Investigation of the Temperature Distribution and Energy Consumption of an Integrated Carbon Fiber Paper-Embedded Electric-Heated Floor

Abstract

1. Introduction

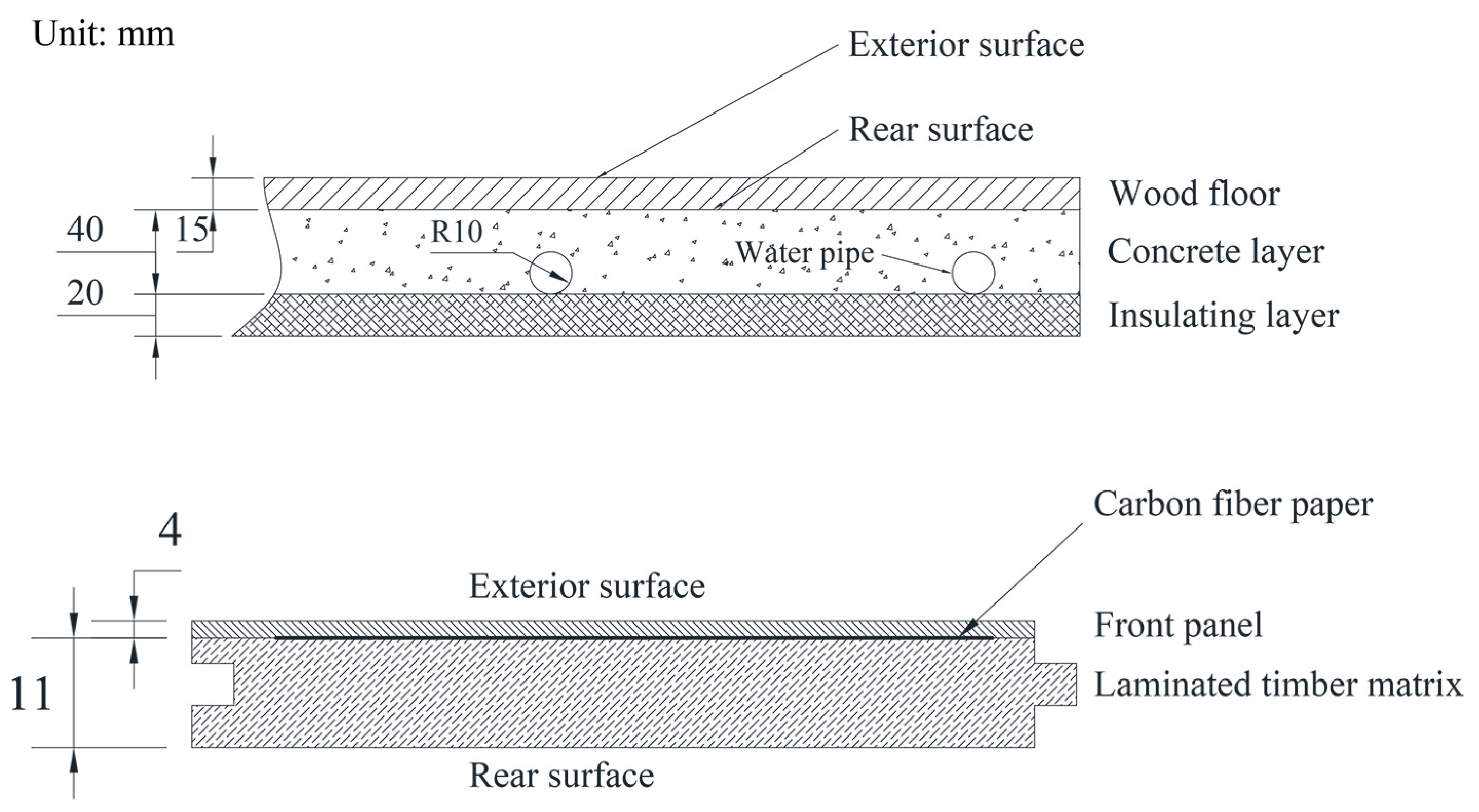

2. Materials and Methods

2.1. Materials

2.2. Methods of Preparing Integrated Electric Floor and Test Room

2.3. Methods of Temperature Distribution Test

2.4. Methods of Energy Consumption Computation

3. Results

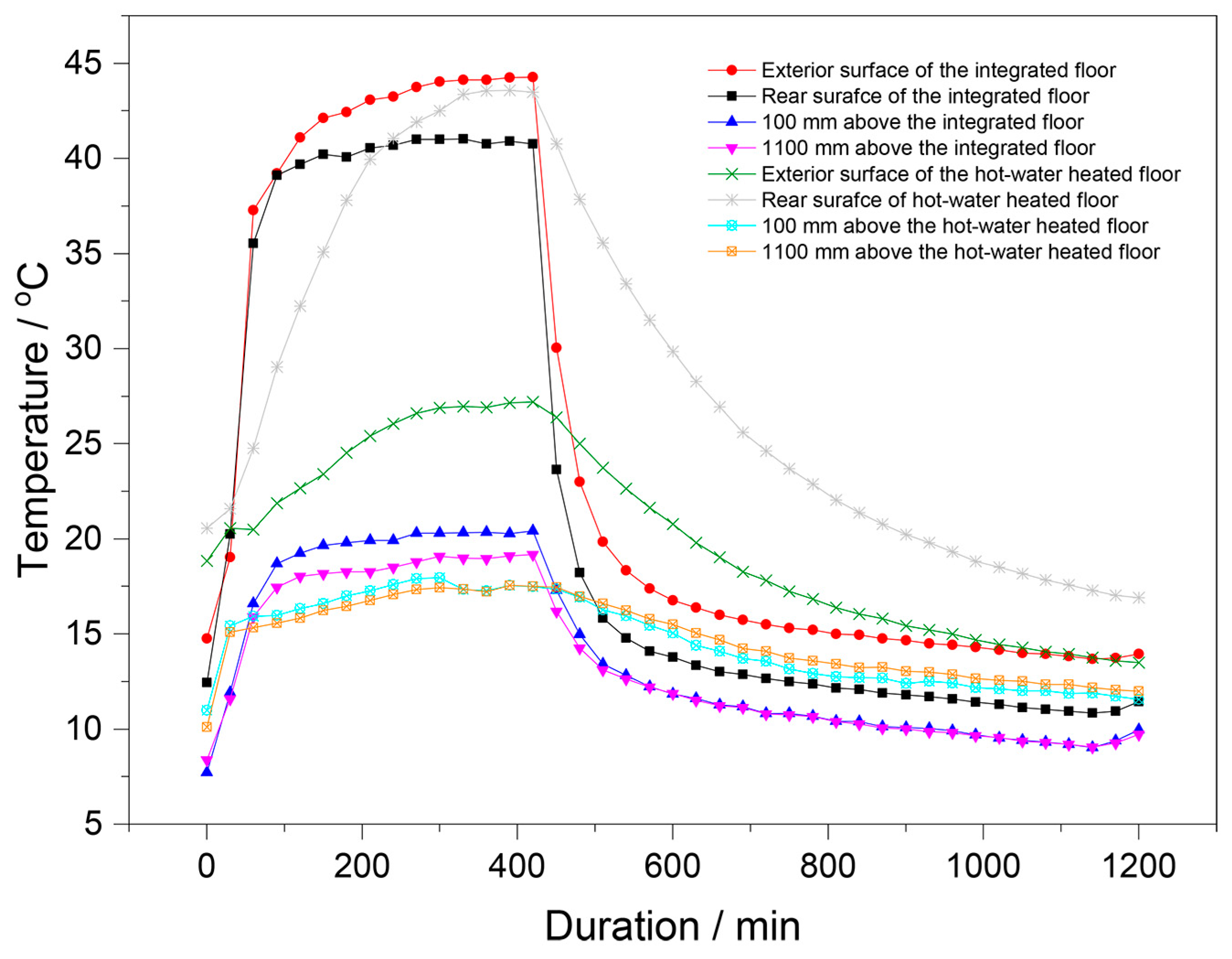

3.1. Temperature Distribution

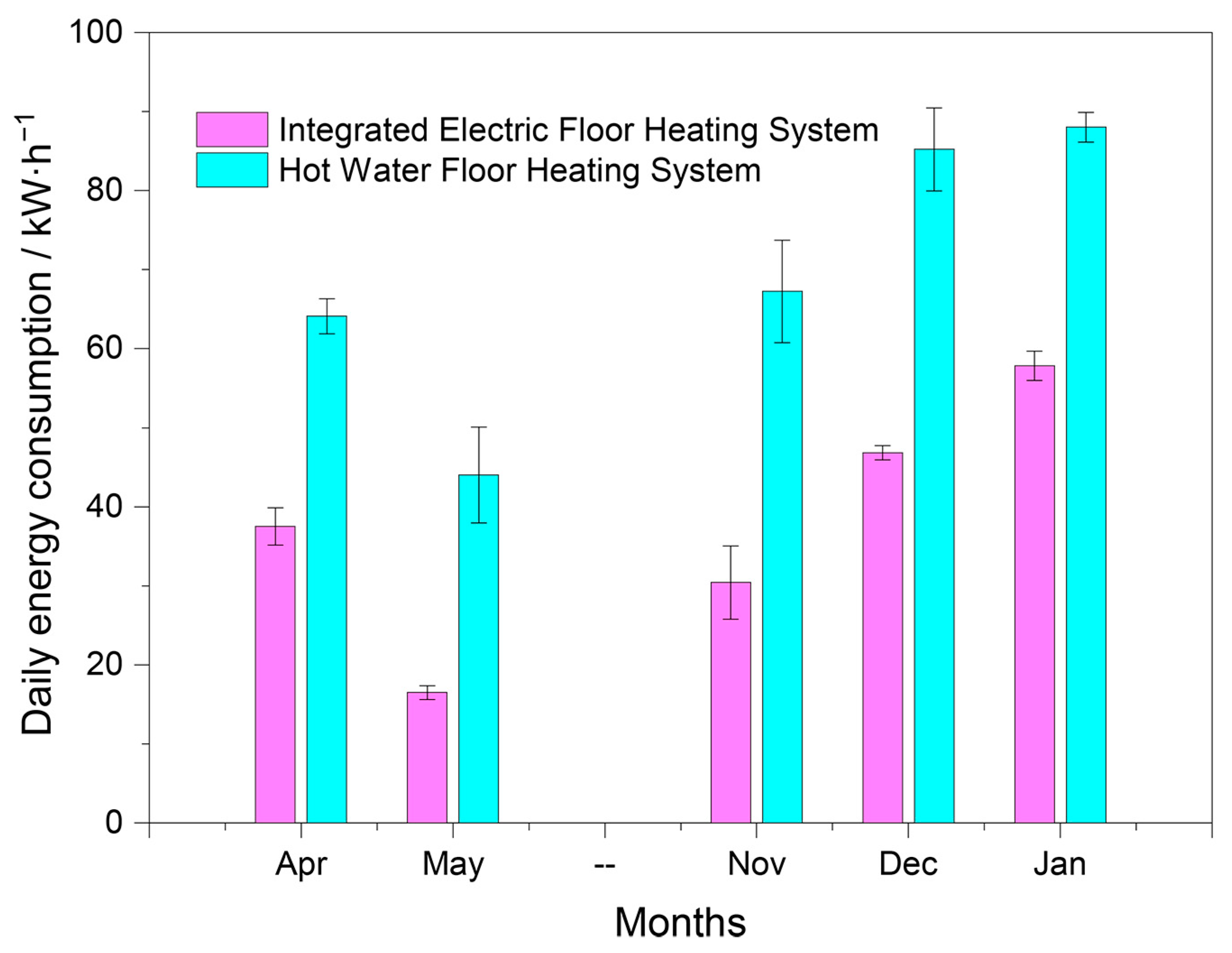

3.2. Energy Consumption

4. Discussion

4.1. Temperature Distribution

4.2. Energy Consumption

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Area, m2 |

| c | Energy utilization rate |

| Gr | Grashor number |

| htot | Total heat transfer rate, W m−2 K−1 |

| hc | Convective heat transfer coefficient, Wm−2 K−1 |

| hr | Radiant heat transfer coefficient, W m−2 K−1 |

| Nu | Nusselt number |

| Pr | Prandtl number |

| T | Time, h |

| t | Temperature, °C |

| W | Electric power, kW h−1 |

| Greek symbols | |

| Φ | Energy, W |

| η | Heat efficiency |

