Abstract

The need to design buildings in compliance with the Paris Agreement goal requirements is urgent, and architects and engineers need to consider energy use and operational and embodied carbon requirements in doing so. Building envelopes will be an important element in the next generation of high-performance buildings and there have been significant advancements in recent years to develop building envelopes that help mitigate the building carbon emissions through energy-conserving low-embodied carbon or carbon-sequestering solutions. The key objective of this article is to present an overview of the state-of-the-art in the field of energy-efficient low-carbon buildings with a focus on envelope systems. This article provides a survey of the literature on energy use and carbon emissions of the United States building stock, presents recent advancements in energy-conserving building envelopes, and highlights reuse–reduce–sequester strategies that mitigate the embodied carbon of buildings. As materials are critical in reducing the energy consumption and carbon emissions of buildings, this paper also presents developments on diverse materials and building envelope solutions that have been effective in creating high-performance buildings, from insulation materials to phase-change materials and aerogels. Finally, the characteristics of a selected number of progressive net-zero-energy guidelines such as Passive House Institute (PHI) standards, Passive House Institute US (Phius) standards, the PowerHouse standard, and the BENG standard are discussed. The findings of this work highlight the increased focus on the design, construction, and engineering strategies that aim to mitigate the carbon emissions of buildings based on a holistic whole-life carbon mitigation approach.

1. Introduction

Characterized by extreme weather events and rising global temperature, climate change is one of the pressing challenges of the 21st century. Controlling global warming to below 1.5 °C has therefore become a critical goal for the global community and is emphasized in the Paris Agreement to address climate change. This goal is only achievable through “immediate and deep emissions reduction across all sectors”, according to the Intergovernmental Panel on Climate Change [1].

The building sector serves as a significant contributor to carbon emissions and climate change through both operational and embodied energy usage and associated emissions. Operational energy encompasses the day-to-day functions of buildings, such as heating and cooling, while embodied energy pertains to the energy consumed during the construction, maintenance, and demolition phases. In this review paper, we review the pivotal role of building envelopes in reducing energy consumption and carbon emissions and improving buildings’ energy efficiency and sufficiency, focusing on innovative engineering solutions aimed at enhancing energy efficiency and sustainability.

Building envelopes play a crucial role in regulating the transfer of heat, air, and moisture between the interior and exterior environments of structures. The effective design and implementation of building envelope technologies offer immense potential for reducing energy consumption and mitigating carbon emissions throughout a building’s life cycle. From passive strategies like improved insulation to active measures such as incorporating renewable energy generation systems, a diverse range of engineering solutions exist to enhance the performance of building envelopes. Through an exploration of these innovative technologies, this paper aims to provide insights into how advancements in engineering can drive sustainable practices within the construction industry.

To achieve these objectives, this review paper adopts a comprehensive methodology that involves synthesizing the existing literature on building envelope solutions aimed at reducing energy consumption and embodied carbon emissions. A straightforward search strategy for review papers is adopted, and the relevant literature on building envelope solutions aimed at reducing energy consumption and embodied carbon emissions is identified and collected. Studies focusing on the performance of building envelope solutions across various regions and climate zones, as well as research on novel materials and emerging energy conservation measures (ECMs) in building envelopes are specifically targeted.

For the selection criteria, studies were selected based on their alignment with the topics building envelope solutions, energy efficiency, and embodied carbon reduction. Factors such as climate considerations, cost implications, energy and carbon savings, durability, and constructability of building envelope solutions were considered. The inclusion criteria encompassed research utilizing experimental approaches, physics-based modeling tools, customized methodologies, and data-driven techniques. For data extraction, information regarding the performance of building envelope solutions in terms of energy efficiency and carbon reduction was extracted from selected studies.

The following sections review the envelope-based energy retrofit approaches, use of integrated energy generation systems for energy sufficiency, embodied carbon in buildings, tools for energy and carbon performance of buildings, and net-zero-energy design standards, and this paper is wrapped up by the conclusions.

2. The Current State of Operational and Embodied Energy Use of the United States Building Stock

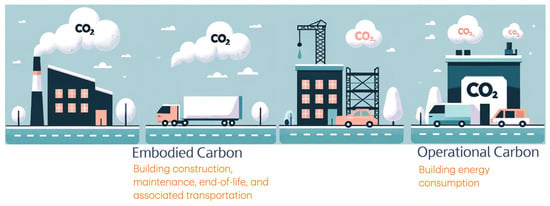

The global and national economies channel energy into the building sector for two distinct purposes that form the two key sources of building carbon emissions: the operation of buildings (e.g., heating and cooling) and their construction and maintenance over the full life cycle (Figure 1). Referred to as operational and embodied energy or carbon, these two aspects of building energy use and carbon emissions are interrelated and require aligned mitigation. Meanwhile, building envelopes are critical in controlling the flow of mass and energy from and into buildings, while significantly affecting building energy use and operational and embodied carbon emissions. There have been notable advancements over the past decade in the development of building envelope technologies for energy conservation and carbon avoidance as well as corresponding modeling and simulation tools to assess the energy and environmental performance of building envelopes.

Figure 1.

The life cycle of construction and its carbon footprint.

