Abstract

A comparative study of the effect of a vacuum preloading combined intermittent heating method and conventional vacuum preloading treatment was designed and carried out through indoor model tests to investigate the optimal intermittent heating time. It is concluded that the mechanism of vacuum preloading combined with the intermittent heating method is to improve the permeability of soil to alleviate the clogging effect, and therefore has a treatment effect far beyond the conventional vacuum preloading method. The results also show that setting a heating time of 120 min and a stopping time of 60 min can obtain the best consolidation effect.

1. Introduction

Engineering waste slurries (such as slurry generated in drilling pile construction sites) contain more fine particles, which are characterized by high water content, strong hydrophilicity, slow self-weight sedimentation, and poor separation, making them extremely difficult to be treated effectively. Vacuum preloading combined with prefabricated vertical drains (PVDs) is one of the most cost-effective methods for accelerating the consolidation of soft clays [1,2,3,4]. However, when treating dredged slurries with high water contents, the improvement efficiency by conventional vacuum preloading is not desirable due to the bending and clogging of PVDs [5,6].

In 1987, Len [7] verified the feasibility of replacing vertical sand wells with horizontal shallow-clay sand wells at Changi Airport in Singapore. Then, horizontal drains combined with the vacuum preloading method were proposed and it was found that the method is not only effective in solving the problem of the bending of drains but also in reducing the damage to the environment. However, using horizontal drains combined with the vacuum preloading method for treating slurries with high water contents is considered as time consuming [8]. Many new composite methods are proposed for these problems. The electro–osmotic combined vacuum preloading method [9,10,11,12,13,14] is to improve the effect of vacuum preloading reinforcement by adding a current field in the soil and making the pore water in the soil flow from the anode to the cathode under the action of the electric field; the air booster vacuum preloading method [15,16,17,18,19,20,21] is to improve the drainage efficiency by injecting high-pressure gas into the soil through a booster pump to form a greater pressure difference between the soil and the drains, and the high-pressure gas can produce fine cracks and form new pore water drainage channels. Moreover, there is strong ramming combined with the vacuum preloading method [22,23,24], mounding combined with the vacuum preloading method [25,26], and the graded vacuum preloading method [27,28,29,30], a method of adding chemical additives to modify and/or solidify the clays [31,32].

Abuel-Naga [33] first proposed the idea of joint heating of shaft drainage in 2006 based on the study of the temperature effect of soil and showed that the thermal drainage consolidation method can significantly accelerate the soft foundation consolidation and drainage process. Tao Haibing [34] and Liu Ganbin [35] designed thermal drainage model tests to further verify that the thermal drainage method can accelerate the soft foundation consolidation process and reduce post-work settlement. In 2011, Artidteang et al. [36] proposed a foundation treatment method with combined vacuum preloading and heating, and found that compared with the ambient temperature case, the settlement of the heated model foundation increased by approximately 40% and the soil consolidation coefficient increased by 1.9 fold. Deng Yuebao et al. [37] concluded that vacuum preloading combined heating technology can accelerate the vacuum preloading drainage consolidation rate, reduce post-work uneven settlement, and improve the bearing capacity of the treated soft soil foundation.

This paper investigates the optimal intermittent heating time of vacuum preloading combined with the intermittent heating method to enhance the consolidation effect and shorten the consolidation time by taking the engineering waste slurry in the Wenzhou area as the research object.

2. Test Materials and Methods

The test soil samples were taken from the Wenzhou Nanbaixiang road project, and the basic physical properties of the soil samples were listed in Table 1.

Table 1.

Basic physical and mechanical indicators of soil.

In this paper, the effect of vacuum preloading combined intermittent heating on the reinforcement of engineering waste slurry were investigated. Heating was activated after 280 h of consolidation. The duration of the heating period was different, but the intermittent heating method was carried out with a ratio of heating to stopping heating time of 2:1. The heating ratio was selected because the larger ratio was not cost-effective while the smaller ratio was not good for increasing the coefficient of consolidation of soil mass [38]. The specific heating time settings are shown in Table 2. Based on the result of Lei et al. [39], when the drainage rate is at 0.1 kg/h, the drainage rate can be considered to enter the slow drainage stage, and combined with the experimental data of Case 0 group, the intermittent heating test of four groups was carried out after 280 h of the start of the test.

Table 2.

Testing program.

