Examination of Damage Evolution in Slurry Masonry Schist Subjected to Biaxial Compressive Stresses

Abstract

1. Introduction

2. Test Profile

2.1. Test Preparation

- Water, sand, and cement were mixed in the appropriate proportions with a mixer until the water was thoroughly incorporated and the consistency was suitable; at this point, the mortar mixing was complete.

- To ensure that the sample was released from the mold smoothly, the bottom of the 300 mm × 300 mm × 80 mm mold was brushed with oil in advance.

- The mold was filled with the mixed cement mortar in layers. First, a layer of mortar was applied to the bottom of the mold, and the mortar surface was smoothed. Subsequently, the moistened schist was placed in the mold. A concrete vibration table was used to vibrate the mold, and the samples were allowed to harden for 24 h after demolding.

- The demolded specimens were transferred to a standard curing room set at a temperature of 20 °C and a relative humidity of 95% for the duration of 28 days.

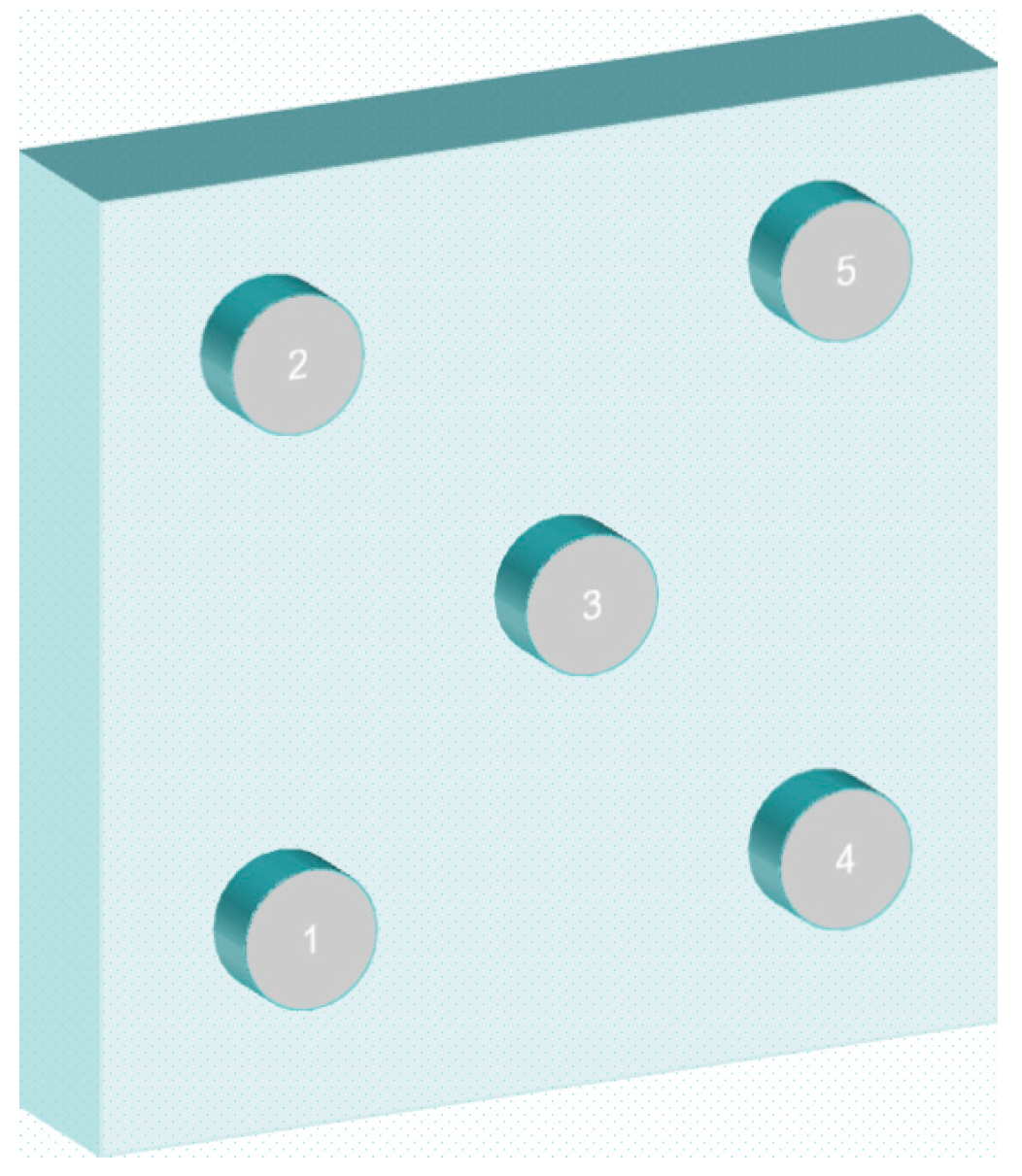

- The surface of each slurry masonry specimen was polished, and Figure 1 shows a drawing of a polished slurry masonry specimen.

- The slurry masonry schist was subjected to freeze–thaw cycles using a high- and low-temperature alternating test chamber. The cyclic temperature range was set to −20 °C to 20 °C, with each freeze–thaw cycle lasting 24 h. The number of freeze–thaw cycles was set to 0, 40, and 80, aligning with the climatic patterns in the North China region.

| Standard Consistency/% | Fineness/mm | Initial Fluidity/mm | 20 min Flow Rate/mm | Solidification Time (min) | 24 h Compressive Strength/ MPa | 24 h Flexural Strength/MPa | |

|---|---|---|---|---|---|---|---|

| 3 d | 7 d | ||||||

| 29.8 | 0.03 | >195 | >180 | 180 | 370 | 25.5 | 6.2 |

| Aperture Size | 7.5 mm | 4.5 mm | 2.5 mm | 1.25 mm | 600 µm | 300 µm | ≤150 µm |

|---|---|---|---|---|---|---|---|

| Subtotal sieve residue % | 0.1 | 0.3 | 10.2 | 18.5 | 26.4 | 44.2 | 0.3 |

| Cumulative sieve rate % | 0.1 | 0.4 | 10.6 | 29.1 | 55.5 | 99.7 | 100 |

| Fineness modulus | 2.5 belongs to the medium sand aggregate | ||||||

| Packing density (g/cm3) | 1.45 | ||||||

| Rock Type | Chemical Composition (%) | ||||

|---|---|---|---|---|---|

| Porous basalt | SiO2 | CaO | Al2O3 | MgO | Fe2O3 |

| 47.45 | 6.75 | 15.18 | 5.42 | 16.03 | |

| Na2O | K2O | TiO2 | SO3 | - | |

| 4.30 | 1.74 | 3.08 | 0.05 | - | |

| Mortar:Aggregate | Water (kg/m3) | Cement (kg/m3) | Sand (kg/m3) | Aggregate (kg/m3) |

