Abstract

The architectural treasures of Zanzibar’s Stone Town, echoing the footprints of ancient civilizations, face an imminent threat of heritage loss due to accelerated material degradation. This underscores the urgent need for an intrinsic examination of building material properties to enhance existing restoration guidelines and effectively safeguard the historical legacy. This study is the first significant step for the extensive procurement of samples to investigate the physical, mechanical, and chemical properties of deteriorating coral stones, mortar, and wood material of Zanzibar’s Stone Town. The results indicate considerable water absorption and varying porosity and densities, highlighting the significant water retention and susceptibility of marine environmental factors. The compressive strength (CS) for coral stone, mortar, and wood falls under 7.6 MPa to 12.2 MPa, 0.5 to 0.9 MPa, and 52.9 to 69.3 MPa, revealing the heterogenous characteristics across the samples. The flexural strength of coral stone and wood was found to be from 2.0 MPa to 3.4 and 72.1 MPa to 98.6 MPa, indicating a high susceptibility to breakage and fracture. Meanwhile, Ultra Pulse Velocity (UPV) averages 1668 to 2070 m/s, revealing void ranges in building materials. Chemical analysis, including X-ray diffraction (XRD) and X-ray fluorescence (XRF), demonstrates higher CaO content in coral stone and mortar, with the predominant mineral aragonite indicating vulnerability to rapid chemical attacks. These results can significantly contribute to future modifications and improvements in restoration guidelines by facilitating the identification and utilization of appropriate materials’ properties. This ensures a high level of compatibility and promotes the sustainable conservation of Stone Town’s architectural heritage.

1. Introduction

Ancient constructions are of great cultural, historical, and archeological significance, serving as testaments to the ingenuity and craftsmanship of past civilizations globally. Across the temporal spectrum, the evolving ambient conditions and detrimental environmental and climatic patterns perpetuate structural deterioration, leading to damage, collapse, and the gradual loss of the original identity and historical value. This highlights the importance of thorough scientific investigations of building materials to evaluate the residual strength and durability of changing environmental pressures that have compromised the preservation efforts for heritage structures, leaving them vulnerable to accelerated decays.

Zanzibar Stone Town, the old city on the western side of the Zanzibar archipelago located on the Indian Ocean Stone, encapsulates the extensive repository of historical and cultural legacy, featuring many ancient structures that showcase the island’s architectural traditions. As a result of its historical, cultural, and economic significance, it was enlisted as a UNESCO World Heritage site in 2000 [1,2,3]. The historic buildings are constructed with unreinforced masonry units such as coral stone, limestone, mortar, and wood characterized by marine sources, and they are currently experiencing rapid degradations which could be regulated through critical investigations of the building materials.

Historical structures in Stone Town have experienced structural and material degradation over time due to various factors. According to the field survey assessments conducted by the Zanzibar Stone Town Conservation Department (2020), 50% of the total houses are in good condition, 30% have deteriorated, and 20% are in poor condition due to structural deformation and insufficient intervention measures. Buildings labeled as poor exhibit indications of settlement and significant fractures, making them vulnerable to collapse. As such, prompt intervention is necessary to prevent further deterioration and preserve the priceless heritage of Zanzibar Stone Town [4,5,6]. In addition, the proximity to the Indian Ocean has rendered these historical structures susceptible to frequent salt attacks, extreme weather fluctuations, and intensified sea erosion, aggravated by the imminent threat of high tidal waves, further amplifying their vulnerability [7,8].

Furthermore, alterations in the functional usage of these structures result in loading shifts, leading to increased structural loads, further intensifying the cracks. Additionally, the tropical climate in the historical area, compounded by heavy rainfall and flooding, intensifies the deterioration of historical structures, particularly those in the Shangani, Forodhani, and Malindi zones. However, the previous restoration efforts in modern construction materials without exploring the historical construction material utilized have proved incompatible with the original building units, leading to accelerated deterioration. For instance, the recent repair efforts involving new mortar coatings over old mortar have resulted in weak bonding and flaking [9,10,11,12]. Therefore, a systematic, thorough investigation of the construction material and subsequent establishment of restoration techniques becomes critical to ensure the preservation and endurance of Stone’s Town heritage.

The conservation of Zanzibar’s ancient construction presents a multifaceted challenge due to the limited understanding of construction materials and their intricate physical, mechanical, and chemical properties. This complexity necessitates physical, mechanical, and chemical analyses, which are crucial in formulating efficient and sustainable strategies for preserving historic structures. These analyses are critical to comprehending the materials’ aging process and response to environmental conditions and ensuring their long-term durability. The assessment involves a detailed exploration of material characteristics, including density, porosity, water absorption, compressive strength (CS), and flexural strength. However, a significant limitation is the need for a large number of samples to conduct these extensive tests, which is often impractical due to the destructive nature of sample collection from historical sites.

To address this, the implementation of non-destructive testing (NDT) methods becomes crucial. NDT allows for the detection of hidden defects, such as cracks, voids, and material degradation, which are not visible to the naked eye, and this can be conducted without resorting to invasive procedures. The assessment of such properties is crucial for the informed selection of construction materials, preservation of structural integrity, and ensuring compatibility with existing historic fabric. Also, the degradation of the material can better be identified by exploring mineralogical compositions that provide insight into their crystalline structure, which is crucial for assessing the material’s historical authenticity and suitability for specific conservation treatments [13,14,15,16,17].

Furthermore, the elemental composition enables a better understanding of the material’s chemical properties and subsequent degradation processes. By incorporating X-ray diffraction (XRD) and X-ray fluorescence (XRF) into the assessment process, alongside NDT and other analyses, a deeper understanding of the construction materials could be achieved. This not only aids in selecting compatible materials for restoration but also ensures the structural preservation and longevity of Zanzibar’s historical structures [14,18,19,20,21,22]. Additionally, these comprehensive efforts are pivotal in maintaining Zanzibar’s cultural heritage and historical integrity for future generations. Therefore, the detailed exploration of physical, mechanical, and chemical properties will assist the conservationist in devising state-of-the-art conservation plans to preserve the original entity of the structure.

Numerous studies on the heritage structures of Stone Town have been conducted over the past several years by some authors [10,23,24,25,26], including an assessment and retrofitting of unreinforced masonry buildings. In Europe, several examples exist of characterizing the physical and mechanical properties of construction materials, such as heritage limestone materials from Hungary [27], freshwater limestones used in Portugal [28], and limestones from Italy and Albania, as well as mortar in Turkey [29]. These techniques involve on-site testing and the use of non-destructive methods [14,20,29,30,31,32,33].

Limited studies have been conducted on investigating material properties concerning historic stone masonry buildings. For instance, Makunza (2017) investigates the physical properties of Zanzibar’s building materials considering the limited frequency of procured samples, which yields inadequate information for developing effective restoration guidelines [9]. At the same time, Ngoma (2009) conducted a study on mortar materials in Stone Town historical buildings, identifying mortar as the most damaged material. Through visual examination, microscopy, X-ray diffraction, and weighing historical mortar was characterized, primarily comprising calcite, quartz, and feldspar. Mortar conditions were classified as hard, soft, and friable, with deteriorated mortar exhibiting a porosity of approximately 27%. These findings contribute to understanding heritage conservation challenges in Stone Town, complementing previous research in the field [34]. Lucian conducted a study similar to the investigation mentioned earlier, focusing on the physical and mechanical properties of building materials in historic structures in Bagamoyo, Tanzania. Through tests and analyses, the study identified poor mortar quality, absorption capacity, and salt damage as key factors contributing to the deterioration [35].

For the effective formulation of conservation guidelines, the evaluation of physical, mechanical, and chemical properties is crucial for selecting appropriate construction materials. Subsequently, the Stone Town conservation authority utilized such inadequate information, leading to the introduction of modern materials and techniques that proved incompatible with the original materials, worsening structural degradation and collapse. In addition, studies in the literature reveal the significant research gap in terms of effective restoration guidelines that depend on comprehensive investigation and evaluation of the building materials for Zanzibar’s Stone Town.

Keeping in view the aforementioned, this study aims to investigate the physical, mechanical, and chemical properties of Zanzibar’s historical Stone Town’s building materials, including coral stone, mortar, and wood, through extensive field and laboratory investigations. The physical properties include the evaluation of porosity, water absorption, bulk density, and specific gravity, respectively. The mechanical properties encapsulate the determination of compressive strength (CS), modulus of elasticity (MOE), flexural strength, and Ultra Pulse Wave Velocity (UPV) across the extensively procured building materials from different locations of the historical Zanzibar Stone Town. A comprehensive chemical investigation was conducted, including X-ray diffraction (XRD) and X-ray fluorescence (XRF) to reveal the material compositions at the mineralogical level. Based on the comprehensive investigation result, the study yields improved and optimized restoration guidelines for effective and compatible restoration strategies.

2. Construction Methods, Materials, and Current State of Buildings

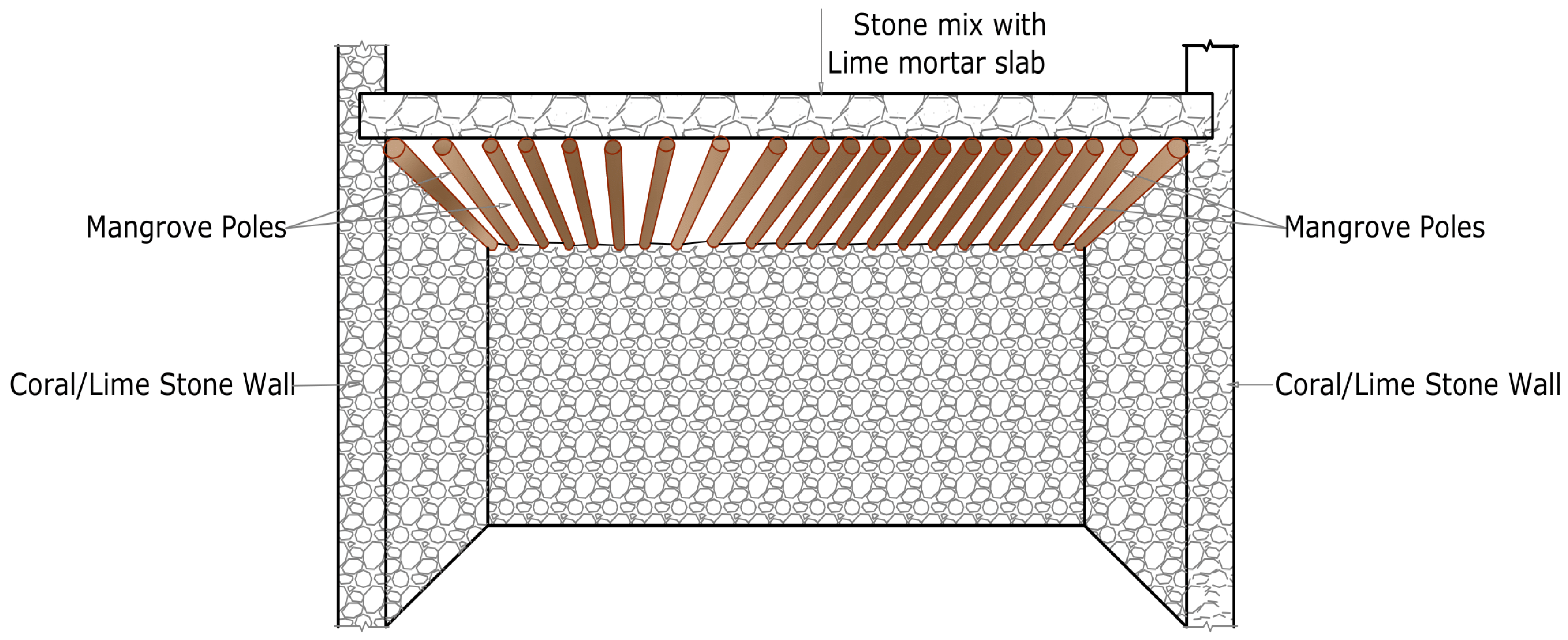

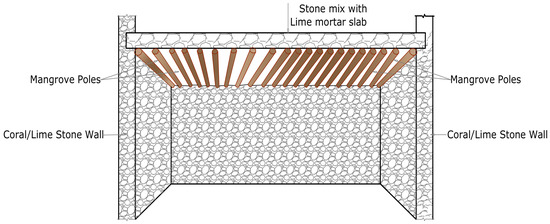

In Zanzibar, most buildings exhibit a height of two to three stories, characterized by thick exterior and interior walls. Historical records indicate that corals, limestone, and lime-based mortars were primarily utilized in the construction of buildings in Zanzibar Stone Town. The walls, constructed using coral or limestone randomly placed in the thick mortar, typically range in thickness from 40 to 100 cm. Subsequently, most of these structures undergo plastering followed by lime-washing. The irregular, rounded shape of the stones used in wall construction poses challenges for efficient bonding, particularly at wall corners and junctions. Meanwhile, the walls meet in a flat butt-joint configuration, lacking interlocking of the elevation. In these cases where openings for doors and windows are required, arches are formed, and mangrove poles support the slab above. The foundation is generally laid at a depth of approximately 50 cm, supporting the walls above the existing ground level (E.G.L). The dimensions of buildings and rooms are determined by the length of locally grown mangrove poles, which support floor and roof slabs and maintain wall stability. Typically, mangrove poles are approximately three-quarters of the width of the wall. The construction of floor slabs features massive and heavy stone masonry blocks, ranging from 30 to 40 cm in thickness, as illustrated in Figure 1 [25,36].

Figure 1.

Typical stone masonry walls and floor systems [25].

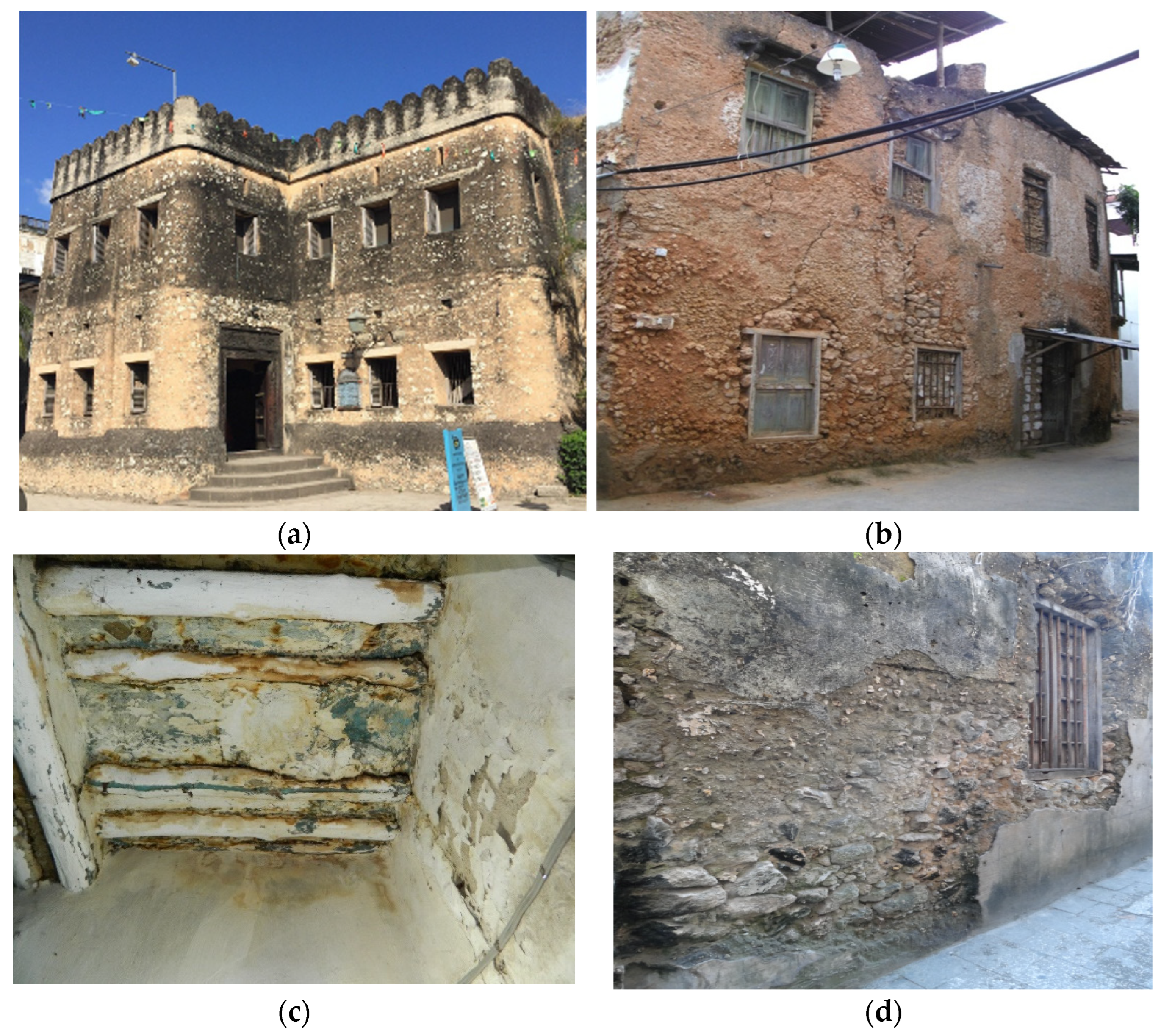

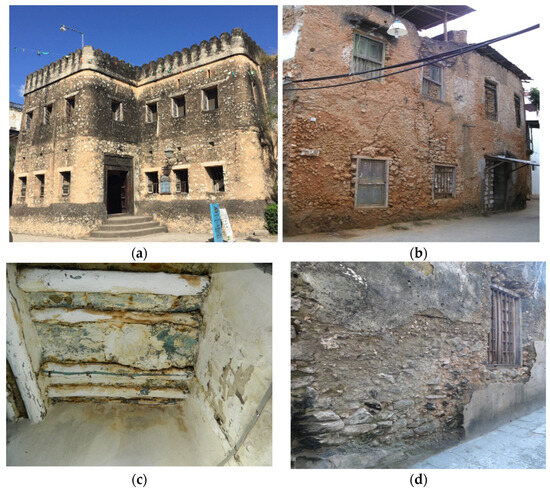

The architectural features and decorative elements, such as niches, are constructed by combining lumps of limestone, coral stone, and lime mortar. Mortars were prepared using fine aggregates sourced from various deposits, including marine deposits and crushed sedimentary rock. Limestone was extracted and burned using an open heap kiln, employing alternating layers of limestone and wood. Additionally, the practice of long-term storage of slaked lime (Ca (OH)2) underwater, known as aging, was commonly employed in Stone Town for prolonged usage [34,37]. Upon examining the current state of most of the restored historic structures in Stone Town, it is evident that the restoration efforts have not been effective. When observing the facades of these historical buildings in Zanzibar’s Stone Town, the stone components appear to be holding up well. At the same time, the mortar, including joint mortar, plaster, and render, exhibits severe deterioration, marked by powdering and scaling, resulting in substantial surface damage (Figure 2a). In an attempt to repair the deteriorating mortar, local contractors and artisans frequently apply fresh mortar over loose old mortar, resulting in weak bonds between the old and new layers, ultimately leading to flaking (Figure 2b). Another factor contributing to the structural issues in Stone Town’s historical buildings is the lack of regular maintenance. This neglect initiates a cycle of deterioration, often causing damage to various structural elements. For instance, leaks in roofs have caused significant harm to the structural integrity of buildings.

Figure 2.

Building damage. (a) External walls material degradation. (b) Loss of mortar and cracks on walls. (c) Degradation of roof slab. (d) Incompatibility between old and new materials.

Additionally, decay and damage to mangrove poles supporting floor and roof slabs have led to collapses (Figure 2c). Furthermore, original building materials are often replaced without fully understanding their properties or addressing their deterioration issues. Modern materials are frequently introduced without proper compatibility testing with the originals, resulting in unintended consequences. For example, the widespread use of cement during restoration has caused irreversible harm to historical masonry, as cement-based mortar restricts movement and induces stress, leading to structural failure. Some new materials also lack the required durability, while others impede internal moisture transfer, as illustrated in Figure 2d. The existing condition of the mortar exhibits softness and friability, as well as susceptibility to deterioration owing to its high fine content, which leaves it vulnerable to leaching phenomena. Moreover, the observed mortar exhibits powdering and scaling, leading to heavy surface loss. Meanwhile, coral stones vary from white to gray, exhibiting softness indicative of a relatively low Mohr hardness rating and susceptibility to abrasion.