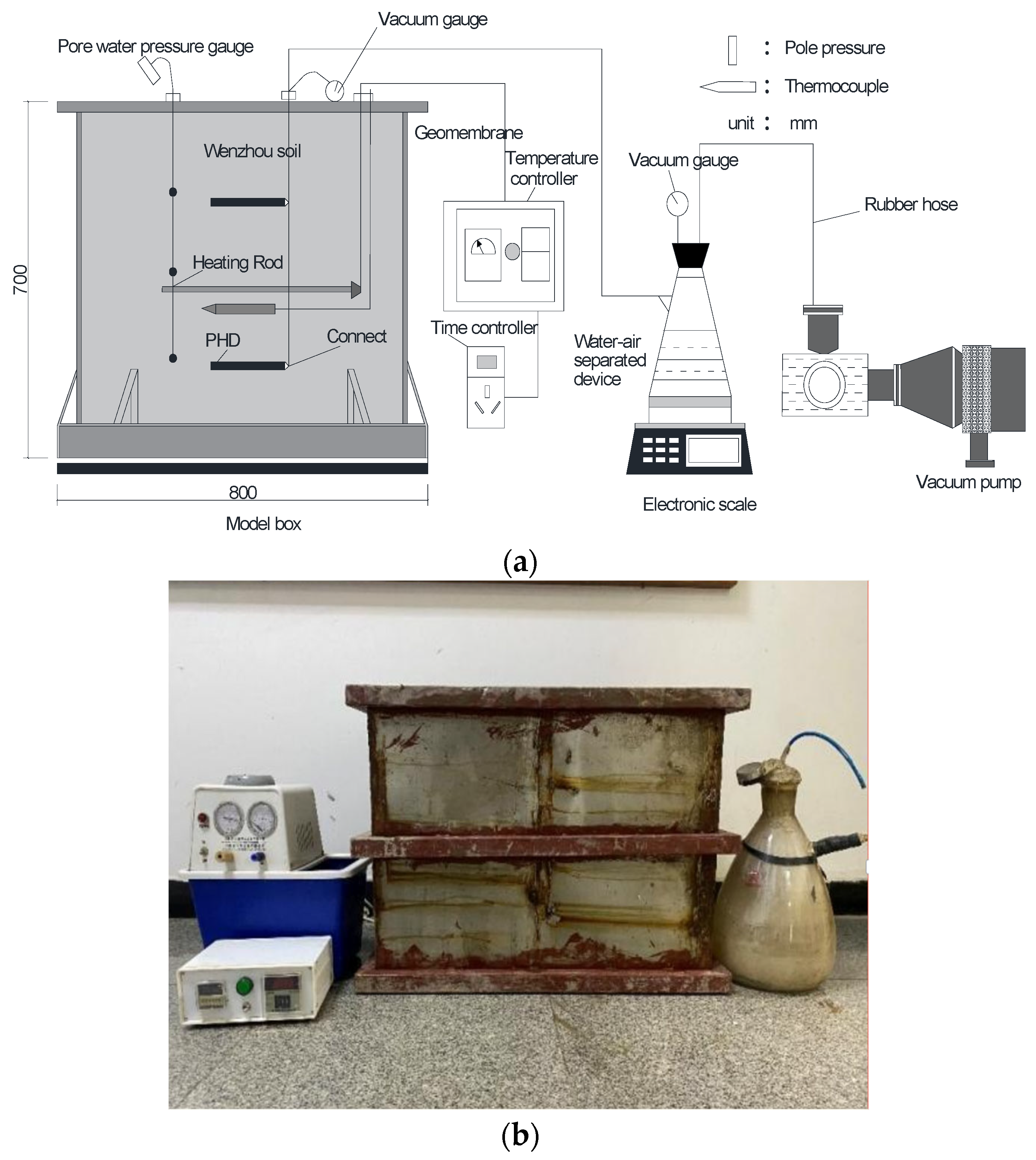

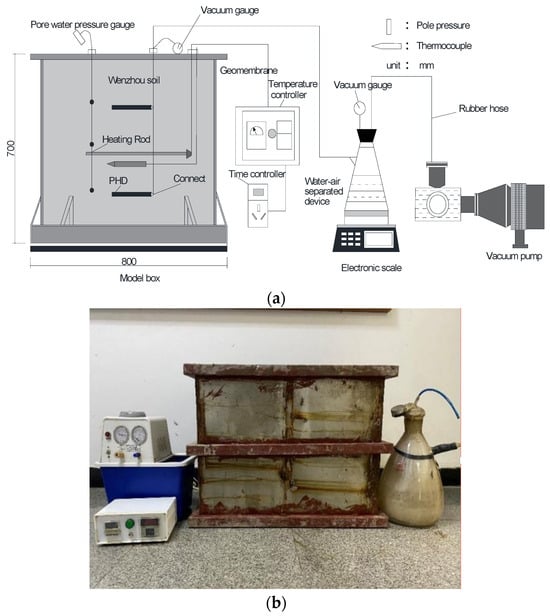

The testing model box was made by stainless steel and had the dimensions of 80 cm × 60 cm × 70 cm (length × width × height) (Figure 1). The well-mixed soil was added into the box layer by layer. When the soil thickness reached 20 cm and 40 cm, two PHDs with length of 30 cm and width of 40 cm were placed. In the middle of the PHDs, a heating rod was installed horizontally to increase the temperature of soil. The rated power of the heating rod is 1000 W, which ensures heating efficiency of the heating rod. When the soil thickness reached 60 cm, a layer of geotextile and a layer of geomembrane were placed to seal the soil sample. The model test simulates the vacuum and heating-induced consolidation of the engineering slurry.

Figure 1.

Testing model box. (a) Schematic drawing. (b) Photo.

3. Test Results and Analysis

3.1. Variation in Water Discharge

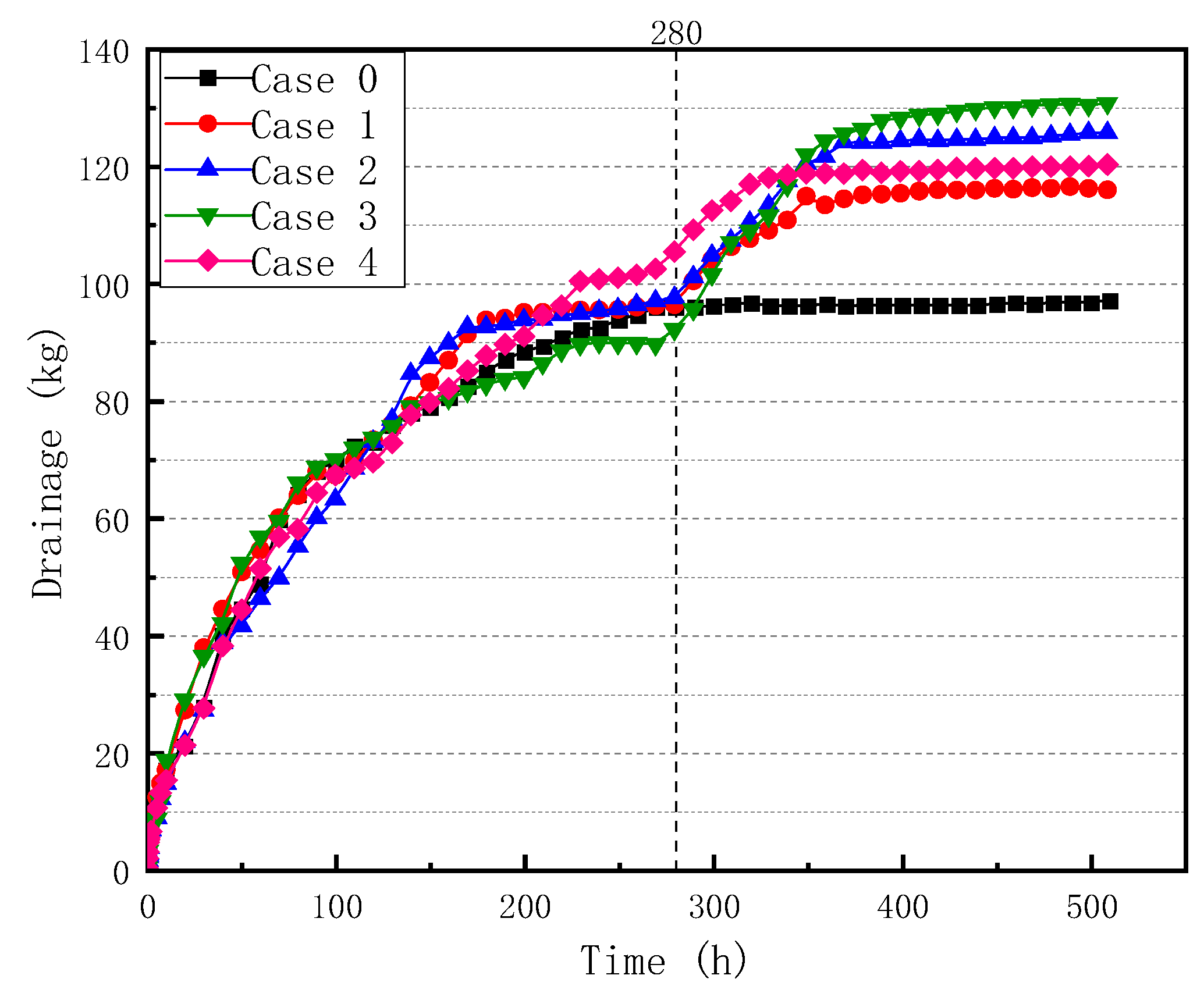

Figure 2 shows the curves of discharged water with time for five groups. Case 0 follows the trend of the drainage change in the conventional vacuum preloading method, i.e., the drainage rate has three typical stages: first fast, then slow, and then gradually stabilized. After approximately 280 h of vacuum consolidation, the drainage remains stable and does not grow; therefore, the drainage process can be regarded as almost finished. After the 280 h heating process was started for Cases 1–4. The drainage rates of Cases 1–4 showed significant increases, which is related to the increase in the permeability of the soil due to heating. The final drainage of Cases 1–4 increases by 19.56%, 29.55%, 34.77%, and 23.94% compared with Case 0. Among the four heating groups, Case 3 had the largest increase in water discharge, which is increased by 11.29%, 3.9%, and 8.04% compared to Case 1, Case 2, and Case 4, respectively, indicating that heating for 120 min and then resting for 60 min without heating is a optimal way to treat the engineering slurry at the late stage of vacuum consolidation.

Figure 2.

Discharge water with time.