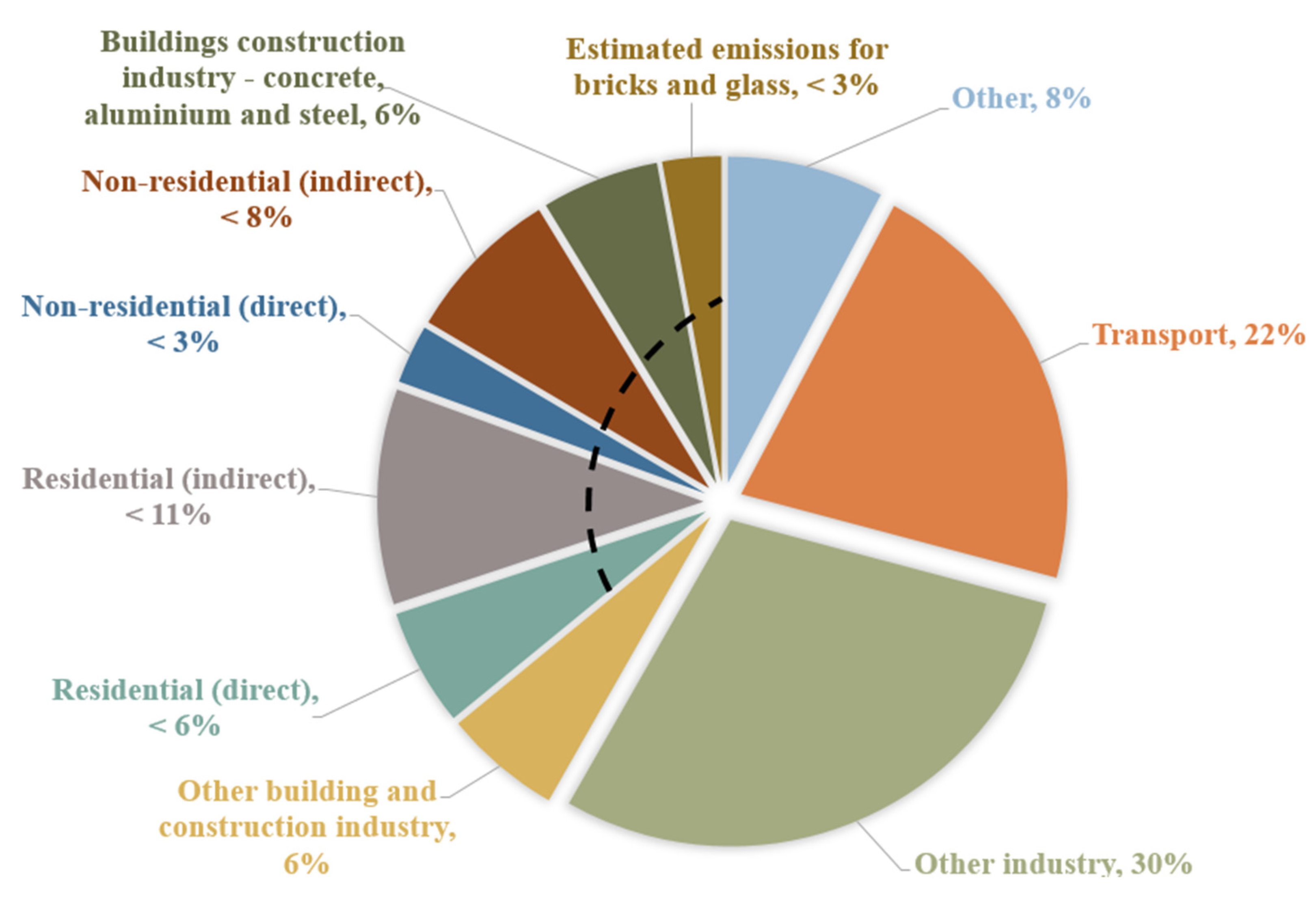

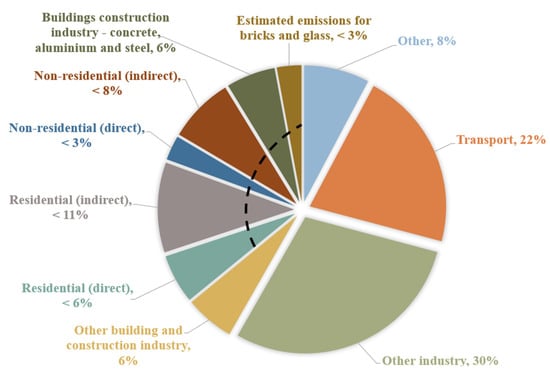

It is helpful to first review some of the data on energy use and carbon emissions of buildings. From 100,410 trillion BTUs of total energy consumed in 2022 in the United States, the commercial and residential sectors accounted for 39% [2], using renewable and non-renewable energy (including the energy loss in the electrical system) for their operation. Space heating (42%), water heating (18%), air conditioning (9%), and lighting (3%) consume 72% of the site energy in the residential sector [3], while the energy use in the commercial sector is primarily caused by space heating (32%), ventilation (11%), lighting (10%), and cooling (9%) [4]. Data show that the operational energy-related carbon emissions of buildings (i.e., operational carbon) were responsible for 30% of greenhouse gas emissions in the United States in 2021 [5]. While data, figures, and estimates on the operational energy use of the U.S. building stock are detailed and comprehensive, the embodied energy data are often limited to figures that represent certain construction materials. However, the building sector causes significant amounts of material and energy use and associated carbon emissions. Gursel et al. [6] estimate the carbon emissions associated with the manufacturing of concrete, steel, and wood to represent 2.1% of U.S. emissions. On a global scale, the manufacturing of construction materials is estimated to cause 11% of global emissions [5]. The United Nations Environment Program also reports that the proportion of global energy and process emissions attributable to buildings in the year 2021 was about 37%, comprising 17% residential (direct and indirect), 11% non-residential (direct and indirect), and 9% building construction industry (including 6% for concrete, aluminum, and steel and 3% for brick and glass) (Figure 2) [7].

Figure 2.

Share of buildings in global energy and process emissions in 2021.

3. Review Methodology

A straightforward search strategy for review papers was adopted, and the relevant literature on building envelope solutions aimed at reducing energy consumption and embodied carbon emissions was identified and collected. Studies focusing on the performance of building envelope solutions across various regions and climate zones, as well as research on novel materials and emerging energy conservation measures (ECMs) in building envelopes were specifically targeted.

For the selection criteria, studies were selected based on their alignment with the topics of building envelope solutions, energy efficiency, and embodied carbon reduction. Factors such as climate considerations, cost implications, energy and carbon savings, durability, and constructability of building envelope solutions are considered in the study. The inclusion criteria encompassed research utilizing experimental approaches, physics-based modeling tools, customized methodologies, and data-driven techniques. For data extraction, information regarding the performance of building envelope solutions in terms of energy efficiency and carbon reduction was extracted from the selected studies.

4. Envelope-Based Approaches to Mitigate Operational Energy Use and Carbon Emissions

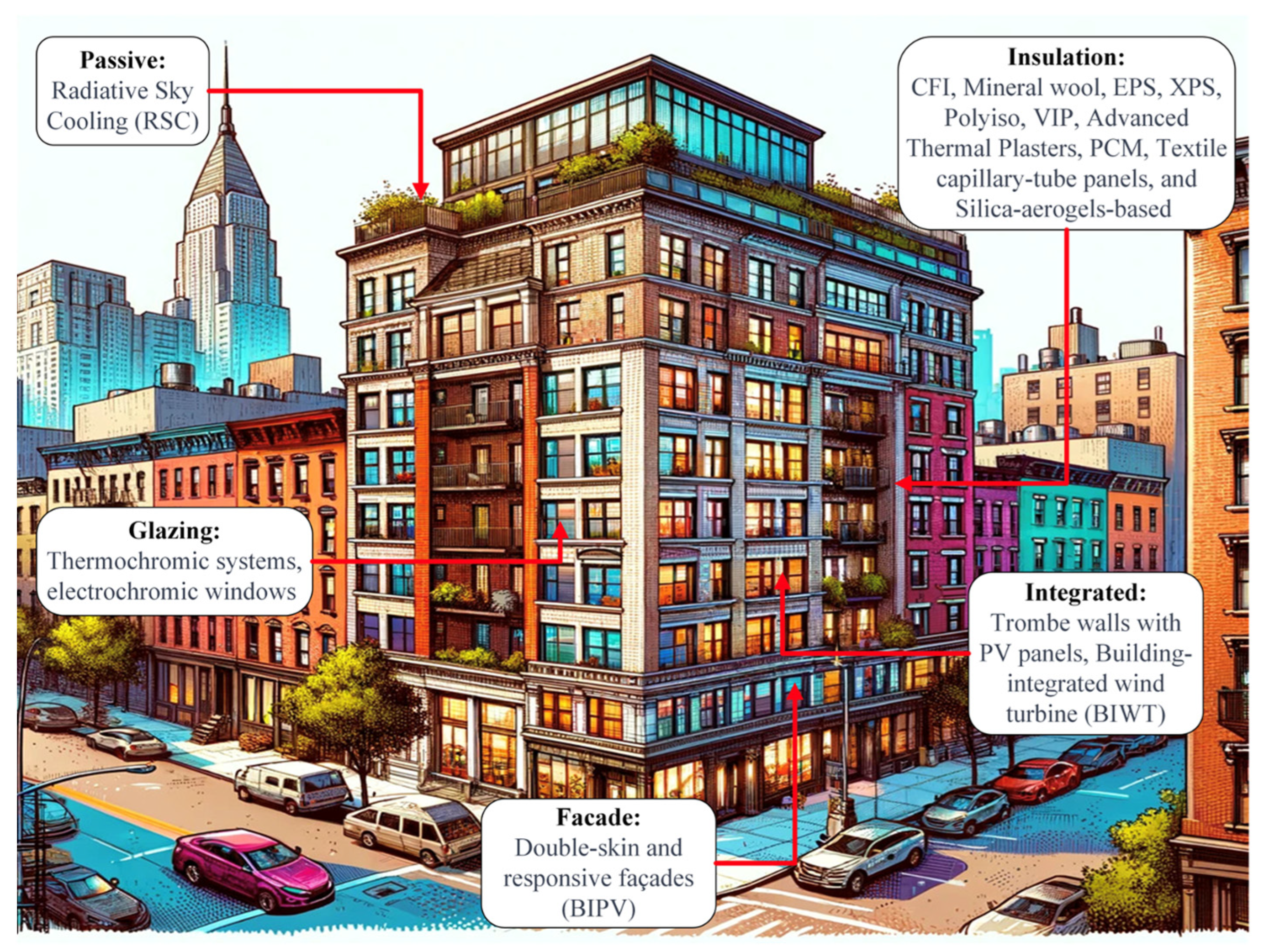

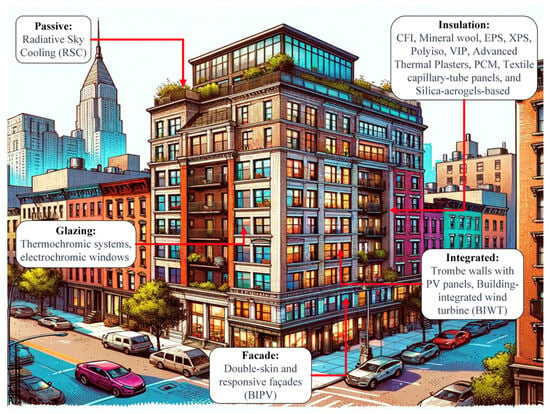

The key objective of this article is to present an overview of the state-of-the-art in the field of energy-efficient low-carbon buildings, with a focus on enclosure systems rather than heating, cooling, energy management control systems, or electrical systems. There are a wide range of building envelope-based energy conservation measures (ECMs) that enhance building energy efficiency, from radiative sky cooling to innovative solutions such as phase-change materials (PCMs), vacuum-insulated panels (VIPs), and aerogels. This paper discusses a selection of these solutions, summarized in Table 1 and schematically shown and summarized in Figure 3. These upgrades demonstrate how existing buildings can be modernized to improve energy performance and reduce environmental impact without necessitating complete reconstruction. The illustration emphasizes the feasibility and effectiveness of applying these technologies to retrofit older buildings for sustainability.

Figure 3.

A schematic overview of the reviewed building envelope energy conservation measures.

Radiative sky cooling (RSC) is an emerging ECM in which cooling naturally occurs, allowing objects to release heat into the cooler air by leveraging temperature differences between the surface and the atmosphere. While RSC is not a passive envelope-based ECM in a strict sense, it can be bundled with them to enhance the performance of the building skins. In a discussion of RSC systems for building energy saving and cooling, Wu et al. [8] present a review of previous experimental and simulation-based studies on RSC, highlight its potential for effective energy conservation, and discuss some of the optimization techniques to improve its performance. The authors also point out the challenges associated with implementing RSC, such as the need for sizable radiative cooling panels and the impact of weather conditions on its effectiveness, and conclude that addressing these challenges needs more research [8]. The RSC studies reviewed by Wu et al. [8] are primarily experimental, showing the knowledge gap in simulation-based studies that document the performance of this ECM. This requires new software tools to be developed or the existing software packages to incorporate new features to help simulate the RSC performance.

