Evaluation on the Adhesion Property of Recycled Asphalt Based on the Multi-Scale Experiments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nomenclature

2.2. Asphalt

2.3. Rejuvenator

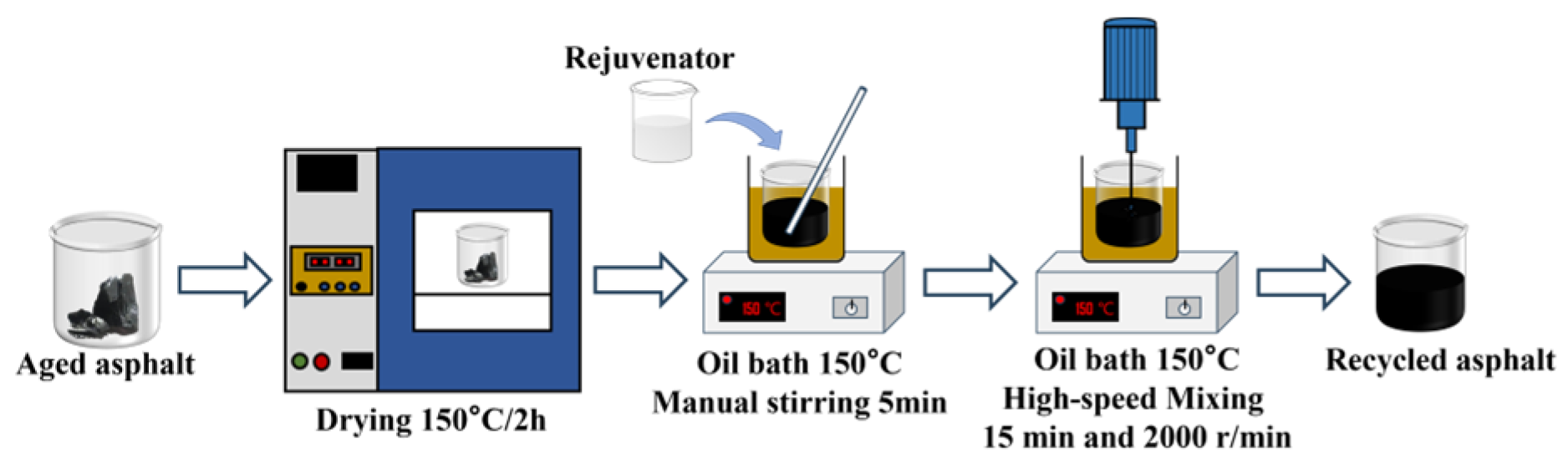

2.4. Preparation of RA

2.5. Methods

2.5.1. PO Test

2.5.2. SFE Test

2.5.3. AFM Test

3. Results

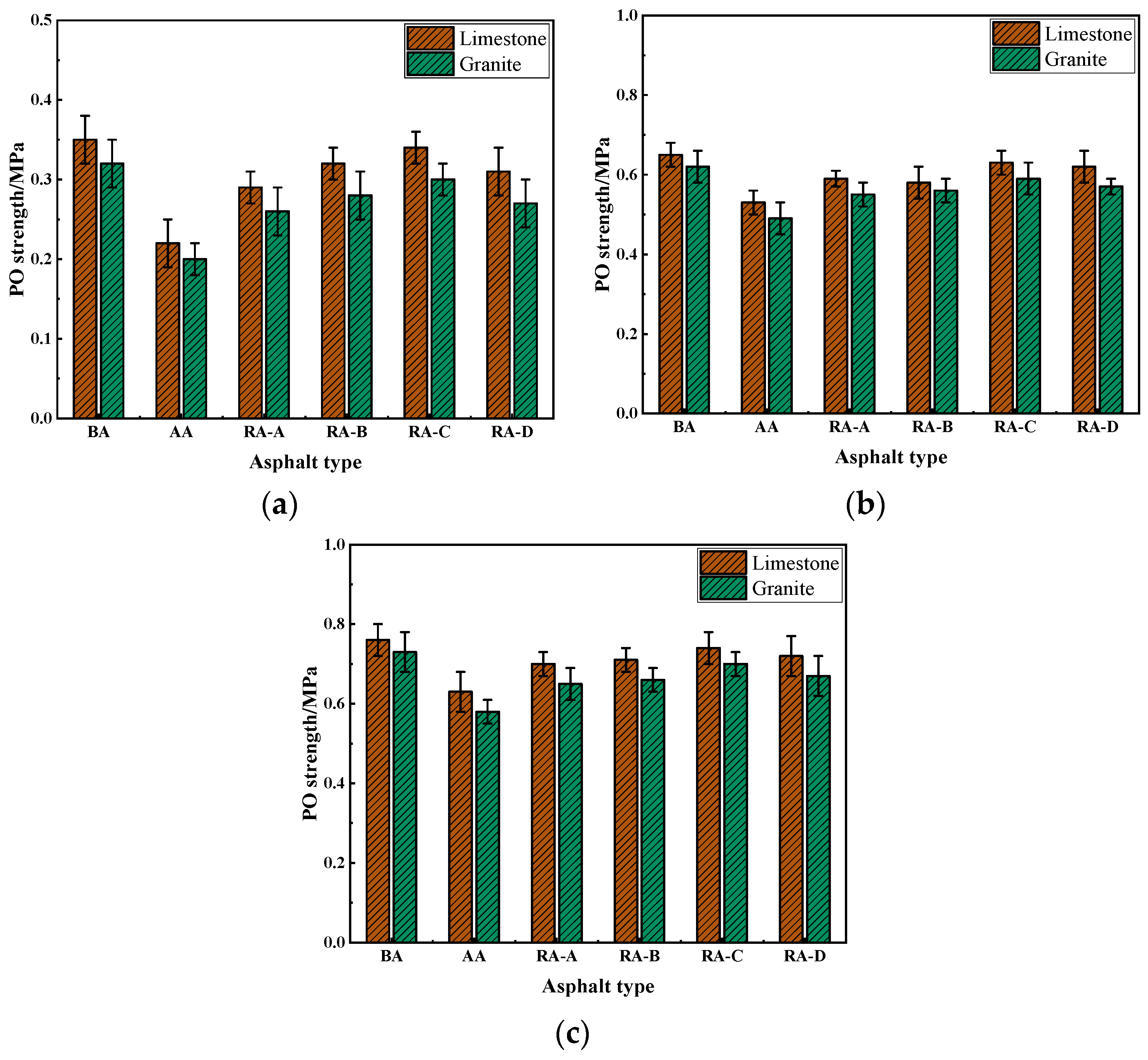

3.1. PO Test

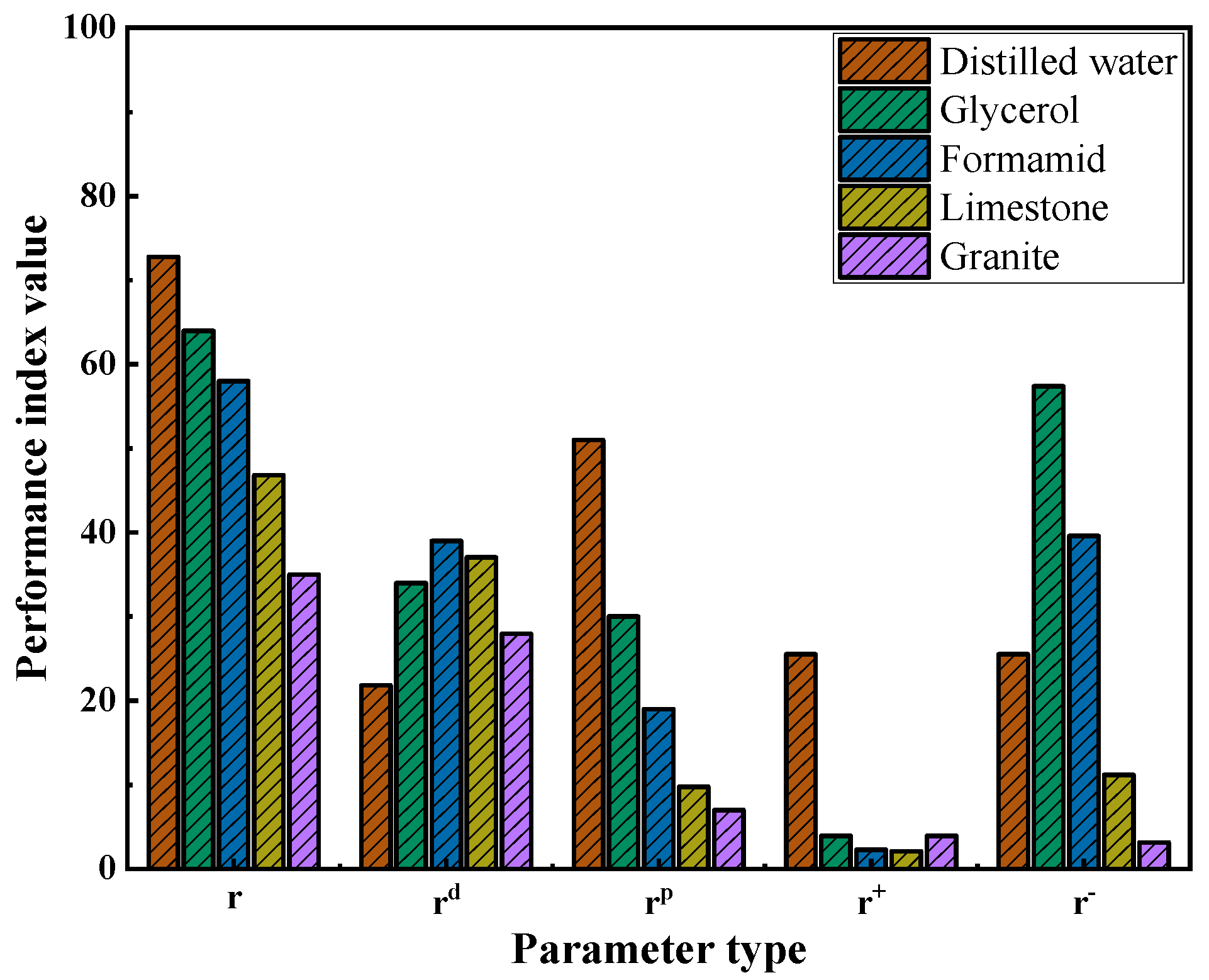

3.2. SFE Test

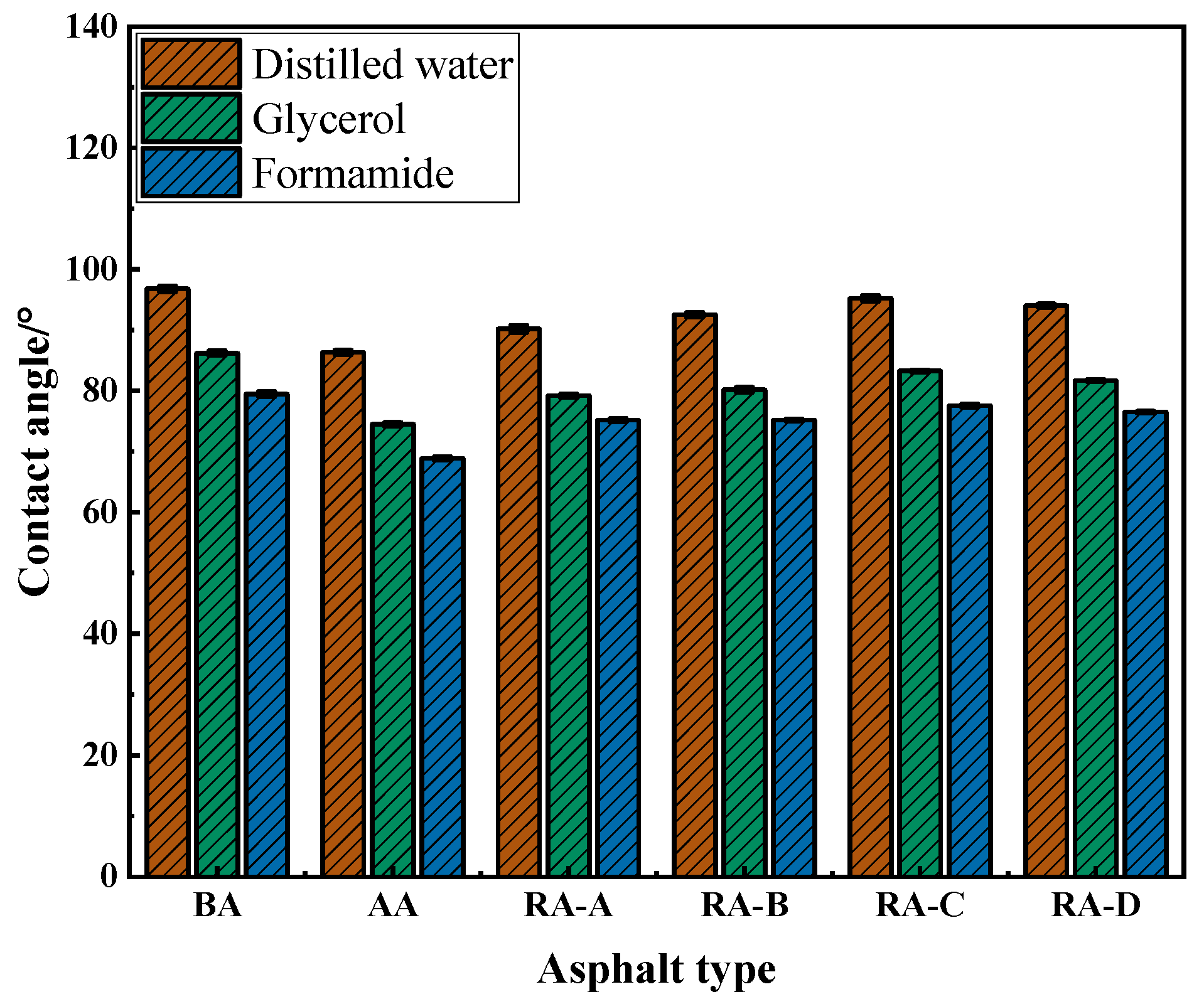

3.2.1. Contact Angle

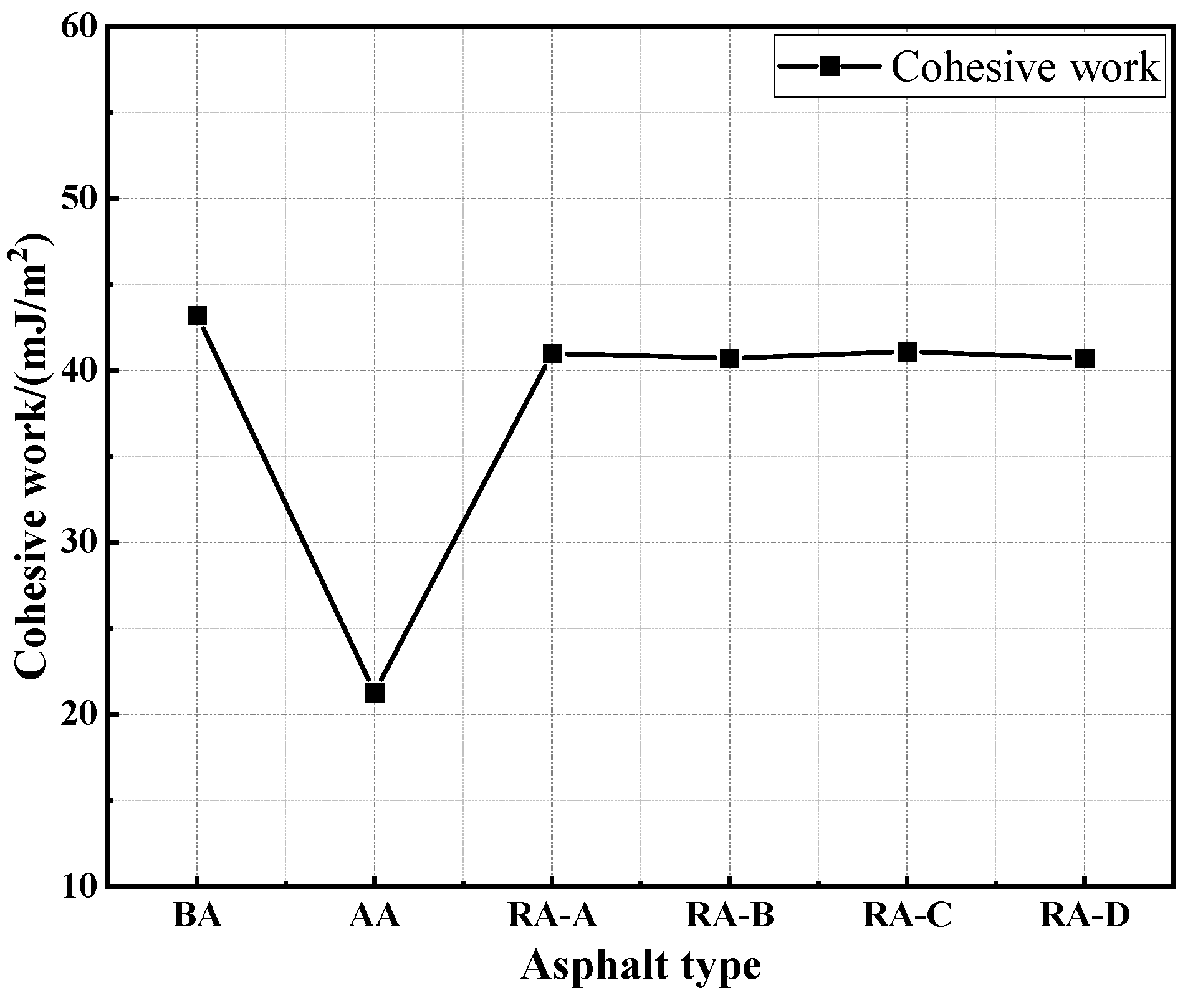

3.2.2. Cohesive Work

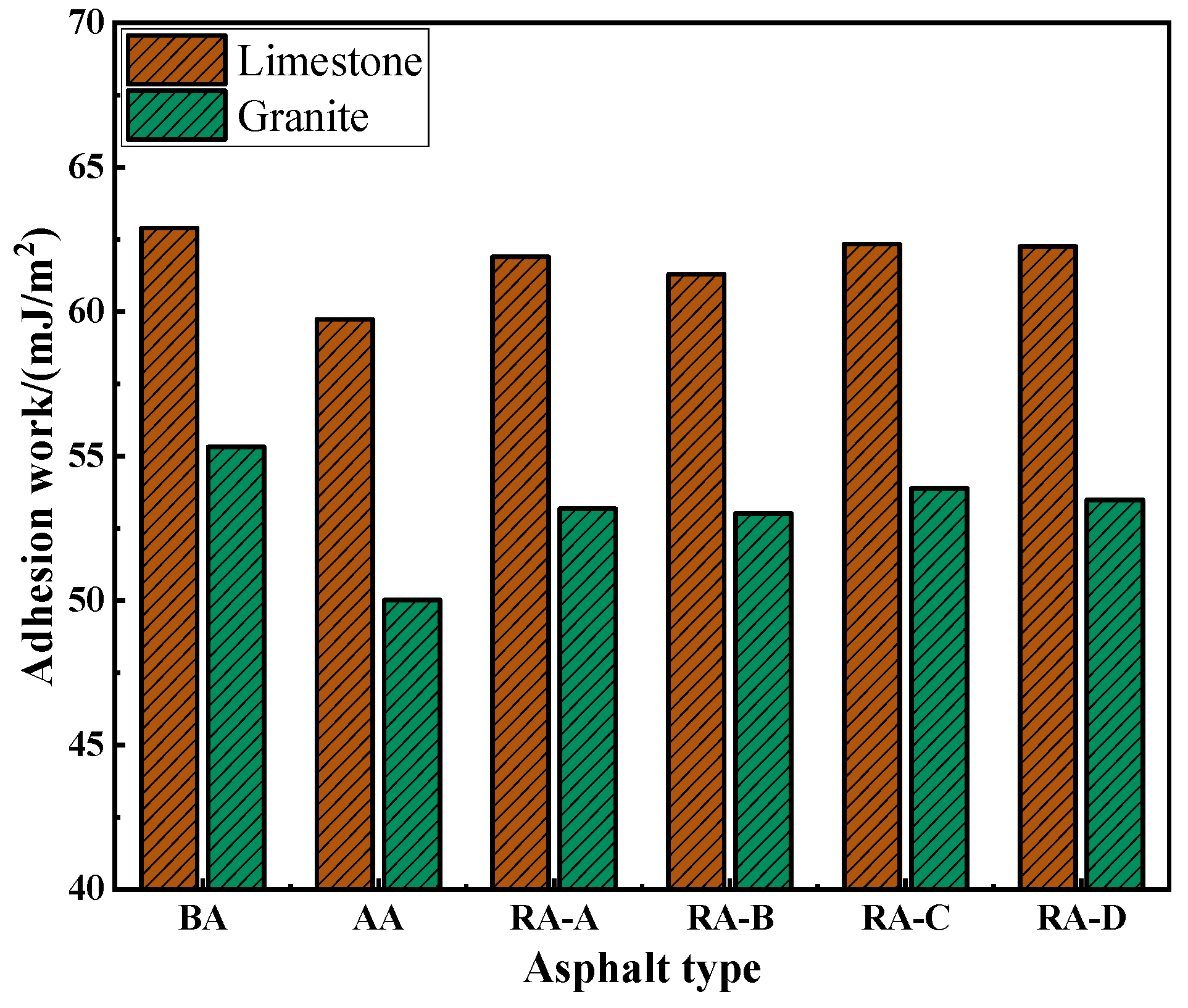

3.2.3. Adhesion Work

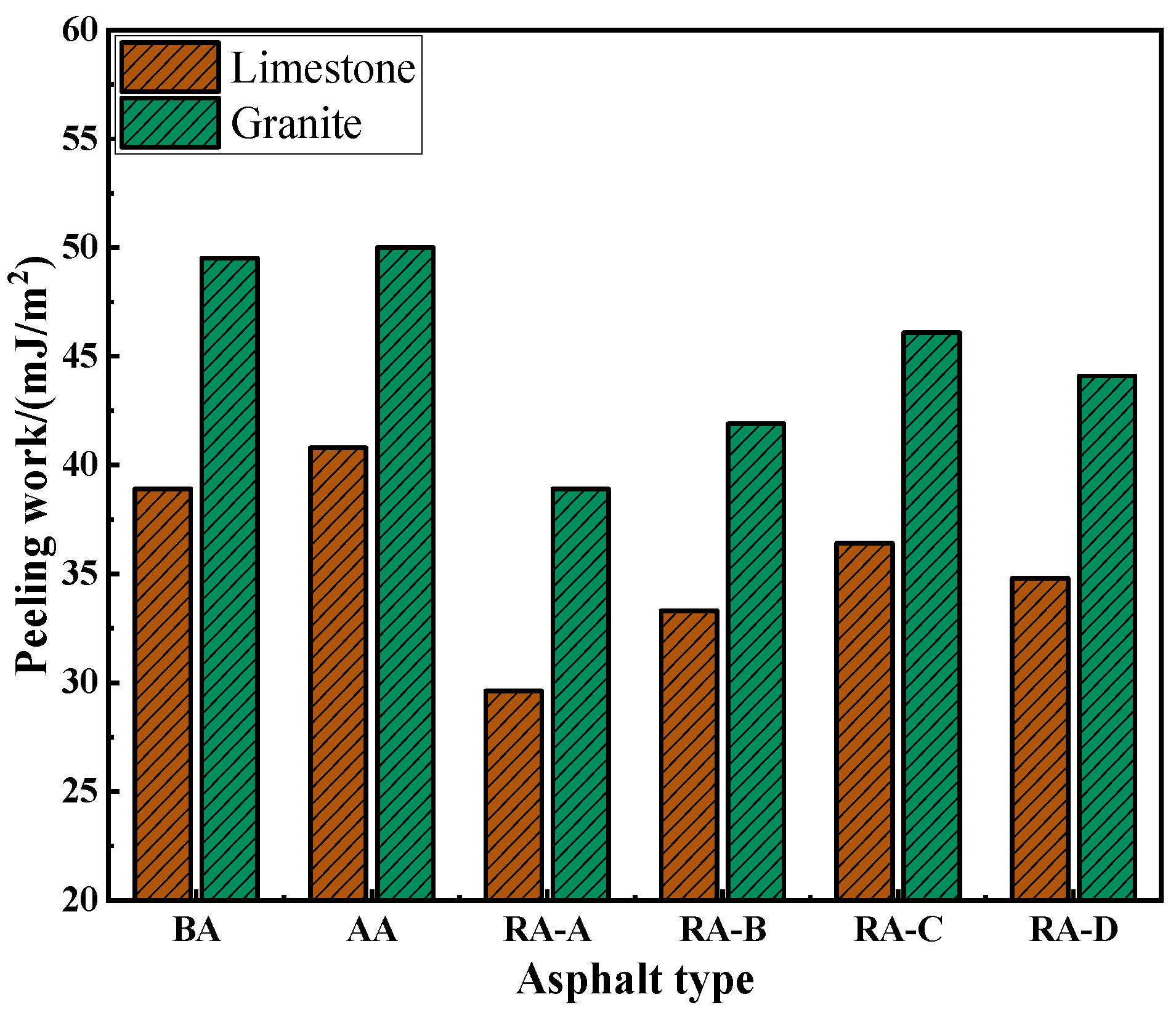

3.2.4. Peeling Work

3.3. AFM Test

