Abstract

The thermal performance of rural building envelopes is mostly non-standardized in Northern China, resulting in significant heat loss. In this study, we take, as an example, the central area of Liaoning province, with the objective of proposing some low-cost and energy-efficient solutions. Through our investigations, we found that heating energy consumption was reduced by 20% and construction costs increased by less than CNY 8000 (USD 1108), which can be accepted by rural residents. In order to achieve this target, the NSGA-II algorithm integrated with Rhino + Grasshopper and EnergyPlus simulation kernel was used to establish a thermal performance optimization model for the heat transfer of rural building envelopes in this severe cold region. Among the above-calculated Pareto optimal solutions, the recommended thickness of insulation layers for room floors, roofs, and external walls was about 70 mm, 50 mm, and 40 mm, respectively. Furthermore, we tried to reduce the window-to-wall ratio as much as possible. Finally, based on both the lower building renovation cost and energy-saving rate, three technical solutions from which rural residents could select, according to their specific needs, are put forward.

1. Introduction

As the income of rural residents has been increased substantially, the living standards of rural people have been improved. However, traditional rural dwellings were constructed in an autonomous manner, posing challenges in ensuring the quality of the indoor environment and leading to high energy consumption. Since the beginning of the 21st century, numerous scholars have conducted research on the improvement of building envelopes and heating systems of rural dwellings in severe cold regions. Xie Lina [1] analyzed the relationship between architecture and climate by examining typical meteorological years of 188 cities in China, quantitatively assessing the feasibility of applying passive solar energy buildings to varying degrees. Song Haihong [2] introduced the concept of rural human settlement ecology for the first time, discussing the ecological status of cold regions from four aspects: agriculture, villages and towns, courtyards, and residential ecosystems, and providing relevant countermeasures. Nowadays, most of the traditional rural dwellings in the Northeast are rural residents’ self-built brick and concrete structures with poor thermal performance of the building envelope [3], where the heat transfer coefficient of rural building envelopes exceeds the standard by 335% [4]. In addition, there are long and low-temperature winters in the cold regions, with the scattered living of rural residents for individual heating, and high energy consumption, who have an annual disposable per capital of CNY 14,618 (USD 2035), which is about half of that of urban residents [5]. Therefore, predicting construction cost, energy consumption, and indoor thermal environment in the early stage of building design is the key to improving the indoor environment in an energy-efficient yet economical way. Jin Hong et al. [6] conducted specialized research on energy-saving building materials for rural architecture in northern cold regions, resulting in significant modifications to walls, doors, windows, and roofs, achieving notable energy-saving and emission-reduction effects. Liu Dan et al. [7] utilized climate buffer zones in building spatial layouts to achieve winter insulation. Wang Xiuping et al. [8] found that with the same fuel consumption, the application of removable film buffer spaces could increase indoor temperatures by 2 to 3 °C during their investigation in the Yanbian region. Li Zhizhuo et al. [9] discovered through simulations of energy-saving renovation measures for rural houses in western Liaoning that adding glass vestibules or sunspaces could raise the average temperature of entrance corridors by 3.5 °C. Dang Qi et al. [10], considering factors such as depth, window-to-wall ratio, and roofing materials, used EnergyPlus simulations and found that a window-to-wall ratio of 0.9 resulted in the lowest indoor energy consumption and optimal daylight factor for rural houses in Baotou. Goia Francesco [11] studied the optimal window-to-wall ratio for office buildings in different European climates to minimize heating and cooling energy consumption and found that the ideal value ranged from 0.30 to 0.45. Additionally, in line with the human-centered living concept, several architects have combined lifestyle and cultural characteristics in their research. Fu Ye [12] optimized the design of new rural architecture layouts using “modular” theory, based on anthropometric data as the basis for functional space dimensions. Guo Hongyuan [13] analyzed the utilization of local renewable energy, residents’ living habits, and the characteristics of rural residential buildings, integrating natural and cultural environments, and establishing corresponding design patterns. Yang Yanan [14], considering the characteristics of rural houses in southern Liaoning, proposed environmentally friendly residential design solutions by drawing on passive design. Furthermore, the improvement in computer performance has made it possible to combine rural house energy-saving optimization with building model optimization algorithms. Ren Zhipeng et al. [15], using Ecotect simulations, analyzed the impact of building envelopes on the energy consumption of rural houses in Daqing, and found that the energy-saving effectiveness was in the order of external doors and windows > external walls > roofs > floors. Ma Li [16] found that improving the thermal storage performance of roofs was most beneficial for energy saving, reducing building energy consumption by 8.9% in optimizing the building envelope of bamboo skeleton combination structure houses. Zheng Shaoqun et al. [17] utilized EnergyPlus 9.0.1 combined with particle swarm optimization to obtain energy-saving optimization results for rural building shape parameters and building envelope parameters in Fujian. Shao Teng et al. [18] also used EnergyPlus software combined with GenOpt to establish an optimization algorithm-based energy-saving design process. The effect of thermal bridges of four external wall types on the thermal performance of the residential building envelope in a hot climate was modeled and assessed. Hameed Al-Awadi et al. have reseached the thermal performance of four wall types, including two layers of cement blocks with insulation in between (Classical), autoclaved aerated concrete bearing (AAC-B), autoclaved aerated concrete column and beam (AAC-CB), and exterior insulation and finish system (EIFS). The experiments show that the AAC-CB wall structure has the lowest performance among the tested wall types [19]. However, advanced control strategies could collaboratively optimize the operation of air-permeable building envelopes (ABPEs) and build energy systems to maximize their energy-saving potential [20]. David A. et al. [21], in their review of building performance optimization technologies, found that the optimality of technical solutions may be constrained by different constraints and objectives. Their report indicated that 70% of surveyed designers preferred multi-objective optimization for building renovations. Attia S., and Longo S. et al. [22,23] found that in the optimization design of low-energy buildings in New Zealand, 75% adopted multi-objective optimization, which was more popular than single-objective algorithms, highlighting the ability of multi-objective optimization to better address the complexities of building energy optimization. Lizana J. et al. [24] proposed a multi-criteria assessment method for different renovation schemes of residential buildings based on performance indices. The results indicated that energy savings could be achieved by improving roof and wall insulation and enhancing heating systems. Pardo N. et al. [25] studied the impact of various renovation measures on energy consumption and carbon dioxide emissions in single-family houses in the European Union. The results showed that high insulation of building envelope is a key measure to reduce energy consumption and carbon dioxide emissions. Ehsan A. et al. [26] proposed a multi-objective optimization model to explore the optimal combination of a building envelope under the dual objectives of residential economics and energy efficiency. Jermyn D. et al. [27] studied a multi-objective optimization model for renovation measures and found that for an existing residential building in Toronto, the parameters of the building envelope had the greatest impact on energy consumption, with energy-saving effects reaching 60% to 80%. Chicherin S. et al. [28,29] focused on operational data and visual and technical inspections, and studied the influence of defining room temperature variables. The revised design method was used to improve the annual performance of the building by about 14.4%. In 2016, Yu Wei [30] applied the multi-objective optimization algorithm to create indoor environments in the Chongqing area. Zhu Li [31] employed Rhino–Grasshopper to construct three northern quadrangle dwelling models and combined them with the Octopus multi-objective optimization tool to optimize the energy consumption, lighting, and thermal comfort of the building comprehensively. Existing studies have demonstrated that multi-objective optimization methods hold promising potential for solving nonlinear coupled optimization problems under the action of multiple variables in buildings. Through comparative analysis, Zhu Dardan [32] found it was feasible to choose EnergyPlus as the computational core for energy consumption simulation of agricultural buildings. Among them, the genetic algorithm (NSGA-II) is fast running speed and good convergence of the solution sets.

