Tensile-to-Shear Crack Transition in the Compression Failure of Steel-Fibre-Reinforced Concrete: Insights from Acoustic Emission Monitoring

Abstract

1. Introduction

2. Experimental Setup

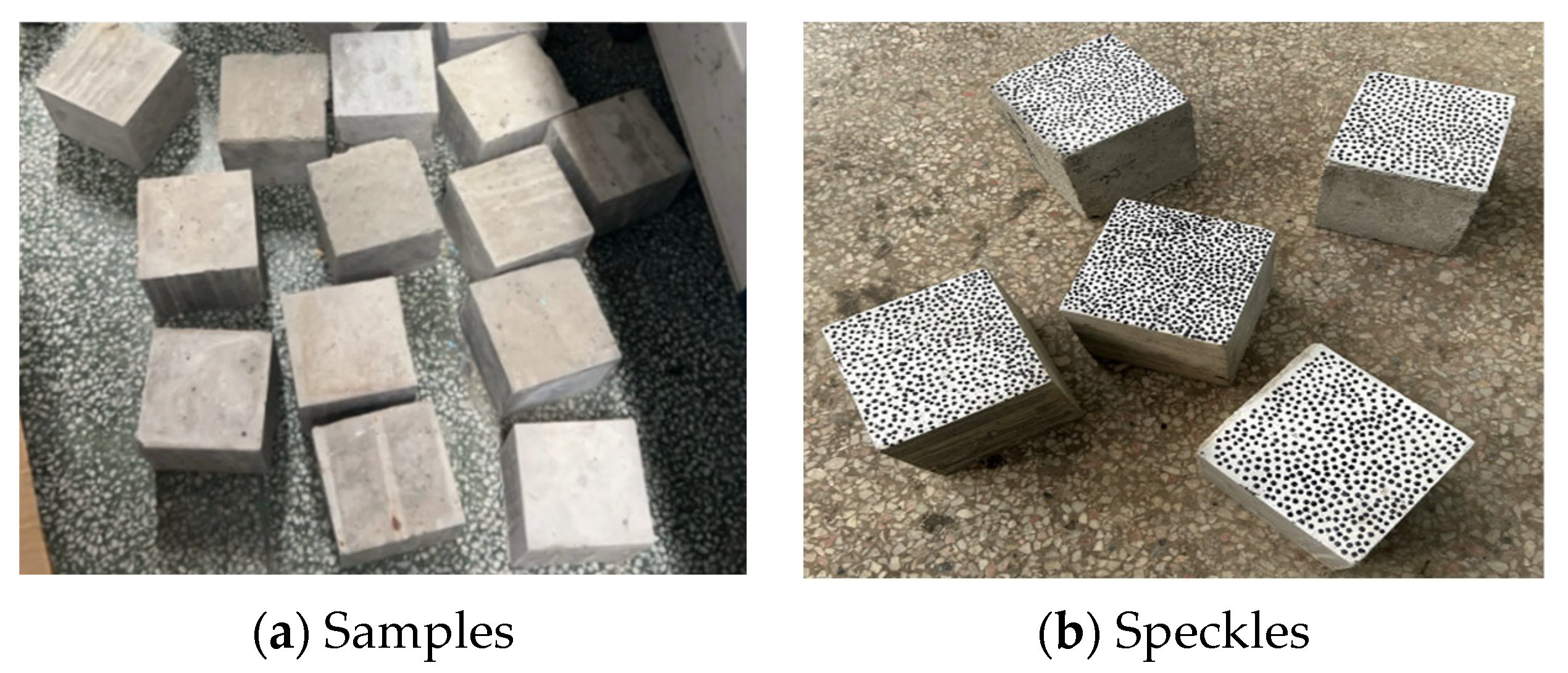