| ε | Floor surface emissivity |

| σ | Stefan–Boltzmann constant, W m−2 K−4 |

| υ | Kinematic viscosity of air, m2 s−1 |

| αV | Coefficient of cubical expansion of air, m2 s−1 |

| α | Thermal diffusivity of air, m2 s−1 |

| λ | Thermal conductivity of air, W m−1 K−1 |

| ι | Characteristic length |

| Subscripts | |

| s | Wooden floor surface |

| a | Indoor air |

| l | Heat loss |

References

- Ji, P.; Rhoads, W.J.; Edwards, M.A.; Pruden, A. Impact of water heater temperature setting and water use frequency on the building plumbing microbiome. ISME J. 2017, 11, 1318–1330. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q. Comfort and energy consumption analysis in buildings with radiant panels. Energy Build. 1990, 14, 287–297. [Google Scholar] [CrossRef]

- Fabrizio, E.; Corgnati, S.P.; Causone, F.; Filippi, M.D. Numerical comparison between energy and comfort performances of radiant heating and cooling systems versus air systems. HVAC&R Res. 2012, 18, 692–708. [Google Scholar]

- Leivo, V.; Prasauskas, T.; Du, L.; Turunen, M.; Kiviste, M.; Aaltonen, A.; Martuzevicius, D.; Haverinen-Shaughnessy, U. Indoor thermal environment, air exchange rates, and carbon dioxide concentrations before and after energy retro fits in Finnish and Lithuanian multi-family buildings. Sci. Total Environ. 2018, 621, 398–406. [Google Scholar] [CrossRef] [PubMed]

- MacNaughton, P.; Cao, X.; Buonocore, J.; Cedeno-Laurent, J.; Spengler, J.; Bernstein, A.; Allen, J. Energy savings, emission reductions, and health co-benefits of the green building movement. J. Expo. Sci. Environ. Epidemiol. 2018, 28, 307–318. [Google Scholar] [CrossRef]

- Bojić, M.; Cvetković, D.; Marjanović, V.; Blagojević, M.; Djordjević, Z. Performances of low temperature radiant heating systems. Energy Build. 2013, 61, 233–238. [Google Scholar] [CrossRef]

- Zhang, L.; Cao, B. Design and analysis of a floor radiant heating system based on energy substitution technology. Appl. Sci. 2018, 8, 491. [Google Scholar] [CrossRef]

- Bean, R.; Olesen, B.W.; Kim, K.W. Part 1 History of Radiant Heating & Cooling Systems. Ashrae J. 2010, 52, 40–47. [Google Scholar]