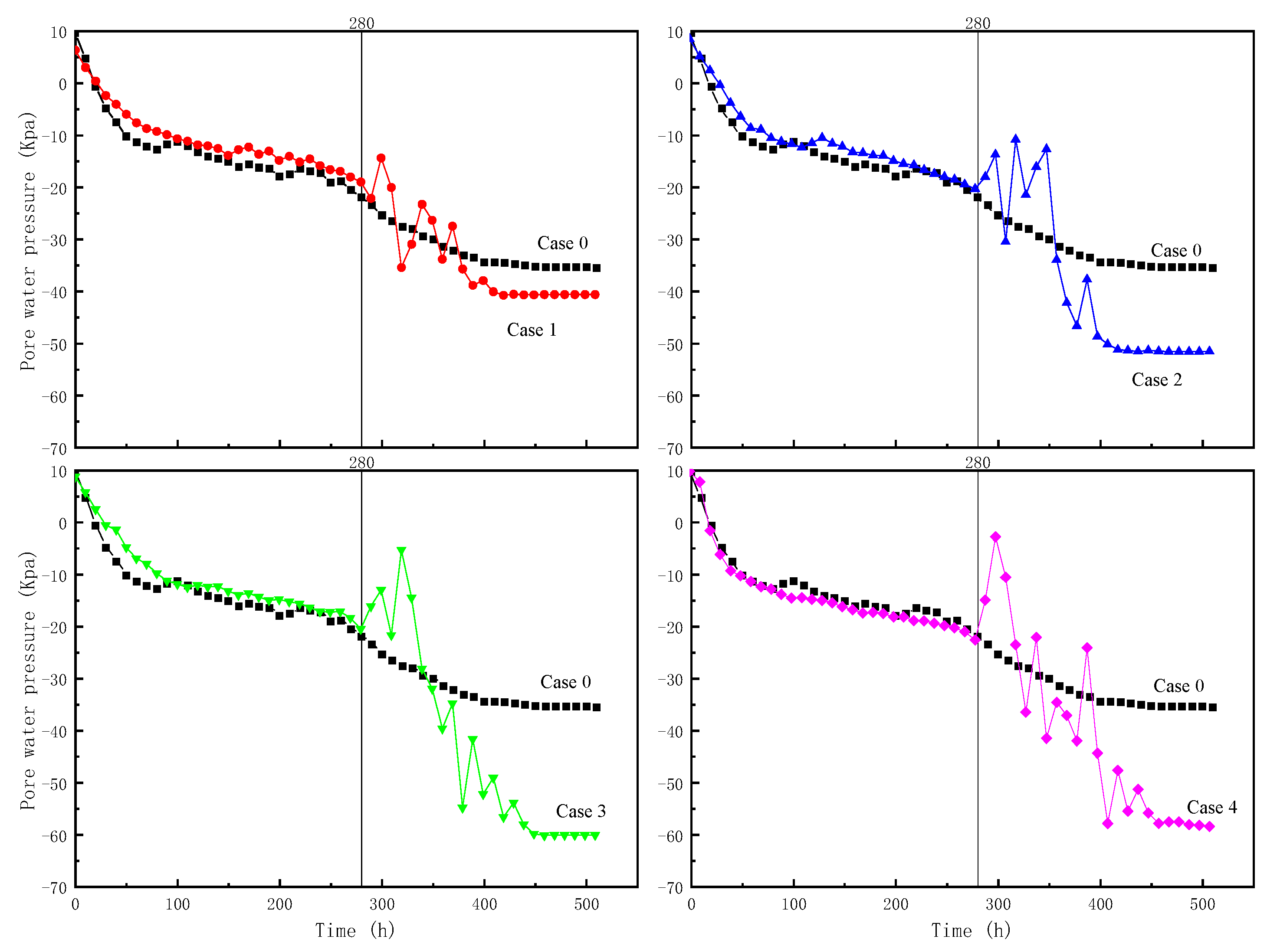

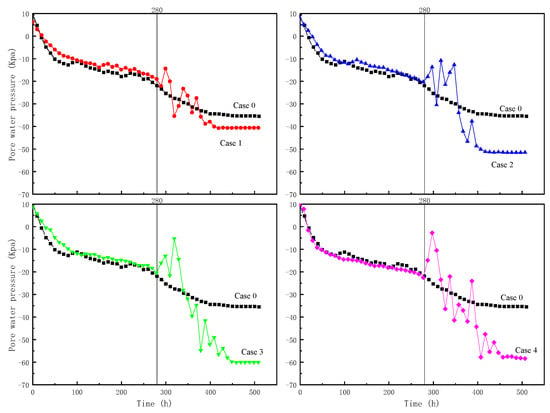

3.2. Pore Water Pressure Variation

The pore water pressure change curve in Figure 3 shows that the four groups of vacuum preloading combined with the intermittent heating method and the conventional group show completely different trends. Before heating, the pore water pressure dissipation curve of the five groups is approximately similar—all are gradually dissipated under slow fluctuations. After heating, the pore water pressure dissipation curve of each heating group has a wide range of fluctuations. The pore pressure of the heating group showed a decrease fluctuation of pore water pressure. At the end of the test, the pore water pressure dissipation in Cases 1–4 increased by 14.83%, 45.72%, 70.78%, and 66.13% compared with Case 0, respectively. Among the heating groups, the average pore water pressure dissipation in Case 3 was greater than that in the other heating groups. This indicates that the temperature interval between the heating and the stopping time used in Case 3 can improve the permeability of the soil more efficiently, which can improve vacuum pressure transfer efficiency.

Figure 3.

Pore water pressure with time.