The energy efficiency achieved with RSC varies by location and season (i.e., climate zone). For example, in Albuquerque, summer savings range from 12% to 21%, and in winter, from 21% to 44%. Similarly, in Atlanta, summer savings are 8% to 17%, while in winter, they are 11% to 25%. Cool roofs’ effectiveness depends on building volume and surface area. They save about 4.1–10.2 kWh/m2 annually or approximately 9% daily. However, RSC’s benefits in summer may be offset in winter due to heat loss. Thus, selecting suitable roofs to reduce winter heat loss is crucial. Saving energy relies on location, season, and building type [8].

Chen et al. [9] assessed the thermal efficiency of passive envelope systems integrating thermally insulated glazing materials and radiative sky cooling for cooling purposes. EnergyPlus, a widely utilized whole-building energy simulation tool, was employed to dynamically address mass and energy balances within building spaces, considering variable internal loads and external conditions. The study focused on eight representative cities across diverse ASHRAE climate zones to evaluate the potential benefits of the proposed passive envelope systems, accounting for regional climatic variations and building characteristics. The results showcased climate-dependent performance patterns in response to different passive envelope technologies. A comprehensive analysis of the simulation outcomes identified optimal envelope designs tailored to each climate region, followed by evaluations of economic and environmental performance. The research shows the promising potential of passive envelope strategies in advancing sustainable low-energy building designs [9].

Another emerging ECS approach is building envelope energy retrofit by taking advantage of the thermal properties (e.g., conductivity and specific heat) of certain materials in thin layers of plasters and coatings. Fantucci et al. [10] discussed the rising demand for highly energy-efficient buildings and extensive energy retrofitting of existing structures, aiming to meet the Paris Agreement’s 40% emission reduction target by 2030. Various advanced building envelope materials were reviewed, including low-emittance materials, advanced thermal plasters, super insulating materials, phase-change materials, and highly reflective coatings. These materials offer exceptional thermal performance, even in thin layers, making them suitable for scenarios where traditional insulation methods are impractical. However, despite their potential, their adoption remains limited due to high costs and a lack of knowledge and data regarding their thermal properties [10].

Another novel material is aerogel, which has been studied as a potential ECM in buildings since its introduction into the construction industry. Zhong et al. [11] conducted a study on developing a hierarchical cellulose aerogel reinforced with in situ assembled cellulose nanofibers for building cooling. Regarding the tools and techniques related to building envelope retrofit, they used EnergyPlus to simulate the cooling energy saving potential of applying aerogel in building envelopes and also involved theoretical models, Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD) analysis, and mechanical testing to characterize aerogel properties. The results showed that the aerogel exhibited excellent mechanical properties, could achieve significant cooling power during the day, and could achieve a theoretical maximum sub-ambient temperature of 12.0 °C and a cooling power of 58.6 W·m−2 during the day [11].

The transparency of aerogel has also made it a suitable ECM in transparent building envelope components such as glazing systems. Abraham et al. [12] discuss the development of a highly transparent aerogel made of silanized cellulose fibers that can be used to improve the energy efficiency of glazing in buildings. The authors used thermal conductivity measurements and numerical energy assessments to evaluate the performance of an aerogel glazing unit. They also used ISO 9050:2003 [13] to determine solar direct transmittance, light transmittance, total solar energy transmittance, ultraviolet transmittance, and other glazing factors. A small Hot-Box apparatus was applied to measure the thermal conductivity of different materials, while a numerical energy assessment was employed to evaluate the energy performance of the aerogel glazing unit, and ISO 9050:2003 was considered to determine the optical properties of the aerogel glazing unit [12].

Ibrahim et al. [14] presented a numerical and experimental investigation into the hygrothermal performance of innovative super-insulating systems that are based on silica aerogels. Environmental inputs and experimental data were collected using sensors, heat flux meters, and a weather station. Numerical models were created using WUFI® Pro 5.3 software, incorporating coupled heat and moisture transfer according to standard EN 15026. Spatial discretization employed the finite volume technique, while the fully implicit scheme handled temporal discretization. The solver iteratively computed temperature and relative humidity profiles until convergence. The results indicated close agreement between the simulated and measured temperature fields, with captured daily dynamics. Statistical parameters, including PRMSE, RMSE, and average absolute difference, were used to assess the simulation–measurement agreement. Overall, the study concluded that these novel super-insulating systems significantly reduced heat flux compared to uninsulated walls, showcasing their potential for efficient thermal insulation [14].

Another category of building envelope ECMs is the integrated systems designed based on the benefits of both passive and active systems, such as Trombe walls and photovoltaic (PV) panels. Duan et al. [15] proposed an innovative Trombe wall system integrating PV panels and aluminum panels layered with photocatalyst and thermal materials to enhance energy harvesting efficiency. This system harnesses solar energy and catalytic oxidation to heat and purify chamber air, thereby enhancing indoor air quality. The results indicate the system’s capability to generate heat, ranging from 6.25 kJ/mol to 17.74 kJ/mol, and electricity, from 0.075 kWh to 0.372 kWh, daily from 9:00 to 16:00. Moreover, the system demonstrates a one-way sterilization efficiency against bacterial aerosols from 0.204 to 0.347. Optimal system performance was observed with a spacing of 25 cm. Experimental tools included a hot-wire anemometer, thermocouple, data acquisition instrument, proportional integration differentiation controller, environmental chamber, electric heater, aerosol generator, ultrasonic humidifier, I-V curve tester, and pyranometer [15]. Such systems are typically modeled and simulated using customized tools, and there is potential for existing BEM tools to incorporate more direct simulation options for similar integrated systems for more accurate energy-saving and generation calculations.

Ascione et al. [16] conducted a review of recent research on energy retrofit through double-skin and responsive facades. The study focused on building skins as the primary means of heat gain and loss between indoors and outdoors. The authors reviewed various technologies, including building-integrated photovoltaic (BIPV) systems, double-skin façades (DSFs), and responsive building components. The reviewed studies employed various computer tools, techniques, and software for energy modeling and energy simulation, such as EnergyPlus, TRNSYS®, DesignBuilder®, GenOpt, and MATLAB®. These tools were used to analyze the performance of different façade systems and their impact on energy consumption, thermal comfort, and overall building performance. The review found that the implementation of DSF and responsive façades can lead to significant energy savings. For example, a simple DSF could lead to up to 90 percent reduction in heating loads and 30 percent reduction in cooling loads. However, the authors also identified the obstacles and critical factors, such as lower efficiency of transparent PV compared with traditional PV, the risk of overheating, and greater cost of responsive components [16].

Si et al. [17] introduced an innovative building envelope design featuring variable thermal properties for passive heating systems. Their study aimed to balance solar heat gain and thermal insulation, addressing a common challenge in traditional passive solar setups. Field measurements were undertaken to validate the effectiveness of this transparent building envelope, particularly in cold plateau regions, under a step control operation strategy. Using DesignBuilder software, the researchers conducted numerical simulations to assess the efficiency of the proposed envelope in increasing indoor temperatures. The simulation outcomes mirrored field measurements, confirming that implementing the operation strategy—opening indoor windows at 10:00 a.m. and closing them at 5:00 p.m.—could maximize solar gain and substantially elevate indoor temperatures. The results indicated that rooms utilizing the proposed envelope design exhibited average temperature increases of 2.0 °C (on sunny days) and 1.5 °C (on cloudy days) compared to those employing three other passive solar envelope operation modes. Overall, the building envelope with variable thermal performance holds significant promise for enhancing indoor thermal comfort in cold plateau regions at a minimal expense [17].

Baek et al. [18] investigated an experimental retrofitting approach for seismic and energy improvements in reinforced concrete (RC) and unreinforced masonry (URM) structures. Their retrofit system integrates prefabricated textile capillary-tube panels with existing building envelopes, affixed using mortar or adhesives. Seismic performance was evaluated on scaled masonry-infilled RC frames and URM walls. Thermal efficiency was gauged via in situ experimentation, showing significant effectiveness. The results indicated enhanced seismic performance, delaying masonry infill cracking and diffuse damage. Retrofitted specimens exhibited improved energy dissipation compared to untreated frames, with the TCP-retrofitted wall showcasing notably higher stiffness, load resistance, and displacement capacity. Additionally, the addition of a C-TRM jacket further bolstered stiffness and lateral resistance. This research underscores the practical viability of TCP retrofitting as a cost-efficient solution for integrated seismic and energy retrofitting of existing structures [18].

Cellulose fiber insulation (CFI) consists of paper stocks blended with chemicals to enhance fire and corrosion resistance, among other properties. Typically, its thermal resistance (R-values or RSI) falls within 0.62–0.69 m2K/W per 25.4 mm (3.5–3.9 ft2·°F·h/BTU per inch) [19]. Mineral wool, on the other hand, is crafted from molten raw materials like stone and slag, turned into fibers, then bonded, and compacted to form insulation batts. It has high fire resistance, high thermal resistance, and low-embodied carbon, making it an attractive insulation choice. Mineral wool’s R-value range is generally close to that of cellulose fiber insulation [20].