2.1. Sample Preparation

2.2. Testing System

2.3. AE Analysis

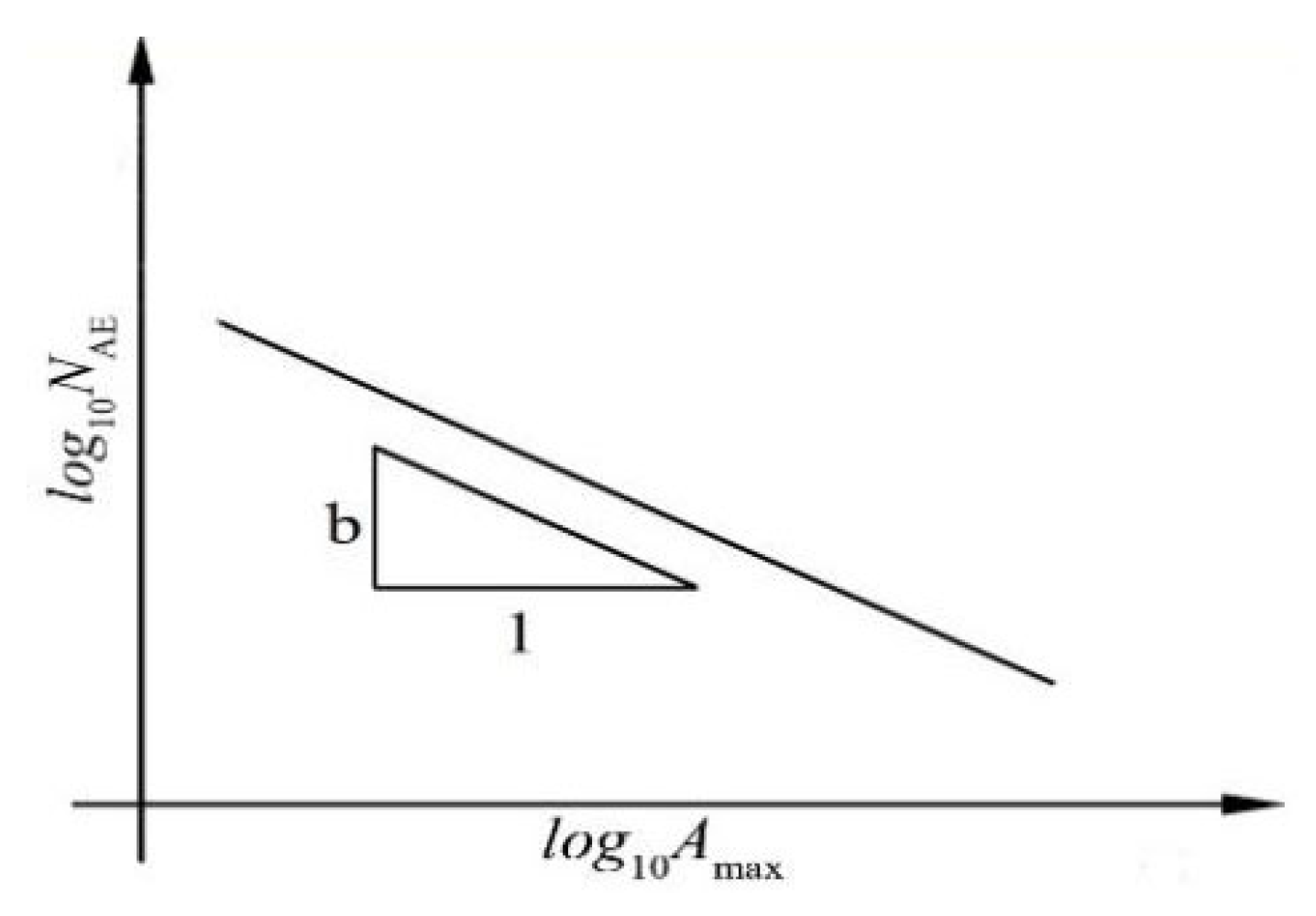

2.3.1. βt and b-Value

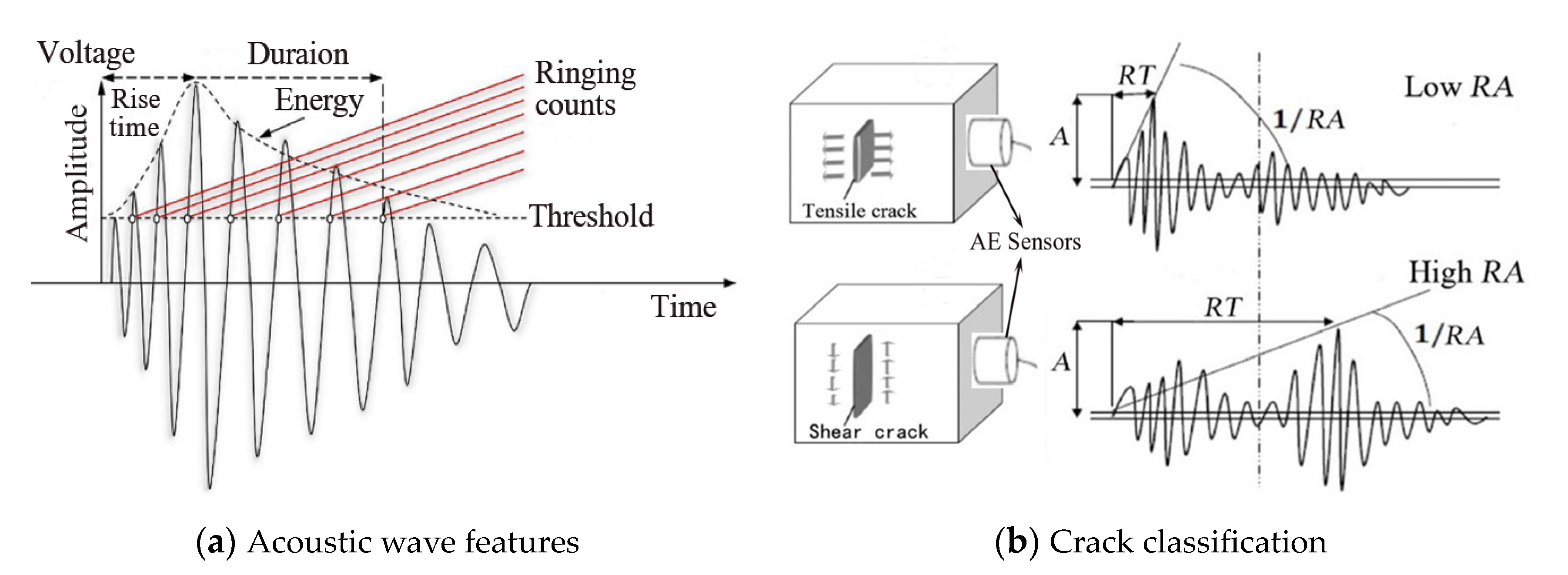

2.3.2. AF and RA

3. Experimental Observations

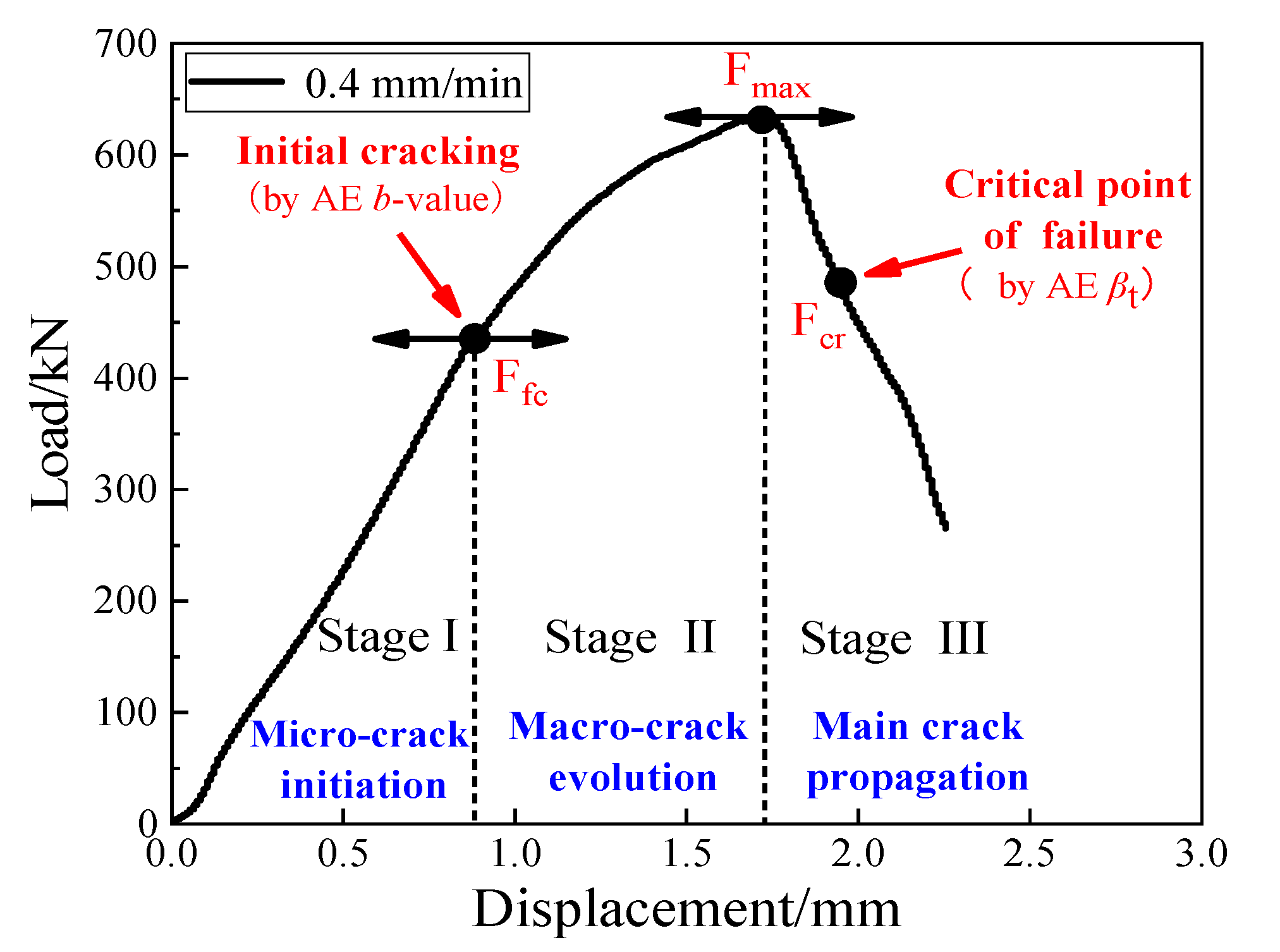