- Bean, R.; Olesen, B.W.; Kim, K.W. Part 2 History of Radiant Heating & Cooling Systems. Ashrae J. 2010, 52, 50–55. [Google Scholar]

- Roberts, W.J.; Mears, D.R.; James, M.F. Floor Heating of Greenhouses. Acta Hortic. 1981, 259–268. [Google Scholar] [CrossRef]

- Cho, S.H.; Zaheer-uddin, M. An experimental study of multiple parameter switching control for radiant floor heating systems. Energy 1999, 24, 433–444. [Google Scholar] [CrossRef]

- Cho, S.H.; Zaheer-uddin, M. Predictive control of intermittently operated radiant floor heating systems. Energy Convers. Manag. 2003, 44, 1333–1342. [Google Scholar] [CrossRef]

- Hu, R.; Niu, J.L. A review of the application of radiant cooling & heating systems in Mainland China. Energy Build. 2012, 52, 11–19. [Google Scholar]

- Qi, H.B.; He, F.Y.; Wang, Q.S.; Li, D.; Lin, L. Simulation Analysis of Heat Transfer on Low Temperature Hot-Water Radiant Floor Heating and Electrical Radiant Floor Heating. Appl. Mech. Mater. 2012, 204–208, 4234–4238. [Google Scholar] [CrossRef]

- Armstrong, T.B. Wire Mesh Floor Heating Systems. IEEE Trans. Ind. Appl. 1978, IA-14, 498–505. [Google Scholar] [CrossRef]