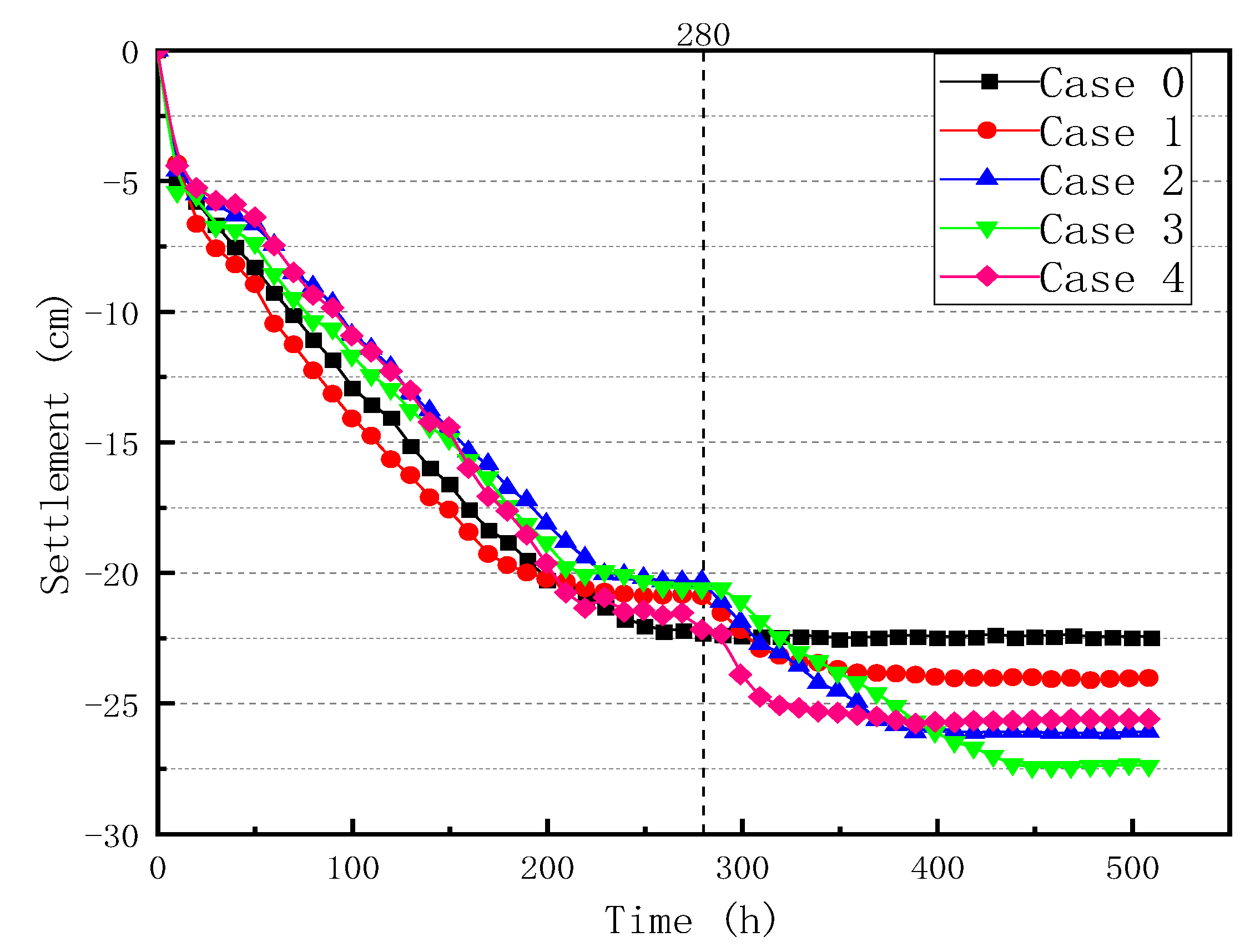

3.3. Settlement Change and Prediction

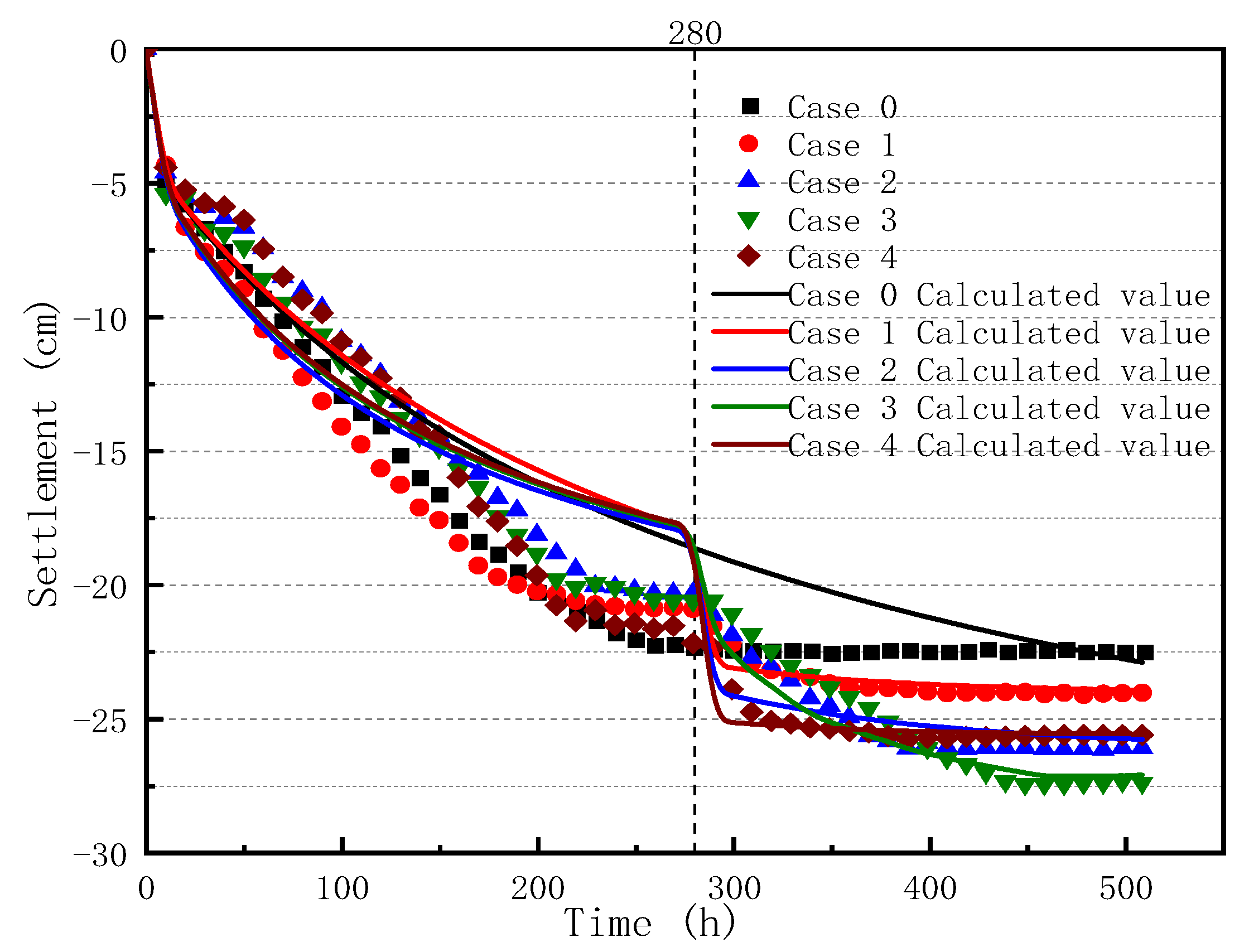

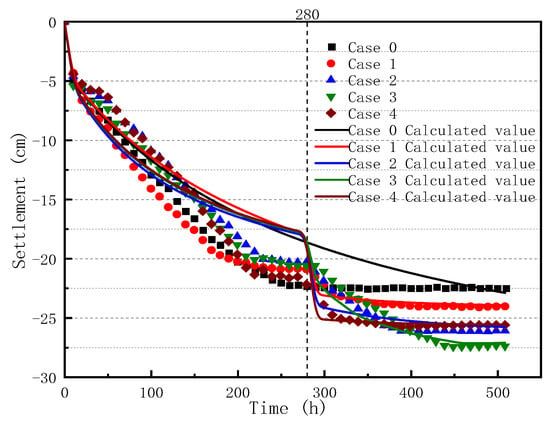

The settlement of each group can be seen from the settlement change curve with time in Figure 4. The tests showed a large settlement change in the early part of the test, and then the drains and its vicinity began to clogging, which prevented soil consolidation. With the intervention of heating, the trend of settlement gradually slowed down, and within 45 h after the start of heating, Cases 1–4 showed a rapid growth phenomenon. The final settlements of Cases 1–4 increased by 7.06%, 16.27%, 22.07%, and 14.08% compared to the conventional vacuum preloading method. Among them, Case 3 showed the largest final settling volume, which was 3.38 cm, 1.31 cm, and 1.8 cm higher than that of Case 1, Case 2, and Case 4, respectively, with an improvement of 12.3%, 4.76%, and 6.55%. It can be found that heating for 120 min and stopping for 60 min make the optimal combination of intermittent heating time.

Figure 4.

Settlement with time.