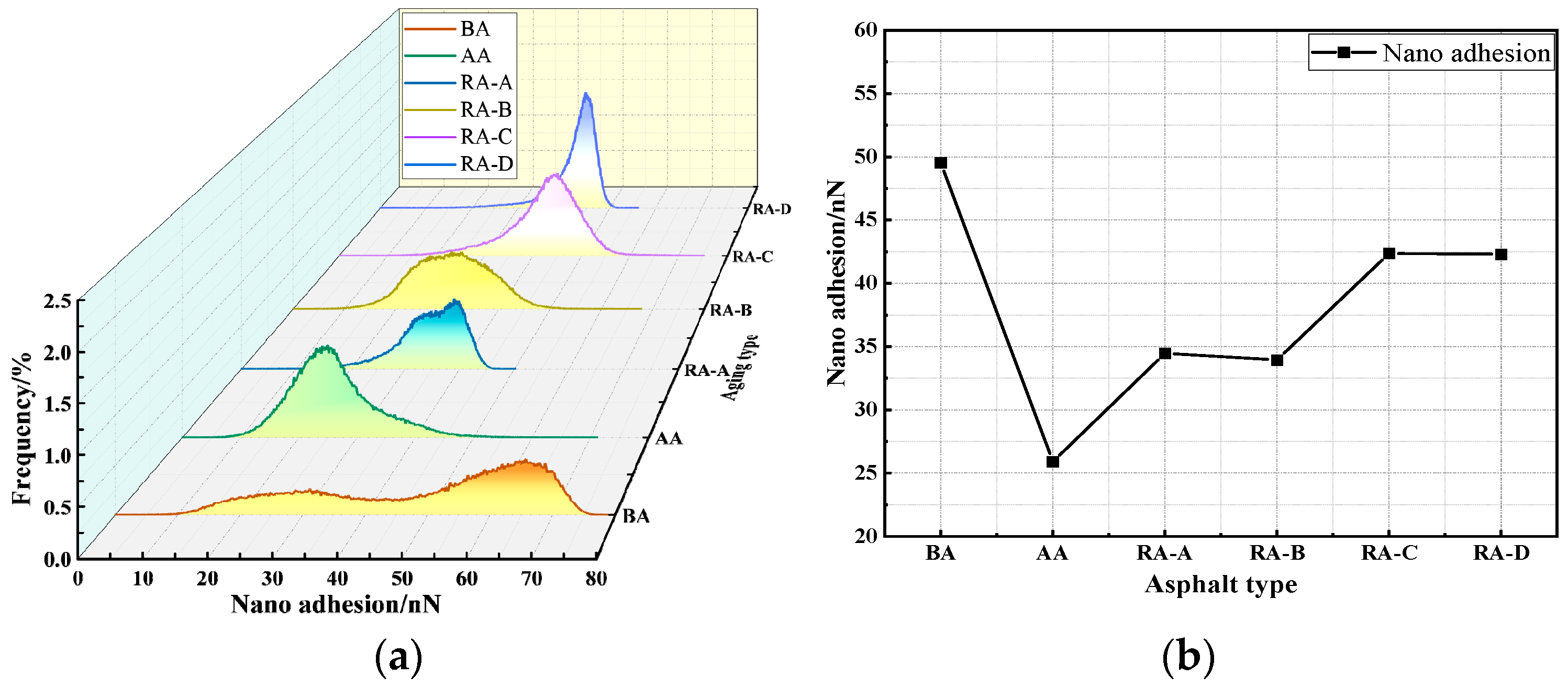

3.3.1. Nano Adhesion

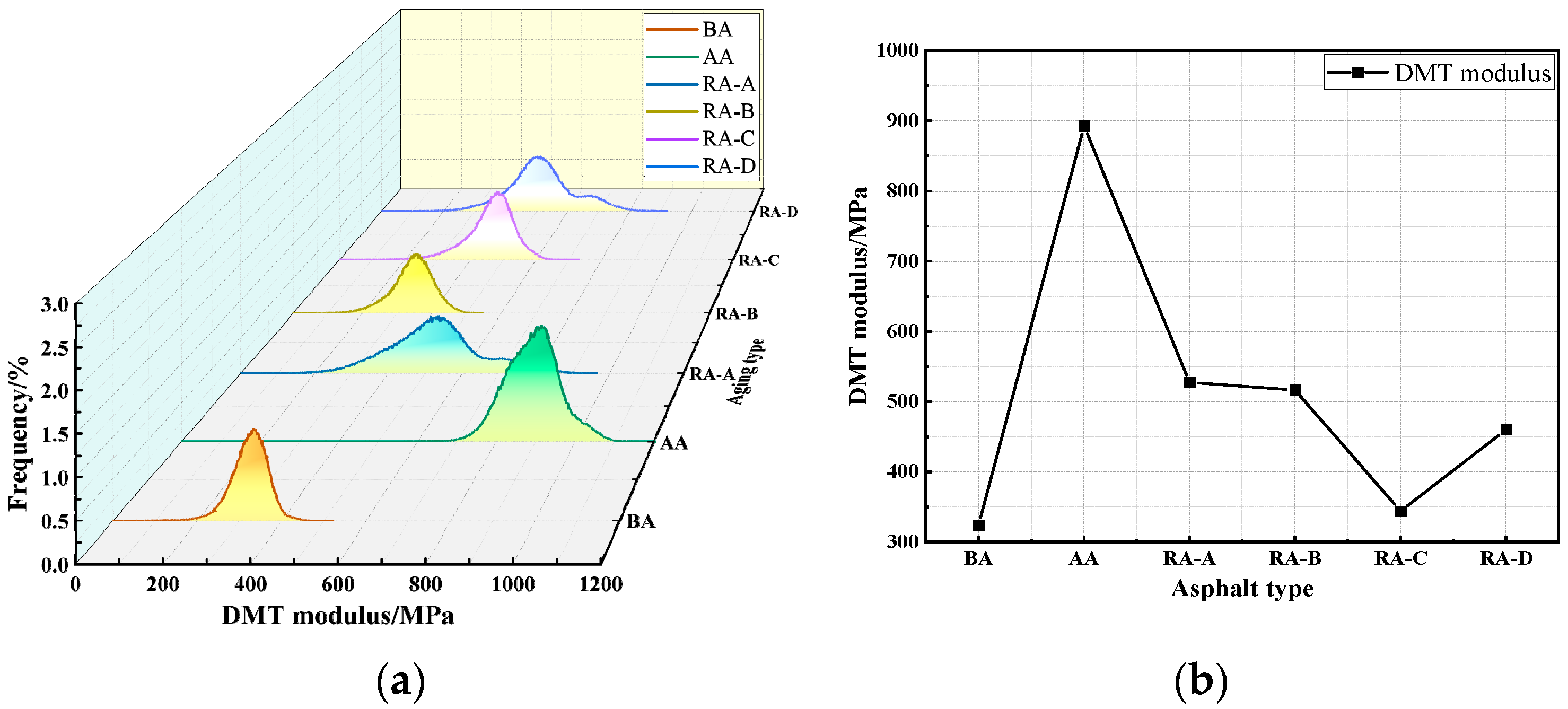

3.3.2. DMT Modulus

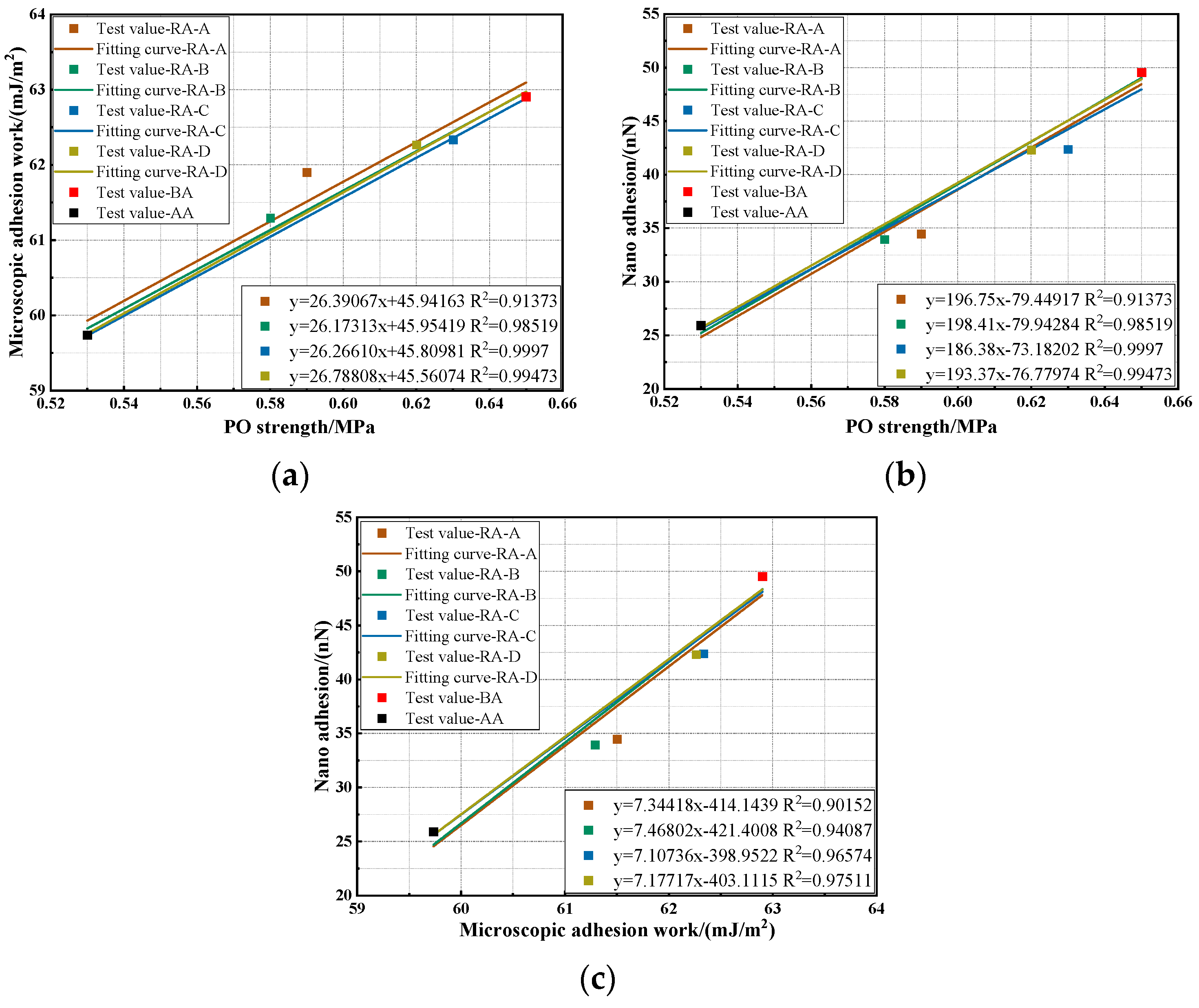

3.4. Correlation Analysis

4. Conclusions

- (1)

- The aging effect degrades the bond strength between AA and aggregate. Conversely, the addition of a rejuvenator effectively enhances their bond strength. Moreover, due to the properties of the aggregate, limestone and asphalt exhibit stronger adhesion properties compared to granite.

- (2)

- The aging process led to a decrease in the hydrophobicity of asphalt, rendering it more susceptible to water damage and cracking, thereby diminishing its adhesion property. Although the addition of the rejuvenator partially