Multi-Factor Orthogonal Experiments and Enhancement Mechanisms of Unconfined Compressive Strength of Soda Residue Cement Lime Soil

Abstract

:1. Introduction

2. Materials and Methods

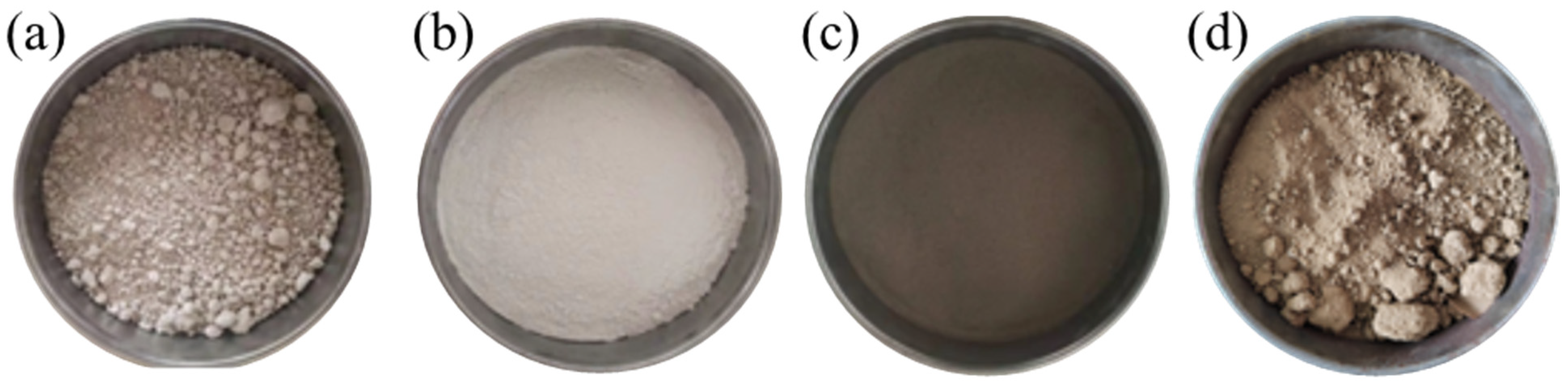

2.1. Materials

2.1.1. Soda Residue

2.1.2. Soil

2.1.3. Lime

2.1.4. Cement

2.2. Orthogonal Experimental Design

2.3. Specimen Preparation

2.4. Testing Methods

2.4.1. Unconfined Compressive Strength (UCS) Tests

2.4.2. Microstructure Analyses

