Study on Mechanical Properties of Nano-TiC- and Nano-SiO2-Modified Basalt Fiber Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Model Optimization Theory and Design Methods

2.2.1. Theoretical Calculation of RSM

2.2.2. Theoretical Calculation of the Thirst Function

2.2.3. Preparation of Concrete

3. Results and Discussion

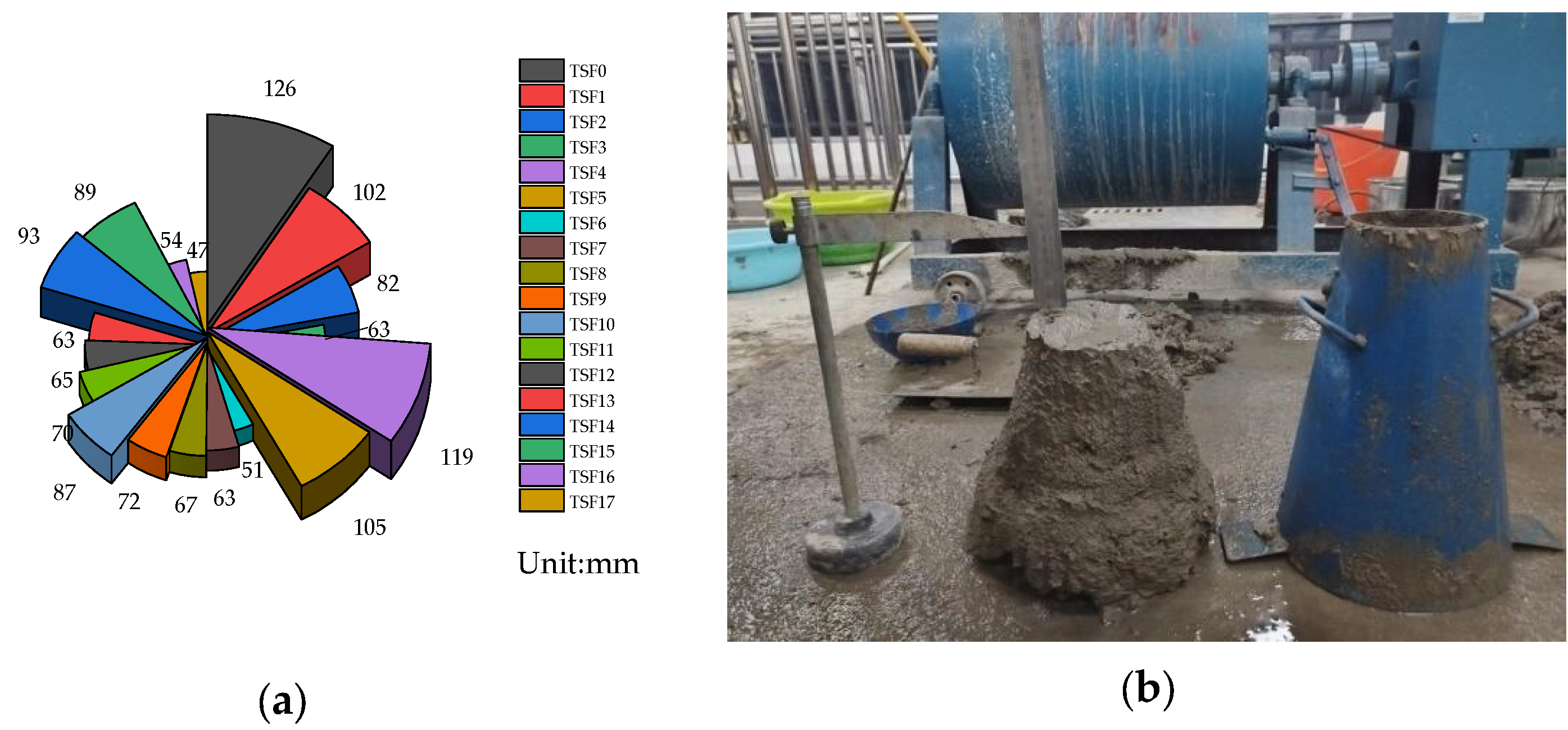

3.1. Analysis of NSF Concrete Slump Results

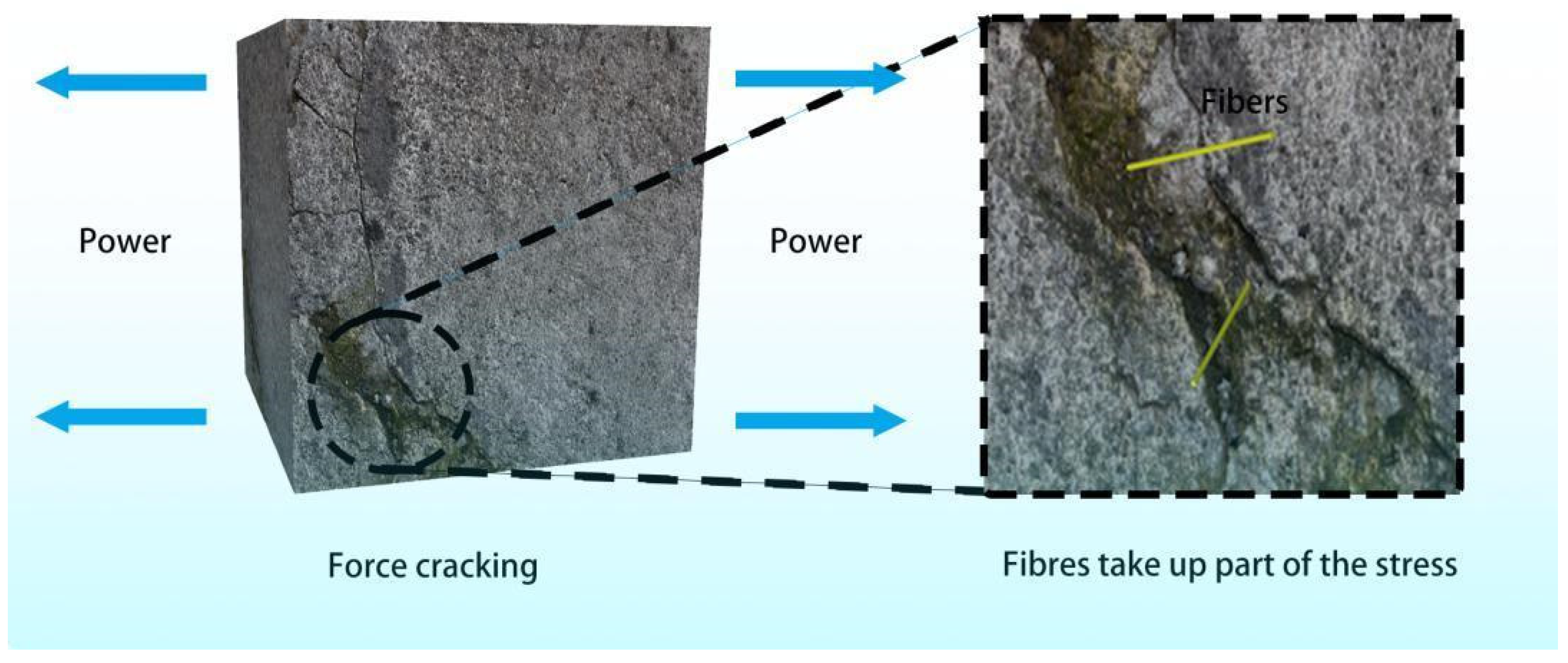

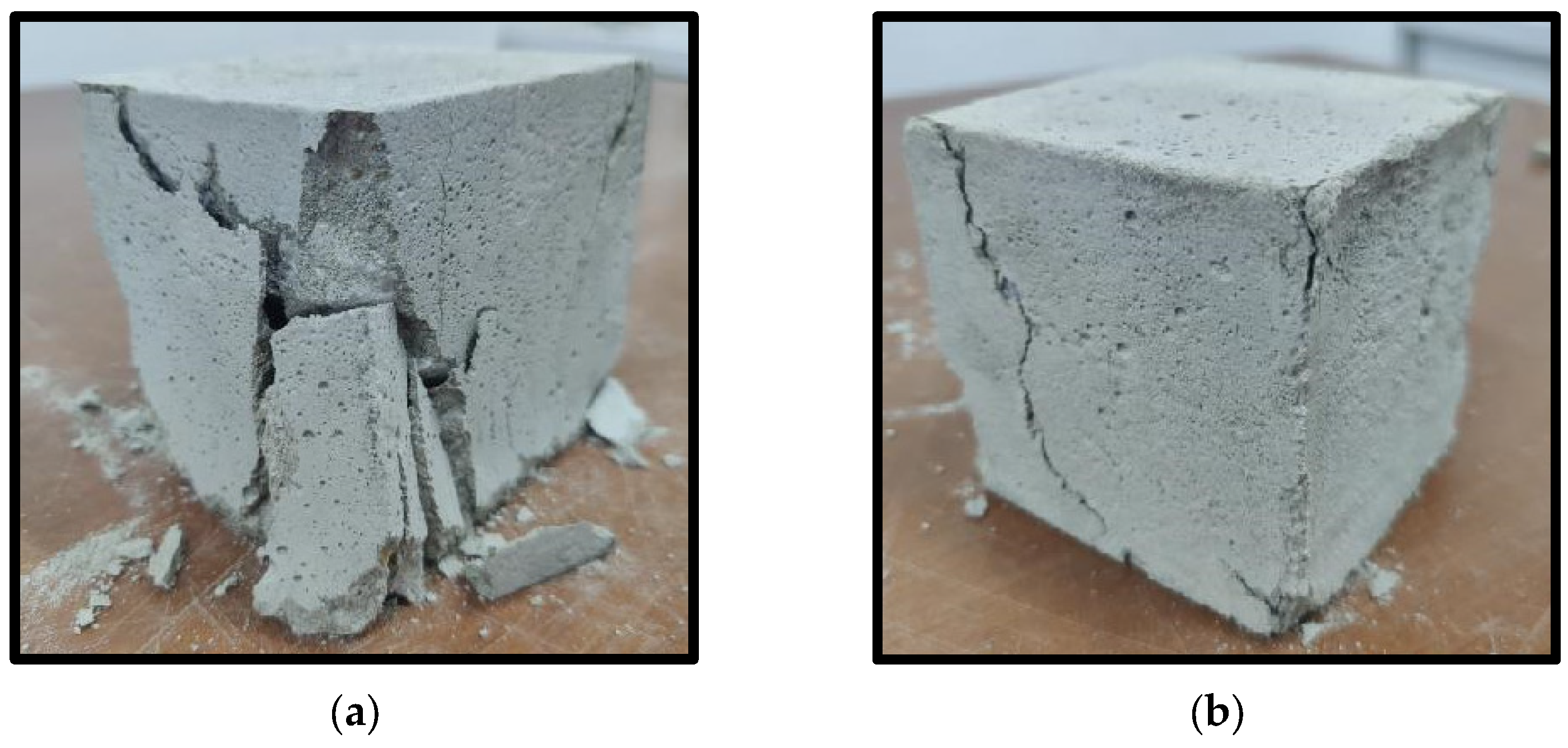

3.2. The Concrete Damage Realization

3.3. Analysis of Mechanical Properties of Concrete

3.3.1. Concrete Prediction Model

3.3.2. RSM Model Test

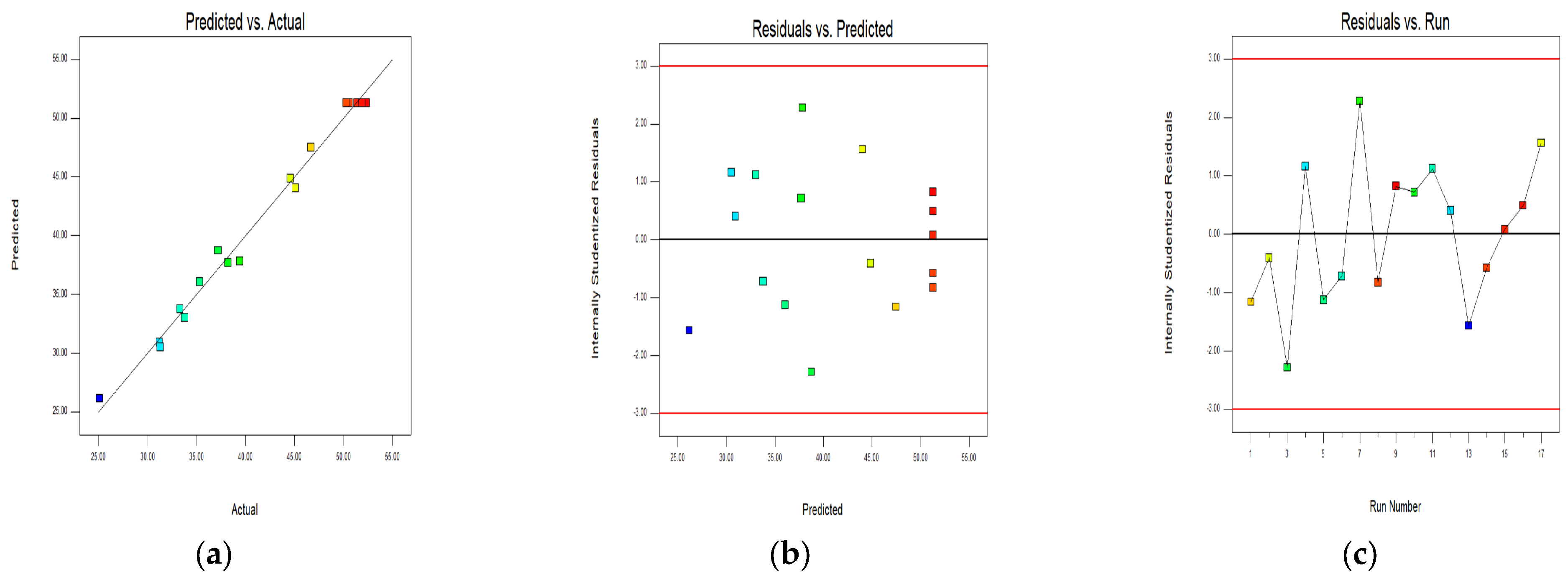

3.3.3. Model Diagnostic Diagrams

3.3.4. Compressive Strength of NSF Concrete

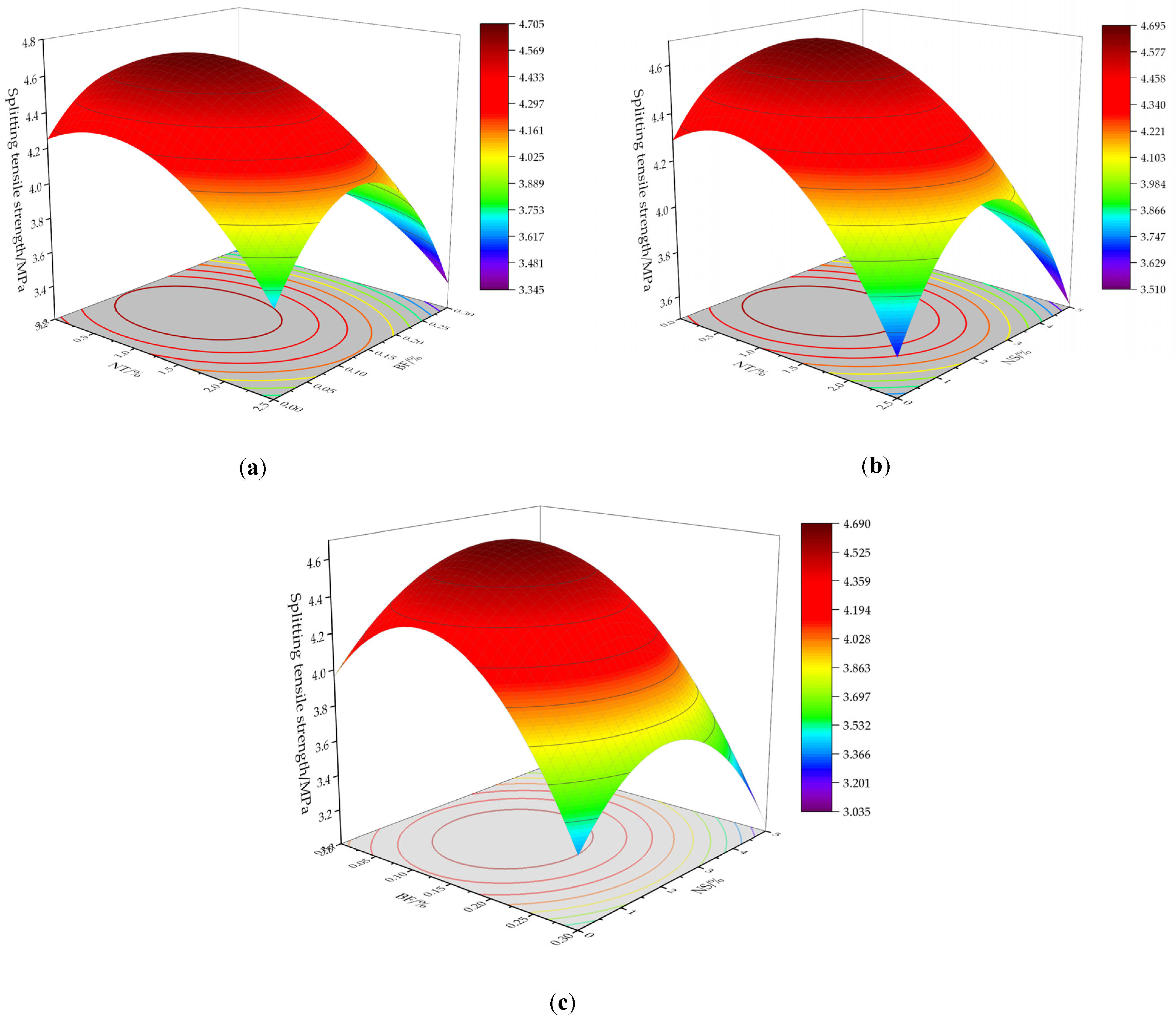

3.3.5. Splitting Tensile Strength of NSF Concrete

3.3.6. Flexural Strength of NSF Concrete

3.4. Modulus of Elasticity Analysis of NSF Concrete

3.5. Optimization of Modified Concrete Design and Analysis of Results

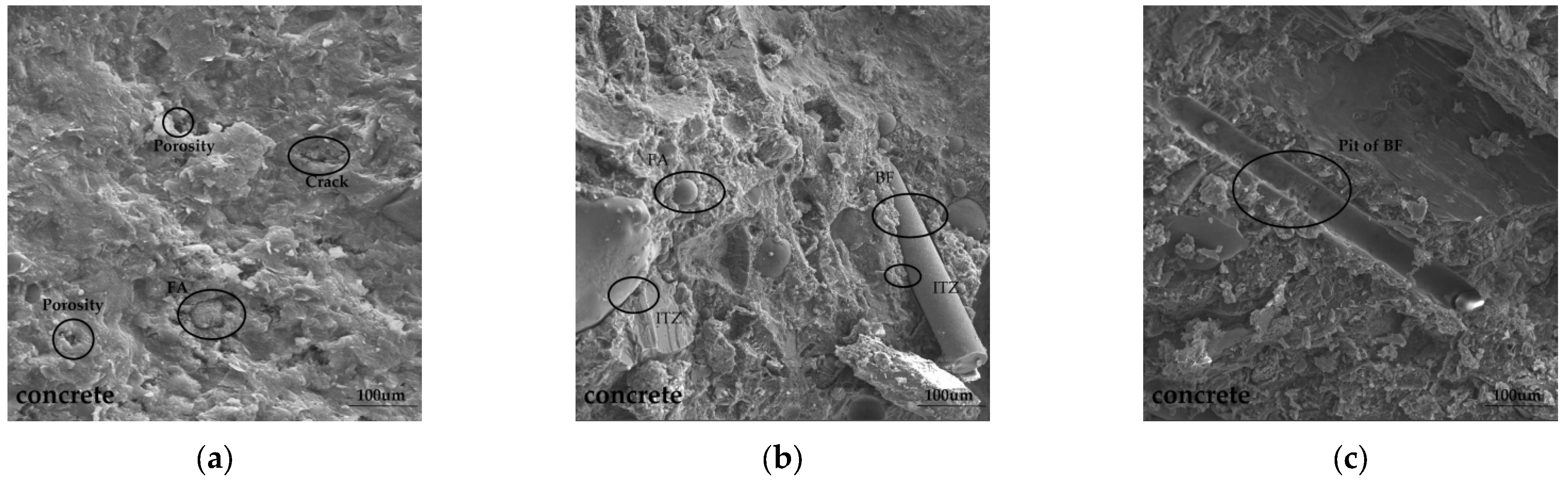

3.6. Analysis of Concrete Microstructure

4. Conclusions

- (1)

- NS, BF, and NT reduced the concrete’s slump. The main reason for the situation is that the larger specific surface area of the nanomaterials and the surface tension of the fibers trapped some of the water, and more water was needed to improve the viscosity of the cement.