In summary, the development of rural residential buildings has shifted from merely ensuring building functionality to multi-objective coordinated design focusing on indoor thermal environment and comfort. However, in the central Liaoning region, most energy-saving renovation schemes lack clarity regarding the creation of indoor thermal environments for rural houses, and there is a scarcity of low-cost multi-objective optimization research specifically aimed at filling a need for an indoor thermal environment. In this study, based on the annual income of rural residents and energy consumption, three types of optimization technical solutions for insulation measures in rural dwellings are proposed. The NSGA-II algorithm was combined with Rhino + Grasshopper as the platform, and Ladybug + Honeybee was utilized to integrate with the EnergyPlus simulation kernel as the objective function solver. This comprehensive approach enabled the establishment of an optimized heat transfer model for the rural building envelope structure. The study aims to address the practical needs of rural life, enhance the indoor living environment of rural dwellings, and reduce heating energy consumption, thereby contributing significantly to sustainable rural development.

2. Characteristics of Rural Building Envelopes

2.1. Investigations and Measurements

Based on a residential basic information survey questionnaire, a statistical analysis was primarily conducted on fundamental building details such as construction age, floor area, heating methods, etc. A total of 121 rural dwellings were visited and their indoor thermal environment was measured. In addition, 247 valid survey questionnaires were collected to evaluate indoor thermal comfort. This sample size exceeds the number required for a standard normal distribution [33]. Furthermore, characteristics investigations of rural residences in a severe cold region (Shenyang) were carried out. Recorded photos for the process of the investigations and measurements are shown in Table 1. Nearly 90% of rural residents in the survey results did not take insulation measures.

Table 1.

Record photos for the process of investigations and measurements.

The investigating results of about 121 rural dwellings, with basic information such as building information, insulation types, and annual income, were obtained and are listed in Table 2. The statistical results of the characteristics of the rural dwellings in the surveyed area are described as follows:

Table 2.

Statistical results of field research in a severe cold region of Northeast China.

- (1)

- Most traditional rural dwellings in the severe cold region of Northeast China were built between 2000 and 2010 (25%), while a considerable number of households (68%) still reside in old rural houses constructed from 1980 to 2000. There are relatively few newly constructed buildings after 2010 (7%). Most rural houses have a small number of functional rooms, including bedrooms, kitchens, and storage spaces, resulting in low space utilization.

- (2)

- A total of 68% of the rural houses had an area of 80–110 m2, which could meet daily living needs. To ensure adequate lighting, 90.5% of the rural houses face south. According to on-site visits, usually only the bedrooms and living rooms were heated.

- (3)

- The thickness of the exterior walls of all rural houses was 370 mm, 86% of the exterior walls were not designed with thermal insulation, and only 14% of them had implemented insulation measures. Additionally, the floors and roofs of these houses were generally not insulated. In this study, by integrating the findings from on-site research, the extruded polystyrene foam insulation board (XPS board) was taken as an example to optimize the design. Its thermal conductivity is 0.030 W/(m·K), and the market price is 380 CNY/m3 (USD52/m3).

- (4)

- The proportion of dwellings that set up vestibules or buffered film spaces (plastic greenhouses) was 52%, while 48% of dwellings instead opted to seal windows with plastic film. It could be seen that the thermal insulation effect of the indoor thermal environment in rural houses during winter was closely related to the construction of buffered film spaces.

- (5)

- According to survey data, the average annual household income in rural areas was approximately CNY 38,000 (USD 5232), and the average per capita annual income was about CNY 13,400 (USD 1845), slightly lower than the per capita disposable income data of CNY 17,000 (USD 2340) provided by the Liaoning Provincial Bureau of Statistics. This indicates that rural residents’ income levels were relatively low. Therefore, economic factors were important considerations when evaluating dwellings’ willingness to renovate rural dwellings.

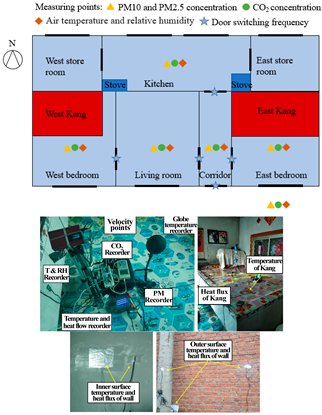

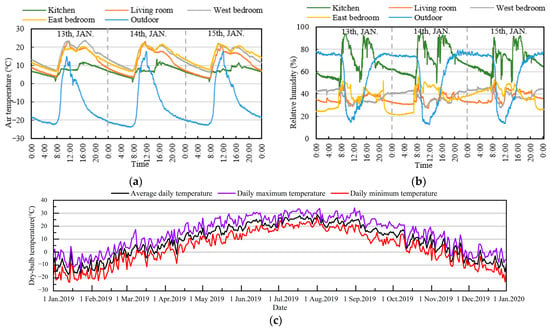

As shown in Figure 1a,b, there is little difference in temperature and relative humidity in the testing days. The annual outdoor temperature in Shenyang is shown in Figure 1c.

Figure 1.

Indoor and outdoor temperature and relative humidity in testing period ((a) Indoor and outdoor air temperature. (b) Indoor and outdoor air relative humidity. (c) Annual outdoor temperature in Shenyang).

The central area of Liaoning belongs to the severe cold region in building thermal engineering, with annual sunshine hours surpassing 3000 h and total solar radiation ranging between 5020 and 6280 MJ/m2 [32]. Focusing on rural dwellings in the central area of Liaoning, this study conducted comprehensive tests to determine typical thermal parameters. These tests encompassed measurements of each surface temperature, indoor and outdoor air temperatures and relative humidity, surface temperatures of the Kang and radiators, and heat flux of building envelopes in a typical rural dwelling of Shenyang during January 2019 and January 2020. The main testing parameters and utilized instruments are outlined in Table 3, All measurements are based on the national standards of [34,35,36].

Table 3.

Instrument parameters used for testing.

2.2. Heat Transfer Characteristics of Kang-Heated Dwelling

The formula for calculating the heat consumption index of rural dwellings is as follows:

where qH is the heat consumption index of the building, W/m2; qHT is the heat transfer through the building envelope per unit time per unit area, W/m2; qINF is the heat loss caused by cold air infiltration, W/m2; and qIH is the heat gain inside the building per unit time per unit area, W/m2.

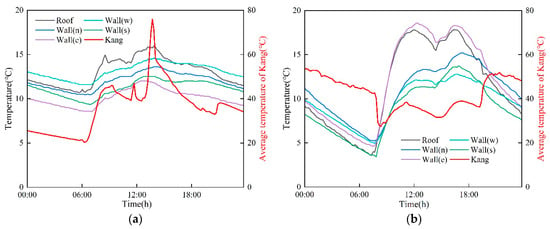

The typical heating system for rural houses includes a Kang heated with a stove and heating radiators. The main heat transfer methods were radiation and convection heat transfer. The heat exchange area on the surface of the Kang was about 4 m2. The inner surface temperatures of rural building envelopes and surface temperatures of the Kang body are shown in Figure 2. It can be seen that higher temperatures appear on the roof, and lower temperatures appear on the east wall.

Figure 2.

Temperature variations ((a) Dwelling I (b) Dwelling II).

To identify the heat transfer of building envelopes in a Kang-heated room, the process of heat transfer was calculated. During the testing, the heat flux of the Kang body generated approximately 201 kW/m2, with 83% transferred via radiation and 17% via convection into the room. The radiation heat transfer between the Kang surface and the inner wall surface was also calculated using Formula (2).

where σb is the blackbody radiation coefficient, W/(m2·K4); ε is the emissivity of the heated ground; εi is the emissivity of the surface, with a value of 0.95 for concrete floors and interior wall plastering; Fi is the angle coefficient of the i-th surface facing the heating ground; Ai is the surface area, m2; Td is the surface temperature of the heating floor, °C; Tw,i is the surface temperature of the wall, °C.

