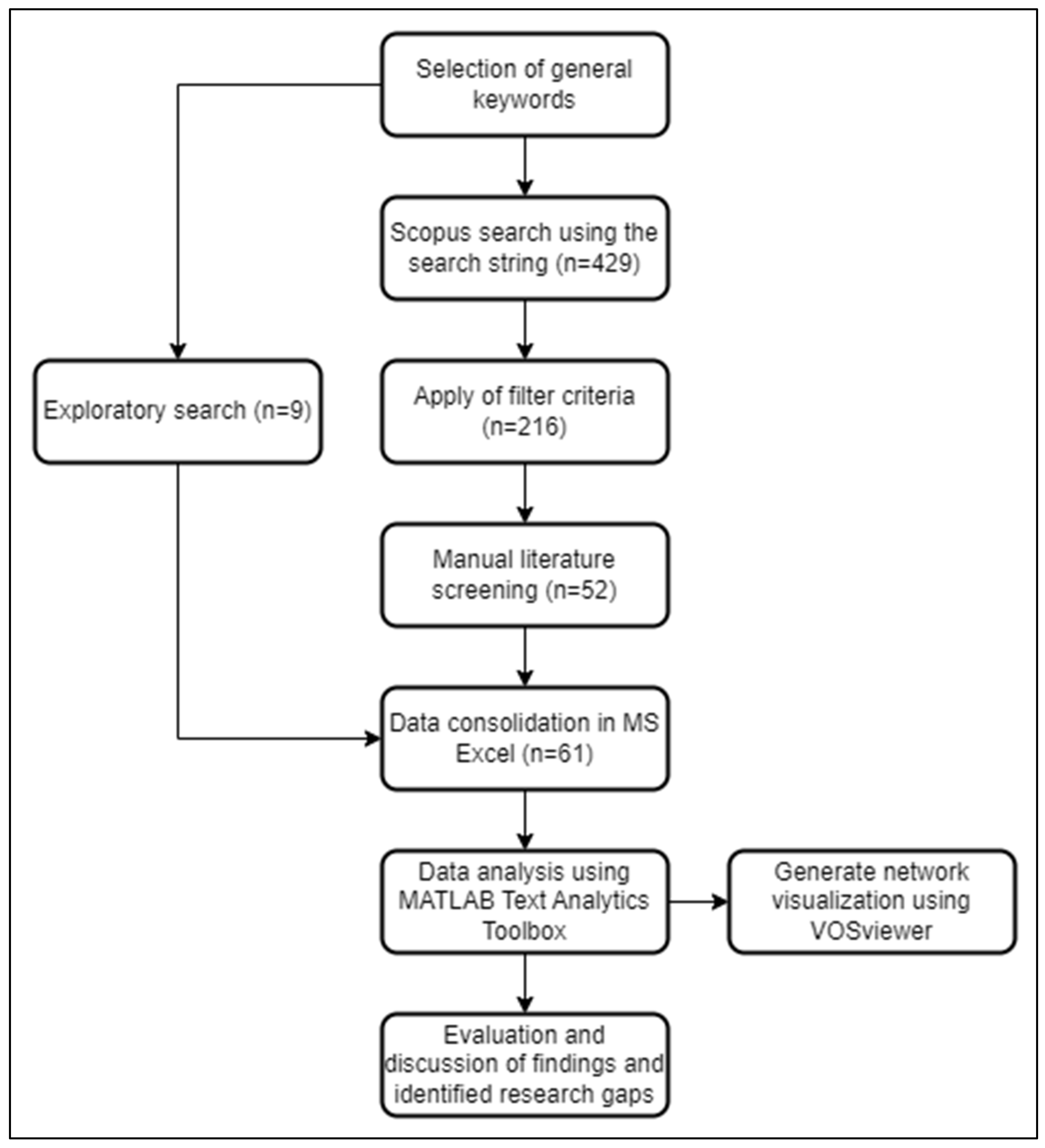

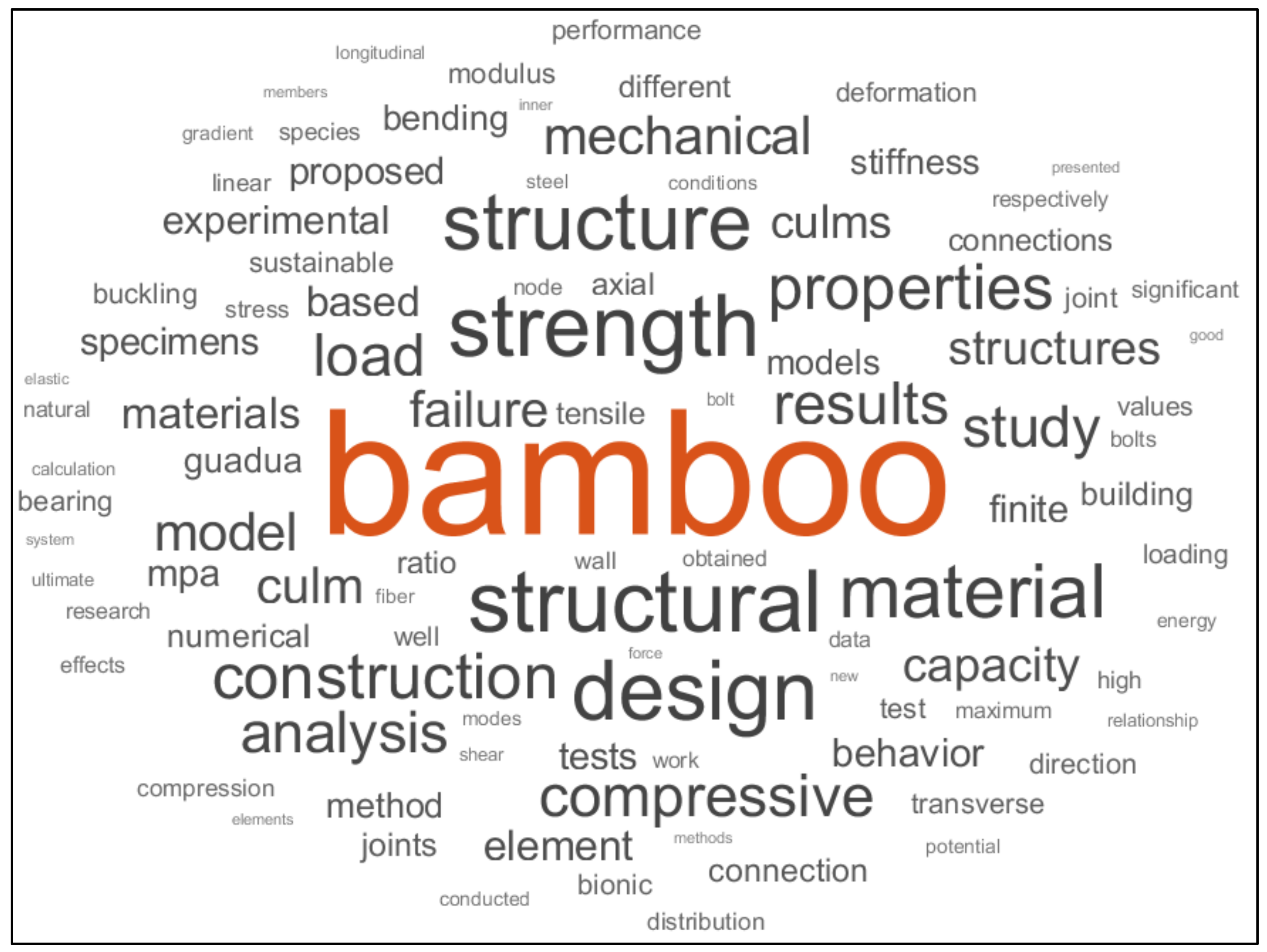

This paper aims to review the current structural analysis and design approaches to bamboo structures in the obtained literature. The study covers bamboo species utilized by researchers, types of bamboo structures, codes, and standards, software, and methods used. Finally, this paper presents the research gaps in the structural analysis and design of bamboo structures by reviewing collected literature.

3.1. Bamboo Species

Bamboo, a type of grass belonging to the subfamily Bambusoideae, is prized for its rapid growth and exceptional strength, making it a valuable resource in various industries, including construction, furniture making, and paper and fabric production. Its natural habitat spans continents, excluding Antarctica and Europe, although some species have been introduced to Europe in recent years [

18]. Ecologically, bamboo thrives in subtropical and tropical regions, displaying remarkable adaptability to diverse climates and environments [

18]. Asia boasts the highest diversity of bamboo species, with China, India, and Japan hosting the most extensive range.

Table 1 lists the different types of bamboo used by researchers in this study.

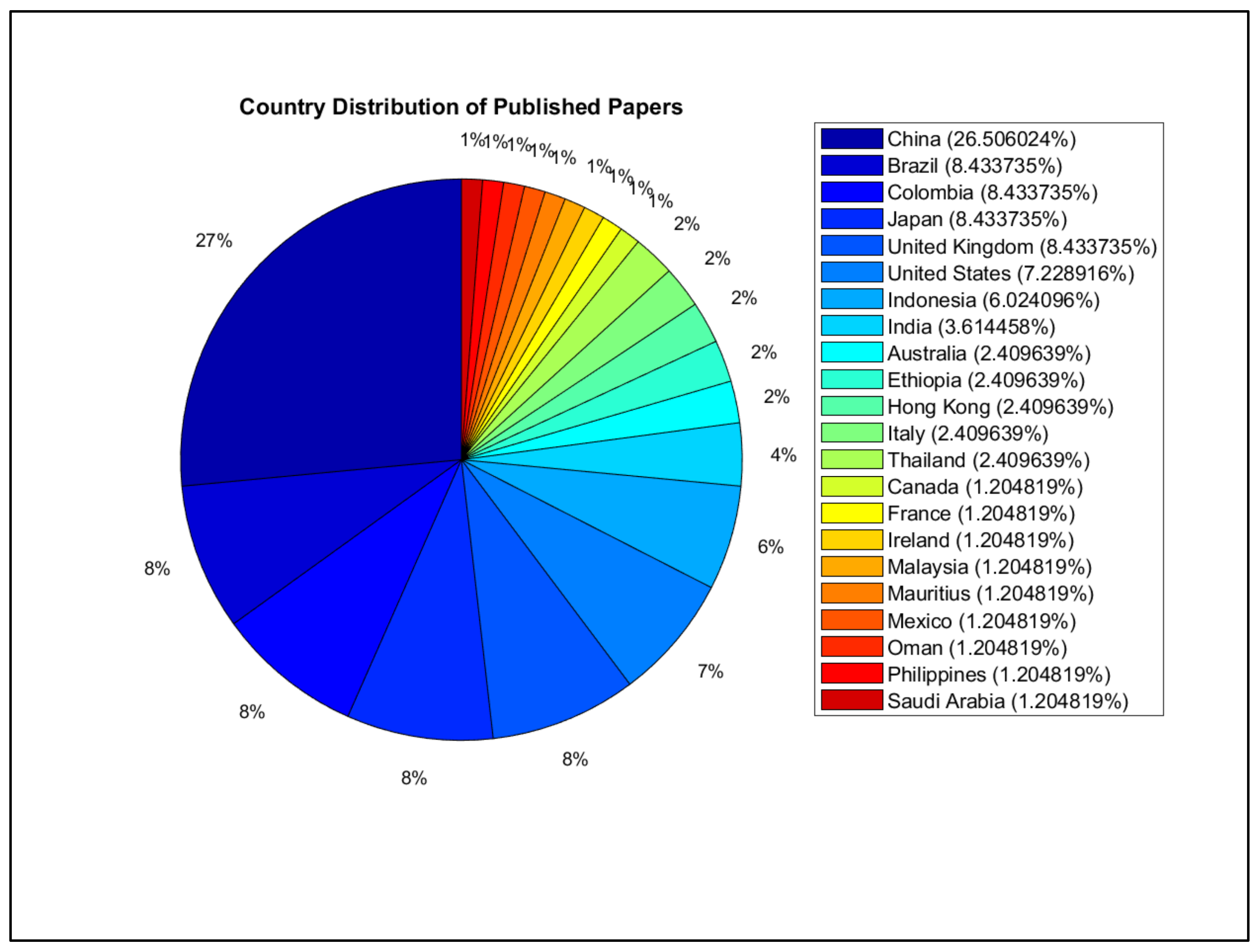

Table 2 shows where these bamboo species are found across different countries. From the literature collected, Moso bamboo emerges as the most studied species, primarily found in China. A significant proportion of the collected papers originate from China, highlighting its leading role in bamboo research publications. The majority of bamboo species presented in

Table 2 are found in countries with high population or high population growth, primarily in Asia and South America. This geographical distribution implies that bamboo can play a significant role in meeting the construction demands in these rapidly growing regions, offering a sustainable alternative to traditional building materials.

Determining the species of bamboo used in construction is crucial. Different bamboo species have varying physical and mechanical properties, such as strength and flexibility [

19]. By accurately identifying the species, engineers and designers can select materials that suit project requirements, ensuring optimal performance and longevity. Documenting bamboo species in construction contributes to industry research and knowledge sharing, fostering advancements in bamboo-based construction techniques.

Table 1.

Bamboo species used by the researchers.

Table 1.