- (2)

- Incorporation of a moderate amount of NT, BF, and NS into concrete improves the damaged state of concrete, and also its microstructure becomes dense. The main reason for the situation is that the fibers dispersed some of the stresses in the concrete and resisted the dislodgement of the cement blocks. Additionally, the material effect of NT and NS reduced the pores in the concrete so that the cement specimens could have better integrity.

- (3)

- The admixture of NT, BF, and NS affects the mechanical properties of concrete. The compressive, splitting tensile, and flexural strengths of concrete were greatly affected by NT, BF, and NS. The interaction of NT and BF significantly affected the concrete’s compressive and flexural strengths. NT and NS significantly affected the concrete splitting tensile strength.

- (4)

- The optimum admixture of NT, BF, and NS was obtained by developing a thirst function optimization model for the mechanical strength of the concrete. Their optimum admixtures were 0.85%, 0.11% and 1.94%, respectively. The difference between the predicted and actual values was also compared using parallel tests and the error results were less than 10%, which shows that optimization model has high accuracy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, S.; Yang, J.; Wang, J. Experimental and theoretical analysis of steel tubed geopolymer concrete columns under axial compression. Constr. Build. Mater. 2024, 411, 134277. [Google Scholar] [CrossRef]

- Garcia, S.L.; Ferreira, J.; Dias, D.; Trindade, J. Theoretical and Experimental Study on Minimum Shear Reinforced Ratio in Concrete Beams. ACI Struct. J. 2024, 121, 47–59. [Google Scholar]

- Mariani, E.; Ingrassia, L.P.; Spadoni, S.; Canestrari, F. Laboratory Investigation on the Use of Geocomposites as Waterproofing Systems for Concrete Bridge Decks. J. Mater. Civ. Eng. 2024, 36, 04023544. [Google Scholar] [CrossRef]

- Concha, N.C. A robust carbonation depth model in recycled aggregate concrete (RAC) using neural network. Expert Syst. Appl. 2024, 237, 121650. [Google Scholar] [CrossRef]

- Li, T.; Nogueira, R.; Pereira, M.F.C.; de Brito, J.; Liu, J. Effect of the incorporation ratio of recycled concrete aggregate on the properties of self-compacting mortar. Cem. Concr. Compos. 2024, 147, 105429. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, W.; Hao, H.; Siew, A.U.; Huang, T.; Ahmed, M.; Pham, T.M. Lateral impact performances of geopolymer concrete columns reinforced with steel-BFRP composite bars. Constr. Build. Mater. 2024, 411, 134411. [Google Scholar] [CrossRef]