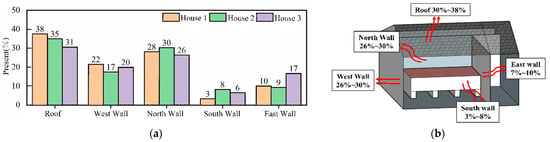

By comparing with these measured results from dwelling I, dwelling II, and dwelling III [37], the heat exchange proportion through each wall and the proportion of radiation heat loss was calculated and determined, as shown in Figure 3, and it reveals that radiant heat exchange through the roof is the most significant, followed by the inner and outer walls directly in contact with the Kang body. It can be seen that the thermal performance of rural building envelopes primarily influences indoor thermal comfort and energy consumption in Kang-heated rural dwellings; thus, thermal performance optimization of building envelopes should be studied.

Figure 3.

Comparison of heat exchange on each surface ((a) Heat exchange proportion through each wall in different dwellings (b) Proportion of heat loss from radiant heat exchange through each building envelope).

3. Multi-Objective Optimization Model

3.1. Calculation Process

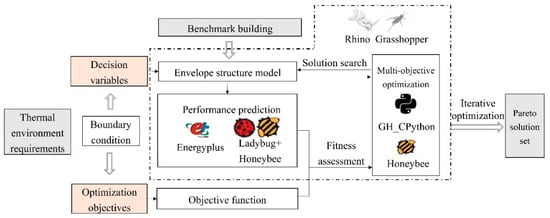

The NSGA-II algorithm can be operated on the Rhino + Grasshopper platform, which can serve as the search engine for solutions. The Ladybug + Honeybee visualization environmental analysis plug-in can be coupled with EnergyPlus energy consumption simulation software to form a multi-objective function solver. Therefore, decision variables can be converted into fitness values. Then, the optimization model for heat transfer through rural building envelopes can be established, as depicted in Figure 4. Firstly, a benchmark model of rural dwellings should be created to determine the decision variables and their corresponding constraints. Through N generations of genetic operation optimization calculations, a non-dominated solution set for the design scheme can ultimately be obtained. In addition, the optimal thickness range for envelope insulation, economic considerations, energy consumption, and indoor thermal comfort should be considered.

Figure 4.

Optimization process of energy consumption and economic rural dwellings.

3.2. Model Establishment

3.2.1. Objective Function

By reviewing relevant standards, the dynamic calculation method of building energy consumption has been used both by the Ministry of Housing and Urban–Rural Development of the People’s Republic of China (JGJ 26-2018) [38] and ISO 52016-1: 2017 [39]. The annual heating energy density can be obtained and taken as an index for evaluating building energy consumption. The renovation cost of building envelopes was used as the optimization objective for economic evaluation. The specific building optimization objective function was as follows.

- (1)

- Density of annual heating energy consumption

The influencing factors of annual heating energy consumption in rural residential buildings mainly include indoor and outdoor air temperature, heat transfer characteristics of building envelopes, and air exchange frequency. Considering that the frequency of indoor air exchange in winter is difficult to control in architectural design, the main focus was on exploring the thermal performance of building envelopes.

The average annual heating energy consumption density was calculated using Formula (3). The lower the value, the better the energy-saving effect of rural houses.

where is the vector of decision variables, given in the next section, N is heating period days, Qh is Heating load in the heating period, ti is the indoor calculated temperature during the heating period, ta is the average outdoor temperature during the heating period, to.h is calculated outdoor temperature for heating, and HEC is the annual average heating energy consumption density indicator, which means the annual heating energy consumption per unit area.

- (2)

- Renovation cost of building envelopes

The building envelope cost (BEC) index indicates the renovation cost of walls, roof, and floor insulation in yuan (converted into U.S. dollars). The calculation formula is as follows:

where Cwall, Cn, Croof, and Cfloor respectively represent the cost of external walls, inner and outer walls in contact with the heated Kang, suspended roofs, and insulation materials on the floor, in yuan.

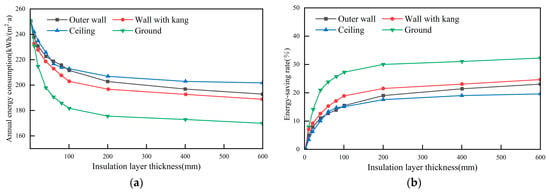

3.2.2. Decision Variable

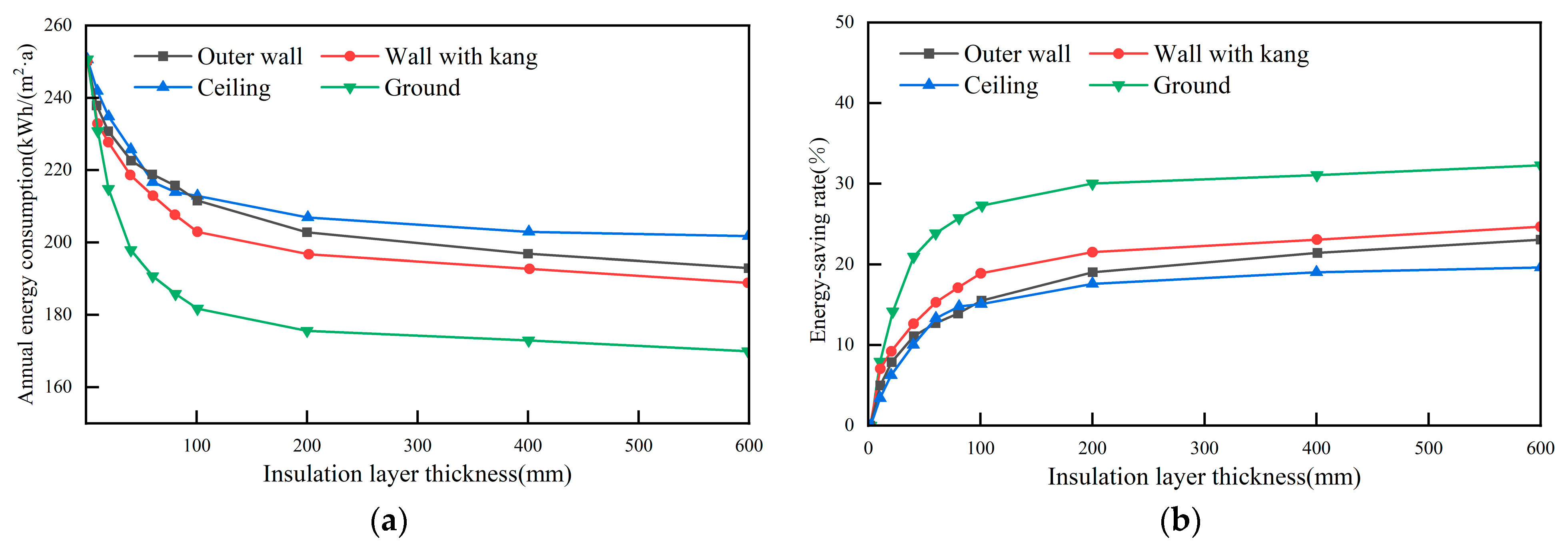

Utilizing the EnergyPlus simulation software, calculated results are illustrated in Figure 5. They reflect that the percentage of building energy consumption can be reduced through each iteration of envelope structure optimization during renovation. The effect of variations in thermal performance parameters of the rural building envelope on energy consumption was analyzed. The results indicate that incorporating insulation layers on walls, roofs, and floors of the benchmark rural dwelling led to a reduction in heating energy consumption ranging from 0 to 30%. Notably, floor insulation exhibited the most significant effect, followed by insulation on the roof and exterior walls. Furthermore, as the thickness of the insulation layer increased, the heating energy consumption decreased, translating to a higher energy-saving rate. Specifically, as shown in Figure 5, when the insulation layer thickness is varied between 0 and 100 mm, the energy-saving effect is most significant. However, when thicknesses are between 100 mm and 200 mm, the reduction in energy consumption is approximately 5%. Additionally, once the thickness of the insulation layer exceeded 200 mm, the annual heating energy consumption and energy saving rate remained unchanged, which suggests that further increments in insulation do not significantly contribute to energy reduction in rural dwellings. Based on these findings, nine parameters were selected as decision variables, including insulation layer thicknesses of the six direction walls, interior wall and north and south window-to-wall ratios, in rural dwellings. XPS board was chosen as the insulation material, with the thickness of the insulation layer serving as a variable in the optimization process.