2.4.3. X-ray Diffraction (XRD) Tests

3. Results and Discussion

3.1. Results of Orthogonal Experiments

3.2. Analysis of Factors Affecting UCS of SRCLS

3.2.1. Effect of SR Content

3.2.2. Effect of Particle Size

3.2.3. Effect of Moisture Content

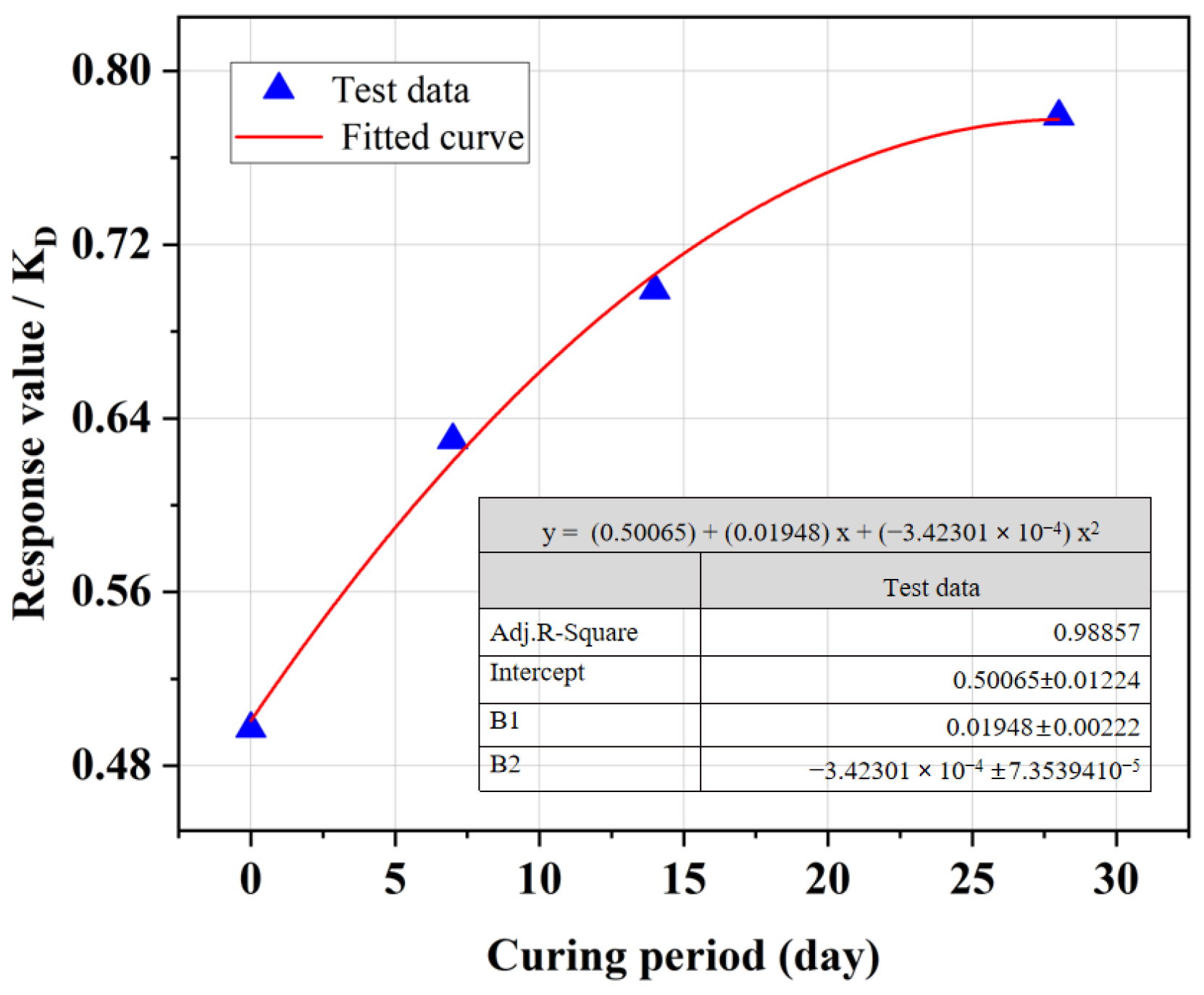

3.2.4. Effect of Curing Period

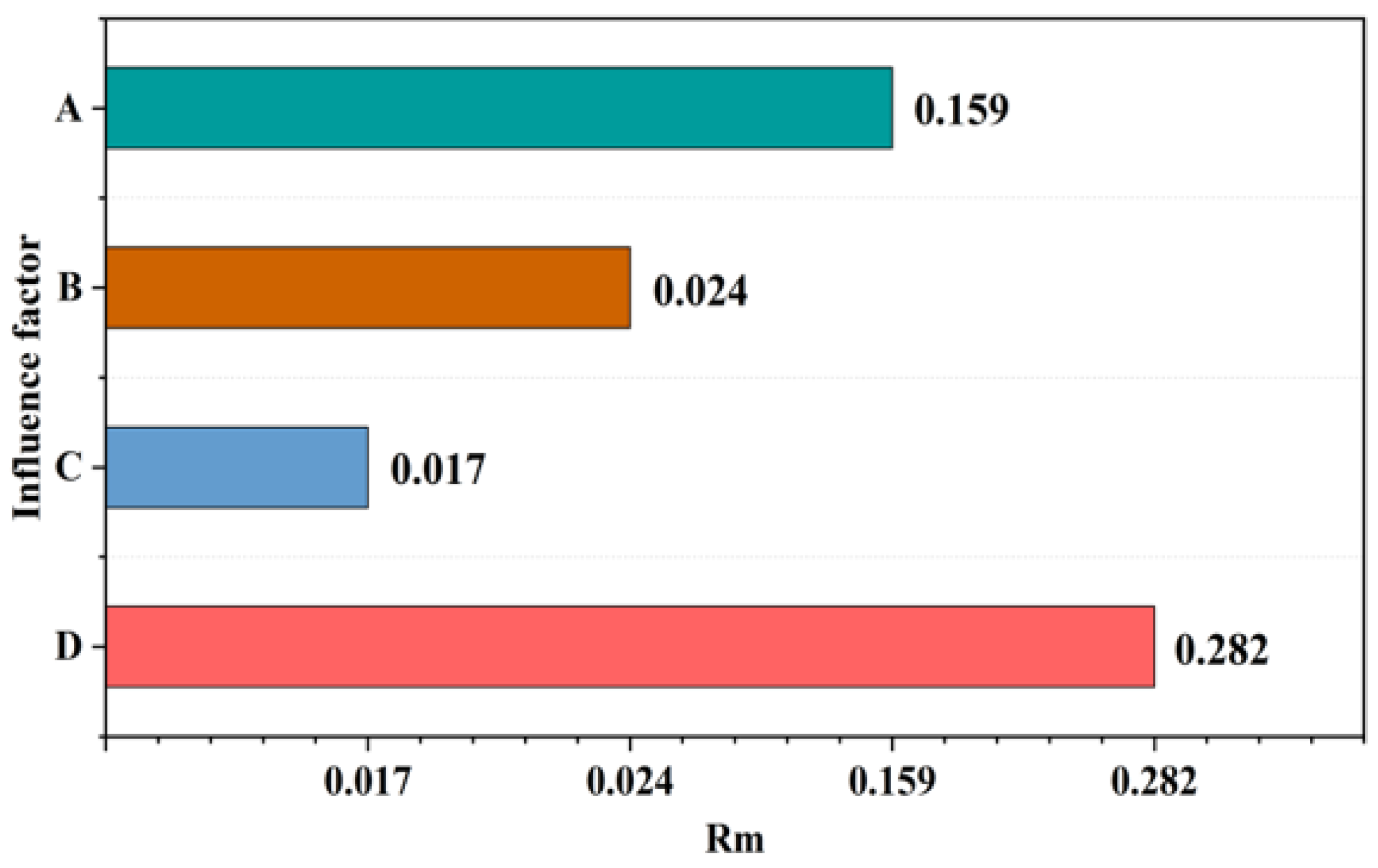

3.3. Sensitivity Analysis of Influencing Factors

- (1)

- Range analysis

- (2)

