1. Introduction

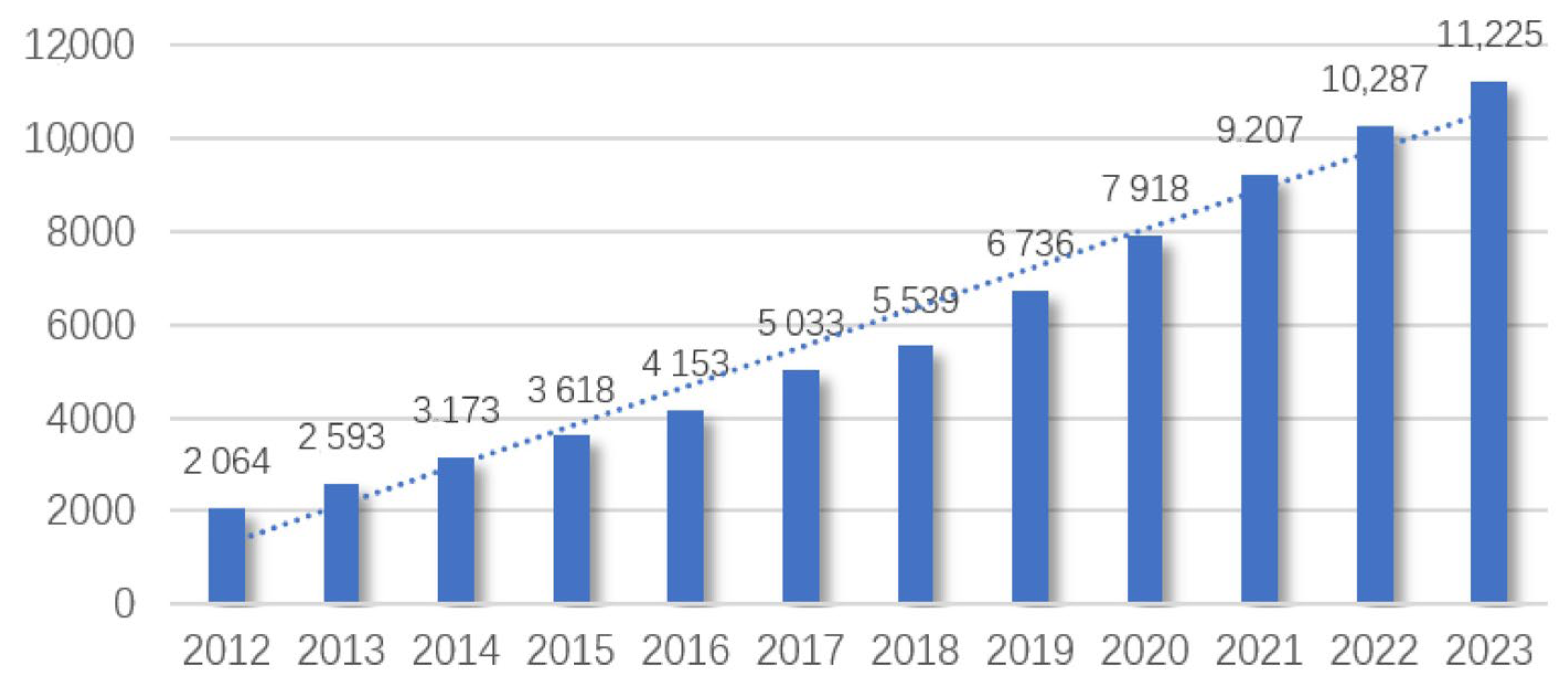

An urban rail transit project is a common infrastructure project in many countries and is very important for urban traffic development, regional economic prosperity, and the improvement of people’s quality of life. According to the “Annual Statistics and Analysis Report of Urban Rail Transit 2023”, by the end of 2023, 338 urban rail transit operation lines had been opened in 59 cities in China, with a total length of 11,224.54 km. As shown in

Figure 1 and

Figure 2, the growth of China’s rail transit projects in recent years.

The subway tunnel traffic project is an excellent travel mode with the advantages of being green and efficient and environmentally friendly and having a large passenger capacity. It is a hot area for the development of traffic levels in major cities in China. However, with the acceleration of subway construction, there are more and more safety accidents in the construction process. Its construction safety issues are highly valued. In the “Guiding Opinions on Further Strengthening the Safety Management of Tunnel Engineering” jointly issued in 2023 by the Office of the Safety Production Committee of the State Council, the Ministry of Housing and Urban-Rural Development, and other units, relevant guidance was proposed for the problem of “low intrinsic safety level of tunnel engineering”. Because of its engineering characteristics with underground construction as the main body, and usually built in the bustling area of the city, the construction process is affected by many factors, such as workers’ behavior, equipment status, construction methods, construction materials, geological conditions, and surrounding environment. The construction process is an extremely complex and high-risk process. Traditional tunnel construction has the disadvantages of high costs, a long construction period, many potential safety hazards, a large environmental impact, and a complex construction process. In order to deal with such problems, modern tunnel engineering introduces new technologies and intelligent means to improve efficiency, reduce costs, enhance safety, and reduce the environmental impact.

Digital twin technology is an innovative method that closely combines the physical world and the digital world. The core idea is to establish a digital model that is highly similar to the real-world object or system. Through real-time data transmission, the digital model can be continuously updated and synchronized with the state of the real world. The digital twin technology of tunnel construction is described as a “multi-physical field and dynamic replication of tunnel entities in cyberspace, high-fidelity description, simulation, prediction and control of entities through two-way connection, and continuous approximation of physical entities through deep learning”.

With the development of digital twins and the deepening of Internet technology companies, digital twins are gradually penetrating all aspects of the rail transit industry, such as project life cycle construction planning, urban rail transit performance evaluation, urban rail train intelligent dispatching control, etc. Kaewunruen et al. [

1] integrated the digital twin technology with the whole life cycle of the subway station project and used the digital twin technology to simulate and analyze the design, construction process, and maintenance management of the subway station through Revit 2018. The Dadongmen subway station in Hefei was verified, and the cost and carbon emission of the subway station were approved. Han, TR et al. [

2] proposed a guidance system based on a digital twin for the emergency evacuation of pedestrians in subway stations, aiming to improve the overall evacuation efficiency and save evacuation time by 23.8%. Zhou, M et al. [

3] studied the integration of train regulation and control by using deep learning and hybrid search methods. Combining a hybrid search algorithm based on particle swarm optimization and the genetic algorithm, an integrated framework of train regulation and control in a subway system based on a digital twin is proposed, which greatly reduces the calculation time of the optimal recommended speed curve in the process of train speed regulation and the total delay and energy consumption of the train.