Figure 5.

Effects of insulation thickness on annual energy consumption and energy saving rate ((a) Annual heating energy consumption (b) Energy saving rate).

3.2.3. Constraint Condition

- (1)

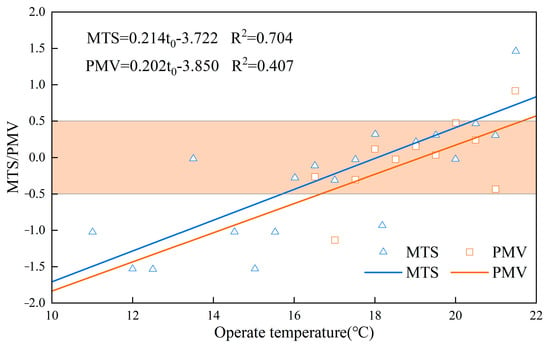

- Thermal neutral operating temperature

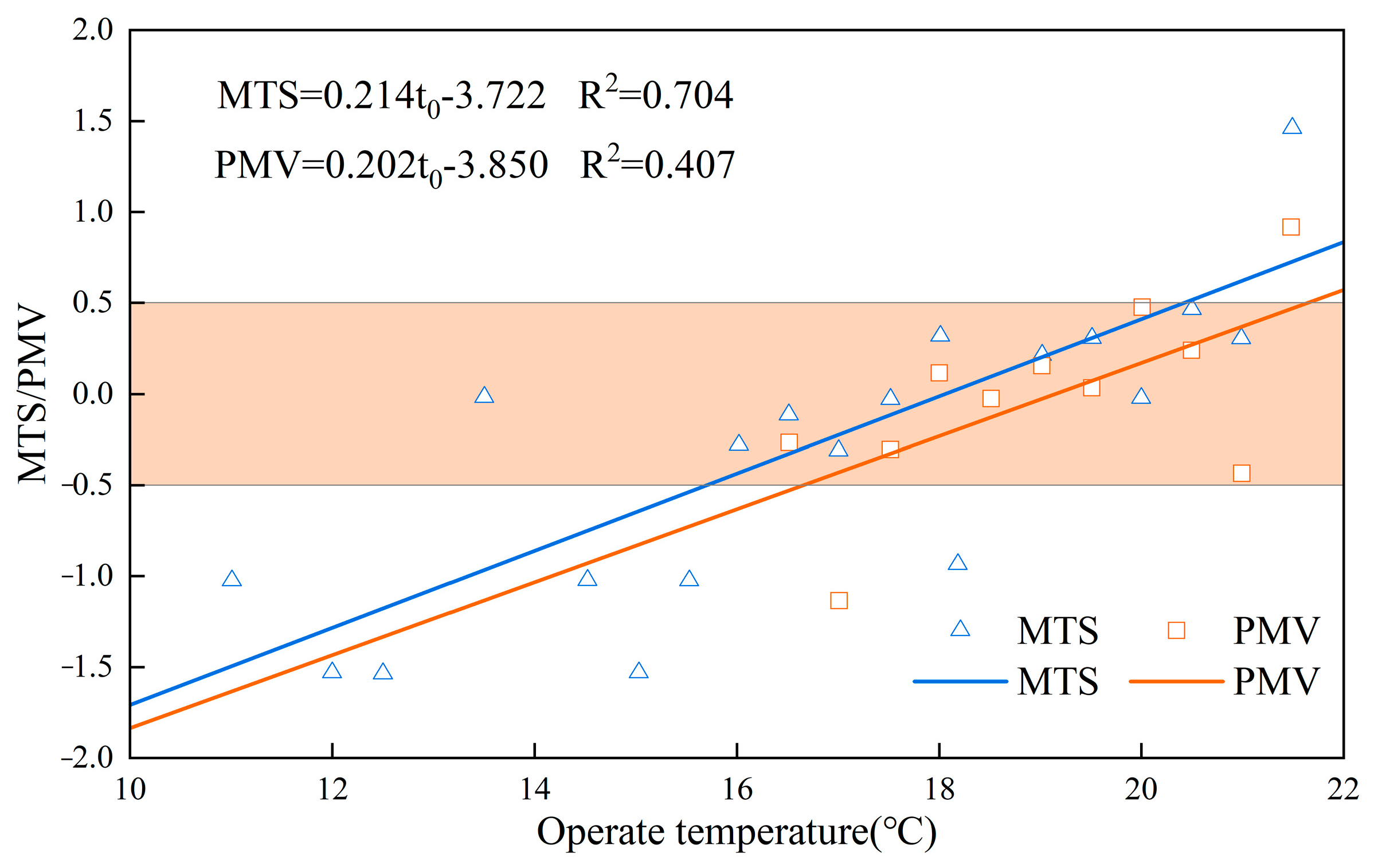

According to the regression analysis of 247 valid questionnaires in rural areas of Shenyang, a significant correlation was found between the operating temperature and mean thermal sensation voting (MTS voting) (F = 2.533, p = 0.001 < 0.01). The operating temperature was calculated based on reference [40], and can comprehensively reflect the comfortable environment of convection and radiation. The fitting result of MTS voting and operating temperature is depicted in Figure 6. The average thermal sensation vote represents the mean of participants’ thermal sensation votes within a specific temperature range. The neutral temperature is the temperature or operating temperature at which the average thermal sensation vote equals zero. At this point, households neither feel hot nor cold, indicating thermal comfort. Regression equation: MTS = 0.214t0 − 3.722 (R2 = 0.705), indicating a thermally neutral operating temperature of 17.4 °C [41]. By setting MTS = [−0.5, 0.5], a 90% acceptable temperature range of [15.0 °C, 18.1 °C] was derived. Therefore, 17.4 °C is adopted as the target value in this study.

Figure 6.

Thermal neutral operating temperature. (Orange area is MTS = [−0.5, 0.5], a 90% acceptable temperature range).

- (2)

- Thickness of insulation layer

As the energy-saving effect could not significantly be improved when the thickness of the insulation layer was infinitely increased, the range of simulation parameters should be limited. As shown in Figure 5, the energy-saving effect experiences a significant increase when the thickness of the insulation layer varies between 1 mm and 100 mm. Consequently, for the purpose of optimization, the range of variation for each decision variable was set between 1 mm and 100 mm. Table 4 summarizes the decision variables and their respective parameter values. Each decision variable has its own constraints. In this study, the thickness of the insulation layer on each exterior wall, roof, and ground was limited to between 0 and 100 mm, while the window–wall ratio was constrained by the practical values commonly found in rural dwellings, specifically 0.45 on the south side and 0.30 on the north side.

Table 4.

Continuous Variables and relevant parameters.

