Adobe Blocks Reinforced with Vegetal Fibres: Mechanical and Thermal Characterisation

Abstract

1. Introduction

Adobe: A Heritage to Be Rediscovered and Preserved

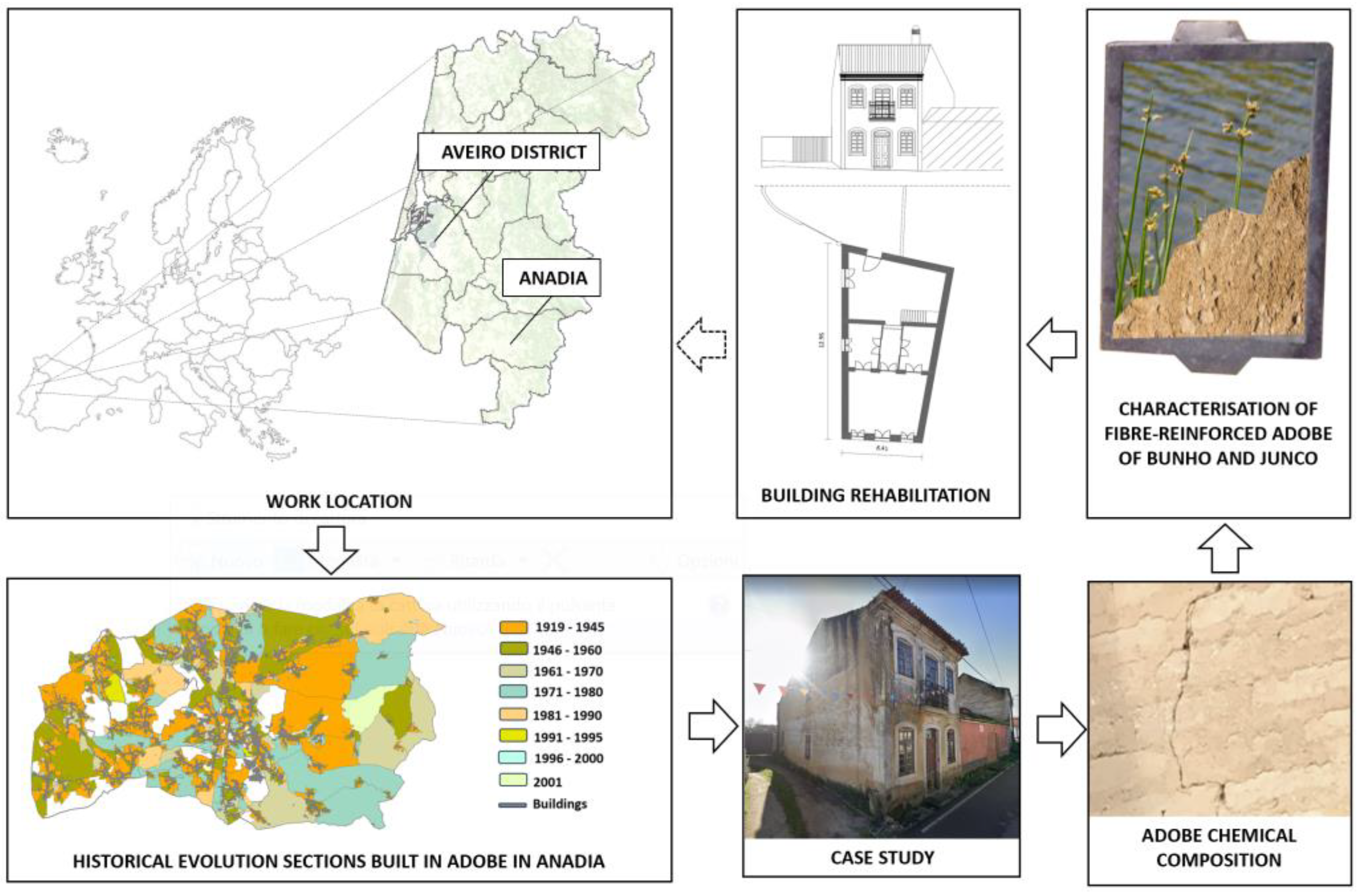

2. Case Study

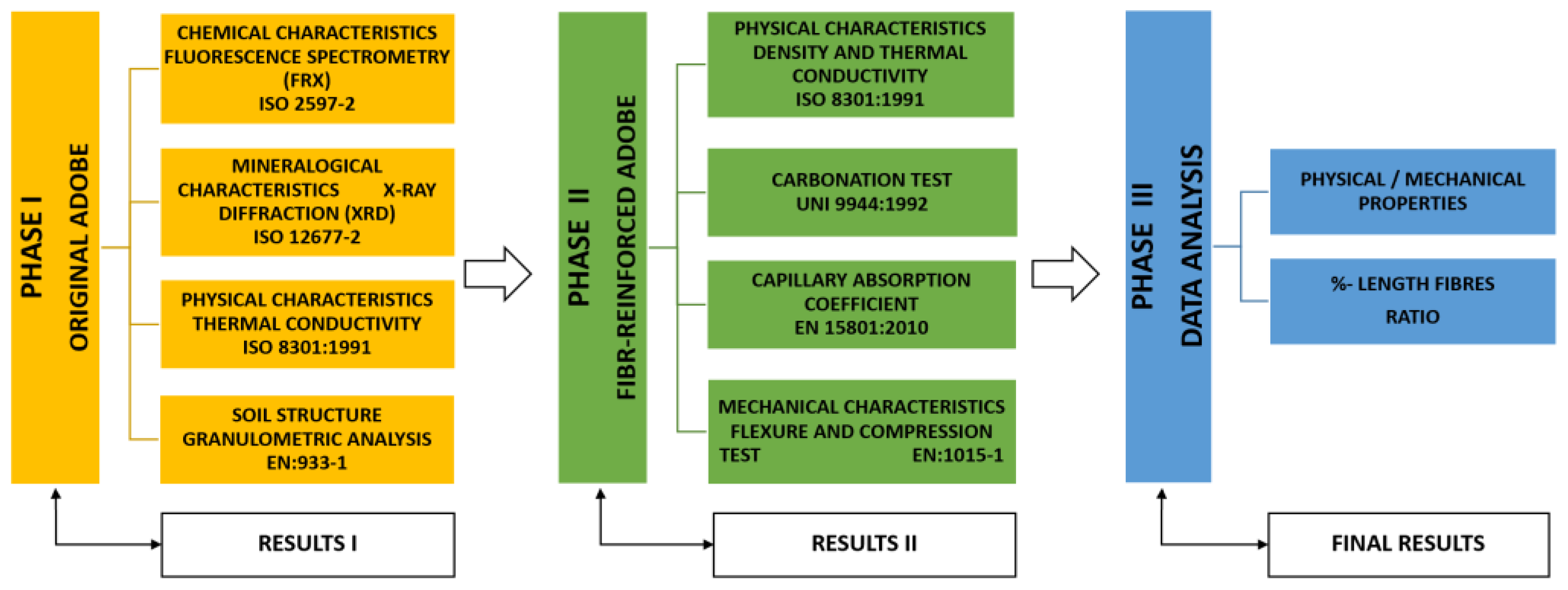

Work Methodology

3. Materials and Method

3.1. Phase I: Characterisation of Original Adobe

3.1.1. X-ray Diffraction (XRD) and Fluorescence Spectrometry (FRX)

3.1.2. Assessment of Aggregate Properties

3.1.3. Determination of the Insoluble Residue in HCl, Capillary Absorption, and Density of the Material

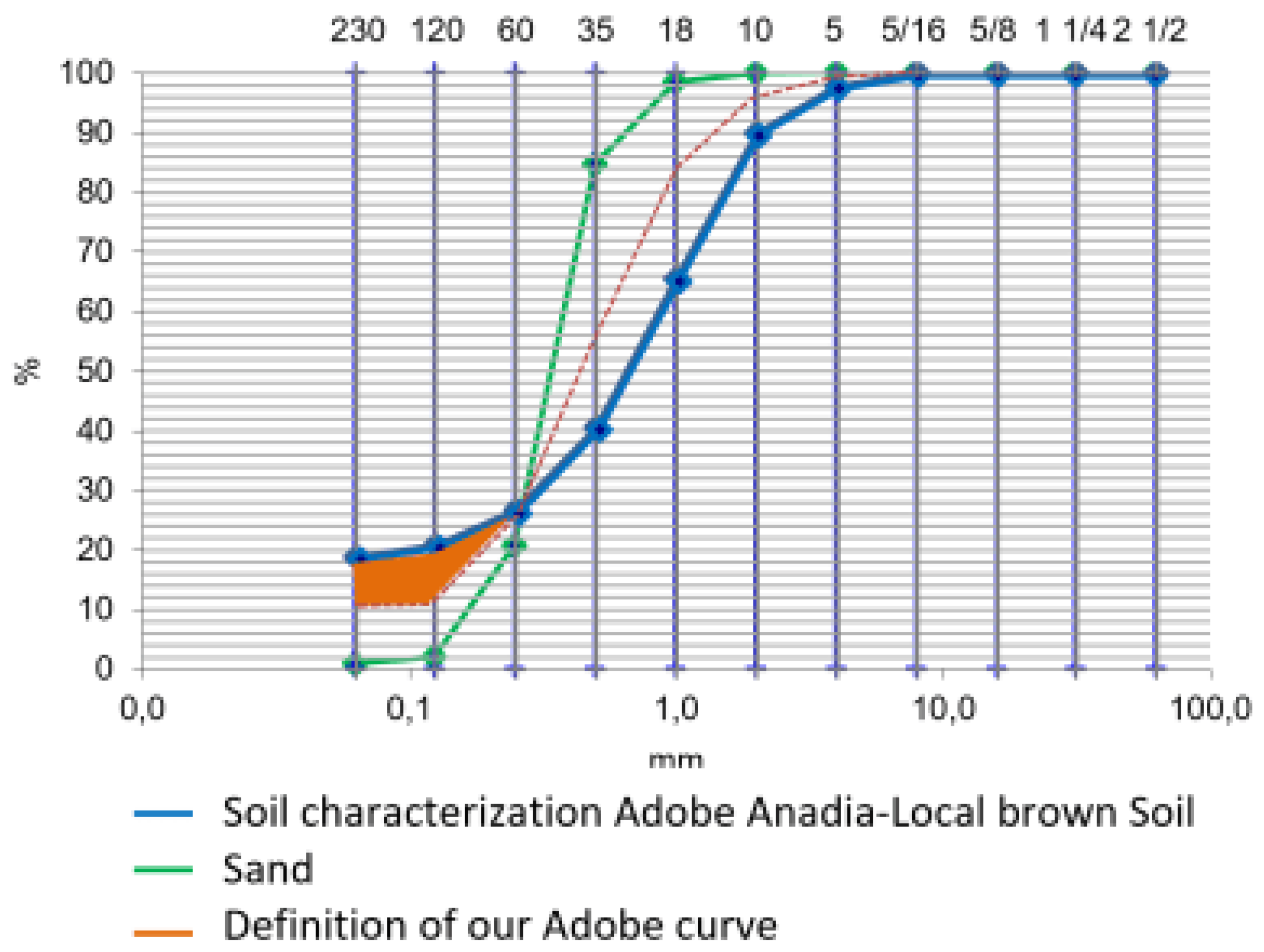