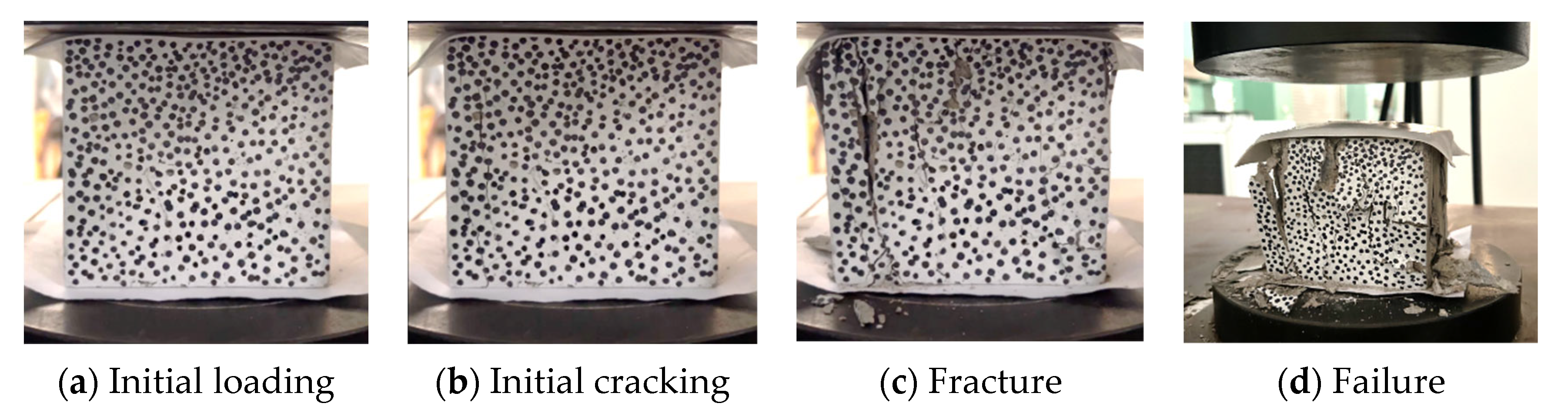

3.1. Damage Stages and Thresholds

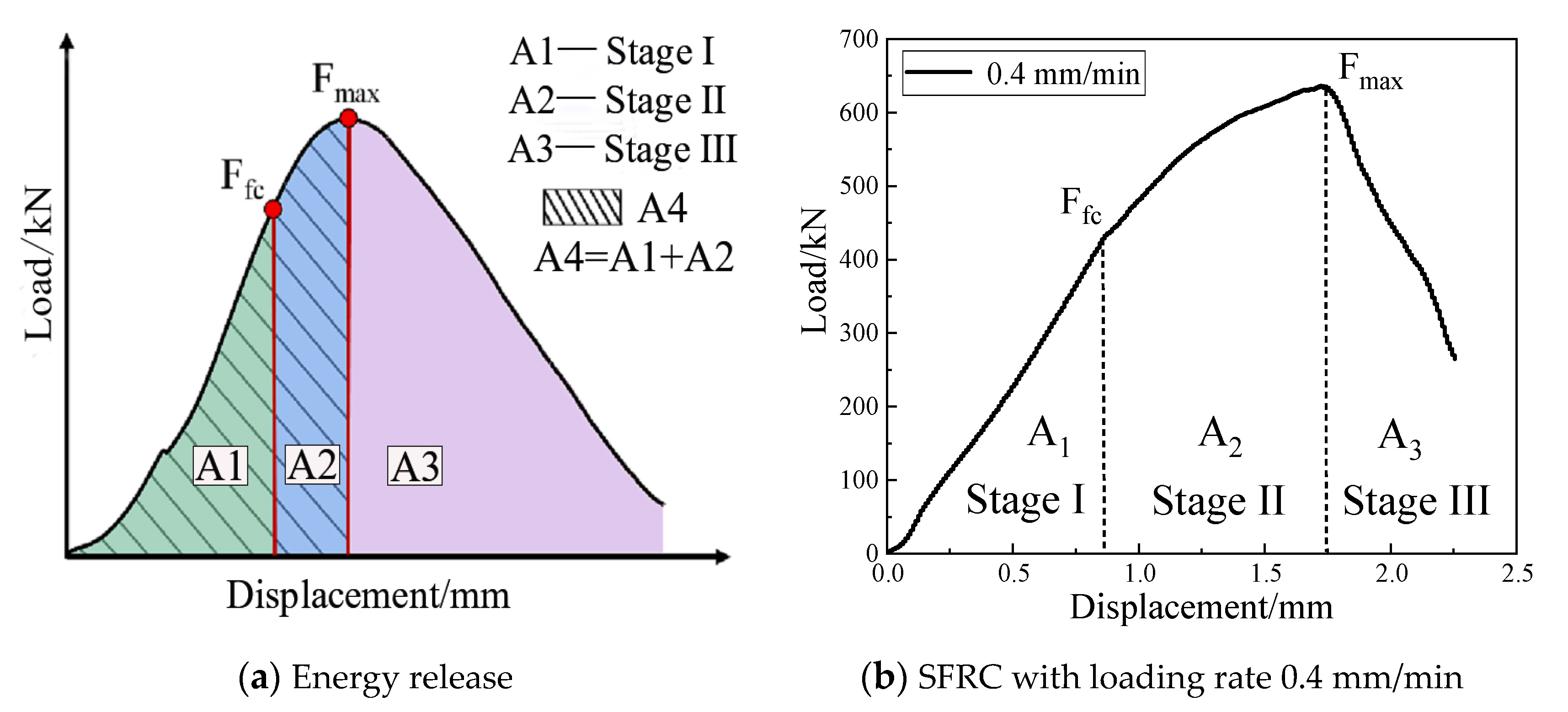

3.2. Compressive Toughness Index (CTI)

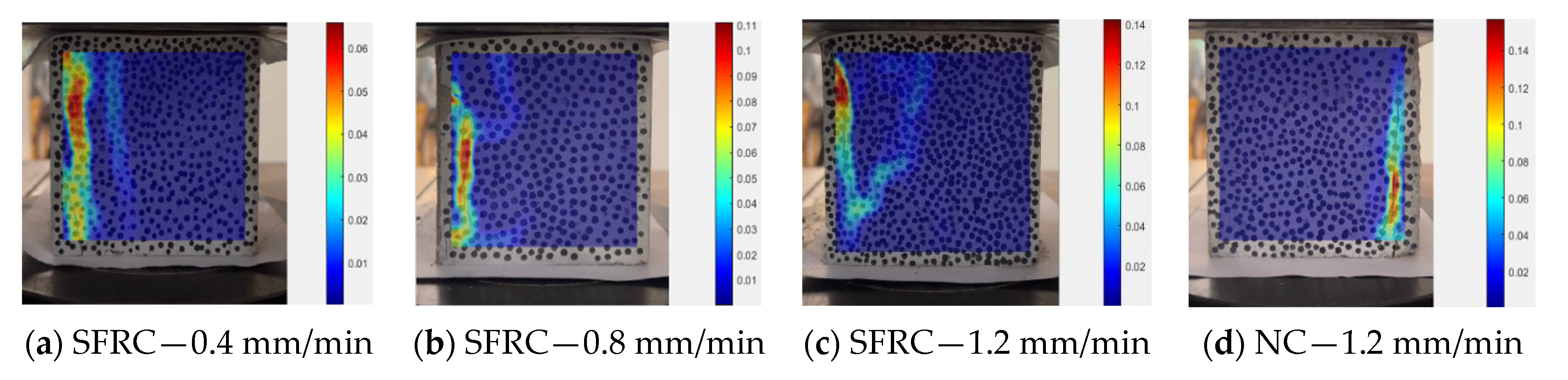

3.3. DIC Monitoring

4. AE Monitoring Results

