Analyzing Critical Factors Influencing the Quality Management in Smart Construction Site: A DEMATEL-ISM-MICMAC Based Approach

Abstract

:1. Introduction

2. Literature Review

2.1. Smart Construction Site

2.2. Construction Quality Management

2.3. Influencing Factors of Quality Management in Smart Construction Site

2.3.1. Human

2.3.2. Machine

2.3.3. Material

2.3.4. Method

2.3.5. Environment

2.4. Critical Influencing Factors of the SCS-QM

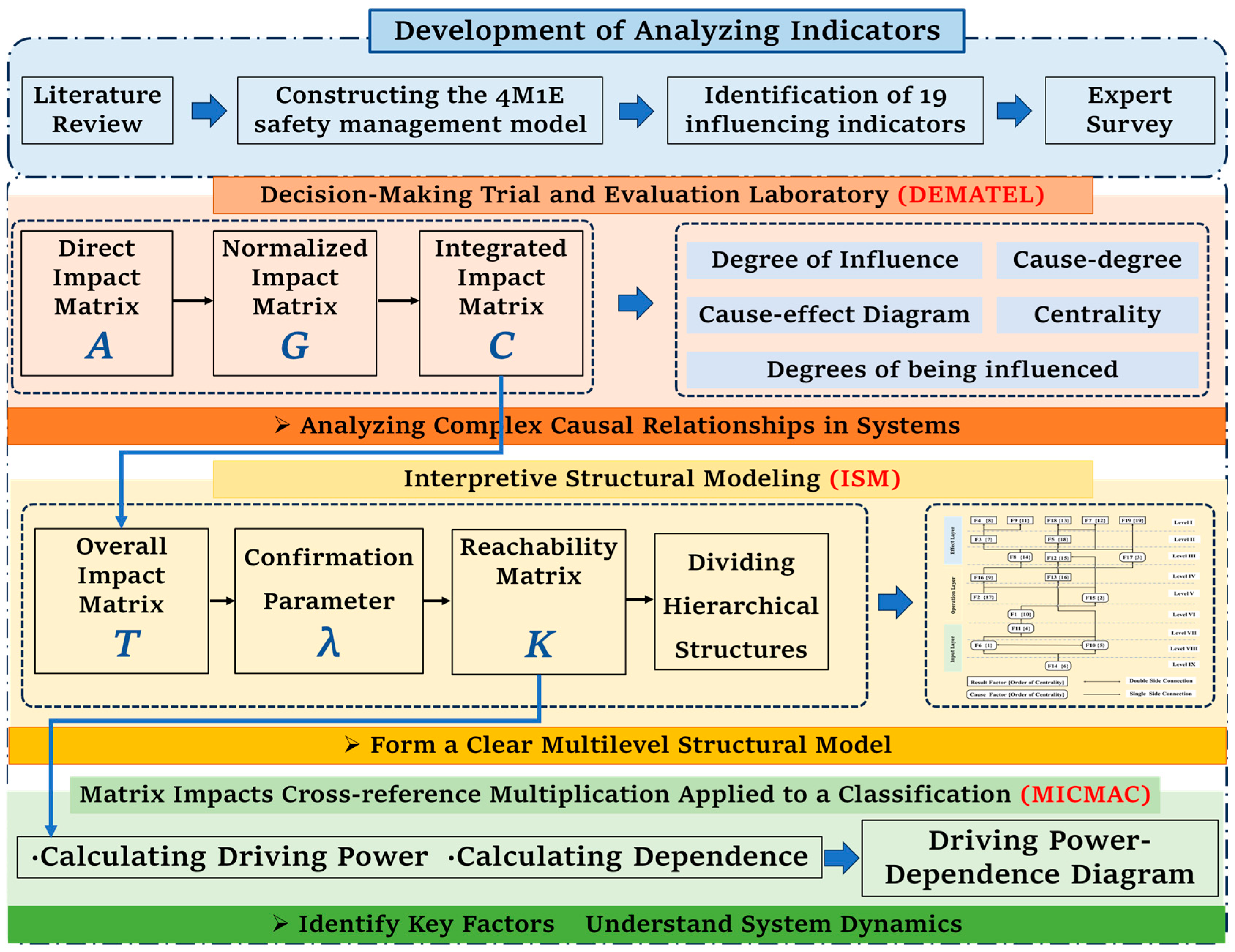

3. Methodology

3.1. Research Framework

3.2. Expert Survey

3.2.1. Expert Interviews

3.2.2. Questionnaire Design

3.3. Data Analysis Methodology

3.3.1. DEMATEL Method

- (1)

- Construct the direct impact matrix A.

- (2)

- Calculate the normalized impact matrix G.

- (3)

- Calculate the integrated impact matrix C.

- (4)

- Calculate four weights of factors.

- (5)

- Constructing the cause-effect diagram

3.3.2. ISM Method

- (1)

- Calculate the Overall Impact matrix T

- (2)

- Confirmation Parameter λ

- (3)

- Construct the reachability matrix K

- (4)

- Hierarchy division based on matrix K

3.3.3. MICMAC Method

- (1)

- Driving Power (Di)

- (2)

- Dependence (Pi)

3.3.4. DEMATEL-ISM-MICMAC Analysis Framework

4. Data Analysis and Results

4.1. Factor Attribute Analysis Based on DEMATEL

Causal Relationship and Importance Analysis

- (1)

- Analysis of Degrees of Influence and Being Influenced: The factors ranking in the top three for degrees of influence (ai) are automation and digitization (F6), regulations and policies (F14), and quality management standards (F15). This indicates that these factors have a significant impact on others. The top three factors for degrees of being influenced (bi) are intelligent performance evaluation (F4), material quality inspection (F9), and intelligent project management procedures (F10), suggesting that these factors are highly susceptible to influence from others.

- (2)

- Analysis of Cause-degree (Ni) and Centrality (Mi): In Figure 2, causal factors are positioned above the axis, indicating that these factors have a significant impact on others. Effect factors are located below the axis, suggesting that these factors are more susceptible to the influence of causal factors. A higher centrality indicates a greater level of importance. The top three factors in terms of influence include automation and digitization (F6), quality management standards (F15), and key technologies and scheme disclosure (F17).