- Variance analysis

4. Microstructure and Strengthening Mechanism

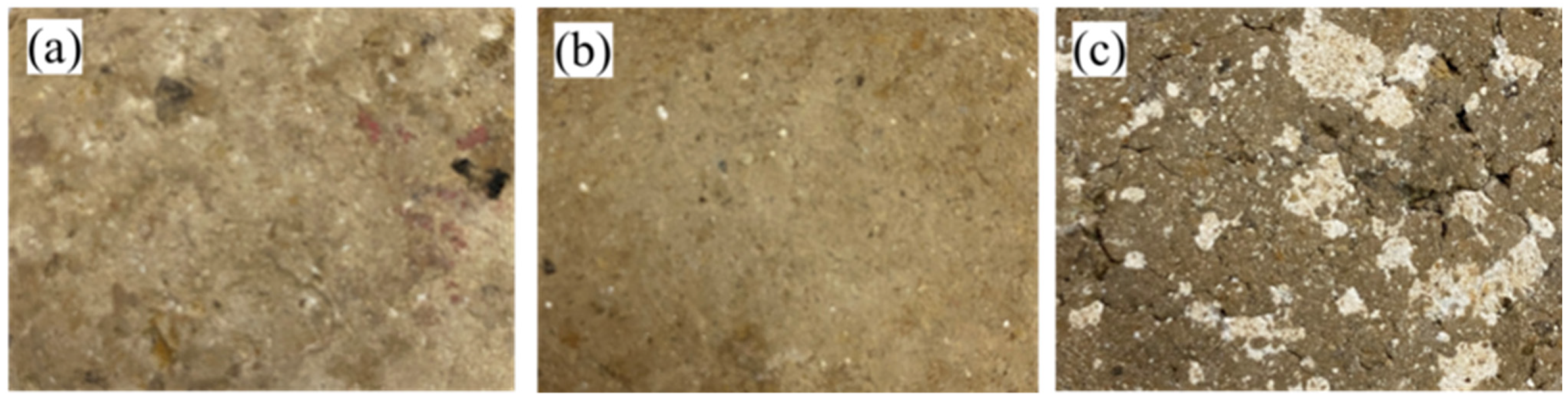

4.1. Influence of SR Content on UCS Patterns

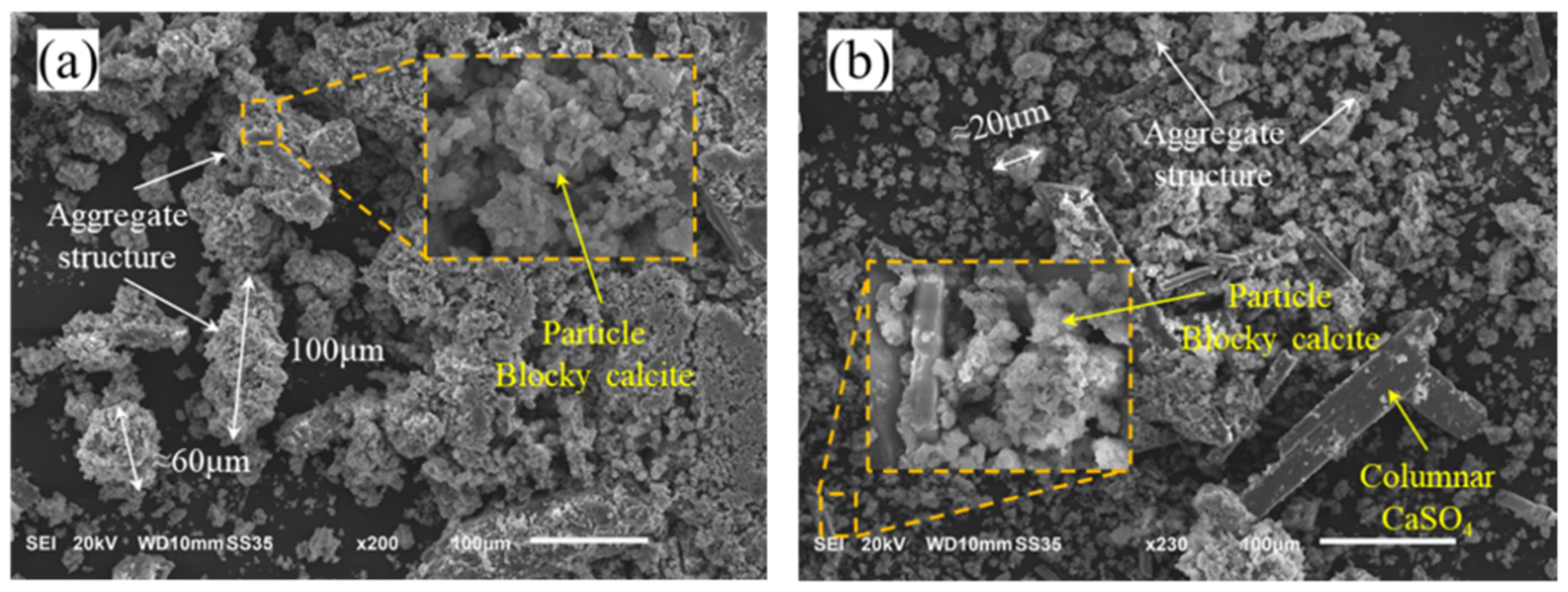

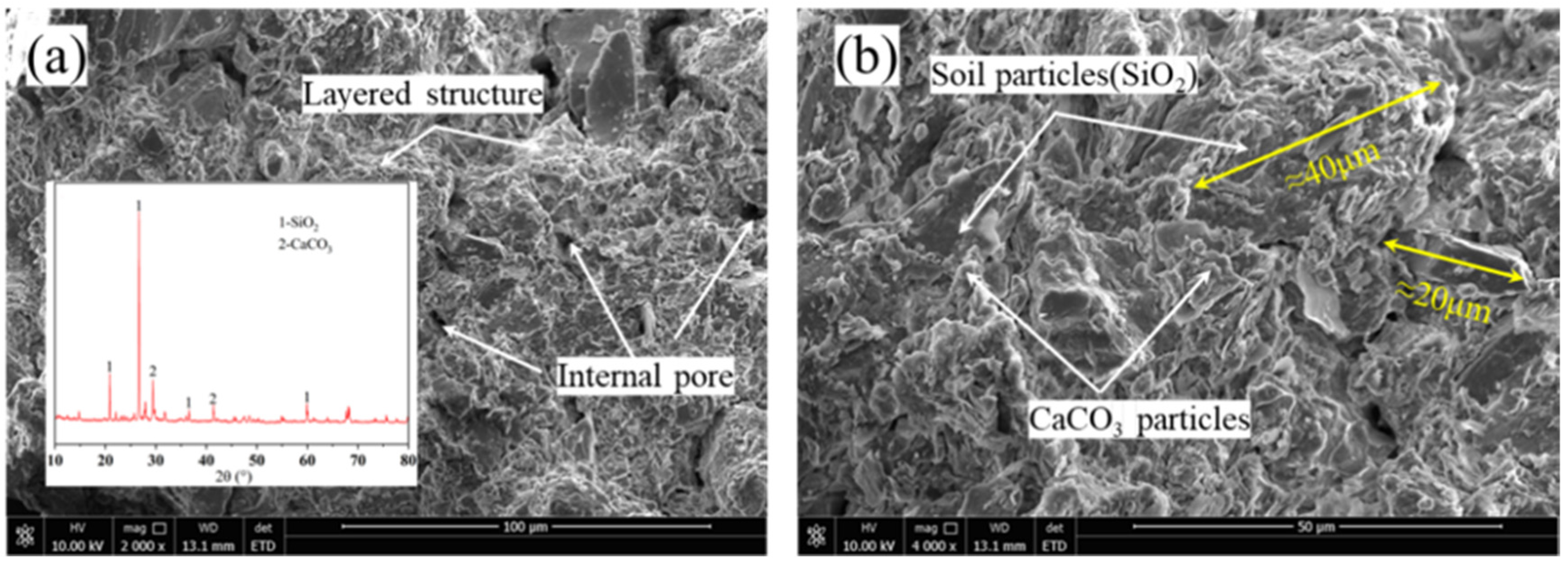

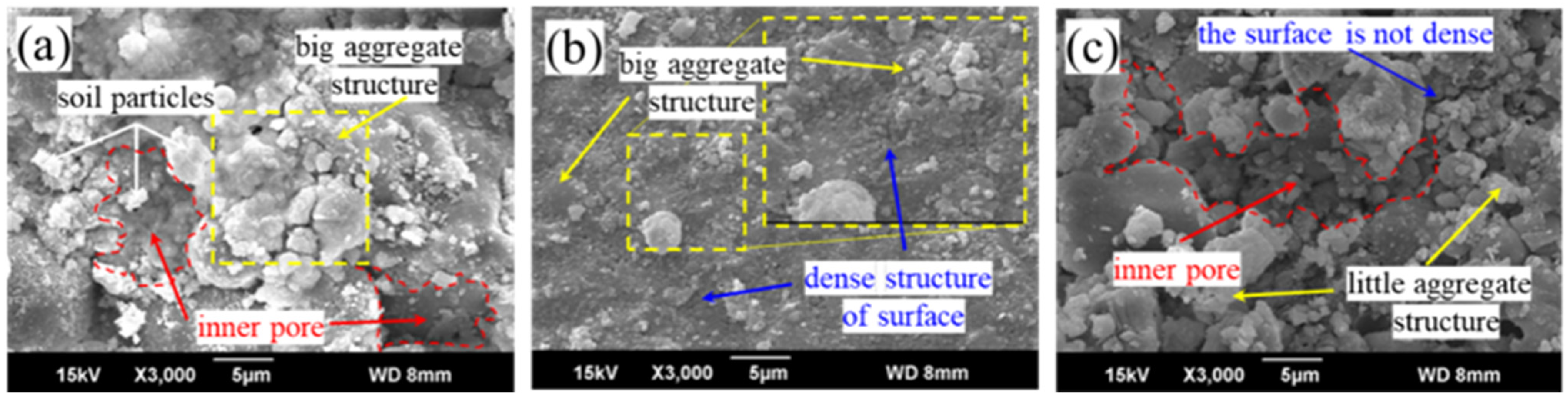

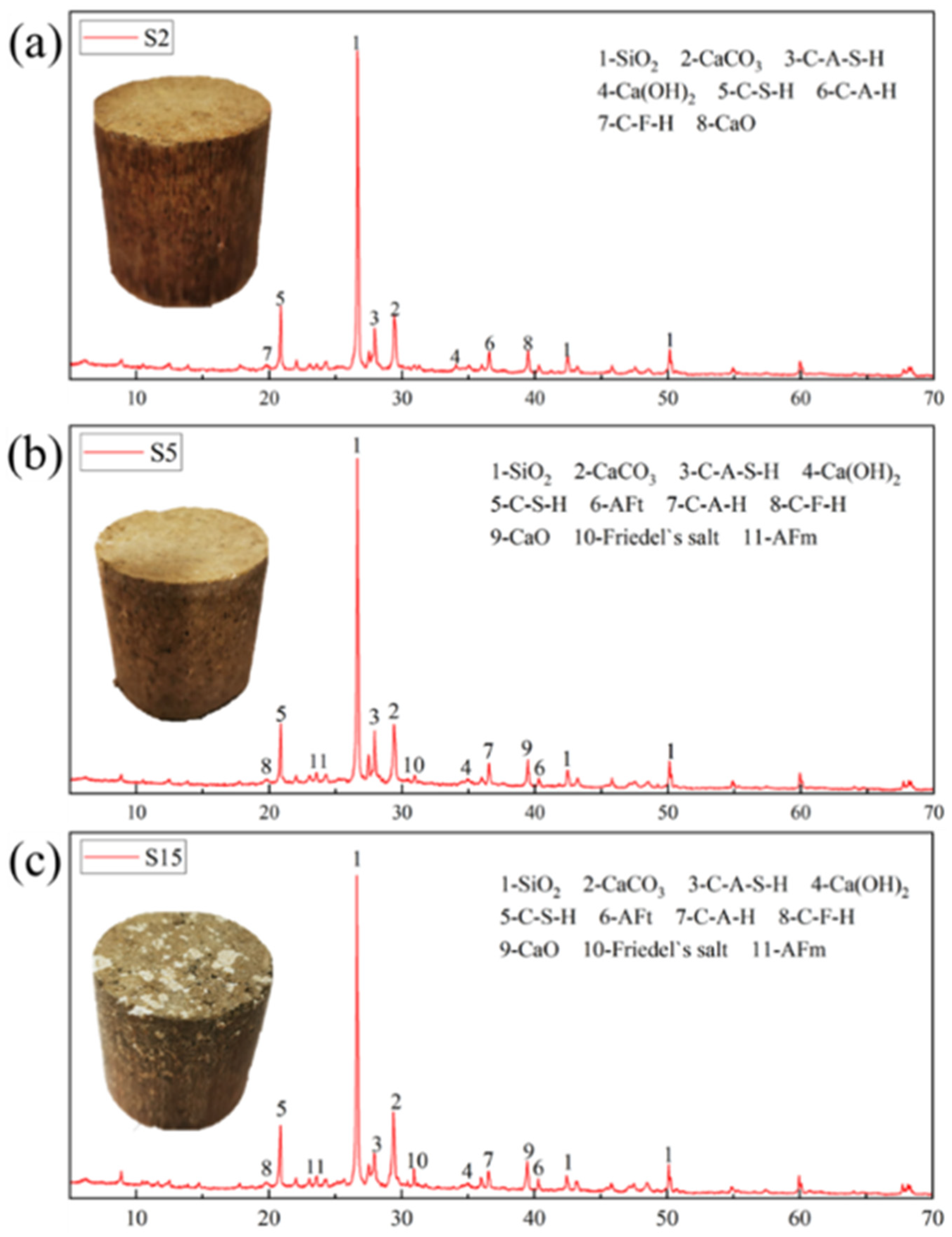

4.2. Microstructure of SRCLS

4.3. Strengthening Mechanism

- (1)

- Fine aggregate filling effect: The high content of CaCO3 in SR allows SR particles to act as fine aggregates in the system, improving the gradation of the system, reducing inter-particle voids, and enhancing internal compactness, thus serving as fillers during strength formation [36].

- (2)

- Partial lime substitution effect: The main component of lime is Ca(OH)2, which reacts with active substances in soil. Similarly, SR contains a significant amount of Ca(OH)2 and has an alkaline nature. Its addition, it increases the alkaline environment of the mixture, further promoting the leaching of active silicon and aluminum ions from the soil [37]. Active SiO2 and Al2O3 in the soil react with Ca(OH)2 in soda residue to produce calcium silicate hydrate (C-S-H) and calcium aluminate hydrate (C-A-H) that partially substitute for lime, as represented by Equations (1) to (2). These cementitious substances bind soil particles together, forming larger aggregates, filling particle voids, thus improving the density and strength of the cement–lime–soil.

- (3)

- Promotion of cement hydration: Compared to the S2 group without SR, XRD tests of the S5 and S15 groups with added SR revealed the presence of AFt and AFm hydration products in SRCLS. C3A in cement hydrated the fastest, reacting with water to form 4CaO·Al2O3·13H2O (C4AH13) [38] in pure water. The SR contained a small amount of CaSO4·2H2O. In the SRCLS system, the hydration product of C3A is ettringite (AFt) [39]. The reaction equations are given by Equations (3) and (4).When CaSO4·2H2O is exhausted in the system, AFm is formed from the reaction between C4AH13 and AFt, as shown in Equation (5). Both AFt and AFm possess stronger cementitious properties than C-S(A)-H, wrapping around soil particle surfaces, enhancing internal compactness, and increasing the material strength.

- (4)

- Chloride ion binding: XRD tests of the S5 and S15 groups revealed the presence of Friedel’s salt in SRCLS. This was attributed to the dissolution of CaCl2 and NaCl from SR, which then combines with the unhydrated C3A and AFt in the system. The former combination involves Cl− directly reacting with C3A to form hydrated calcium chloride containing chlorine (Friedel’s salt) [40], while the latter involves Cl− substituting for the sulfate ions of AFt to form Friedel’s salt [41]. These reactions are represented by Equations (6)–(8).

5. Conclusions

- (1)

- With the gradual increase in SR content within the range of 0% to 9%, SRCLS UCS initially increased and then decreased. As the SR particle size or SRCLS moisture content increased gradually, the SRCLS UCS gradually decreased, while an increase in curing age led to a gradual increase in SRCLS UCS.