3.1.4. Particle Size Analysis

3.1.5. Thermal Conductivity

3.2. Phase 2: Fibre-Reinforced Adobes—Production and Characterisation

3.2.1. Production of Adobe with Fibres

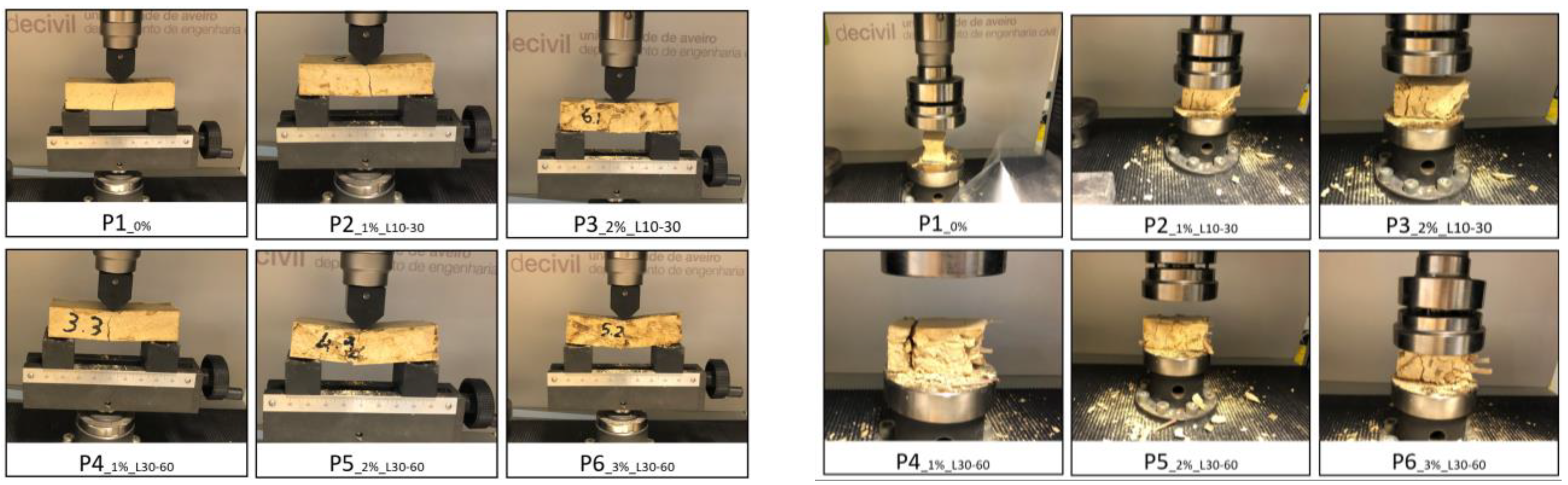

3.2.2. Physical and Mechanical Characterisation

3.2.3. Carbonation Test and Capillary Absorption Coefficient

4. Results and Use

4.1. Results for Characterication Results on Original Adobe and then Section

4.1.1. X-ray Diffraction (XRD) and X-ray Fluorescence Spectrometry (FRX)

4.1.2. Determination of the Residue Insoluble in HCl, Capillary Absorption Density, and Conductivity of the Original Adobe