3. Field Data Collection and Sampling Methods

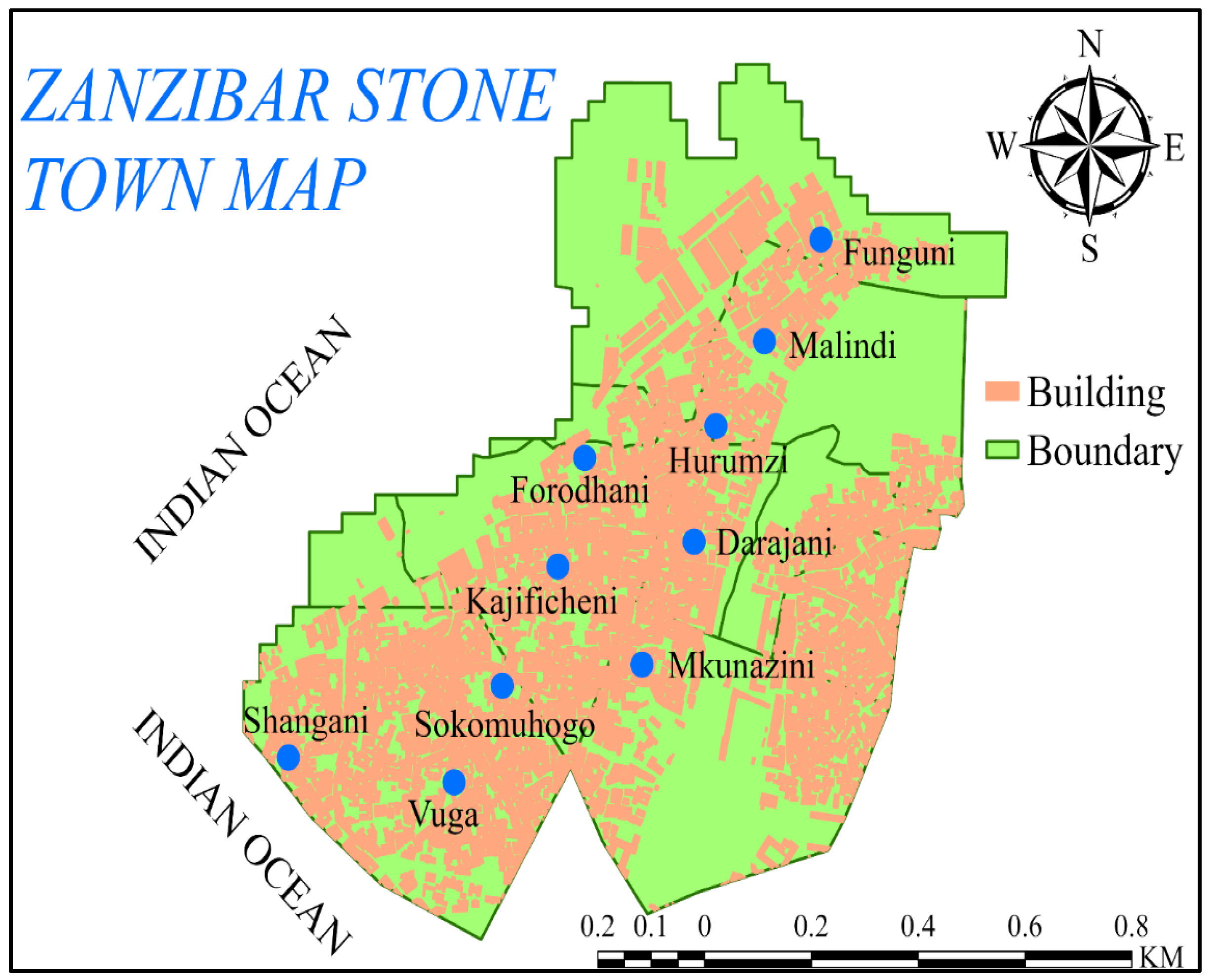

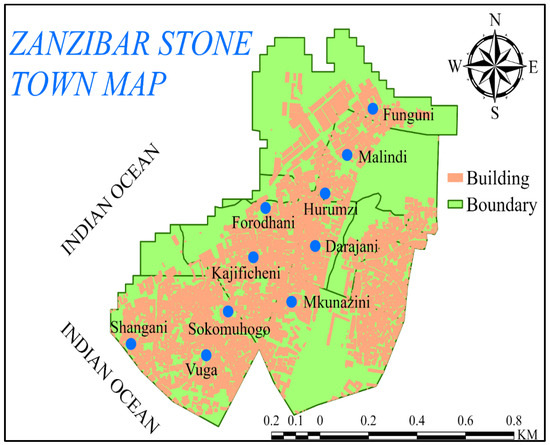

Field data collection was conducted across ten zones within Zanzibar Stone Town, as delineated in Figure 3. Two distinct sampling approaches were adopted to ensure a comprehensive representation of historical construction materials. Initially, six locations were selected from recently demolished old houses and collapsed structures, as shown in Figure 4. The acquired building material sample included coral stone, mortars, and wood. Subsequently, four samples were procured from the ongoing renovation of buildings, as shown in Figure 5. The sampling techniques involved using hammers, chisels, and drilling machines to extract samples. The samples were then sliced into appropriate dimensions using a circular saw, with surfaces carefully smoothed for analysis. Each sample of stone, mortar, and wood was carefully labeled with the first letter of the location’s name within the Stone Town Zone, followed by a unique identification number. For example, S-1 was collected from Shangani, F-2 from Funguni, H-3 from Hurumzi, K-4 from Kajificheni, H-5 from Malindi, D-6 from Darajani, F-7 from Forodhani, SK-8 from Sokomuhugo, M-9 from Mkunazini, and V-10 from Vuga (shown in Figure 3). After sampling, specimens were stored in airtight plastic bags, ready for further analysis tailored to the investigation’s objectives.

Figure 3.

Map demonstrating the geographical location of examined samples in Zanzibar Stone Town. (drawn by the author).

Figure 4.

Example of the collapsed building (photos by author).

Figure 5.

Example building renovation (photos by author).

The sampling strategy for investigating construction materials in Zanzibar Stone Town focused on selecting diverse locations representing various stages of degradation and architectural significance. These locations were chosen to capture and explore the range of materials used in construction, aiding in the comprehensive analysis of physical, mechanical, and chemical characteristics. Cumulatively, samples were obtained from each location and meticulously prepared to meet standardized dimensions, which included cutting, reshaping, and smoothing according to the required testing guidelines. Each experiment was conducted on at least three specimens, and the average of the obtained values was recorded. Controlled conditions were maintained for the specimens to standardize moisture levels and minimize variability in the results.

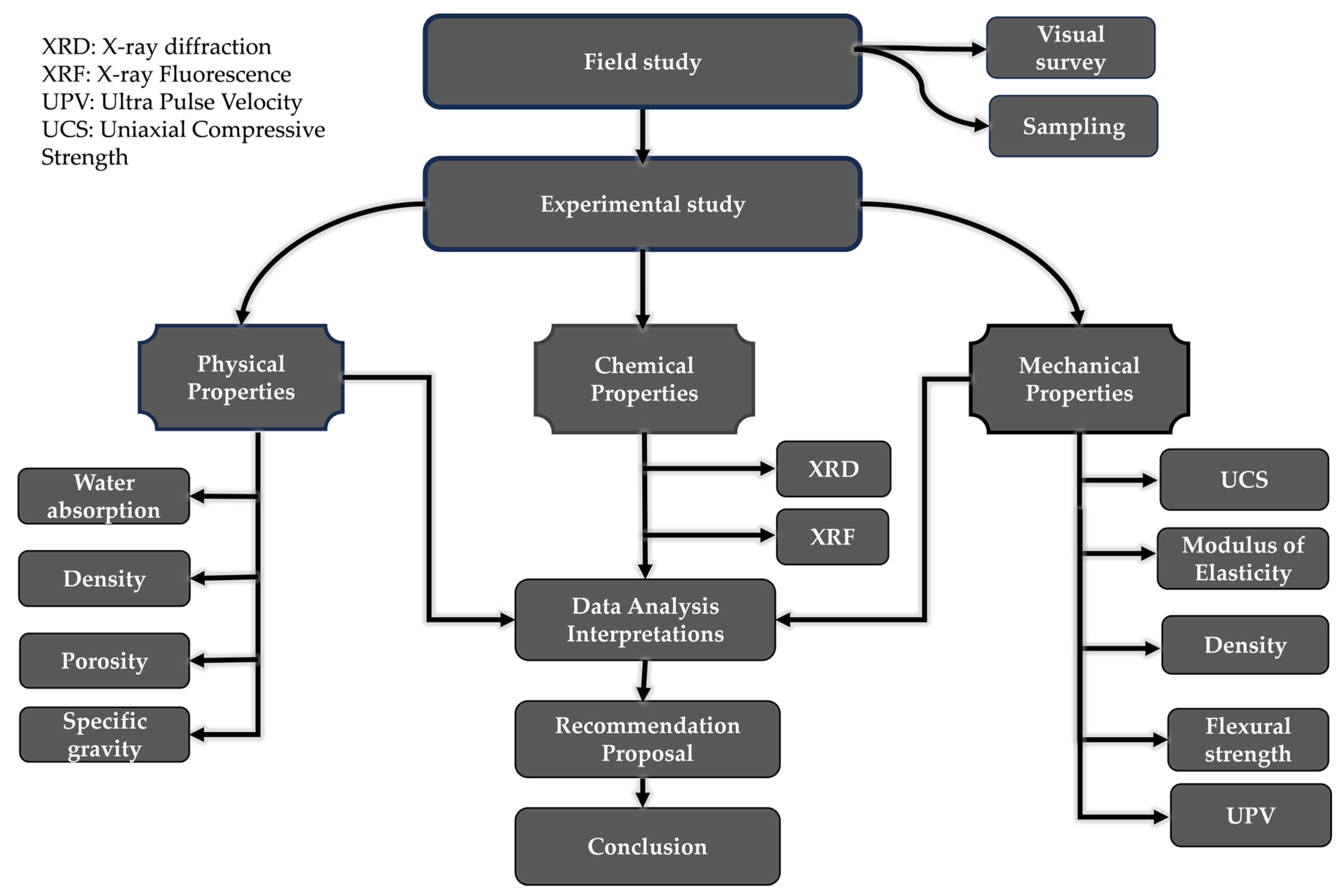

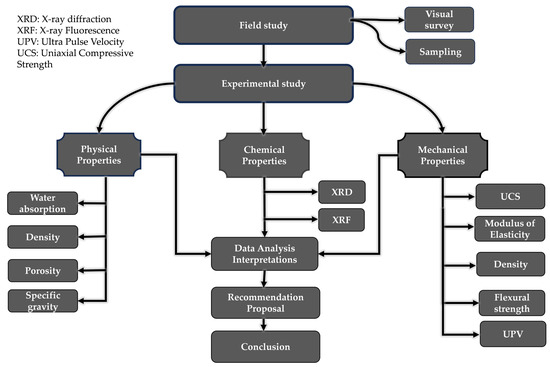

4. Methodological and Experimental Approach

The methodology for this study follows the workflow depicted in Figure 6, which involves the comprehensive investigation of the physical, mechanical, and chemical properties of the construction material for the historical Zanzibar Stone Town, which commenced with an extensive procurement of representative samples across the ten designated zones (Figure 3). The physical testing involves the evaluation of moisture content, bulk density, porosity, and specific gravity for extensively procured samples. The mechanical properties evaluation encapsulates the assessment of compressive strength (CS), flexural strength (FS), modulus of elasticity (E), and in situ Ultra Pulse Velocity (UPV). Chemical analysis testing including X-ray fluorescence (XRF) and X-ray diffraction (XRD) was also conducted to explore the mineralogical compositions.

Figure 6.

Methodological flow chart.

Before mechanical characterization, all specimens underwent physical characterization testing and were subsequently grouped for destructive testing. Additionally, specimens were dried in the oven, weighed to determine their dry mass, and allowed to naturally cool to room temperature. However, if saturation was required for testing purposes, specimens were immersed in water and successively weighed until saturation was confirmed. The coral and mortar samples were subsequently investigated for physical attributes involving a series of tests, including water absorption, specific gravity, bulk density, and porosity, conducted in accordance with ASTM standards C97/C97M [38,39].

However, the compressive strength (CS) test was conducted under the ASTM C170/C170M standard [40]. The process entailed placing the specimen on the compression plate and applying a uniformly distributed load, continuously increasing until the specimen broke (Figure 7a,c). A total of twenty cubic specimens (70 mm × 70 mm × 70 mm) were tested, with ten specimens having the load applied parallel to the anisotropy plane (X-axis) and the other ten specimens having the load applied perpendicular to the anisotropy plane (Z-axis). The testing apparatus utilized was an Instron 5582 Universal Testing Machine (UTM) (Instron Corporation, Norwood, MA, USA) with a capacity press with a maximum load capacity of 3000 kN, equipped with a microprocessor control.

Figure 7.

Photos of different laboratory experiments for coral stone, mortar, and wooden specimens (photos by author).

The material’s flexural strength was assessed based on the ASTM C880/C880M-15 standard [34,35]. The test involved placing the specimen between two rollers and applying a load to the center point until the specimen broke. The direction of the force application was taken into account, and ten specimens (each measuring 30 mm × 100 mm × 350 mm) were tested for each direction: perpendicular to the edge of the anisotropy planes (X-axis), parallel (Y-axis), and perpendicular (Z-axis). The testing machine was an Instron 5582 Universal Testing Machine (UTM) with a capacity press with a maximum load capacity of 3000 kN (Figure 7b).

The coral stone and mortar samples underwent Ultra Pulse Velocity (UPV) testing, following ASTM C597 standard [41]. UPV testing, a non-destructive method, determines the speed of ultrasonic waves within a material. The Proceq Pundit PL-200 (Proceq, Schwerzenbach, Switzerland) was used for testing, as shown in Figure 7e. A grid structure facilitated precise transducer placement on opposing faces of the specimen. Ultrasonic waves were transmitted through the specimen by the pulse transducer and received by the reception transducer. UPV values were computed based on wave distance and time, with each specimen yielding three test points across each sample. These measurements determined the modulus of elasticity (E) using established equations [41]. Poisson’s ratio (ν) was also calculated using longitudinal and transverse wave velocities obtained from the UPV measurements [41].

Meanwhile, the XRD and XRF were performed in accordance with ASTM E1361 [42] guidelines to determine the mineralogical composition for the determination of a specific conservation treatment. The XRD was conducted using a Bruker D8 Advance diffractometer (Bruker Corporation, Billerica, MA, USA), with measurements taken from 5° to 70° 2θ at an angle increment of 0.02° for a duration of 1 second per angle measurement, as shown in Figure 7f [16,17,37].

Moreover, compression tests of wood samples were conducted on small clear specimens according to JIS Z 2101 [38,39], using an Instron 5582 Universal Testing Machine (UTM) with a capacity of ±100 kN. The UTM measured load with an accuracy of 0.5% and deflection with an accuracy of 0.25 µm. Specimens were loaded at a controlled rate of 0.6 mm/min using flat platens, as shown in Figure 7g. Tests were performed on specimens measuring 25 mm × 25 mm × 75 mm, applying a compressive load parallel to the fibers until failure. The compressive modulus of elasticity (Ec) was calculated from the stress-strain curve over the elastic portion, based on stress and strain at 40% and 10% of the ultimate compressive [38,39].

Additionally, bending tests of wood samples were conducted using the Instron 5582 Universal Testing Machine, employing a horizontally supported three-point bending fixture. Specimens, sized 25 × 25 × 350 mm, were placed on rollers 710 mm apart, with a 25 mm overhang at each end. A 2.5 mm/min load rate was applied at mid-span using a steel bearing block with a radius of 75 mm (Figure 7h). The modulus of elasticity (Eb) was calculated based on load and deflection at mid-span, following JIS (1994) guidelines. The modulus was determined from the slope between 10% and 40% of the ultimate load, with only one sample tested per specimen due to sample limitation. Correlations for physical and mechanical properties were developed to ascertain the inter-parametric relationships. Subsequently, the restoration guidelines for future renovation work were developed considering factors such as susceptibility to degradation over time, compatibility with existing materials, and construction techniques.

5. Results

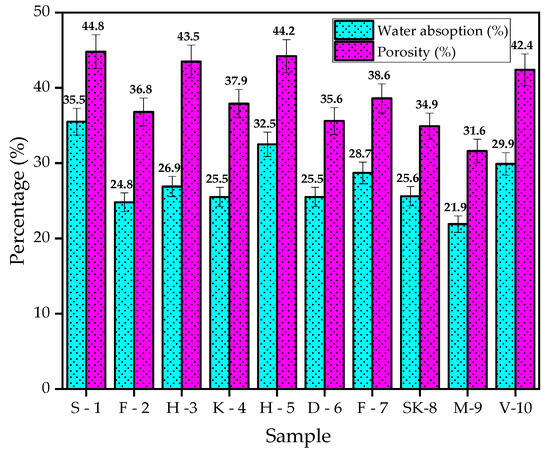

5.1. Physical Properties of Coral Stone

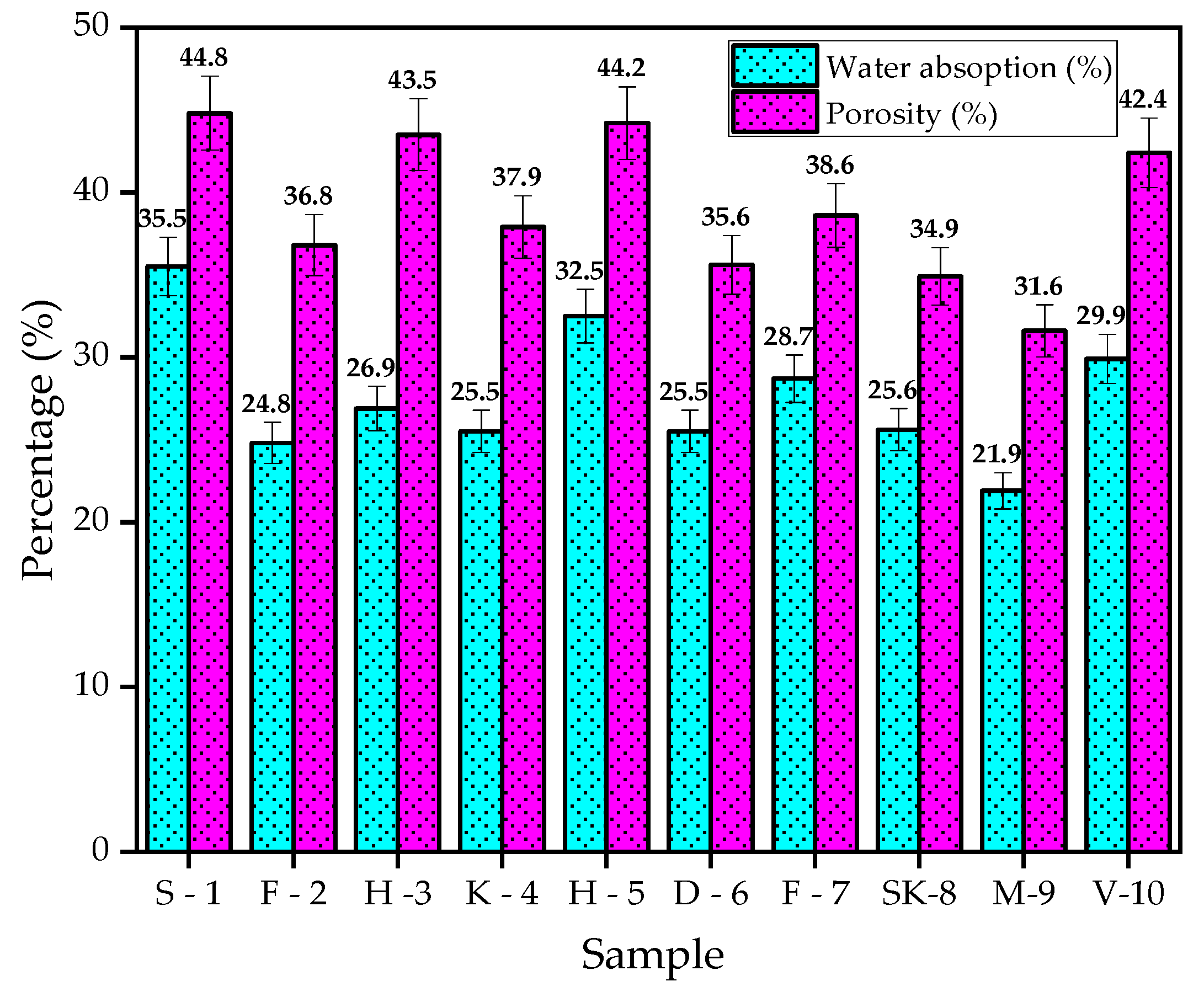

The experimental investigation reveals distinct physical properties of coral stone samples obtained from historical structures in Zanzibar Stone Town, as shown in Table 1. The porosity of samples obtained from different locations ranges from 31.6% to 44.8%, indicating diverse pore structures within the specimens. Similarly, water absorption values range from 21.9% to 35.5%, closely corresponding to the observed porosity levels, as depicted in Figure 8. This correlation between water absorption and porosity underscores the robust intrinsic relationship between these parameters within the examined coral stone samples.