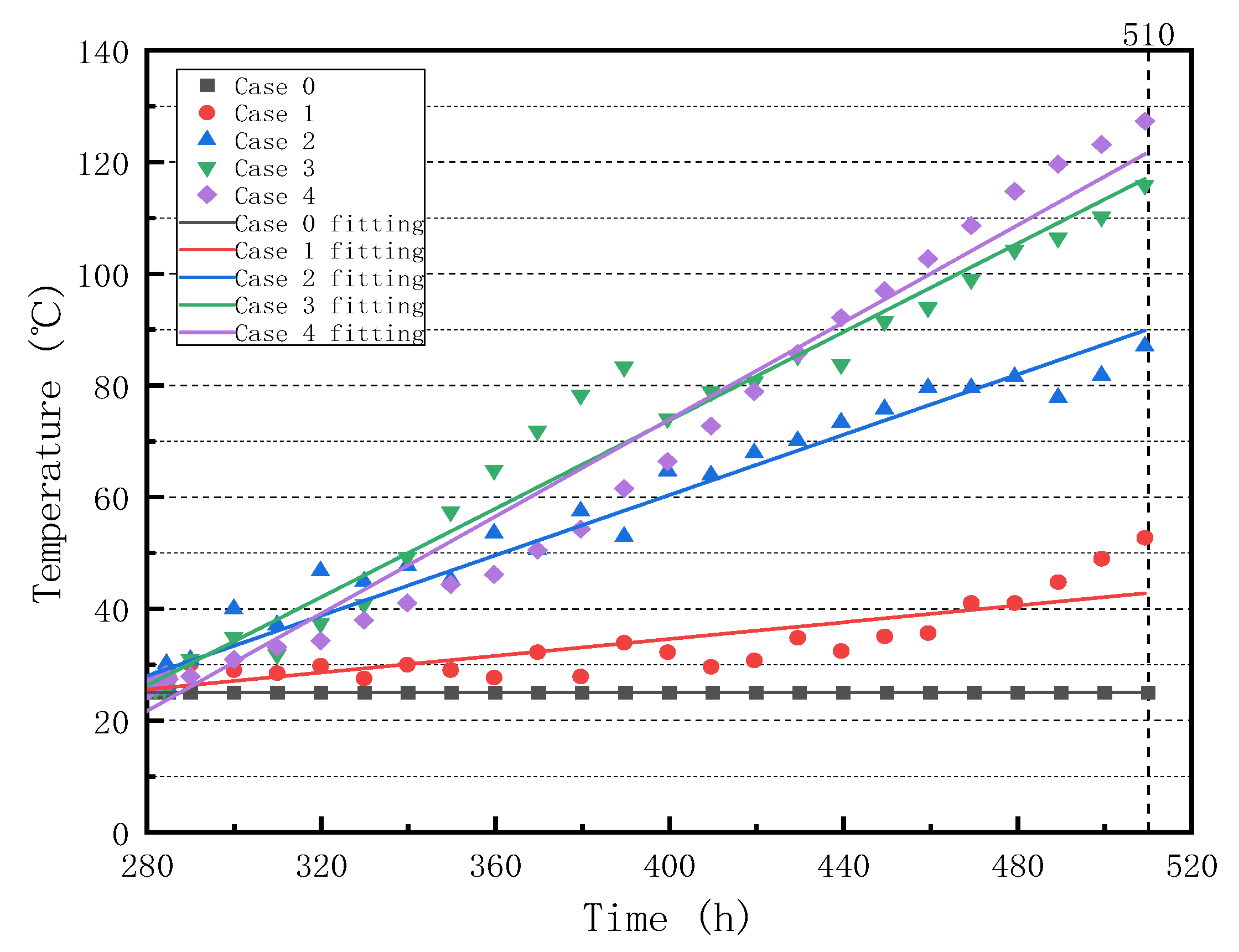

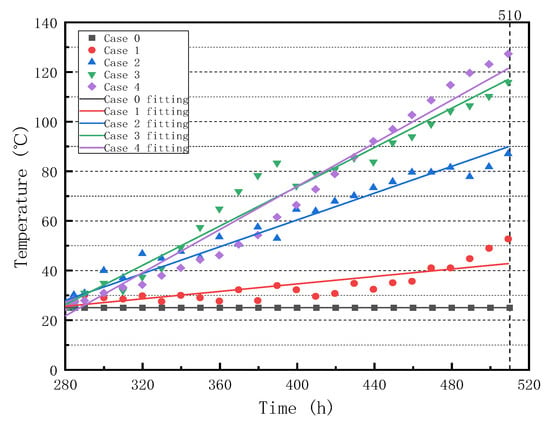

Figure 5 shows the temperature variation and its fitting curve during the intermittent heating phase, from which it can be seen that the variation in soil temperature follows a linear relationship. The temperature calculation point at this time is determined according to the fitted temperature value corresponding to 395 h.

Figure 5.

Full-time temperature fitting graph.

Observation of the settling curve reveals that the settling can be divided into two major parts, the conventional vacuum preloading stage before 280 h and vacuum preloading combined with the intermittent heating method stage from 280 h to 500 h, respectively. There is a clear trend in the settling curve at 280 h, so the conventional single settling prediction method becomes inapplicable. In this paper, a non-single settlement prediction formula is used, i.e., a double curve method is used to predict the settlement in the conventional vacuum preloading stage; the final settlement multiplied by the average consolidation coefficient is used in the heating stage to determine the effect of the combined vacuum preloading intermittent heating method on the settlement. The empirical hyperbolic equation is:

where S0 is the initial soil thickness; α is the linear fitted intercept of settlement–time curve; β is the slope of the linear fitted intercept of settlement–time curve; t1 is the conventional vacuum preloading time (0 ≤ t1 < 235).

The settling curve equation can be expressed as:

where is the average degree of consolidation subjected to PVD-induced consolidation. Horizontal drains were used in this test, so the method of the modified coefficient of consolidation is used [40]. The modified coefficient fp is calculated according to Equations (3) and (4)

where Sv is the horizontal drainage board vertical spacing (m); Sh is the horizontal drainage board horizontal spacing; W is the width of the PHDs.

The size of the model box used in this test is 80 cm × 60 cm × 70 cm (length × width × height), and the vertical spacing between the two drainage boards is 20 cm, so the Sv in the formula is 0.2 m, and the horizontal spacing is taken as the length of the model box 0.8 m. Then, Sv/Sh = 0.2/0.8 = 0.25, and the ratio is found to be less than the minimum value of 0.5 specified in the Formula (2). W is 0.4 m, W/Sh = 0.4/0.8 = 0.5, and fp is taken as 1.88 by substituting the data: The average consolidation factor of horizontal drainage slabs is calculated according to Equations (5)–(7):

where is modified soil consolidation factor (m2/d); t is time (d); cv is the vertical consolidation coefficient of the soil (m2/d); fp is correction factor; L is the length of the drain (m); bc is the thickness of smeared area (m); kv is the vertical permeability of the soil (m/d); qw is the discharged capacity of the drain (m3/d); kc is the soil permeability of smeared area (m/d); kv/kc can be taken from 50 to 300 and the low value is taken when the water content of the soil is low. Equation (5) is applicable for vacuum consolidation of engineering slurry subject to the horizontal drains. For vacuum preloading combined with the intermittent heating method, some corrections to the formula are needed to consider the effect of the heating. The effect of temperature on the permeability of soil can be expressed as:

Then, Equations (7) and (5) change into:

Then, the settlement can be calculated from:

The basic parameters required to quantify the above theory through practical arithmetic examples are shown in Table 3 below:

Table 3.

Basic parameters.

Figure 6 shows the comparison of calculated values and the measured values during the full time, from which it can be seen that the calculated settlement is mainly consistent with the experimental value. The rationality of settlement calculation method is verified. Once again, the acceleration effect of temperature on settlement was proved.

Figure 6.

Full-time settlement fitting diagram.