3.2.4. Mathematical Model

Based on the aforementioned analysis, a mathematical model was established with the building envelope structure of a heating rural dwelling as the decision variable, the economy and energy consumption as the optimization objectives, and the limit value of the heat transfer coefficient of the envelope was given in the specification as the limiting condition. The specific mathematical expression of rural dwellings objective optimization is as follows:

where the total cost of construction and renovation and the total heating energy consumption are chosen as the objective functions in this study, and the objective function , is the construction cost; is the heating energy consumption value; is the decision vector; n is the number of decision variables, n = 9 in this study; m and are the number of inequality constraints and their vectors, each decision variable has its constraint, m = 9. X and S denote the feasible decision and criterion space, respectively.

3.3. Boundary Condition

Three-dimensional modeling of the rural dwelling was conducted using Rhino software 8.0, combining the measured results and relevant references to determine the thermal parameters of the building envelope, parameters of the heating system, ground temperatures, and initial conditions for the dwelling heated with a Kang.

- (1)

- Thermal parameters of the rural building envelope

The common practice for exterior walls of rural dwellings was a non-insulated “three-seven wall” with the main material being sintered clay bricks with a heat transfer coefficient of 1.53 W/(m2·K). The exterior windows were ordinary 3 mm single-glazed windows with a heat transfer coefficient of 5.8 W/(m2·K). The window-to-wall ratio on the south side was 50%, while that on the north side was 30%. There were no exterior windows on the east and west sides. Combining the calculation method given in reference [42], taking CO2 as a tracer gas, the ventilation rate of the heated room with a Kang was calculated to be 1.6 times/h.

- (2)

- Indoor condition settings

Based on the heat loss path of the reference fireplace, the radiation heat dissipation ratio of the fireplace was set to 0.83, while for the heating radiator, it was set to 0.45 [43,44]. Additionally, based on the research results, the heating schedule and personnel presence in the main functional rooms were determined, as shown in Table 5.

Table 5.

The practical occupancy in the rural house.

- (3)

- The meteorological data

As per the investigations on outdoor temperature and relative humidity in Section 2.1, these variations were similar to the data characteristics of typical meteorological year databases. Therefore, typical meteorological year databases were used for calculation in Energyplus.

- (4)

- Ground temperature

The average temperature of ground from November to March in Shenyang rural dwellings was measured as the ground temperature design data for this study, as listed in Table 6.

Table 6.

Monthly distribution of ground temperature.

- (5)

- Parameter setting of NSGA-II algorithm

In order to enhance the convergence and computational efficiency of the NSGA-II algorithm, the values of population size, crossover probability, and mutation probability are listed in Table 7, respectively.

Table 7.

Algorithm parameter settings.

3.4. Verification of Model Accuracy

To verify the accuracy of the model, an energy consumption comparison was conducted on the initial building model. The calculated annual average heating energy density of the building was 242 kWh/(m2·a). When converted to standard coal, it amounted to 2.4 t/a, which was similar to the standard coal consumption of 2.1 t/a for northern rural houses with combined heating by a suspended heated Kang and radiators heating [18], proving the credibility of the calculation results. At the same time, simultaneously referring to the two evaluation indicators provided by ASHRAE14-2014: Normalized Mean Deviation Error (NMBE) and Coefficient of Variation (CVRMSE) of Root Mean Square Error; the expressions are shown in Formulas (6) and (7) for validation, and the NMBE and CVRMSE calculation results were 3.4% and 29.8%, respectively, within the range required by ASHRAE14-2014 specifications (NMBE within 10%, CVRMSE within 30%), indicating that the established rural house model has a certain accuracy and could be used for subsequent discussions and calculation. The discrepancy in the results was attributed to the selection of a higher outdoor air temperature than the actual outdoor air temperature, leading to a lower simulation value of unit time heat consumption during the afternoon period.

where Es,i represents simulated data; Em,i represents measured data; Em represents the average of measured data; and n represents the number of hours calculated; p = 1.