4.1.3. Assessment of Aggregate Properties: Granulometric Analysis

4.2. Characterisation of Fibre-Containing Adobes

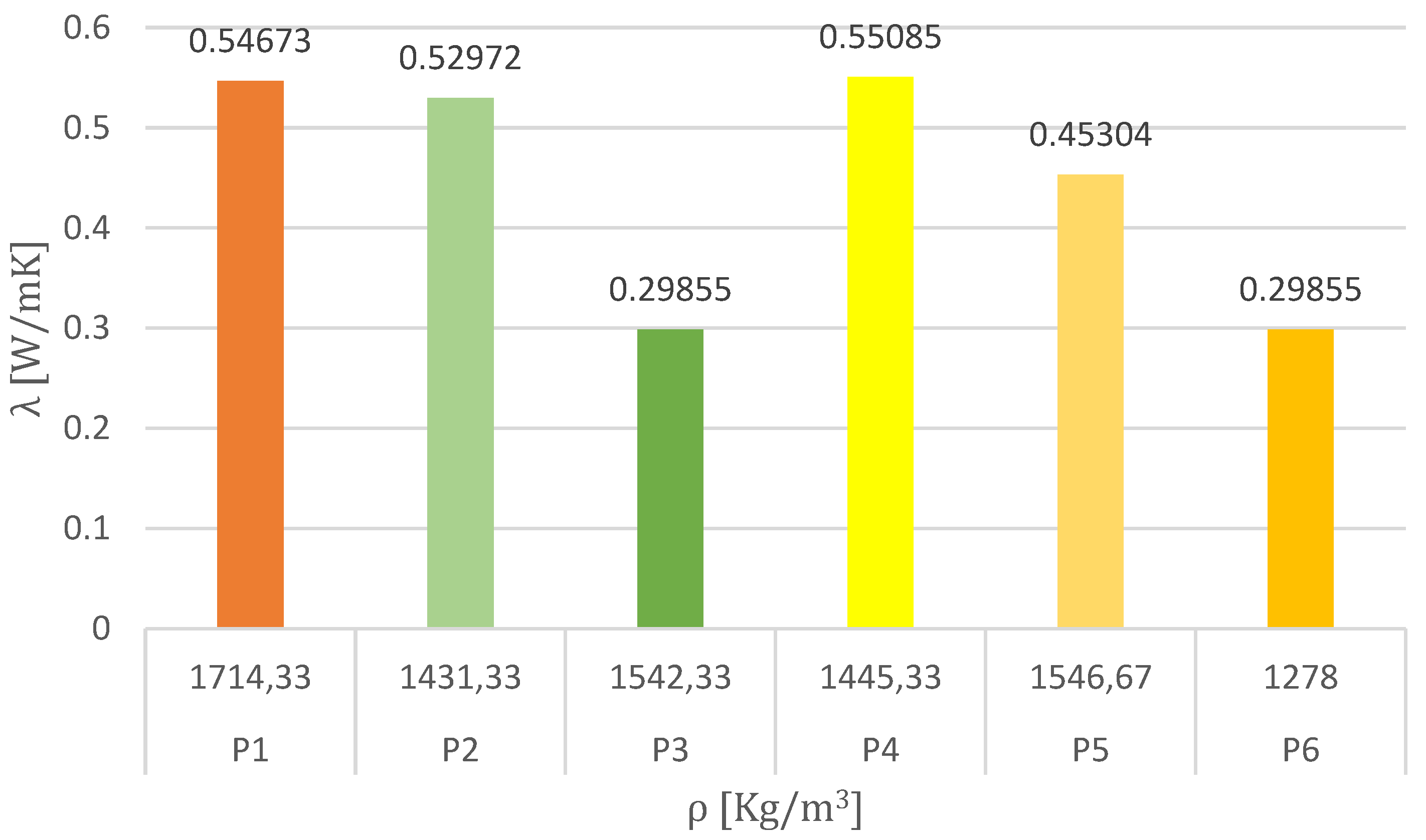

4.2.1. Physical Properties: Density and Thermal Conductivity

4.2.2. Results Carbonation Test and Capillary Absorption Coefficient