Apart from loose insulation materials, various types of rigid board insulation are available, including expanded polystyrene (EPS), extruded polystyrene (XPS), and polyisocyanurate (polyiso), each with differing levels of embodied carbon. EPS, commonly used in walls, roofs, and floors, typically offers an R-value ranging from 0.63 to 0.70 m2K/W per 25.4 mm (3.6–4.0 ft2·°F·h/BTU per inch). XPS, stronger and denser than EPS, finds application in walls and below-grade slabs, with a semipermeable nature and an R-value of approximately 0.79 to 0.88 m2K/W per 25.4 mm (4.5–5.0 ft2·°F·h/BTU per inch). Polyiso, the priciest among these options, has the highest thermal resistance, typically ranging from 1.23 to 1.41 m2K/W per 25.4 mm (7.0–8.0 ft2·°F·h/BTU per inch), often featuring reflective foil facing on both sides to enhance resistance to radiant heat transfer. Additionally, advanced systems like vacuum-insulated panels (VIPs) offer highly efficient insulation within minimal thickness, typically with thermal conductivity ranging from 0.004 W/(mK) to 0.008 W/(mK) [21]. Phase-change materials (PCMs) also have immense potential for building envelope applications as they can absorb external heat in the form of latent heat through a phase transition, for example from solid to liquid [22], and release it with a delay to warm up the building.

While insulation materials are key to preventing heat loss from opaque envelop components, glazing systems are the weakest of the building envelope components when it comes to thermal resistance. Because glazing is a major component in the assessment of heating and cooling loads, thermal comfort, and energy demand of a building ([23,24]), proper specification of glazing systems can reduce summer heat gain and winter heat loss [25]. Accordingly, various glazing technologies have been developed and are being introduced to increase such thermal resistance. Of course, because glazing needs to also provide natural lighting and visual transmissibility, such systems are in general evaluated based on the following three main performance attributes: the thermal U-factor, the Solar Heat Gain Coefficient (SHGC), and the Visual Transmittance (Tvis).

U-factor reflects the rate of heat flow (in Btu/(hr * ft2 * °F)) through conduction, convection, and radiation (NFRC 2005). SHGC quantifies the solar heat transmitted through a material/system, ranging from 0 (no transmission) to 1 (full transmission). Tvis indicates the percentage of visible light passing through glazing, with 1 representing full transmission and 0 indicating no transmission. The selection criteria for glazing systems encompass energy efficiency, sustainability, maintenance, durability, noise control, fire resistance, visual aesthetics, and structural resilience in natural disasters [26,27].

Building envelopes are responsible for approximately 36% of total building energy usage, primarily attributed to heat gain and loss [28]. Accordingly, replacing inefficient single-glazed window units with their newer, more energy-efficient counterparts offers the first step in this direction, which is consistent with the goal of the U.S Department of Energy (DOE) Building Technologies Program (BT) to develop market-viable zero energy buildings (ZEBs) by 2025.

As new emerging areas, dynamic and adaptive curtain wall systems [29] are among the leading technologies, which can be adaptable and adjustable to environmental fluctuations. Adaptive envelopes provide advancements in performance regarding building energy efficiency and economics, through real-time behavior and configuration adjustments [30]. Adaptability is often achieved through a combination of mechanical, electrical, and chemical approaches [29]. These adaptive façades consist of multifunctional highly adaptive systems that can be at material-, component-, and/or system-level implementations [31].

Various technologies employ coatings to decrease glazing emittance, while some incorporate “honeycomb” fill layers for enhanced thermal insulation. Additionally, products utilize polycarbonate or similar materials to boost performance. Thermochromic glazing is recognized as a smart, energy-saving window technology [32]. Advanced window systems such as switchable electrochromic or gas chromic windows are other opportunities to reduce the overall energy loads of buildings [33,34].

5. Use of Locally Renewable Energy Sources for Building Operations to Balance Energy Consumption

With the current trends toward electrification and the desire for greater energy self-sufficiency, there is a growing interest in the adoption of photovoltaic (PV) systems for local energy generation [35]. These systems have the potential to generate a significant portion, if not all, of a household’s daily electrical energy demand, either from rooftop installations or as integrated components of the building structure itself [36]. Today, there are a variety of products that differ in configuration and efficiency, but the most common PV systems for houses are roof-mounted PV arrays, generally made up of crystalline silicon cells that are normally installed on special frames attached to roofs.

PV arrays can be categorized into three main types based on the arrangement and assemblies of the silicon cells [35]. The first one is mono-crystalline, which is the most efficient and expensive type of PV cell, with an average efficiency between 18 and 20% [37]. Poly-crystalline panels are less efficient (14–17%) compared to mono-crystalline cells. Then, there are thin films (amorphous), which is a thin layer of silicon deposited on a base material such as metal or glass to create a solar panel. These amorphous solar panels are less efficient (9–10%) than mono- or poly-crystalline panels. However, the advantage of thin-film cells is that they can be applied to different (including curved) surfaces [37].

As a more recent technology, building-integrated photovoltaics (BIPVs) are becoming more popular as they integrate PV arrays with building fabrics [38,39]. When compared to roof-mounted systems, BIPV systems have the added benefit of increasing the potential for renewable energy while also saving money and time during installation by replacing traditional building components. Examples of BIPV systems include shingles, tiles, and glazing [40]. As one example of BIPV application to glazing, photovoltaic (PV) cells are securely laminated between two designated glazing panes, completely integrating PV technology with glass. Its adaptability makes it suitable for many uses where conventional glass would be used, such as facades, skylights, curtain walls, and windows.

The integration of wind turbines with building facades and envelopes represents a creative approach towards sustainable energy generation within urban environments and is predicted by researched to potentially become an integral part of future buildings [41]. Park et al. [42] introduced a novel building-integrated wind turbine (BIWT) setup that leverages the building facade, a traditionally overlooked space in conventional BIWT systems. The setup incorporates a guide vane to capture and amplify wind velocity, complemented by a custom rotor design. Positioned as a potential eco-friendly energy solution for urban settings, the system’s projected power generation capacity was assessed in relation to a residential building’s energy demands. The analysis suggests that the proposed system could potentially fulfill approximately 6.3% of the building’s electricity requirements [42].

Table 1.

Summary of reviewed building envelope energy conservation measures and their energy saving potential.

Table 1.

Summary of reviewed building envelope energy conservation measures and their energy saving potential.

| ECM Category | Description | Examples | Study | Energy Savings/Generation |

|---|---|---|---|---|

| Radiative Sky Cooling (RSC) | Natural cooling leveraging temperature differences | - | Wu et al. [8] | Varies by region/season; e.g., 12–21% in summer and 21–44% in winter in Albuquerque |

| Passive Envelope Systems | Includes insulated glazing and radiative sky cooling | - | Chen et al. [9] | Dependent on climate zone and building characteristics |

| Energy Retrofit | Use of high thermal property materials in thin layers | Advanced thermal plasters, PCM | Fantucci et al. [10] | Not specified |

| Aerogel | Highly insulating material suitable for glazing systems | Hierarchical cellulose aerogel | Zhong et al. [11] | The theoretical maximum sub-ambient temperature of 12.0 °C and cooling power of 58.6 W·m−2 |

| Super-Insulating Systems | Based on silica aerogels | Silica-aerogel-based systems | Ibrahim et al. [14] | Not specified, but reduced heat flux compared to un-insulated reference |

| Integrated Systems | Combines passive and active systems | Trombe walls with PV panels | Duan et al. [15] | Heat: 6.25–17.74 kJ/mol; electricity: 0.075–0.372 kWh/day |

| Integrating wind turbines into the building façade/envelope or the structure | Building-integrated wind turbine (BIWT) | Park et al. [42] | Potentially fulfills about 6.3% of the building’s electricity requirements | |

| Responsive Façades | Retrofit via double-skin and responsive façades | BIPV systems, DSF | Ascione et al. [16] | Up to 90% heating load reduction and 30% cooling load reduction |

| Variable Thermal Performance Envelope | Balances solar gain and insulation in passive solar systems | - | Si et al. [17] | Average temperature increase of 2.0 °C (sunny) and 1.5 °C (cloudy) |

| Seismic-Plus-Energy Retrofit | Prefabricated panels for seismic and energy performance | Textile capillary-tube panels | Baek et al. [18] | High efficiency noted, specific savings not quantified |

| Insulation Materials | Prevents heat loss from opaque envelope components | CFI, mineral wool, EPS, XPS, Polyiso, VIP, PCM | Cellulose Insulation Manufacturers Association [19] | Varies by material; e.g., CFI: 4.1–10.2 kWh/m2 annually |

| Glazing Systems | Increases thermal resistance of glazing | Thermochromic systems, electrochromic windows | Warwick et al. [32] | Depend on U-factor, SHGC, and Tvis values |

6. Embodied Carbon—The Reuse–Reduce–Sequester Approach

As modern buildings now consume less operational energy, thanks to insulation materials and high-performance window systems used in their building skins, the focus pivots toward embodied energy and carbon as the next decarbonization step. Embodied energy is defined as the amount of energy (in the form of fossil fuel and electricity) required to produce the unit weight of a usable material, including the transportation involved [43]. Embodied carbon is the equivalent carbon dioxide of the greenhouse gas emissions released in the partial life cycle (cradle-to-gate) or full life cycle (cradle-to-grave) of a building.