4. Analysis of Results

4.1. Multi-Objective Optimization

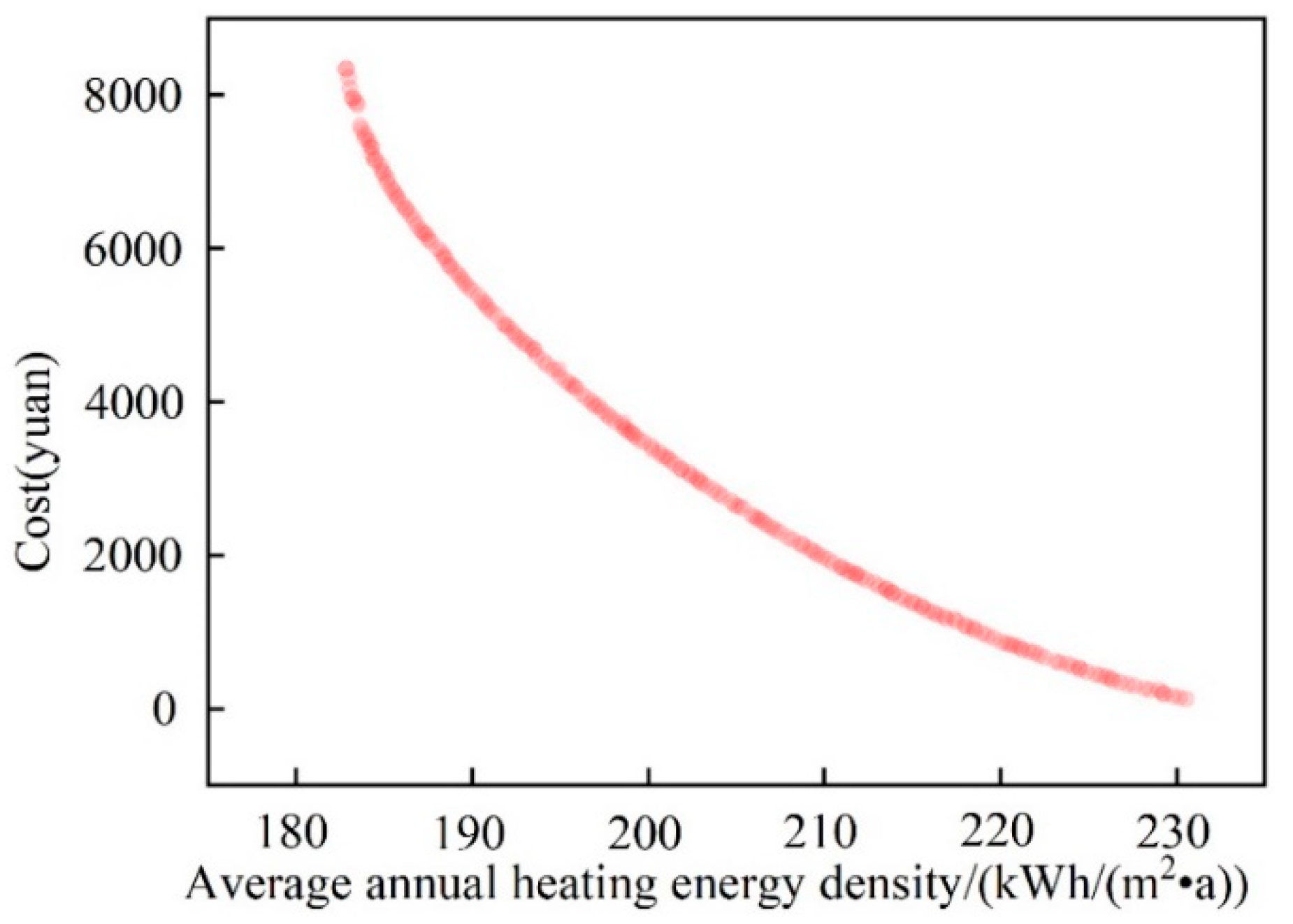

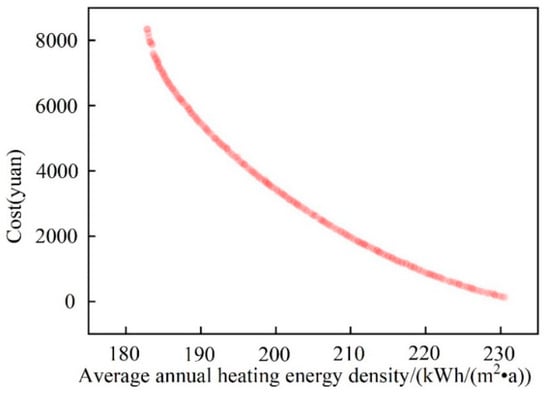

A. optimize algorithm-related programs in Appendix A, after 200 iterations, the results converged, yielding a total of 20,100 feasible solutions, including 200 Pareto-optimal solutions. Figure 7 illustrates the distribution of the optimization calculation population and the Pareto-optimal solutions, considering the dual objectives of economic efficiency and energy consumption. The initial design scheme had an average annual heating energy consumption density ranging from 100 to 220 kWh/(m2·a), while the final generation of buildings had an average annual heating energy consumption density ranging from 180 to 230 kWh/(m2·a), indicating a maximum reduction of 22% in building energy consumption. The total cost of rural dwelling reconstruction amounted to CNY 8000 (USD 1100), which was lower than the annual disposable income of rural residents, making it economically feasible.

Figure 7.

The results of multi-objective optimization. (Data points outside the box represented outliers and were excluded from the analysis).

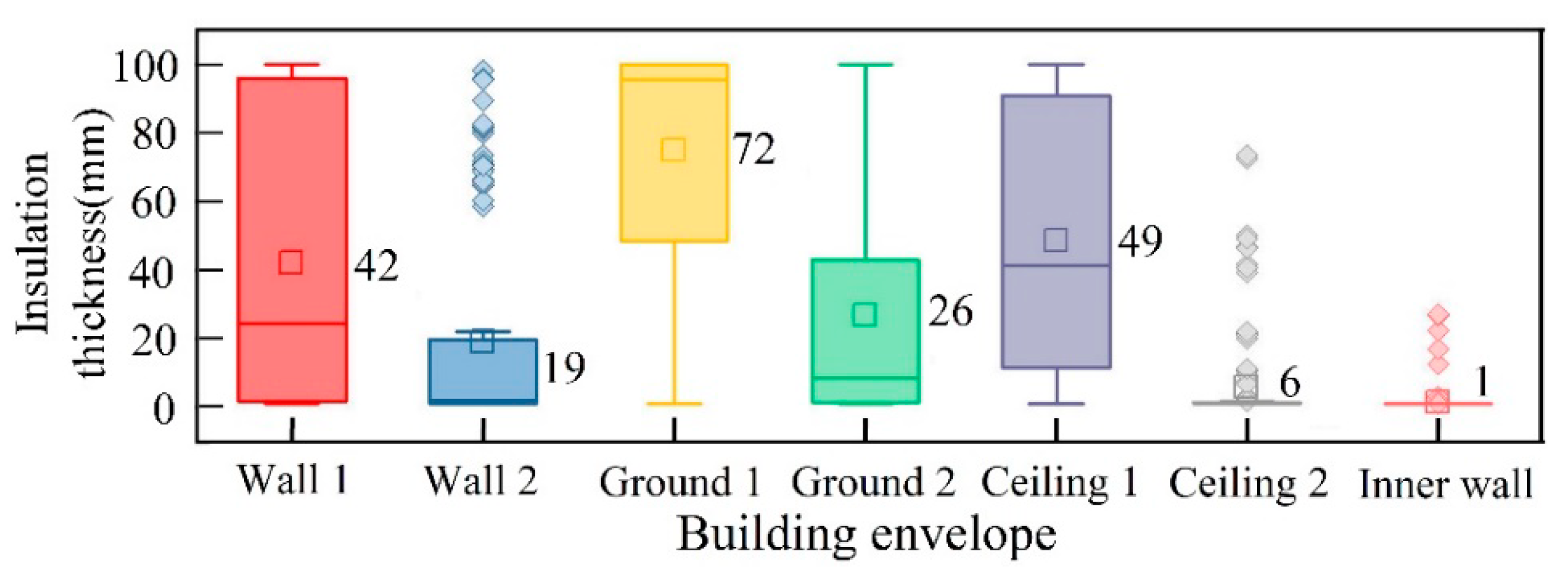

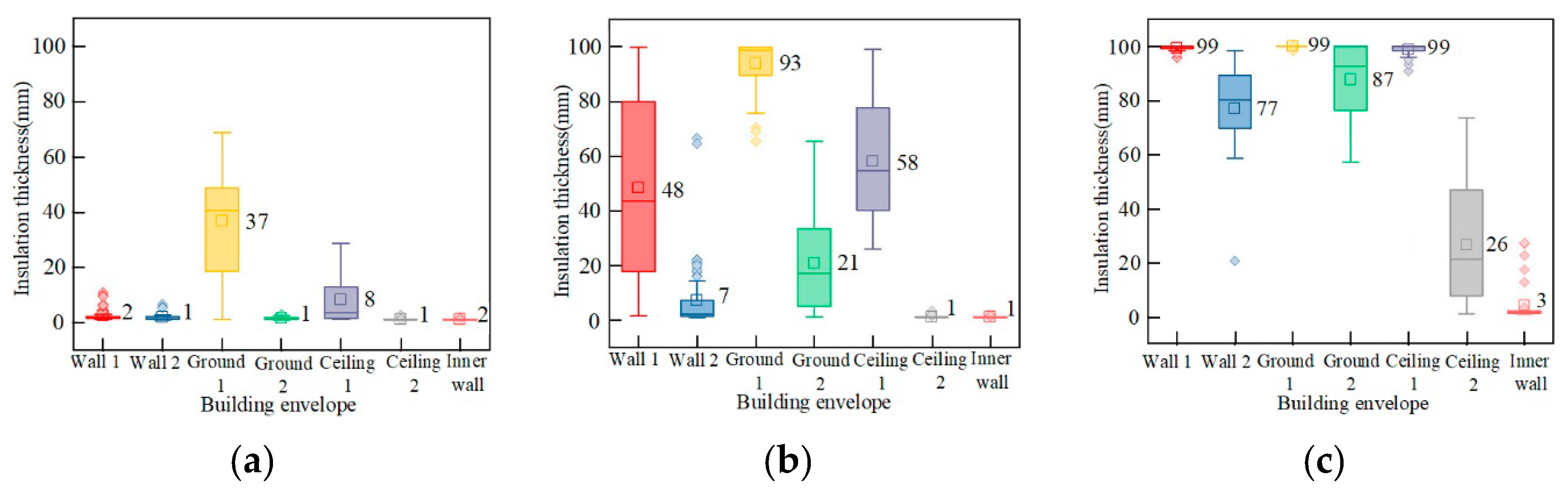

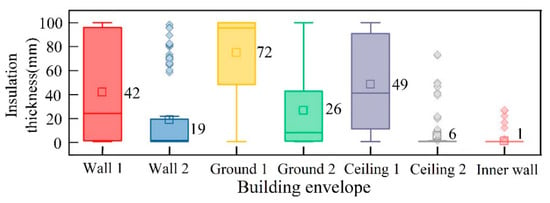

Figure 8 illustrates the threshold distribution of the insulation layer of the envelope structure in the case of Pareto-optimal solutions, where the thickness of the insulation layer was ranked from high to low as follows: bedroom and living room floor (70 mm), roof (50 mm), exterior wall (40 mm), and the remaining rooms’ floor and exterior wall (30 mm and 20 mm). These areas should be prioritized for insulation.

Figure 8.

The parameter range of the Pareto optimal envelope structure. (The diamond symbol represents outliers).