|---|---|---|---|---|

| 1:3 | 280 | 250.2 | 1208.3 | 5215.4 |

2.2. Experimental Design

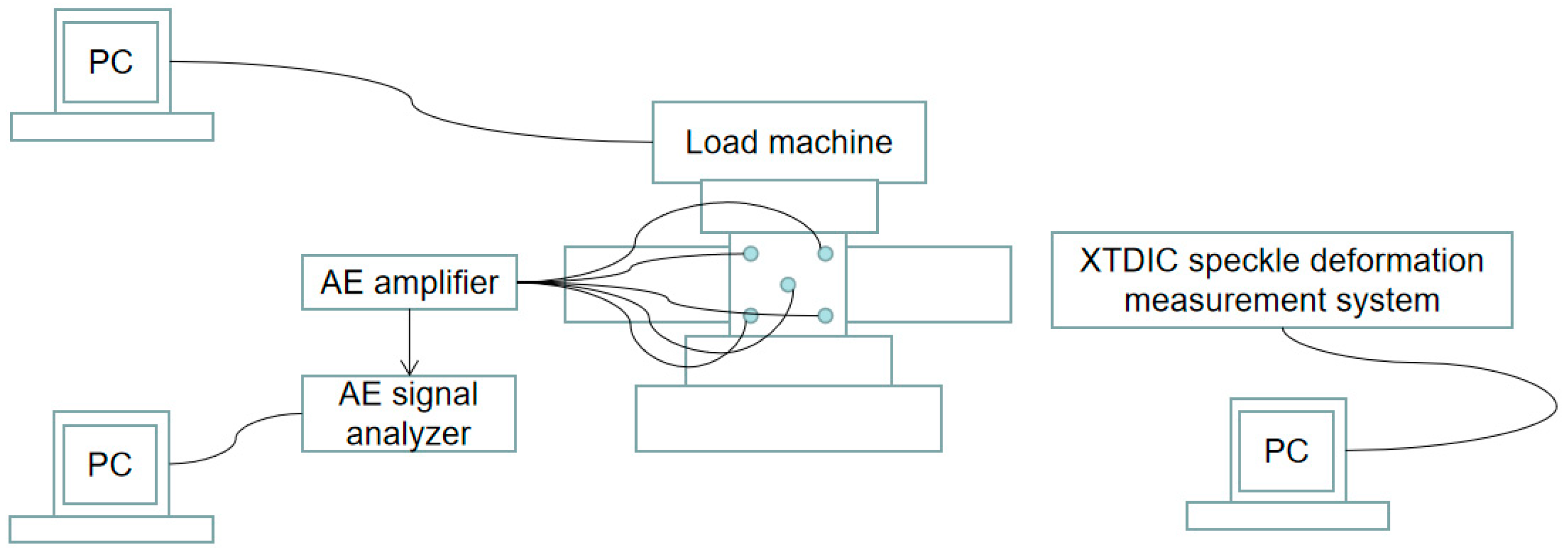

2.3. Test Methods

2.3.1. DIC Test Method

2.3.2. Acoustic Emission Test Method

3. Test Results and Analysis

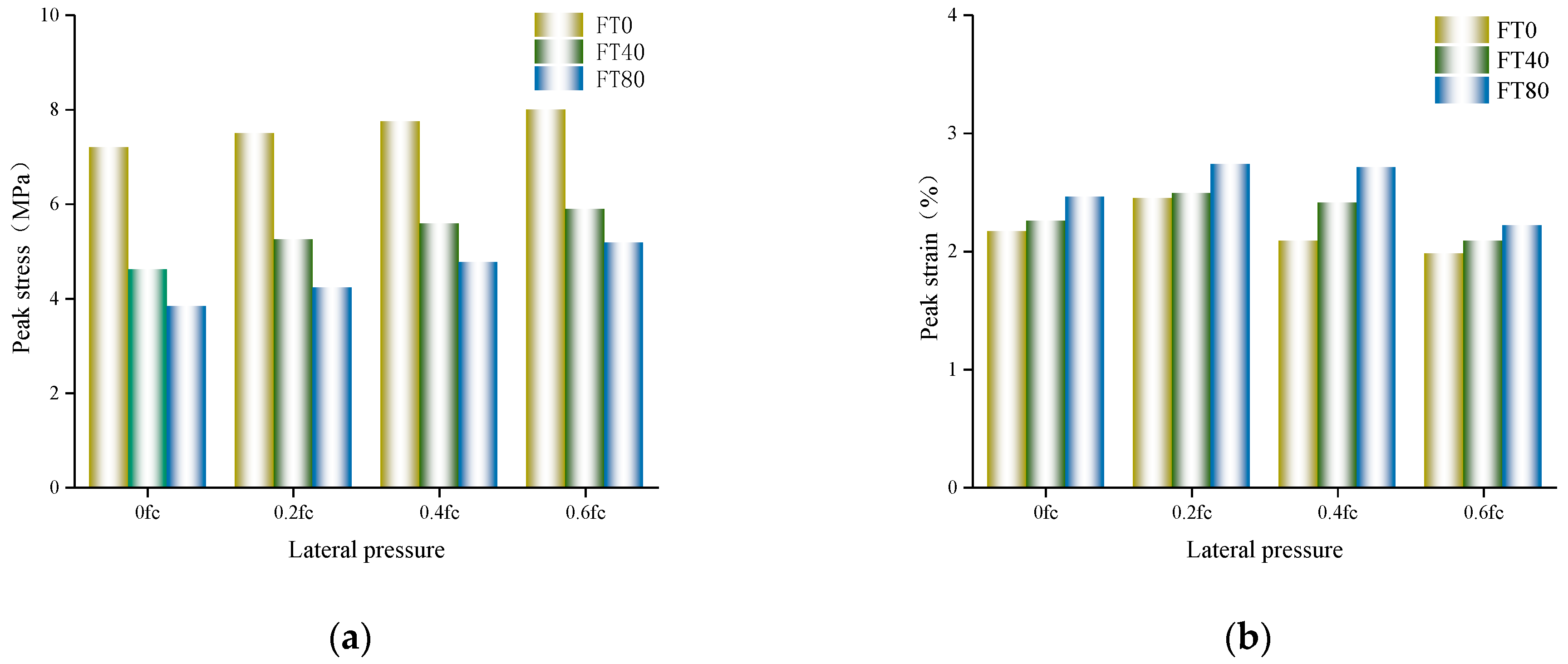

3.1. Peak Stress and Peak Strain

3.2. Acoustic Emission Signal Analysis

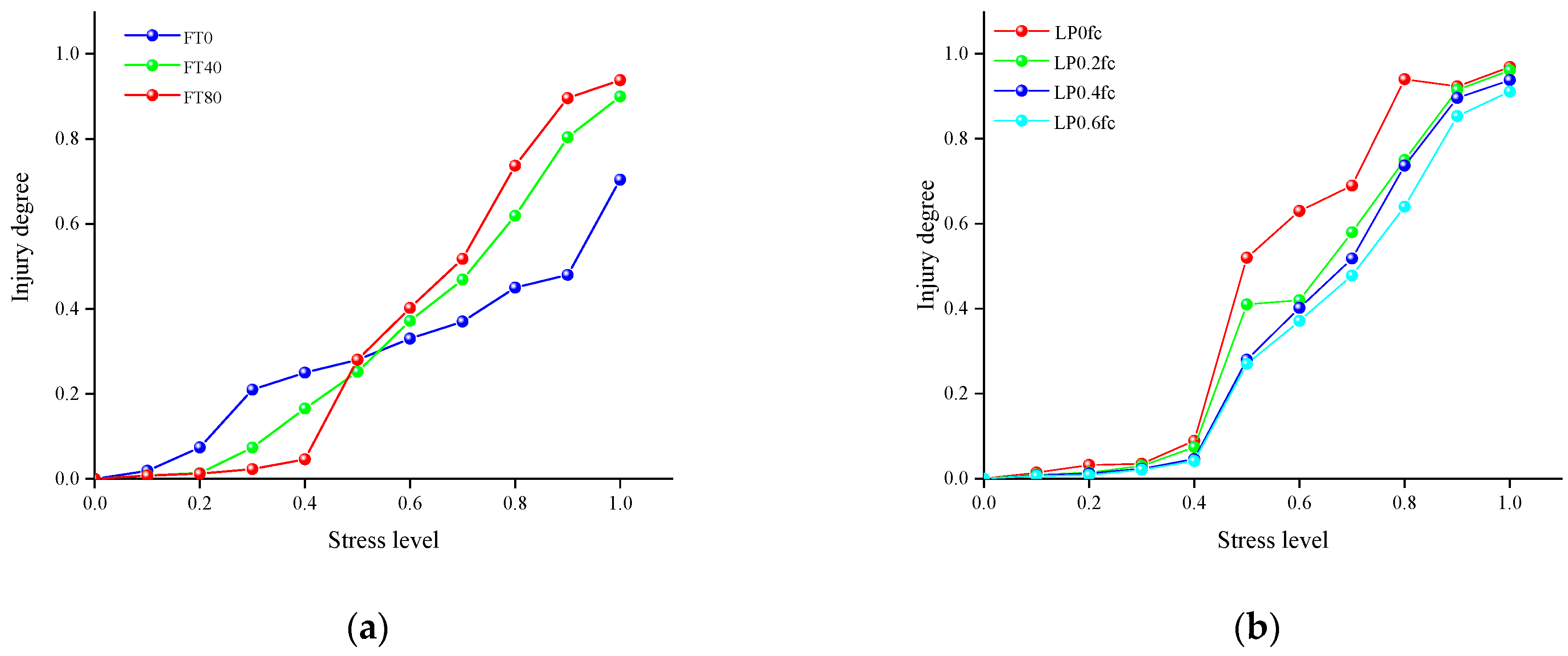

3.2.1. Damage Path Analysis

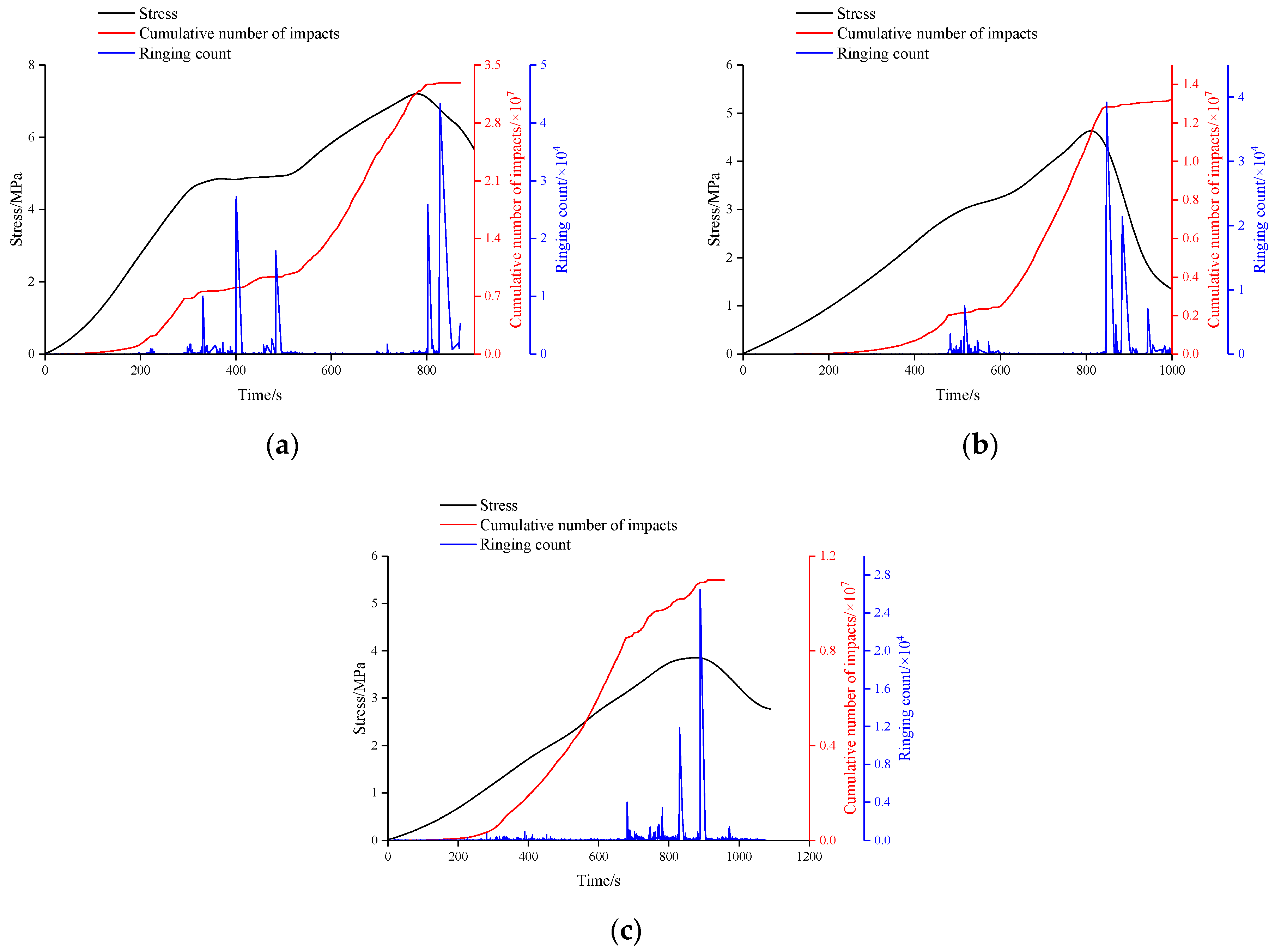

3.2.2. Stress, Acoustic Emission Ringing Count, and Cumulative Impact Curve Characteristics

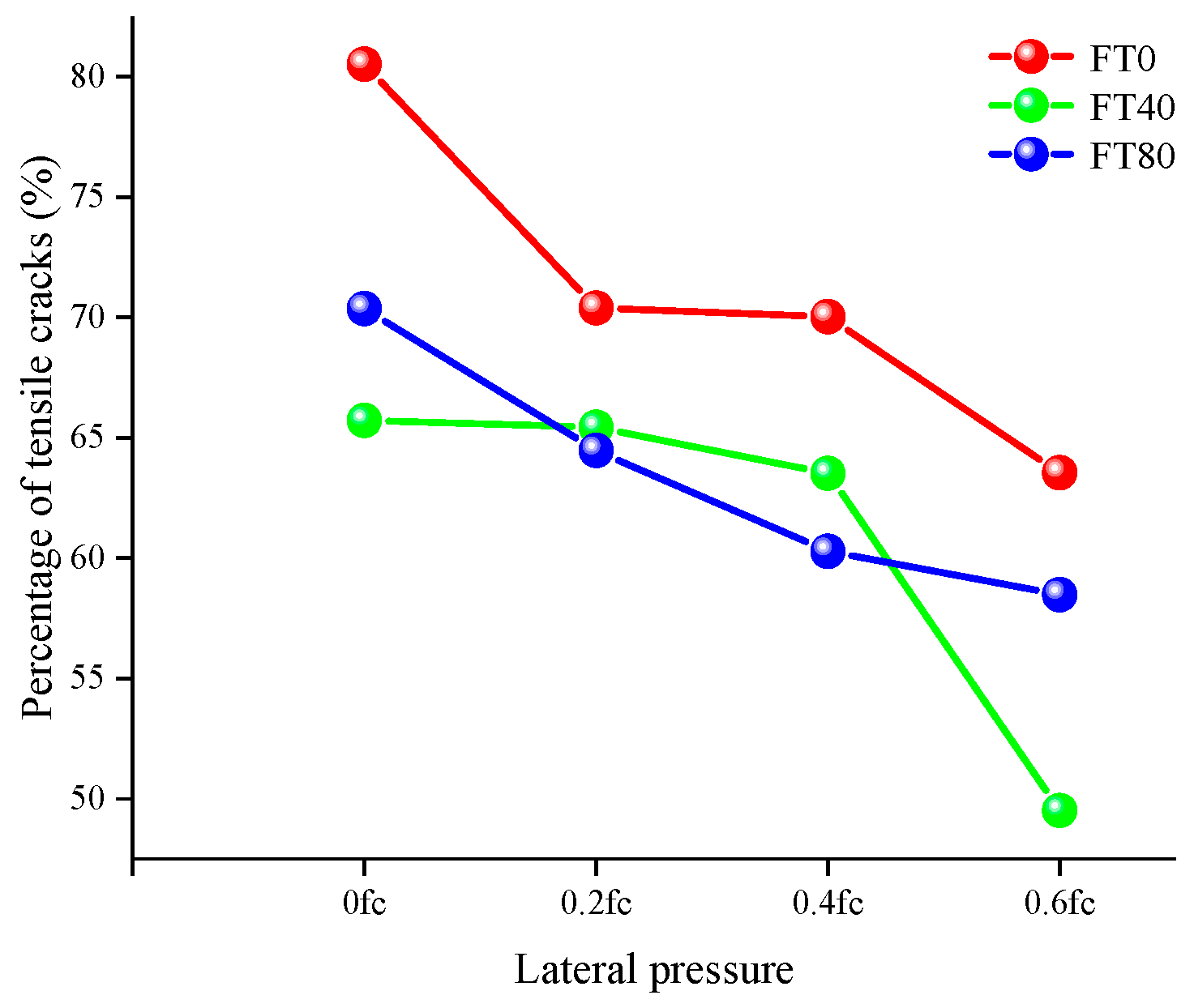

3.2.3. Crack Classification Analysis Based on Acoustic Emission Parameters

3.2.4. (B) Value Analysis

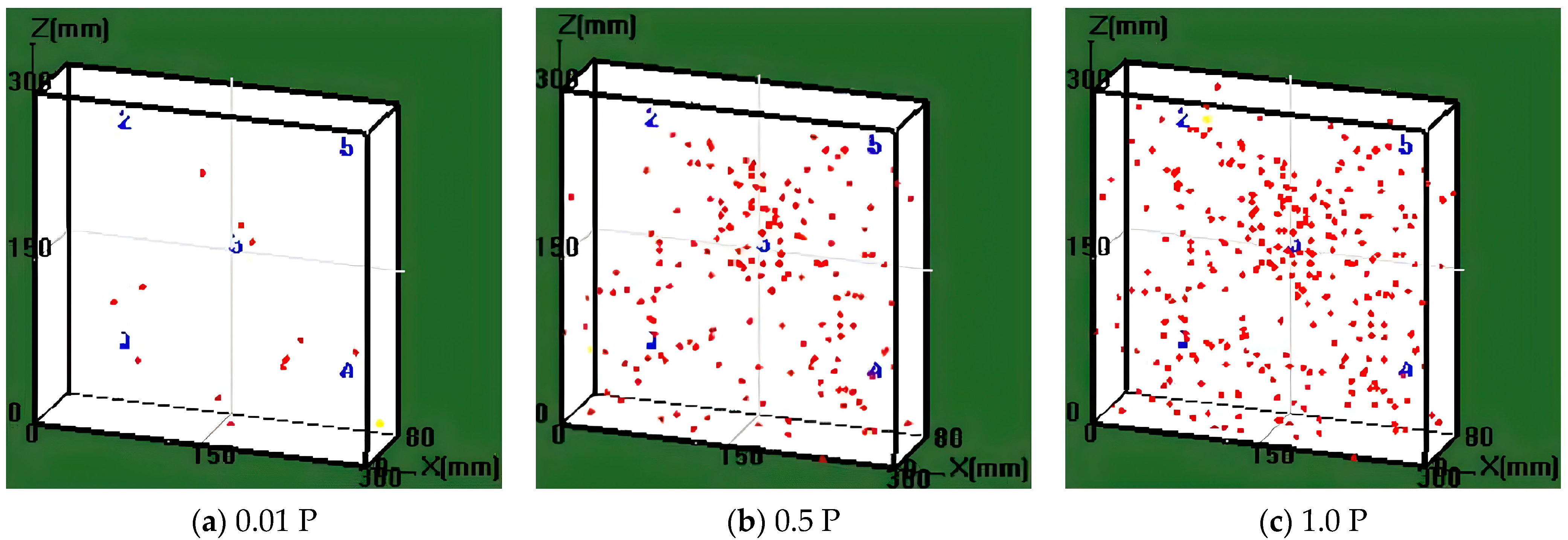

3.2.5. Analysis of Damage Localization Points

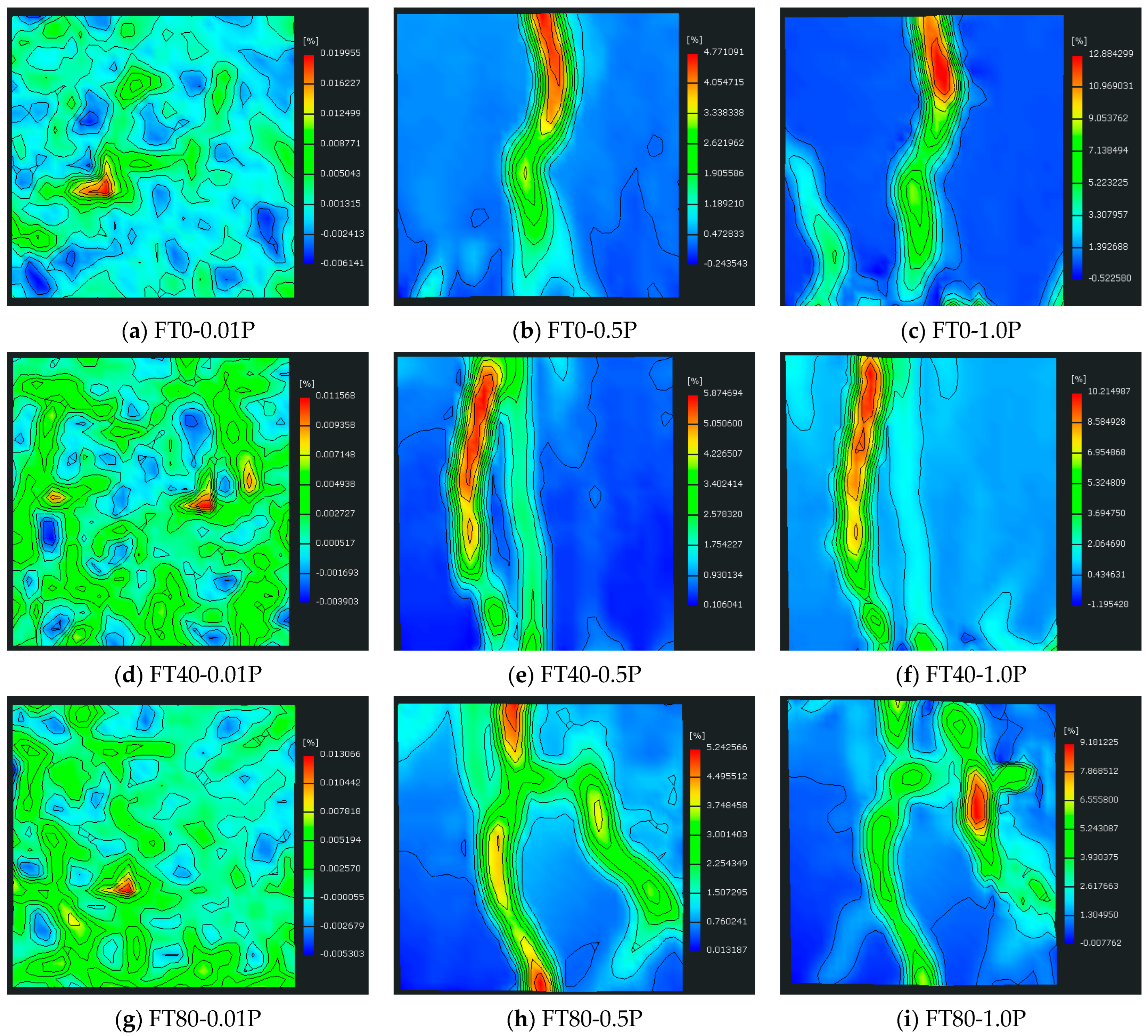