Bamboo species used by the researchers.

| Species ID | Scientific Name of Bamboo (Local Name) | Reference |

|---|

| S-1 | Bambusa Bluemeana (Thorny/Spiny/Ori bamboo) | [20] |

| S-2 | Bambusa tuldoides | [21] |

| S-3 | Dendrocalamus asper | [22] |

| S-4 | Dendrocalamus sericeus | [23,24] |

| S-5 | Gigantochloa atroviolacea | [19] |

| S-6 | Gigantochloa apus | [19] |

| S-7 | Gigantochloa pseudoarundinacea | [19] |

| S-8 | Guadua angustifolia Kunth | [25,26,27] |

| S-9 | Phyllostachys aurea | [28,29] |

| S-10 | Phyllostachys bambusoides | [30,31] |

| S-11 | Phyllostachys edulis/Phyllostachys pubescens (Moso bamboo) | [28,32,33,34,35,36,37,38,39,40] |

| S-12 | Phyllostachys viridiglaucescens | [41] |

| S-13 | Bambusa pervariabilis | [42] |

| S-14 | Gigantochloa atter | [43] |

| S-15 | Bambusa Stenostachya | [44,45] |

| S-16 | Bambusa Vulgaris | [46] |

| S-17 | Dendrocalamus strictus | [47] |

Table 2.

Bamboo species distribution by country.

Table 2.

Bamboo species distribution by country.

| Countries | Species ID | | |

|---|

| S-1 | S-2 | S-3 | S-4 | S-5 | S-6 | S-7 | S-8 | S-9 | S-10 | S-11 | S-12 | S-13 | S-14 | S-15 | S-16 | S-17 |

|---|

| Brazil | | ✓ | | | | | | | ✓ | | ✓ | | | | | ✓ | |

| China | | | | | | | | | | | ✓ | | ✓ | | | | |

| Colombia | | | | | | | | ✓ | | | | | | | ✓ | | |

| Ireland | | | | | | | | | | | ✓ | | | | | | |

| Italy | | | | | | | | | | | | ✓ | | | | | |

| Japan | | | | | | | | | | ✓ | | | | | | | |

| Malaysia | | | ✓ | | ✓ | ✓ | ✓ | | | | | | | | | | |

| Philippines | ✓ | | | | | | | | | | | | | | | | |

| Thailand | | | | ✓ | | | | | | | | | | | | | |

| Indonesia | | | | | | | | | | | | | | ✓ | | | |

| USA | | | | | | | | | | | | | | | ✓ | | |

| India | | | | | | | | | | | | | | | | | ✓ |

3.2. Bamboo Structures

A bamboo structure refers to any building or construction primarily or partly constructed using bamboo as a central structural component. This research specifically focuses on utilizing bamboo culms without significant modification to their natural form. The literature compiled, as outlined in

Table 3, illustrates different types of bamboo structures, including active bending structures, bamboo truss frame-unit constructions, bridges, and space frames. Moreover, this study investigates bamboo assemblies like sandwich panels and joint connections. The wide-ranging uses of bamboo highlight its versatility and strength, making it an attractive option for construction, particularly in developing countries.

Table 3 outlines various types of bamboo structures identified in the literature. These include active bending structures [

39], bamboo trusses [

27], joint connections [

34,

38,

48], bamboo bridges [

26], frame-unit bamboo [

40], and bamboo sandwich panels [

21] which are all composed of bamboo culms. Wang et al. [

40] investigated the performance of frame-unit bamboo structure systems [

40]. Frame-unit bamboo structures are built by joining prefabricated sections into a grid-like pattern. Essentially, they are made from straight bamboo culms arranged in geometric shapes like triangles. To connect these pieces, bolts are used because they are easy to apply, affordable, and provide stiffness in the connection. The bolt connection is popular for joining round bamboo sections, and is commonly used in constructing these type of structures [

11]. Active bending structures utilize curved beams or shells, while bamboo trusses are constructed from bamboo culms or multi-culm axial members [

39]. The study used bolts as a connection to ensure robust connection and compatibility with bamboo materials. Bamboo bridges are made from bamboo culms, offering a sustainable option for spanning gaps [

26]. The bamboo bridge structure analyzed in the study used a type of connection known as bolted-mortar infill (BMI), where the bamboo cavity is filled with mortar to provide stiffness when connected by bolts. However, a disadvantage of using the BMI connection is its longevity for cement and bamboo, which have different shrinkage rates [

26]. Bamboo sandwich panels combine thin skins with a low-density core for insulation and durability in construction. The study by Oliveira et al. [

21] presents experimental and numerical investigations of a novel sandwich panel consisting of an aluminum skin and bamboo culm core. The bamboo culm core provides added strength and is lightweight. Puri et al. (2017) [

49] presents prefabricated bamboo-reinforced walls for low-cost housing, conducting cost and environmental impact analyses.

The study of structural analysis in bamboo construction is vital for several reasons. Firstly, it enables engineers and architects to design bamboo structures that meet safety, efficiency, and durability standards. By understanding bamboo’s behavior under various loads and conditions, practitioners can optimize designs for buildings and infrastructure. Additionally, structural analysis helps identify potential weaknesses in bamboo structures, allowing for the implementation of reinforcement or mitigation measures. Despite its advantageous qualities, bamboo still faces technical and cultural barriers as an alternative structural material. Variability in physical properties poses challenges [

19], and existing international standards, such as ISO 22157 [

51], have limitations in accurately assessing bamboo’s potential [

52]. Additionally, the current codes may restrict complex structures and limit applications, such as curved elements. However, bamboo offers notable advantages, including a high strength-to-weight ratio and resilience to dynamic loads like earthquakes. Its ease of harvesting and low energy requirements for preparation further enhances its appeal as a sustainable building material. Bamboo structures showcase the unique properties of bamboo, such as its flexibility, resilience, and aesthetic appeal.