Table 1.

Average values of physical properties of coral stone.

Figure 8.

Water absorption and porosity stone.

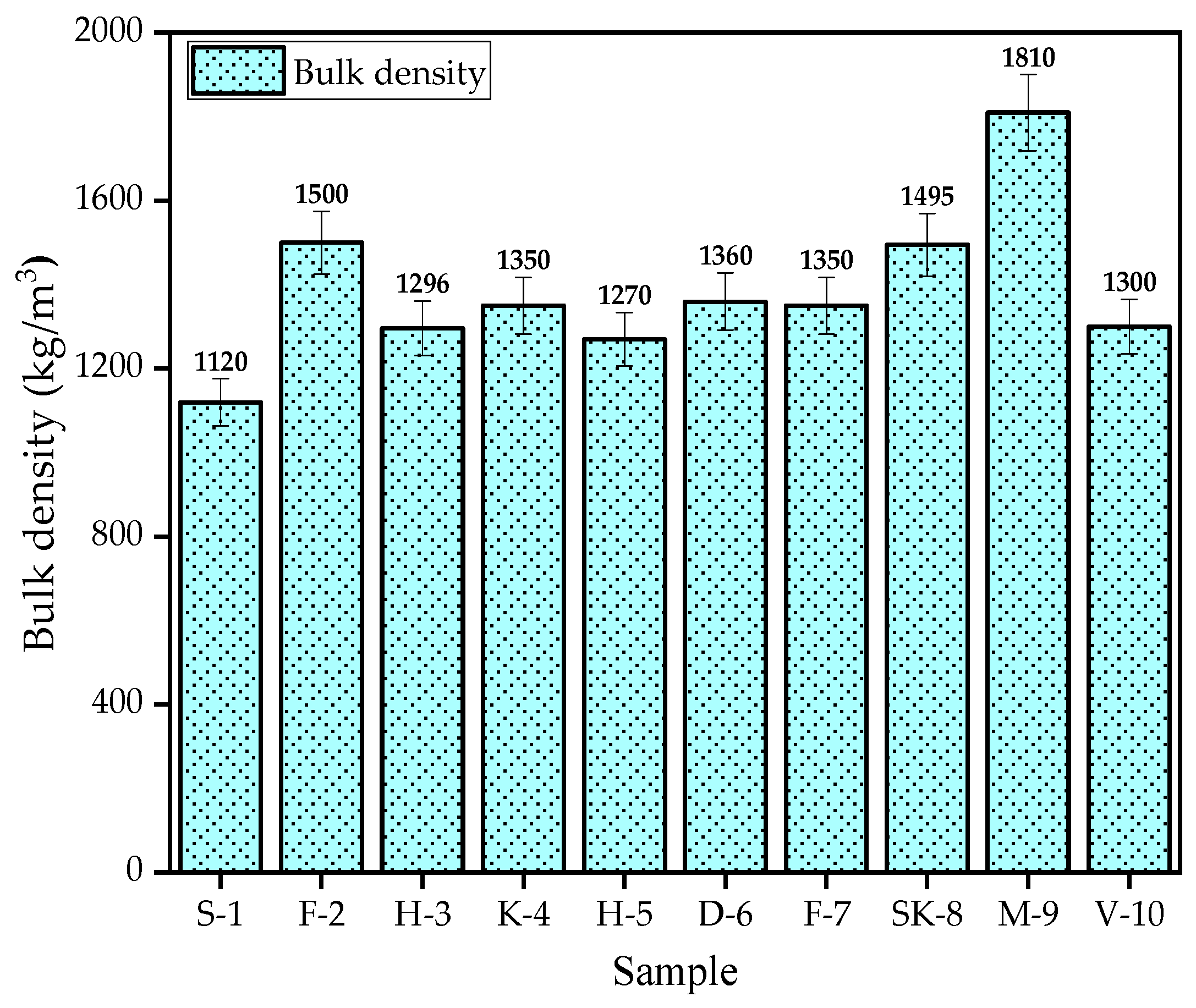

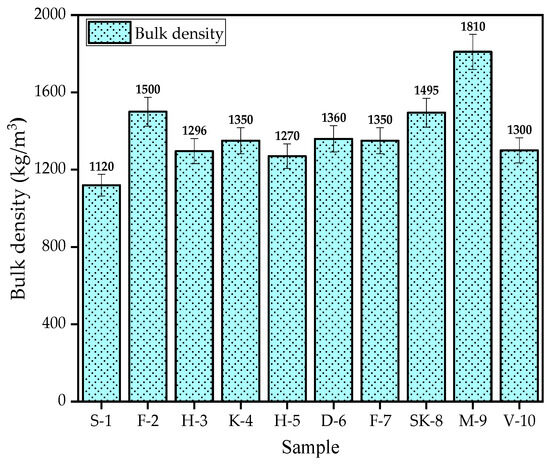

On the other hand, bulk density assessments yield values spanning from 1120 to 1810 kg/m³, with an average of 1395 kg/m³, classifying Zanzibar coral stone within the low-density spectrum as per established criteria [43], as illustrated in Figure 9. Furthermore, the bulk density was observed to be lowest for S-1, while the percentage of water absorption and porosity exhibited the highest values for the same specimen. Despite variances in bulk density, specific gravity measurements remain relatively consistent, varying between 1.3 and 1.6.

Figure 9.

The density of the coral stone.

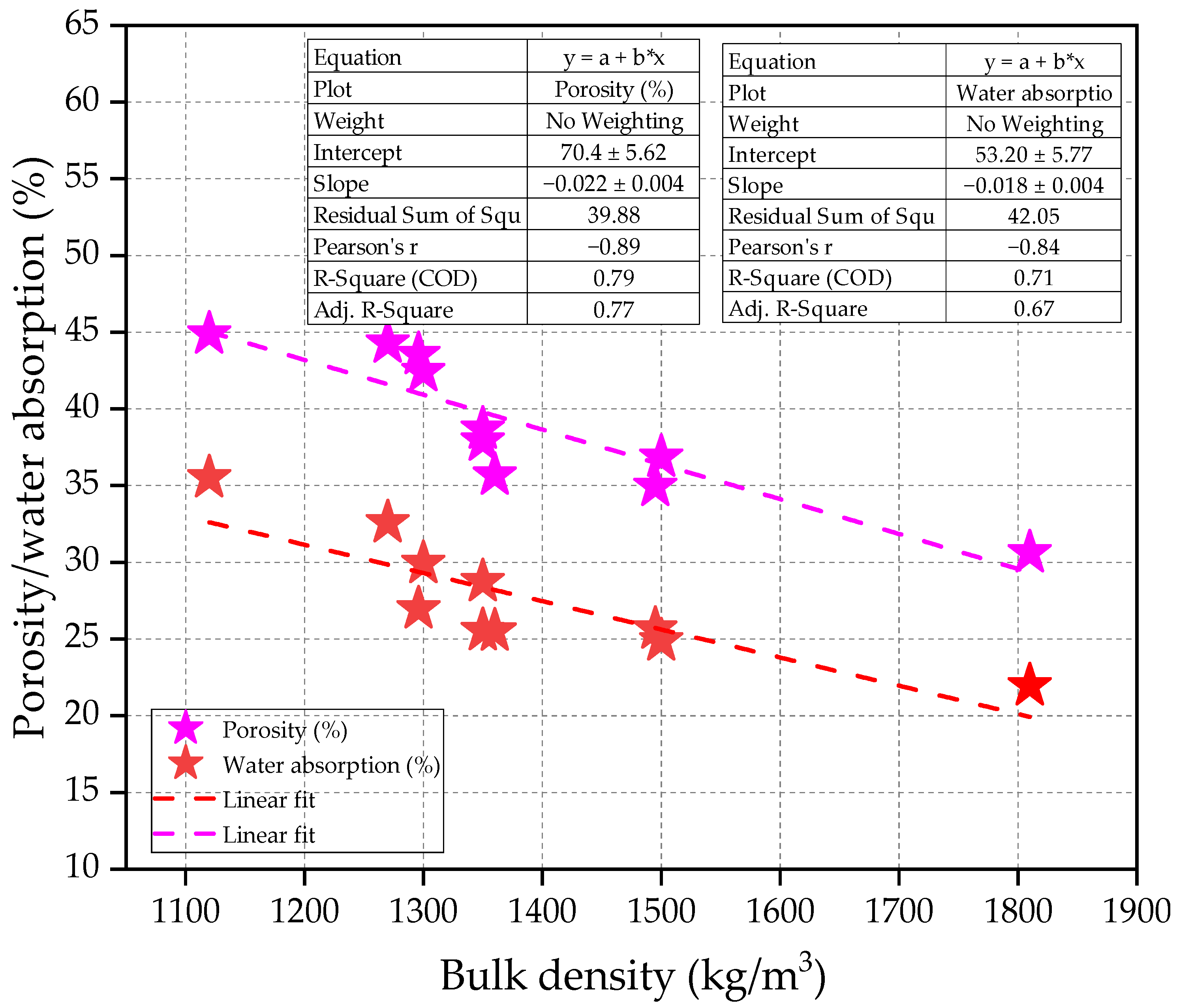

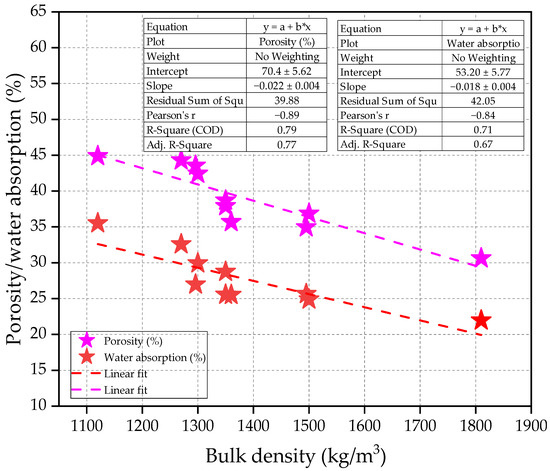

Figure 10 displays an inverse relationship between bulk density, porosity, and water absorption for historical coral stones. As bulk density increases, both porosity and water absorption decrease, evidenced by the strong negative correlations indicated by Pearson’s r values of −0.89 for porosity and −0.84 for water absorption. This signals that denser materials, with higher bulk densities, tend to have fewer and smaller pores, leading to reduced water absorption capabilities. The high R-squared values, approximately 79% for porosity and 71% for water absorption indicate that changes in bulk density can explain a significant portion of the variation in these properties.

Figure 10.

Correlation between density vs. porosity and water absorption of coral stone.

5.2. Mechanical Properties of Coral Stone

Extensive testing, including compressive strength (CS), flexural strength (FS), modulus of elasticity (E), and in situ Ultra Pulse Velocity (UPV) of coral stones, was conducted on well-prepared samples, yielding a distinct range of results regarding the aforementioned properties, as indicated in Table 2. The CS measures the material’s ability to sustain compressive stresses, revealing values ranging from 7.6 MPa to 15.1 MPa, with the lowest and highest values attributed to specimens designated S-1 and M-9, respectively.

Table 2.

Average values of mechanical properties of coral stone samples.

On the other hand, the flexural strength values, which quantify the material’s bending resistance before breakage, ranged from 2.0 MPa to 3.4 MPa, with the highest and lowest values attributed to SK-8 and K-4, respectively, with an average range of 2.7 MPa. The compressive and flexural range indicates the higher variability of procured specimens across the Stone Town construction, indicating the prevalence of bending-induced stresses. Furthermore, the specimens were investigated along parallel and perpendicular directions, revealing the insignificant influence of loading direction on mechanical strength. This uniformity in strength across orientations suggests that the microstructure of coral stone is relatively homogeneous, leading to consistent mechanical behavior irrespective of testing directions.

Further, the UPV test yields a distinct range of velocities between 3427 and 5012 (m/s), with the lowest and highest values pertaining to K-4 and SK-8 zone specimens having an average estimated value of 4166.3 m/s. The lower velocities signal the weak microstructural composition vulnerable to a higher degree of depreciation against the extreme environmental and weathering effects. Meanwhile, the modulus of elasticity (E) falls under the range of 1231 to 2358 MPa, with an average of all the procured samples computed to be 1650 MPa, suggesting low to moderate lateral expansion under extreme compressive stresses.

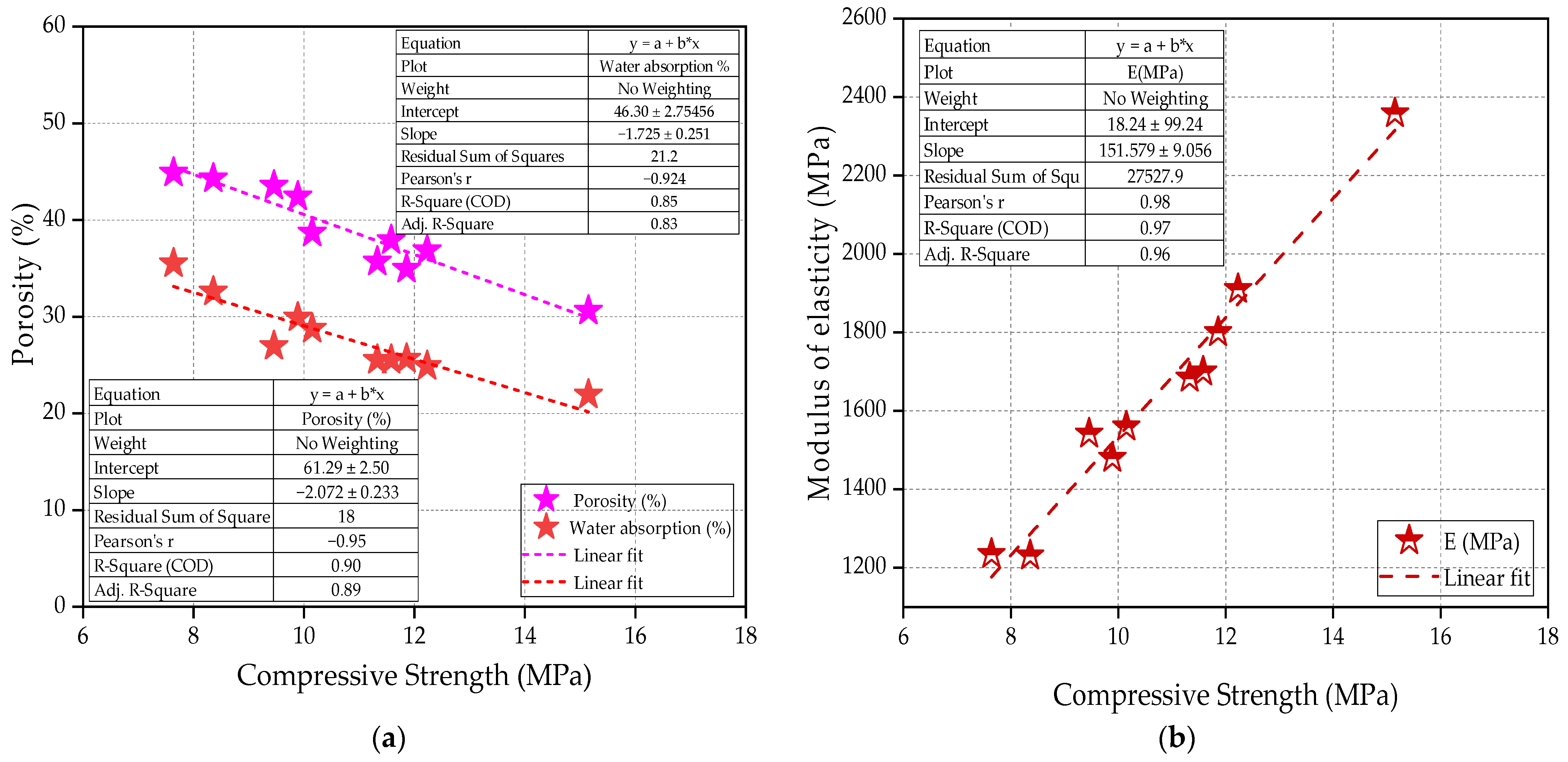

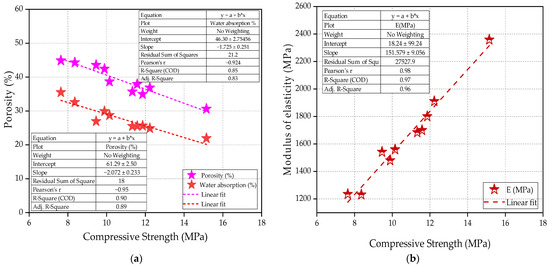

The empirical correlations were developed between the compressive strength and various parameters, revealing a significant association with water absorption, porosity, and modulus of elasticity (E), respectively. Figure 11a illustrates a negative correlation between the compressive strength (MPa) and both porosity (%) and water absorption (%) of the tested samples. The linear regression for porosity (y = 61.29 − 2.01x) shows a strong negative correlation (Pearson’s r = −0.953), with an R-squared value of 0.9, indicating that higher compressive strength leads to lower porosity, signifying denser materials. Similarly, the regression for water absorption (y = 46.30 − 1.725x) also exhibits a strong negative correlation (Pearson’s r = −0.925), with an R-squared value of 0.855, suggesting higher compressive strength results in lower water absorption, indicating better durability.

Figure 11.

Correlation between mechanical and physical properties of coral stone. (a,b) Compressive Strength vs. modulus of elasticity.

Figure 11b illustrates the relationship between the modulus of elasticity (E) and the compressive strength of a material, demonstrating a positive linear correlation between these two mechanical properties. As compressive strength increases, the modulus of elasticity also increases, indicating that materials capable of withstanding higher compressive forces tend to be stiffer and less deformable under load. These correlations provide invaluable insights for restoration efforts, guiding material selection and construction techniques to ensure structural integrity and longevity in future renovation projects.