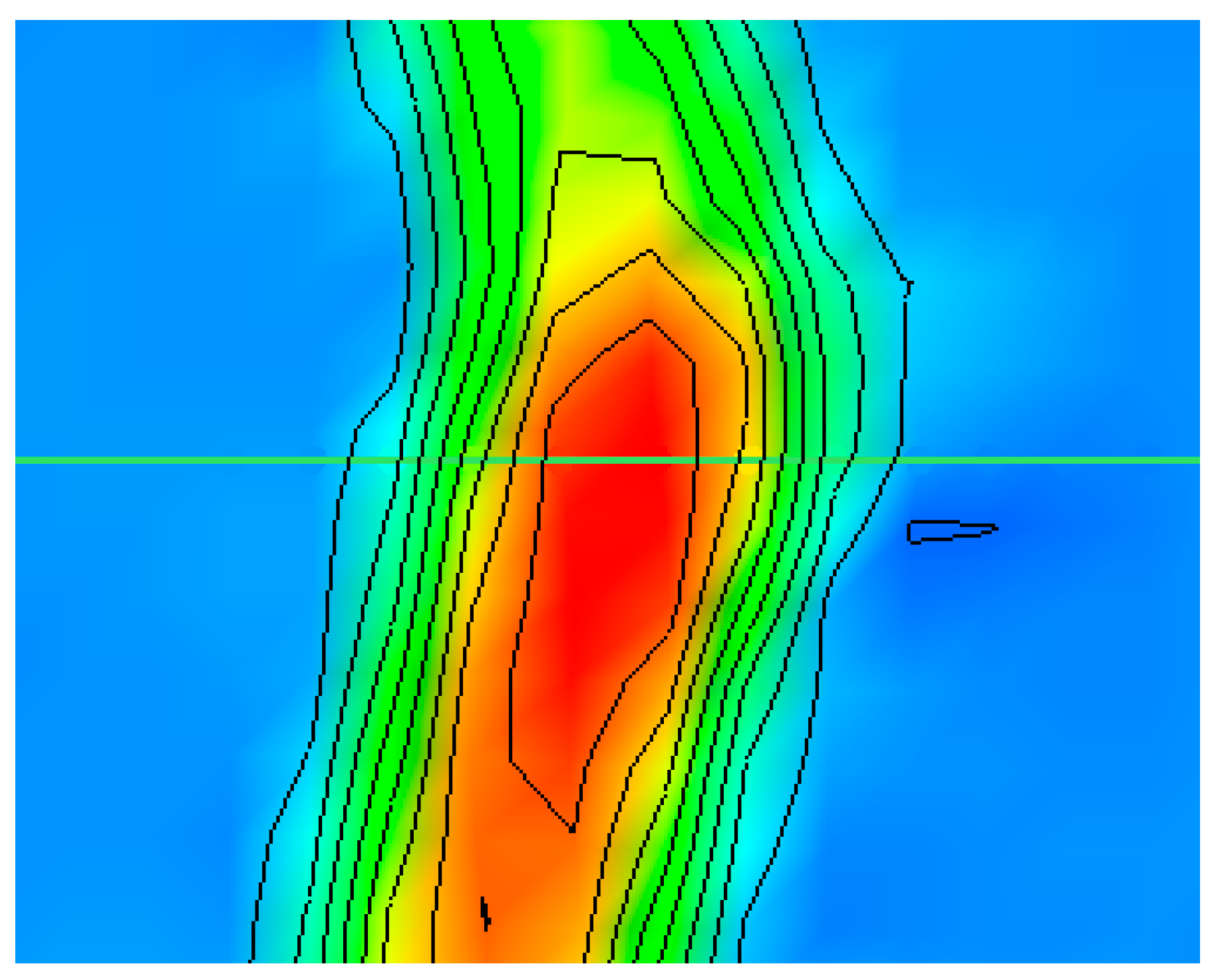

3.2.6. Maximum Principal Strain Analysis

4. Conclusions

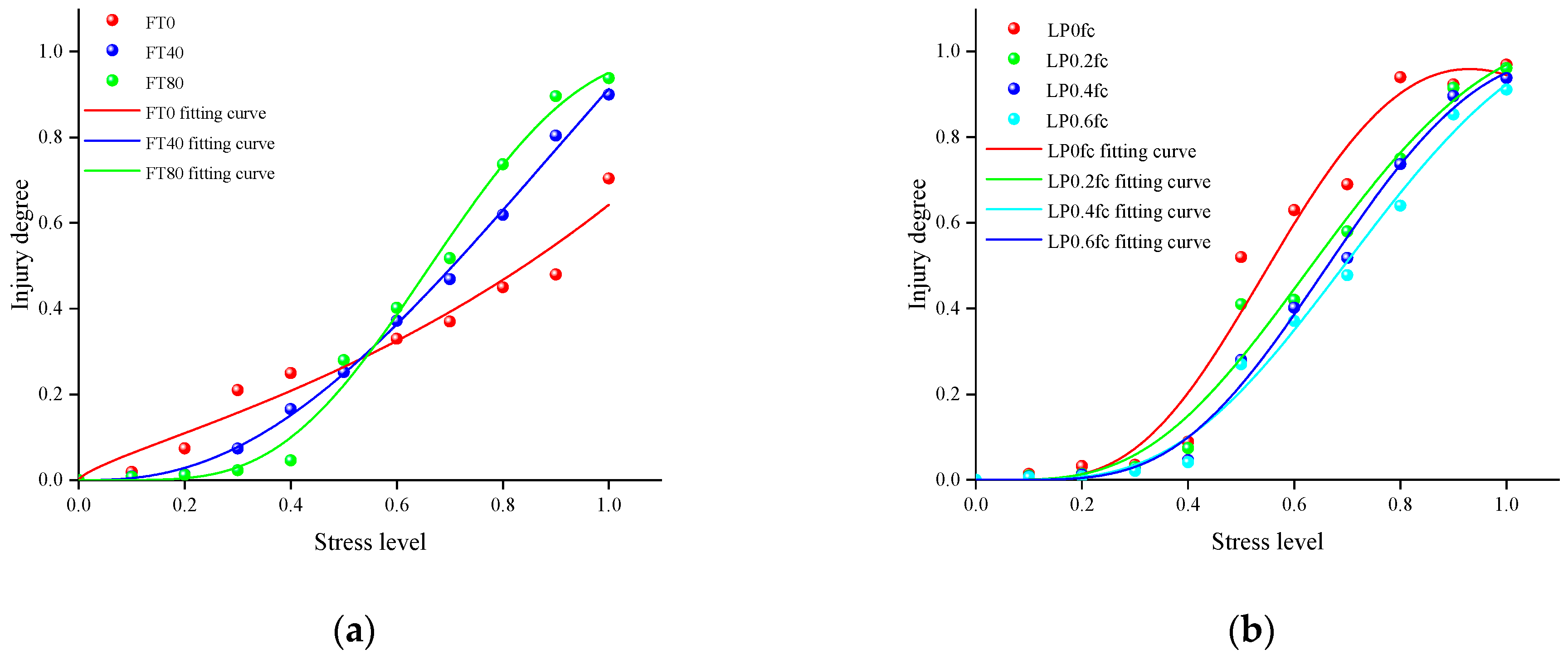

- Freezing and thawing cycles expedite the damage process in slurry masonry schist during loading. As the number of freeze–thaw cycles increases, the damage evolution path shifts forward. Despite the overlap of the starting and ending points of the damage curve, the curve’s trajectory significantly shortens, resulting in earlier damage to the slurry masonry schist during the loading process. The presence of lateral pressure partially inhibits the development of damage in slurry masonry schist.

- The fracturing of the slurry schist is dominated by tensile damage and, to a lesser extent, by shear damage. The presence of lateral pressure produces lateral expansion constraints during the vertical compression of the slurry