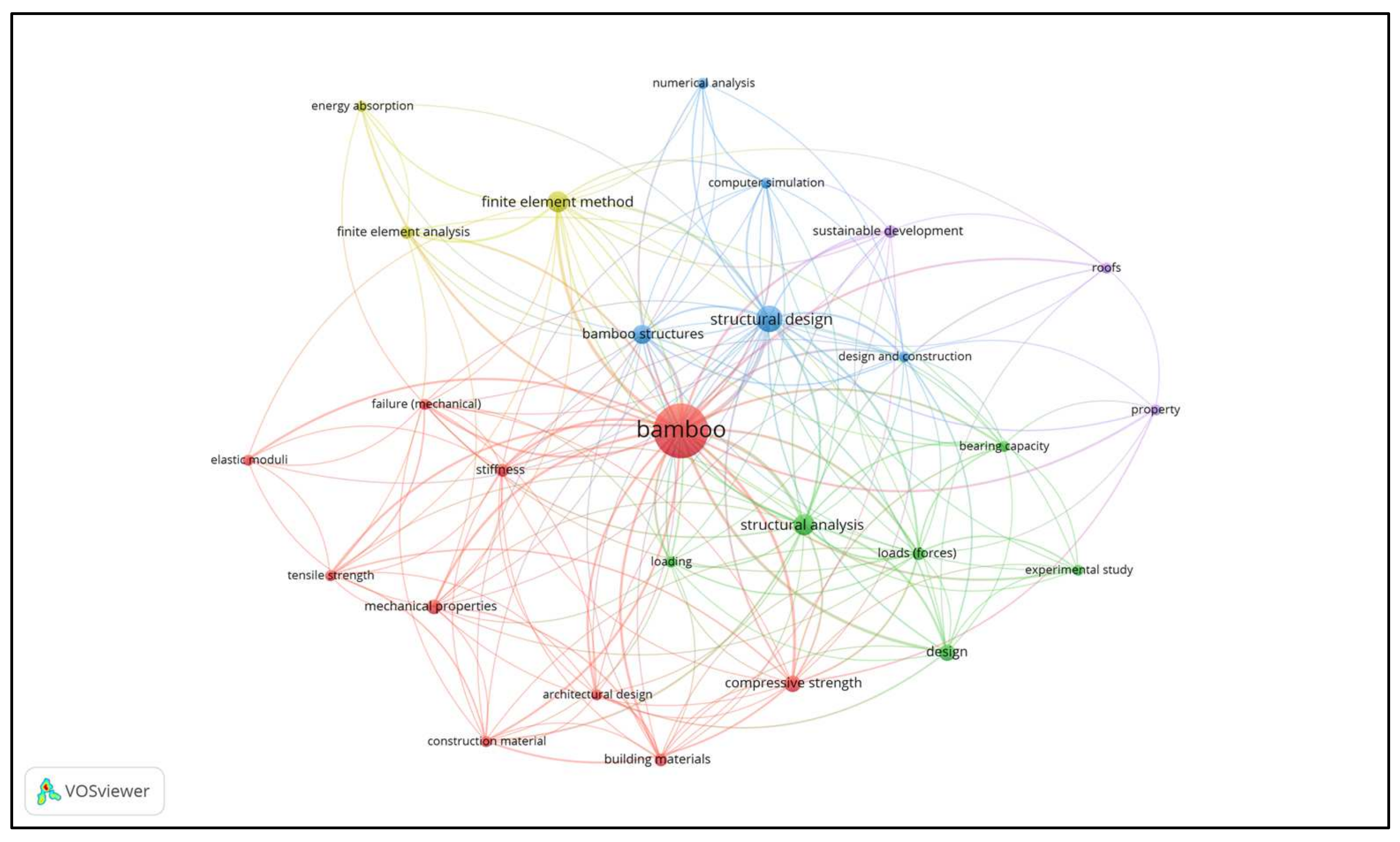

Numerous studies have delved into the mechanical properties of bamboo [

19,

33,

36,

47] and explored methods and tools for modeling bamboo connections [

34,

38,

48] in structural analysis. Aniñon and Garciano [

11] conducted a review of bamboo connections, recommending further studies that consider factors such as species, age, treatment type, and failure modes, with a particular emphasis on long-term behavior. Despite these efforts, the design of bamboo structures is still in its infancy. Structural design involves selecting materials and geometries that can withstand applied loads, ensuring the structure can safely and efficiently bear them while meeting criteria like strength, stiffness, and durability. It integrates findings from structural analysis to inform decisions about member sizes, reinforcement needs, and connection details.

3.3. Codes and Standards for Structural Analysis and Design of Bamboo Structures

Structural codes and standards serve as guidelines and regulations that ensure the safety, reliability, and quality of constructed buildings and infrastructures. They establish minimum requirements for structural design, materials, construction methods, and performance criteria to mitigate risks and ensure compliance with legal and safety standards.

Table 4 displays the codes and standards referenced by the researchers in the literature. The key aspects utilized for structural analysis and design include serviceability limits, load parameters, and geometric considerations. Serviceability limits refer to constraints such as deflection limits relevant for public safety. Load parameters encompass factors like self-weight, dead loads, live loads, and lateral loads expected to be borne by the structure. Geometric considerations involve the shape, size, and configuration of the structure, including the dimensions of the structural elements, the arrangement and connectivity of these elements, and the overall architectural layout.

Bamboo offers excellent potential for construction due to its impressive strength-to-weight ratio. Johanssen [

53] compared the strength-to-weight ratios of various construction materials, finding the following values in

: concrete (0.003), steel (0.02), timber (0.013), and bamboo (0.017). However, bamboo’s natural variability in geometry poses challenges for structural design [

19,

54,

55]. High variability in these properties, including diameter, thickness, and length, can significantly impact structural analysis and design, making it difficult to predict material behavior under various loads. To effectively design bamboo structures, it is crucial to establish physical properties like diameter and thickness alongside their corresponding strength capacities. ISO 22157 [

51] specifies test procedures for specimens obtained from round bamboo culms. These testing methods yield data that can establish fundamental physical and mechanical properties for use in structural engineering design. The standard provides guidelines for measuring key properties of bamboo. These include basic characteristics like weight, density, and moisture content, as well as material strength properties like strength parallel and perpendicular to the fiber direction, compression, tension, bending, and modulus of elasticity. Recent structural codes for bamboo structures, such as those in Brazil and Colombia, adhere to the guidelines outlined in ISO 22157 [

51] in the evaluation of material strength. These new codes and standards, particularly in their methods for evaluating bamboo’s strength properties, were influenced by ISO 22157 [

51].

The Brazilian code addresses geometric considerations, particularly bamboo grading. Under NBR-16828-2 [

56], test methods for determining bamboo’s physical and mechanical properties are outlined, and a procedure to derive mechanical constants, also available in ISO standards, is provided. NBR-16828-1 [

57] focuses on bamboo structural design. In 2010, Colombia adopted the NSR-10 [

58] seismic-resistant design and construction code, which introduced a section on

Guadua structures, emphasizing bamboo as the main material. It sets requirements for structural and seismic-resistant designs, including methodologies for beam, column, and wall design. However, the code lacks provisions for connection design and is limited to the

Guadua angustifolia Kunth bamboo species. Moreover, NSR-10 [

58] does not cover connection design procedures. Both the Brazilian and Colombian codes require structural elements using bamboo to follow the Allowable Stress Design (ASD) method, ensuring maximum stress in the element stays within the material’s elastic range. Allowable stresses are determined through experiments outlined in the same code.

