Seismic Behavior of Composite Columns with High-Strength Concrete-Filled Steel Tube Flanges and Honeycomb Steel Webs Subjected to Freeze-Thaw Cycles

Abstract

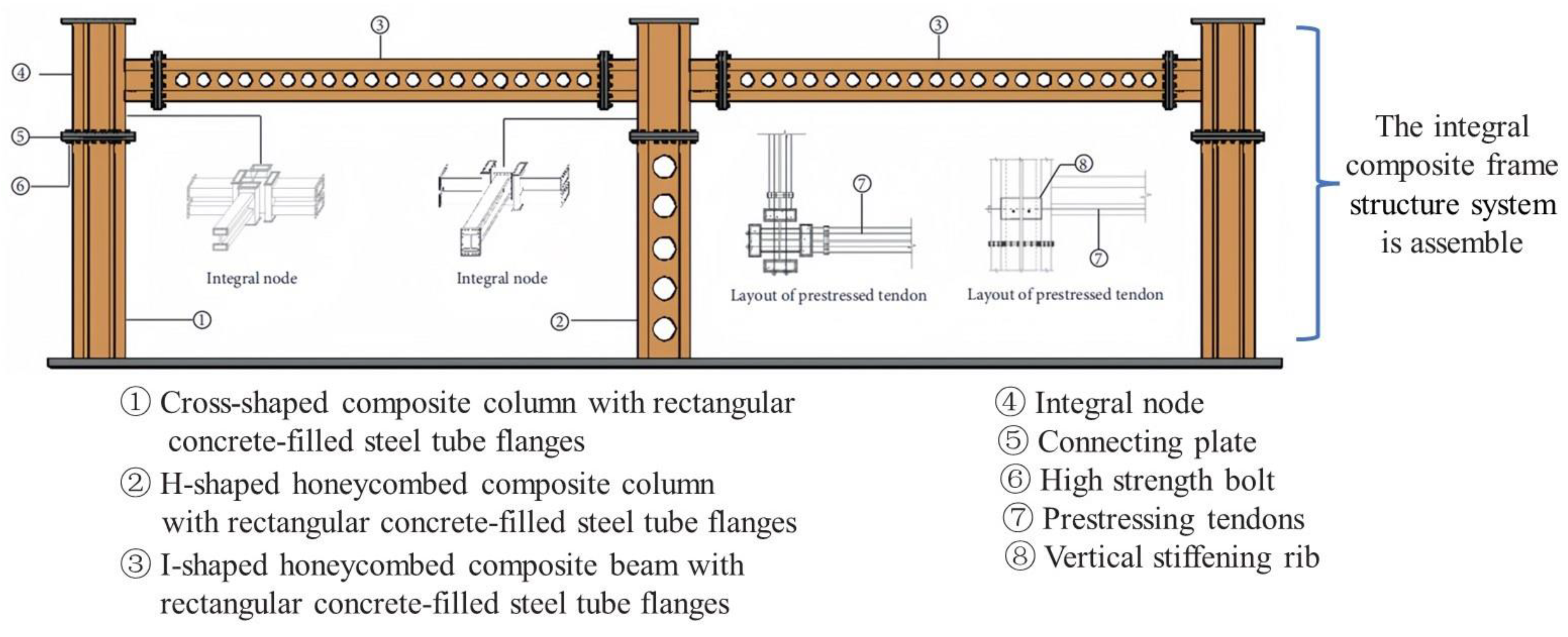