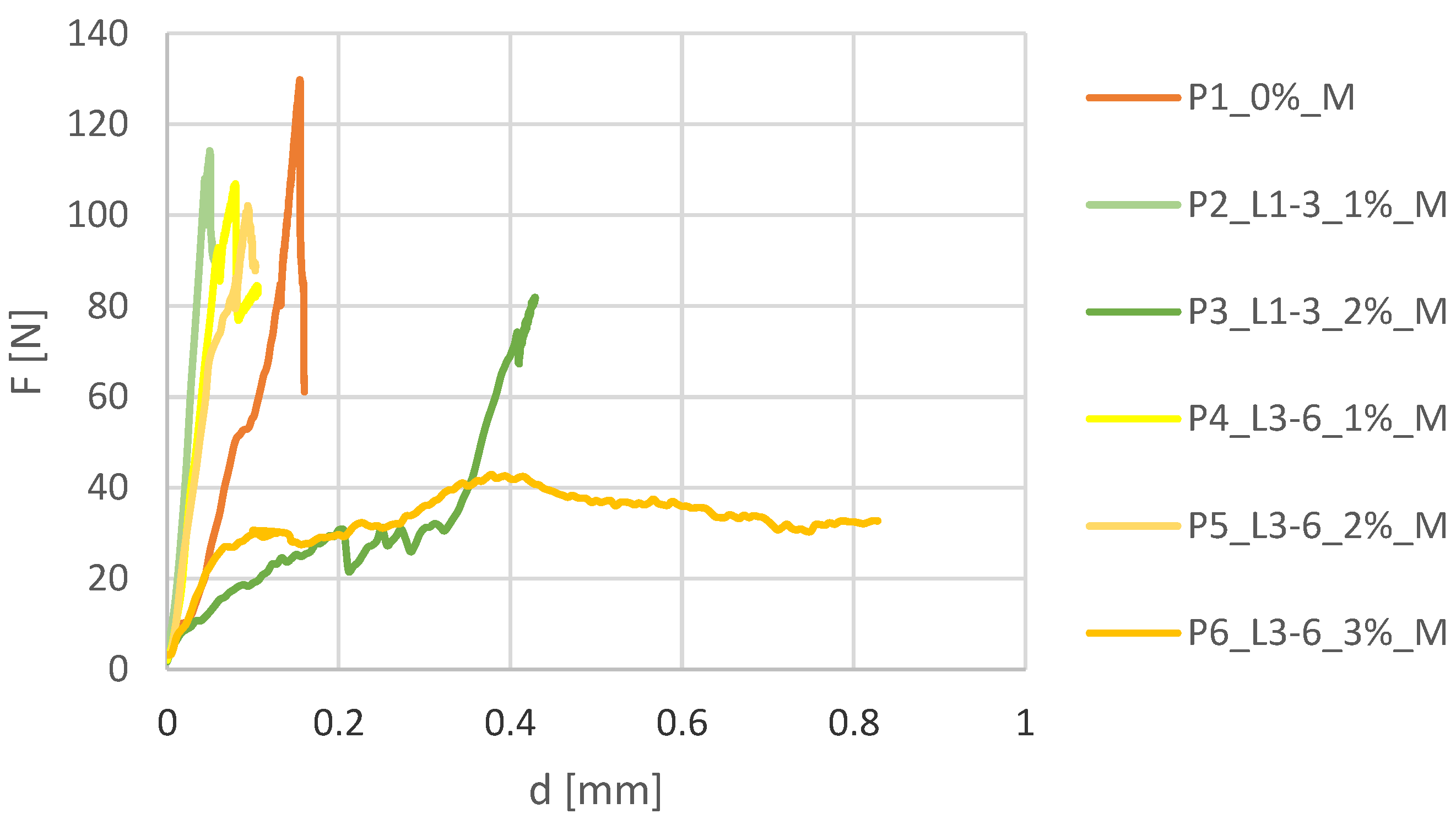

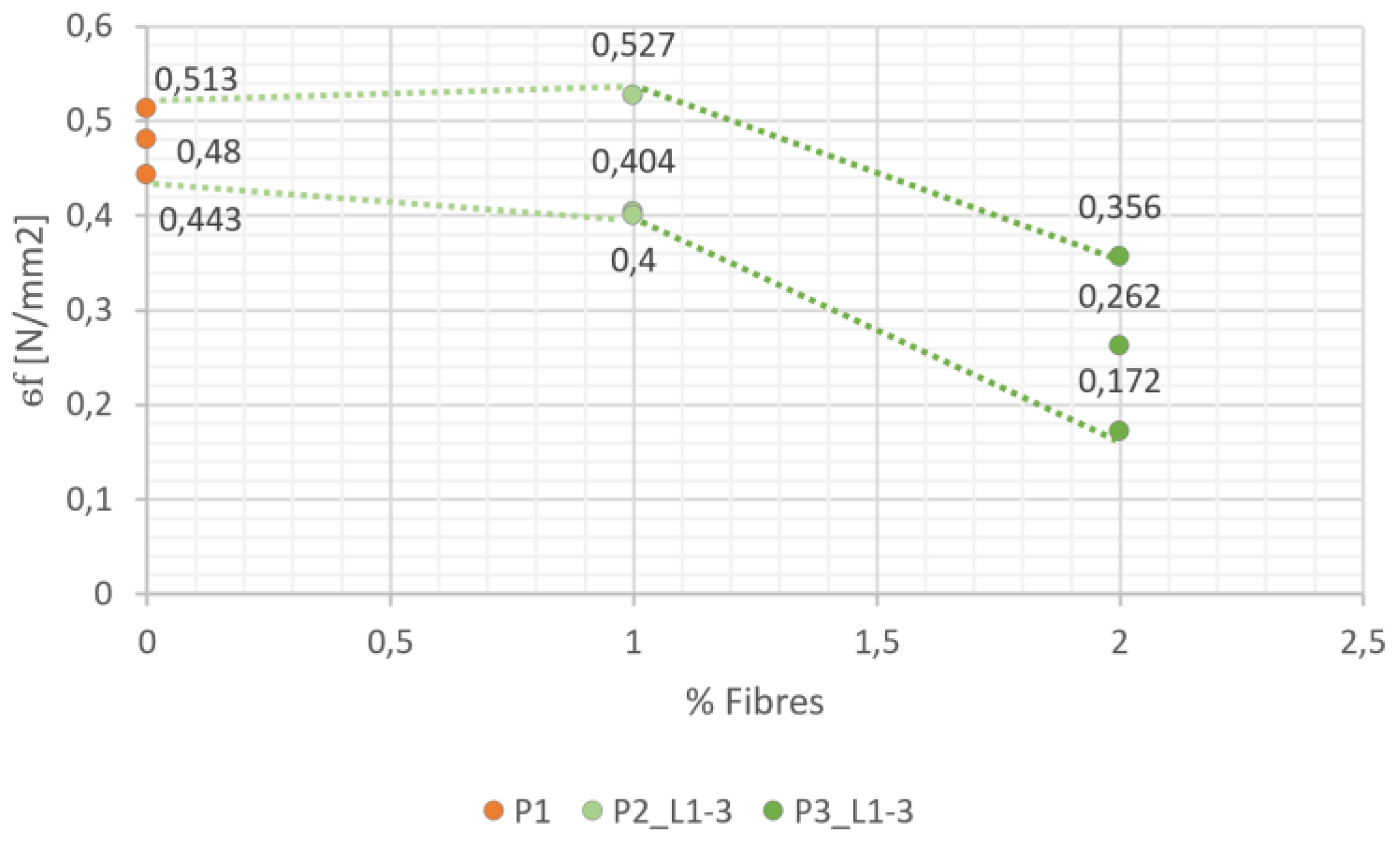

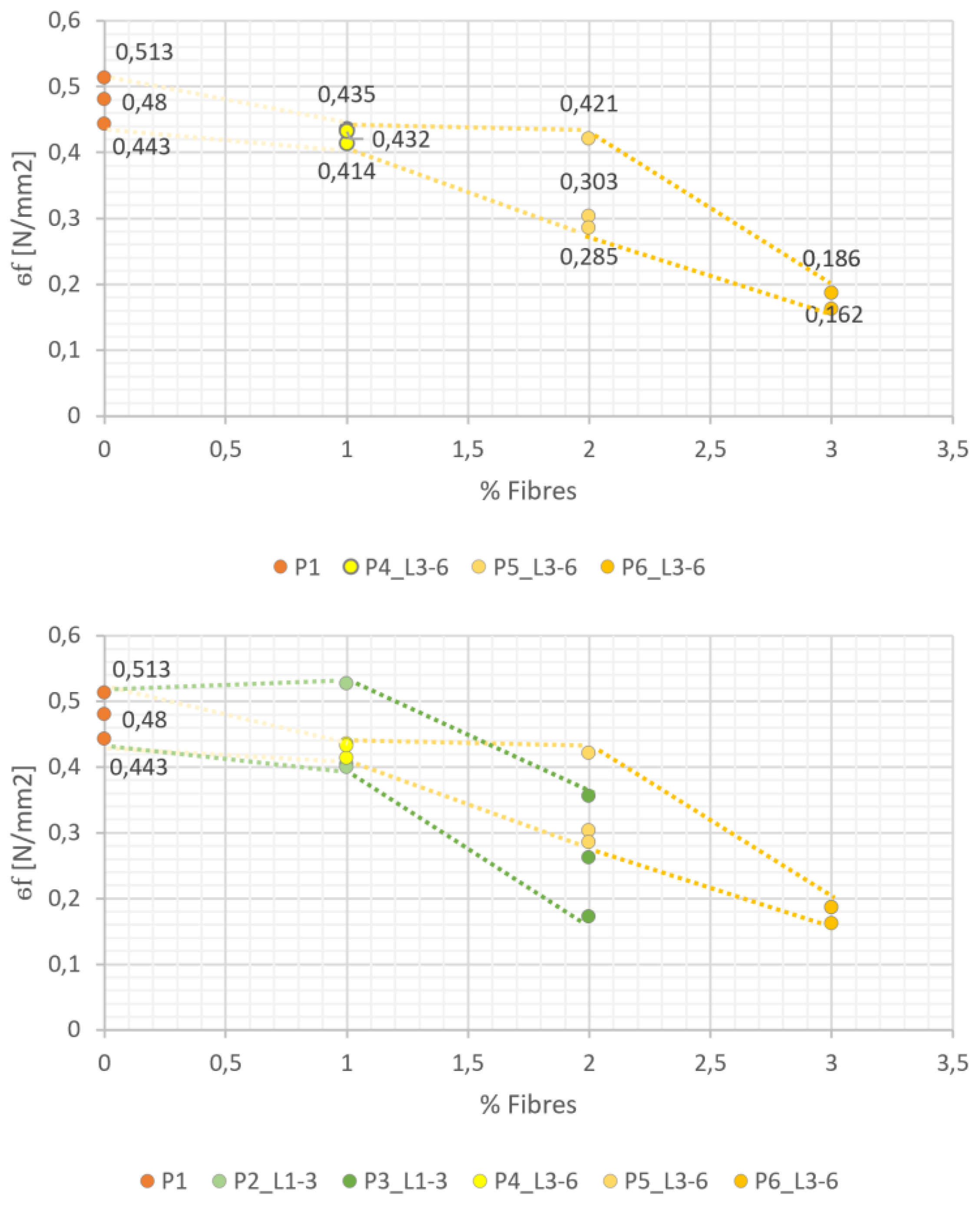

4.2.3. Mechanical Properties: Flexure

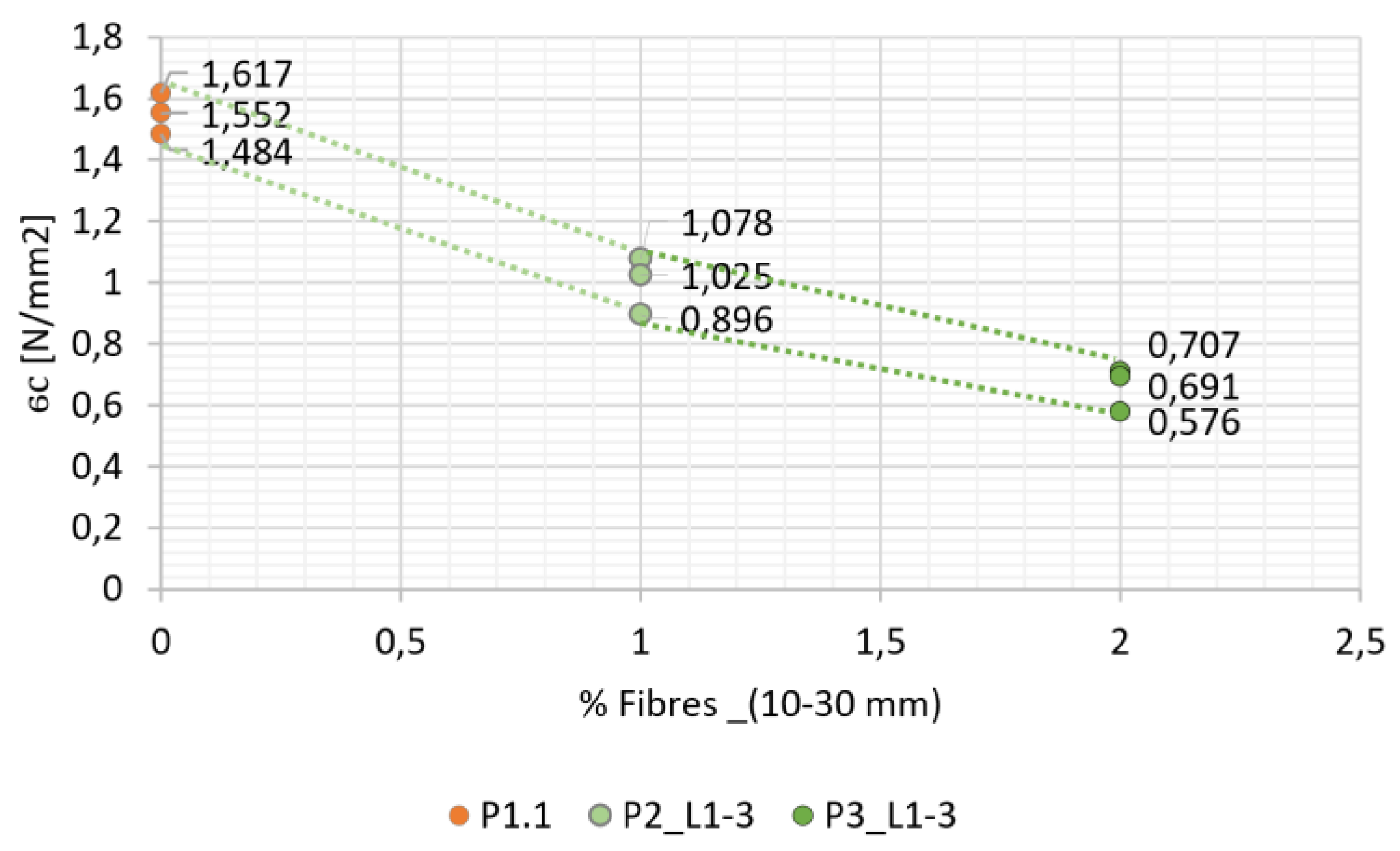