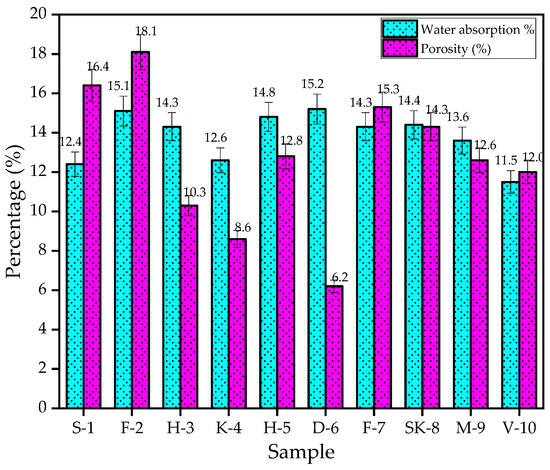

5.3. Physical Properties of Mortar

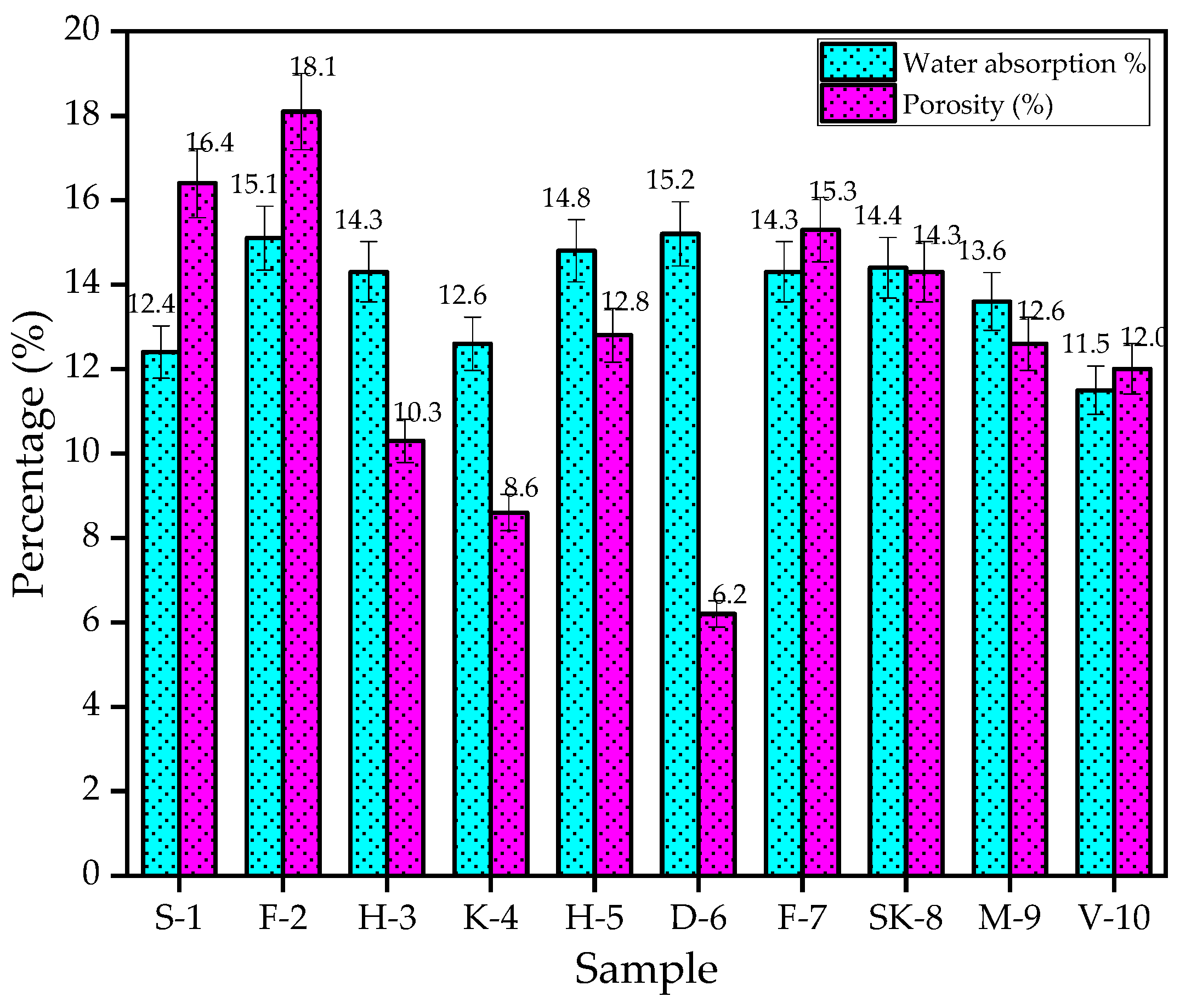

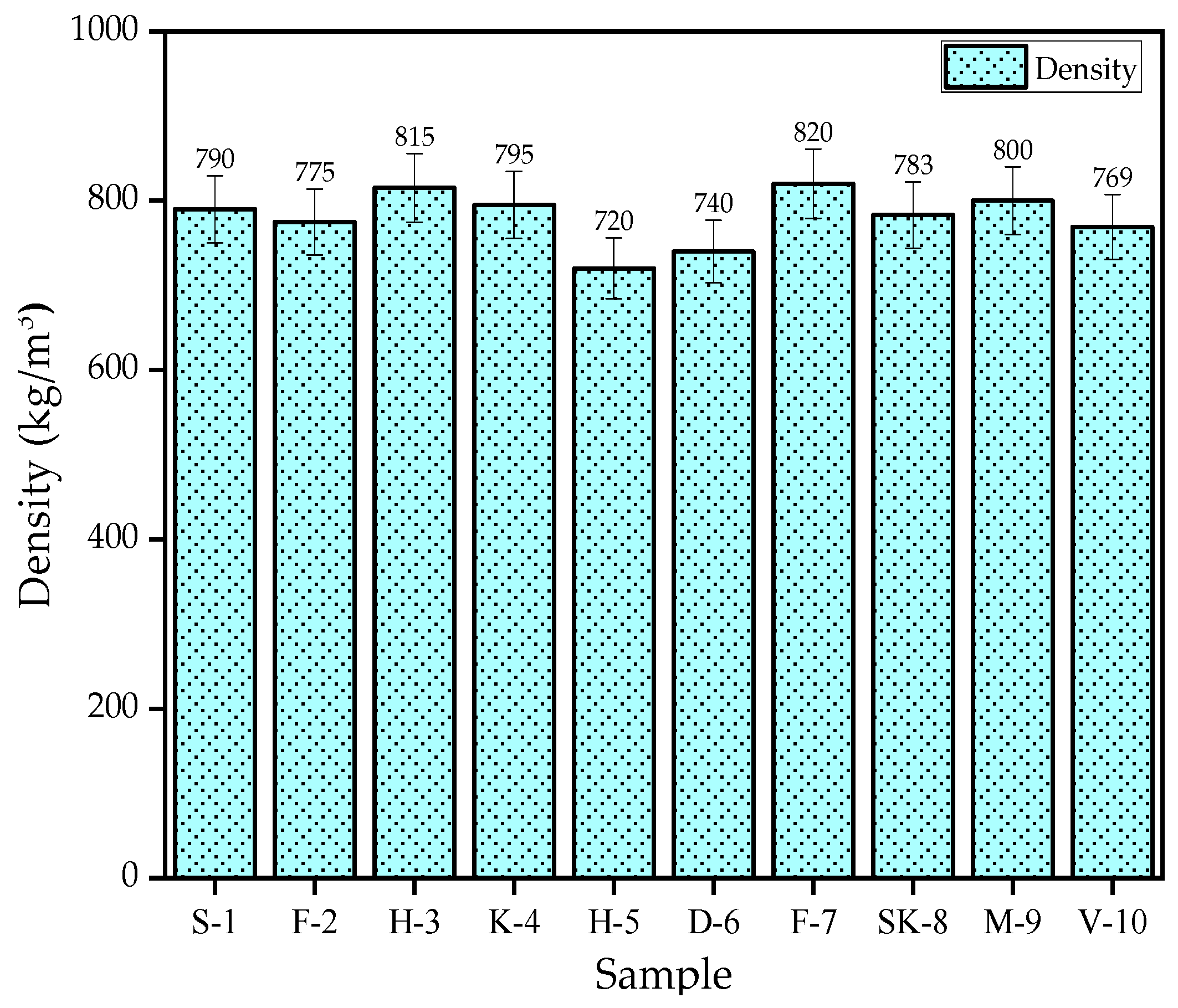

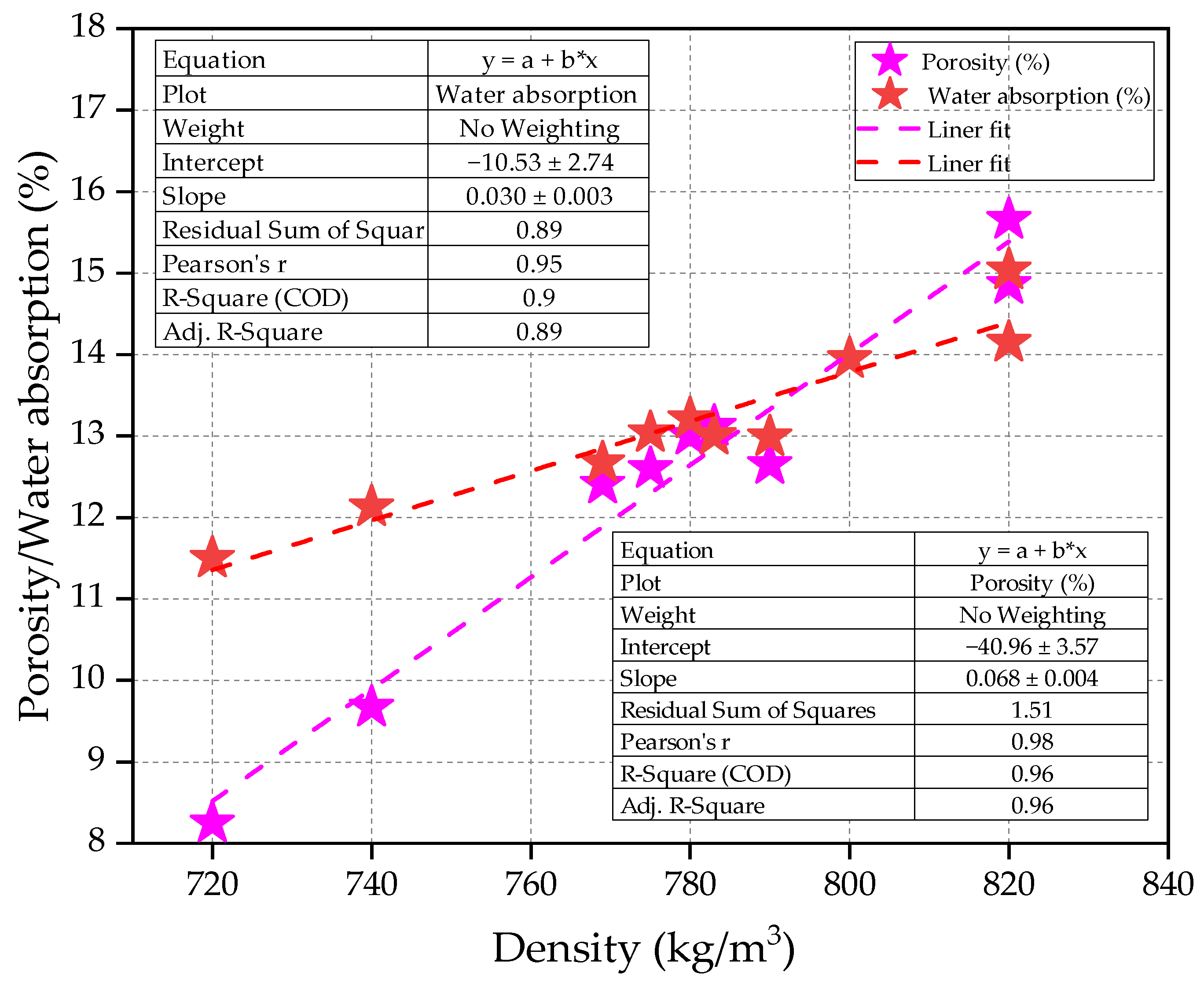

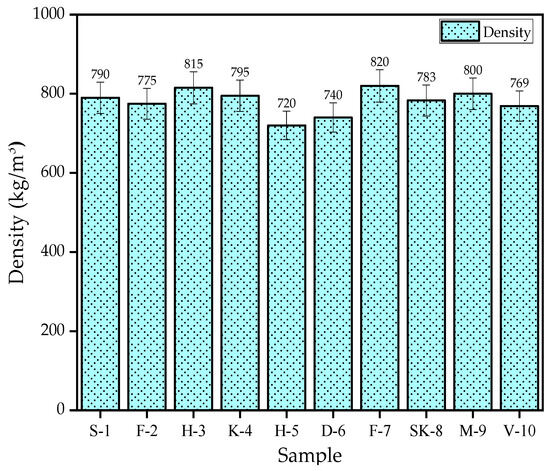

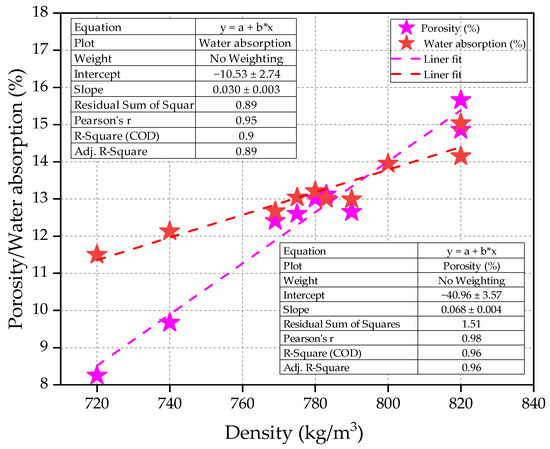

The physical characteristics of mortar samples were examined to assess their water absorption capacity, density, and porosity to ascertain their implications for structural integrity and longevity (shown in Table 3 and Figure 12 and Figure 13). The results revealed water absorption rates spanning from 11.5% to 15.2% across the sampled specimens, with the D-6 samples exhibiting the highest absorption while the V-10 sample displayed the lowest due to the decay and deterioration condition of the building. Concurrently, the dry density of the samples demonstrates a range from 720 kg/m3 to 820 kg/m3. At the same time, the porosity measurements yielded values ranging between 6.2% and 18.1%, with the strong correlation between density and porosity having R2 = 0.9 to 0.97 as shown in Figure 14.

Table 3.

Average values of physical properties of mortar samples.

Figure 12.

Water absorption and porosity of mortar.

Figure 13.

The density of the mortar.

Figure 14.

Correlation between density vs. porosity and water absorption of mortar.

5.4. Mechanical Properties of Mortar

The mechanical properties of mortar samples were assessed through compressive strength (CS), Ultra Pulse Velocity (UPV), and Poisson ratio (v), yielding distinct ranges of mortar utilized for the construction of Zanzibar Stone Town. The results revealed a CS range spanning from 0.5 to 0.9 MPa, with the lowest and highest values attributed to specimens K-4 and H-5, respectively, with an average value computed to be 0.7, as depicted in Table 4. The lowest compressive strength of the K-4 specimen indicates lower strength compared to standard mortar samples. Under extreme compressive stresses, the sample becomes brittle, exhibiting a vertical fracture pattern. Vertical cracks in the sample indicate shear planes, crumbling, and powdering, signaling extremely weak binding that exceeds the inherent tensile and cohesion strength due to mortar age and subsequent extreme environmental and tropical impacts over time.

Table 4.

Average values of mechanical properties of mortar samples.

Meanwhile, the Ultra Pulse Velocity (UPV) exhibits a range between 1668 and 2070 m/s, with the lowest and highest values pertaining to specimens H-5 and K-4, respectively. The significant variation in UPV across the various specimens highlights differences in the internal structure of the mortar and material properties. Higher velocities indicate a highly dense micropore structure, while lower ranges demonstrate defective internal bonding with frequent voids.

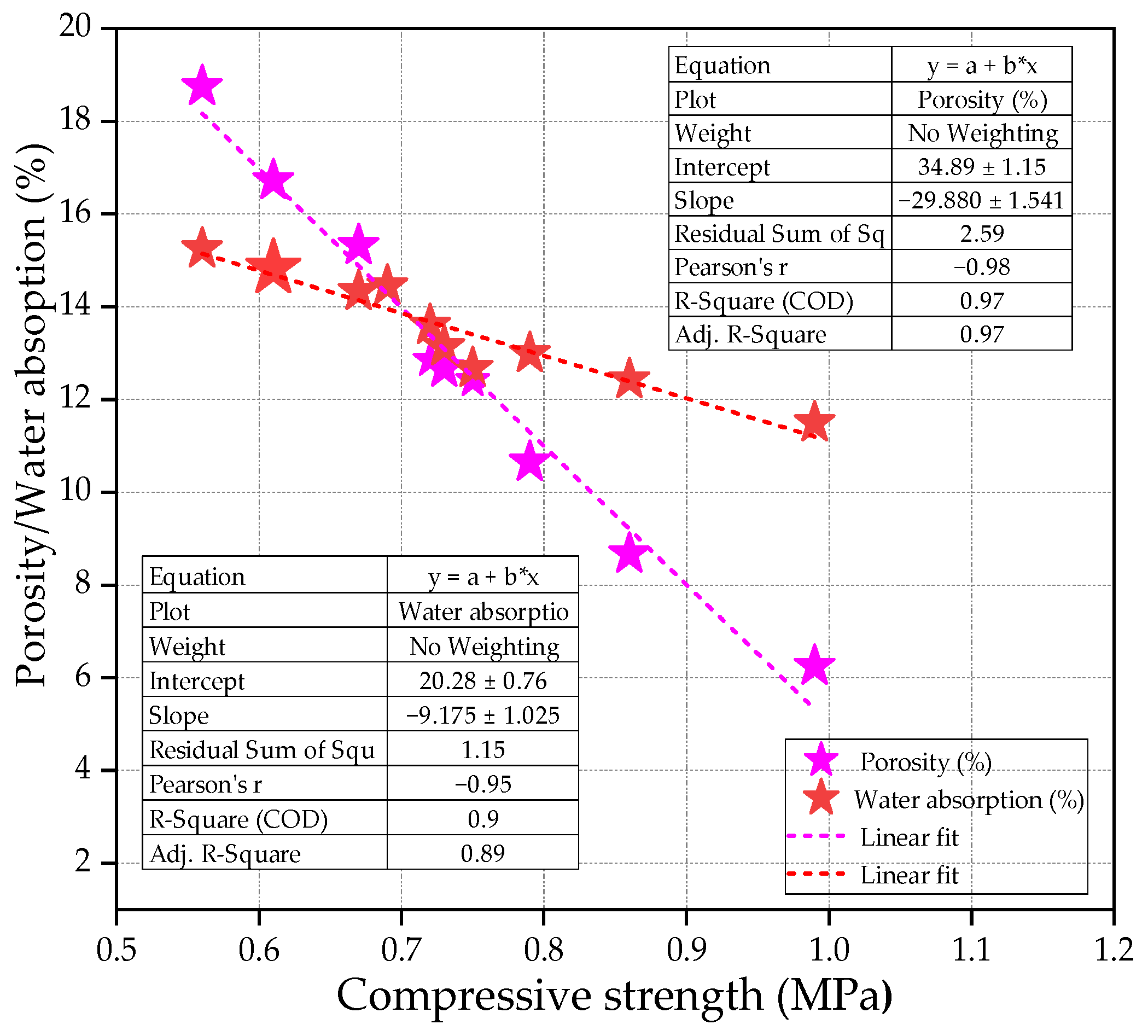

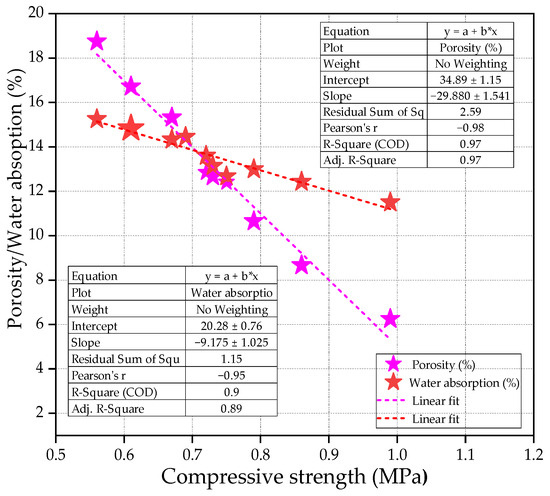

Figure 15 illustrates a negative correlation between the compressive strength, porosity, and water absorption of the tested samples. This indicates that higher compressive strength leads to lower porosity, signifying denser materials. Similarly, the regression for water absorption also exhibits a strong negative correlation, suggesting that higher compressive strength results in lower water absorption, indicating better durability.