- (2)

- Appropriate SR content effectively enhanced the UCS of SRCLS, while excessive SR content decreased the material’s UCS value. The optimal mix ratio for SRCLS was SR:cement:lime:soil = 3%:3%:6%:100%. Naturally-dried SR is suitable for use as raw material, with a recommended particle size controlled at 0.15 mm.

- (3)

- Range analysis and variance analysis of the orthogonal experiment indicate that the factors affecting the UCS of SRCLS, in order of importance, are curing age, SR content, particle size, and SR moisture content. Among these, curing age and SR content are relatively more significant factors affecting the UCS.

- (4)

- An adequate SR content can serve as a fine aggregate filler, a substitute for lime, promote cement hydration, and combine with chloride ions. This improves the grading of SRCLS and promoting the formation of cementitious products from AFm, AFt, and Friedel’s salt, ultimately enhancing the strength of SRCLS.

- (5)

- The paper also identified several areas for improvement and further in-depth exploration including different types of soils, lime, and cement dosages as well as SRCLS moisture content.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.; Liu, C.; Zuo, L.; Wang, L.; Zhu, Q.; Liu, Y.; Zhou, B. Synthesis and characterization of fly ash geopolymer paste for goaf backfill: Reuse of soda residue. J. Clean. Prod. 2020, 260, 121045. [Google Scholar] [CrossRef]

- Sun, S.; Zheng, Q.; Tang, J.; Zhang, G.; Zhou, L.; Shang, W. Experimental research on expansive soil improved by soda residue. Chin. J. Geotech. Eng. 2012, 33, 1608–1612. [Google Scholar]

- He, J.; Wang, X.-Q.; Su, Y.; Li, Z.-X.; Shi, X.-K. Shear Strength of Stabilized Clay Treated with Soda Residue and Ground Granulated Blast Furnace Slag. J. Mater. Civ. Eng. 2019, 31, 06018029. [Google Scholar] [CrossRef]

- Yang, Y.B.; Pu, Y.Q.; Yan, W.J.; Guo, W.; Wang, H.C. Microstructure and Chloride Ion Dissolution Characteristics of Soda Residue. J. South China Univ. Technol. (Nat. Sci. Ed.) 2017, 45, 82–89. [Google Scholar]

- Yan, Y.; Chen, C.; Li, Q.; Sun, X.; Wang, L. Arsenate removal from groundwater by modified alkaline residue. Desalination Water Treat. 2016, 57, 20401–20410. [Google Scholar] [CrossRef]

- Wu, P.; Wang, Q.; Liu, Q.; Lv, X.J. Preparation and hydration characteristics of soda residue-slagbased cementitious materials. J. China Univ. Min. Technol. 2022, 51, 802–811. [Google Scholar] [CrossRef]

- Xu, D.; Ni, W.; Wang, Q.; Xu, C.; Jiang, Y. Preparation of clinker-free concrete by using soda residue composite cementitious material. J. Harbin Inst. Technol. 2020, 52, 151–160. [Google Scholar]

- Zhao, X.; Liu, C.; Wang, L.; Zuo, L.; Zhu, Q.; Ma, W. Physical and mechanical properties and micro characteristics of fly ash-based geopolymers incorporating soda residue. Cem. Concr. Compos. 2019, 98, 125–136. [Google Scholar] [CrossRef]

- Kasikowski, T.; Buczkowski, R.; Cichosz, M. Utilisation of synthetic soda-ash industry by-products. Int. J. Prod. Econ. 2008, 112, 971–984. [Google Scholar] [CrossRef]

- Liu, D.; Liu, Y.; Wang, Z. Preparation of Pavement Brick from Soda Residue. J. Ceram. 2014, 35, 629–633. [Google Scholar] [CrossRef]

- Zhao, X.H.; Liu, C.Y.; Wang, W.J.; Zhu, N. Experimental Research on Physical and Mechanical Properties of Soda Residue Mixing Soils Used for Filling Embankment. Bull. Chin. Ceram. Soc. 2017, 36, 1406–1411+1423. [Google Scholar] [CrossRef]

- Wang, F.; Xu, Z.; Yan, L.; Cao, P. Study on test methods and geotechnical properties of soda residue. Chin. J. Geotech. Eng. 2007, 29, 1211–1214. [Google Scholar]

- Yu, H.; Hu, L.; Xu, Q. Consolidation Mechanism of Chloride Ion in Soda Residue from Ammonia Soda Process Method. J. Wuhan Univ. Technol. (Mater. Sci.) 2023, 38, 616–622. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, X.; Zhou, B. Performance Optimization and Characterization of Soda Residue-Fly Ash Geopolymer Paste for Goaf Backfill: Beta-Hemihydrate Gypsum Alternative to Sodium Silicate. Materials 2020, 13, 5604. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Liang, Y.; Jiang, L.; Zhang, C.; Wang, Q. Characteristics of ammonia-soda residue and its reuse in magnesium oxychloride cement pastes. Constr. Build. Mater. 2021, 300, 123981. [Google Scholar] [CrossRef]

- Jia, S.H. Experimental Study on the Solidification Mechanism and Mechanical Properties of Lime Cement Composite Soil. Ph.D. Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2011. [Google Scholar]

- Chen, Y.C. Evaluating greenhouse gas emissions and energy recovery from municipal and industrial solid waste using waste-to-energy technology. J. Clean. Prod. 2018, 192, 262–269. [Google Scholar] [CrossRef]