:1. Introduction

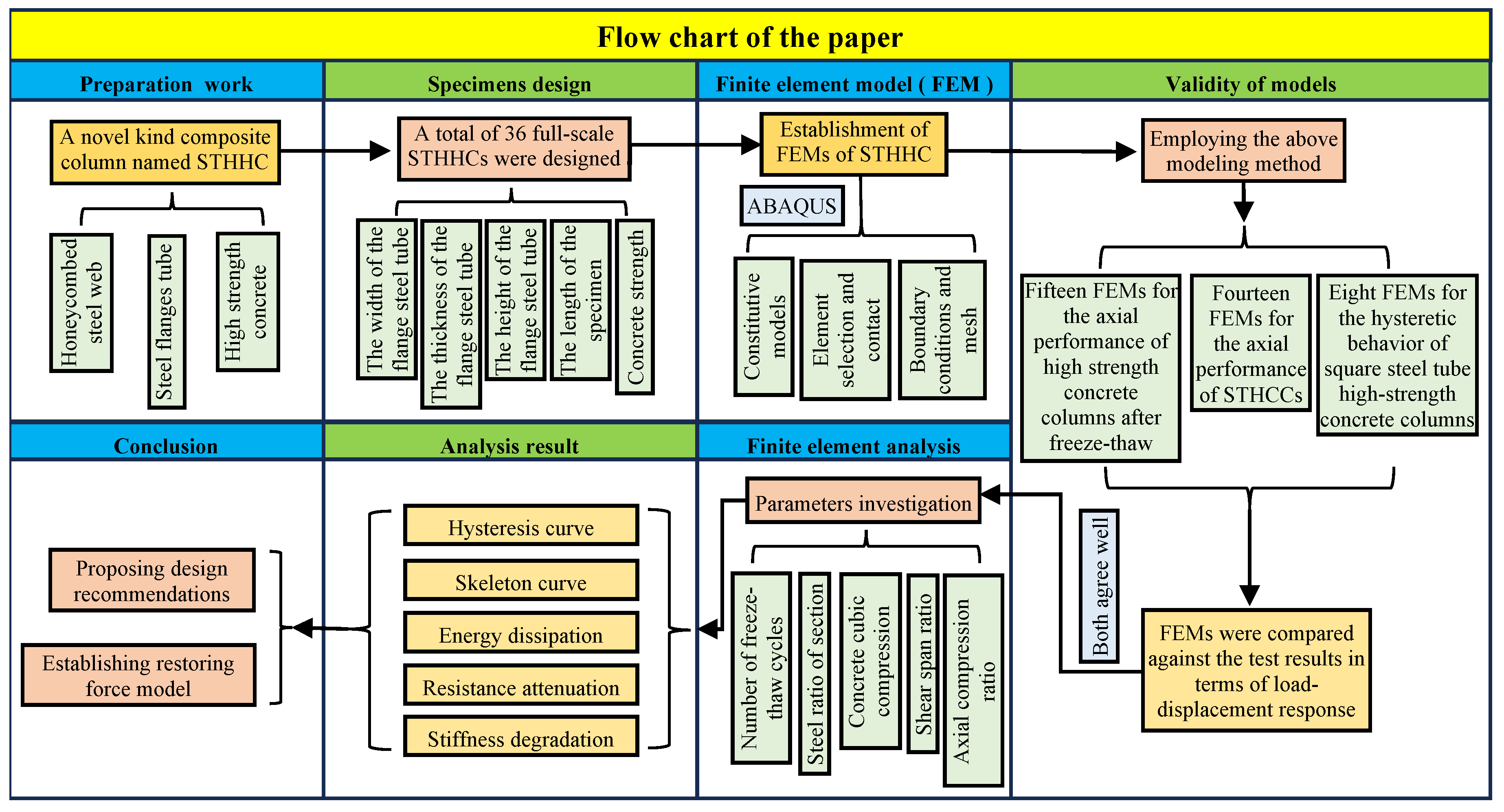

2. Analysis Process of the Paper

3. Specimen Design

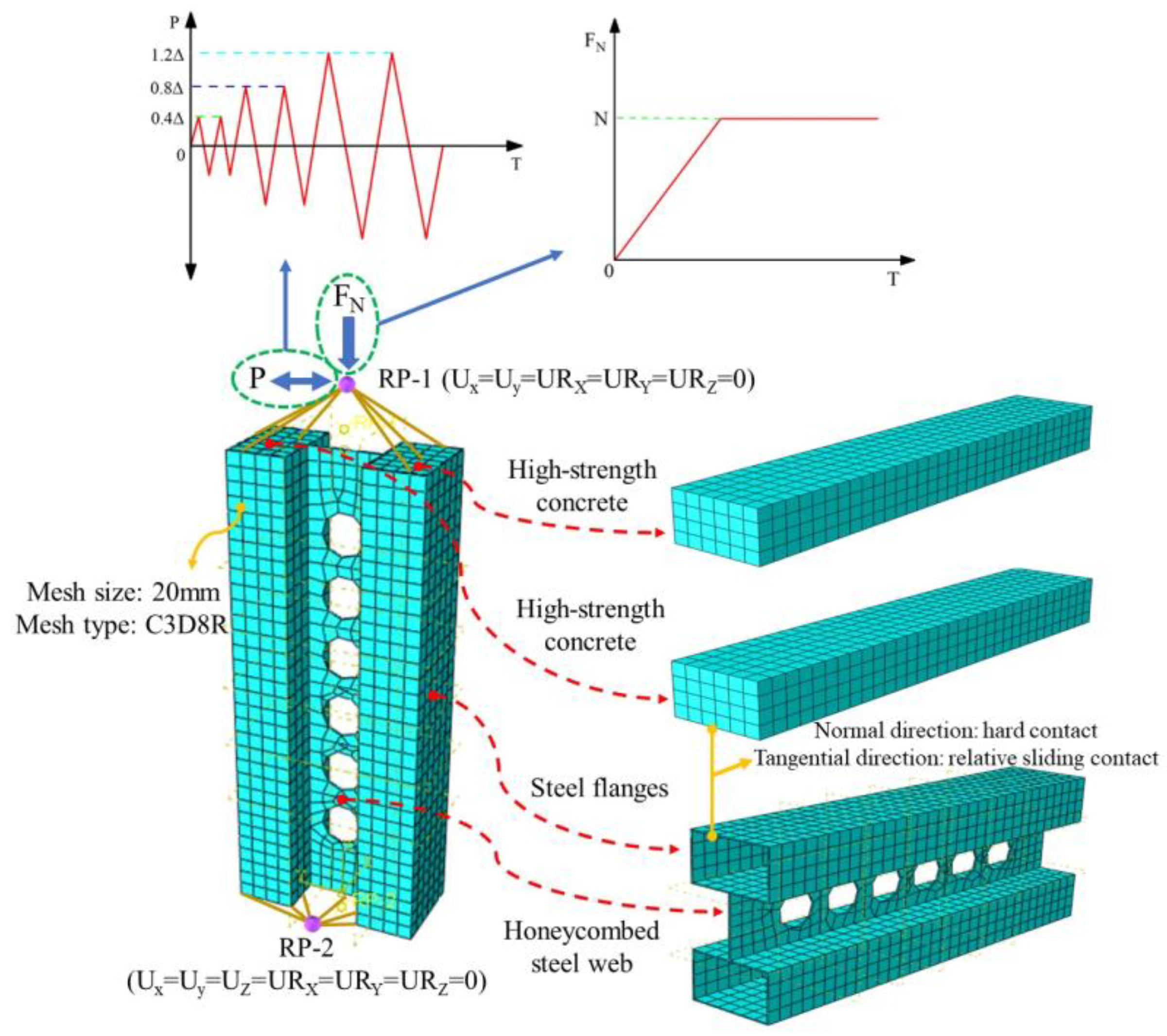

4. Finite Element Model (FEM)

4.1. Constitutive Models of Materials

- (1)

- The compression analysis stress-strain relationship expression is as follows:

- (2)

- The tensile stress-strain relationship formulation is as follows:

4.2. The Establishment of FEM

4.2.1. The Selection of Element and Contact

4.2.2. Boundary Conditions and Loading

4.2.3. Grid Division

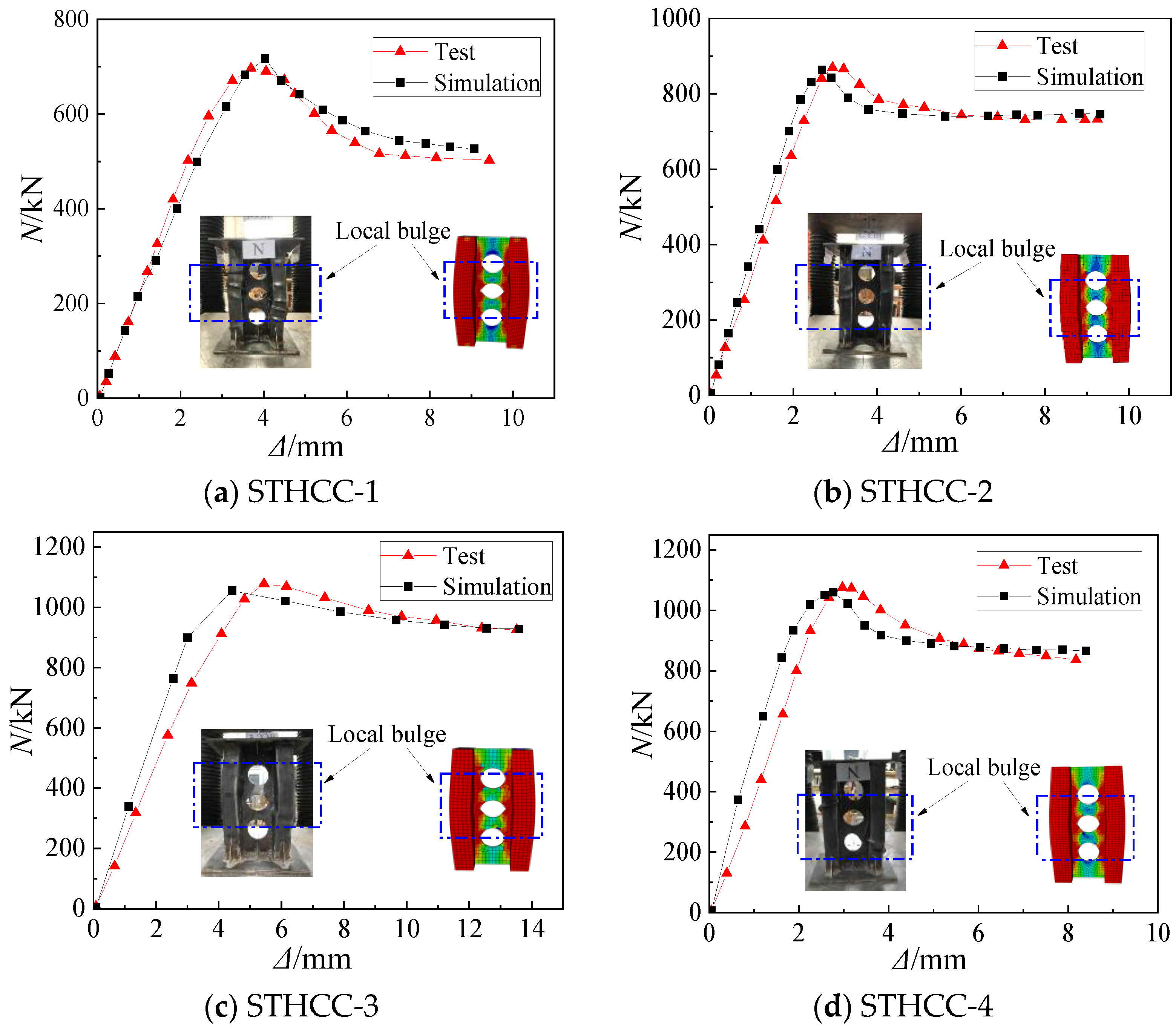

4.3. Experimental Verification of Finite Element Models

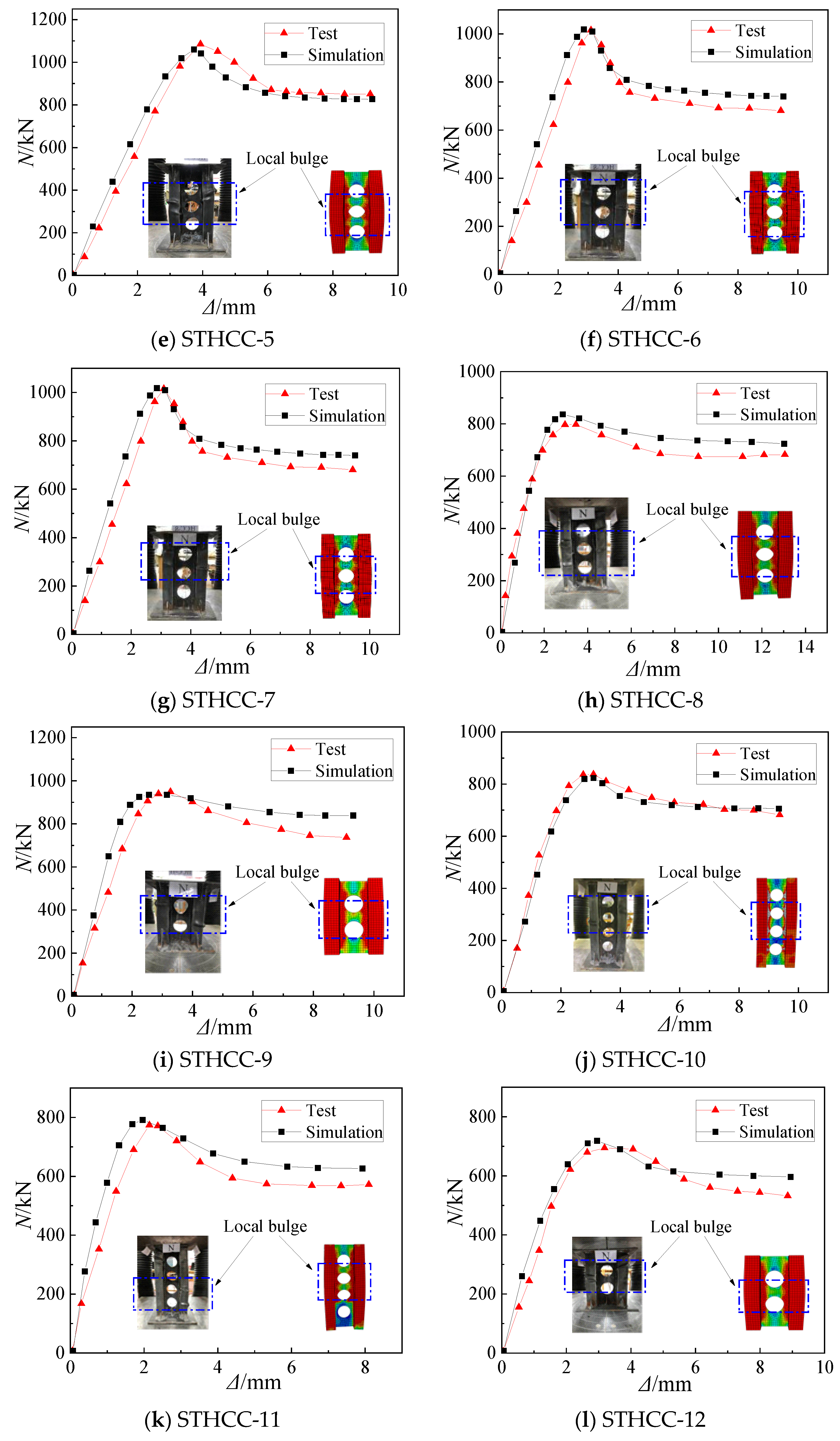

4.3.1. STHCC Model Validation