Figure 15.

Correlation between compressive strength vs. porosity/water absorption of mortar.

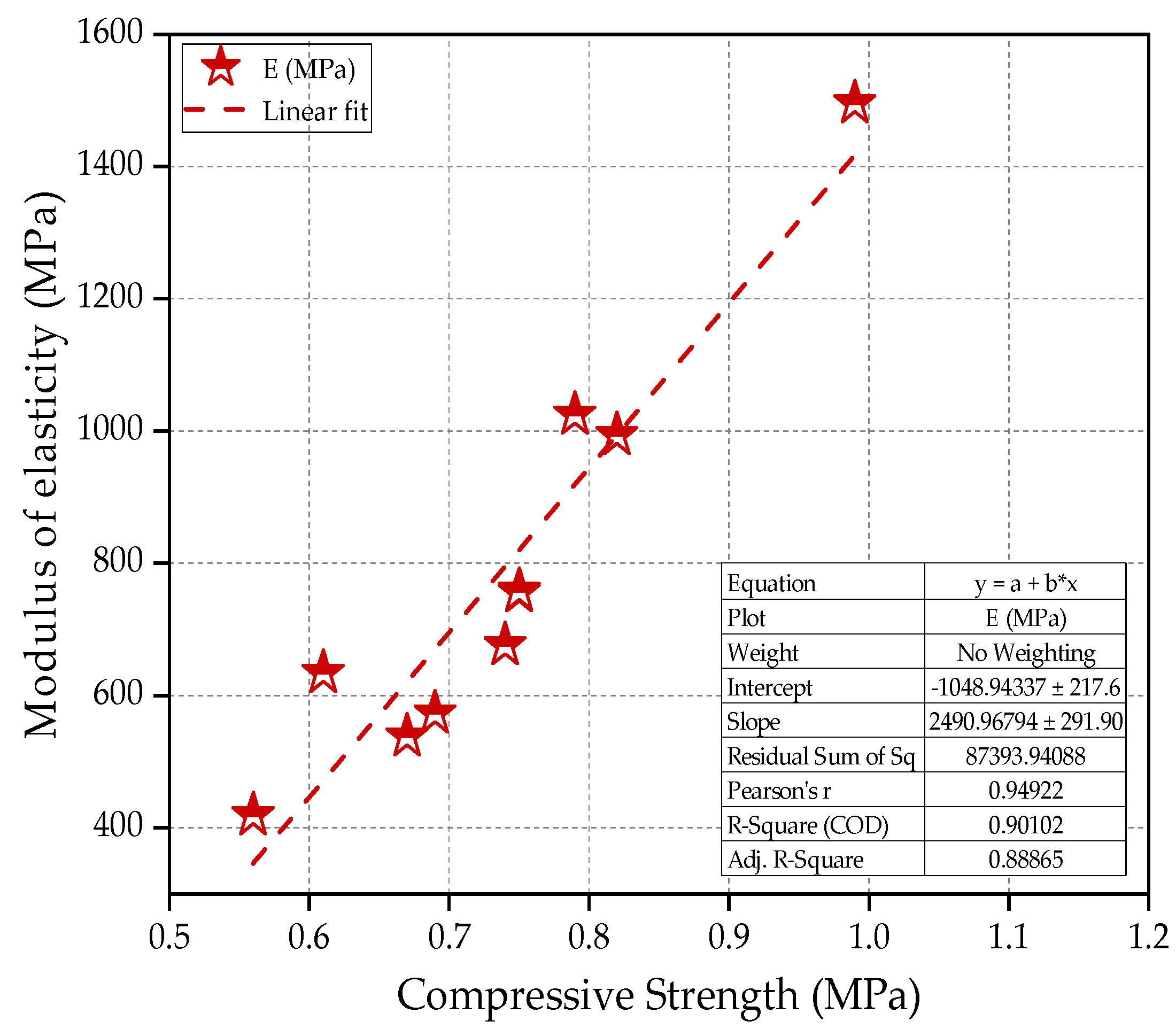

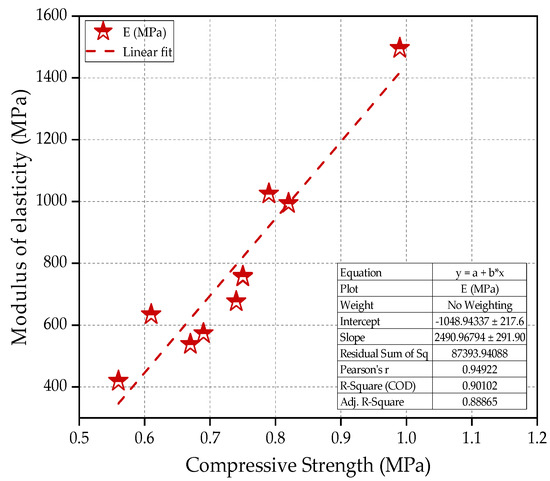

Meanwhile, the modulus of elasticity (E) falls under the range of 538 to 1496 MPa, with an average of all the procured samples computed to be 786.9 MPa and v ranges between 0.01 and 0.1, with the lowest value attributed to specimen K-4. Figure 16 illustrates the relationship between a mortar material’s modulus of elasticity and compressive strength, showcasing a positive linear correlation between these two mechanical properties. As compressive strength increases, the modulus of elasticity also increases, indicating that materials capable of withstanding higher compressive forces tend to be stiffer and less deformable under load. This correlation underscores the intrinsic interplay between the physical attributes of mortar specimens, highlighting the importance of considering these factors in material characterization and structural assessment.

Figure 16.

Correlation between compressive strength vs. modulus of elasticity of mortar.

5.5. Chemical Investigations of Coral Stone and Mortar

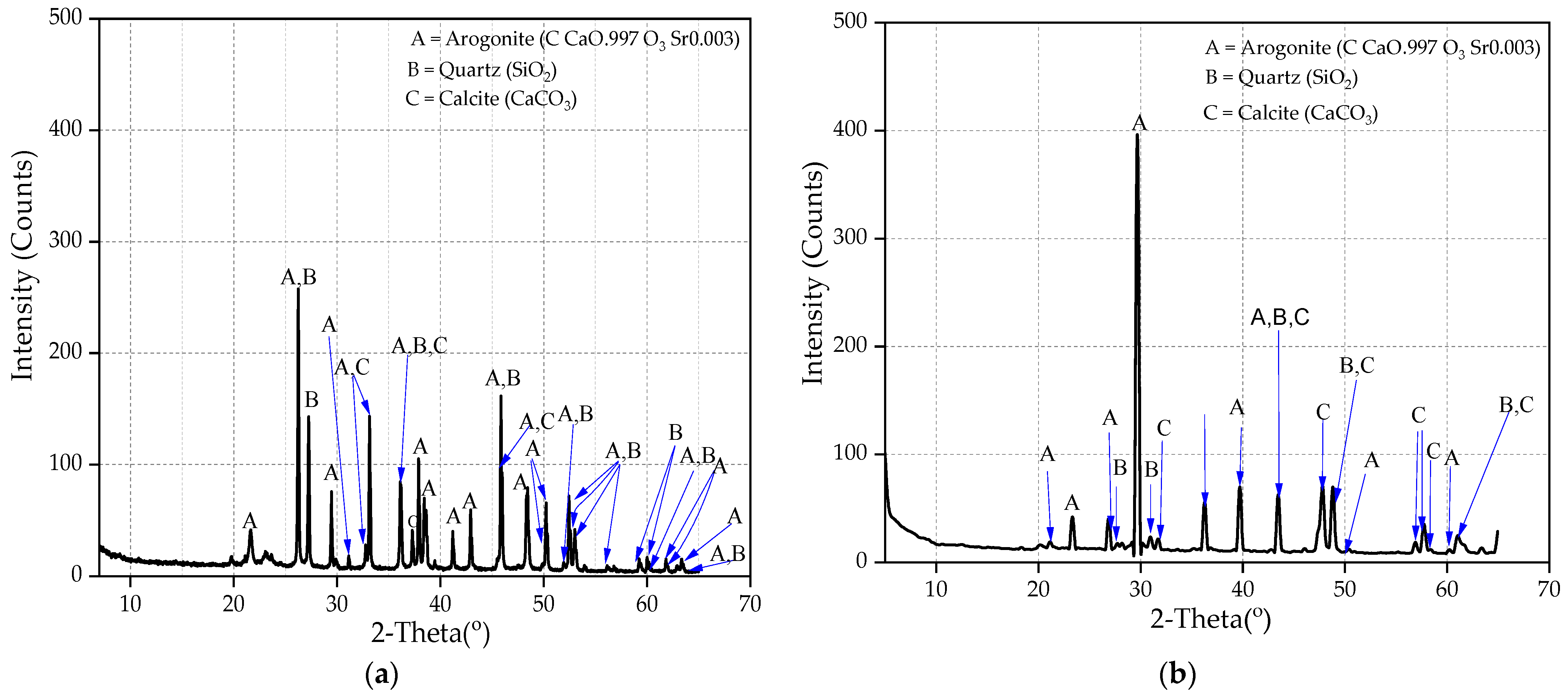

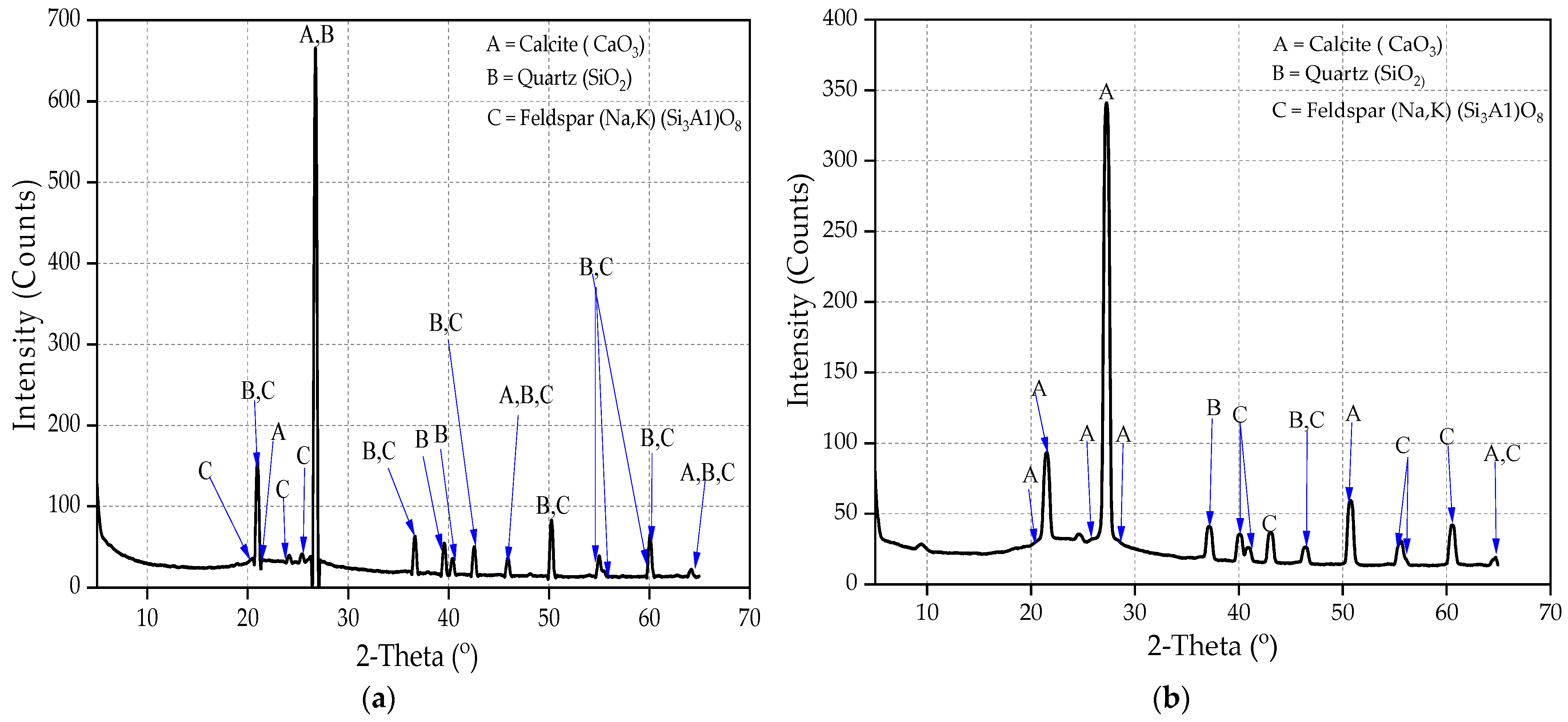

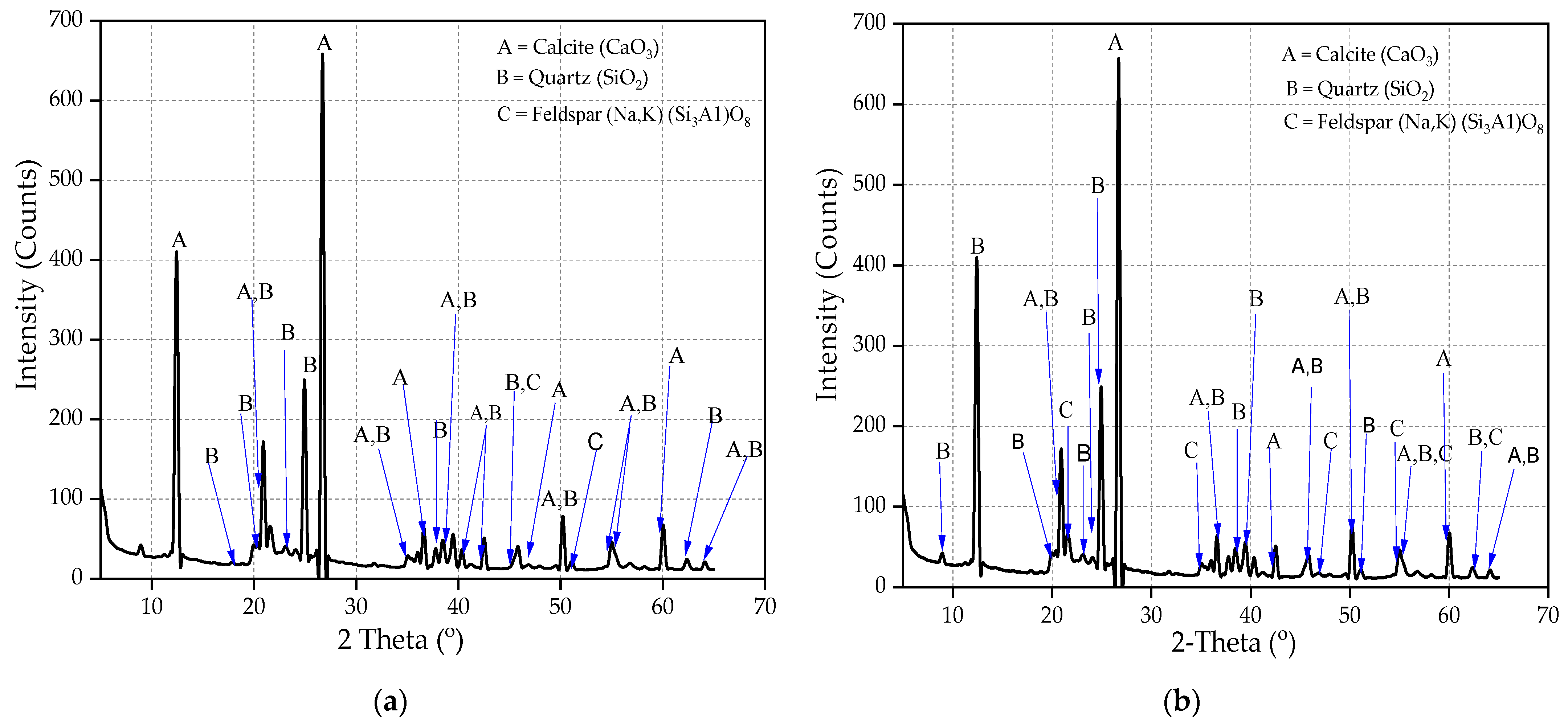

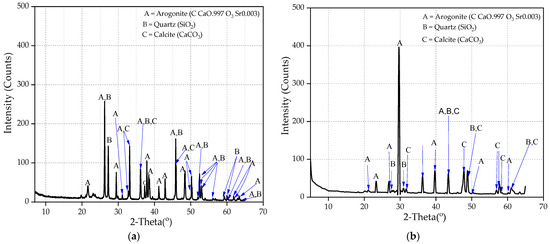

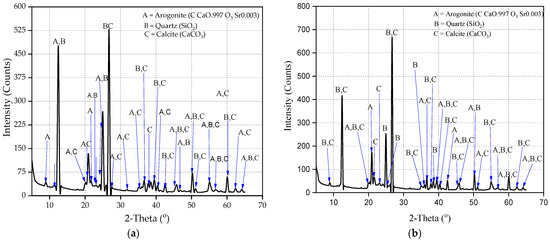

The XRD diffractogram of the coral stone samples reveals the mineralogical composition, as illustrated in Figure 17, Figure 18 and Figure 19. The significant peaks indicate the presence of the mineral aragonite, which is the polymorph of calcium carbonate. The higher percentage of, i.e., 95.6% aragonite minerals, as indicated by intense peaks, signals some degree of metamorphism, as the formation of aragonite generally develops under high pressure and temperature. In addition, the quartz (SiO2) exists in a small portion, i.e., 3.4%, indicating the presence of silicious content. A minor presence of lime (CaO), found to be 0.9%, demonstrates the extent of weathered limestone or the unreacted lime from the original sedimentary rock. Moreover, the variation in 2 theta degree demonstrates the angles at which the X-ray diffracted corresponding to the lattice spacing (d [Å]), intensity (intensity (I/I0), and full width at half maximum (FWHM) and the identification of matched phases for individual peaks. The FWHM values indicate the crystallite size and the level of crystallinity within the sample. Generally, narrower peaks (lower FWHM values) indicate a higher degree of crystallinity, showing the presence of micro strains or smaller crystal sizes delineated by the higher weathering or mechanical stresses. Moreover, the results indicate a weak crystalline structure, highlighting the requirement for conservations using consolidates that may improve the resistance of limestone against future decay.

Figure 17.

XRD diffractograms of coral stone samples. (a) S-1 samples, (b) F-2 samples.

Figure 18.

XRD analysis of the coral stone samples. (a) H-3 samples, (b) K-4 samples.

Figure 19.

XRD analysis of the coral stone samples. (a) M-9 samples, (b) V-10 samples.

Meanwhile, the XRF analysis reveals the distinct percentages of chemical compositions for coral stone used in the historical construction of Zanzibar’s Stone Town (Table 5). The results indicate that coral stone contains a significant amount of calcium oxide (CaO) at 91.9%, suggesting a calcareous source predominantly made up of aragonite. However, the CaO content ranges from 64.5% to 91.5%, with an average of 77.9% across the various samples. This indicates that the stone originated from a marine environment, exhibiting the presence of minor elements such as strontium oxide (SrO) at approximately 0.8%, which highlights its inherent vulnerability to damage from salt attacks. The SiO2 content is relatively low across all samples, ranging from 0.4% to 10.3%, with an average content of 6.5%. The varying degrees of Al2O3 in the S-1 and V-10 samples, estimated to be 1.2% and 22.5%, respectively, indicate different degrees of terrigenous material inclusion within the coral stone. The presence of other oxides like sodium oxide (Na2O), sulfur trioxide (SO3), strontium oxide (SrO), and magnesium oxide (MgO) in varying amounts provides insights into the environmental conditions of the material formation and the potential influences of non-marine sources.

Table 5.