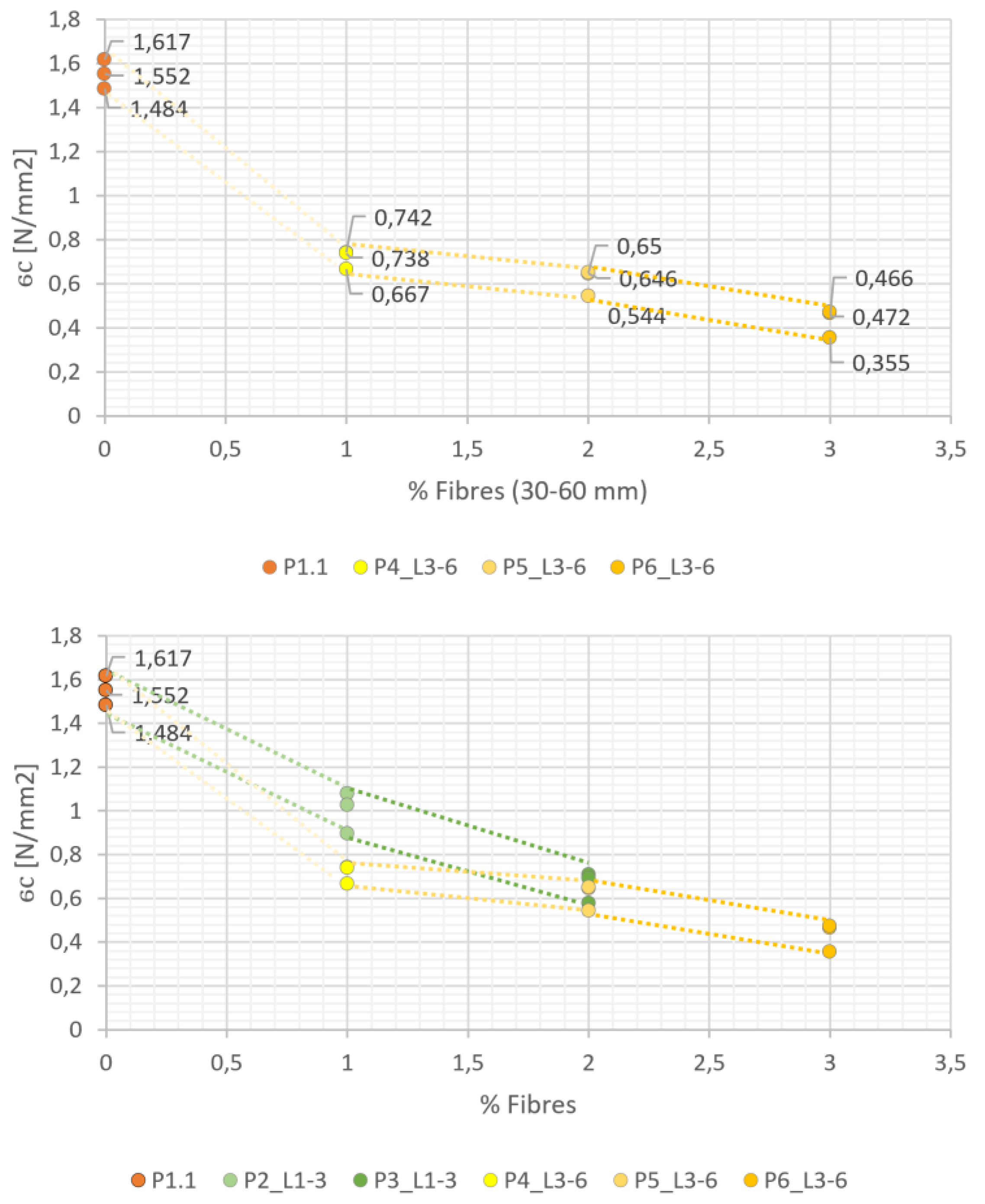

4.2.4. Mechanical Properties: Compression

4.2.5. Elasticity Module

5. Discussion of Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Adobe Sample | Acronym | Fibres % | Fmax (σc) [N] | σc [MPa] | Fmax (σf) [N] | σf [MPa] |