Several international standards have been used in studies for material mechanical property tests. Among these standards are ISO 22157:2019 [

51], ASTM D143 [

59], ASTM C469 [

60], BS EN 26891 [

61], and AC 162 [

62]. The tests are for other materials, mainly timber. Only ISO 22157:2019 [

51] is dedicated to bamboo culm. Among the codes, ISO provides a comprehensive list of tests that cover material strength determination, material grading, and design of bamboo structures.

ASTM is a standards organization that develops and publishes technical international standards for a wide range of materials, with headquarters in the United States. ASTM D143 [

59] test methods cover tests on small clear specimens of wood. ASTM C469 [

60] presents the test methods for the static modulus of elasticity and Poisson’s ratio of concrete in compression. ASTM D2915 [

63] is used for data analysis of test results

BS EN 26891 [

61] is a British standard for timber structures that outlines the general principles for the determination of strength and deformation characteristics. AC 162 [

62] establishes guidelines for evaluation of structural bamboo.

ISO 22157:2019 [

51] specifies test procedures for round bamboo culms to establish their physical and mechanical properties for structural engineering design and scientific purposes. It includes methods for assessing moisture content, density, mass per unit length, and strength properties parallel and perpendicular to the fiber direction (compression, tension, and bending). It also outlines procedures to estimate the moduli of elasticity in bending, compression, and tension.

ISO 19624:2018 [

64] outlines procedures for visually and mechanically grading round or pole bamboo for structural applications. Visual grading is based on observable characteristics, while mechanical grading uses non-destructive measurements to determine properties that correlate with grade-defining values.

ISO 22156:2021 [

65] applies to designing bamboo structures with round bamboo load-bearing elements or shear panel systems, covering one- and two-story residential, small commercial, institutional, and light industrial buildings up to 7 m high. It focuses on mechanical resistance, serviceability, and durability requirements, permitting allowable load-bearing capacity design (ACD) and allowable stress design (ASD) approaches, which can be combined. It also recognizes partial safety factor design (PSFD), load and resistance factor design (LRFD), and documented design by testing approaches. While thermal and sound insulation are not addressed, the document covers construction material quality impacting compliance with design requirements. It includes modification factors for bamboo materials suitable for construction, based on empirical data. The document does not apply to structures made from engineered bamboo products or bamboo-reinforced materials where bamboo is not the primary load-bearing component.

SNI-5 standard is the standard for timber construction design procedures in Indonesia. The study of [

50] used SNI-5 as reference for the loadings and load parameters for the structure.

China has also several codes. The first is JG/T 199 [

66], a full culm bamboo standard for testing methods of determining the physical and mechanical properties like compression, tension modulus of elasticity, and flexure [

66]. China construction standards concerning bamboo also include the JGJ 254 technical code for bamboo scafold safety in construction, and the GB/T 2690 local code of China for bamboo timber [

67].

Table 4.

Codes and standards used by the researchers.

Table 4.

Codes and standards used by the researchers.

| Codes and Standards | Provision | Related

Material | Subject | International | Local | Country | Reference |

|---|

| AC 162 | Evaluation of bamboo | Bamboo | Test Methods | | ✓ | Canada | [62] |

| ASTM D143 [59] | Standard Test methods | Timber | Test Methods | ✓ | | | [20,22,59] |

| ASTM C469 [60] | Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression | Concrete | Test Methods | ✓ | | | [22,60] |

| ASTM D2915 [63] | Standard Practice for Sampling and Data-Analysis | Timber/Wood | Data Analysis | ✓ | | | [25,63] |

| BS EN 26891 | Test procedures for Connections | Timber | Test Methods | ✓ | | | [38,61] |

| NBR8681 [68] | Load

Parameters | Steel, Concrete | Design | | ✓ | Brazil | [28,29,68] |

| NBR16828 [56,57] | Loading Conditions, Material Geometry | Steel, Concrete | Material Grading, Loading Parameters | | ✓ | Brazil | [29,56,57] |

| NSR-10 [58] | Design Procedure, Loading Parameters | Bamboo | Design | | ✓ | Colombia | [26,27,69] |

| ISO 19624:2018 [64] | Grading Procedures | Bamboo | Material Grading | ✓ | | | [64] |

| ISO 22156:2021 [65] | Design Guidelines | Bamboo | Design | ✓ | | | [23,65,70] |

| ISO 22157:2019 [51] | Test Procedures | Bamboo | Test Methods | ✓ | | | [19,20,23,24,25,33,36,48,51] |

| SNI-5 | Load Parameters | Timber | Design | | ✓ | Indonesia | [50] |

| GB/T 2690 | Design Guidelines | Bamboo timber | Design | | ✓ | China | [67] |

| JG/T 199 | Testing procedure | Bamboo | Test Methods | | ✓ | China | [66] |

| JGJ 254 | Design guidelines | Bamboo | Design | | ✓ | China | [71] |

| Not mentioned | | | | | | | [30,31,34,35,39,40,41,72,73] |

3.4. Software Packages for Structural Analysis of Bamboo Structures

Table 5 categorizes the structural software packages utilized by researchers into three main types of applications: analysis, design, and investigation. Analysis involves the calculation and determination of the effects of predetermined loads on the structure. Design, on the other hand, is the process of determining the dimensions of structural members based on the results obtained from structural analysis. Lastly, investigation entails determining the behavior of the structure under load until failure occurs, aiding in the identification of weaknesses and informing improvements for enhanced performance and safety. Software packages considered by researchers are as follows: Abaqus (version 2016) [

74], Ansys (version 18) [

75], CAD (version 23), LS-DYNA (version 4.3), OpenSeesPy (Version 2.5.0), Karamba3D (version 2.2.0), Galileo (version 2019), Grasshopper (version Rhino 6), Oasys (version 2022), and SAP2000 (version 23 and version 16) [

76].

Abaqus [

74] is software for finite element analysis and computer-aided engineering, originally released in 1978. It can simulate complex real-world problems for a wide range of industries like mechanical engineering, electrical engineering, and civil engineering. Abaqus offers options to model complex materials and can accurately replicate material non-linearity. In the literature, Abaqus is the most popular software for structural analysis and finite element investigations as shown in

Table 5. Ramful [

30] investigates failure modes of bamboo bolt connections in uniaxial tension. The study models bamboo as an orthotropic material in the finite element formulation to capture the inhomogeneity of bamboo. The study used Abaqus to model the orthotropic nature of bamboo. The finite element model shows the damage mechanisms in bamboo connection. The study provided useful insights into the damage mechanisms that prevail in bamboo bolt connections. Meanwhile, Ramful et al. [

31] studied how the geometry of bamboo and its material composition affect how it breaks. The study used finite element modeling to investigate what happens when bamboo is bent, compressed, twisted, and shifted. This study models the

Phyllostachys bambusoides species of bamboo. F. Wang and Yang [

38] examined dowel-type bamboo joints through experimentation and finite element analysis using Abaqus software, conducting parametric studies to assess influencing variables.