4.2. Hierarchy of Factors Using ISM

Hierarchical Structure Analysis

- (1)

- Input Layer (Levels VII to IX): This layer forms the foundation of the SCS-QM system, incorporating fundamental factors with long-term influences on the system’s upper elements. Crucial factors in this layer include regulations and policies (F14), automation and digitization (F6), intelligent project management procedures (F10), and intelligent management of construction documents and data (F11).

- (2)

- Operation Layer (Levels IV to VI): Positioned in the middle, this layer contains factors that bridge the foundational input factors with the uppermost effect-oriented elements. It includes intelligent training systems (F1), worker health monitoring (F2), quality management standards (F15), construction project acceptance procedures (F16), and quality protection monitoring in construction site operations (F13).

- (3)

- Effect Layer (Levels I to III): This topmost layer includes surface-level direct factors that immediately impact the SCS-QM. It encompasses a wide array of functions, such as intelligent performance evaluation (F4), material quality inspection (F9), intelligent environmental monitoring (F18), intelligent equipment maintenance (F7), intelligent disaster early warning (F19), intelligent worker behavior monitoring (F3), intelligent equipment monitoring (F5), smart material tracking systems (F8), emergency management systems (F12), and key technologies and scheme disclosure (F17).

4.3. Results of Driver–Dependency Relationship of Critical Factors Influencing the Development of SCS-QM

Driver–Dependency Relationship Analysis

- (1)

- Autonomous Factors (Quadrant I): These factors are characterized by low dependency and driving power, implying that the influence on the system is generally indirect or weaker. Included in this quadrant are worker health monitoring (F2), intelligent equipment monitoring (F5), intelligent disaster early warning (F19), smart material tracking systems (F8), emergency management systems (F12), and quality protection monitoring in construction site operations (F13).

- (2)

- Independent Factors (Quadrant II): Situated in this quadrant are factors that exhibit strong driving power but low dependency, making them pivotal to the system’s functioning. This group includes intelligent training systems (F1), intelligent management of construction documents and data (F11), automation and digitization (F6), intelligent project management procedures (F10), and regulations and policies (F14). These elements are crucial, often exerting substantial direct influence across the system.

- (3)

- Linkage Factors (Quadrant III): Factors in this quadrant have both high driving power and high dependency, which makes them highly dynamic and critical for transmitting influences and integrating feedback within the system. This group consists of quality management standards (F15) and key technologies and scheme disclosure (F17).

- (4)

- Dependent Factors (Quadrant IV): These factors have strong dependency but weak driving power, typically positioned at the upper echelons of the ISM model and influenced predominantly by other elements. The ability of these elements to directly influence other parts of the system is limited, making the impact largely indirect. Included here are intelligent worker behavior monitoring (F3), intelligent performance evaluation (F4), intelligent equipment maintenance (F7), material quality inspection (F9), construction project acceptance procedures (F16), and intelligent environmental monitoring (F18).

4.4. Comprehensive Analysis of SCS-QM Influencing Factors Based on the Hybrid Research Framework

- (1)

- Input Layer: This layer incorporates five factors (F14, F6, F10, F11, F1), all situated within the independent quadrant, underscoring their role as fundamental drivers of SCS-QM development. Enhancements in these factors can indirectly and directly catalyze the advancement of SCS-QM by influencing the dynamics of upper-layer factors. Additionally, MICMAC analysis highlights that factors F6, F11, F10, F14, and F1 possess high centrality, thereby exerting significant impacts on SCS-QM.

- (2)

- Operation Layer: Encompassing seven factors (F8, F12, F17, F16, F13, F2, F15), this layer presents a diverse interaction of roles. Factors F2, F8, F12, and F13, situated in the Autonomous quadrant, display low centrality, indicating minimal mutual interactions and impacts within the SCS-QM system. Conversely, factors F15 and F17, located in the Linkage quadrant, show high centrality and play a pivotal role in transmitting influences across the system, thereby heavily impacting SCS-QM. Factor F16, positioned in the Dependent quadrant, also demonstrates high centrality, underscoring its significant influence on SCS-QM despite its high susceptibility to other influences.

- (3)

- Effect Layer: This layer consists of seven factors (F4, F9, F18, F7, F19, F3, F5). Factors F3, F4, and F9, located in the Dependent quadrant, exhibit high centrality, having a direct and profound influence on SCS-QM. Meanwhile, factors F7 and F18, also in the Dependent quadrant, and factors F5 and F19, in the Autonomous quadrant, show lower centrality, indicating a comparatively reduced impact on the SCS-QM system.

5. Discussions

5.1. Discussion of Analysis Results

- (1)

- The research delineates that automation and digitization (F6) wield the most significant influence within the SCS-QM framework. These elements are pivotal in deploying intelligent quality control mechanisms within smart construction environments. Enhancements in automation and digitization equip smart construction sites with advanced management technologies and elevated operational efficiencies, thereby catalyzing the progression of SCS-QM [14,86]. Simultaneously, regulations and policies (F14) serve as a cornerstone within the ISM system, shaping the entire SCS-QM landscape. These specific regulations and policies directly influence management procedures, set monitoring standards, and promote the integration of innovative technologies. Additionally, intelligent training systems (F1), intelligent project management procedures (F10), and intelligent management of construction documents and data (F11) exert considerable effects on the SCS-QM system [85]. Intelligent training systems augment safety awareness among workers and clarify operational protocols at smart construction sites, directly impacting the quality of projects [54]. The robust drivers of intelligent project management processes, in conjunction with automation and digitization, affect other elements and the overall SCS-QM system. Effective and scientifically-driven project management processes amalgamate various monitoring methods to establish appropriate operational norms, significantly enhancing the quality management efficacy and standards at smart construction sites. Intelligent management of construction documents and data establishes the digital infrastructure of the entire SCS-QM system, offering strong data support and facilitating the intelligent management and analysis of complex data from monitoring systems, thereby guiding quality management decisions at smart construction sites [71,87].