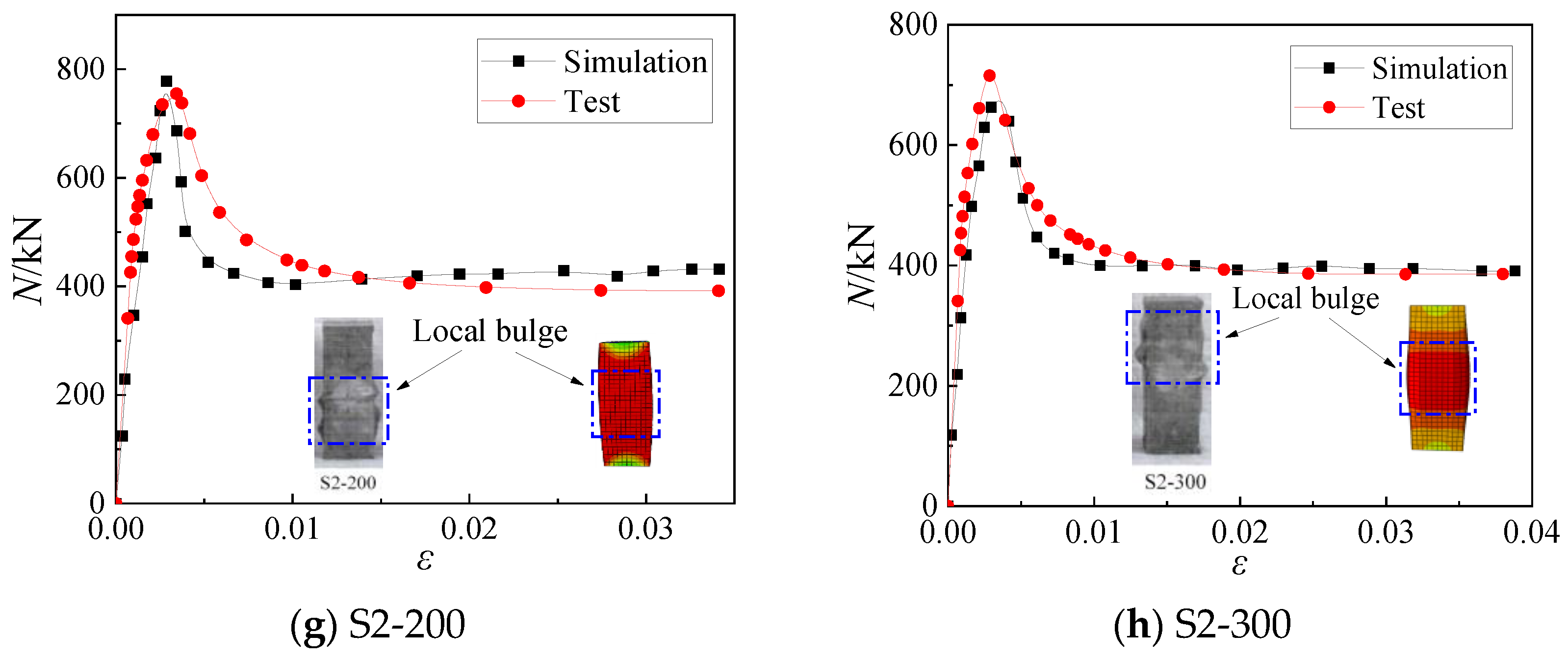

4.3.2. Model Validation of Short Columns with Concrete-Filled Square Steel Tubes