|---|---|---|---|---|---|---|

| P1.1 | 2375.00 | 1.48 | 189.06 | 0.44 | ||

| P1* | P1.2 | 0 | 2484.38 | 1.55 | 219.06 | 0.51 |

| P1.3 | 2587.50 | 1.61 | 205 | 0.48 | ||

| Average | 2482.29 | 1.55 | 204.37 | 0.48 | ||

| Stand. Dev. | 106.26 | 0.06 | 15.01 | 0.03 | ||

| Variation | 0.04 | 0.04 | 0.07 | 0.07 | ||

| P2.1_L1-3 | 1725.00 | 1.07 | 225.00 | 0.52 | ||

| P2 | P2.2_L1-3 | 1 | 164.63 | 1.02 | 172.50 | 0.40 |

| P2.3_L1-3 | 1434.38 | 0.89 | 170.94 | 0.40 | ||

| Media | 1600.00 | 1.00 | 189.48 | 0.44 | ||

| Stand. Dev. | 149.51 | 0.09 | 30.77 | 0.07 | ||

| Variation | 0.09 | 0.09 | 1.16 | 0.16 | ||

| P3.1_L1-3 | 921.87 | 0.57 | 152.18 | 0.35 | ||

| P3 | P3.2_L1-3 | 2 | 1131.25 | 0.70 | 111.87 | 0.26 |

| P3.3_L1-3 | 1106.25 | 0.69 | 73.43 | 0.17 | ||

| Media | 1053.13 | 0.65 | 112.50 | 0.26 | ||

| Stand. Dev. | 114.35 | 0.071 | 39.37 | 0.09 | ||

| Variation | 0.11 | 0.11 | 0.35 | 0.35 | ||

| P4.1_L3-6 | 1068.75 | 0.66 | 176.87 | 0.41 | ||

| P4 | P4.2_L3-6 | 1 | 1187.50 | 0.74 | 185.94 | 0.43 |

| P4.3_L3-6 | 1181.25 | 0.73 | 184.68 | 0.43 | ||

| Media | 1145.83 | 0.71 | 182.50 | 0.42 | ||

| Stand. Dev. | 66.83 | 0.04 | 4.91 | 0.01 | ||

| Variation | 0.058 | 0.06 | 0.02 | 0.027 | ||

| P5.1_L3-6 | 1034.38 | 0.64 | 129.37 | 0.30 | ||

| P5 | P5.2_L3-6 | 2 | 1040.63 | 0.65 | 179.68 | 0.42 |

| P5.3_L3-6 ** | 871.87 | 0.54 | 121.87 | 0.28 | ||

| Media | 982.29 | 0.59 | 143.64 | 0.33 | ||

| Stand. Dev. | 95.67 | 0.09 | 31.43 | 0.07 | ||

| Variation | 0.09 | 0.09 | 0.21 | 0.21 | ||

| P6.1_L3-6 | 568.75 | 0.35 | 79.37 | 0.18 | ||

| P6 | P6.2_L3-6 | 3 | 746.87 | 0.46 | 79.68 | 0.18 |

| P6.3_L3-6 | 576.25 | 0.47 | 69.37 | 0.16 | ||

| Media | 690.62 | 0.43 | 76.14 | 0.17 | ||

| Stand. Dev. | 105.65 | 0.06 | 5.86 | 0.01 | ||

| Variation | 0.15 | 0.15 | 0.07 | 0.07 | ||

| Media | 1315.70 | 0.82 | 151.44 | 0.35 | ||

| Stand. Dev. | 607.09 | 0.37 | 51.40 | 0.12 | ||

| Variation | 0.45 | 0.45 | 0.34 | 0.34 |

References

- International Energy Agency. Available online: http://www.iea.org/ (accessed on 20 July 2023).

- Piaia, E.; Turillazzi, B.; Di Giulio, R.; Sebastian, R. Advancing the Decarbonization of the Construction Sector: Lifecycle Quality and Performance Assurance of Nearly Zero-Energy Buildings. Sustainability 2024, 16, 3687. [Google Scholar] [CrossRef]

- MacDougall, C. Natural building materials in mainstream construction: Lessons from the UK. J. Green Build. 2008, 3, 1–14. [Google Scholar] [CrossRef]

- Beckett, C.; Jaquin, P.A.; Morel, J.C. Weathering the storm: A framework to assess the resistance of earthen structures to water damage. Constr. Build. Mater. 2020, 242, 118098. [Google Scholar] [CrossRef]

- Schroeder, H. Sustainable Building with Earth; Springer: Cham, Switzerland, 2016; Volume 582. [Google Scholar]

- Moriset, S.; Rakotomamonjy, B.; Gandreau, D. Can earthen architectural heritage save us? Built Herit. 2021, 5, 19. [Google Scholar] [CrossRef]

- Pinto, R. Génese e Evolução dos Solos; Universidade Técnica de Lisboa, lnstituto Supàrior de Agronomia, Departamento de Giências do Ambiente: Lisboa, Portugal, 1969; pp. 15–16. [Google Scholar]

- Rua, M.H. Os dez Livros de Arquitectura de Vitrúvio; Edição ICIST: Kaunas, Lithuania, 1998; pp. 535–538. [Google Scholar]

- Adam, J.P.; Guidobaldi, M.P.; Torelli, M.; Torelli, M. L’arte di Costruire Presso i Romani: Materiali e Tecniche; Longanesi: Milan, Italy, 1988. [Google Scholar]

- Motta, M. Construções Rurais em Alvenaria de Terra Crua no Baixo Alentejo; Universidade Técnica de Lisboa, Instituto Superior Técnico: Lisboa, Portugal, 1997. [Google Scholar]

- Shukla, A.; Tiwari, G.N.; Sodha, M.S. Embodied energy analysis of adobe house. Renew. Energy 2009, 34, 755–761. [Google Scholar] [CrossRef]

- Lima, J.; Faria, P.; Santos Silva, A. Earth plasters: The influence of clay mineralogy in the plasters’ properties. Int. J. Archit. Herit. 2020, 14, 948–963. [Google Scholar] [CrossRef]

- Fabbri, A.; McGregor, F.; Costa, I.; Faria, P. Correction to: Effect of temperature on the sorption curves of earthen materials. Mater. Struct. 2019, 52, 24. [Google Scholar] [CrossRef]

- Silva, A.; Oliveira, I.; Silva, V.; Mirão, J.; Faria, P. Vernacular Caramel’ s Adobe Masonry Dwellings–Material Characterization. Int. J. Archit. Herit. 2022, 16, 67–84. [Google Scholar] [CrossRef]

- Sposito, S.; Scalisi, F. Sustainable architecture: The eco-efficiency earth construction. Eur. J. Sustain. Dev. 2017, 6, 246. [Google Scholar]

- Olacia, E.; Pisello, A.L.; Chiodo, V.; Maisano, S.; Frazzica, A.; Cabeza, L.F. Sustainable adobe bricks with seagrass fibres. Mechanical and thermal properties characterization. Constr. Build. Mater. 2020, 239, 117669. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Nivetha, C.; Kumar, P.D.; Saravanan, B.; Gogulnath, V. Green composite form of eco–friendly concrete by adding PVA fiber. J. Green Eng. (JGE) 2020, 10, 3084–3101. [Google Scholar]

- Papayianni, I.; Pachta, V. Earth block houses of historic centers. A sustainable upgrading with compatible repair materials. Procedia Environ. Sci. 2017, 38, 274–282. [Google Scholar] [CrossRef]

- Rafi, M.M.; Varum, H. Seismic performance of adobe construction. Sustain. Resilient Infrastruct. 2017, 2, 8–21. [Google Scholar] [CrossRef]

- Galindo, A.L.; Ruiz, J.T.; Lopez, J.G. Mineral quantification in sepiolite-palygorskite deposits using X-ray diffraction and chemical data. Clay Miner. 1996, 31, 217–224. [Google Scholar] [CrossRef]

- Millogo, Y.; Hajjaji, M.; Ouedraogo, R. Microstructure and physical properties of lime-clayey adobe bricks. Constr. Build. Mater. 2008, 22, 2386–2392. [Google Scholar] [CrossRef]

- Gokulnath, V.; Vijayan, D.S.; Kathirvel, P.; Karthikraja, S.; Saravanan, B. Behaviour of retro fitted beams using natural fibers. Mater. Today Proc. 2020, 33, 949–953. [Google Scholar] [CrossRef]

- Millogo, Y.; Morel, J.C.; Aubert, J.E.; Ghavami, K. Experimental analysis of Pressed Adobe Blocks reinforced with Hibiscus cannabinus fibers. Constr. Build. Mater. 2014, 52, 71–78. [Google Scholar] [CrossRef]

- Segetin, M.; Jayaraman, K.; Xu, X. Harakeke reinforcement of soil–cement building materials: Manufacturability and properties. Build. Environ. 2007, 42, 3066–3079. [Google Scholar] [CrossRef]

- Regione Piemonte L.R. 2/06, Norme per la valorizzazione delle costruzioni in terra cruda. 2006. BUR Piemonte, 3. Available online: https://www.gazzettaufficiale.it/atto/regioni/caricaDettaglioAtto/originario?atto.dataPubblicazioneGazzetta=2007-06-30&atto.codiceRedazionale=006R0449 (accessed on 28 July 2023).