- Jeong, Y.-S.; Jung, H.-K. Thermal Performance Analysis of Reinforced Concrete Floor Structure with Radiant Floor Heating System in Apartment Housing. Adv. Mater. Sci. Eng. 2015, 2015, 1–7. [Google Scholar] [CrossRef]

- Obata, Y.; Takeuchi, K.; Kawazoe, M.; Kanayama, K. Design of Functionally Graded Wood-Based Board for Floor Heating System with Higher Energy Efficiency. Mater. Sci. Forum 2003, 423–425, 819–824. [Google Scholar] [CrossRef]

- Yan, Q.Y.; Jin, L.L. Numerical Simulation of the Thermal Performance of Cable Radiant Heating Floors with Different Structure. Adv. Mater. Res. 2012, 512–515, 3047–3050. [Google Scholar] [CrossRef]

- Thieblemont, H.; Haghighat, F.; Moreau, A. Thermal Energy Storage for Building Load Management: Application to Electrically Heated Floor. Appl. Sci. 2016, 6, 194. [Google Scholar] [CrossRef]

- Fontana, L. Thermal performance of radiant heating floors in furnished enclosed spaces. Appl. Therm. Eng. 2011, 31, 1547–1555. [Google Scholar] [CrossRef]

- Kim, T.; Chung, D.D.L. Carbon fiber mats as resistive heating elements. Carbon 2003, 41, 2436–2440. [Google Scholar] [CrossRef]

- Shi, Y.Z.; Wang, B. Mechanical properties of carbon fiber/cellulose composite papers modified by hot-melting fibers. Prog. Nat. Sci.-Mater. 2014, 24, 56–60. [Google Scholar] [CrossRef]

- Li, H.B.; Fang, G.G.; Deng, Y.J.; Shen, K.Z.; Shi, Y.Q.; Ding, L.B.; Han, S.M.; Jiao, J. The preparation of carbon fiber paper and its formation characterization. China Pulp Pap. Ind. 2015, 36, 6–9. (In Chinese) [Google Scholar]

- Jabbour, L.; Chaussy, D.; Eyraud, B.; Beneventi, D. Highly conductive graphite/carbon fiber/cellulose composite papers. Compos. Sci. Technol. 2012, 72, 616–623. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, L.; Lan, X.Z.; Zhang, Q.L.; Chen, X.Y.; Zhao, X.C. Research on Electrothermal Properties of a Composite Carbon Fiber Paper. Mater. Sci. Forum 2012, 724, 420–424. [Google Scholar] [CrossRef]

- Yang, L.; Cheng, S.; Ding, Y.; Zhu, X.; Wang, Z.L.; Liu, M. Hierarchical network architectures of carbon fiber paper supported cobalt oxide nanonet for high-capacity pseudo-capacitors. Nano Lett. 2012, 12, 321–325. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Shen, Z. Carbon fiber paper for fuel cell electrode. Fuel 2002, 81, 2199–2201. [Google Scholar] [CrossRef]

- Kong, D.; Wang, H.; Lu, Z.; Cui, Y. CoSe2 Nanoparticles Grown on Carbon Fiber Paper: An Efficient and Stable Electrocatalyst for Hydrogen Evolution Reaction. J. Am. Chem. Soc. 2014, 136, 4897–4900. [Google Scholar] [CrossRef]

- Song, J.B.; Yuan, Q.; Liu, X.; Wang, D.; Fu, F.; Yang, W. Combination of Nitrogen Plasma Modification and Waterborne Polyurethane Treatment of Carbon Fiber Paper Used for Electric Heating of Wood Floors. BioResources 2015, 10, 5820–5829. [Google Scholar] [CrossRef]

- Song, J.B.; Hu, H.B.; Zhang, M.X.; Huang, B.; Yuan, Z.H. Thermal Aging Properties and Electric Heating Behaviors of Carbon Fiber Paper-based Electric Heating Wood Floors. Bioresources 2017, 12, 9466–9475. [Google Scholar] [CrossRef]

- Huang, C.J.; Bao, Y.J.; Li, N.; Xiao, R.C.; Wu, Z.X.; Chen, Y.H. Adhesives used to make bamboo/wood composite electro-thermal plywood. J. Zhejiang A&F Univ. 2017, 34, 369–373. (In Chinese) [Google Scholar]