The construction of a new generation of smart cities puts forward higher requirements for the digitization and intelligence of subway tunnel engineering. Digital twin technology effectively supports high-fidelity modeling, virtual reality mapping, and analysis-based decision-making, but the research is still in its infancy. Therefore, this paper makes a systematic conceptual analysis and bibliometric analysis, expounds on the framework, characteristics, and key technologies of digital twin technology applied in intelligent subway tunnels, deeply discusses the inherent complexity and uncertainty of subway tunnel construction, and carefully studies the application of digital twin in the whole life cycle of subway tunnel engineering. A comprehensive analysis shows that the application of digital twin technology in subway tunnel engineering has important theoretical and practical significance. Through continuous technological innovation and practical exploration in the future, digital twin technology is expected to become a key force in promoting the intelligent and digital development of subway tunnel engineering.

2. Background Study

2.1. Construction Method of Subway Tunnel

Different from traditional tunnel engineering, urban subway tunnel engineering is located underground in a city. It is necessary to consider the arrangement of various underground pipelines and facilities and the problems of traffic management and noise control during construction. In addition, urban subway tunnel engineering has very high safety requirements.

In order to complete the subway tunnel project quickly and economically while maintaining high quality, and especially to ensure the safety of construction, it is necessary to understand the characteristics of tunnel engineering, which is of great significance for decision-making construction methods and the implementation of project investment. The common construction methods of urban subway tunnels are shown in

Table 1.

Although tunnel construction technology has been developed to a new level of maturity, it is impossible to fully grasp the geological conditions in construction before excavation due to the complex geological environment, the lack of basic information, and the limitations of various aspects such as survey methods. The specific geological conditions revealed during the excavation process must make necessary adjustments and amendments to the original design plan. Therefore, the design of tunnel engineering cannot ensure that it is foolproof before construction, which makes a large number of risks exist objectively in the process of tunnel construction. In addition, due to the lack of understanding of the safety risks of tunnel engineering, risk management is not in place, and the subway may also have potential safety hazards in the operation process. In recent years, there have been many accidents at home and abroad.

On 1 December 2019, a ground collapse occurred in the construction area of Shahe Station of Guangzhou Metro Line 11, as shown in

Figure 3. The direct cause of the accident was the superposition of a special geological environment and other factors encountered in the construction of the underground excavation method, which caused the permeable collapse of the vault of the tunnel face. The indirect cause was that there were two abnormal water seepage falling blocks during construction, but it did not attract enough attention from the project department and did not prevent the accident in time.

On 20 July 2021, Zhengzhou continued to suffer from extremely heavy rain, causing severe urban waterlogging, as shown in

Figure 4. Water accumulated to break the water retaining wall of the entrance and exit line into the mainline section, resulting in a train on Line 5 being surrounded by floods, causing casualties. The direct cause of the accident is the poor handling by the relevant parties, the failure of traffic command and dispatch, the illegal change in the design of the parking lot, and the lax control of the construction quality of the water retaining wall.

2.2. The Complexity and Safety Risk of Subway Tunnel Construction

Based on the abovementioned different methods of subway tunnel construction characteristics and accident cases, it can be seen that subway tunnel construction is a dynamic and complex process involving uncertain and changeable geological conditions [

5]; these geological conditions are gradually exposed through excavation or blasting. The uncertainty of geological conditions may lead to potential safety hazards, such as rock collapse and groundwater inflow. The engineering technology requirements are high, and the support structure, ventilation system, drainage design, and other aspects need to be considered. Personnel management also needs to ensure the safety awareness and skill training of construction personnel. At present, there are many problems in the development of underground engineering, such as insufficient information under concealed geological conditions, which make it difficult to guarantee the quality of the project [

6]; limited perception ability superimposes hydrological, climatic, and variable geological conditions, resulting in uncontrollable engineering risks. The existing analysis methods often select typical sections for idealized analysis, and the authenticity needs to be improved [

7]. The common bottleneck of the abovementioned situation lies in the low degree of interaction and integration between the underground engineering entity and the virtual model. There are defects in describing and predicting the physical behavior of geology and structure, and there is a lack of theoretical and technical means for the perception, expression, and analysis of the real characteristics of underground engineering.

At present, the monitoring video collected by the monitoring system in tunnel construction is displayed in a polling manner. This method relies on management personnel to carry out manual real-time monitoring, resulting in a large monitoring workload and easy-to-cause omissions and misjudgments. In addition, safety management work relies too much on the on-site inspection of professionals and management and control remedies when the risk is more serious. There is a certain lag problem [

8], and it is impossible to provide an effective management and control strategy for the safety risks in the construction process in time.

Therefore, in the process of solving the problem of safety risk management in subway tunnel construction, in view of the lack of systematic risk factor management and the difficulty of the timely prediction, analysis, and management of risk factor status, we should focus on the rapid development of technology, and introduce more advanced technology and automation equipment, such as UAV, sensor technology, digital twin intelligent monitoring systems, etc., which can improve the safety and efficiency of tunnel construction.

2.3. Overview of Digital Twins

Digital twin technology was originally applied to military fields represented by aviation and aerospace, such as non-destructive testing and evaluation, structural health monitoring, structural demolition evaluation, load and environmental characterization, characterization modeling and testing, prediction, and risk analysis [

9]. In recent years, with the development of information technology such as cloud computing, the internet of things, big data, and artificial intelligence, the application of digital twins has gradually expanded to various civil industries, especially in the manufacturing industry, such as product digital twins and digital twin workshops and digital factories. At present, digital twin technology has attracted the attention of many industries in urgent need of digital transformation and has been explored and applied in many fields, such as automobiles, ships, power, medical, and smart cities.

By visually simulating real objects in virtual space, digital twin technology can help researchers improve the accuracy and efficiency of product design and manufacturing. This technology can be applied to product lifecycle management. Through the dual drive of data and models, it can realize the simulation, prediction, monitoring, optimization, and control of products, support the continuous innovation and rapid response of business, and promote the optimization and upgrading of the industry [

10]. In summary, digital twin technology has five typical characteristics, namely, interoperability, scalability, real-time, fidelity, and closed loop [

11]. The typical characteristics of digital twins are shown in

Table 2.

In the process of the intelligent management of urban rail transit construction, digital virtual mapping is constructed by integrating cutting-edge technologies such as a building information model (BIM), a geographic information system (GIS), the internet of things (IoT), and artificial intelligence (AI), which complement each other with physical entities. This integrated digital twin environment not only realizes the real-time monitoring of the whole life cycle of construction projects but also promotes the integration and dynamic analysis of construction data, thus significantly improving the integration, visibility, and intelligence level of project management [

12]. Through this highly integrated digital means, the construction and management of urban rail transit can achieve seamless docking between virtuality and reality and promote technological innovation and the management optimization of the entire industry.