schist, and the greater the lateral pressure is, the stronger the constraints on tensile cracks. Freeze–thaw cycles damage the internal structure of the slurry schist, and the percentage of tensile cracks fluctuates. Lateral pressure and freeze–thaw cycles induce alterations in the fracture pattern of the slurry schists.

- The fluctuation in the acoustic emission (b) value offers crucial insights into crack ex-tension and damage within slurry masonry schist. An increase in the (b) value signifies a prevalence of microcracks within the material, whereas a decrease indicates a dominance of larger crack extension and penetration. Fluctuations in the (b) value reveal the damage evolution of the slurry masonry schist during various loading stages.

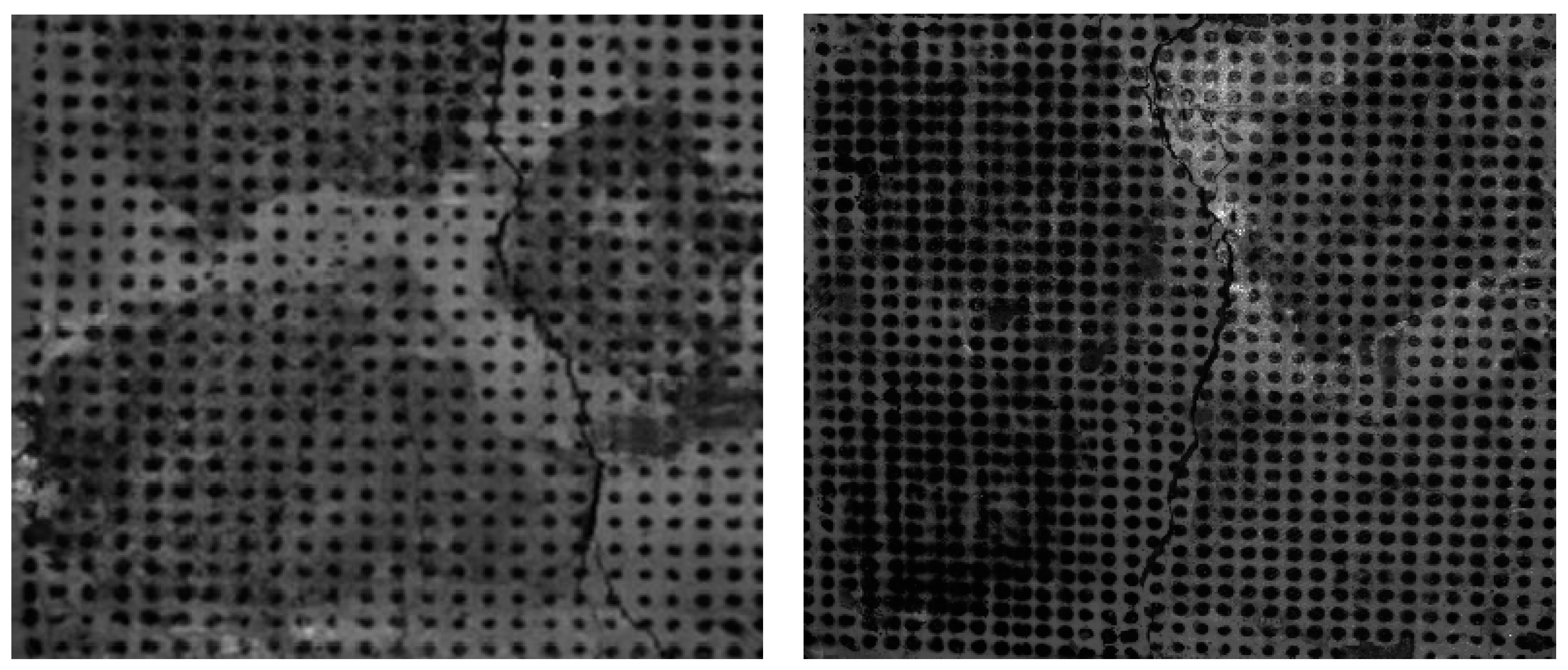