Embodied carbon mitigation is a three-fold strategy involving reuse, reduction, and sequester [44]. The reuse of existing buildings, or parts of them such as substructures and superstructures, can significantly reduce the demand for new materials and, hence, save the embodied carbon. The manufacturing of materials such as concrete releases significant GHG emissions, which is 11% in the case of concrete [44], and the reuse of existing structures can play an important role in reducing the demand for these materials. It is equally vital to reduce embodied carbon by developing low-embodied carbon alternatives to high-impact materials such as concrete. Alternative cementitious materials such as fly ash and slag cement in concrete, calcined clay as binder, and bio-based aggregates are some of the practices used in the industry to reduce the carbon footprint of concrete. Sequestering is another strategy that involves taking advantage of the carbon dioxide stored in the mass of materials such as wood during photosynthesis. Due to their carbon neutral and carbon negative attributes, bio-composite materials are gaining traction in the construction sector. Hemp stands out as a notable material choice, finding application in lumber production [45] and as a key component in hempcrete, a bio-aggregate concrete. Hempcrete consists of hemp hurds, the inner core of the hemp plant, combined with a lime-based binder. This lightweight concrete, composed mainly of lime and hemp shives (fibrous waste), offers a sustainable building solution [46]. Hempcrete (as cast in place or as blocks) is currently mainly used to make walls, although floor slabs, ceiling, and roof insulation can be made as well.

Engineered wood products such as cross-laminated timber (CLT), glue-laminated timber (GLT), and dowel-laminated timber (DLT) have also gained popularity in the construction industry because of their carbon sequestration capabilities and their suitability for diverse residential, educational, commercial, and light industrial applications in the building structures and envelopes. While the predominant use of these products is currently in the construction of mid- to high-rise timber buildings, there is a gradual emergence of examples showing their applications in low-rise single-family houses [47].

7. Tools for Energy Performance Assessment of Building Envelopes

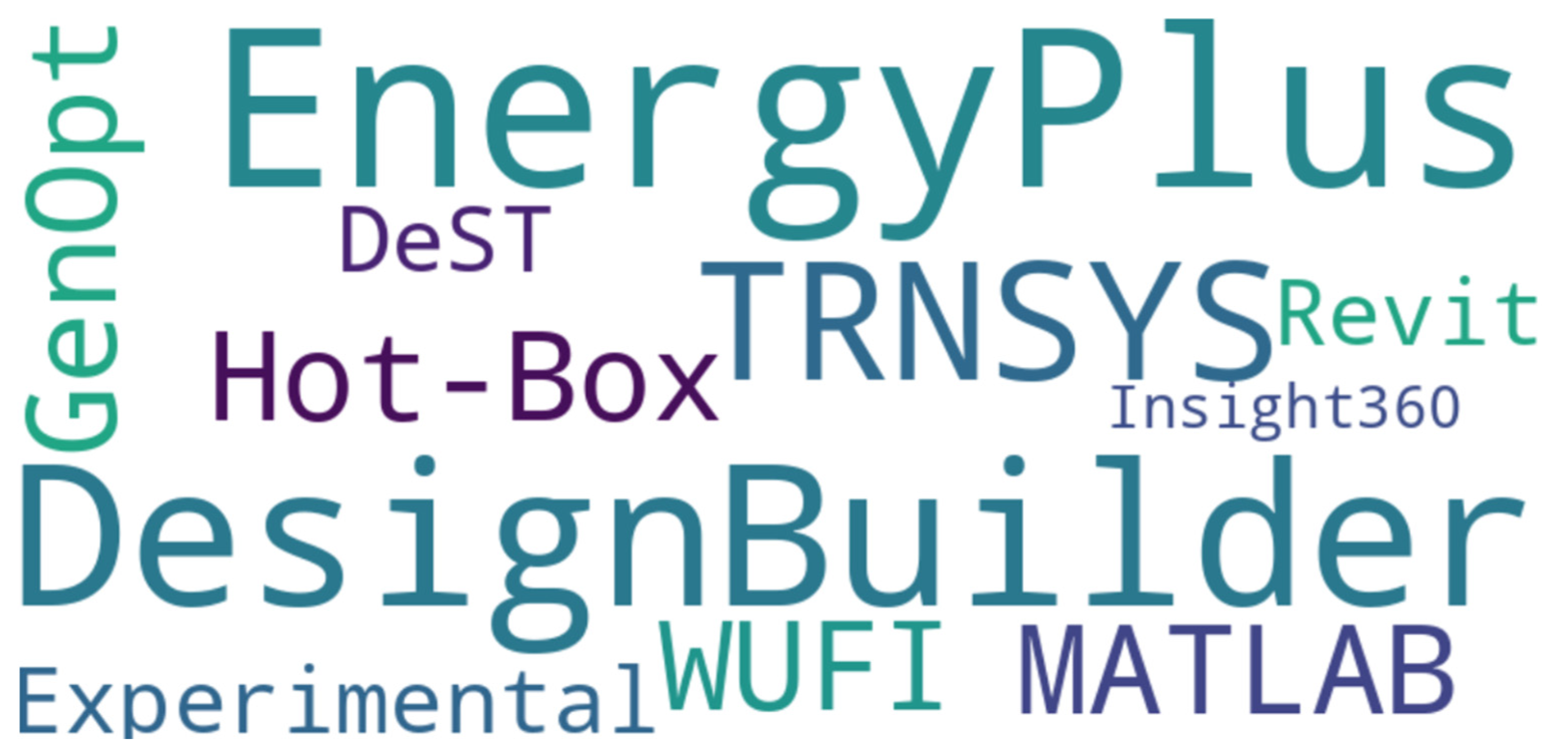

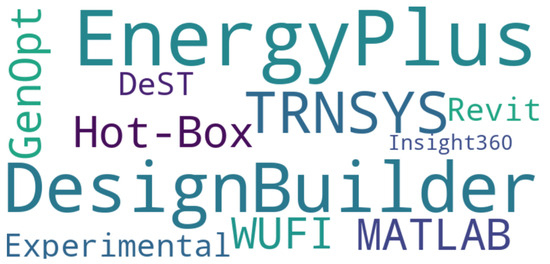

Our review of the building-envelope-based ECM literature demonstrates the application of both the existing energy simulation tools that remain effective and the innovative modeling techniques developed to address the evolving requirements. This work also shows that some ECMs have been studied only experimentally, showing a potential for future numerical or simulation-based studies. The findings are reported below and listed in Table 2 and visualized in Figure 4 based on their use frequency.

Table 2.

Summary of computer tools and techniques in the studies on innovative building envelope ECMs.

Figure 4.

A visual representation of software and tools frequency in energy modeling research for building envelope energy conservation measures.

Researchers have made strides in developing novel computer tools to enhance the accuracy of analyzing emerging energy conservation measures (ECMs). Yan et al. [45] discussed the complexities and challenges encountered in Building Energy Modeling Programs (BEMPs) while introducing DeST 3.0, a next-generation BEMP. The authors categorized BEMPs into three distinct types: software grounded in a simulation kernel, standalone modules integrated with other software for specific functions, and software utilizing comprehensive room/zone and simplified system models. That paper elaborated on the challenges encountered in building energy-consumption simulations, including capability, calculability, and compatibility issues. DeST 3.0 tackles these challenges by developing advanced simulation modules for building envelopes, occupant behavior, and energy systems used by more than ten national/regional energy-saving standards. They concluded by discussing DeST 3.0’s applications in analyzing building energy conservation across extensive projects covering over 200 million m2, such as Beijing Capital Airport Terminal 3, the National Grand Theater, Beijing Olympic Main Stadium, Beijing Daxing International Airport, and Beijing Winter Olympic Main Stadium [48].

Combining physics-based and data-driven approaches is becoming increasingly common in building energy modeling and simulation, especially in studying the energy savings for various ECMs. Thrampoulidis et al. [49] proposed a machine learning-based surrogate model to yield optimal solutions for building retrofit. The model is designed to reduce the computational cost of retrofit simulations while maintaining accuracy. The authors used DesignBuilder software to simulate the energy performance of a building before and after retrofitting. They then used a machine learning algorithm to train a surrogate model that approximates the energy performance of the retrofitted building. The model was validated using a case study of a Swiss residential building. The results show that the surrogate model can accurately predict the energy performance of the retrofitted building while reducing the computational cost of the simulation. The article highlights the importance of computer modeling and simulation techniques in optimizing building retrofit solutions [49].

Milosevic et al. [50] undertook a study on sustainable retrofit approaches for the “Djuro Djakovic” residential complex in Sarajevo, Bosnia, and Herzegovina. Their main aim was to assess the performance of specific modules within this complex. The research methodologies involved archival and empirical data analysis alongside computational modeling and simulations using BIM software. A comprehensive 3D BIM model of typical residential modules was created based on original drawings and current photographs. The analysis included scrutiny of formal and spatial characteristics, and environmental response assessments were conducted using Revit and Insight 360 simulations. Despite suboptimal environmental adaptation in hillside buildings, the implemented building envelope systems were found to be remarkably advanced for their era [50].