- (2)

- Quality management standards (F15) are identified as the second most influential factor within the SCS-QM system. The development of these standards profoundly impacts SCS-QM, laying both the policy and operational foundation for quality management. This factor is also notably influenced by other determinants, such as regulations related to smart construction, the degree of automation and digitization in projects, and the overall project management workflows [88,89]. Enhancements to F15 should simultaneously address these aspects. Key technologies and scheme disclosure (F17), ranking third in terms of direct impact on the SCS-QM system, is also prone to external influences. Disclosing essential technologies and construction processes identifies critical risks and challenges during construction phases, enabling the implementation of strategies to enhance project quality significantly, which in turn impacts SCS-QM. This factor must also consider legal regulations and quality management standards during its optimization [59].

- (3)

- Intelligent worker behavior monitoring (F3), intelligent performance evaluation (F4), material quality inspection (F9), and construction project acceptance procedures (F16) exert an indirect yet substantial influence on the SCS-QM system. Located within the ISM’s effect layer, factors F3, F4, and F9 are influenced by foundational elements, thereby indirectly impacting SCS-QM. Within project quality management, monitoring human aspects holds central importance; thus, intelligent oversight of worker behavior and performance evaluations are crucial for ensuring compliance with operational standards. These factors are affected by various elements such as worker training, health conditions, and project management processes. Enhancements to these indirect factors should prioritize foundational elements, such as improving the quality of worker training and conducting health inspections to ensure personnel adhere to precise construction standards and requirements. The quality monitoring of construction materials also significantly influences project quality, although the quality of on-site materials largely depends on traceability and control over the production and transportation processes of materials, making this an indirect influence on project quality [59]. The outcomes of construction project acceptance procedures considerably affect SCS-QM, with acceptance results directly determining the compliance with quality standards of completed project segments. However, the management of project quality relies more on proactive prevention and in-process control, making post-completion acceptance an indirect yet vital factor [37].

5.2. Strategies for Enhancing SCS-QM

Proposed Strategic Enhancements Based on Research Insights

6. Conclusions

7. Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singh, A.; Kumar, V.; Verma, P.; Kandasamy, J. Identification and severity assessment of challenges in the adoption of industry 4.0 in Indian construction industry. Asia Pac. Manag. Rev. 2023, 28, 299–315. [Google Scholar] [CrossRef]

- Demirkesen, S.; Tezel, A. Investigating major challenges for industry 4.0 adoption among construction companies. Constr. Constr. Archit. Manag. 2022, 29, 1470–1503. [Google Scholar] [CrossRef]

- Oti-Sarpong, K.; Parn, E.A.; Burgess, G.; Zaki, M. Transforming the construction sector: An institutional complexity perspective. Constr. Innov.-Engl. 2022, 22, 361–387. [Google Scholar] [CrossRef]

- Wu, W.; Ji, Z.; Liang, H. The Impact of New infrastructure Construction on Optimization and Upgrading of Industrial Structure. Buildings 2023, 13, 2580. [Google Scholar] [CrossRef]

- Peng, S.; Wang, J.; Sun, H.; Guo, Z. How Does the Spatial Misallocation of Land Resources Affect Urban Industrial Transformation and Upgrading? Evidence from China. Land 2022, 11, 1630. [Google Scholar] [CrossRef]

- Wu, P. An Analysis on Performance Evaluation and Coordination Strategies of Transformation and Upgrading of Manufacturing Small and Micro Enterprises: An Empirical Study Based on AHP-Regression. Tob. Regul. Sci. 2021, 7, 3586–3602. [Google Scholar] [CrossRef]

- Yang, R.; Wakefield, R.; Lyu, S.N.; Jayasuriya, S.; Han, F.L.; Yi, X.; Yang, X.C.; Amarasinghe, G.; Chen, S.P. Public and private blockchain in construction business process and information integration. Autom. Constr. 2020, 118, 103276. [Google Scholar] [CrossRef]

- Hunhevicz, J.J.; Hall, D.M. Do you need a blockchain in construction? Use case categories and decision framework for DLT design options. Adv. Constr. Inform. 2020, 45, 101094. [Google Scholar] [CrossRef]

- Mahmudnia, D.; Arashpour, M.; Yang, R.B.C. Blockchain in construction management: Applications, advantages and limitations. Autom. Constr. 2022, 140, 104379. [Google Scholar] [CrossRef]

- Xu, C.-y.; Chen, G.; Hua, H. Quality problems and countermeasures in construction process. J. Archit. Environ. Struct. Constr. Res. 2020, 3, 24–27. [Google Scholar] [CrossRef]

- Rochman, K.; Susetyo, B. Improvement of cost performance accompanied by quality control using value construction and six sigma methods in high-rise building project. Int. J. Constr. Technol. 2020, 9, 560. [Google Scholar]

- Zhang, Y.; Zhuang, Y.; Zhang, Z.; Yao, Y. Design of engineering quality inspection and evaluation system. In Proceedings of the Second International Conference on Digital Society and Intelligent Systems (DSInS 2022), Chengdu, China, 1 April 2023; p. 125991L. [Google Scholar]

- Dharsono, M. Information System Design on Project Supervision Related to Quality Control Effectiveness Using Android-Based Smartphone Applications. Sch. J. Constr. Technol. 2021, 8, 205–216. [Google Scholar] [CrossRef]

- Jiang, W.; Ding, L.; Zhou, C. Cyber physical system for safety management in smart construction site. Constr. Constr. Archit. Manag. 2021, 28, 788–808. [Google Scholar] [CrossRef]

- Lu, W.; Li, X.; Xue, F.; Zhao, R.; Wu, L.; Yeh, A.G.O. Exploring smart construction objects as blockchain oracles in construction supply chain management. Autom. Constr. 2021, 129, 103816. [Google Scholar] [CrossRef]