Chemical composition of coral stone samples.

Additionally, the XRF analysis indicates a dominant composition of CaO (91.9%). In contrast, the XRD analysis reveals aragonite, a polymorph of calcium carbonate (CaCO3), as the major crystalline phase present in the stone sample. This apparent discrepancy can be attributed to several factors. Firstly, the sample preparation or measurement conditions for XRF might have induced partial decomposition of CaCO3 to CaO and CO2. This thermal decomposition is a recognized process that can occur under high temperatures. Secondly, while XRD specifically identifies the crystalline phases present, XRF determines the elemental composition, which means it cannot distinguish between different calcium-containing compounds. Finally, the sample may be heterogeneous, containing both aragonite and CaO, with XRD detecting the crystalline aragonite and XRF measuring the total calcium content, including CaO.

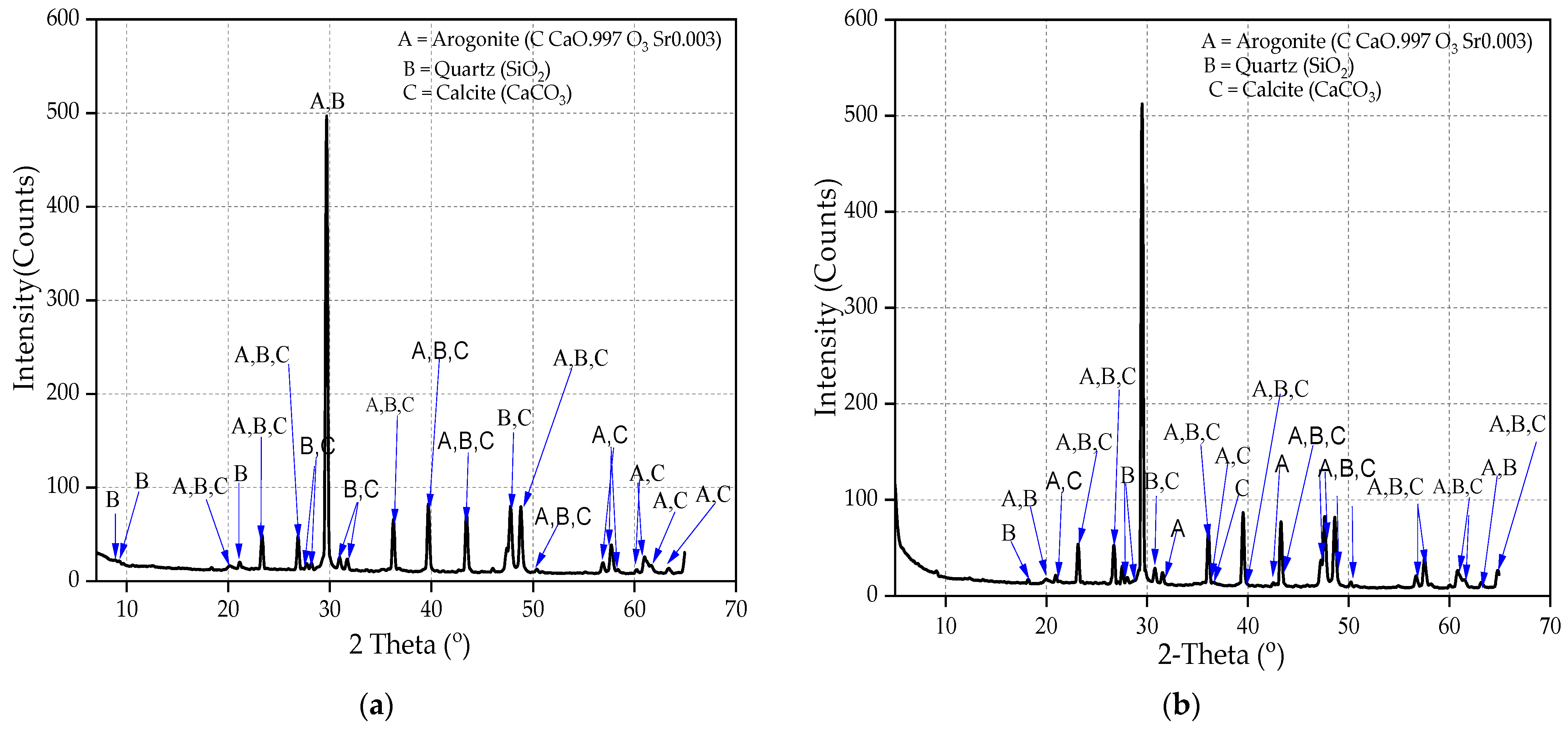

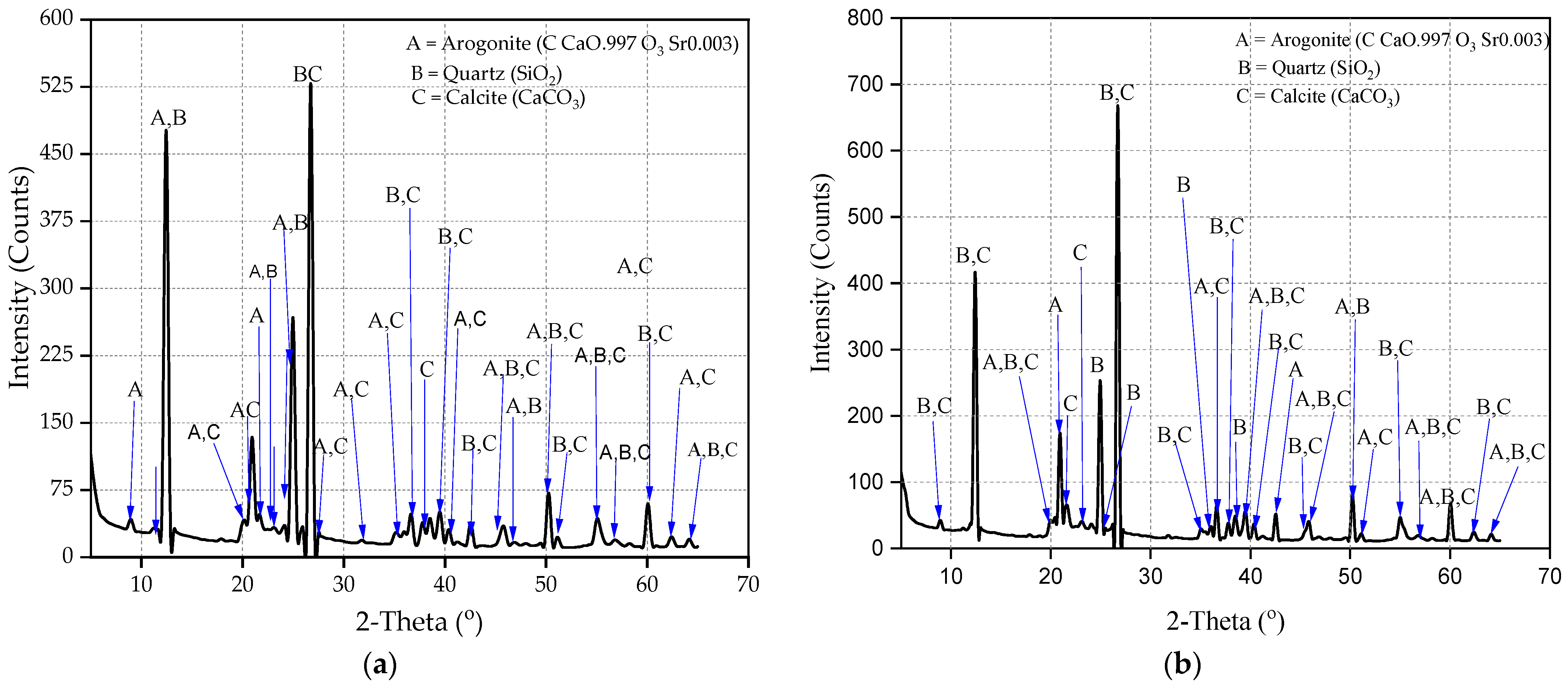

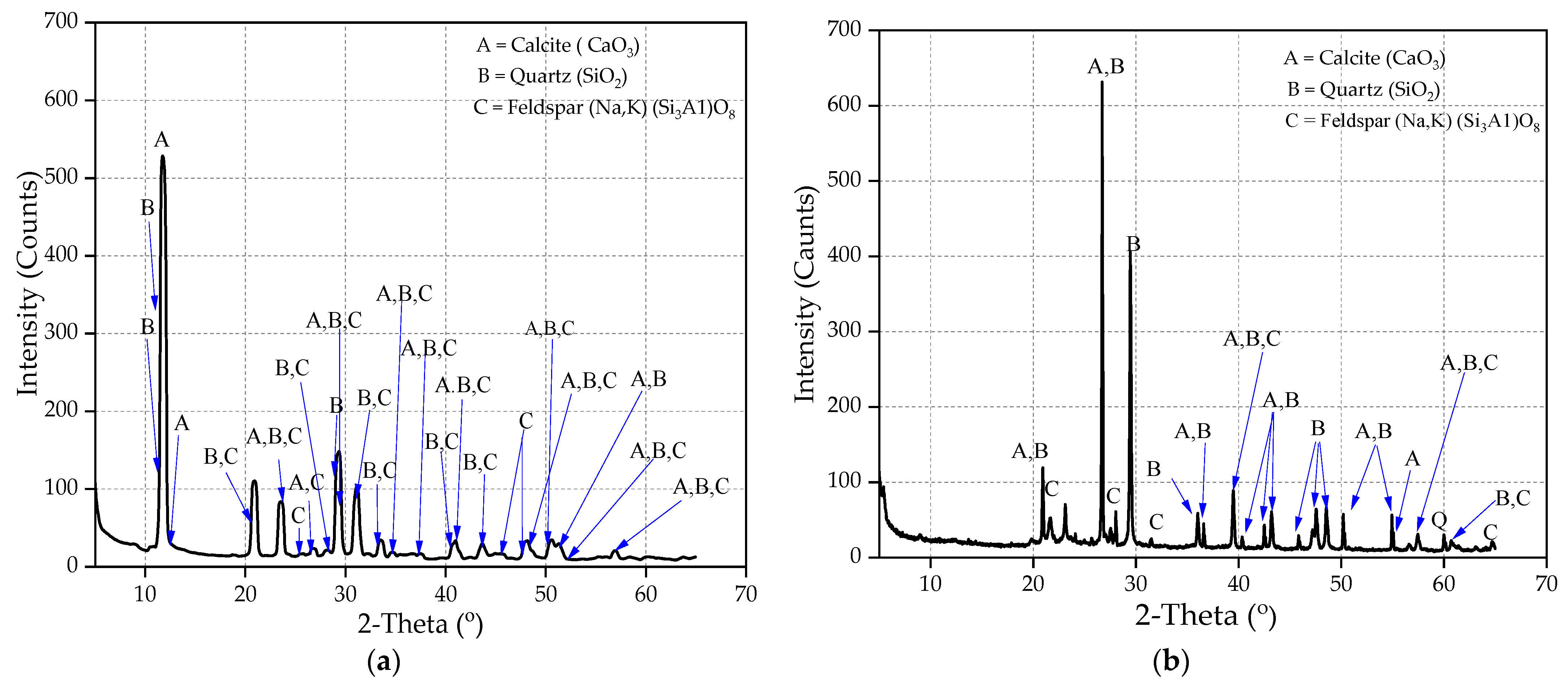

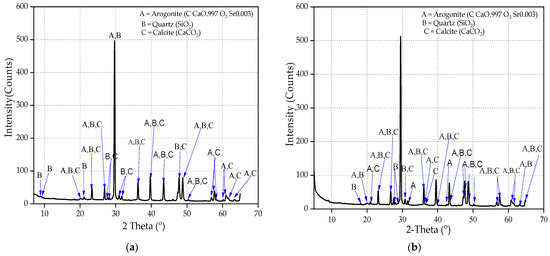

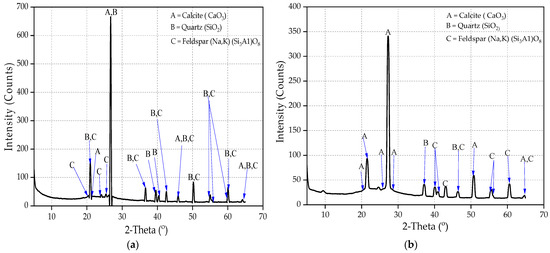

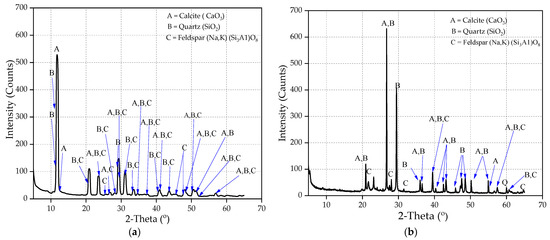

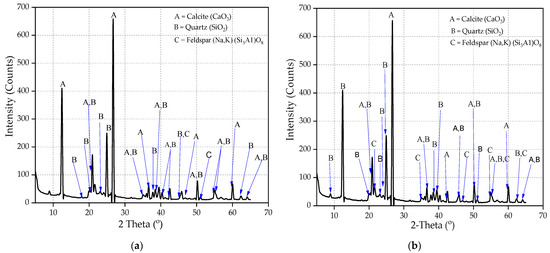

On the other hand, the results of the chemical examination of the historical mortar are given in Table 6, while the mineralogical compositions of the mortar examined by XRD analysis are presented in Figure 20, Figure 21 and Figure 22. XRD analysis for the mortar reveals a predominant composition of calcite (CaO3) and quartz (SiO2), ranging between 50.7% and 47%, with a minor component of feldspar ((Na, K (Si3Al) O8 of 2.4%, respectively. This mineralogical profile is characterized by calcite serving as a binder and quartz as an aggregate, indicating good compatibility with masonry and appropriate mechanical properties for structural integrity [44,45].

Table 6.

Chemical composition of mortar samples.

Figure 20.

XRD analysis of the mortar samples. (a) S-1 samples, (b) F-2 samples.

Figure 21.

XRD analysis of the mortar samples. (a) H-3 samples, (b) K-4 samples.

Figure 22.

XRD analysis of the mortar samples. (a) M-9 samples, (b) V-10 samples.

Likewise, the XRF reveals that the lime mortar contains an average content of CaO ranging from about 35.1% to 46.9%, along with larger amounts of silica (SiO2) alumina (Al2O3) with an average % estimated to be 20.3% and 10.7%, respectively. This suggests the presence of sand and potentially pozzolanic elements, indicating historical construction methods. The significant concentration of chloride (Cl) ranging from 0.2% to 1.8% in the mortar presents a potential hazard of salt-induced damage, requiring meticulous attention during repair endeavors to avoid material deterioration. Overall, the XRF study is crucial for preserving historical buildings by using scientific methods to choose appropriate materials and restoration processes that match the original structure and how it interacts with the environment.

5.6. Physical and Mechanical Properties of Wood

5.6.1. Density and Moisture Content Results

The exploration and identification of parameters like density and moisture content for wooden building materials (mangroves) pertaining to historical artifacts is a crucial factor influencing the physical properties like weight, strength, and susceptibility to biological degradation over time. The inherent density of the mangroves was investigated to be in the range of 687 kg/mm3 to 783 kg/mm3, highlighting distinct variation across the procured specimen with an average computed to be 737.3 Kg/m3. The lower densities suggest the weak resistance of mangroves caused by extreme humidity and frequent termite attacks, leaving the internal pour structure with decay and fractures. Meanwhile, the moisture content results reveal a range between 8.2% and 13.0%, which yields the interaction of wooden material with its environment. The M-9 sample was found to have the lowest moisture content among all the specimens, while SK-8 exhibited the highest values (Table 7). A higher moisture content range indicates potential vulnerabilities to mold, rot, and decay over time, while a lower percentage of moisture signals potential brittleness, making it prone to cracking. In this extreme environment, with higher levels of humidity, preemptive preservation efforts are necessary to maintain structural integrity and prevent moisture-induced decay, which is critical for the longevity of historical buildings.

Table 7.

Summary of physical properties of wood samples.

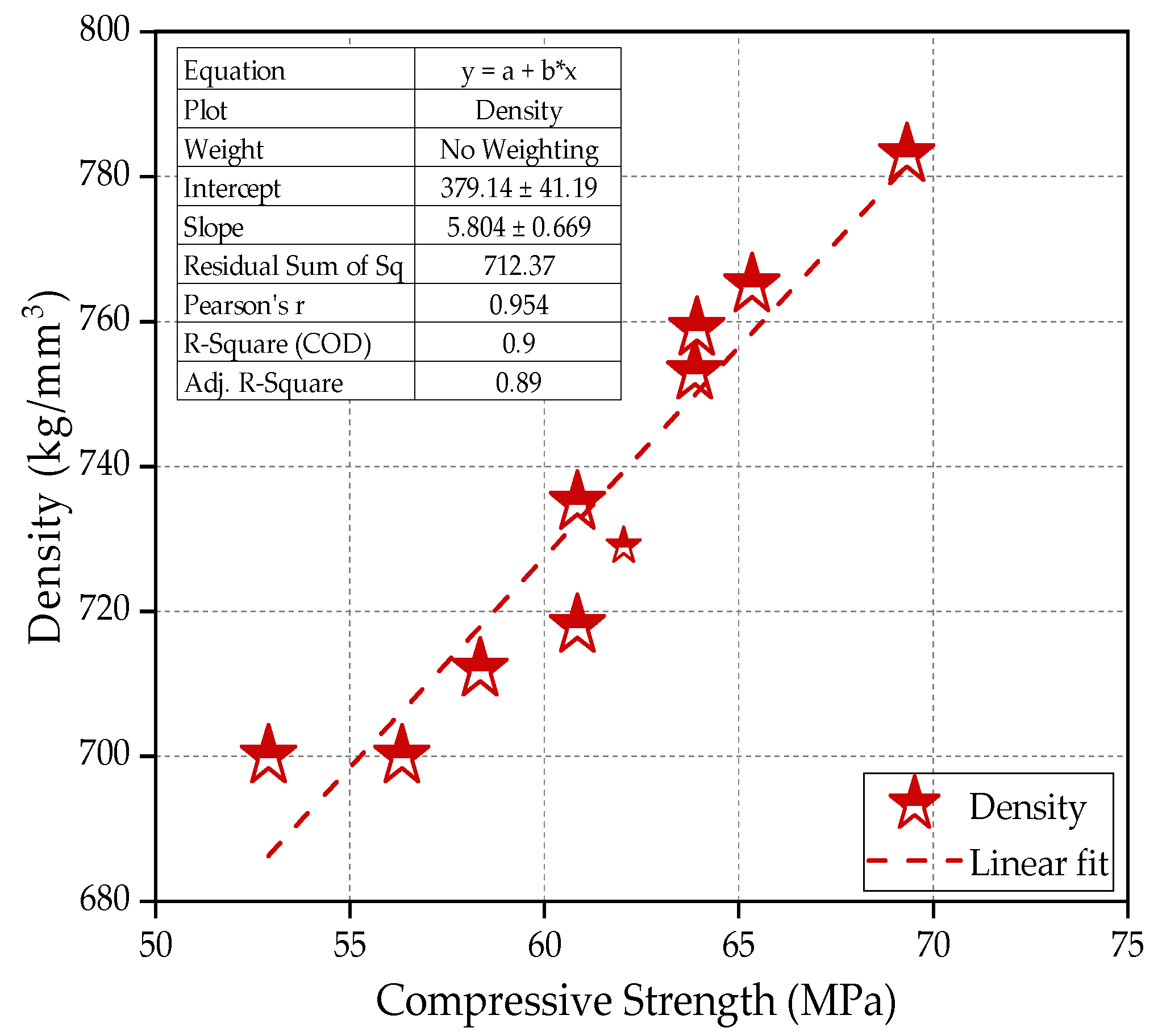

5.6.2. Mechanical Properties of Wood

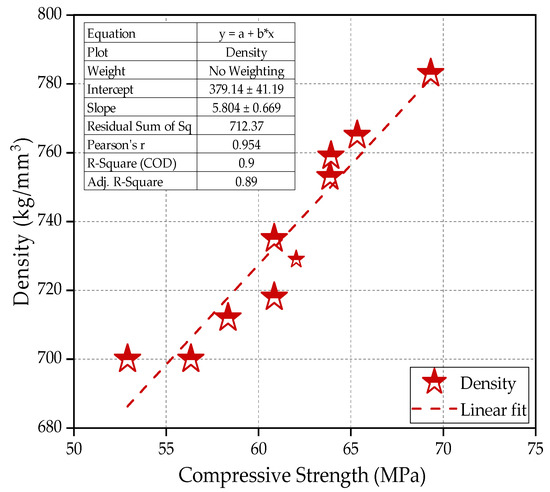

A comprehensive examination of the mechanical characteristics of historical wooden materials was performed to serve as a framework for establishing restoration guidelines, with outcomes presented in Table 8. The CS test, performed in accordance with the JIS Z 2101 standard [46], reveals distinct variations in results across the procured samples, with values ranging between 52.9 and 69.3 MPa. Sample S-1 demonstrates the lower threshold, while H-5 exhibits the highest value. Moreover, the temperature fluctuation could cause the wooden material to swell and contract, leading to microfractures. However, a good correlation between compressive strength and density was found (R2 = 0.90), demonstrating a strict link between the mechanical properties of the wood and its physical properties (Figure 23).