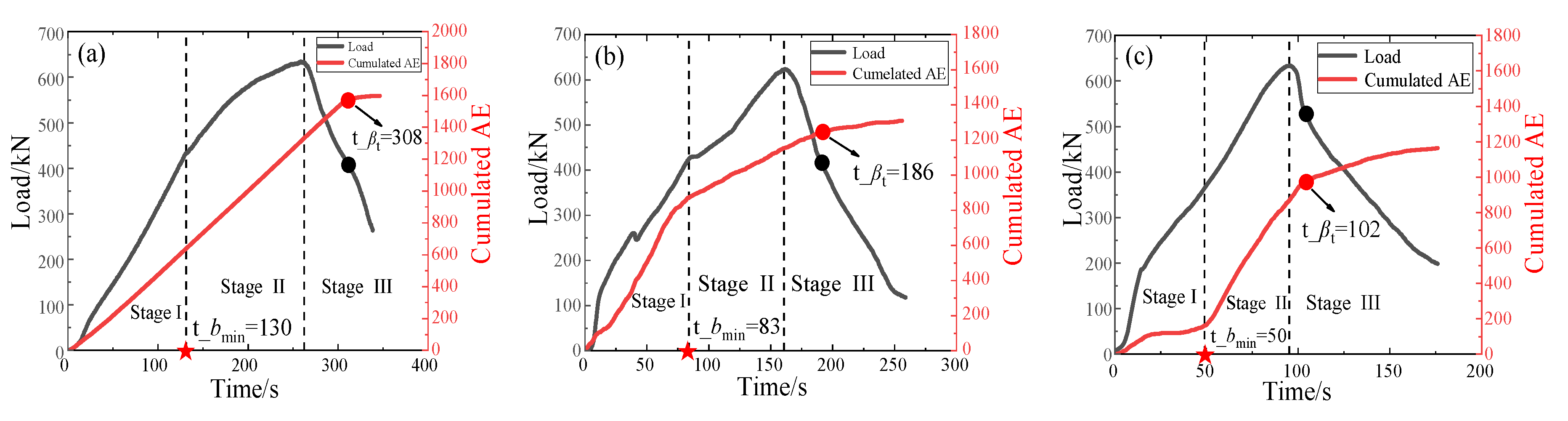

4.1. βt and b-Values

4.2. Cumulated AE and Loading History

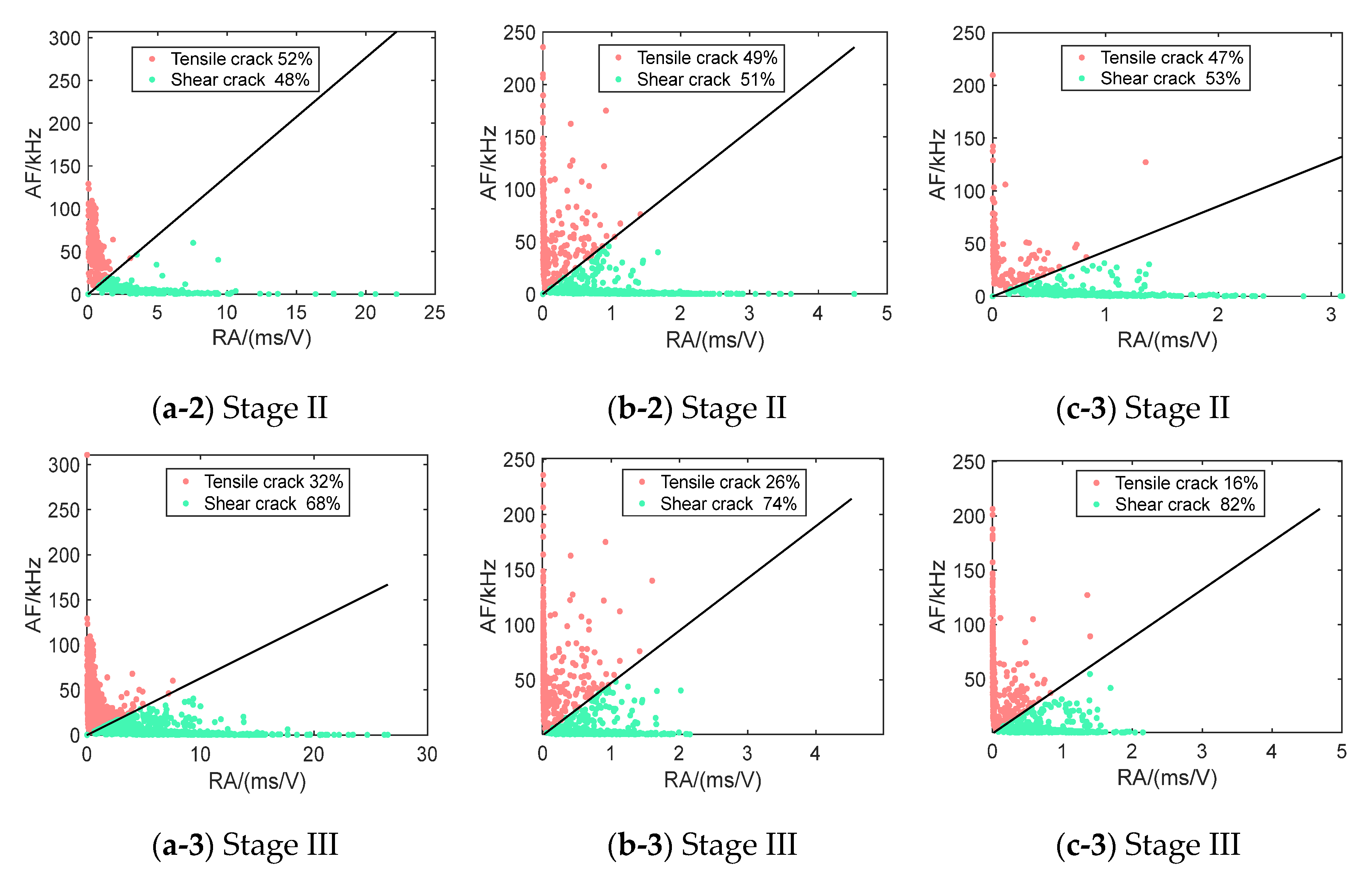

4.3. Crack Mechanisms Analysed by AF and RA

5. Failure Mechanisms

6. Conclusions

- (1)