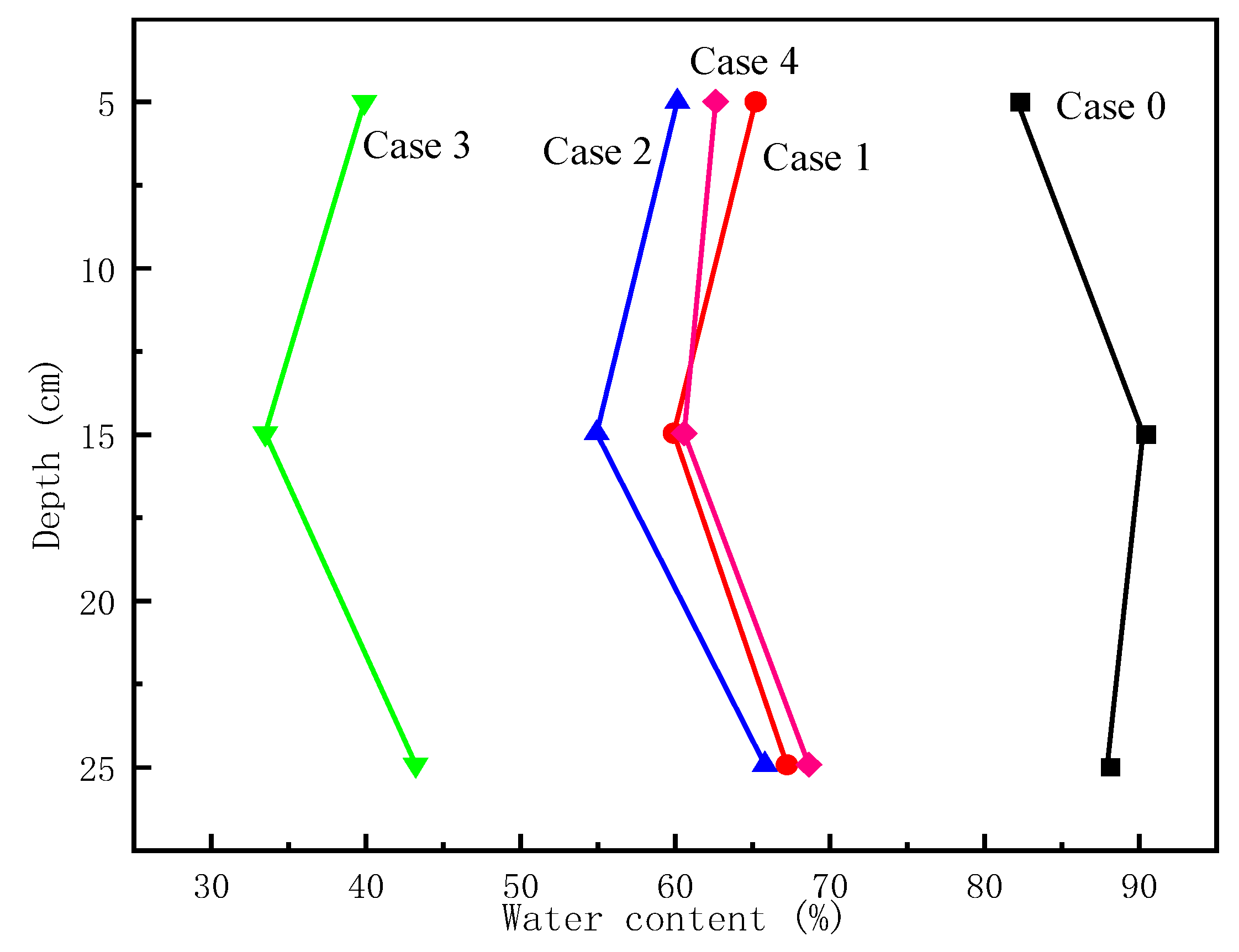

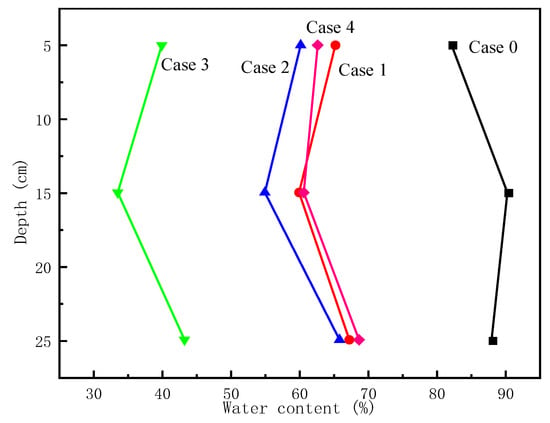

3.4. Water Content and Vane Shear Strength

At the end of the test, the soil was sampled and its moisture content and vane shear strength were measured. According to the difference in depth and distance, the water content at different depths is shown in Figure 7, from which it can be seen that the trend of water content of the soil treated by vacuum preloading combined with the intermittent heating method and the water content of the soil treated by the conventional vacuum preloading method have obvious differences.

Figure 7.

Variation in water content with depth.

Compared with the initial water content, the water content in all five groups of indoor model tests was substantially reduced, and the average water content in the upper, middle and lower layers of the model box decreased to 86.98%, 64.23%, 60.4%, 38.92% and 64.08%, respectively. This indicates that vacuum preloading combined with the intermittent heating method is more effective in treating engineering and alleviating clogging of drains.