As a theoretical and technical system with strong universality, digital twins are the most widely used in the field of intelligent manufacturing. In contrast, the application research of digital twin technology in the field of rail transit started late and mainly focused on visual monitoring, system evaluation, and project management, and the application was relatively singular.

At present, digital twins have become a hot topic in the field of urban rail transit research at home and abroad, and they are an important technical path to building a new type of smart city [

13]. Based on the information technology system of digital identification, automatic perception, network connection, inclusive computing, intelligent control, and platform service and the subway information space model, a twin system matching the physical urban rail transit is reconstructed in the digital space to realize the holographic simulation, dynamic monitoring, real-time diagnosis, and accurate prediction of the state of the physical entity of urban rail transit in the real environment to promote the full-factor digitization and virtualization [

14] and full-state real-time visualization of urban rail transit and promote the collaborative intelligence of subway operation management to realize the collaborative interaction and parallel operation of the physical subway and digital twin subway.

3. Bibliometric Analysis

3.1. Annual Number of Published Papers

The digital twin intelligent subway tunnel refers to the application of digital twin technology in the whole lifecycle process of urban underground rail transit design, construction, operation, and maintenance and the introduction of the internet of things, sensors, data analysis, remote communication, and other information technology means to realize the digital operation of the whole lifecycle process of the tunnel. It can simulate and monitor the operation status, equipment health status, and environmental parameters of the subway tunnel in real time and improve the information and intelligence level of construction management and control. The operation and maintenance stage can assist in realizing the intelligent monitoring, prediction, and optimization management of the subway tunnel system.

The core collection of Web of Science was searched, with “Digital Twin” and “Tunnel Engineering” as keywords. A total of 100 papers related to the digital twin of subway tunnels published from 1 January 2017 to 1 May 2024 were retrieved. A bibliometric analysis was performed with CiteSpace 6.3. Since digital twin technology has been a topic of concern in recent years and digital twin technology began to be applied to the subway field late, the earlier published articles in the core collection of Web of Science with low relevance to the research content were artificially screened, and the search scope was limited to 1 January 2017.

Figure 5 shows the annual variation curve of literature quantity. It can be seen from the figure that since 2017, scholars at home and abroad have begun to pay attention to and study the related fields of the digital twin of underground tunnels. Since then, the number of papers has been on the rise, especially in recent years, the number of related papers has increased exponentially. It can be seen that the digital twin smart subway tunnel has been widely studied by more and more scholars in recent years, and it is predicted that more research results in this field will be published in the future.

3.2. Development Context–Keyword Timeline Map

Figure 6 is the keyword timeline map. In the figure, the seven tags on the right, #0~#6, are automatically generated keyword clusters reflecting the research topic of the literature; each keyword cluster axis is the keyword that constitutes the cluster, and they are arranged from left to right according to the time axis according to the year of the first occurrence. The connection between keywords represents that these two words appear in the same article; the larger the node in the graph, the more frequently the keywords shown by the node appear.

Through literature reading and keyword analysis with the help of CiteSpace, the development of digital twins in the field of subway tunnels can be roughly systematized. After recent years of development, related research in the field of digital twin subway tunnels has gradually improved.

Digital twin modeling of subway tunnels is regarded as the beginning of intelligent engineering. By constructing a high-fidelity digital twin model of the subway tunnel system, intelligent management and optimization can be realized in the whole lifecycle of the subway to improve the operation efficiency and service quality of the subway system. In order to ensure the accuracy and effectiveness of the digital twin model of the subway tunnel, it is necessary to calibrate the constructed model to make it closer to the actual operation or use the state of the physical object and ensure the accuracy of the model. In addition, in order to facilitate the operation of adding, deleting, modifying, and checking the digital twin model of the subway tunnel, as well as the effective use of model verification and calibration information, model management is also essential.

The dynamic monitoring and measurement of tunnel construction can be regarded as the basis of intelligent construction. By monitoring the data on surface subsidence and clearance convergence, the risk of tunnel construction can be identified. With the deepening of machine learning-related research, studies based on time series, neural networks, and other algorithms predict the subsequent change value through the early monitoring and measurement data, realize the early warning of risks, provide a scientific basis for tunnel construction, and reduce the possibility of disasters.

Under the influence of tunnel excavation length, adjacent tunnels [

15], complex geology, and the foundation pit engineering of urban high-rise buildings, in order to improve construction efficiency and ensure personnel safety, the application of mechanical equipment such as tunnel boring machines and large trolleys has become more and more critical. The focus of intelligent construction has also shifted from data analysis to improving the mechanization degree of construction equipment and adopting intelligent control technology, such as the use of full-computer rock drilling trolleys and tunnel boring machines.

Mechanized equipment will produce a large amount of construction data during operation. Initially, scholars used the data management system of the equipment itself to develop a visual operating system with auxiliary decision-making and construction schedule management to facilitate on-site construction. Later, scholars are no longer satisfied with the secondary development of the data management system of the equipment itself and have begun to turn their attention to the information integration platform. Using internet technology, they develop intelligent construction systems with data storage, processing, intelligent algorithms, and visual management to further develop the value of construction data.

3.3. Research Status and Hotspot–Keyword Co-Occurrence Map

Figure 7 is the keyword co-occurrence graph generated by using the original data. The size of each keyword node represents the frequency of its occurrence, and the proximity between keywords represents the correlation level. After manually screening synonymous keywords and unnecessary keywords, the keyword co-occurrence map was generated.

Through the keyword co-occurrence map, it can be found that the research on digital twin smart subway tunnels mainly focuses on digital twin technology to build the digital twin framework of the subway and applies it to the whole lifecycle of subway engineering, including safety risk management and control based on digital twin technology, a digital twin subway operation and maintenance platform, etc. In the process of the application of digital twin technology, virtual reality, BIM, deep learning, UAV, and other related intelligent technologies are combined. Compared with the ideal full lifecycle intelligent use of digital twin energy technology, the current research is not comprehensive and mature enough. It is a partial, limited scope of application and intelligent construction with a low degree of intelligence. It does not require human participation, or humans only as an auxiliary intelligent construction has not yet arrived. Although there are still limitations and challenges in the current research, it can be predicted that with the continuous advancement of technology and the non-promotion of applications, the digital twin research of smart subway tunnels will become more and more comprehensive and mature. This will provide more efficient, safe, and sustainable solutions for the planning, construction, and operation of subway projects and provide better protection for urban traffic development and travel.