- Xiao, R.C.; Chen, Y.H.; Bao, Y.J.; Huang, C.J. Electrifying Aging Performance of Bamboo-wood Thermoelectric Composites. China Wood Industry 2017, 31, 19–23. (In Chinese) [Google Scholar]

- Yuan, Q.P.; Fu, F. Application of Carbon Fiber Paper in Integrated Wooden Electric Heating Composite. BioResources 2014, 9, 5662–5675. [Google Scholar] [CrossRef]

- Bao, Y.J.; Huang, C.J.; Chen, Y.H.; Dai, Y.P. Longitudinal scale effect of electro-thermal effectiveness of front panel of the integrated wooden electric heating composite based on carbon fiber paper. Acta Mater. Compos. Sin. 2020, 37, 3214–3219. (In Chinese) [Google Scholar]

- ANSI/ASHRAE Standard 55-2013; Standard 55-2013 User’s Manual: Thermal Environmental Conditions for Human Occupancy. ASHRAE Research: Atlanta, GA, USA, 2016.

- Yang, S.; Tao, W. Heat Transfer, 4th ed.; Higher Education Press: Beijing, China, 2006. (In Chinese) [Google Scholar]

- Zhou, G.; He, J. Thermal performance of a radiant floor heating system with different heat storage materials and heating pipes. Appl. Energy 2015, 138, 648–660. [Google Scholar] [CrossRef]

- Koca, A.; Gemici, Z.; Bedir, K.; Böke, E.; Kanbur, B.B.; Topaçoğlu, Y. Thermal Comfort Analysis of Novel Low Exergy Radiant Heating Cooling System and Energy Saving Potential Comparing to Conventional Systems. In Progress in Exergy, Energy, and the Environment; Springer: Berlin/Heidelberg, Germany, 2014; pp. 435–445. [Google Scholar]

| Parameters | g m s−2 | m2 s−1 | m2 s−1 | W m−1 K−1 | m |

|---|---|---|---|---|---|

| Value | 9.8 | 15.06 × 10−6 | 21.4 × 10−6 | 2.59 × 10−2 | 1.2 |

| Statistic | Integrated Electric-Heated Floor Test Room | Hot Water-Heated Floor Test Room | ||||||

|---|---|---|---|---|---|---|---|---|

| Exterior Surface | Rear Surface | 100 mm | 1100 mm | Exterior Surface | Rear Surface | 100 mm | 1100 mm | |

| M | 42.55 | 40.11 | 19.68 | 18.37 | 25.09 | 38.34 | 17.10 | 16.75 |

| SD | 2.17 | 1.49 | 1.05 | 0.90 | 2.29 | 6.23 | 0.68 | 0.78 |

| CV | 5.10% | 3.71% | 5.35% | 4.88% | 9.12% | 16.25% | 3.98% | 4.65% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.; Li, N.; He, S.; Weng, X.; Shu, Y.; Yang, G.; Bao, Y. Investigation of the Temperature Distribution and Energy Consumption of an Integrated Carbon Fiber Paper-Embedded Electric-Heated Floor. Buildings 2024, 14, 2097. https://doi.org/10.3390/buildings14072097

Huang C, Li N, He S, Weng X, Shu Y, Yang G, Bao Y. Investigation of the Temperature Distribution and Energy Consumption of an Integrated Carbon Fiber Paper-Embedded Electric-Heated Floor. Buildings. 2024; 14(7):2097. https://doi.org/10.3390/buildings14072097

Chicago/Turabian StyleHuang, Chengjian, Neng Li, Sheng He, Xiang Weng, Yi Shu, Guang Yang, and Yongjie Bao. 2024. "Investigation of the Temperature Distribution and Energy Consumption of an Integrated Carbon Fiber Paper-Embedded Electric-Heated Floor" Buildings 14, no. 7: 2097. https://doi.org/10.3390/buildings14072097

APA StyleHuang, C., Li, N., He, S., Weng, X., Shu, Y., Yang, G., & Bao, Y. (2024). Investigation of the Temperature Distribution and Energy Consumption of an Integrated Carbon Fiber Paper-Embedded Electric-Heated Floor. Buildings, 14(7), 2097. https://doi.org/10.3390/buildings14072097