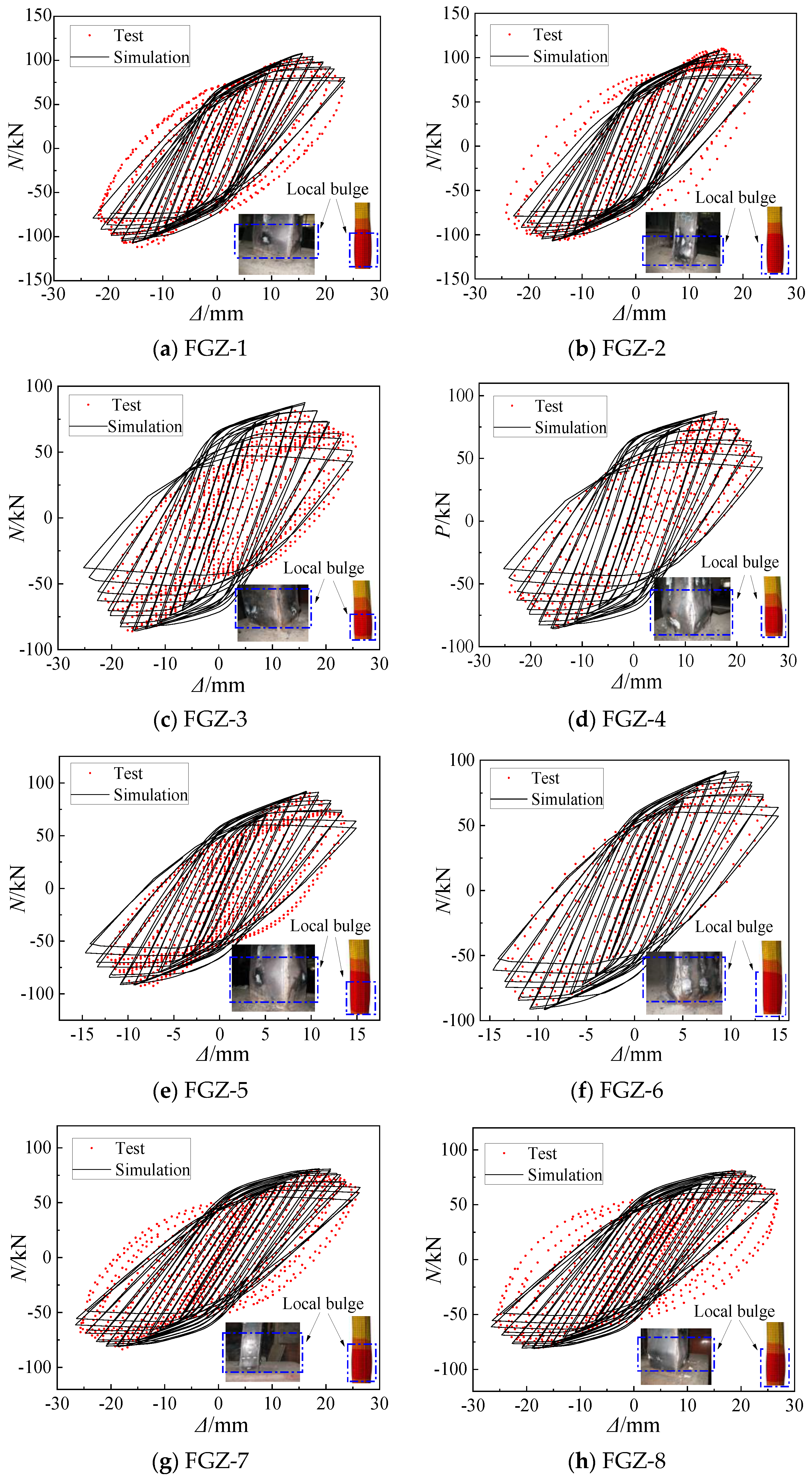

4.3.3. Model Validation of High-Strength Concrete Columns with Square Steel Tubes

5. Parameter Investigation

5.1. Hysteresis Curves