3.4. Collaborating Institutions—Source Co-Occurrence Map

The use of CiteSpace to analyze the source institutions of the relevant literature is shown in

Figure 8. The relevant research on digital twin smart subway tunnels is mainly based on universities, research institutes, and construction units focusing on railway construction, which reflects that the current digital twin smart subway tunnel projects are mostly concentrated on theoretical and technical research and have not yet been greatly applied in practical projects.

Most of the cooperation between institutions is geographically close universities and construction units. The research institutions with more papers are concentrated in the eastern coastal areas of China, such as Tongji University, the Dalian University of Technology, Shanghai Jiaotong University, and the Taiyuan University of Technology. Combined with China’s actual national conditions, urban rail transit is mostly concentrated in provincial capitals and large cities. It can be found that the output of research results is closely related to the geographical location of subway projects, and related projects are mostly in scientific research cooperation with neighboring universities.

4. Application of Digital Twin in Subway Tunnel Engineering

4.1. Subway Digital Twin Modeling

Based on the digital twin five-dimensional model constructed by Tao Fei [

10], some scholars have proposed a multi-dimensional model of subway tunnels based on digital twins. The main framework is the physical layer, the virtual layer, the functional layer, and the connection between layers, as shown in

Figure 9. The physical layer includes the subway tunnel construction site entity and the sensor equipment used to collect data during the construction process, such as vibrating string strain gauges, laser convergence meters, vibration sensors, gas monitors, and accelerometers for monitoring deformation and construction quality. The construction physical entity includes various information, such as personnel information, mechanical equipment information, construction material information, construction method information, and construction environment information (human, machine, material, method, ring), which are collected by various sensors and fed back to the digital twin model of the virtual layer in real time [

9]. The virtual layer is the core of the framework, which not only includes the digital twin model that integrates all kinds of information data in the construction process but also includes the machine learning algorithm model for analyzing the massive data generated in the construction process and the simulation data of the digital twin model. Its main body is a multi-dimensional set model, including three dimensions of geometry, physics, and semantics. The functional layer includes functions such as risk factor coupling analysis and risk factor prediction. The functions are realized based on the virtual layer, which guides the construction process of the physical world. In summary, the physical layer is the foundation and data source of the virtual layer, the virtual layer is the means and basis of the functional layer, and the functional layer is the basis for the physical layer to carry out the risk management of the construction process.

The establishment of a multi-dimensional set model in the three dimensions of geometry, physics, and semantics is the most challenging aspect of the research and application of digital twin technology in the field of subway tunnel construction. The logic of the twin framework is shown in

Figure 10. Although there is a lack of fully functional native DT, existing modeling methods can be used to create DTs, for example, the well-studied point cloud, BIM, and parametric modeling methods. In addition, AI models play a crucial role in identifying patterns and anomalies in data collected from sensors, enabling the prediction of tunnel behavior under complex conditions.

It should be acknowledged that various application scenarios have unique requirements for DT. It is neither reasonable nor necessary to develop a general DT modeling method. On the contrary, semantic models and interoperability are useful principles for enhancing the DT value of migration and scalability. In order to promote data fusion, dynamic analysis, and optimal decision-making, DT must have high fidelity, fusibility, reconfigurability, computability, and evolvability.

4.1.1. Geometric Model

High-Fidelity Model Based on Point Cloud

Point clouds represent geometric features in a discrete but real form. However, the point cloud that needs to be scanned or reconstructed is only a whole set of geometric objects or points, which needs to be classified and segmented for further spatial or numerical analysis. Point cloud processing usually includes the following steps: preprocessing, model alignment, blank completion, object recognition and classification, segmentation, model reconstruction, and lightweight processing.

The existing three-dimensional scanning technology can obtain dense point clouds representing the surface of the scanned object. However, the massive nature of disordered point cloud data leads to a prolonged data processing time, and it is necessary to use specific data structures to manage large-scale point clouds. Wang, Yixuan, et al. [

16] proposed a novel three-layer hybrid index point cloud data structure, which combines the index strategy based on grid, quadtree, and k-d tree and has higher index establishment and neighborhood search speeds. Shukor, SAA, et al. [

17] calculated the angle difference between the surfaces of two-point cloud geometric entities that need to be registered and then used it to adjust the second point cloud to match and register with the first point cloud data. Cura, R, et al. [

18] proposed a comprehensive and efficient point cloud management system. It can meet the basic needs of point cloud users, including fast loading, compressed storage, powerful patch and point filtering, convenient data access and export, integrated processing, etc.

The point cloud provides a high-fidelity reflection of the actual geometric state of the physical entity and promotes the creation of various models, including the ground model (GSM), earthwork model, tunnel working face model, tunnel structure model, and mechanical model. Facts have proved that point clouds are of great value in progress management, quality inspection, and risk control based on geometric models. For example, Bao, Y, et al. [

19] proposed a tunnel point cloud denoising method to meet the requirements of tunnel point cloud data measurement and provide support for the efficient, accurate, and automated daily maintenance and surveying of tunnels. Reja, VK, et al. [

20] used computer vision and point cloud reconstruction to establish a digital twin for construction progress tracking and realized the optimal control of the project. Pan, ZG, et al. [

21] proposed a slope excavation quality evaluation method based on point cloud data and compared it with the BIM model using a quality evaluation method. The research shows that it can show the weak areas of construction and estimate the slope excavation quality effectively, quickly, and accurately. Zhang, YX, et al. [

22] proposed a segmentation algorithm for continuous slice point clouds along the tunnel axis and evaluated the section deformation using ellipse fitting, which has better efficiency and accuracy than previous algorithms. Based on 3D point cloud technology, Rausch et al. [

23] reduced the average error of completion from 50.4 mm to 5.69 mm. Li, YY, et al. [

24] used the YOLO-T tunnel wall image target recognition method and a variety of point cloud data processing methods to create a high-precision three-dimensional tunnel model, with an accuracy of better than 0.7 cm. In addition, Anton, D, et al. [

25] demonstrated the feasibility of structural analysis based on laser scanning point clouds of historical buildings.

Although point cloud is still an important method for DT high-fidelity geometric modeling, it has the following limitations:

The scanning method is easily affected by environmental occlusions, resulting in a decrease in local accuracy, especially in irregular solid models;

The generation, processing, and utilization efficiency of large-scale and high-precision point clouds is low. Therefore, the point cloud is more suitable for small-scale, high-precision models, such as tunnel surface sketches, or large-scale rough models, such as ground models, to meet the timeliness requirements;

The processing and analysis of point clouds, especially the segmentation and recognition process, require high computing power to support fast feedback. Therefore, the connection should be strengthened to achieve high-speed and stable communication between point cloud acquisition, processing, analysis, and decision-making terminals.