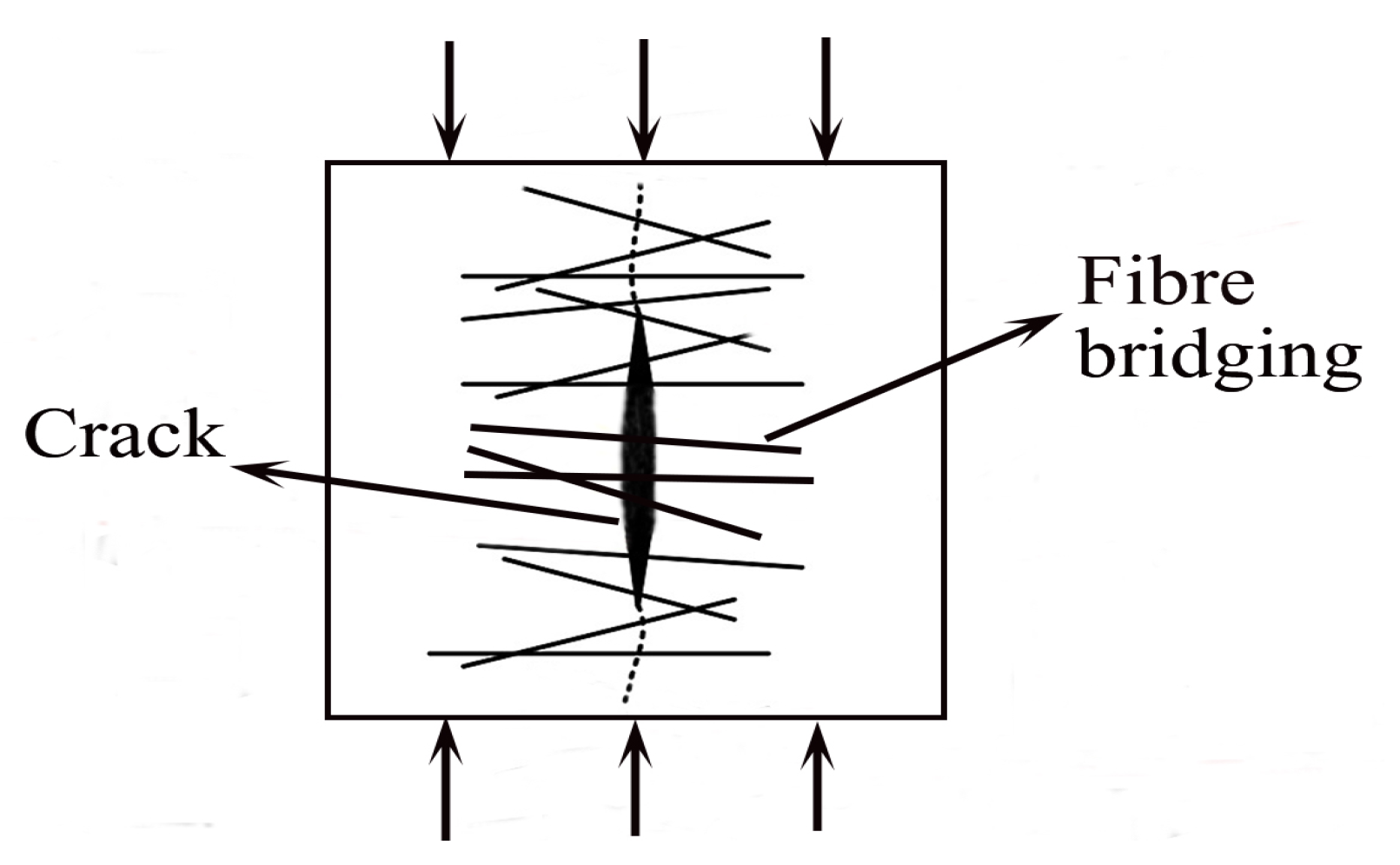

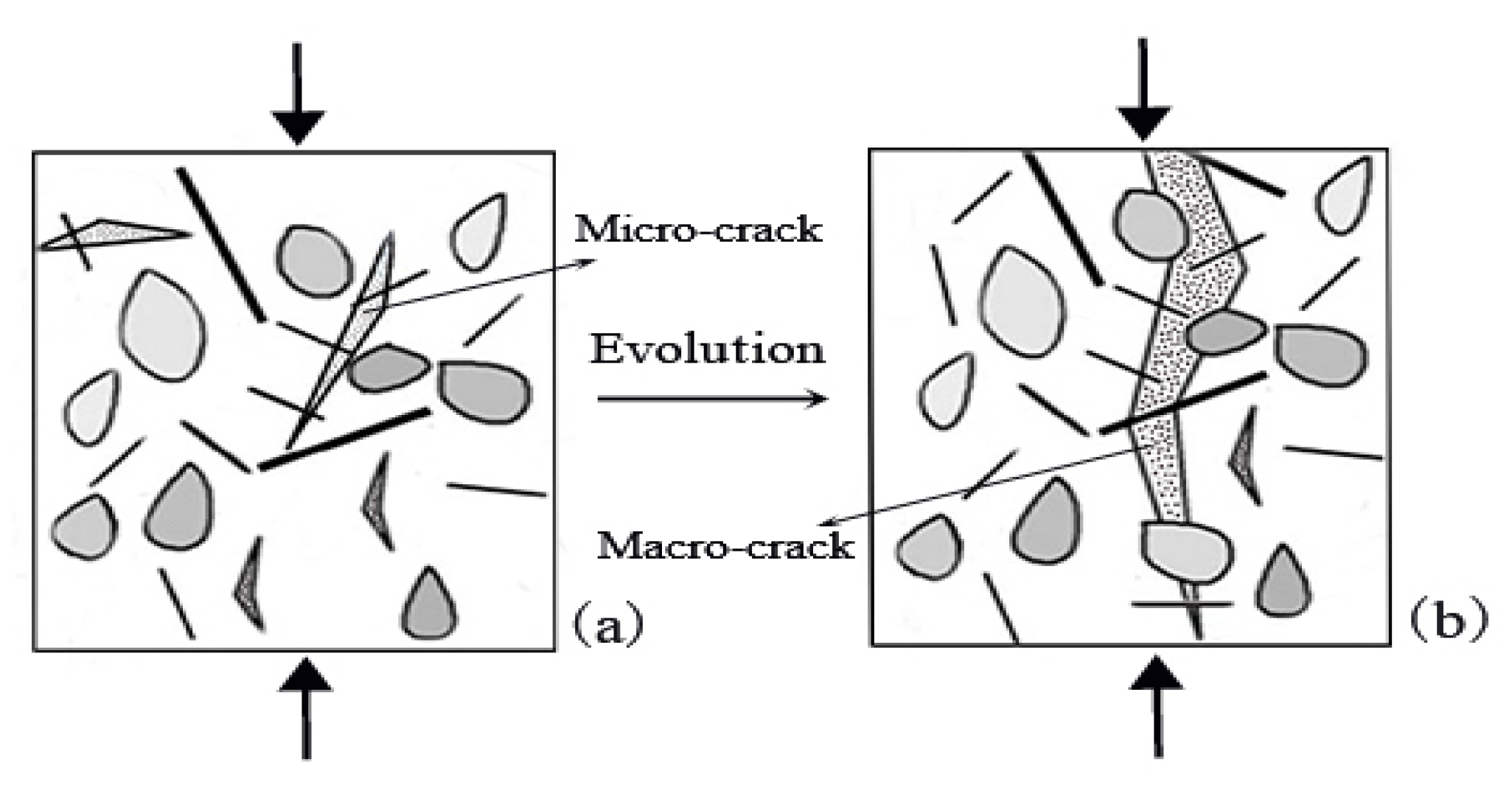

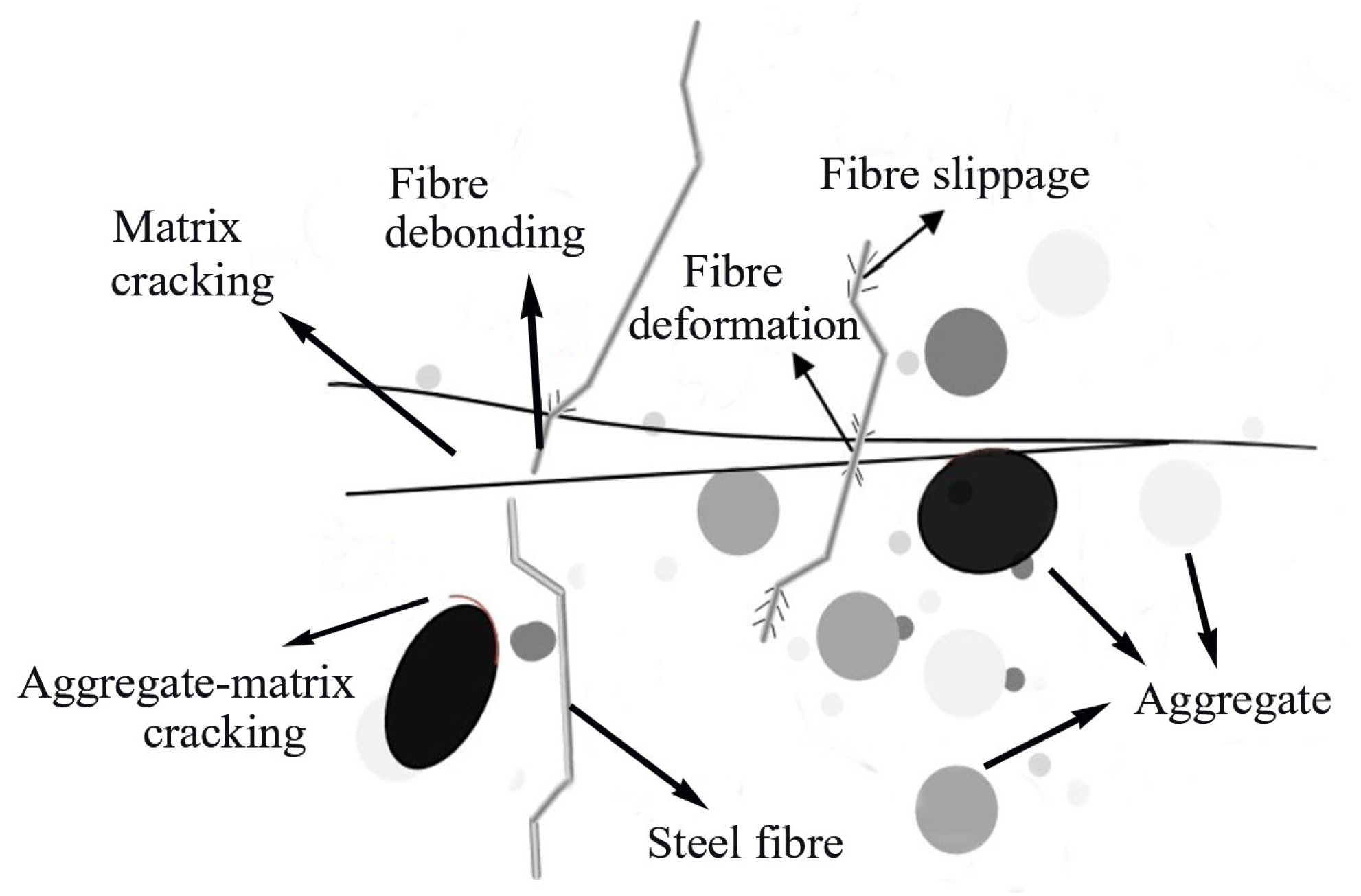

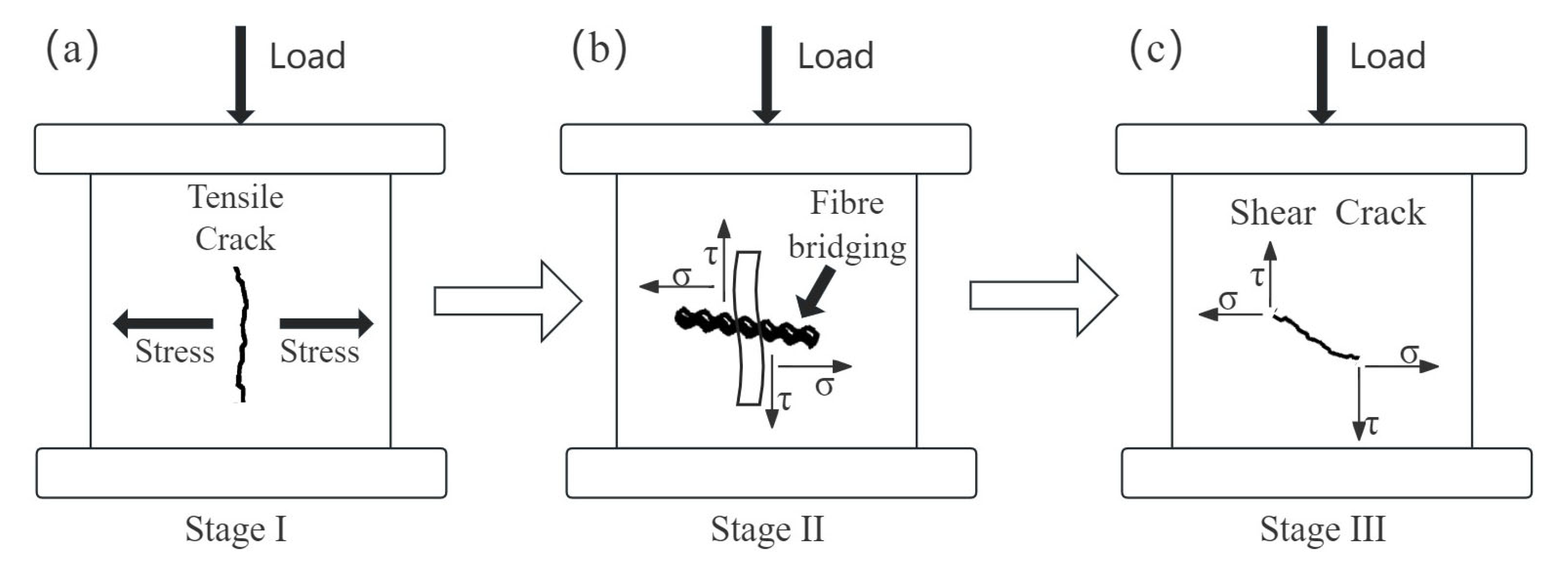

- In the early fracturing stage, fibres did not exert their toughening effects, with the AE signals originating from the matrix and aggregate–matrix interface cracking. In the intermediate stage, as macro-cracks extend, fibres begin to restrain the crack propagation, whereas AE arises from the fibre debonding. In the final stage, the fibre bridging action prevents large-scale fracture surfaces, with AE originating from fibre slippage or pull-out.

- (2)

- The Compressive Toughness Index serves as a damage parameter to assess the impact of fibres on the toughness of the concrete matrix. The toughness of SFRC is influenced by the loading rate, where high loading rates lead to relatively brittle fracturing, whereas low loading rates allow the samples to release energy in a more ductile way.

- (3)

- DIC monitoring reveals that SFRC exhibits better integrity compared to NC when damaged, shifting from brittle to ductile behaviour. SFRC cracks display dense and slender morphology, whereas NC presents a single vertical crack with a larger width. As the loading rate increases, the dominant cracks in SFRC shift from tensile to shear, accompanied by large transverse deformations.