Botticelli et al. [51] conducted a study to investigate how innovative fenestration systems can reduce cooling energy usage in buildings by harnessing passive technologies and understanding the dynamics of building envelopes. The windows in their study featured integrated shading systems and motorized sashes for opening, controllable using a smart building management system. Preliminary findings from the field monitoring and numerical analyses were presented. Field observations revealed that combining solar protection and night ventilation lowered indoor temperatures by 1.4 and 2.2 °C in rooms equipped with new triple and double-glazed units, respectively, compared to older windows. A calibrated numerical model, using monitored data, demonstrated that solar protection and nighttime cooling could achieve up to 76% energy savings. TRNSYS 17, capable of simulating building thermal responses in transient regimes, was utilized for implementing and calibrating the numerical model [51].

8. Tools for Embodied Carbon Performance Assessment of Building Skins

To understand and quantify embodied energy and embodied carbon, a life cycle assessment (LCA) is used which helps assess the diverse life cycle environmental impacts of a product or a building, including global warming potential, acidification potential, eutrophication potential, smog formation potential, and other types of impacts. The main life cycle stages that are considered in the life cycle assessment of buildings are defined in compliance with ISO 14040 (ISO 2006) [52], ISO 14044 (ISO 2006) [53], and EN 15978 [54] and include the product stage (A1–A3; including raw material extraction, transportation, and material manufacturing), construction stage (A4–A5), use stage (B1–B5; involving use, maintenance, repair, replacement, and refurbishment), end-of-life stage (C1–C4), and sometimes beyond-life stage (D) [55]. For each stage, the LCA method enables one to capture the types and quantities of consumed materials, primary energy, and the released greenhouse gas emissions; assess the environmental impacts; and identify limitations, opportunities, and aspects to improve upon [56]. A cradle-to-gate LCA concerns the A1–A3 stages of the building life cycle while a cradle-to-grave LCA provides a comprehensive assessment including all life cycle stages. The product stage (A1–A3) is considered to be the life stage that causes the highest embodied carbon due to extensive amounts of consumed energy and emitted carbon involved in the manufacturing of construction materials. The analysis of the use stage, i.e., the stage in which the building is occupied, often involves data availability and data quality challenges mainly because the type and frequencies of the maintenance practices vary significantly from building to building and limited documentation of such practices exist.

There exist a variety of LCA tools for the assessment of embodied carbon and environmental impacts of building envelope systems. Awareness of the strengths and limitations of these tools helps with buildings’ LCA to generate results with minimum uncertainty. The state-of-the-art building LCA tools in the market can be classified based on their capability in comprehensive modeling into whole-building LCA tools and non-whole-building tools. The whole-building LCA tools are capable of modeling the entire building including structure, building envelope, and sometimes building systems. Examples of whole-building LCA tools include OpenLCA [57], Sima Pro [58], Gabi [59], EC3 [60], Tally Plugin [61] to Revit, OneClick LCA [62], Athena Impact Estimator for Buildings [63], and other similar tools [64,65,66,67,68,69,70,71], which provide the capability to assess and communicate some or diverse environmental impacts over the complete life cycle of buildings. The non-whole-building LCA tools [71,72,73] can capture certain building components only. For example, the Structural Carbon Tool [74] is a tool used for the assessment of embodied carbon of structures, while the Kaleidoscope [72] is a tool used for building envelope embodied carbon modeling. The key limitations of non-whole-building LCA tools are their inability to capture all building components, their limited coverage of the full building life cycle, and their limited capturing of non-embodied carbon of environmental impacts. The LCA tools can also be classified based on their capability to couple with energy simulation software. While tools such as ECCOlab [67] provide a fully integrated modeling experience that allows for modeling of both embodied carbon and energy use in one single platform, other tools such as Tally [61] and One Click LCA [62] are available as plugins to build digital modeling tools, which when used along with energy simulation plugins could facilitate both LCA and energy modeling for one digital model. There are also tools such as Athena Impact Estimator for Buildings which, even though they do not present direct coupling with energy simulation, allow for manual inputting of energy use data to assess embodied carbon, operational carbon, and other life cycle environmental impacts. Table 3 provides a comprehensive list of popular LCA tools used to assess the environmental impacts of buildings and their characteristics.

Table 3.

The list of popular building LCA tools.

The embodied carbon and environmental impacts of construction materials and building products are also reported in detail in the Environmental Product Declaration (EPD) reports. These reports are developed in compliance with EN 15804 + A2 requirements [75] and verified by third parties that use the LCA technique and data and information provided by manufacturers as their primary source of data. EPDs often have a cradle-to-gate scope. EC3 [60] is a searchable tool that compiles with the EPDs of various building products, which could link to some building LCA tools to help customize their LCA results.

9. Net-Zero-Energy Design Standards

There are multiple standards for the design and construction of low-energy and net-zero-energy buildings that affect the way building envelopes are designed, specified, and constructed. This section covers a selected number of such standards for net-zero-energy buildings used in different countries, including those developed by the Passive House Institute (PHI) and Passive House Institute US (Phius), Norway’s PowerHouse standard, and the Dutch BENG standard.

Originating in Germany, with roots in the passive buildings of the 20th century in North America, the Passive House Institute (PHI) established stringent requirements for building energy efficiency and thermal comfort by focusing on creating air-tight and super-insulated envelopes with no thermal bridges and with high-efficiency windows as a means of minimizing energy consumption, coupled with heat recovery and optimized solar gain [76]. Buildings with Passive House Certification save more than 75% of the energy used for space heating and cooling when compared with a typical new construction and up to 90% compared to a typical existing home [76]. PHI specifies criteria in three categories of buildings: Passive House, EnerPHit, and PHI Low Energy. The criteria for certified Passive Houses include thresholds in four areas including heating demand/load, cooling demand, airtightness, and renewable primary energy (PER). Additionally, PHI offers the EnerPHit Standard for retrofit projects through which they must meet general airtightness and PER criteria and also choose to meet the requirements of either a component criteria method or an energy demand method. The component criteria method involves climatic-class-based prescriptive requirements for opaque envelope (ground insulation, exterior insulation, interior insulation, and paint color use (for hot and very hot climates)), windows (U-value, SHGC), and window solar loads during cooling periods), and ventilation (minimum heat or ventilation recovery rate) [77]. The PHI Low Energy Building standard involves less stringent requirements and is suitable for buildings that are not able to satisfy the Passive House or EnerPHit requirements.

Developed in the United States, Phius is the voluntary standard that uses the same principles as PHI but involves certification requirements that vary on a climate-specific basis, as compared with the fixed requirements of PHI standards. The Phius standard includes provisions for new buildings (Phius CORE and Phius ZERO) and for retrofit projects (Phius CORE REVIVE and Phius ZERO REVIVE) based on two prescriptive and performance certification paths. In the performance path, thresholds have been established for four criteria, including annual heating demand, annual cooling demand, peak heating demand, and peak cooling demand that vary based on building-related factors (building type, envelope area, floor area, occupant density, and unit density) and project location (i.e., climate zone) [77]. Prescriptive CORE measures prescribe criteria related to airtightness, compactness (i.e., building envelope area), solar protection (SHGC, window area, orientation, and shading), moisture risk limitation, thermal enclosure, mechanical ventilation and systems, lighting, appliances, water heating, and electric vehicle ready [77].

Another noteworthy standard is Norway’s Powerhouse Paris Proof voluntary standard, which sets maximum and total CO2 emissions based on both embodied and operational carbon and certifies buildings that generate more energy than the energy they consume over their life cycle for both their operation and construction [78]. This standard is different from the PHI and Phius standards in that it additionally considers embodied energy and carbon in its certification by promoting recycling, reuse, and low-embodied carbon materials.

The BENG standard that defines “nearly energy-neutral building” requirements is the mandatory building energy code for new residential and non-residential buildings in the Netherlands. The code defines thresholds for three energy indicators, including maximum energy demand per unit of floor area per year, maximum primary fossil fuel use per unit of floor area per year, and minimum share of renewable energy [79]. These requirements vary based on the building type.

10. Conclusions

This work provides a survey of the literature on building envelope developments as related to energy use and embodied carbon. The key purpose is to synthesize existing knowledge and insights on the specific topic of building envelopes, providing readers with a comprehensive overview of the subject matter. Through this approach, this work aims to offer valuable insights and perspectives to researchers, practitioners, and enthusiasts interested in gaining a deeper understanding of building envelope energy retrofit.