High-Fidelity Model Based on BIM

BIM technology can integrate all kinds of relevant information about construction projects, and it has become a trend to use it in the whole lifecycle management of subway station project planning, design, construction, and management. At present, the BIM software used in each stage of the subway station in China is mainly based on Autodesk series software. The application of Autodesk software in each stage of the subway station project is shown in

Figure 11.

At the current stage, the utilization rate of BIM in China’s civil construction projects has increased significantly and demonstrated its powerful functions, but it is still not widely used in infrastructure construction. The advantages of BIM application in urban subway station projects are also very significant; in the early planning stage of urban subway stations, BIM technology is used to shape the three-dimensional model of subway stations and surrounding cities in combination with project data, which can observe the design effect in real time and facilitate better modification and optimization. Ye, Y, et al. [

26] developed a BIM design system for railway tunnels, which realized the functions of model assembly along the line, auxiliary hole layout, and automatic cutting based on three-dimensional coordinates of the line. Sharafat, A, et al. [

27] established a new multi-model tunnel information modeling framework based on BIM, which improves project management, construction, and delivery by integrating five interrelated data models and project performance data of drilling and blasting tunnel construction.

The three-dimensional model based on BIM technology can not only cover engineering information, such as buildings, structures, track tunnels, and comprehensive pipelines, of subway stations but also includes information on social humanities, the surrounding environment, and other elements, such as population distribution, traffic network layout, etc., to analyze the functional layout of urban subway stations, calculate and analyze the average passenger flow, track the network scale and distance, etc., and the main body and auxiliary volume of station buildings can be calculated. Based on BIM technology, all data are summarized in the same database, which can make it easier to query and call data in the whole lifecycle of a subway. Jiang, HR, et al. [

28] collected tunnel construction data based on the internet of things and applied BIM technology for information integration. BIM feedback analysis is fast and accurate. Zhang, N, et al. [

29] combined BIM technology with PyroSim software to visually simulate the safe evacuation of people in subway station fires. On the basis of the built BIM model, combined with finite element analysis software, the simulation analysis of tunnel mechanical properties can be realized. For example, Huang, H, et al. [

30] realized the accurate interaction between BIM and the finite element method and compared the simulated settlement displacement of the existing tunnel with the monitoring results to verify the reliability of the simulation analysis.

In addition, the biggest advantage of BIM in urban subway project cost is that it can automatically calculate the cost according to predefined rules, such as assigning component cost parameters, establishing a BIM cost model, and using software to calculate the required engineering quantity according to a specific floor plane and a specified elevation. While greatly reducing the workload, it also provides more accurate cost results. In the construction process of Haicang Tunnel, Li, S, et al. [

31] used BIM 3D combined with a time schedule and cost to make the construction process more controllable and facilitate the implementation and deployment of the construction plan.

In addition, with the help of the BIM site function, a sudden change between the construction and the environment can be found in advance, and the mutual influence between the two can be fully considered. In view of the data authenticity and three-dimensional visibility of the BIM model, it can facilitate the discovery of design problems and the demonstration and optimization of the scheme and enhance the communication between Party A and the designer. In addition, the element primitives of the BIM model are created with reference to the actual data. Not only is the information of the model components parameterized but the components are also interrelated. Once a certain parameter changes, it will affect the whole body, and all the relevant places in the whole information model will change accordingly. This will undoubtedly reduce the workload of the designer and ensure the reliability and consistency of the drawing information.

Parameterized Model Based on Real Data

Parametric modeling is a kind of computer-aided design method that has resulted from the development of computer technology. It has been widely used in industrial design and other fields. Using parametric modeling, the design can be flexibly adjusted according to the application scenario and object characteristics. It is suitable for project design, such as shield tunnels, and can reflect the assembly relationship, strain field, and risk distribution between various components. Tunnel modeling is carried out by means of parametric modeling. After the designer adjusts the tunnel alignment, the model will be automatically updated. The program can capture the design intention according to the rules, and the designer can also more accurately define the response mode of the model after some adjustments to automatically create different tunnel intervals in the same project and shorten the design cycle.

From the basic principle, so-called parametric modeling is used to describe the various rules, intentions, and methods used in the modeling process, according to the user’s intentions and design rules to change the parameters. Specific to the design of a shield tunnel, specific parameters that can reflect the corresponding technical characteristics of a shield tunnel are used to describe the tunnel geometry and to parameterize and digitally associate the corresponding tunnel structure characteristic parameters with the shield tunnel geometry to form an organic whole between the parameters. Through the one-to-one constraint relationship between the tunnel modeling parameters, the designer only needs to change the specific value of one or some tunnel structure characteristic parameters between similar projects, and the corresponding software program can automatically identify and use the size characteristics of the parametric design to drive the tunnel geometry. For example, Koch et al. [

32] directly established an integrated model of structure and geology by extending IFC. Goedert et al. [

33] used image recognition to extract construction progress information from on-site structures and drive the creation and update of parametric models. Luo, HB, et al. [

34] developed a new parametric modeling method for shield tunnel segment rings and evaluated it in actual tunnel construction projects. Similarly, Xie, P, et al. [

35] also proposed a parametric tunnel segment library that realized the information management and spatial constraints of shield lining segments.

The parametric modeling method overcomes the disadvantage that the size value used in traditional CAD modeling to express the geometric elements cannot be changed arbitrarily once it is determined. When the traditional method is used to model the tunnel, the original geometric elements must be deleted before the model is modified, and then the new geometric elements must be redrawn or constructed. This makes the designer have to repeatedly delete and redraw a lot of work, which restricts the work efficiency. In contrast, parametric design not only improves design accuracy but also improves the efficiency of design optimization and improves the degree of informatization in the engineering design industry. At present, there are three mainstream parametric modeling methods, namely, the process construction method based on the generation process [

36], the artificial intelligence method based on geometric reasoning [

37], and the variable geometry method based on geometric constraints [

38].

4.1.2. Physical Model

The digital twin physical model of the subway tunnel is an advanced simulation system that creates a virtual copy of the subway entity through high-precision digital means. The model uses the real-time data collected by the sensor network and the historical data of the subway construction and system operation to form a dynamic and interactive subway operation model. By accurately simulating the physical characteristics and operating status of the subway, this physical model can not only predict system behavior and performance in a virtual environment but also provide decision support before potential risks occur, thereby optimizing operation and maintenance strategies and improving the overall safety and efficiency of the system. In addition, the subway digital twin physical model can also be closely combined with the semantic model to enhance the intelligence level of the model through semantic understanding to achieve in-depth insight and a real-time response to the complex interaction of the subway system.

