SVMs approach to land grade evaluation. Proc. SPIE Int. Soc. Opt. Eng. 2009, 7492, 1–7. [Google Scholar] [CrossRef]

- Reddy, S.L. Optimal land grading based on genetic algorithms. J. Irrig. Drain. Eng. ASCE 1996, 122, 183–188. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, Y.; Zheng, N.; Cheng, Y.; Zhu, J.; Zhong, W.; Sun, Y.; Zhao, J.; Dong, B.; Wang, Y.; Ren, J. A Linear Optimization for Slope Leveling of Ground-Mounted Centralized Photovoltaic Sites. Buildings 2024, 14, 1858. https://doi.org/10.3390/buildings14061858

Tao Y, Zheng N, Cheng Y, Zhu J, Zhong W, Sun Y, Zhao J, Dong B, Wang Y, Ren J. A Linear Optimization for Slope Leveling of Ground-Mounted Centralized Photovoltaic Sites. Buildings. 2024; 14(6):1858. https://doi.org/10.3390/buildings14061858

Chicago/Turabian StyleTao, Yanli, Nan Zheng, Yuanzhe Cheng, Jianfeng Zhu, Weibin Zhong, Yasong Sun, Jianyong Zhao, Baoshun Dong, Yongming Wang, and Jinming Ren. 2024. "A Linear Optimization for Slope Leveling of Ground-Mounted Centralized Photovoltaic Sites" Buildings 14, no. 6: 1858. https://doi.org/10.3390/buildings14061858

APA StyleTao, Y., Zheng, N., Cheng, Y., Zhu, J., Zhong, W., Sun, Y., Zhao, J., Dong, B., Wang, Y., & Ren, J. (2024). A Linear Optimization for Slope Leveling of Ground-Mounted Centralized Photovoltaic Sites. Buildings, 14(6), 1858. https://doi.org/10.3390/buildings14061858