- Lindholm, C.; Paananen, J.; Stevanovic, M.; Weiste, E.; Valkeapää, T. Requests for concrete actions in interaction: How support workers manage client participation in mental health rehabilitation. Pragmatics 2024, 34, 190–214. [Google Scholar] [CrossRef]

- Soylev, T.A.; François, R. Quality of steel–concrete interface and corrosion of reinforcing steel. Cem. Concr. Res. 2003, 33, 1407–1415. [Google Scholar] [CrossRef]

- Liu, X.; Wang, S.; Han, F.; Qin, J.; Lu, L.; Xue, Q.; Ji, Y. Mechanical relationship between compressive strength and sulfate erosion depth of basalt fiber reinforced concrete. Constr. Build. Mater. 2024, 411, 134412. [Google Scholar] [CrossRef]

- Rahman, M.N.; Serin, S.; Ozer, H. Effectiveness of a Pullout Test Method Developed to Characterize Fundamental Fiber-Matrix Interfacial Mechanisms in Viscoelastic Asphalt Concrete. J. Mater. Civ. Eng. 2024, 36, 04024185. [Google Scholar] [CrossRef]

- Alex, A.G.; Jose, P.A.; Antony, M.R.; Dhanalakshmi, K. The Effect of Partial Replacement of Cement with Diatomaceous Earth (DE) and Polypropylene Fibers (PPF) on Fresh, Hardened, and Durability Properties of Concrete. Int. J. Concr. Struct. Mater. 2024, 18, 24. [Google Scholar] [CrossRef]