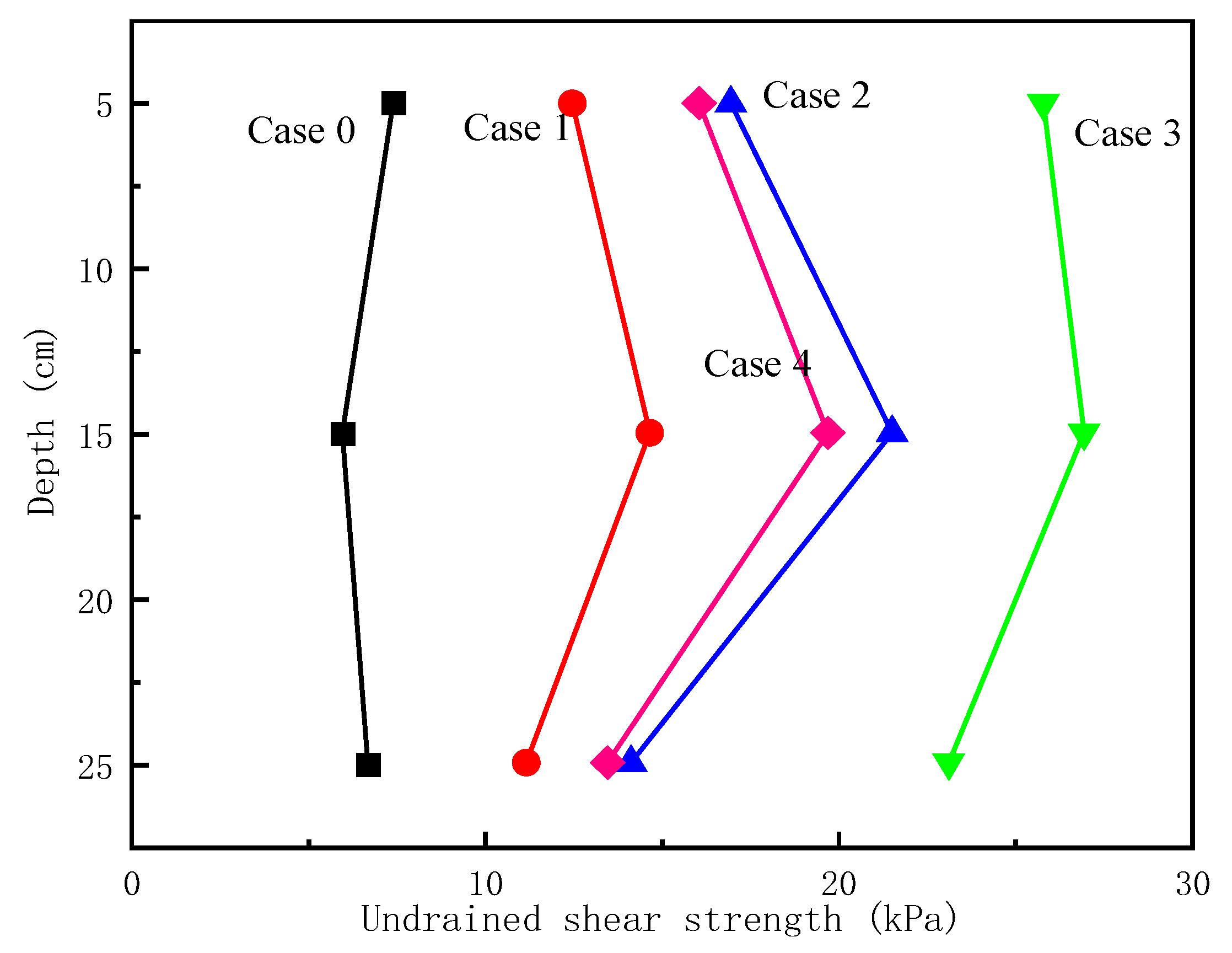

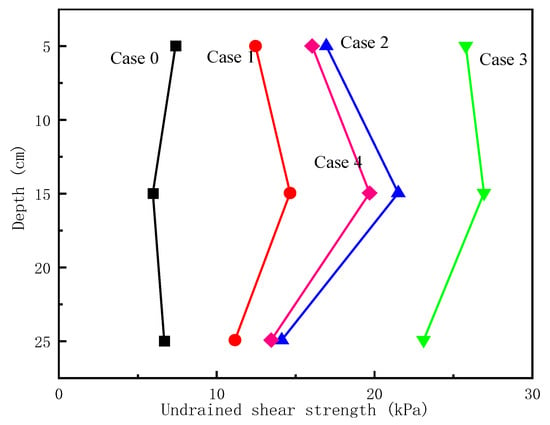

The vane shear strength distribution law can be seen in Figure 8, with the results of the vane shear strength test conducted in different vertical positions for each group. The test results show that compared with the initial strength, the overall vane shear strength of all five groups tested was significantly improved. In addition, the cross-plate shear strength of Case 3 was improved by 100.47%, 45.93% and 55.98%, respectively, compared with the other three groups using vacuum preloading combined with the intermittent heating method. This indicates that the consolidation effect of vacuum preloading combined with the intermittent heating method is more obvious, and this further indicates that the blockage is relieved by the temperature effect, which effectively reduces the negative effect of clogging.

Figure 8.

Undrained shear strength.

4. Conclusions

A controlled test was set up in this experiment to investigate the effects caused by different heating times on the formation of clogged mud layers at the same heating time ratio, and the degree of relief of clogging of drains. Based on the results of the indoor model test data indicators, the following conclusions were drawn:

- (1)

- The enhancement of the reinforcement effect is not proportional to the length of heating time—too long a heating time is not conducive to the enhancement of the reinforcement effect. Heating for 120 min and stopping for 60 min have the best effect, as the test results have a certain reference to further promote engineering waste mud reinforcement and relieve the clogging in engineering practice.

- (2)

- Compared with the conventional horizontal drainage board vacuum preloading method, vacuum preloading combined with the intermittent heating method leads to a better reinforcement effect of engineering waste mud. The test results show that the drainage volume of vacuum preloading combined with the intermittent heating method increased by 34.77% compared with the conventional vacuum preloading method; the average settlement volume increased by 22.07%; the water content decreased by 55.25%; the undrained vane shear strength increased by 279.1%.

- (3)

- Comparing the drainage consolidation effect of vacuum preloading combined with the intermittent heating method, under the same heating time ratio, vacuum preloading combined with the intermittent heating method improves the permeability of soil through the temperature effect of soil, which accelerates the reinforcement of engineering waste slurry.

Author Contributions

Conceptualization, C.Z. and X.L.; methodology, H.F. and Q.L.; software, Y.G., X.L. and X.W.; validation, Y.G.; formal analysis, C.Z.; investigation, Q.L. and X.W.; resources, H.F.; data curation, Y.G.; writing—original draft preparation, C.Z. and X.L.; writing—review and editing, C.Z.; visualization, H.F.; supervision, H.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (52178350) and the Zhejiang Provincial Natural Science Foundation of China (LY20E080029).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author/s.

Acknowledgments

The findings presented in this article were made possible through the diligent guidance of the authors’ supervisor and the invaluable assistance of classmates, as well as the care and help of the teachers in the research group. With their collective help, the authors were able to obtain the lake test data. The unwavering support of the family and girlfriend of one of the authors was also instrumental. The authors extend sincere gratitude to all of them.

Conflicts of Interest

Authors Chaozhou Zhang and Xiaoliang Wang were employed by the company Leqing Transportation Water Conservancy Investment Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Bergado, D.T.; Balasubramaniam, A.S.; Jonathan Fannin, R.; Holtz, R.D. Prefabricated vertical drains (PVDs) in soft Bangkok clay: A case study of the new Bangkok International Airport project. Can. Geotech. J. 2002, 39, 304–315. [Google Scholar] [CrossRef]

- Bergado, D.T.; Jamsawang, P.; Jongpradist, P.; Likitlersuang, S.; Pantaeng, C.; Kovittayanun, N.; Baez, F. Case study and numerical simulation of PVD improved soft Bangkok clay with surcharge and vacuum preloading using a modified air-water separation system. Geotext. Geomembr. 2022, 50, 137–153. [Google Scholar] [CrossRef]

- Chen, Z.; Ni, P.; Mei, G.; Chen, Y. Semi-analytical solution for consolidation of ground with partially penetrating PVDs under the free-strain condition. J. Eng. Mech. 2021, 147, 04020148. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Y.; Lu, Y.; Chen, G.; Deng, Q.; Xu, Y.; Ye, P. Influence of prefabricated vertical drains spacing on FeCl3-vacuum consolidation of a landfill sludge. Soils Found. 2021, 61, 1630–1644. [Google Scholar] [CrossRef]

- Bao, S.F.; Lou, Y.; Dong, Z.L.; Mo, H.H.; Chen, P.S.; Zhou, R.B. Causes and countermeasures for vacuum consolidation failure of newly-dredged mud foundation. Chin. J. Geotech. Eng. 2014, 36, 1350–1359. (In Chinese) [Google Scholar] [CrossRef]

- Gue, S.S.; Tan, Y.C.; Liew, S.S.; Ng, H.B. Failure of an embankment treated with vacuum preloading method. In Proceedings of the 15th International Conference on Soils Mechanics and Geotechnical Engineering, Istanbul, Turkey, 27–31 August 2001; Volume 3, pp. 1749–1751. [Google Scholar]

- Lee, S.L.; Karunaratne, G.P.; Yong, K.Y.; Ganeshan, V. Layered clay-sand scheme of land reclamation. J. Geotech. Constr. 1987, 113, 984–995. [Google Scholar] [CrossRef]

- Chen, H.; Chu, J.; Guo, W.; Wu, S. Land reclamation using the horizontal drainage enhanced geotextile sheet method. Geotext. Geomembr. 2023, 50, 131–150. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.J.; Liu, F.Y. Intermittent vacuum preloading combined with electro-osmotic reinforcement of blown soft soils. Chin. J. Highw. 2016, 29, 37–45. [Google Scholar]

- Liu, F.; Zhang, Z.; Wang, J.; Yuan, G.; Fu, H. Macro and microscopic analysis of graded vacuum preloading combined with intermittent electro-osmosis for reinforcement of dredged silt. J. Rock Mech. Eng. 2020, 39, 1893–1901. [Google Scholar]

- Wang, J.; Zhang, L.; Liu, F.; Fu, H. Experimental study of combined vacuum preloading-electrical infiltration method for strengthening soft clay foundations. J. Rock Mech. Eng. 2014, 33, 4181–4192. [Google Scholar]