- Shen, W.; Liu, Y.; Yan, B.; Wang, J.; He, P.; Zhou, C.; Huo, X.; Zhang, W.; Xu, G.; Xu, G. Cement industry of China: Driving force, environment impact and sustainable development. Renew. Sustain. Energy Rev. 2017, 75, 618–628. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef] [PubMed]

- Shen, W. Preparation and Application of Eco-Pavement Base Materials from Industrial Solid Waste. Master’s Thesis, China Building Materials Industry Press, Beijing, China, 2021. [Google Scholar]

- Wang, X.; Li, Y.; He, L.; Zhang, Z.; Wang, G.; Jin, L.; Jia, M. Analysis of Carbon Dioxide and Atmospheric Pollutant Emissions from China’s Cement Industry from 2011 to 2022; China Environmental Monitoring: Beijing, China, 2024; pp. 1–11. [Google Scholar]

- Guo, W.; Zhang, Z.; Xu, Z.; Zhang, J.; Bai, Y.; Zhao, Q.; Qiu, Y. Mechanical properties and compressive constitutive relation of solid waste-based concrete activated by soda residue-carbide slag. Constr. Build. Mater. 2022, 333, 127352. [Google Scholar] [CrossRef]

- Yan, C.; Song, X.; Zhu, P.; Sun, Y.; Li, Y.; Zhang, J. Experimental Study on Strength Characteristics of High-Moisture Alkali Slag. Chin. J. Geotech. Eng. 2007, 29, 6. [Google Scholar]

- Zhu, S.; Tang, Y.; Xu, Q.; Zhang, K.; Li, H.; Zhu, Z.; Yin, W. Mechanical Properties Test and Enhancement Mechanism of Lime Soil Modified by High Content Soda Residue for Road Use. Coatings 2022, 12, 1539. [Google Scholar] [CrossRef]

- Zhang, P.; Zhao, X.; Jiang, D.; Xu, S.; Zong, Z. Experimental Study on Unconfined Compressive Strength and Water Stability of Alkali Slag Soil. Highway 2020, 65, 212–218. [Google Scholar]

- Guo, Q.; Li, B.; Ding, J.; Chen, J.; Sun, S.; Ma, Y. Experimental Study on Road Performance of Industrial Waste Slag Improved Mud Shield Tunneling Slag Soil [J/OL]. J. Civ. Environ. Eng. 2024, 1–11. [Google Scholar]

- Li, H.; Zhu, S.; Yin, W.; Zhu, Z.; Zhang, K.; Bai, X.; Liu, D.; Tang, Y. Study on Strength Test and Application of Lime Soil in Pavement Base Modified by Soda Residue. Adv. Civ. Eng. 2022, 2022, 4887647. [Google Scholar]

- Xu, J. Research on Alkali Slag Subgrade Treatment. Ph.D. Thesis, Tianjin University, Tianjin, China, 2009. [Google Scholar]

- Yin, W.; Zhang, K.; Ouyang, S.; Bai, X.; Sun, W.; Zhao, J. Experimental Study on Gangue Backfilling Materials Improved by Soda Residue and Field Measurement of Surface Subsidence. Front. Earth Sci. 2021, 9, 747675. [Google Scholar] [CrossRef]

- Zhao, X.; Shen, Z.; Zhao, G.; Liang, T. Experimental study on shear strength characteristics of mud construction waste lightweight soil. Mar. Georesources Geotechnol. 2022, 40, 1184–1192. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- Liu, Q.; Sun, J.; Lu, C. Modern Testing and Analysis Methods for Materials; Tsinghua University Press: Beijing, China, September 2014. [Google Scholar]

- JTG/T F20-2015; Technical Guidelines for Construction of Highway Roadbases. China Communications Press: Beijing, China, 2015.

- Yahye, M.A.; Liu, L.; Honglin, W.U.; Sun, Y.; Sun, H.; Ma, J.; Zhang, L. Experimental research on mechanical properties of Fiber-Reinforced Polyurethane Elastic Concrete (FRPEC). Constr. Build. Mater. 2022, 328, 126929. [Google Scholar]

- Zhang, L. Experimental Study on Strength of Composite Cemented Soil Based on Orthogonal Test. Eng. Constr. Des. 2021, 21, 99–101. [Google Scholar]

- Mehdipour, I.; Khayat, H.K. Elucidating how particle packing controls rheology and strength development of dense cementitious suspensions. Cem. Concr. Compos. 2019, 104, 103413. [Google Scholar] [CrossRef]

- Zhang, S.; Xie, S.; Yang, X. Study on Mechanism of Volcanic Ash Modified Coarse Grained Sulfate Saline Soil Roadbed Fillers and Its Action Mechanism. Chin. J. Geotech. Eng. 2019, 41, 588–594. [Google Scholar]

- Li, L.; Xie, Y.; Feng, Z.; Zhu, C. Cement Hydration Mechanism and Its Research Methods. Concrete 2011, 6, 76–80. [Google Scholar]

- Xu, Z.; Zhang, M.; Xu, H. Study on Hydration Mechanism of Lime-Gypsum-Fly Ash Cement Slurry. J. Environ. Eng. 2009, 3, 1879–1884. [Google Scholar]

- Cheng, Y.; Huang, X. Experimental Study on the Influence of Chloride Salt on the Strength of Alkali Activated Slag Paste. J. Beijing Univ. Aeronaut. Astronaut. 2015, 41, 693–700. [Google Scholar]