- Zou, Q.Q.; Fu, B.; Chen, J.F.; Teng, J.G. Stress-strain behaviour of carbon fibre reinforced polymer-confined concrete containing macro fibres recycled from waste glass fibre reinforced polymer. Adv. Struct. Eng. 2024, 27, 1189–1208. [Google Scholar] [CrossRef]

- Gong, S.; Su, M.; Zhang, J.; Peng, H. Flexural behavior of reinforced concrete beams strengthened with gradually prestressed near surface mounted carbon fiber-reinforced polymer strips under static and fatigue loading. Adv. Struct. Eng. 2024, 27, 1234–1250. [Google Scholar] [CrossRef]

- Yang, X.; Huang, J.; Peng, L.; He, Y. Research on the mechanism of elevated permeability resistance in recycled glass fiber reinforced concrete. Case Stud. Constr. Mater. 2024, 20, e03173. [Google Scholar] [CrossRef]

- Kunchariyakun, K.; Sinyoung, S.; MacKenzie, K.J.D.; Boonyung, W.; Suwannaphong, C.; Pantong, K.; Dungsang, P. Experimental study of lightweight concrete prepared from super absorbent polymers (SAPs) and glass fibers (GF). J. Asian Archit. Build. Eng. 2024, 23, 994–1006. [Google Scholar] [CrossRef]

- Pournoori, P.; Davarpanah, T.Q.A.; Rajaee, A.; Ghodratnama, M.; Abrishami, S.; Masoodi, A.R. Experimental exploration of fracture behavior (pure mode III) in eco-friendly steel fiber-reinforced self-compacting concrete with waste tempered glass as coarse aggregates. Sci. Rep. 2024, 14, 9043. [Google Scholar] [CrossRef]

- Xu, X.; Jiang, Z.; Wan, M.; Liu, P.; Zeng, H. Experimental study on performance of reinforced concrete short columns repaired and strengthened with Basalt fiber ultra-high-performance concrete (BF-UHPC). In Structures; Elsevier: Amsterdam, The Netherlands, 2024; Volume 62, p. 106170. [Google Scholar]

- Zhou, C.; Dai, F.; Liu, Y.; Wei, M.; Gai, W. Experimental assessment on the dynamic mechanical characteristics and cracking mechanism of hybrid basalt-sisal fiber reinforced concrete. J. Build. Eng. 2024, 88, 109151. [Google Scholar] [CrossRef]

- Yang, W.; Huang, Y.; Tang, Z.; Xiong, X.; Li, C.; Zhong, X.; Liu, L.; Zhou, H.; Zhang, X. Impermeability performance and corrosion resistance mechanism of basalt fiber recycled concrete under the coastal tidal environment. Constr. Build. Mater. 2024, 411, 134510. [Google Scholar] [CrossRef]

- Luo, H.Y.; Jiang, J.S.; Zhao, K. Damage characteristics of basalt fiber recycled concrete under freeze-thaw cycle based on energy dissipation. Compos. Sci. Eng. 2023, 5, 86–93. [Google Scholar]

- Deng, Z.; Ding, J. Experimental Study on the Dispersibility and Flexural Toughness of Basalt Fibers in BFRC. China Concr. Cem. Prod. 2020, 1, 47–50. [Google Scholar]

- Wang, L.; Zhao, Y.; Song, B.; Xing, Y.; He, X. Fracture behavior of basalt fiber-reinforced concrete subjected to high temperatures. Struct. Concr. 2023, 24, 3147–3161. [Google Scholar] [CrossRef]

- Fahmy, M.A.; Abu El-Hassan, M.M.; Kamh, G.M.; Bashandy, A.A. Investigation of Using Nano-silica, Silica Fume and Fly Ash in High Strength Concrete. Eng. Res. J. 2020, 43, 211–221. [Google Scholar] [CrossRef]

- Yang, L.; Zhu, Z.; Zhang, D.; Sun, H.; Huo, W.; Zhang, J.; Wan, Y.; Zhang, C. Influence mechanism of Nano-SiO2 on geopolymer recycled concrete: Change mechanism of the microstructure and the anti-carbonation mechanism. Cem. Concr. Compos. 2024, 146, 105364. [Google Scholar] [CrossRef]

- Fang, J.; Zhao, L.; Shi, J. Frost resistance and pore structure of concrete incorporated with rubber aggregates and nano-SiO2. Materials 2021, 14, 1170. [Google Scholar] [CrossRef]

- Han, J.; Wang, J.; Li, G.; Zhang, L.; Lu, Y.; Qin, Y. Effect of Modified Nano-SiO2 Film-forming Composite Coating on Hydrophobicity and Carbonation Resistance of Concrete. Sci. Technol. Eng. 2019, 19, 268–273. [Google Scholar]

- Zhang, P.; Fu, S.; Zhang, K.; Zhang, T. Mechanical properties of polyvinyl alcohol fiber-reinforced concrete composite containing fly ash and nano-SiO2. Sci. Adv. Mater. 2018, 10, 769–778. [Google Scholar]

- Gulati, K.C. A Thermomechanical Theory of Composite Materials; University of Texas at Austin: Austin, TX, USA, 1972. [Google Scholar]

- Onyelowe, K.C.; Ebid, A.M.; Ghadikolaee, M.R. GRG-optimized response surface powered prediction of concrete mix design chart for the optimization of concrete compressive strength based on industrial waste precursor effect. Asian J. Civ. Eng. 2024, 25, 997–1006. [Google Scholar] [CrossRef]

- Ren, F.; Du, J.; Yang, X.; Huang, X. Optimization on a novel irregular snowflake fin for thermal energy storage using response surface method. Int. J. Heat Mass Transf. 2023, 200, 123521. [Google Scholar] [CrossRef]

- Chen, H.; Deng, T.; Du, T.; Chen, B.; Skibniewski, M.J.; Zhang, L. An RF and LSSVM–NSGA-II method for the multi-objective optimization of high-performance concrete durability. Cem. Concr. Compos. 2022, 129, 104446. [Google Scholar] [CrossRef]

- Chang, G.; Hua, X.; Liu, X.; Chen, L.; Wang, E.; Sun, B. Fluidity influencing factor analysis and ratio optimization of new filling slurry based on the response surface method. J. Renew. Mater. 2022, 10, 1439. [Google Scholar] [CrossRef]