mitigated this adverse effect, the adhesion properties of RA remained slightly inferior to those of BA. Notably, the naphthenic oil-based rejuvenator demonstrated a more pronounced ability to restore the adhesion property of AA.

- (3)

- The calculation results of the nano mechanical properties showed that the aging effect led to a decrease in the nano adhesion and an increase in the DMT modulus of asphalt, which implied that AA was more inclined to elastic deformation and its adhesion properties were decreased. The incorporation of rejuvenators showed a considerable restoring effect on the nano adhesion property of AA, the performance index values of RA were extremely close to BA, and the rejuvenating effects of several rejuvenators were similar to the macroscopic and microscopic test results.

- (4)

- The correlation analysis revealed that the adhesion property of RA exhibited a robust relationship across various mechanical properties indices at different scales, which remained consistent regardless of the type of rejuvenator used. The slopes of the regression equations for several RA samples at different scales showed remarkably similar values with high precision. This consistency suggests that, despite variations in mechanical test methods and conditions across different scales, there exists a uniformity in the evaluation of the trends in adhesion properties between RA and aggregates.

- (5)

- This study investigates the evolution mechanism of the adhesion properties of recycled asphalt at different scales. The research findings can provide a reference for the optimization of recycled asphalt formulations and processes, enhance the durability and performance of pavements, promote the reuse of waste materials, reduce the environmental impact, and lower the costs of road construction and maintenance. Additionally, these findings can aid in driving technological innovation, establishing industry standards, and providing scientific guidance for practical engineering in future research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, Y.; Yi, J.; Huang, T. Study on Rheological and Mechanical Properties of Rock-Compound-Additive-Modified Asphalt and Its Mixture. Materials 2023, 16, 3771. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Guo, J.; Ma, S.; Zhang, H.; Su, C.; Wang, X.; Li, Z.; Wei, J.; Cui, S. Effect of Solid-Solid Phase Change Material’s Direct Interaction on Physical and Rheological Properties of Asphalt. Coatings 2022, 12, 625. [Google Scholar] [CrossRef]

- Chen, B.; Dong, F.; Yu, X.; Zheng, C. Evaluation of Properties and Micro-Characteristics of Waste Polyurethane/Styrene-Butadiene-Styrene Composite Modified Asphalt. Polymers 2021, 13, 2249. [Google Scholar] [CrossRef]

- Wang, J.; Xu, J.; Liu, L. Variability Investigation of Reclaimed Asphalt Pavement Materials. J. Mater. Civ. Eng. 2024, 36, 04023558. [Google Scholar] [CrossRef]