4.1.3. Semantic Model

The subway digital twin semantic model can be regarded as a high-dimensional fusion of subway system information. It effectively reduces the volume and complexity of data by finely extracting and associating complex data in various stages, such as planning, operation, and maintenance, and constructs a correlation data set suitable for different application scenarios. In essence, the semantic model means the establishment of features and relationships that can be understood by machines, and it is a profound insight into the complex characteristics of the system. Taking a three-dimensional model as an example, a simple model can be used for visualization, but when it is processed using segmentation and object recognition, more complex information can be extracted, such as geometric contact relationship and size information, which are the basis of engineering applications. Through the rigorous definition of ontology and the rich association of the knowledge graph, the semantic model integrates the physical elements, such as the geometric shape, material characteristics, and construction process of a subway tunnel, with the management elements, such as real-time data, environmental variables, and safety indicators in the construction process, and carries out deep semantic fusion and intelligent reasoning.

Using computer vision technology based on deep learning, a large amount of unstructured data (such as pictures and videos) in underground engineering can currently be transformed into available semantic feature information. These technologies can complete tasks such as image classification, object detection, pose estimation, and image segmentation and achieve fast and accurate semantic extraction. Such technology enables the digital twin model to update, analyze, and optimize decisions in real time according to event triggering.

Although the application scenarios of digital twins are very extensive, the existing modeling methods still lack the necessary versatility, and the semantic model, as a bridge between interdisciplinary information and knowledge, is a key way to effectively expand knowledge. Compared with black box or gray box machine learning methods, the knowledge graph of the knowledge model provides a fast, readable, easy-to-modify, and updated scheme for the solution of common problems by symbolically organizing traditional knowledge and combining the efficiency of computer processing and the reasoning of expert knowledge. A knowledge graph is essentially composed of ontology and its interconnection. Using natural language processing (NLP) and deep learning technology, engineering ontology and corresponding relationships can be extracted, and IfcOWL and RDF can be used to solidify and express knowledge.

4.2. Application of Digital Twin Technology in the Tunnel Construction Process

4.2.1. Digital Twin Data Acquisition

At present, most of the subway structure construction monitoring is still mainly dependent on the traditional internet of things data monitoring method. Taking a subway internet of things data platform as an example, after collecting bridge data through sensors, the platform uses traditional Excel reports for data analysis. In the whole monitoring process, the systems are relatively independent and lack effective connection, and the overall monitoring level is lagging behind. These problems limit the intelligence and information development of subway construction monitoring to a certain extent, and it is difficult to achieve dynamic real-time feedback. In this regard, based on the data monitoring of the internet of things, the virtual simulation model and digital management are integrated into the whole lifecycle of subway construction monitoring through digital twin technology to realize the monitoring, simulation, and optimization of the whole process, which is the key to solve the information fusion.

With the improvement of availability and affordability, the network has become the most widely used sensing method, providing near-real-time capabilities. However, at the tunnel construction site, the wired network is fragile and may be disturbed by construction activities. A wireless sensor network (WSN) provides flexible sensor deployment by connecting sensors through ZigBee, Bluetooth, LoRa, and Wi-Fi. Some studies have proved the effectiveness of WSN, which can achieve larger-scale distributed sensing. For example, Wang, YS, et al. [

39] deployed automated WSNs in subway tunnels to ensure structural stability by continuously monitoring stress levels. Madni, MA, et al. [

40] proposed a method for data acquisition and storage in the production process using sensors. Zheng, P, et al. [

41] proposed a bottom-up data acquisition and sensing platform to collect workshop production data through edge computing.

Due to the concealment of tunnel construction and the real-time nature of subway operation, once completed, the inspection of the internal structure becomes cumbersome. By improving the durability of the sensor, the embedded sensor designed for construction monitoring can be used continuously during the operation and maintenance phase after completion. Schroeder, G et al. [

42] proposed a method of real-time data display based on web services and augmented reality. The architecture concept diagram is shown in

Figure 12. Mourtzis, D, et al. [

43] explored the integration of remote services into the monitoring framework to provide long-term maintenance for devices and the information interaction between device software applications and physical entities through cloud services. The fiber optic sensor (FOS) network has been widely used in strain and settlement monitoring during the construction and operation stages. It has the ability to measure multiple physical quantities (temperature, stress, vibration, tilt, etc.) long-term and in real time. Li, MH, et al. [

44] demonstrated the application of distributed FOSs in the measurement of longitudinal bending strain and axial thermal strain of concealed pipelines.

Based on an actual tunnel construction project in China, a TBM construction rock machine digital twin tunneling platform is built to collect relevant data information. As shown in

Figure 13, the three-dimensional model view of TBM construction tunneling excavation is displayed. This is also the carrier of the geometric model of the TBM construction rock machine digital twin tunneling platform. The three-dimensional model view maps the cutting rock mass of the TBM cutterhead and the telescopic support of the boots in the physical space, restores the tunneling action of the TBM equipment and the tunneling attitude of the TBM in real time, and realizes the geometric mapping of the virtual space of the digital twin physical entity. In addition, the tunneling parameters after data preprocessing are presented through the data panel, and the data size and trend are displayed in the form of a line chart.

4.2.2. Construction Deformation Monitoring and Early Warning

In the process of subway tunnel construction, due to the inhomogeneity, anisotropy, and environmental factors of rock and soil composition and structure, the risk of surface subsidence deformation and collapse is very serious, which poses a great threat to construction safety. In order to ensure the safety and smooth progress of construction activities, construction monitoring has become an indispensable link. Digital twin technology can provide accurate data and indicators through real-time monitoring and the measurement of key elements, such as surrounding rock and supporting structure, to help predict risks, optimize construction parameters, and provide the timely identification of and response to potential safety hazards, thereby improving the safety and efficiency of tunnel construction. By constructing a virtual model that is highly consistent with the actual construction environment, the digital twin technology realizes accurate monitoring and measurement of key construction sites, such as subway station foundation pits, interval tunnels, shaft ventilation shafts, and underground pipelines.

In the field of subway construction monitoring and measurement, obtaining dynamic data closely related to engineering and environmental safety is the primary task of construction personnel. Although the traditional manual data processing method can evaluate the monitoring data, its time-consuming and labor-intensive characteristics limit the efficiency. In contrast, the real-time construction deformation monitoring and early warning mechanism based on digital twin technology is constructed. As shown in

Figure 14, it can not only accurately simulate and monitor the construction process but also accurately predict the deformation trend of rock and soil mass, providing a dynamic guarantee mechanism for construction safety. The technology integrates on-site monitoring data and uses advanced algorithms to analyze the potential causes of deformation and provide early warning so that the engineering team can take preventive measures before the actual deformation occurs.