- Rahnamayiezekavat, P.; Mourad, M.; Mostafa, S.; Moon, S.; Senaratne, S. Enriching BIM with Unmanned Aerial Systems Data for Enhancing Construction Management Operations. Sustainability 2022, 14, 11362. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, M.; Zhao, L.; Chen, M. Analysis of Factors Affecting Prefabricated Building Quality Based on ISM-BN. Sustainability 2023, 15, 9682. [Google Scholar] [CrossRef]

- Feng, X.; Li, E.; Li, J.; Wei, C. Critical influencing factors of employees’ green behavior: Three-stage hybrid fuzzy DEMATEL-ISM-MICMAC approach. Environ. Dev. Sustain. 2023, 26, 17783–17811. [Google Scholar] [CrossRef]

- Farahsari, P.S.; Farahzadi, A.; Rezazadeh, J.; Bagheri, A. A Survey on Indoor Positioning Systems for IoT-Based Applications. Ieee Internet Things J. 2022, 9, 7680–7699. [Google Scholar] [CrossRef]

- Sarker, I.H.; Khan, A.I.; Abushark, Y.B.; Alsolami, F. Internet of Things (IoT) Security Intelligence: A Comprehensive Overview, Machine Learning Solutions and Research Directions. Mob. Netw. Appl. 2023, 28, 296–312. [Google Scholar] [CrossRef]

- Wang, M.D.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Wu, C.K.; Li, X.; Guo, Y.J.; Wang, J.; Ren, Z.L.; Wang, M.; Yang, Z.L. Natural language processing for smart construction: Current status and future directions. Autom. Constr. 2022, 134, 104059. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L.M. Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arch. Comput. Methods Constr. 2023, 30, 1081–1110. [Google Scholar] [CrossRef]

- Wei, Z.Q.; Zhu, M.Y.; Zhang, N.; Wang, L.; Zou, Y.Y.; Meng, Z.Y.; Wu, H.C.; Feng, Z.Y. UAV-Assisted Data Collection for Internet of Things: A Survey. Ieee Internet Things J. 2022, 9, 15460–15483. [Google Scholar] [CrossRef]

- Márquez-Sánchez, S.; Campero-Jurado, I.; Robles-Camarillo, D.; Rodríguez, S.; Corchado-Rodríguez, J.M. BeSafe B2.0 Smart Multisensory Platform for Safety in Workplaces. Sensors 2021, 21, 3372. [Google Scholar] [CrossRef]

- Jin, R.; Zhang, H.; Liu, D.H.; Yan, X.Z. IoT-based detecting, locating and alarming of unauthorized intrusion on construction sites. Autom. Constr. 2020, 118, 103278. [Google Scholar] [CrossRef]

- Lee, C.; Park, J.; Seol, S. Development and demonstration of smart construction safety technology using drones. Forum Public Saf. Cult. 2023, 24, 93–105. [Google Scholar] [CrossRef]

- Barbero Briones, S.; Dorronsoro Diaz, C.; Marcos Celestino, S.; Montejo Berlingen, J.; Salazar Salegui, P. Method for producing iso-plantic aspheric monofocal intraocular lens, involves obtaining definition of measurement for improving optical quality. WO2011151497-A9, 23 May 2013. [Google Scholar]

- Nikolaienko, S.; Vikarchuk, O.; Lewandowska, H. IMPLEMENTATION OF QUALITY MANAGEMENT SYSTEM FOR PRODUCTS AND SERVICES IN UKRAINE. Econ. Manag. Innov. 2021, 1. [Google Scholar] [CrossRef] [PubMed]

- Aamir, H.; Quartey-Papafio, T.; Ikram, M. Critical Factors in Process Quality of Construction Construction Projects during Building Design Phase. Int. J. Grey Syst. 2021, 1, 69–82. [Google Scholar] [CrossRef]

- Mao, Y.; Xu, T. Research of 4M1E’s effect on construction quality based on structural equation model. In Proceedings of the 4th International Conference on Construction and Risk Management (ERM), The Fields Institute, Toronto, ON, Canada, 28–30 October 2011; pp. 213–220. [Google Scholar]

- Zhou, H.; Zhao, Y.H.; Shen, Q.; Yang, L.; Cai, H.B. Risk assessment and management via multi-source information fusion for undersea tunnel construction. Autom. Constr. 2020, 111, 103050. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L.; Wu, X.; Skibniewski, M.J. Multi-classifier information fusion in risk analysis. Inf. Fusion 2020, 60, 121–136. [Google Scholar] [CrossRef]

- Yidan, Z.; Quan, S.; Zhang, C.; Wang, C.; Lv, Y.; Cong, T. Exploration of Smart Construction Site Management Applications Based on BIM. Front. Comput. Intell. Syst. 2023, 4, 96–98. [Google Scholar] [CrossRef]

- Hu, M.; Wu, H.; Chan, Q.; Wu, J.; Chen, G.; Zhang, Y. Intelligent Construction Construction Management: On-Site Construction Management. AI-Based Serv. Smart Cities Urban Infrastruct. 2021, 2021, 140–161. [Google Scholar]

- Zhang, M. Research on the Application of Intelligent Construction Site in Construction Site Management. IOP Conf. Ser. Mater. Sci. Constr. 2020, 768, 062005. [Google Scholar] [CrossRef]

- Xie, X.; Deng, L.; Xiao, M.; Luo, H.; Fang, R. New-Generation Quality and Safety Management of the Construction Industry. Strateg. Study CAE 2021, 23, 71–78. [Google Scholar] [CrossRef]

- Shan, B.; Wang, X.; Zhang, X.; Huang, P.; Li, Q. Intelligent Identification of Violation of Rules in Construction Site Based on Artificial Intelligence Image Recognition Technology. In Proceedings of the 2023 4th International Conference for Emerging Technology (INCET), Belgaum, India, 26–28 May 2023; pp. 1–5. [Google Scholar]