Table 8.

Summary of mechanical properties of wood samples.

Figure 23.

Compressive strength vs. density of wood samples.

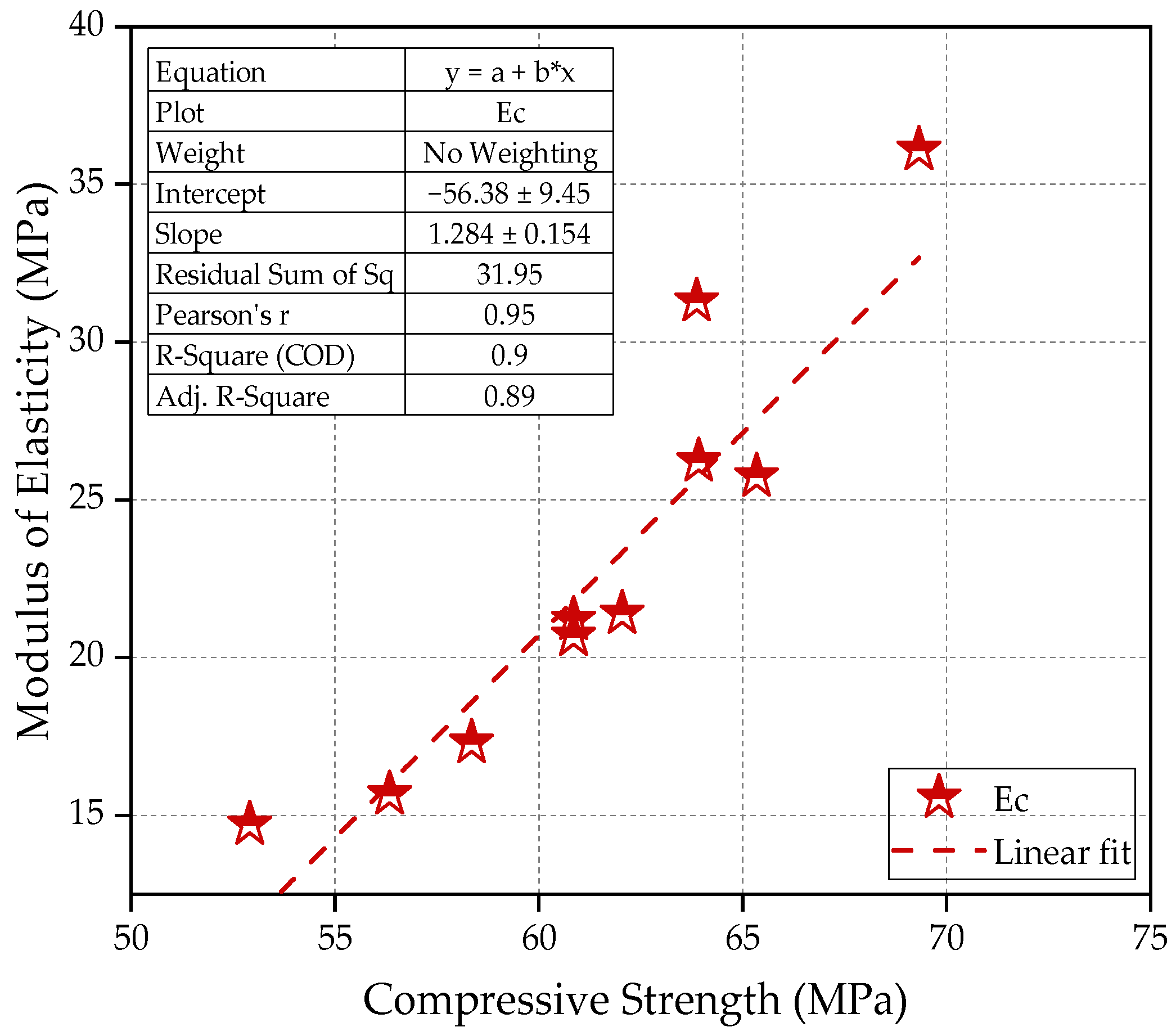

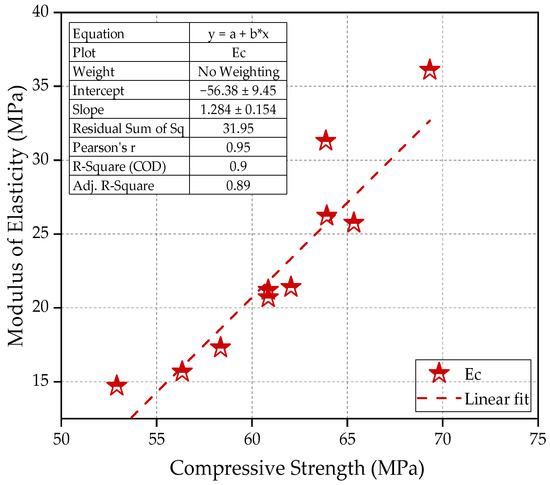

The modulus of elasticity (E) was calculated based on the slope of the load-deflection curve at 40% and 10% of the maximum load. The deflection at the mid-span exhibited a shear and tension failure yield of higher and low values, respectively [46]. Conversely, the values for the mean modulus of elasticity in compression (Ec) of the wood species evaluated range from 15.4 to 36.1 MPa. It should be noted that the linear relationships between compressive strength and modulus of elasticity (Ec) were strong, with correlation coefficients (R2 = 0.95, Figure 24). Therefore, the compressive strength of wood samples is linearly increased with an increasing modulus of elasticity. Based on the results, wood density strongly influences properties such as compressive strength and stiffness, which play a critical role in wood materials.

Figure 24.

Compressive strength vs. modulus of elasticity of wood samples.

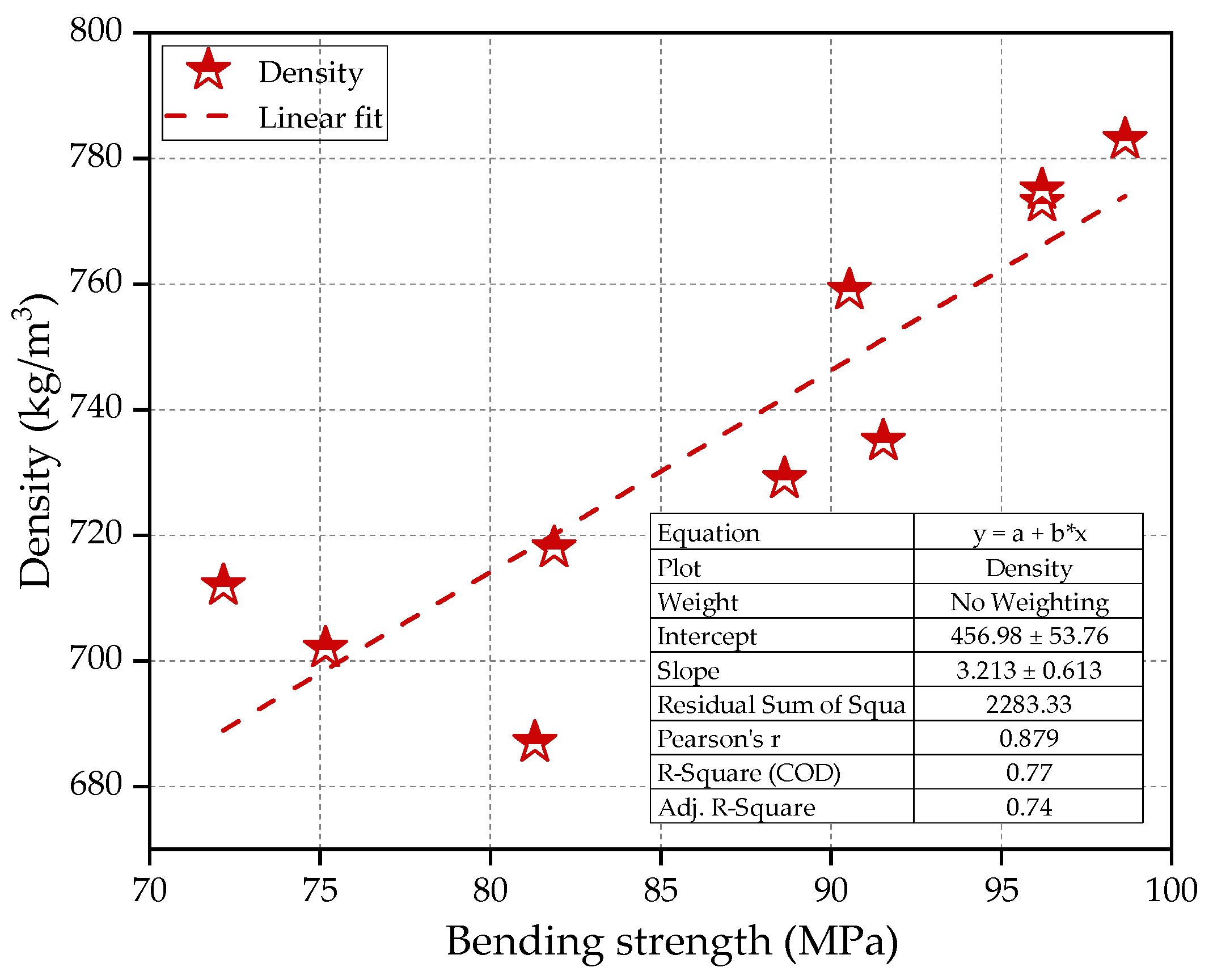

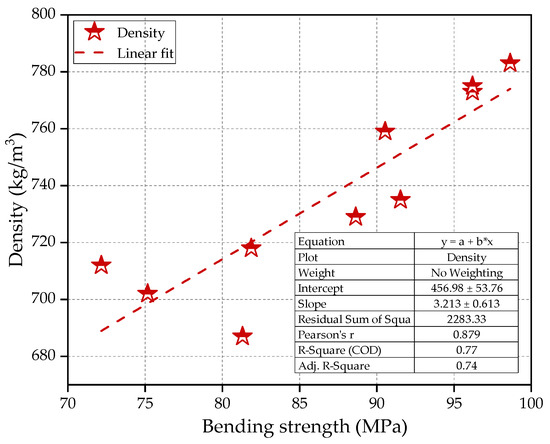

On the other hand, the bending resistance was investigated for various samples, revealing a range between 72.1 MPa and 98.6 MPa. The lowest and highest values were observed for specimens F-2 and M-9, respectively. Furthermore, a linear increase in bending strength was observed with an increase in density, as shown in Figure 25.

Figure 25.

Bending strength vs. density of wood samples.

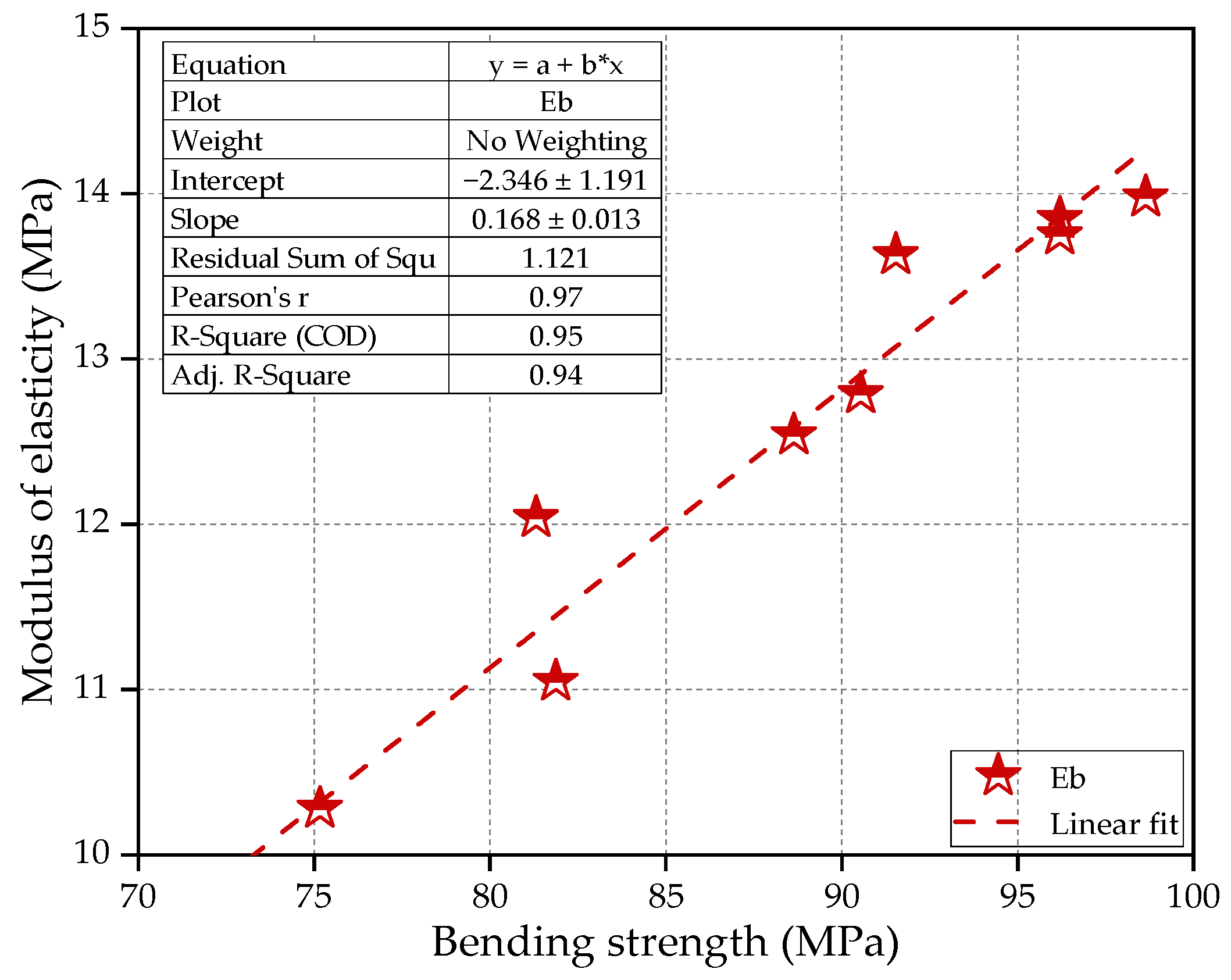

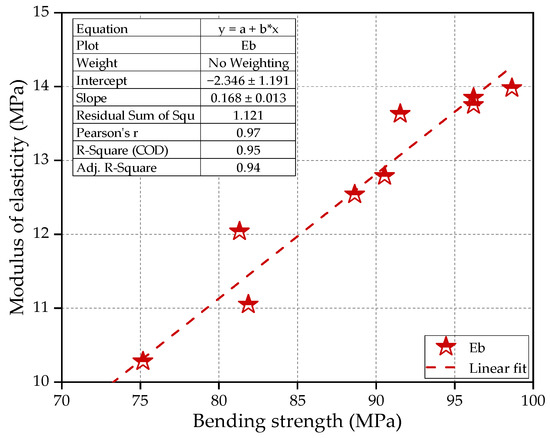

The modulus of elasticity in bending (Eb) value is estimated to range from 9.5 to 13.8 MPa. Moreover, it is pertinent to mention that values for Eb calculated for the bending specimens were significantly lower than those determined by axial compression testing. The investigated parameters were statistically assessed using regression correlation to evaluate and establish the relationship of bending strength with Eb, as shown in Figure 26. The R2 values were computed to be 0.95, yielding a considerable association among the investigated values, which signifies a strong predictive relationship between these properties. This high degree of correlation indicates that the Eb and density are reliable predictors of bending stress in historical wooden materials and can thus be used to effectively inform and guide restoration practices.

Figure 26.

Bending strength vs. modulus of elasticity of wood.

6. Conclusions

This study involves extensive field and laboratory investigations to determine the physical, mechanical, and chemical properties of building materials of historical Zanzibar’s Stone Town, leading to the formulation of the following conclusions.

The comprehensive analysis of coral stone and historical lime mortar has elucidated their distinct physical, mechanical, and chemical properties, which are essential for conserving cultural heritage structures. The physical examination of coral stone revealed substantial variability in water absorption (21.9 to 32.5%), bulk density (1120 to 1810 kg/m3), porosity (31.6 to 44.8%), and specific gravity (1.3 to 1.6), signifying a heterogeneous composition and microstructure of the building material. In contrast, the mortar showed more stable properties, with water absorption (11.5 to 15.2%), density (720 to 820 kg/m3), and porosity (6.25 to 18.1%). For historical wood materials, the moisture content ratio ranged from 8.65% to 13.02%, and density from 687 kg/m3 to 783 kg/m3.

The mechanical strength analysis of coral stone yielded a compressive strength (CS) between 7.6 MPa and 15.1 MPa, flexural strength from 2.0 MPa to 3.4 MPa, and modulus of elasticity (E) from 3427 to 5012 MPa. The mortar’s mechanical properties, characterized by CS, are 0.5 to 0.9 MPa, the UPV ranges between 1668 and 2070 m/s, and the modulus of elasticity from 538 to 1496 MPa, with a Poisson’s ratio between 0.05 and 0.1. Furthermore, the historical wood materials exhibited a CS from 52.9 to 69.3 MPa, flexural strength between 72.1 and 98.6 MPa, and modulus of elasticity (E) from 9.5 to 36.1 MPa.

Chemical assessments conducted via XRF revealed that coral stone primarily comprises calcium oxide (CaO), constituting 91.1% of its mineral composition, thus indicating its calcareous nature and marine origin. Similarly, the mortar exhibits a CaO content of 46.9%. The results of the chemical analysis conducted on both the stones and mortar revealed that the mortar contained a minimal percentage of calcium oxide (CaO) (46.9%), indicating poor cement and hydraulic properties. Furthermore, XRD analysis corroborated these findings by highlighting intense peaks for aragonite and calcite minerals in coral stone. The X-ray diffraction (XRD) measurements demonstrated the presence of quartz, feldspars, and calcite in the mortars, suggesting a loss of binding capacity due to the presence of weak zones at the particle interface. For restoration efforts, the high CaO content is crucial as it indicates that restoration materials should be compatible with calcareous stones. The enhanced restoration protocols must rigorously align with both the chemical and physical profiles of the original stone, fostering structural resilience and historical authenticity.

Based on a physical, mechanical, and chemical assessment of the investigated building materials suggests the inherent vulnerabilities associated with higher water absorption, lower density, low CS, and flexural strength, indicating the targeted reinforcement with emphasis on the utilization of compatible building materials. Therefore, the results from this study provide a comprehensive understanding of different material properties and can assist in implementing the improved restoration efforts, thereby ensuring the longevity of the historical entities of the Zanzibar Stone Town.