- Ma, Y.; Ding, Y.; Zheng, K.; Polaczyk, P.; Zhang, M.; Xiao, R.; Huang, B. Effects of Immobilized RAP Binder on Asphalt-Aggregate Interaction and Performance of 100% Recycled Asphalt Mixtures. J. Mater. Civ. Eng. 2023, 35, 04023029. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Barbieri, D.; Lou, B.; Hoff, I. The classification and reutilisation of recycled asphalt pavement binder: Norwegian case study. Case Stud. Constr. Mater. 2022, 17, e01491. [Google Scholar] [CrossRef]

- Li, Z.; Guo, T.; Chen, Y.; Bian, X.; Jiang, X.; Hao, M.; Zhao, X.; Liu, J. Study on rheological properties of warm mix large proportion recycled asphalt. Mater. Res. Express 2022, 9, 105101. [Google Scholar] [CrossRef]

- Yin, P.; Pan, B. Evaluation of temperature sensitivity of recycled asphalt based on numerical analysis model and thermal analysis kinetics. Constr. Build. Mater. 2022, 344, 128153. [Google Scholar] [CrossRef]

- Ma, T.; Huang, X.; Zhao, Y.L.; Zhang, Y. Evaluation of the diffusion and distribution of the rejuvenator for hot asphalt recycling. Constr. Build. Mater. 2015, 98, 530–536. [Google Scholar] [CrossRef]

- Li, M.; Liu, L.; Xing, C.; Liu, L.; Wang, H. Influence of rejuvenator preheating temperature and recycled mixture’s curing time on performance of hot recycled mixtures. Constr. Build. Mater. 2021, 295, 123616. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, H.; Zhang, Z. Study on the mechanism of the repeated asphalt ageing and recycling based on the macro-performance. Road Mater. Pavement Des. 2015, 17, 920–932. [Google Scholar] [CrossRef]

- Ding, Z.; Jiang, X.; Li, H.; Li, P.; Chen, J. Influences of Waste-Utilizing Rejuvenator on Properties of Recycled Asphalt Binders. J. Mater. Civ. Eng. 2023, 35, 04022387. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, Z.; Yang, J.; Li, X. Performance Characterization of Biorecycled Asphalt and Gray Correlation Analysis between Its Components and Macroproperties. J. Mater. Civ. Eng. 2022, 34, 04021490. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, L.; Qin, Y. Aging mechanism of SBS modified asphalt based on chemical reaction kinetics. Constr. Build. Mater. 2015, 91, 47–56. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, C.; Chen, T.; Zhang, W.; Yao, K.; Fan, C.; Liang, M.; Guo, C.; Yao, Z. Evaluation on the mechanical performance of recycled asphalt mixtures incorporated with high percentage of RAP and self-developed rejuvenators. Constr. Build. Mater. 2021, 269, 121337. [Google Scholar] [CrossRef]

- Yi, X.; Chen, H.; Wang, H.; Shi, C.; Yang, J. The feasibility of using epoxy asphalt to recycle a mixture containing 100% reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2022, 319, 126122. [Google Scholar] [CrossRef]

- Li, B.; Li, A.; Chen, X.; Nan, X.; Li, Z.; Qiu, K.; Ji, H. Multi-scale investigation on the adhesion properties of warm-mixed recycled SBS modified asphalt. Constr. Build. Mater. 2023, 377, 131129. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Lu, Y.; Zhou, X.; Hu, Y.; Sun, J.; Fu, G. Effect of dynamic water pressure on the adhesion behavior of recycled asphalt-aggregate interface by molecular dynamics method. Constr. Build. Mater. 2023, 382, 131296. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Song, S.; Wang, R.; Jiang, J.; Yan, C. Study on the Adhesion Characteristics of Asphalt-Aggregate Interface in Cold Recycled Asphalt Mixtures. J. Mater. Civ. Eng. 2023, 35, 04023283. [Google Scholar] [CrossRef]

- Chen, R.; Zhu, H.; Ou, L.; Xu, Y. Effect of Re-Recycling on Rheology and Microstructure of Asphalt Binder. Materials 2022, 15, 6641. [Google Scholar] [CrossRef]

- Zhao, K.; Song, S.; Wei, Y.; Li, G.; Guo, F. Adhesion Properties of Recycled High-Viscosity Asphalt-Aggregate Interface under Dynamic Water Erosion. Materials 2023, 16, 6203. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Li, Q.; Wang, J.; Zhao, Z.; Jin, D. Physical and chemical evaluation of adhesion recovery property of aged high-viscosity asphalt based on specialized composite rejuvenators. J. Clean. Prod. 2023, 414, 137758. [Google Scholar] [CrossRef]

- Ji, H.; Li, B.; Li, A.; Li, Z.; Han, J.; Liu, Z. Adhesion mechanism of warm-mixed recycled SBS Modified Asphalt Binder: Surface free energy, microstructure and chemical compositions. Case Stud. Constr. Mater. 2023, 19, e02426. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.; Li, H.; Chen, W. A Study on the Microscopic Properties of the Oil–Stone Interfacial Phase of a Reclaimed Asphalt Mixture Based on Molecular Dynamics Simulation. Coatings 2023, 13, 1717. [Google Scholar] [CrossRef]

- Peng, C.; Yang, D.; Liu, Y.; You, Z.; Xu, F.; Guan, P.; Ruan, D.; Ning, Y.; Ye, Z. Study on the effect of carbon nanotubes on the properties of wasted engine oil recycled asphalt binder. Constr. Build. Mater. 2023, 400, 132800. [Google Scholar] [CrossRef]

- Chiu, C.; Hsu, T.; Yang, W. Life cycle assessment on using recycled materials for rehabilitating asphalt pavements. Resour. Conserv. Recycl. 2008, 52, 545–556. [Google Scholar] [CrossRef]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. People’s Communications Press: Beijing, China, 2004.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Communications Press: Beijing, China, 2011.