Ansys [

75] is software widely used for finite element analysis in structural engineering, offering solver options such as linear dynamics, non-linearities, and explicit dynamics. Ansys software includes features designed to simulate anisotropic materials and other non-linear material models. Khatry and Mishra [

73] utilized Ansys to model bamboo as an orthotropic material, representing it with three layers. In their study, Lefevre et al. [

34] introduced a novel bamboo joint design employing custom-machined wooden blocks and metal hose clamps, supported by experimental validation. Candelaria and Hernandez [

20] investigated bamboo as a composite material, modeling it in Ansys with laminated layers possessing unique mechanical properties, shaped as a rectangular beam, and loaded until failure. Similarly, F. Wang and Yang [

38] examined dowel-type bamboo joints through experimentation and finite element analysis using Abaqus software, conducting parametric studies to assess influencing variables. Villegas et al. [

27] explored a truss structure assembled with bamboo culms and slats, utilizing steel clamps to prevent longitudinal splitting, with the study including full-scale experiments and theoretical modeling in Ansys, applying loads according to the Columbian Building Standard.

SAP2000 [

76] is a versatile civil engineering tool capable of analyzing and designing structural systems with varying levels of complexity, in both 2D and 3D. While SAP2000 offers a variety of analysis tools and supports isotropic, orthotropic, and anisotropic materials, it is not as specialized for these purposes as Abaqus and Ansys software. Quintero et al. [

26] analyzed a 20 m long footbridge, a Howe truss, utilizing SAP2000, assuming the truss members only bear axial forces, in compliance with the Colombian national regulation NSR-10. Seixas et al. [

28] devised an ultralight structural system with modular space frames, utilizing the finite element method to assess structural forces. Their proposed structure featured hinged flexible connections enabling deployable mechanisms and free joint rotation, thereby minimizing torsional stress in bamboo structural members. SAP2000 facilitated the structural analysis and design of the entire system. Taufani and Nugroho [

50] used the software SAP2000 for the structural analysis of a bamboo school building.

Tahmasebinia et al. [

77] performed finite element analysis using Strand7 to assess the strength and serviceability of three initial structures made from natural bamboo and their bamboo scrimber counterparts. Strand7 [

78] is finite element software used for modeling and analysis in civil engineering, but it is typically limited to conventional building materials such as concrete, steel, timber, aluminum, and glass. The analysis resulted in the proposal of a new structure incorporating design improvements based on the comparative analysis of the initial models. The study emphasizes the challenges of using natural bamboo, particularly its non-homogeneous and anisotropic properties, which constrain its application in curved roof designs.

Seixas et al. (2021) [

29] demonstrate the combination of computer-aided design (CAD) software and SAP2000 for the structural design of bamboo structures. CAD software facilitates the creation of 3D and 2D models of physical objects such as bridges and buildings, while SAP2000 is a versatile civil engineering tool capable of analyzing and designing structural systems. The study focuses on an active bending bamboo space structure, for which CAD was utilized to model the structure’s shape, while SAP2000 was employed for structural analysis. The integration of both software packages enabled the modeling and analysis of the bamboo structure, with geometry and mechanical properties established beforehand. CAD was utilized to create models of the active bending arch, followed by SAP2000 for stress determination in structural members, with loading conditions adhering to the Brazilian Code NBR 8681.

Karamba3D is an interactive, parametric engineering tool that allows quick and accurate finite element analysis (FEA). Karamba3D is embedded in the parametric environment of Grasshopper in the 3D modeling program Rhino3D. This makes it easy to combine parameterized geometric models, finite element calculations, and optimization algorithms. Grasshopper is a visual programming interface for the 3D modeling program Rhinoceros. Rhinoceros uses non-uniform rational B-splines (NURBS) to precisely and mathematically model geometry. An algorithmic approach enables designers to create complex forms and rapidly generate alternative designs.

Estrada Meza et al. [

79] used Grasshopper and Karamba3D to create three-dimensional modeling of the bamboo structure. Estrada Meza et al. (Estrada Meza et al., 2022) utilized a combination of Karamba3D and Grasshopper software to explore the use of parametric tools for designing complex shapes. Initially, they applied the NSR-10 Colombian code to analytically solve and design the mechanical behavior of double-curved shells. These results were compared with those obtained using the Karamba3D add-on, and verification was successful when both sets of results matched. Similarly, Nurdia et al. [

43] employed Karamba3D and Grasshopper software to design bamboo grid shell structures, focusing on form-finding and optimization to achieve structurally efficient forms.

In the study by de Albuquerque et al. [

80], the results from experimental tests were compared with numerical predictions using a relative error parameter for static stresses and natural frequencies. This comparison enabled the indirect determination of the prestress level applied in the sisal ropes of the tensegrity module. Galileo software was used for numerical analysis. Galileo is free finite element analysis software with a graphical user interface. It aims to be as general as possible while maintaining a user-friendly approach. Currently, Galileo can perform modal, buckling, static, transient, and dynamic analysis with both linear and non-linear options. However, Galileo is limited to modeling isotropic materials and cannot accommodate complex material non-linearity.

Another software package used by researchers in the literature is Oasys. Oasys [

81] provides a range of analysis and design solutions for buildings, bridges, geotechnical engineering, and pedestrian movement. However, the software is limited to modeling isotropic materials. Nonetheless, Oasys can be used in conjunction with other software, such as LS-DYNA, which can model anisotropic materials. Chiacchiera et al. [

41] describe a research study on the structural and constructional properties of bamboo strips. The study included experimental tests on a full-scale structure. In addition to field tests, the bamboo roofs were modeled using finite-element analysis software to evaluate the correspondence between experimental and analytical data.

Michels et al. [

70] examined the relationship between the structural behavior of the roof system and bamboo joints, conducting finite element analysis with Karamba3D, followed by laboratory tests on the most critical joints. Chand et al. [

47] experimentally determined the tensile strength of bamboo parallel and perpendicular to the fiber direction, creating a finite element model with Abaqus to compare stress and strain values under tensile load with experimental results. Torres et al. [

82] performed diametric compression tests to determine the circumferential Young’s modulus of

Guadua angustifolia and

Phyllostachys pubescens, using finite element analysis for validation. García et al. [

83] focused on the circumferential mechanical properties of

Guadua angustifolia bamboo specimens, examining shear modulus, Young’s modulus, and Poisson’s ratio.

Most reviewed papers used software packages for investigation of the mechanical behavior of bamboo culm and bamboo connections. Among the software packages discussed, Abaqus and Ansys offer the most extensive features for solving material non-linearity and analyzing structural systems of varying complexity. However, due to their extensive capabilities, these programs require significantly more processing resources compared to the other software packages mentioned in

Table 5. The advantage of using software packages is they enable parametric studies. This allows rapid exploration of scenarios, precise simulation of complex systems, easy adjustment of parameters, and elimination of the need for physical prototypes, saving time and resources.