- (4)

- AE b-value can determine the exact time of initial cracking in SFRC, whereas βt can determine the occurrence of unstable fracturing process. As the loading rate increases, the regression curve of the b-value shows a downward trend, revealing unstable crack propagation.

- (5)

- The fibre bridging action facilitates the shift from tensile to shear cracks, thus becoming the main cause of SFRC failure. AF and RA analysis describes a progressive tensile-to-shear crack transition. Since the quantity of shear cracks significantly increases before SFRC failure, this can serve as a safety warning. As the loading rate increases, there is a corresponding increase in the quantity of shear cracks, leading to a decrease in the overall ductility and toughness of SFRC.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Accornero, F.; Rubino, A.; Carpinteri, A. Post-cracking regimes in the flexural behaviour of fibre-reinforced concrete beams. Int. J. Solids Struct. 2022, 248, 111637. [Google Scholar] [CrossRef]

- Accornero, F.; Rubino, A.; Carpinteri, A. Ultra-low cycle fatigue (ULCF) in fibre-reinforced concrete beams. Theor. Appl. Fract. Mech. 2022, 120, 103392. [Google Scholar] [CrossRef]

- Zhou, M.; He, X.; Wang, H.; Wu, C.; He, J. Mesoscale modeling of polypropylene fiber reinforced concrete under split tension using discrete element method. Constr. Build. Mater. 2023, 404, 133274. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, J.-J.; Park, J.-J. Effect of fiber spacing on dynamic pullout behavior of multiple straight steel fibers in ultra-high-performance concrete. Constr. Build. Mater. 2019, 210, 461–472. [Google Scholar] [CrossRef]

- Zheng, Q.; Li, C.; He, B.; Jiang, Z. Revealing the effect of silica fume on the flexural behavior of ultra-high-performance fiber-reinforced concrete by acoustic emission technique. Cem. Concr. Compos. 2022, 131, 104563. [Google Scholar] [CrossRef]

- Han, Q.; Yang, G.; Xu, J.; Fu, Z.; Lacidogna, G.; Carpinteri, A. Acoustic emission data analyses based on crumb rubber concrete beam bending tests. Eng. Fract. Mech. 2019, 210, 189–202. [Google Scholar] [CrossRef]

- Lacidogna, G.; Piana, G.; Accornero, F.; Carpinteri, A. Multi-technique damage monitoring of concrete beams: Acoustic Emission, Digital Image Correlation, Dynamic Identification. Constr. Build. Mater. 2020, 242, 118114. [Google Scholar] [CrossRef]

- Li, W.; Jiang, Z.; Yu, Q. Multiple damaging and self-healing properties of cement paste incorporating microcapsules. Constr. Build. Mater. 2020, 255, 119302. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Accornero, F. Fluctuations of 1/f Noise in Damaging Structures Analyzed by Acoustic Emission. Appl. Sci. 2018, 8, 1685. [Google Scholar] [CrossRef]

- Aggelis, D.G. Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Commun. 2011, 38, 153–157. [Google Scholar] [CrossRef]

- Aggelis, D.; Mpalaskas, A.; Matikas, T. Investigation of different fracture modes in cement-based materials by acoustic emission. Cem. Concr. Res. 2013, 48, 1–8. [Google Scholar] [CrossRef]

- Rasheed, M.A.; Prakash, S.S.; Raju, G.; Kawasaki, Y. Fracture studies on synthetic fiber reinforced cellular concrete using acoustic emission technique. Constr. Build. Mater. 2018, 169, 100–112. [Google Scholar] [CrossRef]

- Golewski, G.L. Measurement of fracture mechanics parameters of concrete containing fly ash thanks to use of Digital Image Correlation (DIC) method. Measurement 2019, 135, 96–105. [Google Scholar] [CrossRef]

- Huang, Z.; Tu, Y.; Meng, S.; Sabau, C.; Popescu, C.; Sas, G. Experimental study on shear deformation of reinforced concrete beams using digital image correlation. Eng. Struct. 2018, 181, 670–698. [Google Scholar] [CrossRef]

- Bello, I.; González-Fonteboa, B.; Wardeh, G.; Martínez-Abella, F. Characterization of concrete behavior under cyclic loading using 2D digital image correlation. J. Build. Eng. 2023, 78, 107709. [Google Scholar] [CrossRef]

- Liu, J.; Kanwal, H.; Tang, C.; Hao, W. Study on flexural properties of 3D printed lattice-reinforced concrete structures using acoustic emission and digital image correlation. Constr. Build. Mater. 2022, 333, 127418. [Google Scholar] [CrossRef]

- Andrushia, A.D.; Lubloy, E. Deep learning based thermal crack detection on structural concrete exposed to elevated temperature. Adv. Struct. Eng. 2021, 24, 1896–1909. [Google Scholar] [CrossRef]

- Meng, K.; Xu, L.; Chi, Y. Experimental investigation on the mechanical behavior of hybrid steel-polypropylene fiber reinforced concrete under conventional triaxial cyclic compression. Constr. Build. Mater. 2021, 291, 123262. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Fu, J.; Zhu, N.; Chen, D.; Wang, Y.; Ding, S. Experimental study on compressive behavior and failure characteristics of imitation steel fiber concrete under uniaxial load. Constr. Build. Mater. 2023, 399, 132599. [Google Scholar] [CrossRef]

- Ren, H.; Li, T.; Ning, J.; Song, S. Analysis of damage characteristics of steel fiber-reinforced concrete based on acoustic emission. Eng. Fail. Anal. 2023, 148, 107166. [Google Scholar] [CrossRef]

- Li, B.; Xu, L.; Shi, Y.; Chi, Y.; Liu, Q.; Li, C. Effects of fiber type, volume fraction and aspect ratio on the flexural and acoustic emission behaviors of steel fiber reinforced concrete. Constr. Build. Mater. 2018, 181, 474–486. [Google Scholar] [CrossRef]

- Xu, J.; Houndehou, J.D.; Wang, Z.; Ma, Q. Experimental investigation on the mechanical properties and damage evolution of steel-fiber-reinforced crumb rubber concrete with porcelain tile waste. Constr. Build. Mater. 2023, 370, 130643. [Google Scholar] [CrossRef]

- Cai, B.; Li, K.; Fu, F. Flexural behavior of steel fiber-reinforced coal gangue aggregate concrete beams. Structures 2023, 52, 131–145. [Google Scholar] [CrossRef]

- Boniface, A.; Saliba, J.; Sbartaï, Z.M.; Ranaivomanana, N.; Balayssac, J.P. Evaluation of the acoustic emission 3D localisation accuracy for the mechanical damage monitoring in concrete. Eng. Fract. Mech. 2020, 223, 106742. [Google Scholar] [CrossRef]

- Zhou, W.; Lv, Z.H.; Li, Z.Y.; Song, X. Acoustic emission response and micro-deformation behavior for compressive buckling failure of multi-delaminated composites. J. Strain Anal. Eng. Des. 2016, 51, 397–407. [Google Scholar] [CrossRef]

- Alam, S.; Loukili, A.; Grondin, F.; Rozière, E. Use of the digital image correlation and acoustic emission technique to study the effect of structural size on cracking of reinforced concrete. Eng. Fract. Mech. 2015, 143, 17–31. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Gao, Z.; Wang, F. A review on fracture properties of steel fiber reinforced concrete. J. Build. Eng. 2023, 67, 105975. [Google Scholar] [CrossRef]