- Kim, Y.-S.; Lee, J.Y.; Yoon, Y.-G.; Oh, T.-K. Effectiveness Analysis for Smart Construction Safety Technology (SCST) by Test Bed Operation on Small- and Medium-Sized Construction Sites. Int. J. Environ. Res. Public Health 2022, 19, 5203. [Google Scholar] [CrossRef] [PubMed]

- Rossi, A.; Vila, Y.; Lusiani, F.; Barsotti, L.; Sani, L.; Ceccarelli, P.; Lanzetta, M. Embedded smart sensor device in construction site machinery. Comput. Ind. 2019, 108, 12–20. [Google Scholar] [CrossRef]

- Luo, Y.; Luo, Z.; Liang, Z. A smart site management platform based on IoT and QR code. Proc. SPIE 2023, 12604, 107. [Google Scholar]

- Bian, X.-W.; Ren, Z.-J. Hardware Design of Intelligent Management System of Construction Site Based on Internet of Things. In Proceedings of the 2017 International Conference on Computational Science and Engineering (ICCSE 2017), Beijing, China, 6–9 July 2017. [Google Scholar]

- Liu, H.; Song, J.; Wang, G. A Scientometric Review of Smart Construction Site in Construction Construction and Management: Analysis and Visualization. Sustainability 2021, 13, 8860. [Google Scholar] [CrossRef]

- Lee, K.-P.; Lee, H.-S.; Park, M.-S.; Kim, E.-J. Construction Material Management Using Smart Mobile Computing. Korean J. Constr. Constr. Manag. 2011, 12, 59–69. [Google Scholar] [CrossRef]

- Yi, Y.; Li, L.; Wang, Y. BIM and IoT Technologies Applied in Material Management System for Construction Projects. In Proceedings of the 2023 2nd International Conference on Artificial Intelligence and Computer Information Technology (AICIT), Yichang, China, 15–17 September 2023; pp. 1–5. [Google Scholar]

- Bucchiarone, A.; Sanctis, M.D.; Hevesi, P.; Hirsch, M.; Abancens, F.J.R.; Vivanco, P.F.; Amiraslanov, O.; Lukowicz, P. Smart Construction: Remote and Adaptable Management of Construction Sites through IoT. IEEE Internet Things Mag. 2019, 2, 38–45. [Google Scholar] [CrossRef]

- Kasim, N.; Razali, S.; Md Ariffin, K. Smart Emergency Detection Framework by IR4.0 for Safety Management among G7 Contractors: A Pilot Study. Int. J. Sustain. Constr. Constr. Technol. 2021, 12, 322–333. [Google Scholar] [CrossRef]

- Niu, Y.; Lu, W.; Xue, F.; Liu, D.; Chen, K.; Fang, D.; Anumba, C. Towards the “third wave”: An SCO-enabled occupational health and safety management system for construction. Saf. Sci. 2019, 111, 213–223. [Google Scholar] [CrossRef]

- Zhong, B.T.; Ding, L.Y.; Luo, H.B.; Zhou, Y.; Hu, Y.Z.; Hu, H.M. Ontology-based semantic modeling of regulation constraint for automated construction quality compliance checking. Autom. Constr. 2012, 28, 58–70. [Google Scholar] [CrossRef]

- Milivojević, L.; Mrazovac Kurilić, S.; Božilović, Z.; Koprivica, S.; Krčadinac, O. Study of Particular Air Quality and Meteorological Parameters at a Construction Site. Atmosphere 2023, 14, 1267. [Google Scholar] [CrossRef]

- Cheung, W.-F.; Lin, T.-H.; Lin, Y.-C. A Real-Time Construction Safety Monitoring System for Hazardous Gas Integrating Wireless Sensor Network and Building Information Modeling Technologies. Sensors 2018, 18, 436. [Google Scholar] [CrossRef]

- Liu, Z.-m.; Zhao, X.; Tan, J.; Tian, H. Model and Simulation of Construction Safety Risk Control Based on Artificial Intelligence Algorithm. Int. Trans. Electr. Energy Syst. 2022, 2022, 1–12. [Google Scholar] [CrossRef]

- Chen, W.T.; Tsai, I.-C.; Merrett, H.C.; Lu, S.T.; Lee, Y.-I.; You, J.-K.; Mortis, L. Construction Safety Success Factors: A Taiwanese Case Study. Sustainability 2020, 12, 6326. [Google Scholar] [CrossRef]

- Tezel, A.; Dobrucali, E.; Demirkesen, S.; Kiral, I.A. Critical Success Factors for Safety Training in the Construction Industry. Buildings 2021, 11, 139. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakolan, M.; Khosravi, Y. Factors influencing safety performance on construction projects: A review. Saf. Sci. 2018, 109, 382–397. [Google Scholar] [CrossRef]

- Ruan, J.; Li, C.; Xue, F.; Hu, J. Identification and Classification of Risk Factors in Municipal Construction Based on JHA. In Proceedings of the 2021 International Conference on E-Commerce and E-Management (ICECEM), Dalian, China, 24–26 September 2021; pp. 110–113. [Google Scholar]

- Costa, O.; Matias, J.; Pimentel, C. Occupational health and safety in construction projects: A case study on chemical industry sector: (Article). Int. J. Occup. Environ. Saf. 2021, 5, 14–21. [Google Scholar] [CrossRef]

- Fang, L.; Mei, B.; Jiang, L.; Sun, J. Investigation of Intelligent Safety Management Information System for Nuclear Power Construction Projects. In Proceedings of the ICITEE2020: The 3rd International Conference on Information Technologies and Electrical Engineering, Changde City, China, 3–5 December 2020; pp. 607–611. [Google Scholar]

- Yuan, E. Safety Monitoring of Construction Equipment based on Multi-sensor Technology. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction (ISARC), Kitakyushu, Japan, 14 October 2020; pp. 677–684. [Google Scholar]

- Limin, Z.; Bo, Y.; Pei, C.; Wenzhao, N.; Rui, L. Intelligent monitoring system for danger sources of infrastructure construction site based on deep learning. In Proceedings of the 2020 5th International Conference on Mechanical, Control and Computer Construction (ICMCCE), Harbin, China, 25–27 December 2020; pp. 1063–1066. [Google Scholar]