- Gazzetta Ufficiale Italiana, n. 378 Legge 24 Diciembre 2003, Disposizioni per la tutela e la valorizzazione dell’architettura rurale. 2004. Available online: https://www.gazzettaufficiale.it/atto/serie_generale/caricaDettaglioAtto/originario?atto.dataPubblicazioneGazzetta=2004-01-17&atto.codiceRedazionale=004G0014&elenco30giorni=false (accessed on 28 July 2023).

- New Mexico Earthen Building Materials Code; GCB-NMBC-14.7.4 (2006); Regulation & Licensing Department, Construction Industries Division, Construction Industries Bureau: Santa Fe, NM, USA, 2006.

- AS 4773.2-2015; Masonry in Small Buildings Construction. Standards Australia Limited: Sydney, Australia, 2015. Available online: https://store.standards.org.au/product/as-4773-2-2015 (accessed on 28 July 2023).

- AS 3700-2018; Masonry Structures. Standards Australia: Sydney, Australia, 2018. Available online: https://wabuildinginspections.com.au/wp-content/uploads/AS3700%202018%20Masonry%20Structures.pdf (accessed on 28 July 2023).

- TS 2514; Production and Usage of Adobe Bricks. Turkish Standards Institution: Ankara, Türkiye, 1997.

- Larsen, K.E. (Ed.) Nara Conference on Authenticity in relation to the World Heritage Convention, Nara, Japan, 1–6 November 1994. Available online: https://whc.unesco.org/archive/nara94.htm (accessed on 30 July 2023).

- Saxton, R.H. Performance of cob as a building material. Struct. Eng. 1995, 73, 111–115. [Google Scholar]

- Varum, H.; Costa, A.; Velosa, A.; Martins, T.; Pereira, H.; Almeida, J. Caracterização mecânica e patológica das construções em Adobe no distrito de Aveiro como suporte em intervenções de reabilitação. Proj. Cult. 2000, 41–45. Available online: https://ria.ua.pt/bitstream/10773/7799/1/I_027.pdf (accessed on 28 June 2023).

- Bruno, P.; Faria, P. Earth mortars use on neolithic domestic structures. Some case studies in Alentejo, Portugal. Conserv. Património 2008, 5–12. Available online: https://www.redalyc.org/pdf/5136/513653433002.pdf (accessed on 2 July 2023).

- García y Bellido, A. Orígenes de la casa redonda de la cultura castreña del NO de la Península. 1971. Available online: https://www.castrosdeasturias.es/descargas/703-garcia-y-bellido-a.-1971.-revista-guimaraes-81-3-4-25-35.-origenes-casa-redonda-cultura-castrea-nw.pdf (accessed on 2 July 2023).

- Istituto National de Estatistica. Censos 2011. Available online: https://censos.ine.pt/ (accessed on 28 June 2023).

- Costa, C.; Arduin, D.; Rocha, F.; Velosa, A. Adobe blocks in the center of Portugal: Main characteristics. Int. J. Archit. Herit. 2021, 15, 467–478. [Google Scholar] [CrossRef]

- Fernandes, M. O adobe e as alvenarias de adobe em Portugal. erra em Seminário; Argumentum: Aveiro, Portugal, 2007; pp. 116–119. [Google Scholar]

- Dias, J. O problema da reconstitução das casas redondas castrejas. In Trabalhos de Antropologia e Etnologia; Instituto De Antropologia, Faculdade de Ciências: Porto, Portugal, 1948; Volume 12, Available online: https://ojs.letras.up.pt/index.php/tae/article/view/8572/7849 (accessed on 13 July 2023).

- Correia, M.; Carlos, G.; Rocha, S. (Eds.) Vernacular Heritage and Earthen Architecture; CRC Press: London, UK, 2013. [Google Scholar] [CrossRef]

- Silveira, D.; Varum, H.; Costa, A.; Lima, E. Levantamento e caracterização do parque edificado em adobe na cidade de Aveiro. digitAR-Revista Digital de Arqueologia. Arquit. Artes 2013. [Google Scholar] [CrossRef][Green Version]

- Tavares, A.; Costa, A.; Varum, H. Adobe and modernism in Ílhavo, Portugal. Int. J. Archit. Herit. 2012, 6, 525–541. [Google Scholar] [CrossRef]

- da Silveira, D.S.G. Constructive and Mechanical Characterisation of Adobe Masonry Walls of Existing Buildings. Doctoral Dissertation, Universidade de Aveiro, Aveiro, Portugal, 2016. [Google Scholar]

- da Costa, A.M.T.A. Integrated Conservation Strategy of Built Heritage. Doctoral Dissertation, Universidade de Aveiro, Aveiro, Portugal, 2015. [Google Scholar]

- Costa, C.; Cerqueira, Â.; Rocha, F.; Velosa, A. The sustainability of adobe construction: Past to future. Int. J. Archit. Herit. 2018, 13, 639–647. [Google Scholar] [CrossRef]

- Formisano, A.; Chiumiento, G. Physical-Mechanical Experimental Tests on Adobe Bricks Reinforced with Hemp Fibres. J. Archit. Constr. 2018, 1, 25–36. [Google Scholar]

- Ouedraogo, M.; Dao, K.; Millogo, Y.; Aubert, J.E.; Messan, A.; Seynou, M.; Zerbo, L.; Gomina, M. Physical, thermal and mechanical properties of adobes stabilized with fonio (Digitaria exilis) straw. J. Build. Eng. 2019, 23, 250–258. [Google Scholar] [CrossRef]

- Babé, C.; Kidmo, D.K.; Tom, A.; Mvondo, R.R.N.; Boum, R.B.E.; Djongyang, N. Thermomechanical characterization and durability of adobes reinforced with millet waste fibers (sorghum bicolor). Case Stud. Constr. Mater. 2020, 13, e00422. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Loganayagan, S.; Kowshika, G.; Ramprakash, C.; Aruneshwaran, M. Adobe blocks reinforced with natural fibres: A review. Mater. Today Proc. 2021, 45, 6493–6499. [Google Scholar] [CrossRef]

- Kim, C.; Shin, H.; Choi, H.K. A phenetic analysis of Typha in Korea and far east Russia. Aquat. Bot. 2003, 75, 33–43. [Google Scholar] [CrossRef]

- Müller-Sämann, K.M.; Reinhardt, G.; Vetter, R.; Gärtner, S. Nachwachsende Rohstoffe in Baden-Württemberg: Identifizierung vorteilhafter Produktlinien zur stofflichen Nutzung unter besonderer Berücksichtigung umweltgerechter Anbauverfahren. Projektabschluss-bericht Forschungszentrum Karlsruhe IfUL Müllheim. 2003. Available online: https://pudi.lubw.de/detailseite/-/publication/28764-Nachwachsende_Rohstoffe_in_Baden-W%C3%BCrttemberg__Identifizierung_vorteilhafter_Produktlinien_zur_stoffl.pdf (accessed on 20 July 2023).

- Niang, I.; Maalouf, C.; Moussa, T.; Bliard, C.; Samin, E.; Thomachot-Schneider, C.; Lachi, M.; Pron, H.; Mai, T.H.; Gaye, S. Hygrothermal performance of various Typha–clay composite. J. Build. Phys. 2018, 42, 316–335. [Google Scholar] [CrossRef]

- ISO 2597-2:2019; Iron Ores—Determination of Total Iron Content. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 12677:2011; Chemical Analysis of Refractory Products by X-ray Fluorescence (XRF)—Fused Cast-Bead Method. International Organization for Standardization: Geneva, Switzerland, 2011.

- ISO 8301:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991.

- CEN EN 933-1:2012; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. European Committee for Standardization: Brussels, Belgium, 2012.

- UNI 9944:1992; Corrosion and Protection of Concrete Reinforcement. Determination of Carbonation Depth and Chloride Ion Penetration Profile in Concrete. Italian Standards Authority: Milan, Italy, 1992.

- UNI EN 15801:2010; Conservation of Cultural Property—Test Methods—Determination of Water Absorption by Capillarity. Italian Standards Authority: Milan, Italy, 2010.

- EN:1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 2020.