Table 5.

Software packages for structural analysis used by the researchers.

Table 5.

Software packages for structural analysis used by the researchers.

| Software | Application | Reference |

|---|

| Structural Analysis | Design | Investigation |

|---|

| Abaqus | X | X | ✓ | [21,38,40,47,48,73,83,84] |

| Abaqus | ✓ | X | ✓ | [39] |

| Abaqus | ✓ | X | X | [23] |

| Ansys | X | X | ✓ | [20,27,34] |

| CAD | ✓ | ✓ | X | [29] |

| Galileo | X | X | ✓ | [80] |

| Grasshopper | X | X | ✓ | [79] |

| Karamba3D | X | X | ✓ | [43,70,79] |

| LS-DYNA | X | X | ✓ | [30,31] |

| Oasys | X | X | ✓ | [41] |

| OpenSeesPy | ✓ | X | X | [39] |

| SAP2000 | X | ✓ | ✓ | [26] |

| SAP2000 | X | X | ✓ | [42] |

| SAP2000 | ✓ | ✓ | X | [28,29,50] |

| Not mentioned | X | X | ✓ | [35,82] |

3.5. Adopted Methodologies

Bamboo structural design is still a novel field with limited established codes and standards, posing challenges for its widespread adoption in construction. One significant challenge in utilizing round bamboo as a construction material is the variability in its physical and mechanical properties, which depend heavily on the region where it is grown. For instance, the same bamboo species can exhibit different properties when grown in South America compared to Southeast Asia due to factors like climate and soil quality. Due to the challenges, ISO recommends that nations develop their codes and standards for bamboo, most often adapting existing timber design standards to transition to bamboo, as illustrated in

Table 4. This approach helps streamline the process and leverages existing knowledge from timber construction to ensure safety and reliability in bamboo structures. Countries that started publishing national codes and standards for bamboo culm are Colombia, Brazil, China, India, and Indonesia.

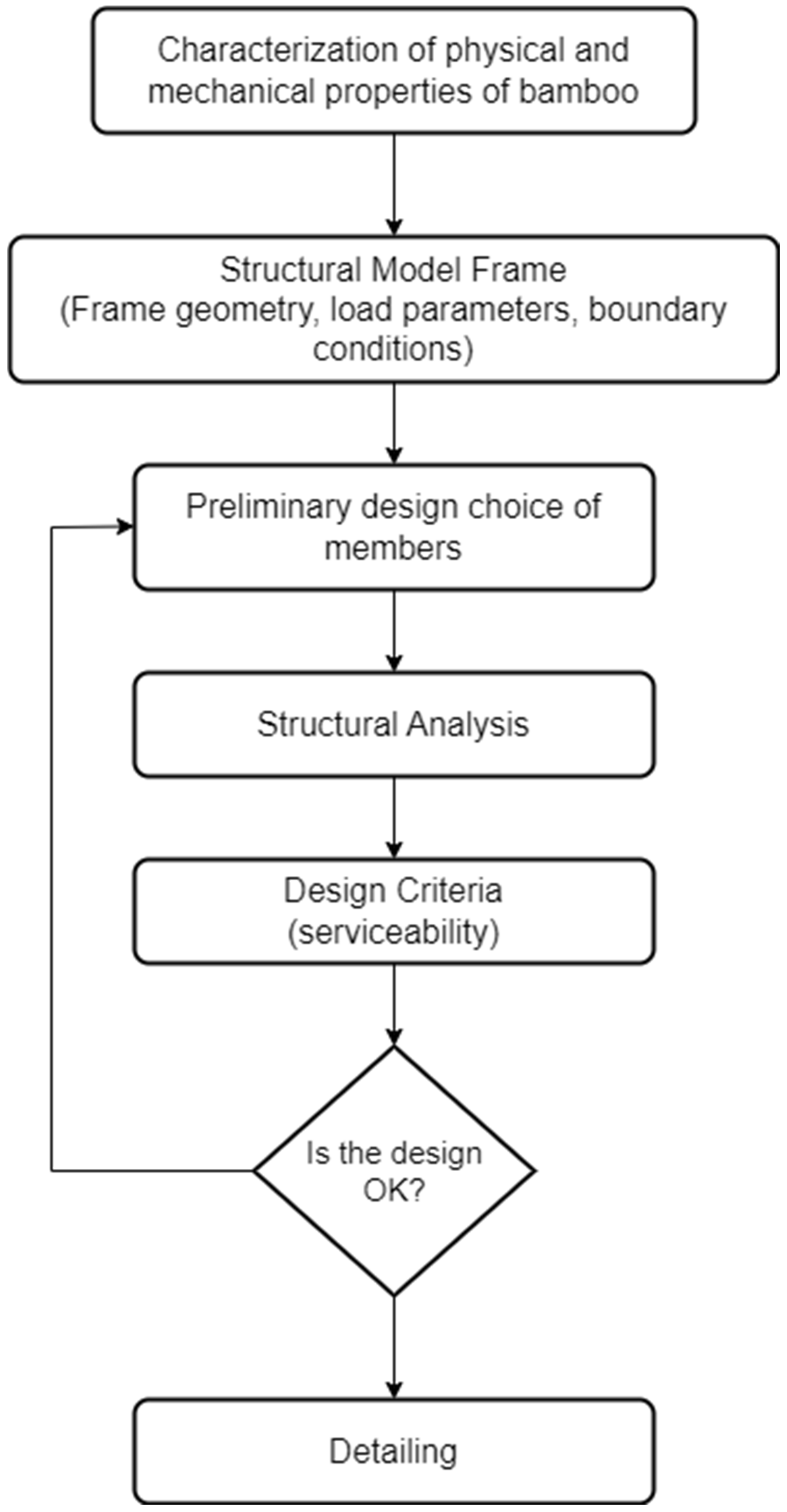

The structural analysis and design process for bamboo structures involve several key steps.

Figure 9 outlines the general steps involved in analyzing and designing bamboo structures. Unlike materials such as steel and concrete, bamboo culms require thorough characterization of their physical and mechanical properties to establish the necessary inputs for structural analysis software. This characterization is crucial because bamboo’s unique properties can significantly influence its performance in construction. Unfortunately, few design codes specify the material properties of bamboo, and among those that do, only a limited number of species are covered. Countries like China, Colombia, and Brazil have developed comprehensive codes that specify mechanical properties for bamboo, promoting its use in sustainable construction. However, for countries lacking dedicated sections in their building codes for bamboo, it becomes essential to establish the material’s physical and mechanical properties independently. This process is complicated by the inherent variability of bamboo; its physical and mechanical properties can differ significantly even among the same species growing in different geographic regions. As a result, a standardized approach to testing and documenting bamboo properties is necessary to enhance its acceptance and application in structural design globally.