- Xu, J. A deep learning approach to building an intelligent video surveillance system. Multimed. Tools Appl. 2021, 80, 5495–5515. [Google Scholar] [CrossRef]

- Cai, S.; Ma, Z.; Skibniewski, M.J.; Bao, S. Construction automation and robotics for high-rise buildings over the past decades: A comprehensive review. Adv. Constr. Inform. 2019, 42, 100989. [Google Scholar] [CrossRef]

- Liu, Y.; Alias, A.H.; Haron, N.A.; Bakar, N.A.; Wang, H. Robotics in the Construction Sector: Trends, Advances, and Challenges. J. Intell. Robot. Syst. 2024, 110, 72. [Google Scholar] [CrossRef]

- Akinradewo, O.I.; Aigbavboa, C.O.; Okafor, C.C.; Oke, A.E.; Thwala, D.W. A Review of the Impact of Construction Automation and Robotics on Project Delivery. IOP Conf. Ser. Mater. Sci. Constr. 2021, 1107, 012011. [Google Scholar] [CrossRef]

- Vijayakumar, M.; Nair, P.S.; Babu, S.B.G.T.; Mahender, K.; Venkateswaran, T.S.; Natrayan, L. Intelligent Systems For Predictive Maintenance In Industrial IoT. In Proceedings of the 2023 10th IEEE Uttar Pradesh Section International Conference on Electrical, Electronics and Computer Construction (UPCON), Gautam Buddha Nagar, India, 1–3 December 2023; pp. 1650–1655. [Google Scholar]

- Garyaev, A.; Garyaev, N. Integration of artificial intelligence and video surveillance technology to monitor construction equipment. E3S Web Conf. 2023, 410, 04002. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Zhang, J.; Luo, X. Substation intelligent security management and control practice based on artificial intelligence and big data analysis. In Proceedings of the 2022 IEEE Conference on Telecommunications, Optics and Computer Science (TOCS), Dalian, China, 11–12 December 2022; pp. 648–653. [Google Scholar]

- Jain, S.; Sanchez, G.; Sunil, T.; Sharma, D.K. Radio frequency identification based materials tracking system for construction industry. Int. J. Reconfigurable Embed. Syst. 2024, 13, 85–95. [Google Scholar] [CrossRef]

- Kasim, N.; Sarpin, N.; Noh, H.; Zainal, R.; Mohamed, S.; Manap, N.; Yahya, M. Automatic Materials Tracking Practices Through RFID Implementation in Construction Projects. MATEC Web Conf. 2019, 266, 05001. [Google Scholar] [CrossRef]

- Sun, Z. Discussion on the Key Links in the Process of Building Material Quality Inspection and Testing. MATEC Web Conf. 2021, 353, 01009. [Google Scholar] [CrossRef]

- Sun, S. Analysis of Building Construction Quality Control and Safety Management. J. Archit. Res. Dev. 2023, 7, 59–63. [Google Scholar] [CrossRef]

- Wang, H. Quality Inspection Method of Building Material Concrete Based on Ultrasonic Tomography. In Proceedings of the 2023 IEEE International Conference on Integrated Circuits and Communication Systems (ICICACS), Raichur, India, 24–25 February 2023; pp. 1–5. [Google Scholar]

- Wang, H.; Xu, X.; Xie, W.; Zheng, H.; Liu, J.; Li, J. Research on Traceable Quality Control Method for Cast-in-Situ Concrete of Transmission Line. In Proceedings of the 2023 Panda Forum on Power and Energy (PandaFPE), Chengdu, China, 27–30 April 2023; pp. 510–515. [Google Scholar]

- Martínez-Rojas, M.; Martín Antolín, R.; Salguero-Caparrós, F.; Rubio-Romero, J.C. Management of construction Safety and Health Plans based on automated content analysis. Autom. Constr. 2020, 120, 103362. [Google Scholar] [CrossRef]

- Orogun, B.; Mohamed, I.O. Developing a maturity model to evaluate the health and safety of sustainable building projects. 2017. Available online: https://legacy.csce.ca/elf/apps/CONFERENCEVIEWER/conferences/2017/pdfs/GEN/FinalPaper_117.pdf (accessed on 25 June 2024).

- Wang, Q.; Shao, W. Application Analysis of Blockchain Technology in the Field of Emergency Management. Adv. Appl. Sci. 2020, 5, 49–56. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, I.; Choi, J. Development of BIM-Based Risk Rating Estimation Automation and a Design-for-Safety Review System. Appl. Sci. 2020, 10, 3902. [Google Scholar] [CrossRef]

- Park, C.; Lee, D.; Khan, N. An Analysis on Safety Risk Judgment Patterns Towards Computer Vision Based Construction Safety Management. In Proceedings of the Creative Construction e-Conference, virtual, 28 June–1 July 2020; pp. 31–38. [Google Scholar]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A Literature Review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Du, Y.-W.; Li, X.-X. Hierarchical DEMATEL method for complex systems. Expert Syst. Appl. 2021, 167, 113871. [Google Scholar] [CrossRef]

- Li, J.; Xu, K. A combined fuzzy DEMATEL and cloud model approach for risk assessment in process industries to improve system reliability. Qual. Reliab. Constr. Int. 2021, 37, 2110–2133. [Google Scholar] [CrossRef]

- Wankhade, N.; Kundu, G. Interpretive Structural Modelling (ISM) Methodology and its application in Supply Chain Research. Int. J. Innov. Technol. Explor. Eng. 2020, 9, 1101–1109. [Google Scholar] [CrossRef]

- Chen, J.-K. Improved DEMATEL-ISM integration approach for complex systems. PLoS ONE 2021, 16, e0254694. [Google Scholar] [CrossRef] [PubMed]

- Bashir, H.; Ojiako, U. An integrated ISM-MICMAC approach for modelling and analysing dependencies among construction parameters in the early design phase. J. Constr. Des. 2020, 31, 461–483. [Google Scholar] [CrossRef]