The realization of deformation monitoring and an early warning system for digital twin subway tunnel construction depends on the deployment of large-scale sensor networks and the integration of advanced data processing technologies. These sensor elements are not only attached to the monitored object but can also dynamically display their spatial location and monitoring attributes in the digital twin model to realize the real-time monitoring of construction deformation. Zhou, Y, et al. [

45] applied digital twin technology to deformation monitoring in the processes of assembly construction production, transportation, and assembly. The results show that it can monitor and accurately predict the damage to building components that may occur due to structural problems and material problems in the whole system in real time.

The role of digital twin technology in deformation monitoring and the early warning of subway tunnel construction is not only reflected in its accurate simulation and real-time monitoring of the construction environment but also in its in-depth analysis and risk assessment of monitoring data, which provides strong technical support for the safe construction of subway projects. Liu et al. [

46] recommended the implementation of DT for a safety assessment of building hoisting. In this study, DT is used to support the identification of potential risks and propose corrective actions. Liu, ZS, et al. [

47] successfully applied DT technology to the safety assessment of building hoisting through a large, prefabricated building project. Ye, ZJ, et al. [

48] proposed a DT-based platform to support the safety management of the tunnel construction site and avoid potential accidents.

4.2.3. Construction Process Risk Management and Control

Digital twin technology significantly improves the accuracy of risk identification and assessment by constructing high-precision virtual construction models and real-time data synchronization in the risk management and control of the subway tunnel construction process. With the help of widely deployed sensor networks to collect key monitoring data and using advanced data analysis algorithms such as machine learning and artificial intelligence, real-time monitoring and the accurate assessment and prediction of risk factors are realized. This technical support tests different construction schemes in a simulated environment and quantitatively evaluates their impact on risk control to optimize the decision-making process, ensure dynamic and systematic construction management, and greatly improve the safety and efficiency of subway tunnel construction. The construction process risk management framework based on a digital twin is shown in

Figure 15.

The quantitative control of construction safety risk based on digital twin technology can prevent and reduce the safety risk in the construction process through the real-time monitoring and prediction of a digital twin model. This method can improve the safety of construction and reduce the probability of accidents to ensure the safety of workers and the smooth progress of the project. Based on DT and D-S evidence theory, Zhu, H, et al. [

49,

50] comprehensively investigated the change degree of the mechanical parameters of prestressed steel structures and beam-column structures under temperature and captured the key components of the structure to realize the intelligent analysis of structural safety. Similarly, Zhao, YH, et al. [

51] used the established DT model to predict the tunnel settlement value, Jiang, WG, et al. [

52] used the established DT model to support the detection of dangerous parts of a tower crane structure, Liu, ZS, et al. [

53] improved the intelligence level of the safety control of a spoke cable truss structure based on digital twin technology.

In the construction stage, the digital twin technology of urban underground rail transit based on all elements can truly reproduce the construction environment and carry out visual three-dimensional construction simulation. By exposing possible problems in the construction site, optimizing the construction sequence, and comparing and analyzing the construction simulation of multiple schemes, the optimal construction scheme is finally determined. In addition, digital twin technology can also simulate and compare the project work plan, check the factors that may affect the construction period during the construction process, analyze the rationality of the schedule, and conduct comprehensive visual control. Aiming at the problem of project schedule lag through big data analysis and pre-judgment, the causes of lag are automatically analyzed, and corresponding disposal measures are taken in time to improve the efficiency of management and decision-making.

4.3. The Role of Digital Twin Technology in Rail Transit Security

The application of digital twin technology in modern rail transit systems is a profound innovation of traditional security strategy. Its role is mainly reflected in comprehensive and accurate entity mapping, real-time data update and analysis, efficient event warning and prediction, and intuitive security decision support.

By constructing a twin model that accurately corresponds to the physical rail transit system, the technology realizes a comprehensive digital mapping of complex rail transit systems. This process involves deploying advanced IoT sensors at key nodes of rail transit, combining video surveillance, face recognition, mobile communication detection, three-dimensional geographic information systems, and satellite positioning technology to transform various elements in the real world into digital information.

The core of digital twin technology applied to rail transit security is that it can create a real-time updated and highly realistic visual reality platform. Based on different visualization platforms created by researchers, it can capture and simulate the dynamic behavior of the physical system to preview various scenarios in the virtual space, providing unprecedented insight and decision support for the safety management of rail transit. Based on the abovementioned platform, a variety of business models, including large passenger flow monitoring, passenger behavior analysis, anti-terrorism, and anti-terrorism research and judgment, can be constructed, data analysis rules can be optimized, and multi-dimensional intelligence analysis, such as alarm situation prediction, high-risk population screening, personnel association analysis, trajectory tracking, relationship network expansion, and case stringing, can be realized to significantly improve the prediction, early warning, and prediction ability of public transport safety events. This platform has become the cornerstone of rail transit security command decision-making. For example, Khajavi et al. [

54] proposed a digital twin solution architecture for security and fire detection. The framework integrates front-end sensing devices and massive data resources and uses advanced big data analysis engines to process heterogeneous data from different sources to achieve autonomous learning and intelligent perception.

Through this visualization platform, the key areas of the station, including structural layout, gates, surveillance cameras, explosion-proof facilities, etc., can be displayed in a three-dimensional and intuitive manner. For key stations and locations, such as entrances and exits, security checkpoints, gates, etc., the monitoring video and the three-dimensional subway station scene achieve seamless integration, providing intuitive real-time geographic information for daily monitoring, emergency command, and anti-terrorism response, and constructing a three-dimensional real-time twin rail transit prevention and control system.

4.4. Intelligent Operation and Maintenance System of Rail Transit Based on Digital Twin

In the operation and maintenance management stages of urban underground rail transit, there are internal environmental risks, such as temperature, humidity, pressure, harmful gas concentration, and oxygen concentration in the subway and on the platforms, external environmental risks, such as road collapse above the tunnel, the construction of adjacent underground engineering, external invasion, and man-made destruction, as well as maintenance risks, such as the personal safety of operators, standardized operation, and the safe operation of monitoring and early warning equipment. In view of the abovementioned operation and maintenance management risk points, urban underground rail transit based on digital twins can realize the functions of normalized intelligent monitoring, prediction and early warning, emergency simulation, and disposal through visual management, virtual roaming, and simulation.