- Du, Z.; Chen, S.; Yin, D.; Yao, D.; Zhang, Z. Experimental Study on Stability of Filling Body in Chloride Salt Erosion Environment. J. China Univ. Min. Technol. 2021, 50, 532–538+547. [Google Scholar]

| Physical and Mechanical Parameters | Chemical Component/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Number | Item | Value | Unit | Number | Composition | Content | Number | Composition | Number |

| 1 | Moisture content | 78.40 | % | 1 | CaO | 52.25 | 6 | MgO | 2.33 |

| 2 | PH | 9.2 | - | 2 | SO3 | 16.97 | 7 | Al2O3 | 1.76 |

| 3 | Plastic limit | 53.96 | % | 3 | Cl | 18.39 | 8 | Fe2O3 | 1.17 |

| 4 | Liquid limit | 83.49 | % | 4 | SiO2 | 4.06 | 9 | K2O | 0.15 |

| 5 | UCS | 0.20 | MPa | 5 | NaO2 | 2.46 | 10 | Other | 0.46 |

| Compositions | CaO | Ca(OH)2 | CaCO3 | Other |

| Content (%) | 47 | 23 | 9 | 21 |

| Compositions | C3S | C2S | C3A | C4AF | Other |

| Content (%) | 48.5 | 26.2 | 11.1 | 12.3 | 1.9 |

| Level | A/% | B/mm | C/% | D/d |

|---|---|---|---|---|

| Xi1 | 0 | 0.15 | 0 | 1 |

| Xi2 | 3 | 1.18 | 43.6% | 7 |

| Xi3 | 6 | 2.36 | 64.5% | 14 |

| Xi4 | 9 | 4.75 | 85.3% | 28 |

| Group | Cement/% | Lime/% | A/% | B/mm | C/% | D/d | Rc/MPa |

|---|---|---|---|---|---|---|---|

| S1 | 3 | 9 | 0 | 0.15 | 0.00 | 1 | 0.517 |

| S2 | 3 | 9 | 0 | 1.18 | 43.60 | 7 | 0.686 |

| S3 | 3 | 9 | 0 | 2.36 | 64.58 | 14 | 0.726 |

| S4 | 3 | 9 | 0 | 4.75 | 85.38 | 28 | 0.815 |

| S5 | 3 | 6 | 3 | 0.15 | 64.58 | 7 | 0.723 |

| S6 | 3 | 6 | 3 | 1.18 | 85.38 | 1 | 0.551 |

| S7 | 3 | 6 | 3 | 2.36 | 0.00 | 28 | 0.867 |

| S8 | 3 | 6 | 3 | 4.75 | 43.60 | 14 | 0.715 |

| S9 | 3 | 3 | 6 | 0.15 | 85.38 | 14 | 0.721 |

| S10 | 3 | 3 | 6 | 1.18 | 64.58 | 28 | 0.737 |

| S11 | 3 | 3 | 6 | 2.36 | 43.60 | 1 | 0.512 |

| S12 | 3 | 3 | 6 | 4.75 | 0.00 | 7 | 0.625 |

| S13 | 3 | 0 | 9 | 0.15 | 43.60 | 28 | 0.696 |

| S14 | 3 | 0 | 9 | 1.18 | 0.00 | 14 | 0.632 |

| S15 | 3 | 0 | 9 | 2.36 | 85.38 | 7 | 0.487 |

| S16 | 3 | 0 | 9 | 4.75 | 64.58 | 1 | 0.407 |

| Target Value | Response Value () | |||

|---|---|---|---|---|

| A | B | C | D | |

| 0.686 | 0.664 | 0.660 | 0.497 | |

| 0.714 | 0.652 | 0.652 | 0.630 | |

| 0.649 | 0.648 | 0.648 | 0.699 | |

| 0.556 | 0.641 | 0.644 | 0.779 | |

| 0.159 | 0.024 | 0.017 | 0.282 | |

| Source of Fluctuation Factors | Degrees of Freedom | SS | MS | F Value | Significance Level |

|---|---|---|---|---|---|

| A | 3 | 0.05728 | 0.01909 | 48.53228 | p < 0.05 |

| B | 3 | 0.00118 | 0.00039 | 1.95496 | p > 0.05 |

| C | 3 | 0.00060 | 0.00020 | 1 | / |

| D | 3 | 0.17120 | 0.05707 | 145.06143 | p < 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, W.; Yin, W.; Wang, X.; Xu, Q.; Wang, G.; Cao, J.; Zhu, S. Multi-Factor Orthogonal Experiments and Enhancement Mechanisms of Unconfined Compressive Strength of Soda Residue Cement Lime Soil. Buildings 2024, 14, 2189. https://doi.org/10.3390/buildings14072189

Cheng W, Yin W, Wang X, Xu Q, Wang G, Cao J, Zhu S. Multi-Factor Orthogonal Experiments and Enhancement Mechanisms of Unconfined Compressive Strength of Soda Residue Cement Lime Soil. Buildings. 2024; 14(7):2189. https://doi.org/10.3390/buildings14072189

Chicago/Turabian StyleCheng, Wenbo, Wei Yin, Xiaoya Wang, Quan Xu, Guodong Wang, Jun Cao, and Shengxue Zhu. 2024. "Multi-Factor Orthogonal Experiments and Enhancement Mechanisms of Unconfined Compressive Strength of Soda Residue Cement Lime Soil" Buildings 14, no. 7: 2189. https://doi.org/10.3390/buildings14072189