This review paper highlights the state-of-the-art and wide range of building envelope solutions that help mitigate energy consumption and embodied carbon emissions of buildings. It shows that the performance of some of these solutions varies with region and climate zone, and architects and engineers employing these solutions must choose them by considering the issues of climate, cost, space requirements, potential energy and carbon saving, constructability, durability, and other factors. This work also shows that the novel materials and building envelopes serving as emerging ECMs have been studied to different extents by experimental approaches, established physics-based approaches (e.g., EnergyPlus, DesignBuilder, and TRNSYS), established customized approaches (e.g., Matlab and GenOpt), numerical or data-driven modeling techniques (e.g., machine learning), or new modeling and simulation tools. Further research is needed to document the performance of some of these ECMs such as RSC using simulation-based methods. With the building energy and embodied carbon regulations becoming more established and stringent in their requirements, the documentation, simulation, modeling, and testing of the building envelopes’ hygrothermal and carbon performance are more than ever. The review of the literature also shows the need for future research to develop user-friendly tools to help layman users understand the tradeoffs between cost, thermal behavior and energy performance, embodied carbon, and durability of various building envelope ECMs. Finally, the trend in the field of building construction materials demonstrates the effort to mitigate the embodied carbon by development of low-embodied carbon materials as well as bio-renewable materials, which can provide carbon sequestration capability.

Author Contributions

Conceptualization, R.A., E.K. and A.M.M.; methodology, R.A., E.K. and A.M.M.; software, R.A. and E.K.; validation, R.A. and E.K.; formal analysis, R.A. and E.K.; investigation, R.A., E.K. and A.M.M.; resources, R.A., E.K. and A.M.M.; data curation, R.A., E.K. and A.M.M.; writing—original draft preparation, R.A., E.K. and A.M.M.; writing—review and editing, R.A., E.K. and A.M.M.; visualization, R.A., E.K. and A.M.M.; supervision, R.A., E.K. and A.M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- IPCC. Climate Change 2022, Mitigation of Climate Change; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2022. [Google Scholar]

- EIA. U.S. Energy Facts Explained—Consumption and Production—U.S. Energy Information Administration (EIA). Available online: https://www.eia.gov/energyexplained/us-energy-facts/ (accessed on 27 December 2023).

- EIA. Residential Energy Consumption Survey (RECS)—Energy Information Administration. Available online: https://www.eia.gov/consumption/residential/ (accessed on 27 December 2023).

- EIA. Energy Information Administration (EIA)—Commercial Buildings Energy Consumption Survey (CBECS) Data. Available online: https://www.eia.gov/consumption/commercial/data/2018/ (accessed on 27 December 2023).

- EPA. Sources of Greenhouse Gas Emissions_US EPA. Available online: https://www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions (accessed on 27 December 2023).

- Gursel, A.P.; Shehabi, A.; Horvath, A. Embodied energy and greenhouse gas emission trends from major construction materials of U.S. office buildings constructed after the mid-1940s. Build. Environ. 2023, 234, 110196. [Google Scholar] [CrossRef]

- United Nations Environment Programme. 2022 Global Status Report for Buildings and Construction: Towards a ZeroEmission, Efficient and Resilient Buildings and Construction Sector. 2022. Available online: https://globalabc.org/sites/default/files/2022-11/FULL%20REPORT_2022%20Buildings-GSR_1.pdf (accessed on 4 February 2024).

- Wu, Y.; Zhao, H.; Sun, H.; Duan, M.; Lin, B.; Wu, S. A review of the application of radiative sky cooling in buildings: Challenges and optimization. Energy Convers. Manag. 2022, 265, 115768. [Google Scholar] [CrossRef]

- Chen, J.; Gong, Q.; Lu, L. Evaluation of passive envelope systems with radiative sky cooling and thermally insulated glazing materials for cooling. J. Clean. Prod. 2023, 398, 136607. [Google Scholar] [CrossRef]

- Fantucci, S.; Serra, V.; Perino, M. Advanced Materials for Opaque Building Envelopes. 2019. Available online: www.ashrae.org (accessed on 20 January 2024).

- Zhong, S.; Yuan, S.; Zhang, X.; Zhang, J.; Xu, L.; Xu, T.; Zuo, T.; Cai, Y.; Yi, L. Supplementary Materials for Hierarchical Cellulose Aerogel Reinforced with In situ Assembled Cellulose Nanofibers for Building Cooling. ACS Appl. Mater. Interfaces 2023, 15, 39807–39817. [Google Scholar] [CrossRef] [PubMed]

- Abraham, E.; Cherpak, V.; Senyuk, B.; Hove, J.B.T.; Lee, T.; Liu, Q.; Smalyukh, I.I. Highly transparent silanized cellulose aerogels for boosting energy efficiency of glazing in buildings. Nat. Energy 2023, 8, 381–396. [Google Scholar] [CrossRef]

- ISO 9050:2003; Glass in Building—Determination of Light Transmittance, Solar Direct Transmittance, Total Solar Energy Transmittance, Ultraviolet Transmittance and Related Glazing Factors. International Organization for Standardization: Vernier, Geneva, 2003. Available online: https://www.iso.org/standard/35062.html (accessed on 18 June 2024).

- Ibrahim, M.; Sayegh, H.; Bianco, L.; Wurtz, E. Hygrothermal performance of novel internal and external super-insulating systems: In-situ experimental study and 1D/2D numerical modeling. Appl. Therm. Eng. 2019, 150, 1306–1327. [Google Scholar] [CrossRef]

- Duan, X.; Shen, C.; Liu, D.; Wu, Y. The performance analysis of a photo/thermal catalytic Trombe wall with energy generation. Renew. Energy 2023, 218, 119361. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; Iovane, T.; Mastellone, M.; Mauro, G.M. The evolution of building energy retrofit via double-skin and responsive façades: A review. Sol. Energy 2021, 224, 703–717. [Google Scholar] [CrossRef]

- Si, P.; Lv, Y.; Rong, X.; Shi, L.; Yan, J.; Wang, X. An innovative building envelope with variable thermal performance for passive heating systems. Appl. Energy 2020, 269, 115175. [Google Scholar] [CrossRef]

- Baek, E.; Pohoryles, D.A.; Kallioras, S.; Bournas, D.A.; Choi, H.; Kim, T. Innovative seismic and energy retrofitting of wall envelopes using prefabricated textile-reinforced concrete panels with an embedded capillary tube system. Eng. Struct. 2022, 265, 114453. [Google Scholar] [CrossRef]

- Cellulose Insulation Manufacturers Association. Standard Practice for Installation of Cellulose Insulation in the United States. Technical Bulletin. February 2023. Available online: https://cellulose.org/wp-content/uploads/2023/02/CIMA-Technical-Bulletin-Standard-Practices-for-Installation-of-Cellulose-Insulation-in-the-United-States.pdf (accessed on 20 January 2024).

- Papadopoulos, A.M. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Kalnæs, S.E.; Jelle, B.P. Vacuum insulation panel products: A state-of-the-art review and future research pathways. Appl. Energy 2014, 116, 355–375. [Google Scholar] [CrossRef]

- Casini, M. Smart materials and nanotechnology for energy retrofit of historic buildings. In Proceedings of the International Conference on Advances in Civil, Structural and Construction Engineering, Rome, Italy, 7–8 June 2014; pp. 28–37. [Google Scholar]

- Pal, S.; Roy, B.; Neogi, S. Heat transfer modelling on windows and glazing under the exposure of solar radiation. Energy Build. 2009, 41, 654–661. [Google Scholar] [CrossRef]

- Cho, S. Analysis of the performance of vacuum glazing in office buildings in Korea: Simulation and experimental studies. Sustainability 2017, 9, 936. [Google Scholar] [CrossRef]

- Ghoshal, S.; Neogi, S. Advance glazing system—Energy efficiency approach for buildings a review. Energy Procedia 2014, 54, 352–358. [Google Scholar] [CrossRef]

- Jayasinghe, C.; Jayasinghe, C. Embodied energy of alternative building materials and their impact on life cycle cost parameters. In Proceedings of the International Conference on Structural Engineering and Construction Management, Kandy, Sri Lanka, 16–18 December 2011. 16p. [Google Scholar] [CrossRef]

- Haynes, R. Embodied Energy Calculations within Life Cycle Analysis of Residential Buildings. 2010. Revised 2013. Available online: https://etoolglobal.com/wp-content/uploads/2012/10/Embodied-Energy-Paper-Richard-Haynes.pdf (accessed on 20 January 2024).

- Cooperman, A.; Dieckmann, J.; Brodrick, J. Home envelope retrofits. ASHRAE J. 2011, 53, 82–85. [Google Scholar]

- Favoino, F.; Jin, Q.; Overend, M. Towards an ideal adaptive glazed façade for office buildings. Energy Procedia 2014, 62, 289–298. [Google Scholar] [CrossRef]

- Aelenei, D.; Aelenei, L.; Vieira, C.P. Adaptive Façade: Concept, Applications, Research Questions. Energy Procedia 2016, 91, 269–275. [Google Scholar] [CrossRef]

- Barozzi, M.; Lienhard, J.; Zanelli, A.; Monticelli, C. The Sustainability of Adaptive Envelopes: Developments of Kinetic Architecture. Procedia Eng. 2016, 155, 275–284. [Google Scholar] [CrossRef]

- Warwick, M.E.A.; Ridley, I.; Binions, R. The effect of transition gradient in thermochromic glazing systems. Energy Build. 2014, 77, 80–90. [Google Scholar] [CrossRef]

- International Energy Agency. Technology Roadmap Energy Efficient Building Envelopes. Available online: www.iea.org (accessed on 20 January 2024).