In the operation and maintenance stage of urban underground rail transit, based on various high-fidelity digital twin models, such as pre-structure and pipelines, all twin data of planning, design, construction, and construction are accumulated, and a complete digital twin of urban underground rail transit can be generated for the intelligent monitoring and maintenance of urban underground rail transit. Through roaming inspection and three-dimensional visualization management, the environment, security, fire protection, train operation, equipment health, and energy consumption of the internal space of the subway platform can be monitored intuitively and in real time, and the working status and abnormal or fault alarm information of each system inside the platform and in the train can be obtained in time, and the fault point can be accurately located to realize the linkage adjustment of subway operation environment equipment, timely disposal of alarm events, optimization of overall energy consumption of the platform, and other normalized intelligent controls.

The effective perception of three-dimensional space and real-world visualization are the basis for the application of urban underground rail transit safety management based on digital twins. By using the increasingly mature new surveying and mapping technology, multi-modal and multi-scale spatial data intelligent extraction technology, high-performance three-dimensional rendering technology, etc., three-dimensional modeling of urban underground rail transit, subway platform ancillary facilities, underground pipelines, and the surrounding environment and buildings is carried out to achieve high-precision, high-efficiency, high-reality, and low-cost automatic full-feature structured expression. Through virtual roaming inspections at any angle, distance, and route in the comprehensive scene of urban underground rail transit, the comprehensive and intuitive perception of the subway line itself and its surrounding environment can provide effective support for checking planning and design defects, optimizing design and implementation plans, and the visual management of operation and maintenance.

4.5. Resource Optimization of Traffic Facilities in Subway Stations Based on Digital Twins

Resource optimization refers to making choices to achieve the purpose of optimal utilization by comparing different uses under limited resources. In terms of subway station facilities, the goal of resource optimization is to arrange different facilities of a certain scale in the appropriate location and direction according to the arrival time, behavior characteristics, and resource constraints of passengers from the perspective of serving passengers’ travel to provide a high-quality service level. Through literature research, the methods of optimizing the resources of the passage facilities in the subway station are mainly divided into two categories, namely, the model method based on mathematical theories such as operational research and probability theory and the simulation method based on computer technology.

At present, in the research process of domestic and foreign scholars on the optimization of the internal traffic facility resources of the subway station, whether it is using the model method or the simulation method, scholars often ignore the optimization of the overall service level of the subway station but optimize the traffic facilities in a specific operation scenario, such as the resource optimization research for the channel facilities. Since the actual operation scenario is a dynamic process, although this research method briefly improves the service level of the facility resources, it may also cause other facility resources to become a bottleneck and cannot solve the problem from the root. Compared with the traditional optimization method of traffic facility resources, the optimization model of subway station traffic facility resources based on digital twins emphasizes the timeliness, dynamism, and continuity of the optimization process.

The optimization scheme of traffic facilities resources in subway stations based on a digital twin is divided into the following two parts: static resource optimization and dynamic resource optimization. Static resource optimization is similar to the traditional resource optimization scheme determined by an offline simulation. Firstly, the historical passenger and traffic flow data are used as simulation inputs, and the problem scene is reproduced repeatedly. According to the simulation results, the problem of resource shortage or surplus under different passenger flow shocks is found, and then the resource optimization scheme of traffic facilities is initialized.

Dynamic resource optimization: Firstly, by collecting the real-time passenger flow and traffic flow data of physical subway stations, real-time monitoring and visualization are carried out in the virtual space, and indicators, such as service time and passenger flow density of various facility resources inside subway stations, are monitored, and then the service levels of facilities and stations are calculated. Then, the subway station is judged in real time whether it reaches the critical threshold of service level (the critical threshold can be set according to the actual congestion of the subway station and the utilization degree of resources and facilities). If the critical level threshold is not reached, the real-time monitoring state is maintained; if the critical level threshold is exceeded, the real-time optimization model of traffic facilities resources is established with the optimization goal of maximizing the overall service level of the station. After that, the parameters in the optimization model are collected through the twin model, and the solver is called to solve the model in real time. Finally, the optimization scheme is simulated and verified in the twin space. If the verification fails, the model is re-simulated. If the verification is passed, the optimization scheme is fed back to the physical subway station control center for on-site implementation.

5. Discussion and Future Direction

The safe construction and intelligent operation and maintenance of the whole lifecycle are the development requirements of subway construction. The wide application of information technology, characterized by wisdom and greenness, has promoted the digital level of subway planning, construction, and operation. Through the analysis of the development history and current situation of digital twin technology in subway tunnels, this paper defines the smart subway tunnel as an information technology system based on a digital technology and platform service and a subway information space model. In the digital space, a twin system matching the subway’s physical entity is reconstructed to realize holographic simulation, dynamic monitoring, real-time diagnosis, and accurate prediction of the state of the subway’s physical entity in the real environment, as well as feedback information, such as safety status and control measures, through simulation calculation and data analysis.

In the current stage, based on the methods of point cloud, BIM, and parametric modeling, the intelligent transformation from data to model is realized, and the expression of subway tunnel modeling and data visualization is completed. Based on the data acquisition of digital twin technology, the virtual simulation model and digital management are integrated into the whole lifecycle of subway construction monitoring to realize the monitoring, simulation, and optimization of the whole process. Through the finite element simulation analysis and the inversion of sensing parameters, the intelligent subway tunnel deeply excavates and processes the sensing data in the processes of construction, operation, and maintenance, feeds back the mechanical state of the structure in real time, evaluates the service performance of the subway tunnel, and finally realizes the time history and integration of the data. In general, the intelligent subway tunnel has reached the stage of a clear concept and the rapid development of technology.

In the future, digital twin technology is expected to be fully applied to the whole lifecycle management of subways, as shown in

Figure 16. With the continuous progress of technology, the application of digital twins in the field of subways will be more extensive, which is of great significance to improve the overall performance of urban rail transit systems.

The existing research on smart tunnels has developed rapidly, and scholars in various fields have made achievements, but there are still some areas that have not yet been explored in the following directions:

In terms of comprehensive information, the aging characteristics of geological structures can be incorporated into the theory of environmental disaster, and the intelligent prediction of unfavorable geology can be realized based on the geological conditions of the tunnel site and structural sensing feedback, which provides a strong guarantee for tunnel design and safe operation and maintenance;

In terms of data timing, the existing data sensing and information collection are often realized by means of machine coordination and personnel field collection, and some collection processes are risky and subjective. Therefore, it is necessary to develop an unmanned tunnel inspection device to improve the accuracy and safety of data collection and to assist with the digital development of information sensing with automated and standardized intelligent equipment operations;

It can be noted that in recent years, more and more cities at home and abroad have launched subway renewal planning. In the future, under the concept of green development, the application of digital twin technology in the planning, demolition, and construction stages of subway renewal and the realization of green and sustainable development of subway renewal have become urgent problems to be solved.