Load parameters are then determined, involving the identification and quantification of various loads the structure will encounter during its service life. In the literature, load parameters are often adopted from existing codes and standards. These loads include self-weight, dead loads (like the structure itself), live loads (such as occupants and furniture), and lateral loads (such as wind and seismic forces). Following this, modeling of the structure starts. The geometry of the digital frame is defined, marking the lines of beams and columns. The preliminary design phase involves selecting the initial number of bamboo culms for columns and beams. The structural analysis step uses mathematical models and engineering principles to assess how the structure will respond to the applied loads. The results of this analysis are then checked against design criteria, such as serviceability limits. If the results do not meet the design criteria, the preliminary design is adjusted until compliance is achieved. The final step is detailing, where the structural elements are meticulously specified and documented for construction.

3.5.1. Material Parameters

Material parameters must first be established before structural analysis. In the literature, the following material parameters are used: density, Poisson’s ratio, shear modulus, and modulus of elasticity.

The elastic modulus, also referred to as Young’s modulus, is a fundamental characteristic of materials that gauges their resistance to elastic deformation when subjected to stress. This property holds immense significance in engineering and materials science as it dictates a material’s capacity to withstand loads while retaining its shape. In the context of bamboo, which is orthotropic, it becomes crucial to consider the modulus of elasticity along three axes for accurate modeling. The shear modulus, on the other hand, indicates the material’s resistance to transverse deformation, allowing it to revert to its original state. Additionally, Poisson’s ratio influences a material’s propensity to develop cracks perpendicular to the direction of stress in anisotropic materials. This ratio plays a pivotal role in determining various mechanical aspects such as stiffness, strength, stability, vibration, and fatigue, along with influencing stress distribution and compatibility conditions in composite materials. Given bamboo’s orthotropic characteristics, understanding these material parameters is particularly essential for precise modeling and structural analysis.

NSR-10 [

69] sets modification coefficients for the permissible stresses of

Guadua angustifolia Kunth, depending on factors like load duration, moisture content, temperature, and lateral stability. The Brazilian code also covers geometric aspects, notably bamboo grading. Following NBR-16828-2 [

56], it delineates test methodologies for assessing both bamboo’s mechanical and physical properties, alongside a process to derive mechanical constants, which are also standardized in ISO protocols.

Table 6 offers detailed studies on bamboo’s Poisson’s ratio, highlighting the differences in species, sample types, and the uniformity of measurements. The table includes data from different bamboo species, specifically S-11, S-1, and S-8, with some studies not specifying the species. The sample types used in these studies include bamboo culms and bamboo strips. The uniformity column in the table indicates the Poisson’s ratio values measured in these studies. As presented by G. Wang et al. [

40], the value of Poisson’s ratio through the culm thickness shows significant variability ranging from 0.008 to 0.4. For example, Lefevre et al. [

34] reported a Poisson’s ratio of 0.35 for S-11 bamboo culms with a single layer. This variability highlights the influence of sample preparation and measurement techniques on the observed mechanical properties. Bamboo’s structural composition varies across its thickness, with different layers exhibiting distinct mechanical properties. Studies that considered three layers (inner, middle, outer), such as those by Candelaria and Hernandez [

20] and Khatry and Mishra [

73], tend to provide a more detailed understanding of the material’s behavior. In contrast, studies that used single-layer samples may not capture the full complexity of the bamboo’s mechanical properties.

Table 7 provides a summary of various studies on the shear modulus of the elasticity of bamboo, highlighting the differences in species, sample types, and the uniformity of measurements. The table includes only one species of bamboo. The sample types used in these studies include bamboo culms.

Table 8 summarizes the findings of different studies on the modulus of elasticity of bamboo. The table highlights the differences in species, sample types, and the uniformity of measurements. The longitudinal direction refers to the modulus of elasticity along the direction of the fibers, while the transverse direction refers to the modulus of elasticity perpendicular to the direction of the fibers. The column for uniform for all directions implies the assumption of bamboo as an isotropic material.

3.5.2. Load Parameters

Self-weight refers to the inherent weight of a structural element or system due to its mass. The self-weight of a structure is determined by the material properties, geometry, and dimensions of its components. The self-weight of a bamboo structure is a significant aspect of its design and analysis. Bamboo’s natural lightness contributes to a lower self-weight compared to conventional construction materials like steel and concrete. Dead loads are the primary vertical loads in structural design, consistently present and permanent within a building. They include partition walls, structural components, and fixed equipment, encompassing elements like beams, the roof, columns, and walls. Live loads, also known as imposed loads, are dynamic or movable loads that do not involve impact or acceleration. These loads consist of items introduced by occupants, such as furniture and movable partitions. Lateral loads are horizontal forces acting on a structure, including wind, seismic, and earth loads, typically resisted by walls and bracing systems. Wind loads can push against or create suction on a building’s surface. Seismic loads, caused by earthquakes, vary based on the building’s location in seismic zones and its potential earthquake activity. The magnitude of seismic loads depends on the building’s weight, with heavier materials like concrete requiring design for greater seismic loading compared to lighter steel-framed structures.

Table 9 shows the load parameters used by the researchers. Quintero et al. [

26] conducted a structural analysis on a bamboo bridge. The study used the Colombian standard NSR-10 [

69] for self-weight, live load, and wind load, while AASHTO LRFD for was used pedestrian live load. The seismic response spectrum was used to obtain the earthquake load. Villegas et al. [

27] used the Colombian standard NSR-10 [

69] for the calculation of the live load and dead load. Seixas et al. [

28,

29] used the Brazilian code for the calculation of the dead load, live load, and wind load. The literature predominantly employs load parameters specific to each country for conducting structural analysis on bamboo structures. Notably, the AASHTO LRFD is the sole international code utilized, serving as the universally accepted design standard for bridges worldwide. Mitchiels et al. [

70] investigate the behavior of the roof structure using NSR-10 as a reference to determine the applied dead load, live load, and wind load. Subsequently, the study [

70] used ISO 22156 [

65] as a reference in determining the allowable capacity of the bamboo joints. Estrada Meza et al. [

79] studied the use of parametric tools to design complex bamboo shell structures. The study used the NSR-10 Colombian code as a reference for the applied load. J. Wang et al. [

39] conducted finite element modeling and simulations of active bending structure prototypes. The study performed a parametric study to determine the performance of the prototypes, but the loading parameters were not mentioned. Most of the collected papers did not use load parameters in their analysis. Instead, they focused on the ultimate capacity of the structure, testing it until failure.