7. Proposal for Restoration Guidelines Improvement

Restoration recommendations for historical stone masonry buildings are essential for maintaining their architectural and cultural value. Based on the findings from the analyzed materials, several key guidelines should be followed to ensure effective restoration and conservation practices. The results of the extensive analysis of coral stone, mortar, and wood sourced from Zanzibar’s historic structures provide a solid foundation for these recommendations. Coral stones exhibit a vulnerable physical and chemical structure due to their higher porosity (ranging from 31.6% to 44.8%) and water absorption (21.9% to 32.5%). Therefore, consolidates are necessary to improve durability. The low bulk density of coral stones, ranging from 1120 kg/m3 to 1810 kg/m3, emphasizes the importance of careful handling to prevent physical stress during restoration. The mechanical strength of coral stones, with compressive and flexural strengths ranging from 7.6 MPa to 15.1 MPa and 2.0 MPa to 3.4 MPa, respectively, requires structural reinforcement in areas subjected to significant load or bending stress [47,48,49,50,51,52].

Meanwhile, the mortar samples, with a CS ranging from 0.5 to 0.9 MPa, necessitate restoration materials that can offer enhanced binding and load-bearing capacity, especially when the specimens exhibit vertical cracking patterns. Furthermore, the mortar specimens exhibit relatively low water absorption rates ranging between 11.5% and 15.2% and a density falling between 720 kg/m3 and 820 kg/m3, indicating a significant need for monitoring and protection against moisture ingress. To address this issue, any friable, dusting, or salt-affected mortar should be carefully removed and replaced with stabilizing mortar made of pure hydraulic lime [53,54,55].

Additionally, preserving the structural integrity of historical wooden materials used in historical buildings requires effective and well-coordinated strategies. Based on the analysis of these materials, the following properties were observed: water absorption, which ranged from 8.65% to 13.02%; density, which ranged from 687 kg/m³ to 783 kg/m³; compressive strength (CS), which ranged from 52.9 to 69.3 MPa; flexural strength, which ranged from 72.1 to 98.6 MPa; and modulus of elasticity (E), which ranged from 9.5 to 36.1 MPa. These results suggest that using materials with similar properties for repairs is crucial to ensure compatibility and maintain structural integrity. To prevent mold and decay, it is essential to maintain appropriate humidity levels through proper ventilation, dehumidifiers, and fungicidal treatments. These measures help control moisture, which is a primary cause of wood deterioration. Furthermore, preventing termite attacks is equally important. This involves implementing chemical barriers, baiting systems, and applying borate-based preservatives to protect the wood from termites and other wood-boring insects [56,57,58,59,60,61,62].

Moreover, the minerals identified through XRD analysis were predominantly aragonite and calcite, contributing to the informed selection of compatible restoration materials. Meanwhile, XRF analysis reveals significant percentages of CaO, with 91.9% and 42.6% found in coral stone and mortar, respectively, along with the presence of chlorides. Recognizing and mitigating salt damage is crucial, necessitating the assessment of salt distribution and accumulation within the mortar. To address this issue, applying a sacrificial plaster on exposed mortar surfaces can effectively protect them from further damage.

Regular monitoring and maintenance are essential to address potential deterioration and ensure the preservation of historical assets. Careful attention should also be paid to selecting compatible materials and techniques to avoid any adverse effects on the original structure. Adhering to these restoration guidelines can safeguard historical stone masonry buildings’ authenticity and cultural heritage for future generations. In conclusion, preserving Zanzibar’s historical buildings requires materials and methods that address the intrinsic physical and mechanical vulnerabilities while respecting the original construction techniques and material compositions to ensure the longevity and integrity of these cultural landmarks.

Author Contributions

Conceptualization, B.S.A.; methodology, B.S.A., J.J.C. and S.O.; software, B.S.A. and K.N.; validation, B.S.A.; formal analysis, B.S.A.; investigation, B.S.A. and J.J.C.; resources, B.S.A.; data curation, B.S.A.; writing—original draft preparation, B.S.A.; writing—review and editing, B.S.A., K.N. and J.J.C.; visualization, B.S.A. and J.J.C.; supervision, J.J.C.; project administration, B.S.A.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study were obtained by the authors with the collaboration of the Stone Town Conservation and Development Authority (STCDA), United Republic of Tanzania, and are available from the authors upon request, subject to approval by the STCDA.

Acknowledgments

The authors express their gratitude to the Stone Town Conservation and Development Authority (STCDA) for granting permission to conduct the field survey. Additionally, we would like to sincerely thank the University of Dar es Salaam (UDSM) for providing the utilities used. Their generous contributions have made it possible to conduct this study and have significantly contributed to its successful completion. We also acknowledge the Japanese Government (MEXT) Scholarship for funding the Ph.D. program, of which this research is a part.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Centre, U.W.H. Stone Town of Zanzibar. Available online: https://whc.unesco.org/en/list/173/ (accessed on 18 February 2024).

- Chami, M. Impact of Cultural Heritage Site Attributes to the Tourist Satisfaction in Zanzibar Stone Town, UNESCO World Heritage Site, Tanzania. Afr. J. Hosp. Tour. Leis. 2018, 7, 1–13. [Google Scholar]

- Rashid, M.; Shateh, H. The Dialectics of Functional and Historical Morphology in the Evolution of a City: The Case of the Stone Town of Zanzibar. J. Archit. 2012, 17, 889–924. [Google Scholar] [CrossRef][Green Version]

- Siravo, F. Zanzibar: A Plan for the Historic Stone Town; Taylor & Francis, Ltd.: Abingdon, UK, 1996; ISBN 2-9700103-0-5. [Google Scholar]

- Sheriff, A. The History & Conservation of Zanzibar Stone Town; Ohio University Press: Athens, OH, USA, 1995; ISBN 0-85255-721-3. [Google Scholar]

- Khalfan, K.; Ogura, N. Influence of outsourced finance on conservation of built heritage in a developing country. J. Archit. Plan. Trans. AIJ 2010, 75, 2507–2515. [Google Scholar] [CrossRef][Green Version]

- Hendriksen, G.; Ishikagi, K.; Moriniere, L.; Egan, C.; Mochizuki, J.; Hochrainer-Stigler, S.; Mechler, R.; Williges, K. Public Investment Planning and Financing Strategy for Disaster Risk Reduction: Review of Zanzibar; UNISDR Working Papers; UNISDR: Geneva Switzerland, 2015. [Google Scholar]

- Stockley, G.M. The Geology of the Zanzibar Protectorate and Its Relation to the East African Mainland. Geol. Mag. 1942, 79, 233–240. [Google Scholar] [CrossRef]

- Makunza, J.K. Restoration of Historic Buildings in Zanzibar. Tanzan. J. Eng. Technol. 2018, 36, 12–22. [Google Scholar] [CrossRef]

- Jasiński, A. Colors of Stone Town in Zanzibar: From White to Black and Back Again. Cities 2021, 117, 103309. [Google Scholar] [CrossRef]

- Longair, S.; Said, F.; Wynne-Jones, S. Colonialism, Heritage and Conservation: Zanzibari Perceptions of the Collapse of the House of Wonders. J. East. Afr. Stud. 2023, 17, 594–614. [Google Scholar] [CrossRef]

- Khalfan, K.A.; Ogura, N. Sustainable Architectural Conservation According to Traditions of Islamic Waqf: The World Heritage–Listed Stone Town of Zanzibar. Int. J. Herit. Stud. 2012, 18, 588–604. [Google Scholar] [CrossRef]

- Charola, A.E. Chemical-Physical Factors in Stone Deterioration. 1988. Available online: https://www.semanticscholar.org/paper/Chemical-physical-factors-in-stone-deterioration-Charola/c331ec8561675daa3223afa23408760e3778445f (accessed on 26 June 2024).

- Grazzini, A.; Lacidogna, G. Mechanical Properties of Historic Masonry Stones Obtained by in Situ Non-Destructive Tests on the St. Agostino Church in Amatrice (Italy). Appl. Sci. 2021, 11, 6352. [Google Scholar] [CrossRef]

- Concu, G.; De Nicolo, B.; Valdes, M. Prediction of Building Limestone Physical and Mechanical Properties by Means of Ultrasonic P-Wave Velocity. Sci. World J. 2014, 2014, e508073. [Google Scholar] [CrossRef]

- Brown, G.; Brindley, G.W. X-Ray Diffraction Procedures for Clay Mineral Identification. In Crystal Structures of Clay Minerals and Their X-ray Identification; Brindley, G.W., Brown, G., Eds.; Mineralogical Society of Great Britain and Ireland: London, UK, 1980; Volume 5, ISBN 978-0-903056-08-3. [Google Scholar]

- Whittig, L.D.; Allardice, W.R. X-Ray Diffraction Techniques. In Methods of Soil Analysis; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 1986; pp. 331–362. ISBN 978-0-89118-864-3. [Google Scholar]

- Salvatici, T.; Calandra, S.; Centauro, I.; Pecchioni, E.; Intrieri, E.; Garzonio, C.A. Monitoring and Evaluation of Sandstone Decay Adopting Non-Destructive Techniques: On-Site Application on Building Stones. Heritage 2020, 3, 1287–1301. [Google Scholar] [CrossRef]

- Patil, S.M.; Kasthurba, A.K.; Patil, M.V. Characterization and Assessment of Stone Deterioration on Heritage Buildings. Case Stud. Constr. Mater. 2021, 15, e00696. [Google Scholar] [CrossRef]

- Binda, L.; Saisi, A.; Tiraboschi, C. Investigation Procedures for the Diagnosis of Historic Masonries. Constr. Build. Mater. 2000, 14, 199–233. [Google Scholar] [CrossRef]

- Özmen, A.; Sayın, E. Evaluation of Material Properties of Cultural Heritage Building by Destructive and Non-Destructive Testing: Malatya Taşhoran Church Case Study. Constr. Build. Mater. 2023, 392, 131693. [Google Scholar] [CrossRef]

- Spoldi, E.; Ippolito, I.; Stella, A.; Russo, S. Non-destructive Techniques for Structural Characterization of Cultural Heritage: A Pilot Case Study. Struct. Control Health Monit. 2021, 28, e282. [Google Scholar] [CrossRef]

- Khalfan, K.A.; Ogura, N. The Contribution of Islamic Waqf to Managing the Conservation of Buildings in the Historic Stone Town of Zanzibar. Int. J. Cult. Prop. 2012, 19, 153–174. [Google Scholar] [CrossRef]

- Khalfan, K.; Besha, R.; Tesha, D. Electromagnetic Shielding Effectiveness of Historic Buildings: The Heritage Stone Town of Zanzibar. J. Civ. Eng. Archit. 2018, 12, 880–889. [Google Scholar] [CrossRef]

- Ali, B.S.; Castro, J.J.; Omi, S.; Nazimi, K. Exploration and Characterization of Dynamic Properties for Cultural Heritage Conservation: A Case Study for Historical Stone Masonry Buildings in Zanzibar. Buildings 2024, 14, 981. [Google Scholar] [CrossRef]

- Steyn, G. An Analysis of an Omani House in Stone Town, Zanzibar 2001. Available online: https://www.researchgate.net/publication/265889781_An_analysis_of_an_Omani_house_in_Stone_Town_Zanzibar (accessed on 26 June 2024).

- Theodoridou, M.; Török, Á. In Situ Investigation of Stone Heritage Sites for Conservation Purposes: A Case Study of the Székesfehérvár Ruin Garden in Hungary. Prog. Earth Planet. Sci. 2019, 6, 15. [Google Scholar] [CrossRef]

- Ademović, N.; Kurtović, A. Influence of Planes of Anisotropy on Physical and Mechanical Properties of Freshwater Limestone (Mudstone). Constr. Build. Mater. 2021, 268, 121174. [Google Scholar] [CrossRef]

- Miriello, D.; Bloise, A.; Crisci, G.M.; Apollaro, C.; La Marca, A. Characterisation of Archaeological Mortars and Plasters from Kyme (Turkey). J. Archaeol. Sci. 2011, 38, 794–804. [Google Scholar] [CrossRef]

- Gupta, M.; Khan, M.A.; Butola, R.; Singari, R.M. Advances in Applications of Non-Destructive Testing (NDT): A Review. Adv. Mater. Process. Technol. 2022, 8, 2286–2307. [Google Scholar] [CrossRef]

- Moropoulou, A.; Labropoulos, K.C.; Delegou, E.T.; Karoglou, M.; Bakolas, A. Non-Destructive Techniques as a Tool for the Protection of Built Cultural Heritage. Constr. Build. Mater. 2013, 48, 1222–1239. [Google Scholar] [CrossRef]

- Avdelidis, N.P.; Moropoulou, A. Applications of Infrared Thermography for the Investigation of Historic Structures. J. Cult. Herit. 2004, 5, 119–127. [Google Scholar] [CrossRef]

- Maravelaki-Kalaitzaki, P.; Bakolas, A.; Moropoulou, A. Physico-Chemical Study of Cretan Ancient Mortars. Cem. Concr. Res. 2003, 33, 651–661. [Google Scholar] [CrossRef]

- Ngoma, A.M. Characterisation and Consolidation of Historical Lime Mortars in Cultural Heritage Buildings and Associated Structures in East Africa. Ph.D. Thesis, Kungliga Tekniska Högskolan, Stockholm, Sweden, 2009. [Google Scholar]

- Lucian, C. Characterisation of Mortar Deterioration in Historic Buildings in Bagamoyo, Tanzania. Int. J. Eng. Adv. Technol. Stud. Tanzan. 2015, 3, 11. [Google Scholar]

- Steel, T.; Battle, S. Conservation and Design Guidelines for Zanzibar Stone Town; Aga Khan Trust for Culture: Geneva, Switzerland, 1998. [Google Scholar]

- Speweik, J. Repointing Historic Masonry Buildings to Last-Return of Lime Putty Mortar. Masonry Magazine, 1997. [Google Scholar]

- Standard Test Methods for Absorption and Bulk Specific Gravity of Dimension Stone. Available online: https://www.astm.org/c0097-02r08.html (accessed on 9 April 2024).

- C1324 Standard Test Method for Examination and Analysis of Hardened Masonry Mortar. Available online: https://www.astm.org/c1324-20a.html (accessed on 9 April 2024).

- Standard Test Method for Compressive Strength of Dimension Stone. Available online: https://www.astm.org/c0170_c0170m-17.html (accessed on 9 April 2024).

- Hong, S.; Yoon, S.; Kim, J.; Lee, C.; Kim, S.; Lee, Y. Evaluation of Condition of Concrete Structures Using Ultrasonic Pulse Velocity Method. Appl. Sci. 2020, 10, 706. [Google Scholar] [CrossRef]

- E1361 Standard Guide for Correction of Interelement Effects in X-ray Spectrometric Analysis. Available online: https://www.astm.org/e1361-02r21.html (accessed on 10 April 2024).

- Widmann, R. International Society for Rock Mechanics Commission on Rock Grouting. In International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts; Elsevier: Amsterdam, The Netherlands, 1996; Volume 33, pp. 807–847. [Google Scholar]

- Middendorf, B.; Hughes, J.J.; Callebaut, K.; Baronio, G.; Papayianni, I. Investigative Methods for the Characterisation of Historic Mortars—Part 1: Mineralogical Characterisation. Mater. Struct. 2005, 38, 761–769. [Google Scholar] [CrossRef]

- Grilo, J.; Santos Silva, A.; Faria, P.; Gameiro, A.; Veiga, R.; Velosa, A. Mechanical and Mineralogical Properties of Natural Hydraulic Lime-Metakaolin Mortars in Different Curing Conditions. Constr. Build. Mater. 2014, 51, 287–294. [Google Scholar] [CrossRef]

- Japanese Standards Association. Japanese Industrial Standards Committee Japanese Industrial Standard (nS): Methods of Test for Woods (nS Z 2101); Japanese Standards Association: Tokyo, Japan, 1994. [Google Scholar]

- Juhásová, E.; Sofronie, R.; Bairrao, R. Stone Masonry in Historical Buildings—Ways to Increase Their Resistance and Durability. Eng. Struct. 2008, 30, 2194–2205. [Google Scholar] [CrossRef]

- Tomaževič, M.; Gams, M.; Berset, T. Strengthening of Stone Masonry Walls with Composite Reinforced Coatings. Bull. Earthq. Eng. 2015, 13, 2003–2027. [Google Scholar] [CrossRef]

- Dipasquale, L.; Rovero, L.; Fratini, F. 15-Ancient Stone Masonry Constructions. In Nonconventional and Vernacular Construction Materials, 2nd ed.; Harries, K.A., Sharma, B., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2020; pp. 403–435. ISBN 978-0-08-102704-2. [Google Scholar]

- Binda, L.; Saisi, A.; Tedeschi, C. Masonry. In Fracture and Failure of Natural Building Stones: Applications in the Restoration of Ancient Monuments; Kourkoulis, S.K., Ed.; Springer: Dordrecht, The Netherlands, 2006; pp. 167–182. ISBN 978-1-4020-5077-0. [Google Scholar]

- Roca, P.; Lourenço, P.B.; Gaetani, A. Historic Construction and Conservation: Materials, Systems and Damage; Routledge: New York, NY, USA, 2019; ISBN 978-0-429-05276-7. [Google Scholar]

- Croci, G. The Conservation and Structural Restoration of Architectural Heritage; WIT Press: Billerica, MA, USA, 1998; ISBN 978-1-85312-482-2. [Google Scholar]

- Dai, S.; Zhong, Y. Sacrificial Protection for Architectural Heritage Conservation and Preliminary Approaches to Restore Historic Fair-Faced Brick Façades in China. Built Herit. 2019, 3, 37–46. [Google Scholar] [CrossRef]

- Lopez-Arce, P.; Doehne, E.; Greenshields, J.; Benavente, D.; Young, D. Treatment of Rising Damp and Salt Decay: The Historic Masonry Buildings of Adelaide, South Australia. Mater. Struct. 2009, 42, 827–848. [Google Scholar] [CrossRef]

- Callebaut, K.; Elsen, J.; Van Balen, K.; Viaene, W. Nineteenth Century Hydraulic Restoration Mortars in the Saint Michael’s Church (Leuven, Belgium): Natural Hydraulic Lime or Cement? Cem. Concr. Res. 2001, 31, 397–403. [Google Scholar] [CrossRef]

- Bertolini, C.; Biglione, G.; Cestari, L.; Corradino, G.; Crivellaro, A.; De Luca, D.; Marzi, T.; Panosch, P.; Pasquino, R. Restoration of Historic Timber Structures: The Great Roof Structures of the Cathedral of Vercelli. In Proceedings of the WCTE World Conference on Timber Engineering, Trentino, Italy, 20–24 June 2010. [Google Scholar]

- Bertolini Cestari, C.; Marzi, T. Conservation of Historic Timber Roof Structures of Italian Architectural Heritage: Diagnosis, Assessment, and Intervention. Int. J. Archit. Herit. 2018, 12, 632–665. [Google Scholar] [CrossRef]

- Novita, N.; Amiruddin, H.; Ibrahim, H.; Jamil, T.M.; Syaukani, S.; Oguri, E.; Eguchi, K. Investigation of Termite Attack on Cultural Heritage Buildings: A Case Study in Aceh Province, Indonesia. Insects 2020, 11, 385. [Google Scholar] [CrossRef] [PubMed]

- D’Agostino, D.; Congedo, P.M. CFD Modeling and Moisture Dynamics Implications of Ventilation Scenarios in Historical Buildings. Build. Environ. 2014, 79, 181–193. [Google Scholar] [CrossRef]

- Ridout, B. Termites and Heritage Buildings: A Study in Integrated Pest Management; Liverpool University Press: Liverpool, UK, 2023; ISBN 978-1-83764-679-1. [Google Scholar]

- Lee, S.; Im, I.; Kim, S. A History of Termite Control and Improvements to Prevent Termites in Wooden Architectural Heritage. Korean J. Herit. Hist. Sci. 2021, 54, 194–215. [Google Scholar] [CrossRef]

- Feilden, B. Conservation of Historic Buildings, 3rd ed.; Routledge: London, UK, 2003; ISBN 978-0-08-050291-5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).