- Jiang, Y.; Chen, X.; Xu, T. Development of sustainable compound bio-oil rejuvenator and its rejuvenation mechanism on long-term aged asphalt. J. Clean. Prod. 2023, 429, 139440. [Google Scholar] [CrossRef]

- Li, J.; Yu, M.; Cui, X.; Wang, W. Properties and Components of Recycled Engine Oil Bottom Rejuvenated Asphalt and Its Grey Relationship Analysis. Adv. Mater. Sci. Eng. 2019, 2019, 2462487. [Google Scholar] [CrossRef]

- Li, Z.; Yin, P.; Liu, F.; Pan, B.; Liu, Y. Composite design of phosphogypsum whisker-based rejuvenator based on RSM and evaluation of rejuvenating effect. J. Mater. Civ. Eng. 2024. [Google Scholar] [CrossRef]

- Kang, X.; Wang, R.; Yue, J.; An, X.; Tang, G. Investigation of the Adhesion Characteristics of a Novel Fast-Melting SBS-Based Modifier to Asphalt-Aggregate Systems Based on a Multiscale Approach. J. Mater. Civ. Eng. 2023, 35, 04023435. [Google Scholar] [CrossRef]

- Huang, W.; Lv, Q.; Xiao, F. Investigation of using binder bond strength test to evaluate adhesion and self-healing properties of modified asphalt binders. Constr. Build. Mater. 2016, 113, 49–56. [Google Scholar] [CrossRef]

- Han, S.; Dong, S.; Liu, M.; Han, X.; Liu, Y. Study on improvement of asphalt adhesion by hydrated lime based on surface free energy method. Constr. Build. Mater. 2019, 227, 116794. [Google Scholar] [CrossRef]

- Zhang, D.; Luo, R. Using the surface free energy (SFE) method to investigate the effects of additives on moisture susceptibility of asphalt mixtures. Int. J. Adhes. Adhes. 2019, 95, 102437. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Wang, Z.; Jing, H.; Yang, B. Investigations on Adhesion Characteristics between High-Content Rubberized Asphalt and Aggregates. Polymers 2022, 14, 5474. [Google Scholar] [CrossRef]

- Li, M.; Liu, L.; Yang, R.; Liu, L. Investigation of the Influence of Aging on the Nanoscale Adhesion of Asphalt from the Perspective of AFM-IR–Based Chemical Properties. J. Mater. Civ. Eng. 2022, 34, 04022240. [Google Scholar] [CrossRef]

- Cui, B.; Gu, X.; Wang, H.; Hu, D. Numerical and experimental evaluation of adhesion properties of asphalt-aggregate interfaces using molecular dynamics simulation and atomic force microscopy. Road Mater. Pavement Des. 2021, 23, 1564–1584. [Google Scholar] [CrossRef]

- Qu, L.; Meng, X.; Mo, L.; Chang, W.; Xiao, Y. Effect of Hydration Products on the Interfacial Bonding Properties between Asphalt Binder and Steel Slag Coarse Aggregate. J. Mater. Civ. Eng. 2023, 35, 04022432. [Google Scholar] [CrossRef]

- Li, M.; Liu, D.; Du, H.; Li, Q.; Hou, X.; Ye, J. Preparation of mesophase pitch by aromatics-rich distillate of naphthenic vacuum gas oil. Appl. Petrochem. Res. 2015, 5, 339–346. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Wang, J.; Si, W.; Hu, D. Quantitative Analysis of Adhesion Characteristics between Crumb Rubber Modified Asphalt and Aggregate Using Surface Free Energy Theory. Materials 2022, 15, 5735. [Google Scholar] [CrossRef]

- Cheng, P.; Zhang, Z.; Yang, Z.; Xu, J.; Li, Y. Investigating the Effectiveness of Nano-Montmorillonite on Asphalt Binder from Rheological, Thermodynamics, and Chemical Perspectives. Materials 2021, 14, 1433. [Google Scholar] [CrossRef]

- Han, X.; Mao, S.; Zeng, S.; Cao, Z.; He, P.; Du, W.; Yu, J. Influence of novel long-chain active composite rejuvenators on interfacial adhesion between aged SBS modified asphalt and aggregate. Constr. Build. Mater. 2022, 328, 127108. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, W.; Guo, C.; Du, X.; Pan, Y.; Gao, J.; Gao, X. Surface Free Energy Theory for Evaluating Moisture Damage in Expandable Polyurethane Grouting Materials. Adv. Eng. Mater. 2022, 24, 2200409. [Google Scholar] [CrossRef]

- Hong, H.; Zhang, H.; Zhang, S. Effect of multi-dimensional nanomaterials on the aging behavior of asphalt by atomic force microscope. Constr. Build. Mater. 2020, 260, 120389. [Google Scholar] [CrossRef]

- Zhai, R.; Ge, L.; Li, Y. The effect of nano-CaCO3/styrene–butadiene rubber (SBR) on fundamental characteristic of hot mix asphalt. Road Mater. Pavement Des. 2018, 21, 1006–1026. [Google Scholar] [CrossRef]

| Abbreviation | Explanation |

|---|---|

| BA | Base asphalt |

| AA | Aged asphalt |

| RA | Recycled asphalt |

| SFE | Surface free energy |

| PO | Pull-off |

| AFM | Atomic force microscopy |

| RTFOT | Rolling thin film oven test |

| TFOT | Thin film oven test |

| PF-QNM | Peak force quantitative nano mechanical |

| A | Bio-oil-based rejuvenator |

| B | Mineral oil-based rejuvenator |

| C | Naphthenic oil-based rejuvenator |

| D | Waste engine oil-based rejuvenator |

| Asphalt Type | Penetration/(0.1 mm/25 °C) | Ductility/(cm/15 °C) | Softening Point/°C |

|---|---|---|---|

| AA | 55 | 53.17 | 56.4 |

| BA | 84 | >100 | 45 |

| BA after RTFOT aging | 61.3 | 56.9 | 55.4 |

| Technical specifications of BA [27] | 80~100 | >100 | ≥44 |

| Requirements after RTFOT or TFOT aging of BA | penetration ratio ≥ 57% | ≥20 | - |

| Test method [28] | T 0604 | T 0605 | T 0606 |

| Performance Index | A | B | C | D |

|---|---|---|---|---|

| Density/(g/cm3) | 0.925 | 0.998 | 1.01 | 0.963 |

| Viscosity/(Pa·s/60 °C) | 0.134 | 0.127 | 0.153 | 0.132 |

| Flash point/°C | 225 | 239 | 231 | 236 |

| Viscosity ratio for RA after RTFOT aging | 1.86 | 1.68 | 1.43 | 1.56 |

| The absolute value of mass loss rate for RA after RTFOT aging/% | 1.27 | 1.01 | 0.76 | 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, P.; Liu, F.; Li, Z.; Pan, B.; Liu, T. Evaluation on the Adhesion Property of Recycled Asphalt Based on the Multi-Scale Experiments. Buildings 2024, 14, 2365. https://doi.org/10.3390/buildings14082365

Yin P, Liu F, Li Z, Pan B, Liu T. Evaluation on the Adhesion Property of Recycled Asphalt Based on the Multi-Scale Experiments. Buildings. 2024; 14(8):2365. https://doi.org/10.3390/buildings14082365

Chicago/Turabian StyleYin, Peng, Fei Liu, Zihan Li, Baofeng Pan, and Tao Liu. 2024. "Evaluation on the Adhesion Property of Recycled Asphalt Based on the Multi-Scale Experiments" Buildings 14, no. 8: 2365. https://doi.org/10.3390/buildings14082365