- Parhi, S.K.; Patro, S.K. Application of R-curve, ANCOVA, and RSM techniques on fracture toughness enhancement in PET fiber-reinforced concrete. Constr. Build. Mater. 2024, 411, 134644. [Google Scholar] [CrossRef]

- Sadeghian, A.; Moradi Shaghaghi, T.; Mohammadi, Y.; Taghipoor, H. Performance Assessment of Hybrid Fibre-Reinforced Concrete (FRC) under Low-Speed Impact: Experimental Analysis and Optimized Mixture. Shock. Vib. 2023, 2023, 7110987. [Google Scholar] [CrossRef]

- Adedokun, S.I.; Anifowose, M.A. Optimal Replacement of Granite Modified with Ife Iron and Steel Slag on Strength Properties of Concrete. Int. J. Eng. Res. Afr. 2022, 58, 183–190. [Google Scholar] [CrossRef]

- Bypour, M.; Yekrangnia, M.; Kioumarsi, M. Predicting the shear capacity of composite steel plate shear wall with the application of RSM. Eng. Struct. 2024, 301, 117263. [Google Scholar] [CrossRef]

- Qu, G.; Zheng, M.; Zhang, W.; Jing, H.; Ou, Z. Preparation and acceleration mechanism of a ternary hardening accelerator for high-performance concrete with full aeolian sand. Constr. Build. Mater. 2023, 369, 130629. [Google Scholar] [CrossRef]

- Alabay, P.; Elaldi, F. Low Velocity Impact Behaviour of Composite Laminates Containing TiC and ZrC Nanoparticles in Resin System. Nano Hybrids Compos. 2023, 38, 25–35. [Google Scholar] [CrossRef]

- Urkhanova, L.A.; Lkhasaranov, S.A.; Buyantuev, S.L. Modification of cement and concrete with carbon nanomaterials, obtained by plasma method. Int. J. Civ. Eng. Technol. 2018, 9, 652–656. [Google Scholar]

- Wu, Z.; Shi, C.; Khayat, K.H.; Wan, S. Effects of different nanomaterials on hardening and performance of ultra-high strength concrete (UHSC). Cem. Concr. Compos. 2016, 70, 24–34. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Sulfate resistance of cement composites containing Nano-Fibrillated Cellulose (NFC). Cem. Concr. Compos. 2023, 135, 104831. [Google Scholar] [CrossRef]

- Gan, Y.; Chen, J.; Zeng, H.; Zeng, D. Whole-process analytical model on progressive collapse response of reinforced concrete structures under middle column loss. Eng. Struct. 2024, 302, 117375. [Google Scholar] [CrossRef]

- Rathod, N.; Gonbare, M.; Pujari, M. Basalt fiber reinforced concrete. Int. J. Sci. Res. 2013, 4, 359–361. [Google Scholar]

- Zhang, X.; Hou, J.; Sun, H.; Zhang, C.; Huang, J.; Wang, J.; Hou, P. Rheological property and stability of nano-silica modified self-compacting concrete with manufactured sand. Constr. Build. Mater. 2023, 401, 132935. [Google Scholar] [CrossRef]

- Box, G.E.P.; Draper, N.R. Empirical Model-Building and Response Surfaces; John Wiley & Sons: Hoboken, NJ, USA, 1987. [Google Scholar]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Debele, A.D.; Demeke, S.; Bekele, T.; Malimo, M. Recycling and reusing potential of disposable low-density polyethylene plastic waste for flexible paver tile construction for outdoor application. Heliyon 2024, 10, e29381. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Building Industry Press: Beijing, China, 2009.

- Traina, L.A.; Mansour, S.A. Biaxial strength and deformational behavior of plain and steel fiber concrete. ACI Mater. J. 1991, 88, 00615123. [Google Scholar]

- Chen, F.; Xu, B.; Jiao, H.; Chen, X.; Shi, Y.; Wang, J.; Li, Z. Triaxial mechanical properties and microstructure visualization of BFRC. Constr. Build. Mater. 2021, 278, 122275. [Google Scholar] [CrossRef]

- Mondal, S.; Ghosh, A.D. Response Surface Methodology-Based Optimization of Bacterial Cell Concentration for Microbial Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 1087–1102. [Google Scholar] [CrossRef]

- Raouache, E.; Logzit, N.; Driss, Z.; Khalfallah, F. Optimization by RSM of reinforced concrete beam process parameters. Am. J. Mech. Eng. 2018, 6, 66–74. [Google Scholar]

- Adamu, M.; Ibrahim, Y.E.; Abdel Daiem, M.M.; Alanazi, H.; Elalaoui, O.; Ali, N.M. Optimization and modelling the mechanical performance of date palm fiber-reinforced concrete incorporating powdered activation carbon using response surface methodology. Materials 2023, 16, 2977. [Google Scholar] [CrossRef]

- Buettner, N.; Iyacu, G.; Akono, A.T. Colloidal nanosilica promotes high-density calcium-silicate-hydrates in fine recycled concrete aggregate mortar. Cem. Concr. Res. 2024, 180, 107498. [Google Scholar] [CrossRef]

- Wang, K.; Wang, W.; Guo, Y.; Liu, Y.; Duan, P.; Shi, W.; Liu, Y. Grey modeling study on mechanical properties and pore structure of concrete with different basalt fiber contents based on NMR. J. Build. Eng. 2024, 89, 109287. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Li, X.; Zhang, Y.; Wu, L. Enhancing Concrete Mechanical Properties through Basalt Fibers and Calcium Sulfate Whiskers: Optimizing Compressive Strength, Elasticity, and Pore Structure. Materials 2024, 17, 1706. [Google Scholar] [CrossRef]

- Chin, S.C.; Shaaban, I.G.; Rizzuto, J.P.; Khan, S.U.; Mohamed, D.; Roslan, N.I.M.; Aziz, A.A. Predictive models for mechanical properties of hybrid fibres reinforced concrete containing bamboo and basalt fibres. Structures 2024, 61, 106093. [Google Scholar] [CrossRef]

- Khan, M.H.; Qiuhong, Z.; Sikandar, M.A.; Khan, B.; Zhu, H.; Khan, M.S. Evaluation of mechanical strength, gamma-ray shielding characteristics, and ITZ microstructural properties of heavyweight concrete using nano-silica (SiO2) and barite aggregates. Constr. Build. Mater. 2024, 419, 135483. [Google Scholar] [CrossRef]