- ISO 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories. International Organization for Standardization: Geneva, Switzerland, 2017.

- Comina, C.; Lancellotta, R.; Foti, S.; Musso, G. Tomografie elettriche su campioni di laboratorio. In Proceedings of the IARG Incontro Annuale dei Ricercatori di Geotecnica, Trento, Italy, 7–9 July 2004. [Google Scholar]

- BS EN 932-2; Tests for General Properties of Aggregates, Part 2: Methods for Reducing Laboratory Samples. British Standard Institution: London, UK, 1999.

- Quagliarini, E.; Lenci, S. The influence of natural stabilizers and natural fibres on the mechanical properties of ancient Roman adobe bricks. J. Cult. Herit. 2010, 11, 309–314. [Google Scholar] [CrossRef]

- Diatta, M.T.; Gaye, S.; Thiam, A.; Azilinon, D. Détermination des propriétés thermo-physique et mécanique du typha australis. In Proceedings of the Congres SFT, Perpignan, France, 24–27 May 2011. [Google Scholar]

- Dieye, Y.; Sambou, V.; Faye, M.; Thiam, A.; Adj, M.; Azilinon, D. Thermo-mechanical characterization of a building material based on Typha Australis. J. Build. Eng. 2017, 9, 142–146. [Google Scholar] [CrossRef]

- Maddison, M.; Mauring, T.; Kirsimäe, K.; Mander, Ü. The humidity buffer capacity of clay–sand plaster filled with phytomass from treatment wetlands. Build. Environ. 2009, 44, 1864–1868. [Google Scholar] [CrossRef]

- Ba, L.; El Abbassi, I.; Ngo, T.T.; Pliya, P.; Kane CS, E.; Darcherif, A.M.; Ndongo, M. Investigation of the length and percentage fiber influence of Typha Australis on biosourced composites. In Proceedings of the E3S Web of Conferences, Pekanbaru, Indonesia, 26 November 2021; EDP Sciences: Les Ulis, France, 2022; Volume 353, p. 01002. [Google Scholar]

- Achenza, M.; Atzeni, C.; Mocci, S.; Sanna, U. Il Manuale Tematico della Terra Cruda: Caratteri, Tecnologie, Buone Pratiche; Dei S.r.l.- Tipografia del Genio Civile: Milan, Italy, 2008; Available online: https://www.sardegnadigitallibrary.it/mmt/fullsize/2009022319494200003.pdf (accessed on 2 June 2023).

- Adobes! Porque não? Integração do adobe como processo construtivo na arquitectura contemporânea. 2017. Available online: https://repositorio-aberto.up.pt/handle/10216/121163 (accessed on 2 June 2023).

- EN 196-1:2005; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2005.

- BS EN 14630:2006; Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Determination of Carbonation Depth in Hardened Concrete by the Phenolphthalein Method. European Standard: Brussels, Belgium, 2007.

- RRUFF Sample Data. Database. Available online: https://rruff.info/al/display=default/ (accessed on 1 September 2023).

- Costa, L.R.R. Caracterização Física, Mineralógica e Mecânica de Adobes de Aveiro. Doctoral Dissertation, Universidade de Aveiro, Aveiro, Portugal, 2014. [Google Scholar]

- Capitolo 8: Chimica applicata, in Manuale prove e sperimentazioni. Istituto Sperimentale per l’Edilizia. 2002. Available online: https://istedil.it/manuale-prove-e-sperimentazioni (accessed on 18 September 2023).

- Charai, M.; Salhi, M.; Horma, O.; Mezrhab, A.; Karkri, M.; Amraqui, S. Thermal and mechanical characterization of adobes bio-sourced with Pennisetum setaceum fibers and an application for modern buildings. Constr. Build. Mater. 2022, 326, 126809. [Google Scholar] [CrossRef]

- Danso, H.; Martinson, D.B.; Ali, M.; Williams, J.B. Physical, mechanical and durability properties of soil building blocks reinforced with natural fibres. Constr. Build. Mater. 2015, 101, 797–809. [Google Scholar] [CrossRef]

- Khoudja, D.; Taallah, B.; Izemmouren, O.; Aggoun, S.; Herihiri, O.; Guettala, A. Mechanical and thermophysical properties of raw earth bricks incorporating date palm waste. Constr. Build. Mater. 2021, 270, 121824. [Google Scholar] [CrossRef]

| Initial Weight (50 g) | m (g) | C (g) | F (g) | Double Weighing (g) m + C | Insoluble Residue (%) |

|---|---|---|---|---|---|

| ma1 | m1 = 44.00 | C1 = 82.85 | F1 = 1.64 | 125.59–125.68 | 1 = 0.008 |

| ma2 | m2 = 48.31 | C2 = 78.34 | F2 = 1.60 | 125.92–129.83 | 2 = 0.009 |

| ma3 | m3 = 49.34 | C3 = 77.59 | F3 = 1.60 | 175.85–117.86 | 3 = 0.009 |

| Adobe Specimens Ref. | Fibres % | Fibre Length [cm] | Soil [kg] | Fine Sand 0.25 µ [kg] | Binder Ca (OH)2 [kg] | Ratio 4:1 (W/St) [kg] |

|---|---|---|---|---|---|---|

| P11 | 0 | 0 | constant value: 17.85 | constant value: 2.16 | constant value: 5 | constant value: 6 |

| P2.x_L1-3 | 1 | 1–3 | ||||

| P3.x_L1-3 | 2 | 1–3 | ||||

| P4.x_L3-6 | 1 | 3–6 | ||||

| P5.x_L3-6 | 2 | 3–6 | ||||

| P6.x_L3-6 | 3 | 3–6 |

| Adobe Sample | Fibres %-L | ρ [kg/m3] | λ [W/(mK)] | Fmax (σc) [N] | σc [MPa | Fmax (σf) [N] | σf [MPa] | |

|---|---|---|---|---|---|---|---|---|

| PHASE I | P0 | - | 1933.71 | 0.754 | ||||

| PHASE II | P1 | - | 1741.33 | 0.546 | 2482.29 | 1.55 | 204.37 | 0.48 |

| P2 | 1%-1–3 cm | 1431.33 | 0.529 | 1600.00 | 1.00 | 189.48 | 0.44 | |

| P3 | 2%-1–3 cm | 1542.33 | 0.298 | 1053.13 | 0.65 | 112.50 | 0.26 | |

| P4 | 1%-3–6 cm | 1445.33 | 0.550 | 1145.83 | 0.71 | 182.50 | 0.42 | |

| P5 | 2%-3–6 cm | 1546.67 | 0.453 | 982.29 | 0.59 | 143.64 | 0.33 | |

| P6 | 3%-3–6 cm | 1279.00 | 0.298 | 1315.70 | 0.82 | 151.44 | 0.35 | |

| PHASE III | Correlation between the properties resulting from the above tests. | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rocco, A.; Vicente, R.; Rodrigues, H.; Ferreira, V. Adobe Blocks Reinforced with Vegetal Fibres: Mechanical and Thermal Characterisation. Buildings 2024, 14, 2582. https://doi.org/10.3390/buildings14082582

Rocco A, Vicente R, Rodrigues H, Ferreira V. Adobe Blocks Reinforced with Vegetal Fibres: Mechanical and Thermal Characterisation. Buildings. 2024; 14(8):2582. https://doi.org/10.3390/buildings14082582

Chicago/Turabian StyleRocco, Angelica, Romeu Vicente, Hugo Rodrigues, and Victor Ferreira. 2024. "Adobe Blocks Reinforced with Vegetal Fibres: Mechanical and Thermal Characterisation" Buildings 14, no. 8: 2582. https://doi.org/10.3390/buildings14082582

APA StyleRocco, A., Vicente, R., Rodrigues, H., & Ferreira, V. (2024). Adobe Blocks Reinforced with Vegetal Fibres: Mechanical and Thermal Characterisation. Buildings, 14(8), 2582. https://doi.org/10.3390/buildings14082582