- Under loading, crack propagation occurs in the interface zone between the aggregate and mortar in slurry masonry schist, and the sudden change in strain indicates that the interface between the aggregate and mortar experiences debonding. During the loading process, the cracks produce macroscopic cracks along the localized zone of strain, leading to damage to the specimens by fracturing. The findings from digital image correlation (DIC) strain monitoring and acoustic emission (AE) signal localization suggest that the primary mode of damage in slurry schist structures is interfacial debonding.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kokutse, N.K.; Temgoua, A.G.T.; Kavazović, Z. Slope stability and vegetation: Conceptual and numerical investigation of mechanical effects. Ecol. Eng. 2016, 86, 146–153. [Google Scholar] [CrossRef]

- Li, J.; Zhou, K.; Liu, W.; Zhang, Y. Analysis of the effect of freeze–thaw cycles on the degradation of mechanical parameters and slope stability. Bull. Eng. Geol. Environ. 2018, 77, 573–580. [Google Scholar] [CrossRef]

- Su, H.; Wu, D.; Lu, Y.; Peng, X.; Wang, X.; Chen, W.; Wang, S. Experimental and numerical study on stability performance of new ecological slope protection using bolt-hinge anchored block. Ecol. Eng. 2021, 172, 106409. [Google Scholar] [CrossRef]

- Gentilini, C.; Govoni, L.; de Miranda, S.; Gottardi, G.; Ubertini, F. Three-dimensional numerical modelling of falling rock protection barriers. Comput. Geotech. 2012, 44, 58–72. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, J.; Duan, Q.; Su, C.; Yan, M.; Dong, Y. The Investigation and 3D Numerical Simulation of Herb Roots in Reinforcing Soil and Stabilizing Slope. KSCE J. Civ. Eng. 2018, 22, 4909–4921. [Google Scholar] [CrossRef]