- Alfonso, D.; Dugarte, M.; Carrillo, J.; Arteta, C.A. Effect of aggregate type on the elastic modulus and compressive behavior of concrete: A case study in Colombia. Constr. Build. Mater. 2024, 411, 134131. [Google Scholar] [CrossRef]

- Alam, M.F.; Shubham, K.; Kumar, S.; Srivastava, A.K.L. Enhancing high-strength self-compacting concrete properties through Nano-silica: Analysis and prediction of mechanical strengths. J. Build. Pathol. Rehabil. 2024, 9, 43. [Google Scholar] [CrossRef]

- Xiao, T.; Liang, X.; Du, S. Development of high-volume fly ash concrete with improved interfacial transition zone. J. Build. Eng. 2024, 87, 109050. [Google Scholar] [CrossRef]

- Zhou, M.; He, X.; Wang, H.; Wu, C.; He, J.; Wei, B. Mechanical properties and microstructure of ITZs in steel and polypropylene hybrid fiber-reinforced concrete. Constr. Build. Mater. 2024, 415, 135119. [Google Scholar] [CrossRef]

- Rajkohila, A.; Chandar, S.P. Assessing the effect of natural fiber on mechanical properties and microstructural characteristics of high strength concrete. Ain Shams Eng. J. 2024, 15, 102666. [Google Scholar] [CrossRef]

- Zhang, D.; Zhu, T.; Ai, Q.; Mao, M.; Li, J.; Yang, Q. Performance of coal gangue concrete with fly ash and ground-granulated blast slag: Rheology, mechanical properties and microstructure. Constr. Build. Mater. 2024, 427, 136250. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, G.; Xu, P.; Fu, L.; Deng, D.; Kuang, X.; Fan, Y. Mechanical properties under compression and microscopy analysis of basalt fiber reinforced recycled aggregate concrete. Materials 2023, 16, 2520. [Google Scholar] [CrossRef]

| Type of Cement | Stability | Times/min | Compressive Strength/MPa | Flexural Strength/MPa | |||

|---|---|---|---|---|---|---|---|

| Condensation | Congeal | 3d | 28d | 3d | 28d | ||

| P.O 42.5 | eligible | 280 | 335 | 24.2 | 46.3 | 5.0 | 6.7 |

| Sand Type | Fineness Modulus | Apparent Density/kg·m−3 | Grain Size/mm | Packing Density/kg·m−3 | Moisture Content/% | Mud Content% |

|---|---|---|---|---|---|---|

| Mesopotamia | 2.4 | 2594 | ≤3 | 1606 | 3.2 | 1.5 |

| Coarse Aggregate | Crushing Indicators/% | Apparent Density/kg·m−3 | Grain Size/mm | Bulk Density /kg·m−3 | Mud Content/% |

|---|---|---|---|---|---|

| crushed stone | 5.4 | 2771 | 10~31 | 1360 | 0.7 |

| Lengths/mm | Monofilament Diameter/μm | Densities/g·cm−3 | Modulus of Elasticity/GPa | Tensile Strength/MPa | Elongation at Break/% |

|---|---|---|---|---|---|

| 12 | 13 | 2.63~2.65 | 91~110 | 3000~4800 | 2.4~3.0 |

| Brochure | Unit | Typology | Level | ||

|---|---|---|---|---|---|

| −1 | 0 | 1 | |||

| A: NT | % | factor | 0 | 1.25 | 2.5 |

| B: BF | % | factor | 0 | 0.15 | 0.3 |

| C: NS | % | factor | 0 | 2.5 | 5 |

| R1: Compressive strength | MPa | response value | |||

| R2: Splitting tensile strength | MPa | response value | |||

| R3: Flexural strength | MPa | response value | |||

| Experimental Group | A | B | C | Degree of Slump | R1 | R2 | R3 | Modulus of Elasticity |

|---|---|---|---|---|---|---|---|---|

| % | % | % | mm | MPa | MPa | MPa | GPa | |

| NSF0 | 0 | 0 | 0 | 126 | 41.2 | 3.8 | 7.24 | 32.5 |

| NSF1 | 0 | 0.15 | 0 | 102 | 44.6 | 4.3 | 7.74 | 35.6 |

| NSF2 | 2.5 | 0.15 | 0 | 82 | 37.2 | 3.6 | 6.94 | 30.7 |

| NSF3 | 1.25 | 0.3 | 0 | 63 | 33.8 | 3.4 | 6.63 | 28.3 |

| NSF4 | 1.25 | 0 | 0 | 112 | 45.1 | 4 | 7.56 | 36.8 |

| NSF5 | 0 | 0 | 2.5 | 105 | 46.7 | 4.2 | 7.82 | 37.2 |

| NSF6 | 2.5 | 0.3 | 2.5 | 51 | 31.3 | 3.4 | 6.35 | 27.1 |

| NSF7 | 0 | 0.3 | 2.5 | 63 | 33.3 | 3.5 | 6.43 | 28.4 |

| NSF8 | 1.25 | 0.15 | 2.5 | 67 | 50.3 | 4.8 | 8.79 | 39.2 |

| NSF9 | 1.25 | 0.15 | 2.5 | 72 | 52.3 | 4.6 | 8.46 | 40.9 |

| NSF10 | 2.5 | 0 | 2.5 | 87 | 38.2 | 3.7 | 6.83 | 31.6 |

| NSF11 | 1.25 | 0.15 | 2.5 | 70 | 50.6 | 4.7 | 8.67 | 41.8 |

| NSF12 | 1.25 | 0.15 | 2.5 | 65 | 51.4 | 4.5 | 8.42 | 41.4 |

| NSF13 | 1.25 | 0.15 | 2.5 | 63 | 51.9 | 4.6 | 8.53 | 40.7 |

| NSF14 | 1.25 | 0 | 5 | 82 | 35.3 | 3.5 | 6.62 | 29.2 |

| NSF15 | 0 | 0.15 | 5 | 89 | 39.4 | 3.7 | 7.03 | 31.3 |

| NSF16 | 2.5 | 0.15 | 5 | 54 | 31.2 | 3.5 | 6.24 | 27.4 |

| NSF17 | 1.25 | 0.3 | 5 | 47 | 25.1 | 3.0 | 5.83 | 24.6 |

| Source | Sum of Square | Degree of Freedom | Mean Square | F Value | p Value | |