- Xiahou, X.E.; Wu, Y.F.; Duan, T.L.; Lin, P.; Li, F.N.; Qu, X.J.; Liu, L.; Li, Q.M.; Liu, J.X. Analyzing Critical Factors for the Smart Construction Site Development: A DEMATEL-ISM Based Approach. Buildings 2022, 12, 116. [Google Scholar] [CrossRef]

- Amici, C.; Rotilio, M.; Berardinis, P.D.; Cucchiella, F. Framework for Computerizing the Processes of a Job and Automating the Operational Management on Site—A Case Study of Demolition and Reconstruction Construction Site. Buildings 2022, 12, 800. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L.M. A BIM-data mining integrated digital twin framework for advanced project management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Ustun, T.S.; Hussain, S.M.S.; Kirchhoff, H.; Ghaddar, B.; Strunz, K.; Lestas, I. Data Standardization for Smart Infrastructure in First-Access Electricity Systems. Proc. IEEE 2019, 107, 1790–1802. [Google Scholar] [CrossRef]

- Ren, C.; Wu, G. Research on Standardization System of Smart Site for Nuclear Power Plant Construction. In Proceedings of the 2022 29th International Conference on Nuclear Construction, Virtual, 8–12 August 2022. [Google Scholar]

- Topchiy, D. Managerial and construction solutions made to ensure the quality of construction and installation work at various stages of the life cycle of a construction facility. Vestn. MGSU 2023, 18, 283–292. [Google Scholar] [CrossRef]

| Category | Factor NO. | Factors | References |

|---|---|---|---|

| Men | F1 | Intelligent Training Systems | [14,52,53,54,55] |

| F2 | Worker Health Monitoring | [14,35,52,56,57] | |

| F3 | Intelligent Worker Behavior Monitoring | [14,35,53,58] | |

| F4 | Intelligent Performance Evaluation | [52,54,55,58] | |

| Machine | F5 | Intelligent Equipment Monitoring | [26,41,59,60,61] |

| F6 | Automation and Digitization | [62,63,64] | |

| F7 | Intelligent Equipment Maintenance | [59,65,66,67] | |

| Material | F8 | Smart Material Tracking Systems | [14,41,68,69] |

| F9 | Material Quality Inspection | [43,70,71,72,73] | |

| Method | F10 | Intelligent Project Management Procedures | [14,26,35,58,59] |

| F11 | Intelligent Management of Construction Documents and Data | [35,36,38,58,74] | |

| F12 | Emergency Management Systems | [71,73,75,76] | |

| F13 | Key Technologies and Scheme Disclosure | [14,53,77,78] | |

| F14 | Regulations and Policies | [14,30,35,53,71,79] | |

| F15 | Quality Management Standards | [14,22,25,42,53,64,79] | |

| F16 | Construction Project Acceptance Procedures | [4,36,45,53,61,73] | |

| F17 | Quality Protection Monitoring in Construction Site Operations | [30,31,35,53,63] | |

| Environment | F18 | Intelligent Environmental Monitoring | [32,51,57,58,79] |

| F19 | Intelligent Disaster Early Warning | [23,28,35,52,53,79] |

| Category | Sub-Category | Quantity (Unit: Persons) |

|---|---|---|

| Duration of Participation in Work or Academic Research | 0–5 years | 1 |

| 5–10 years | 5 | |

| Over 10 years | 3 | |

| Type of Employment | Owner | 1 |

| Construction enterprise | 4 | |

| Design enterprise | 1 | |

| Government regulatory department | 1 | |

| Universities and other scientific institutions | 2 | |

| Professional Rank | None | 0 |

| Junior | 2 | |

| Intermediate | 4 | |

| Senior | 3 | |

| Number of Smart Construction-Related Projects in Which They Were Involved | 3–5 | 3 |

| 5–10 | 4 | |

| More than 10 | 2 |

| Value | Descriptions |

|---|---|

| 0 | Factor i has no influence on factor j |

| 1 | Factor i has weak influence on factor j |

| 2 | Factor i has moderate influence on factor j |

| 3 | Factor i has strong influence on factor j |

| 4 | Factor i has very strong influence on factor j |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 | F16 | F17 | F18 | F19 | |

| F1 | 0 | 0 | 3 | 2 | 0 | 0 | 1 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 3 | 2 | 2 | 1 | 0 |

| F2 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 |

| F3 | 0 | 0 | 0 | 4 | 0 | 0 | 1 | 0 | 3 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| F4 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F5 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 |

| F6 | 3 | 0 | 3 | 3 | 0 | 0 | 1 | 1 | 3 | 3 | 4 | 0 | 3 | 0 | 4 | 4 | 4 | 1 | 0 |

| F7 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F8 | 1 | 0 | 2 | 1 | 0 | 0 | 2 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 |

| F9 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| F10 | 2 | 0 | 1 | 2 | 0 | 2 | 1 | 0 | 2 | 0 | 4 | 0 | 2 | 0 | 2 | 2 | 3 | 1 | 0 |

| F11 | 3 | 1 | 4 | 4 | 0 | 0 | 1 | 2 | 4 | 0 | 0 | 0 | 0 | 0 | 4 | 4 | 2 | 1 | 0 |

| F12 | 0 | 0 | 0 | 0 | 2 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 0 |

| F13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F14 | 1 | 0 | 2 | 1 | 0 | 4 | 1 | 0 | 1 | 4 | 2 | 4 | 4 | 0 | 2 | 2 | 0 | 1 | 0 |

| F15 | 0 | 0 | 4 | 4 | 0 | 2 | 1 | 1 | 3 | 2 | 0 | 2 | 1 | 2 | 0 | 3 | 3 | 1 | 0 |

| F16 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 2 | 0 | 0 |

| F17 | 1 | 1 | 2 | 4 | 0 | 0 | 4 | 1 | 4 | 0 | 1 | 1 | 1 | 0 | 2 | 1 | 0 | 4 | 2 |

| F18 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F19 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| Factors | ai | bi | Mi | Ni | Rank | Attribute |