- Yu, S.Y.; Ren, X.H.; Zhang, J.X.; Wang, H.J.; Sun, Z.H.; Zhou, Y. Numerical simulation on the stability of rock slope based on an improved SPH Method. J. Mt. Sci. 2021, 18, 1937–1950. [Google Scholar] [CrossRef]

- Liu, Y.; Han, D.; Liu, N.; Wang, W. Reinforcement mechanism analysis of lattice beam and prestressed anchor rod system for loess slope. Front. Earth Sci. 2023, 11, 1121172. [Google Scholar] [CrossRef]

- Zhu, X.; Chen, Z.; Ren, Y. The Application of Ecological Treatment Technology of Bolt and Lattice Beam in Highway Mountain Slope Support. Geotech. Geol. Eng. 2019, 37, 1891–1896. [Google Scholar] [CrossRef]

- Zhang, J.J.; Niu, J.Y.; Fu, X.; Cao, L.C.; Xie, Q. Shaking table test of seismic responses of anchor cable and lattice beam reinforced slope. J. Mt. Sci. 2020, 17, 1251–1268. [Google Scholar] [CrossRef]

- Li, J.; Hu, D.; Li, L.; Li, C. Research on Application of Lattice Anchor System Design and Construction Monitoring in Slope Protection. IOP Conf. Series Earth Environ. Sci. 2021, 781, 22049. [Google Scholar] [CrossRef]

- Dong, J.; Li, Z.Q.; Yan, X.; Liu, Y.; Zhao, S.R.; Qian, R.; Jiang, T. Effects of coarse aggregates on the mechanical properties, durability and microscopic behaviour of mortar rubble. Constr. Build. Mater. 2022, 354, 129187. [Google Scholar] [CrossRef]

- Caliskan, S.; Karihaloo, B.L.; Barr, B.I.G. Study of rock—Mortar interfaces. Part I: Surface roughness of rock aggregates and microstructural characteristics of interface. Mag. Concr. Res. 2002, 54, 449–461. [Google Scholar] [CrossRef]

- Li, Z.Q.; Chen, H.; Dong, J.; Yan, X.; Zhao, S.R.; Zheng, Y.H.; Liu, Y. Study of the Failure Mechanism of Mortar Rubble Using Digital Image Correlation, Acoustic Emission and Scanning Electron Microscopy. Buildings 2022, 12, 1313. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

- Pan, J.; Shen, Y.; Yang, G.; Zhang, H.; Yang, H.; Zhou, Z. Debonding behaviors and micro-mechanism of the interface transition zone in sandstone-concrete interface in response to freeze-thaw conditions. Cold Reg. Sci. Technol. 2021, 191, 103359. [Google Scholar] [CrossRef]

- Jin, L.; Fan, L.; Li, P.; Du, X. Size effect of axial-loaded concrete-filled steel tubular columns with different confinement coefficients. Eng. Struct. 2019, 198, 109503. [Google Scholar] [CrossRef]

- Jin, L.; Li, J.; Yu, W.; Du, X. Size effect modelling for dynamic biaxial compressive strength of concrete: Influence of lateral stress ratio and strain rate. Int. J. Impact Eng. 2021, 156, 103942. [Google Scholar] [CrossRef]

- Jin, L.; Li, J.; Yu, W.; Du, X. Mesoscopic simulations on the strength and size effect of concrete under biaxial loading. Eng. Fract. Mech. 2021, 253, 107870. [Google Scholar] [CrossRef]

- Murad, Y.Z. Predictive model for bidirectional shear strength of reinforced concrete columns subjected to biaxial cyclic loading. Eng. Struct. 2021, 244, 112781. [Google Scholar] [CrossRef]

- Van Mier, J.G.M.; Vonk, R.A. Fracture of concrete under multiaxial stress-recent developments. Mater. Struct. 1991, 24, 61–65. [Google Scholar] [CrossRef]

- Shang, H.S.; Song, Y.P. Experimental study of strength and deformation of plain concrete under biaxial compression after freezing and thawing cycles. Cem. Concr. Res. 2006, 36, 1857–1864. [Google Scholar] [CrossRef]

- Zhu, W.C.; Teng, J.G.; Tang, C.A. Numerical simulation of strength envelope and fracture patterns of concrete under biaxial loading. Mag. Concr. Res. 2002, 54, 395–409. [Google Scholar] [CrossRef]

- Tschegg, E.K.; Elser, M.; Kreuzer, H. Model fracture behaviour of concrete under biaxial loading. J. Mater. Sci. 1995, 30, 235–242. [Google Scholar] [CrossRef]

- Wang, H.T.; Zhou, Y.; Shen, J.Y. Experimental study of dynamic biaxial compressive properties of full grade aggregate concrete after freeze thaw cycles. Cold Reg. Sci. Technol. 2023, 205, 103710. [Google Scholar] [CrossRef]

- He, Z.J.; Ding, M.J.; Zhang, X.J.; Zhang, X.S. The Biaxial Compressive Mechanical Properties and Strength Criterion of Recycled Aggregate Concrete Under Different Dynamic Strain Rates. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 125–146. [Google Scholar] [CrossRef]

- Gao, S.; Hu, G. Experimental Study on Biaxial Dynamic Compressive Properties of ECC. Materials 2021, 14, 1257. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Dong, J.; Jiang, T.; Feng, K.; Cheng, S.; Liu, Y.; Tian, X. Experimental Study on the Dynamic Fracture Characteristics of Mortar–Rock Interface Zones with Different Interface Inclinations and Shapes. Materials 2023, 16, 5475. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Rong, H.; Zheng, J.; Xu, F.; Dong, W. An experimental investigation on the FPZ properties in concrete using digital image correlation technique. Eng. Fract. Mech. 2011, 78, 2978–2990. [Google Scholar] [CrossRef]

- Fayyad, T.M.; Lees, J.M. Application of Digital Image Correlation to Reinforced Concrete Fracture. Procedia Mater. Sci. 2014, 3, 1585–1590. [Google Scholar] [CrossRef]

- Alam, S.Y.; Loukili, A.; Grondin, F. Monitoring size effect on crack opening in concrete by digital image correlation. Eur. J. Environ. Civ. Eng. 2012, 16, 818–836. [Google Scholar] [CrossRef]

- Jing, G.; Yunchang, D.; You, R.; Siahkouhi, M. Comparison study of crack propagation in rubberized and conventional prestressed concrete sleepers using digital image correlation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2022, 236, 350–361. [Google Scholar] [CrossRef]

- Thirumalaiselvi, A.; Sindu, B.S.; Sasmal, S. Crack propagation studies in strain hardened concrete using acoustic emission and digital image correlation investigations. Eur. J. Environ. Civ. Eng. 2022, 26, 4346–4373. [Google Scholar] [CrossRef]

- Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Failure mechanism of fibre reinforced concrete under splitting test using digital image correlation. Mater. Struct. 2015, 48, 2713–2726. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.; Wang, Q.; Xiao, J. Deformation field and crack analyses of concrete using digital image correlation method. Front. Struct. Civ. Eng. 2019, 13, 1183–1199. [Google Scholar] [CrossRef]

- Li, D.; Huang, P.; Chen, Z.; Yao, G.; Guo, X.; Zheng, X.; Yang, Y. Experimental study on fracture and fatigue crack propagation processes in concrete based on DIC technology. Eng. Fract. Mech. 2020, 235, 107166. [Google Scholar] [CrossRef]