- Raheem, A.A.; Issa, R.R.A.; Olbina, S. Environmental Performance and Economic Analysis of Different Glazing–Sunshade Systems Using Simulation Tools. J. Comput. Civ. Eng. 2016, 30, C5016001. [Google Scholar] [CrossRef]

- PennState. Penn Staters Invited to Review University Self-Study Report. PennState. Available online: https://www.psu.edu/news/administration/story/penn-staters-invited-review-university-self-study-report/ (accessed on 20 January 2024).

- Guidebook for Solar Photovoltaic Projects in Philadelphia. Available online: https://www.phila.gov/media/20160421161005/solar-photovoltaic-project-guidebook.pdf (accessed on 23 January 2024).

- Lombardi, V. The Solar Energy System Handbook: A Practical Guide to Solar Power System Design for Homeowners. 2012. Available online: https://readara.com/the-solar-energy-system-handbook-a-practical-guide-to-solar-power-system-design-for-homeowners/9781508433934/philip-crouch/technology-engineering/power-resources-alternative-renewable/book. (accessed on 20 December 2023).

- Wang, L.; Memari, A.M. The State-of-the-art Review of BIPV Systems for Detached Single-family Homes. In Proceedings of the 7th Residential Building Design and Construction Conference, University Park, PA, USA, 27–28 March 2024; Memari, A.M., Ed.; Penn State University: University Park, PA, USA, 2024; pp. 254–265. [Google Scholar]

- Memari, A.M.; Iulo, L.D.; Solnosky, R.L.; Stultz, C.R. Building Integrated Photovoltaic Systems for Single Family Dwellings: Innovation Concepts. Open J. Civ. Eng. 2014, 4, 102–119. [Google Scholar] [CrossRef][Green Version]

- Tripathy, M.; Sadhu, P.; Panda, S. A critical review on building integrated photovoltaic products and their applications. Renew. Sustain. Energy Rev. 2016, 61, 451–465. [Google Scholar] [CrossRef]

- Bobrova, D. Building-integrated wind turbines in the aspect of architectural shaping. Procedia Eng. 2015, 117, 404–410. [Google Scholar] [CrossRef]

- Park, J.; Jung, H.J.; Lee, S.W.; Park, J. A new building-integrated wind turbine system utilizing the building. Energies 2015, 8, 11846–11870. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Embodied Carbon Actions—Architecture 2030. Available online: https://www.architecture2030.org/embodied-carbon-actions/ (accessed on 27 December 2023).

- HEMPWOOD, “HEMPWOOD”, HEMPWOOD. Available online: https://hempwood.com/ (accessed on 20 January 2024).

- Zuabi, W.; Memari, A.M. Review of Hempcrete as a Sustainable Building Material. Int. J. Archit. Eng. Constr. 2021, 10, 1–17. [Google Scholar]

- Jellen, A.C.; Memari, A.M. Structural Design of a Cross-Laminated Timber (CLT) Single-Family Home; PHRC: University Park, PA, USA, 2022. [Google Scholar]

- Yan, D.; Zhou, X.; An, J.; Kang, X.; Bu, F.; Chen, Y.; Pan, Y.; Gao, Y.; Zhang, Q.; Zhou, H.; et al. DeST 3.0: A new-generation building performance simulation platform. Build. Simul. 2022, 15, 1849–1868. [Google Scholar] [CrossRef]

- Thrampoulidis, E.; Mavromatidis, G.; Lucchi, A.; Orehounig, K. A machine learning-based surrogate model to approximate optimal building retrofit solutions. Appl. Energy 2021, 281, 116024. [Google Scholar] [CrossRef]

- Milosevic, S.; Aksamija, A. Sustainable Retrofit Strategies for an Existing and Historically Significant Residential Complex: Environmental Response and Facade Performance Analysis; Check for updates ® 238; Springer: Cham, Switzerland, 2023; Volume 529, pp. 237–252. [Google Scholar] [CrossRef]

- Botticelli, M.; Agnoli, S.; Romano, S.; Zinzi, M. Exploiting Passive Cooling in Office Buildings with Advanced Automated Glazing Systems: Preliminary Analyses from a Field Study; Springer: Singapore, 2023; pp. 525–534. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Vernier, Geneva, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 18 June 2024).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Vernier, Geneva, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 18 June 2024).

- EN 15978_2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Standards: Brussel, Belgium, 2011. Available online: https://standards.iteh.ai/catalog/standards/cen/62c22cef-5666-4719-91f9-c21cb6aa0ab3/en-15978-2011 (accessed on 27 December 2023).

- Bayer, C.; Gamble, M.; Gentry, R.; Joshi, S. AIA Guide to Building Life Cycle Assessment in Practice Authorship and Acknowledgments A Guide to Life Cycle Assessment of Buildings 2; The American Institute of Architect: New Yor, NY, USA, 2010. [Google Scholar]

- Lehtinen, H.; Saarentaus, A.; Rouhiainen, J.; Pitts, M.; Azapagic, A. A Review of LCA Methods and Tools and Their Suitability for SMEs List of Contents. 2011. Available online: www.biochem-project.eu (accessed on 22 December 2023).

- OpenLCA. The Open Source Life Cycle and Sustainability Software. 2023. Available online: https://www.openlca.org/open-source/ (accessed on 20 January 2024).

- SimaPro. Life Cycle Assessment for Informed Changemakers. 2023. Available online: https://simapro.com/ (accessed on 22 December 2023).

- Sphera. Gabi: Life Cycle Assessment Tool for Experts. 2023. Available online: https://sphera.com/life-cycle-assessment-lca-software/ (accessed on 22 December 2023).

- EC3. Embodied Carbon in Construction Calculator (EC3); Carbon Leadership Forum: Seattle, WA, USA, 2021; Available online: https://carbonleadershipforum.org/ec3-tool/ (accessed on 20 January 2024).

- Tally. Tally, Life Cycle Assessment App. 2024. Available online: https://www.ifu.com/lca-software/ (accessed on 22 December 2023).

- OneClickLCA, “OneClickLCA,” OneClickLCA. Available online: https://www.oneclicklca.com/ (accessed on 20 January 2024).

- Athena. About Environmental Building Declarations; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2018. [Google Scholar]

- Beacon. “Beacon”, Thornton Tomasetti. 2023. Available online: https://www.thorntontomasetti.com/capability/beacon (accessed on 22 December 2023).

- ETool LCD. “ETool LCD”. 2023. Available online: https://etool.app/ (accessed on 22 December 2023).

- ELODIE. ELODIE: A Tool for the Environmental Assessment of Building. 2023. Available online: http://www.irbnet.de/daten/iconda/CIB19053.pdf (accessed on 22 December 2023).

- ECCOLAB. “ECCOLAB”. 2023. Available online: https://eccolab.co/overview.html (accessed on 22 December 2023).

- eLCA. Life Cycle Assessment within BNB1—Online-Tool eLCA and Materials Database OeKOBAU.DAT. BNB. 2023. Available online: http://www.irbnet.de/daten/iconda/CIB_DC28525.pdf (accessed on 22 December 2023).

- TOTEM. TOTEM: Tool to Optimise the Total Environmental Impact of Materials. 2023. Available online: https://www.totem-building.be/ (accessed on 22 December 2023).

- LCAbyg. LCAbug. 2023. Available online: https://www.lcabyg.dk/en/ (accessed on 22 December 2023).

- 2050 Materials. Embodied Carbon Optimizer Tool. 2024. Available online: https://app.2050-materials.com/tools/dot_selection (accessed on 22 December 2023).

- Payette. Kaleidoscope Embodied Carbon Design Tools. 2023. Available online: https://www.payette.com/kaleidoscope/ (accessed on 22 December 2023).

- H\B:ERT. H\B:ERT Emissions Reduction Tool. Hawkins\Brown. 2023. Available online: https://www.hawkinsbrown.com/sub-services/hbert-emissions-reduction-tool/ (accessed on 22 December 2023).

- The Institution of Structural Engineers. The Structural Carbon Tool—Version 2. Available online: https://www.istructe.org/resources/guidance/the-structural-carbon-tool/ (accessed on 20 January 2024).

- EN 15804+A2; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/c98127b4-8dc2-48a4-9338-3e1366b16669/en-15804-2012a2-2019 (accessed on 20 January 2024).

- PHI. 25 Years Passive House—Interview with Dr. Wolfgang Feist. Passive House Institute. Available online: https://passivehouse.com/02_informations/01_whatisapassivehouse/01_whatisapassivehouse.htm (accessed on 20 January 2024).

- Phius 2021 Passive Building Standard Certification Guidebook. Available online: www.Phius.org (accessed on 20 January 2024).

- PowerHouse. What is a Powerhouse? PowerHouse. Available online: https://www.powerhouse.no/en/what-defines-the-powerhouse-standard/ (accessed on 20 January 2024).

- Energieprestatie—BENG. Available online: https://www.rvo.nl/onderwerpen/wetten-en-regels-gebouwen/beng (accessed on 27 December 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).