|---|---|---|---|---|---|---|

| Model | 1193.99 | 9 | 132.67 | 71.70 | <0.0001 | significant |

| A | 85.15 | 1 | 85.15 | 46.02 | 0.0003 | |

| BF | 218.40 | 1 | 218.40 | 118.03 | <0.0001 | |

| C | 110.26 | 1 | 110.26 | 59.59 | 0.0001 | |

| AB | 10.56 | 1 | 10.56 | 5.71 | 0.0482 | |

| AC | 0.16 | 1 | 0.16 | 0.086 | 0.7772 | |

| BC | 0.30 | 1 | 0.30 | 0.16 | 0.6980 | |

| A2 | 119.39 | 1 | 119.39 | 64.52 | <0.0001 | |

| B2 | 311.41 | 1 | 311.41 | 168.30 | <0.0001 | |

| C2 | 261.12 | 1 | 261.12 | 141.12 | <0.0001 | |

| Residual | 12.95 | 7 | 1.85 | |||

| Lack of Fit | 10.09 | 3 | 3.36 | 4.71 | 0.0844 | not significant |

| Cor Total | 1206.94 | 16 |

| Source | Sum of Square | Degree of Freedom | Mean Square | F Value | p Value | |

|---|---|---|---|---|---|---|

| Model | 4.91 | 9 | 0.55 | 54.97 | <0.0001 | significant |

| A | 0.28 | 1 | 0.28 | 28.33 | 0.0011 | |

| B | 0.55 | 1 | 0.55 | 55.52 | 0.0001 | |

| C | 0.32 | 1 | 0.32 | 32.23 | 0.0008 | |

| AB | 0.040 | 1 | 0.040 | 4.03 | 0.0847 | |

| AC | 0.063 | 1 | 0.063 | 6.29 | 0.0405 | |

| BC | 2.50 × 10−3 | 1 | 2.50 × 10−3 | 0.25 | 0.6312 | |

| A2 | 0.43 | 1 | 0.43 | 43.43 | 0.0003 | |

| B2 | 1.62 | 1 | 1.62 | 163.02 | <0.0001 | |

| C2 | 1.25 | 1 | 1.25 | 125.96 | <0.0001 | |

| Residual | 0.070 | 7 | 9.929 × 10−3 | |||

| Lack of Fit | 0.017 | 3 | 5.833 × 10−3 | 0.45 | 0.7318 | not significant |

| Cor Total | 4.98 | 16 |

| Source | Sum of Square | Degree of Freedom | Mean Square | F Value | p Value | |

|---|---|---|---|---|---|---|

| Model | 14.84 | 9 | 1.65 | 79.73 | <0.0001 | Significant |

| A | 0.88 | 1 | 0.88 | 42.77 | 0.0003 | |

| B | 1.61 | 1 | 1.61 | 77.91 | <0.0001 | |

| C | 1.24 | 1 | 1.24 | 59.98 | 0.0001 | |

| AB | 0.21 | 1 | 0.21 | 10.01 | 0.0158 | |

| AC | 2.500 × 10−5 | 1 | 2.500 × 10−5 | 1.209 × 10−3 | 0.9732 | |

| BC | 4.900 × 10−3 | 1 | 4.900 × 10−3 | 0.24 | 0.6413 | |

| A2 | 2.03 | 1 | 2.03 | 98.21 | <0.0001 | |

| B2 | 4.40 | 1 | 4.40 | 212.68 | <0.0001 | |

| C2 | 3.35 | 1 | 3.35 | 162.02 | <0.0001 | |

| Residual | 0.14 | 7 | 0.021 | |||

| Lack of Fit | 0.050 | 3 | 0.017 | 0.71 | 0.5954 | not Significant |

| Cor Total | 14.98 | 16 |

| Form | Goal | Lower Limit | Upper Limit |

|---|---|---|---|

| A | in range | 0 | 2.5 |

| B | in range | 0 | 0.3 |

| C | in range | 0 | 5 |

| R1 | maximize | 25.1 MPa | 52.3 MPa |

| R2 | maximize | 3.0 MPa | 4.8 MPa |

| R3 | maximize | 5.83 MPa | 8.79 MPa |

| Experimental Group | Predicted Value/MPa | Actual Value/% | Inaccuracy/% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | R3 | R1 | R2 | R3 | R1 | R2 | R3 | |

| 1 | 53.1 | 4.7 | 8.72 | 50.2 | 4.3 | 7.94 | 5.78 | 9.3 | 9.82 |

| 2 | 53.4 | 4.8 | 8.69 | 9.03 | 2.08 | 1.83 | |||

| 3 | 48.7 | 4.5 | 8.56 | 0.56 | 4.26 | 0.35 |

| Typology | R1/MPa | R2/MPa | R3/MPa | Enhancement Ratio/% | ||

|---|---|---|---|---|---|---|

| R1 | R2 | R3 | ||||

| TBF0 | 41.2 | 3.8 | 7.24 | - | - | - |

| Projected value | 53.1 | 4.7 | 8.72 | 28.88 | 23.68 | 20.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Wang, Z.; Wang, X.; Wen, Y.; Du, Y.; Ji, F. Study on Mechanical Properties of Nano-TiC- and Nano-SiO2-Modified Basalt Fiber Concrete. Buildings 2024, 14, 2120. https://doi.org/10.3390/buildings14072120

Yang X, Wang Z, Wang X, Wen Y, Du Y, Ji F. Study on Mechanical Properties of Nano-TiC- and Nano-SiO2-Modified Basalt Fiber Concrete. Buildings. 2024; 14(7):2120. https://doi.org/10.3390/buildings14072120

Chicago/Turabian StyleYang, Xin, Zhengjun Wang, Xinzheng Wang, Yajing Wen, Yingxin Du, and Fengchun Ji. 2024. "Study on Mechanical Properties of Nano-TiC- and Nano-SiO2-Modified Basalt Fiber Concrete" Buildings 14, no. 7: 2120. https://doi.org/10.3390/buildings14072120

APA StyleYang, X., Wang, Z., Wang, X., Wen, Y., Du, Y., & Ji, F. (2024). Study on Mechanical Properties of Nano-TiC- and Nano-SiO2-Modified Basalt Fiber Concrete. Buildings, 14(7), 2120. https://doi.org/10.3390/buildings14072120