|---|---|---|---|---|---|---|

| F1 | 0.633 | 0.443 | 1.076 | 0.189 | 10 | Causal |

| F2 | 0.208 | 0.282 | 0.490 | −0.075 | 17 | Effect |

| F3 | 0.317 | 0.911 | 1.229 | −0.594 | 7 | Effect |

| F4 | 0.063 | 1.056 | 1.119 | −0.993 | 8 | Effect |

| F5 | 0.112 | 0.128 | 0.240 | −0.016 | 18 | Effect |

| F6 | 1.179 | 0.759 | 1.938 | 0.420 | 1 | Causal |

| F7 | 0.033 | 0.710 | 0.743 | −0.678 | 12 | Effect |

| F8 | 0.351 | 0.303 | 0.654 | 0.048 | 14 | Causal |

| F9 | 0.117 | 0.958 | 1.075 | −0.841 | 11 | Effect |

| F10 | 1.074 | 0.377 | 1.451 | 0.698 | 5 | Causal |

| F11 | 1.152 | 0.433 | 1.585 | 0.719 | 4 | Causal |

| F12 | 0.307 | 0.339 | 0.646 | −0.033 | 15 | Effect |

| F13 | 0.071 | 0.433 | 0.503 | −0.362 | 16 | Effect |

| F14 | 1.294 | 0.131 | 1.425 | 1.162 | 6 | Causal |

| F15 | 1.583 | 0.328 | 1.911 | 1.255 | 2 | Causal |

| F16 | 0.274 | 0.804 | 1.078 | −0.530 | 9 | Effect |

| F17 | 0.975 | 0.651 | 1.626 | 0.324 | 3 | Causal |

| F18 | 0.033 | 0.640 | 0.673 | −0.607 | 13 | Effect |

| F19 | 0.056 | 0.142 | 0.198 | −0.086 | 19 | Effect |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 | F16 | F17 | F18 | F19 | |

| F1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 |

| F2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| F3 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F4 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F5 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| F6 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 |

| F7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F8 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F10 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 |

| F11 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 |

| F12 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| F14 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 |

| F15 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 0 |

| F16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| F17 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 |

| F18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| F19 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| Factors | Reachability Set R(Si) | Antecedent Set R′(Si) | Intersection | Hierarchy |

|---|---|---|---|---|

| F1 | 1, 3, 4, 9, 15, 16, 17 | 1, 6, 10, 11 | 1 | VI |

| F2 | 2, 16 | 2 | 2 | VI |

| F3 | 3, 4, 9 | 1, 3, 6, 8, 10, 11, 14, 15, 17 | 3 | II |

| F4 | 4 | 1, 3, 4, 6, 10, 11, 14, 15, 17 | 4 | I |

| F5 | 5, 7, 18 | 5, 12 | 5 | II |

| F6 | 1, 3, 4, 6, 7, 9, 10, 11, 13, 15, 16, 17, 18 | 6, 10, 14, 15 | 6, 10, 15 | VIII |

| F7 | 7 | 5, 6, 7, 8, 10, 11, 14, 15, 17 | 7 | I |

| F8 | 3, 7, 8 | 8, 11, 16 | 8 | III |

| F9 | 9 | 1, 3, 6, 9, 10, 11, 14, 15, 17 | 9 | I |

| F10 | 1, 3, 4, 6, 7, 9, 10, 11, 13, 15, 16, 17, 18 | 6, 10, 14, 15 | 6, 10, 15 | VIII |

| F11 | 1, 3, 4, 7, 8, 9, 11, 15, 16, 17 | 6, 10, 11, 14 | 11 | VII |

| F12 | 5, 12 | 12, 13, 14, 15 | 12 | III |

| F13 | 12, 13 | 6, 10, 13, 14 | 13 | IV |

| F14 | 3, 4, 6, 7, 9, 10, 11, 12, 13, 14, 15, 16 | 14, 15 | 14, 15 | IX |

| F15 | 3, 4, 7, 9, 10, 12, 15, 16, 17, 18 | 1, 10, 11, 15, 17 | 10, 15, 17 | V |

| F16 | 8, 16, 17 | 1, 2, 6, 10, 11, 14, 15, 16 | 16 | IV |

| F17 | 3, 4, 7, 9, 17, 18, 19 | 1, 6, 10, 11, 16, 17 | 17 | III |

| F18 | 18 | 5, 6, 10, 15, 17, 18 | 18 | I |

| F19 | 19 | 17, 19 | 19 | I |

| Layer | Driving Power-Dependence | Centrality | Factors | Impact on SCS-QM |

|---|---|---|---|---|

| Input Layer | Independent | High | F1, F6, F10, F11, F14 | Direct High |

| Operation Layer | Autonomous | Low | F2, F8, F12, F13 | Weak |

| Linkage | High | F15, F17 | Direct High | |

| Dependent | High | F16 | Indirect High | |

| Effect Layer | Dependent | High | F3, F4, F9 | Indirect High |

| Low | F7, F18 | Weak | ||

| Autonomous | Low | F5, F19 | Weak |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Liu, J.; Li, Z.; Xiahou, X.; Li, Q. Analyzing Critical Factors Influencing the Quality Management in Smart Construction Site: A DEMATEL-ISM-MICMAC Based Approach. Buildings 2024, 14, 2400. https://doi.org/10.3390/buildings14082400

Zhang S, Liu J, Li Z, Xiahou X, Li Q. Analyzing Critical Factors Influencing the Quality Management in Smart Construction Site: A DEMATEL-ISM-MICMAC Based Approach. Buildings. 2024; 14(8):2400. https://doi.org/10.3390/buildings14082400

Chicago/Turabian StyleZhang, Shuolin, Jianzhao Liu, Zirui Li, Xiaer Xiahou, and Qiming Li. 2024. "Analyzing Critical Factors Influencing the Quality Management in Smart Construction Site: A DEMATEL-ISM-MICMAC Based Approach" Buildings 14, no. 8: 2400. https://doi.org/10.3390/buildings14082400