4.2. Preferred Solution

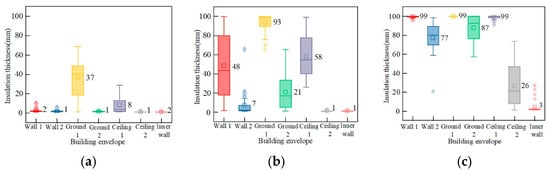

The comprehensive optimal solution sets were grouped into three categories of technology templates based on renovation cost, allowing rural residents to select the optimal design solution according to indoor thermal environment needs. Figure 9 illustrates the Pareto-optimal solutions and the three types of envelope threshold energy-saving technology groupings.

Figure 9.

Energy-saving technology grouping ((a) Economically optimal technology (b) Trade-off optimal technology (c) Optimal energy-saving technology). Number 1 represents the bedroom and living room group; Number 2 represents the kitchen utility room group. Data points outside the box represent outliers and were excluded from the analysis.

- (1)

- Economically optimal energy-saving technology. The Pareto-optimal solution with the renovation cost lower than CNY 2000 (USD 275) is selected, as shown in Figure 9a. In this case, the insulation is concentrated in the bedroom–living room floor and the bedroom–living room roof, with average thicknesses of 40 mm and 10 mm, indicating that the insulation yields better energy-saving effects and higher economic benefits. Rural residents should give priority to the renovation of this area when upgrading their farmhouses. Compared to the reference house, the energy-saving rate is within 10%, making it a more economically viable technology within the calculation cycle.

- (2)

- Assessing the optimal energy-saving technology. The Pareto-optimal solution with retrofit costs ranging from CNY 2000 (USD 275) to CNY 6000 (USD 826) is selected, as shown in Figure 9b. In this case, the thickness of the insulation layer is prioritized for the bedroom living room floor, roof, and external wall, followed by the remaining room floor external wall, with thicknesses of 90 mm, 60 mm, 50 mm, 20 mm, and 10 mm, respectively. Given limited funds, rural residents focusing on retrofitting the bedroom–living room exterior envelope insulation of their rural dwellings will yield better results. Furthermore, compared to the reference building, the energy-saving rate is 10%~18%, which is the technical template that weighs the energy-saving effect and economy.

- (3)

- Optimal technology for the energy-saving effect. The Pareto-optimal solution with the renovation costs exceeding CNY 6000 (USD 826) is selected, as shown in Figure 9c. In this scenario, where the exterior envelope insulation of the bedroom–living room is already well-insulated, additional insulation is added to the ground, exterior walls, and roof of the heating room, with average thicknesses of 90 mm, 80 mm, and 30 mm, respectively. Furthermore, additional interior wall insulation can be considered. Compared with the reference building, the energy-saving rate is more than 20%, but the cost increment is also the highest.

5. Conclusions

In this paper, a multi-objective optimization technology process that considers both energy consumption and cost control is constructed based on the characteristics of rural houses in cold regions and the application of energy-saving technologies. An example of a rural house in the central area of Liaoning is employed for application and analysis, leading to the following conclusions:

- (1)

- In Kang-heated rural dwellings, roof, internal walls, and external walls directly in contact with the Kang exhibit the highest radiation heat losses, ranging from 30% to 38%, 26% to 30%, and 17% to 22%, respectively. This indicates that insulation measures must be added to these areas.

- (2)

- The average annual heating energy consumption density of buildings corresponding to the optimal solution set for low-cost and low-energy consumption ranges from 180 to 230 kWh/(m2·a), resulting in a potential reduction in building energy consumption of up to 22%. The total cost of energy-saving renovations for rural houses can reach CNY 8000 (USD 1100), which is lower than the annual disposable income of rural residents, rendering them economically feasible.

- (3)

- By employing the multi-objective optimization NSGA-II algorithm, three energy-saving schemes suitable for rural residential construction in the central area of Liaoning were identified: the economically optimal energy-saving scheme, the balanced optimal energy-saving scheme, and the energy-saving effect optimal scheme. The corresponding building renovation costs were less than CNY 2000 (USD 275), between CNY 2000 and 6000, and more than CNY 6000 (USD 826), respectively. Based on the annual disposable income of farmers and the optimization results, the balanced optimal energy-saving technology is recommended as the best scheme in this context. The energy-saving rate ranged from 10% to 18%.

Author Contributions

X.Z. (Xueyan Zhang) and B.C. designed the study, X.Z. (Xueyan Zhang), X.Z. (Xingkuo Zhang) and J.Z. (Jiayi Zhao) conducted the data analyses and wrote the first draft of the manuscript, B.C., J.R.Z., J.S., J.Z. (Jiayin Zhu) and B.W. contributed to the discussion and revisions. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Nature Science Foundation of China (No. 52078098 and No. 51608092), and the National Key Point Research and Invention Program of the Thirteenth (No. 2018YFDll00701-2).

Data Availability Statement

All the data utilized in the current research are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to thank the survey participants who allowed us to carry out this research.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A. Optimize Algorithm-Related Programs

- ① Definition of decision variables

- class MyProblem(Problem):

- def __init__(self,path,xl,xu,**kwargs):

- super().__init__(n_var = 9, n_obj = 2, n_constr = 0,

- xl = xl, xu = xu, elementwise_evaluation = True,**kwargs)

- self.path = path

- def _evaluate(self, x, out, *args, **kwargs):

- f1,f2 = main_run(self.path,[x[0],x[1],x[2],x[3],x[4],x[5],x[6],x[7],x[8]])

- out[‘F’] = [f1,f2]

- xl = np.array([0.001,0.001,0.001,0.001,0.001,0.001,0.001,0.01,0.01])

- xu = np.array([0.1,0.1,0.1,0.1,0.1,0.1,0.1,0.45,0.30])

- ② NSGA-II algorithm call

- algorithm = NSGA2(

- pop_size = 100,

- sampling = get_sampling(“real_random”),

- crossover = get_crossover(“real_sbx”, prob = 0.9, eta = 15),

- mutation = get_mutation(“real_pm”, eta = 20),

- eliminate_duplicates = True)

- termination = get_termination(“n_gen”, 200)

- res = minimize(problem,algorithm,termination,seed = 1,save_history = True,verbose = True)

- print(‘Threads:’, res.exec_time)

References

- Xie, L.N. Climate Division for Passive Solar Buildings. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2016. [Google Scholar]

- Song, H.H. Analysis and Countermeasures on Ecological Problems of Rural human Inhabitation Environment in Bitter Cold District. Low Temp. Build. Technol. 2006, 28, 28–30. [Google Scholar]

- Jiang, Y.; Peng, C.; Shan, H. Classification of building energy consumption in China. Constr. Sci. Technol. 2015, 19, 22–26. [Google Scholar]

- Liu, K.C. Energy consumption testing and analysis of existing brick residential envelope in severe cold regions. Pet. Petrochem. Energy Conserv. 2013, 3, 18–19. [Google Scholar]

- Wang, H.W.; Chen, S.; Guo, J.X. A study on the current situation and influencing factors of farm household income. Coop. Econ. Technol. 2020, 24, 54–56. [Google Scholar]

- Jin, H. Research on Energy saving Technologies for Rural Residential Buildings in Heilongjiang Province. Constr. Technol. 2009, 8, 32–33. [Google Scholar]

- Liu, D.; Yang, L.; Hu, A.A. Energy Efficiency Design of New Rural House in the Central Shaanxi Plain. Build. Energy Effic. 2010, 38, 7–10. [Google Scholar]

- Wang, X.P.; Jin, H.; Chen, C.H. Research on Sustainable Design of Korean Ethnic Rural Residences in Yanbian Area; Architectural Physics Branch of China Architectural Society: Beijing, China, 2005; Volume 5. [Google Scholar]