- Wang, J.; Ma, J.; Liu, F.; Mi, W.; Cai, Y.; Fu, H.; Wang, P. Experimental study on the improvement of marine clay slurry by electroosmosis-vacuum preloading. Geotext. Geomembr. 2016, 44, 615–622. [Google Scholar] [CrossRef]

- Cui, Y.; Tu, J.; Wang, X.; Diao, H.; Ge, Q. Design method and verification of electroosmosis-vacuum preloading method for sand-interlayered soft foundation. Adv. Civilconstr. 2020, 2020, 1929842. [Google Scholar] [CrossRef]

- Liu, F.; Li, Z.; Yuan, G.; Wang, J. Experimental study of vacuum preloading combined with intermittent electro-osmotic reinforcement of dredged mud. J. Civ. Environ. Eng. 2021, 43, 1–9. (In English) [Google Scholar]

- Zeng, F.J.; Wei, H.X.; Wang, J.; Fu, H. Indoor model test of deep pressurized vacuum preloading method for soft ground foundation. Ind. Constr. 2014, 44, 90–94. [Google Scholar]

- Shi, L.; Hu, D.; Cai, Y.; Pan, D.; Sun, H. A preliminary investigation on the response and reinforcement mechanism of pressurized vacuum pre-pressurized blow-filled silt holes during compaction. Geotechnics 2020, 41, 185–193. [Google Scholar]

- Lei, H.; Hu, Y.; Zheng, G.; Liu, J.; Wang, L.; Liu, Y. Improved air-booster vacuum preloading method for newly dredged fills: Laboratory model study. Mar. Georesour. Geotechnol. 2020, 38, 493–510. [Google Scholar] [CrossRef]

- Feng, S.; Lei, H.; Lin, C. Analysis of ground deformation development and settlement prediction by air-boosted vacuum preloading. J. Rock Mech. Geotech. 2022, 14, 272–288. [Google Scholar] [CrossRef]

- Wang, M. Experimental Study of Air-Injected Pressurized Vacuum Preloading for Reinforcing Deep Blown Soils. Master’s Thesis, Tianjin University, Tianjin, China, 2019. [Google Scholar]

- Shen, Y.; Wang, H.; Tian, Y.; Feng, R.; Liu, J.; Wu, L. A new approach to improve soft ground in a railway station applying air-boosted vacuum preloading. Geotech. Test. J. 2015, 38, 373–386. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, Y.; Geng, S.; Qi, Y.; Dong, S.; Xin, X.; Sun, J.; Zheng, H. Consolidation theory of homogeneous multilayer treatment by air-boosted vacuum preloading. Eur. J. Environ. Civ. Constr. 2022, 26, 5634–5652. [Google Scholar] [CrossRef]

- Liu, J. Indoor Model Experimental Study of Vacuum Preloading Combined with Power Compaction for Treatment of Blown Land Foundation. Ph.D. Thesis, Wenzhou University, Wenzhou, China, 2019. [Google Scholar]

- Liu, Y.L. Analysis of the effect of vacuum preloading combined with strong ramming method for treating soft ground foundation. Constr. Technol. 2016, 45, 102–106. [Google Scholar]

- He, T.-W. Vacuum preloading combined with strong ramming to strengthen deep blown land foundations. Surv. Sci. Technol. 2015, 4, 34–38. [Google Scholar]

- Wu, J.; Xuan, Y.; Deng, Y.; Li, X.; Zha, F.; Zhou, A. Combined vacuum and surcharge preloading method to improve Lianyungang soft marine clay for embankment widening project: A case. Geotext. Geomembr. 2021, 49, 452–465. [Google Scholar] [CrossRef]

- Ding, J.; Wan, X.; Zhang, C.; He, Z.; Zhao, L. Case study: Ground improvement of Yangtze river floodplain soils with combined vacuum and surcharge preloading method. Int. J. Geomech. 2019, 19, 05019008. [Google Scholar] [CrossRef]

- Xu, P.B.; Lu, S.Q.; Zhang, J.T. Research and application on laws of consolidation time calculate in saturated soft clay soil by using vacuum-surcharge combined preloading method. Adv. Mater. Res. 2012, 594, 42–45. [Google Scholar] [CrossRef]

- Zhang, W.B.; Yang, J.G.; Peng, J.; Lei, Q.; Liu, L. Experimental study on graded loading vacuum preloading reinforcement of blown flowing mud. J. Riverhead Univ. Nat. Sci. Ed. 2019, 47, 541–547. [Google Scholar]

- Shan, W.; Chen, H.; Yuan, X.; Ma, W.; Li, H. Mechanism of pore water seepage in soil reinforced by step vacuum preloading. Bull. Constr. Geol. Environ. 2021, 80, 2777–2787. [Google Scholar] [CrossRef]

- Xiong, Z.; Wang, M.; Yan, Q.; Wang, Y.; Wang, Y.; Zhu, X.; Li, Q.; Wang, Z. Model experimental study of conventional and graded vacuum preloading. Coast. Eng. 2018, 37, 43–49. [Google Scholar]

- Daraei, A.; Sherwani, A.F.H.; Faraj, R.H.; Mohammad, S.; Kurdo, S.; Zare, S.; Mahmoodzadeh, A. Stabilization of problematic soil by utilizing cementitious materials. Innov. Infrastruct. Solut. 2019, 4, 33. [Google Scholar] [CrossRef]

- Daraei, A.; Herki, B.M.; Sherwani, A.F.; Zare, S. Slope Stability in Swelling Soils Using Cement Grout: A Case Study. Int. J. Geosynth. Ground Eng. 2018, 4, 10. [Google Scholar] [CrossRef]

- Abuel-Naga, H.M.; Bergado, D.T.; Chaiprakaikeow, S. Innovative thermal technique for enhancing the performance of prefabricated vertical drain during the preloading process. Geotext. Geomembr. 2006, 24, 359–370. [Google Scholar] [CrossRef]

- Tao, H.-B.; Liu, G.-B.; Xie, K.-H.; Deng, Y.-B.; Yin, T.-F. Thermal drainage consolidation principal structure model for vertical shaft foundations and experimental validation. J. Geotech. Eng. 2015, 37, 1077–1085. [Google Scholar]

- Liu, G.; Fan, G.; Tao, H.; Yin, T.; Deng, Y. Experiments on thermal drainage consolidation model for vertical shaft foundations. J. Cent. South Univ. Nat. Sci. Ed. 2017, 48, 448–456. [Google Scholar]

- Artidteang, S.; Bergado, D.T.; Saowapakpiboon, J.; Teerachaikulpanich, N.; Kumar, A. Enhancement of efficiency of prefabricated vertical drains using surcharge, vacuum and heat preloading. Geosynth. Int. 2011, 18, 35–47. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, F.; Liu, Q.; Wang, T.; Liu, G. Development of temperature-controlled soft ground model test device and its application. Waterw. Port 2018, 39, 223–229. [Google Scholar]

- Gong, Y.J. Experimental Study on Reinforcement Construction Waste Mud by Vacuum Preloading Combined with Intermittent Heating. Bachelor’s Thesis, Wenzhou University, Wenzhou, China, 2023. (In Chinese). [Google Scholar]

- Lei, H.; Liu, A.; Liu, J.; Li, C. Analysis of factors influencing the effect of alternating vacuum preloading method for reinforcement of ultra-soft ground foundation. J. Rock Mech. Eng. 2022, 41, 377–388. [Google Scholar]

- Chai, J.C.; Wang, J.; Ding, W.; Qiao, Y. Method for calculating horizontal drain induced non-linear and large strain degree of consolidation. Geotext. Geomembr. 2022, 50, 231–237. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).