- Cui, K.; Xu, L.; Tao, T.; Huang, L.; Li, J.; Hong, J.; Li, H.; Chi, Y. Mechanical behavior of multiscale hybrid fiber reinforced recycled aggregate concrete subject to uniaxial compression. J. Build. Eng. 2023, 71, 106504. [Google Scholar] [CrossRef]

- Rooholamini, H.; Hassani, A.; Aliha, M. Fracture properties of hybrid fibre-reinforced roller-compacted concrete in mode I with consideration of possible kinked crack. Constr. Build. Mater. 2018, 187, 248–256. [Google Scholar] [CrossRef]

- Li, N.; Jin, Z.; Long, G.; Chen, L.; Fu, Q.; Yu, Y.; Zhang, X.; Xiong, C. Impact resistance of steel fiber-reinforced self-compacting concrete (SCC) at high strain rates. J. Build. Eng. 2021, 38, 102212. [Google Scholar] [CrossRef]

- Nguyen, D.-L.; Lam, M.N.-T.; Kim, D.-J.; Song, J. Direct tensile self-sensing and fracture energy of steel-fiber-reinforced concretes. Compos. B Eng. 2020, 183, 107714. [Google Scholar] [CrossRef]

- Yin, Y.; Ren, Q.; Shen, L. Study on the effect of aggregate distribution on mechanical properties and damage cracks of concrete based on multifractal theory. Constr. Build. Mater. 2020, 262, 120086. [Google Scholar] [CrossRef]

- Lacidogna, G.; Manuello, A.; Niccolini, G.; Accornero, F.; Carpinteri, A. Acoustic emission wireless monitoring of structures. In Acoustic Emission and Related Non-Destructive Evaluation Techniques in the Fracture Mechanics of Concrete; Woodhead Publishing: Cambridge, UK, 2015; pp. 15–40. [Google Scholar]

- Colombo, I.S.; Main, I.G.; Forde, M.C. Assessing damage of reinforced concrete beam using “b-value” analysis of acoustic emission signals. J. Mater. Civ. Eng. 2003, 15, 280–286. [Google Scholar] [CrossRef]

- Carpinteri, A.; Xu, J.; Lacidogna, G.; Manuello, A. Reliable onset time determination and source location of acoustic emissions in concrete structures. Cem. Concr. Compos. 2012, 34, 529–537. [Google Scholar] [CrossRef]

- JCMS-III B5706; Monitoring Method for Active Cracks in Concrete by Acoustic Emission. Federation of Construction Materials Industries: Tokyo, Japan, 2003.

- Ohtsu, M. Recommendation of RILEM TC 212-ACD: Acoustic emission and related nde techniques for crack detection and damage evaluation in concrete: Test method for classification of active cracks in concrete by acoustic emission. Mater. Struct. 2010, 43, 1187–1189. [Google Scholar] [CrossRef]

- Noorsuhada, M. An overview on fatigue damage assessment of reinforced concrete structures with the aid of acoustic emission technique. Constr. Build. Mater. 2016, 112, 424–439. [Google Scholar] [CrossRef]

- Xu, J.; Niu, X.; Ma, Q.; Han, Q. Mechanical properties and damage analysis of rubber cement mortar mixed with ceramic waste aggregate based on acoustic emission monitoring technology. Constr. Build. Mater. 2021, 309, 125084. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Gashti, M.F. Effects of alkaline solution to binder ratio on fracture parameters of steel fiber reinforced heavyweight geopolymer concrete. Theor. Appl. Fract. Mech. 2021, 113, 102967. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Use of glass and nylon fibers in concrete for controlling early age micro cracking in bridge decks. Constr. Build. Mater. 2016, 125, 800–808. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J.; Xu, Z.; Li, S. Experimental study of compressive behavior of polypropylene-fiber-reinforced and polypropylene-fiber-fabric-reinforced concrete. Constr. Build. Mater. 2019, 194, 216–225. [Google Scholar] [CrossRef]

- Carpinteri, A.; Accornero, F. Multiple snap-back instabilities in progressive microcracking coalescence. Eng. Fract. Mech. 2018, 187, 272–281. [Google Scholar] [CrossRef]

- Lacidogna, G.; Accornero, F.; Carpinteri, A. Influence of snap-back instabilities on Acoustic Emission damage monitoring. Eng. Fract. Mech. 2019, 210, 3–12. [Google Scholar] [CrossRef]

- Jang, S.-J.; Yun, H.-D. Combined effects of steel fiber and coarse aggregate size on the compressive and flexural toughness of high-strength concrete. Compos. Struct. 2018, 185, 203–211. [Google Scholar] [CrossRef]

- Ran, J.; Li, T.; Chen, D.; Shang, L.; Li, W.; Zhu, Q. Mechanical properties of concrete reinforced with corrugated steel fiber under uniaxial compression and tension. Structures 2021, 34, 1890–1902. [Google Scholar] [CrossRef]

- Carpinteri, A.; Accornero, F. Residual crack opening in fibre-reinforced structural elements subjected to cyclic loading. Strength. Fract. Comp. 2020, 12, 63–74. [Google Scholar] [CrossRef]

- Carpinteri, A.; Accornero, F.; Rubino, A. Scale effects in the post-cracking behaviour of fibre-reinforced concrete beams. Int. J. Fract. 2023, 240, 1–16. [Google Scholar] [CrossRef]

| Component | Cement | Sand | Stone | Water | Steel Fibre | Carboxylate Water Reducer |

|---|---|---|---|---|---|---|

| Dosage | 480 | 713 | 1032 | 155 | 75 | 9.6 |

| Material | Compression Strength (MPa) | Elastic Modulus (GPa) | Flexural Strength (MPa) | Splitting Strength (MPa) |

|---|---|---|---|---|

| SFRC | 64.8 | 39.0 | 6.8 | 4.6 |

| Loading Rate | A1/(kN·mm) | A2/(kN·mm) | A4/(kN·mm) | CTI (A4/A1) |

|---|---|---|---|---|

| 0.4 mm/min | 173 | 492 | 665 | 3.84 |

| 0.8 mm/min | 210 | 490 | 700 | 3.33 |

| 1.2 mm/min | 275 | 489 | 764 | 2.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Z.; Zhu, Z.; Accornero, F. Tensile-to-Shear Crack Transition in the Compression Failure of Steel-Fibre-Reinforced Concrete: Insights from Acoustic Emission Monitoring. Buildings 2024, 14, 2039. https://doi.org/10.3390/buildings14072039

Jiang Z, Zhu Z, Accornero F. Tensile-to-Shear Crack Transition in the Compression Failure of Steel-Fibre-Reinforced Concrete: Insights from Acoustic Emission Monitoring. Buildings. 2024; 14(7):2039. https://doi.org/10.3390/buildings14072039

Chicago/Turabian StyleJiang, Zihan, Zhiwen Zhu, and Federico Accornero. 2024. "Tensile-to-Shear Crack Transition in the Compression Failure of Steel-Fibre-Reinforced Concrete: Insights from Acoustic Emission Monitoring" Buildings 14, no. 7: 2039. https://doi.org/10.3390/buildings14072039

APA StyleJiang, Z., Zhu, Z., & Accornero, F. (2024). Tensile-to-Shear Crack Transition in the Compression Failure of Steel-Fibre-Reinforced Concrete: Insights from Acoustic Emission Monitoring. Buildings, 14(7), 2039. https://doi.org/10.3390/buildings14072039