- Li, Z.Z.; Liu, Z. Energy Efficiency and Indoor Thermal Comfort of Rural Residential Buildings in Western Liaoning Providence. Build. Energy Effic. 2018, 46, 134–139. [Google Scholar]

- Dang, Q. Research on Optimization Design of Attached Sunspace in Severe Cold Rural Area Based on Indoor Luminous and Thermal Environment—A Case Study of Baotou. Mater’s Thesis, Inner Mongolia University of Science and Technology, Hohhot, China, 2019. [Google Scholar] [CrossRef]

- Goia, F. Search for the optimal window-to-wall ratio in office buildings in different European climates and the implications on total energy saving potential. Sol. Energy 2016, 132, 467–492. [Google Scholar] [CrossRef]

- Fu, Y. Living Mode and Design of New Rural Housing. Master’s Thesis, Tianjin University, Tianjin, China, 2010. [Google Scholar]

- Guo, H.Y. The Research of The Design Patterns of The Livable Rural Houses in Changchun. Master’s Thesis, Jilin University of Architecture and Technology, Jilin, China, 2014. [Google Scholar]

- Yang, Y.N. Research on Rural Environment-Friendly Housing Design Based on Lifestyle in Southern Liaoning. Master’s Thesis, Dalian University of Technology, Dalian, China, 2013. [Google Scholar]

- Ren, Z.P. Research on Optimal Design of Farm Buildings in Cold Region Based on Energy Consumption Analysis. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2020. [Google Scholar] [CrossRef]

- Ma, Y. Research on Indoor Thermal Environment of Rural House in The Northeast Severe Cold Area. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

- Zheng, S.Q. Study on Energy-Saving Model of Rural Residential Buildings in Quanzhou, Fujian Province. Master’s Thesis, Tianjin University, Tianjin, China, 2017. [Google Scholar]

- Shao, T.; Jin, H. Optimization Design of Energy Saving for Rural Houses in Severe Cold Regions Based on an Optimization Algorithm. Build. Sci. 2019, 35, 99–107. [Google Scholar] [CrossRef]

- Al-Awadi, H.; Alajmi, A.; Abou-Ziyan, H. Effect of Thermal Bridges of Different External Wall Types on the Thermal Performance of Residential Building Envelope in a Hot Climate. Buildings 2022, 12, 312. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, Z.; Zhu, Q.; Shi, H.; Yu, Z.; Xu, X. Air-Permeable Building Envelopes for Building Ventilation and Heat Recovery: Research Progress and Future Perspectives. Buildings 2024, 14, 42. [Google Scholar] [CrossRef]

- Coley, D.A.; Schukat, S. Low-energy design: Combining computer-based optimization and human judgement. Build. Environ. 2002, 37, 1241–1247. [Google Scholar] [CrossRef]

- Attia, S.; Hamdy, M.; O’Brien, W.; Carlucci, S. Assessing gaps and needs for integrating building performance optimization tools in net zero energy buildings design. Energy Build. 2013, 60, 110–124. [Google Scholar] [CrossRef]

- Longo, S.; Montana, F.; Riva Sanseverino, E. A review on optimization and cost-optimal methodologies in low-energy buildings design and environmental considerations. Sustain. Cities Soc. 2019, 45, 87–104. [Google Scholar] [CrossRef]

- Lizana, J.; Molina-Huelva, M.; Chacartegui, R. Multi-criteria assessment for the effective decision management in residential energy retrofitting. Energy Build. 2016, 129, 284–307. [Google Scholar] [CrossRef]

- Pardo, N.; Thiel, C. Evaluation of several measures to improve the energy efficiency and CO2 emission in the European single-family houses. Energy Build. 2012, 49, 619–630. [Google Scholar] [CrossRef]

- Asadi, E.; Da Silva, M.G.; Antunes, C.H.; Dias, L. Multi-objective optimization for building retrofit strategies: A model and an application. Energy Build. 2012, 44, 81–87. [Google Scholar] [CrossRef]

- Jermyn, D.; Richman, R. A process for developing deep energy retrofit strategies for single-family housing typologies: Three Toronto case studies. Energy Build. 2016, 116, 522–534. [Google Scholar] [CrossRef]

- Chicherin, S.; Zhuikov, A.; Junussova, L. Factors Affecting Indoor Temperature in the Case of District Heating. Sustainability 2023, 15, 15603. [Google Scholar] [CrossRef]

- Chicherin, S.; Zhuikov, A.; Junussova, L. District Heating for Poorly Insulated Residential Buildings—Comparing Results of Visual Study, Thermography, and Modeling. Sustainability 2023, 15, 14908. [Google Scholar] [CrossRef]

- Yu, W.; Wang, D.; Li, B.Z. A multi-objective design approach for the creation of low energy consumption in indoor thermal environment of residential buildings. Civ. Archit. Environ. Eng. 2016, 38, 13–19. [Google Scholar]

- Zhu, L.; Wang, B.; Sun, Y. Multi-objective optimization for energy consumption, daylighting and thermal comfort performance of rural tourism buildings in north China. Build. Environ. 2020, 176, 106841. [Google Scholar] [CrossRef]

- Zhu, D.D.; Yan, D.; Wang, B.; Hong, T.Z. Comparison of building energy simulation software: DeST, EnergyPlus and DOE-2. Build. Sci. 2012, 28 (Suppl. 2), 213–222. [Google Scholar]

- Ning, H.R. Research on Human Thermal Comfort and Thermal Adaptation in Heating Building Environments in Severe Cold Area. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- GB/T 50785-2012; Evaluation Standard for Indoor Thermal Environment in Civil Buildings. China Construction Industry Press: Beijing, China, 2012.

- GB/T 15405-2006; Thermal Specifications and Testing Method for Passive Solar Houses. China Construction Industry Press: Beijing, China, 2006.

- JGJ/T 358-2015; Technical Specification for Rural Kang System. China Construction Industry Press: Beijing, China, 2015.

- Fan, X.Y.; Chen, B.; Zhang, X.Y. Field study on heat transfer and pollutant diffusion paths characteristics of overall rural houses based on stove Kang in northern China. Build. Sci. 2019, 35, 9–15. [Google Scholar]

- JGJ 26-2018; Energy-Saving Design Standards for Residential Buildings in Severe Cold and Cold Regions. China Construction Industry Press: Beijing, China, 2018.

- ISO 52016-1:2017; Energy Performance of Buildings—Energy Needs for Heating and Cooling, Internal Temperatures and Sensible and Latent Heat Loads—Part 1: Calculation Procedures. ISO: Geneva, Switzerland, 2017.

- Zhao, J.Y. Research on the Low-Cost Energy-Efficient Optimization of Rural House in Central Liaoning to Meet Indoor Thermal Requirements. Master’s Thesis, Dalian University of Technology, Dalian, China, 2021. [Google Scholar]

- Zhu, Y.X. Built Environment, 4th ed.; Architectural Industry Press: Beijing, China, 2017; pp. 111–113. [Google Scholar]

- Qi, M.W.; Li, X.F.; Huang, H. Discussion on Measuring Ventilation Rates of Dorms through Tracer Gas Method with Human Body as CO2 Release Source. Build. Sci. 2013, 29, 50–57. [Google Scholar]

- Zhang, X.; Chen, W.-L.; Yu, W.-J.; Ma, Y.-X.; Yang, R.-Q. Experimental study of radiation-convection heat release ratio of commonly used heating radiators. Heat. Vent. Air Cond. 1994, 6, 13–15. [Google Scholar]

- Jin, X.; Tan, Y.F.; Yu, K.C. Test and analysis of the thermal performance of combined elevated Kang and radiator heating system in northern rural areas. J. Harbin Inst. Technol. 2019, 51, 179–186. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).