- Lakavath, C.; Prakash, S.S. Interface Shear Behavior of Ultrahigh-Performance Fiber-Reinforced Concrete Using Digital Image Correlation Technique. J. Mater. Civ. Eng. 2024, 36, 04023589. [Google Scholar] [CrossRef]

- Ohno, K.; Ohtsu, M. Crack classification in concrete based on acoustic emission. Constr. Build. Mater. 2010, 24, 2339–2346. [Google Scholar] [CrossRef]

- Grosse, C.U.; Finck, F. Quantitative evaluation of fracture processes in concrete using signal-based acoustic emission techniques. Cem. Concr. Compos. 2006, 28, 330–336. [Google Scholar] [CrossRef]

- Sagar, R.V.; Prasad, B.R.; Kumar, S.S. An experimental study on cracking evolution in concrete and cement mortar by the b-value analysis of acoustic emission technique. Cem. Concr. Res. 2012, 42, 1094–1104. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, S.S.; Liu, H.; Liu, X.Y.; Li, X.C.; Zheng, S.Z.; Cao, Z.X. Research on dynamic splitting tensile damage characteristics of steel fiber reinforced concrete under freeze-thaw cycle environment based on AE. J. Build. Eng. 2024, 84, 108490. [Google Scholar] [CrossRef]

- Barbosh, M.; Sadhu, A. Damage identification in concrete structures using a hybrid time–frequency decomposition of acoustic emission responses. J. Civ. Struct. Health Monit. 2024, 14, 237–253. [Google Scholar] [CrossRef]

- Alam, S.Y.; Saliba, J.; Loukili, A. Fracture examination in concrete through combined digital image correlation and acoustic emission techniques. Constr. Build. Mater. 2014, 69, 232–242. [Google Scholar] [CrossRef]

- Fan, X.; Li, S.; Chen, X.; Liu, S.; Guo, Y. Fracture behaviour analysis of the full-graded concrete based on digital image correlation and acoustic emission technique. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1274–1289. [Google Scholar] [CrossRef]

- Feiteira, J.; Tsangouri, E.; Gruyaert, E.; Lors, C.; Louis, G.; De Belie, N. Monitoring crack movement in polymer-based self-healing concrete through digital image correlation, acoustic emission analysis and SEM in-situ loading. Mater. Des. 2017, 115, 238–246. [Google Scholar] [CrossRef]

- Shang, S.; Song, Y. Dynamic biaxial tensile–compressive strength and failure criterion of plain concrete. Constr. Build. Mater. 2013, 40, 322–329. [Google Scholar] [CrossRef]

- Sun, Y.; Pang, J.H.; Wong, C.K.; Su, F. Finite element formulation for a digital image correlation method. Appl. Opt. 2005, 44, 7357–7363. [Google Scholar] [CrossRef] [PubMed]

- Kachanov, L.M. Rupture time under creep conditions. Int. J. Fract. 1999, 97, 11–18. [Google Scholar] [CrossRef]

- Lian, S.; Zheng, K.; Zhao, Y.; Bi, J.; Wang, C.; Huang, Y.S. Investigation the effect of freeze–thaw cycle on fracture mode classification in concrete based on acoustic emission parameter analysis. Constr. Build. Mater. 2023, 362, 129789. [Google Scholar] [CrossRef]

- Zhao, Y.-R.; Wang, L.; Lei, Z.-K.; Han, X.-F.; Shi, J.-N. Study on bending damage and failure of basalt fiber reinforced concrete under freeze-thaw cycles. Constr. Build. Mater. 2018, 163, 460–470. [Google Scholar] [CrossRef]

- Ohtsu, M. Rate process analysis of acoustic emission activity in core test of concrete. Doboku Gakkai Ronbunshu 1992, 1992, 211–217. [Google Scholar] [CrossRef]

- Ohtsu, M.; Watanabe, H. Quantitative damage estimation of concrete by acoustic emission. Constr. Build. Mater. 2001, 15, 217–224. [Google Scholar] [CrossRef]

- Nosov, V.V.; Chaplin, I.E.; Gilyazetdinov, E.R.; Grigoriev, E.V.; Pavlenko, I.A. Micromechanics, nanophysics and non-destructive testing of the strength of structural materials. Mater. Phys. Mech. 2019, 42, 808–824. [Google Scholar]

- Li, Z.; Dong, J.; Chen, H.; Wu, Z.; Feng, K.; Zhang, G.; Jiang, T. Mechanical behaviour and acoustic emission characteristics of basalt fibre mortar rubble under uniaxial cyclic compression. Constr. Build. Mater. 2023, 393, 132145. [Google Scholar] [CrossRef]

- Xu, J.; Niu, X.; Yao, Z. Mechanical properties and acoustic emission data analyses of crumb rubber concrete under biaxial compression stress states. Constr. Build. Mater. 2021, 298, 123778. [Google Scholar] [CrossRef]

| Pixel Size | Capture | Matching Method | Search Range Radius | Background Check Threshold | Continuity Threshold |

|---|---|---|---|---|---|

| 1960 × 1280 | 2 Hz | Horizontal matching | 75 | 1 | 1 |

| Sampling Frequency | PDT | HDT | HLF | High Pass On-Board Filter | Low Pass On-Board Filter |

|---|---|---|---|---|---|

| 2.5 MHz | 100 μs | 300 μs | 200 μs | 100 kHz | 20 kHz |

| Test Conditions | a | b | c/Nm | R2 |

|---|---|---|---|---|

| FT0 | 0.689 | 0.825 | 0.282 | 0.938 |

| FT40 | 2.758 | −1.222 | 3.099 | 0.991 |

| FT80 | 24.241 | −22.318 | 4.631 | 0.926 |

| LP0fc | 5.661 | −6.086 | 415.227 | 0.962 |

| LP0.2fc | 4.659 | −4.007 | 53.253 | 0.975 |

| LP0.4fc | 6.018 | −5.432 | 217.341 | 0.989 |

| LP0.6fc | 5.092 | −4.076 | 54.396 | 0.986 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, J.; Cheng, S.; Chen, H.; Zhang, H.; Zhao, Y.; Zhang, G.; Gong, F. Examination of Damage Evolution in Slurry Masonry Schist Subjected to Biaxial Compressive Stresses. Buildings 2024, 14, 1942. https://doi.org/10.3390/buildings14071942

Dong J, Cheng S, Chen H, Zhang H, Zhao Y, Zhang G, Gong F. Examination of Damage Evolution in Slurry Masonry Schist Subjected to Biaxial Compressive Stresses. Buildings. 2024; 14(7):1942. https://doi.org/10.3390/buildings14071942

Chicago/Turabian StyleDong, Jie, Siwu Cheng, Hongyun Chen, Hongfeng Zhang, Yadong Zhao, Guoxiang Zhang, and Fengwu Gong. 2024. "Examination of Damage Evolution in Slurry Masonry Schist Subjected to Biaxial Compressive Stresses" Buildings 14, no. 7: 1942. https://doi.org/10.3390/buildings14071942

APA StyleDong, J., Cheng, S., Chen, H., Zhang, H., Zhao, Y., Zhang, G., & Gong, F. (2024). Examination of Damage Evolution in Slurry Masonry Schist Subjected to Biaxial Compressive Stresses. Buildings, 14(7), 1942. https://doi.org/10.3390/buildings14071942