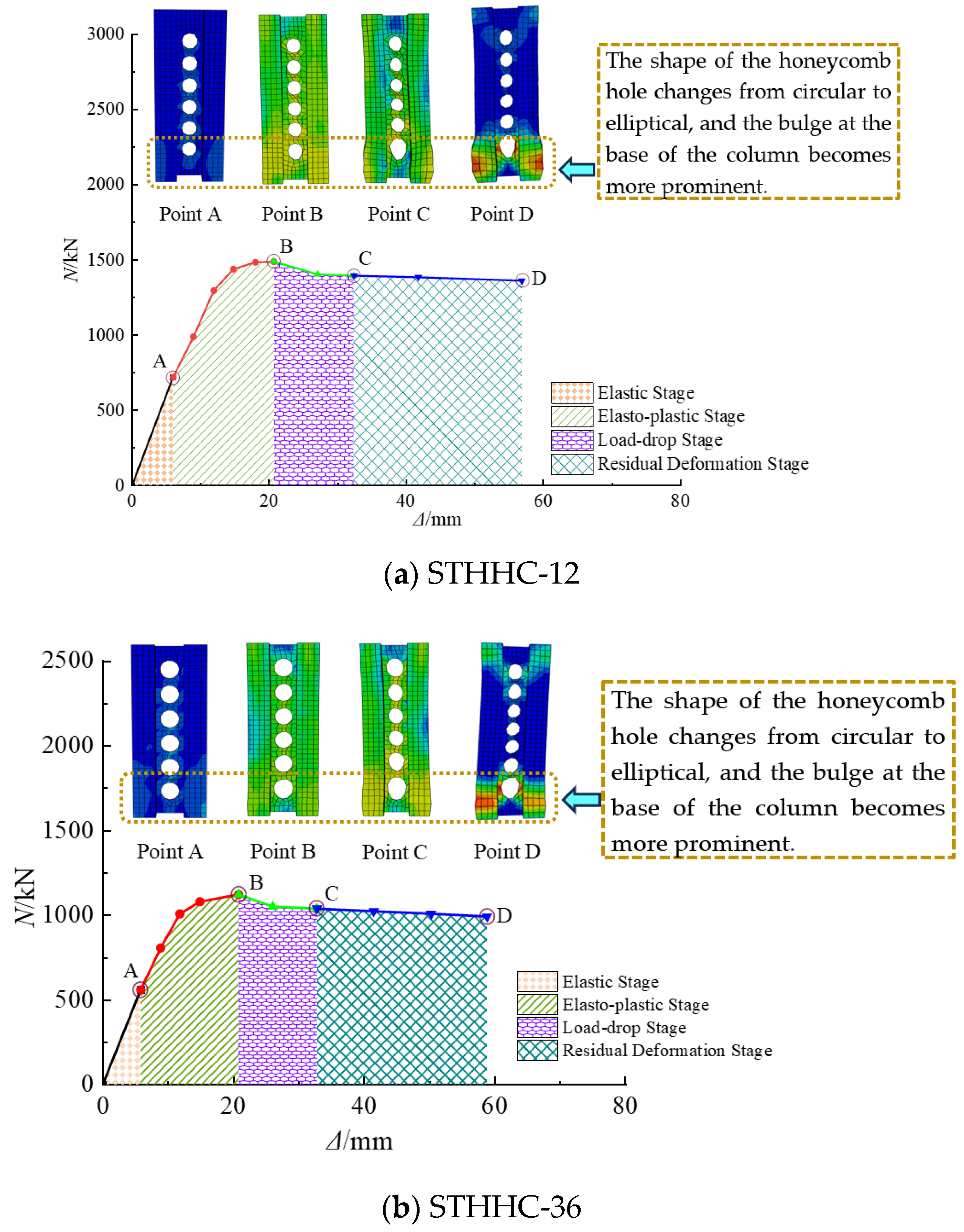

5.2. Skeleton Curves

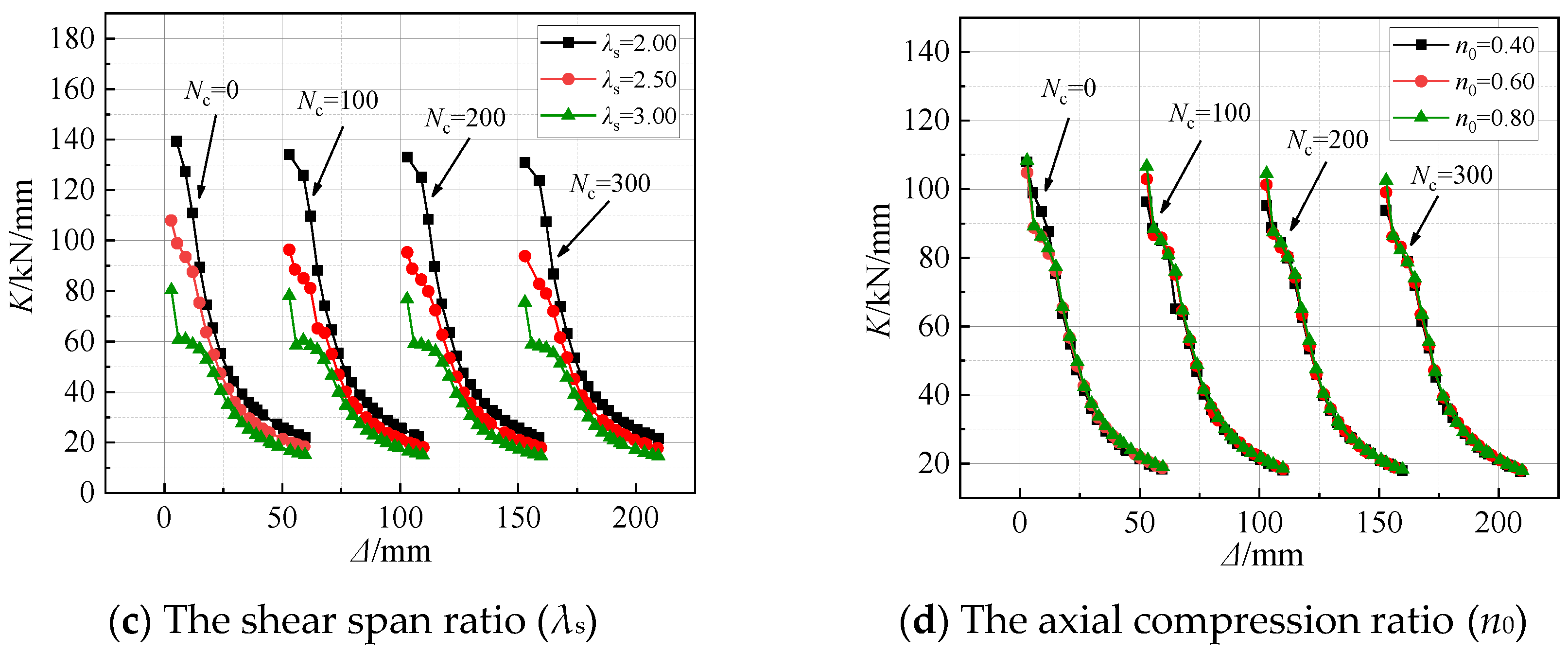

5.3. Energy Dissipation Capacity

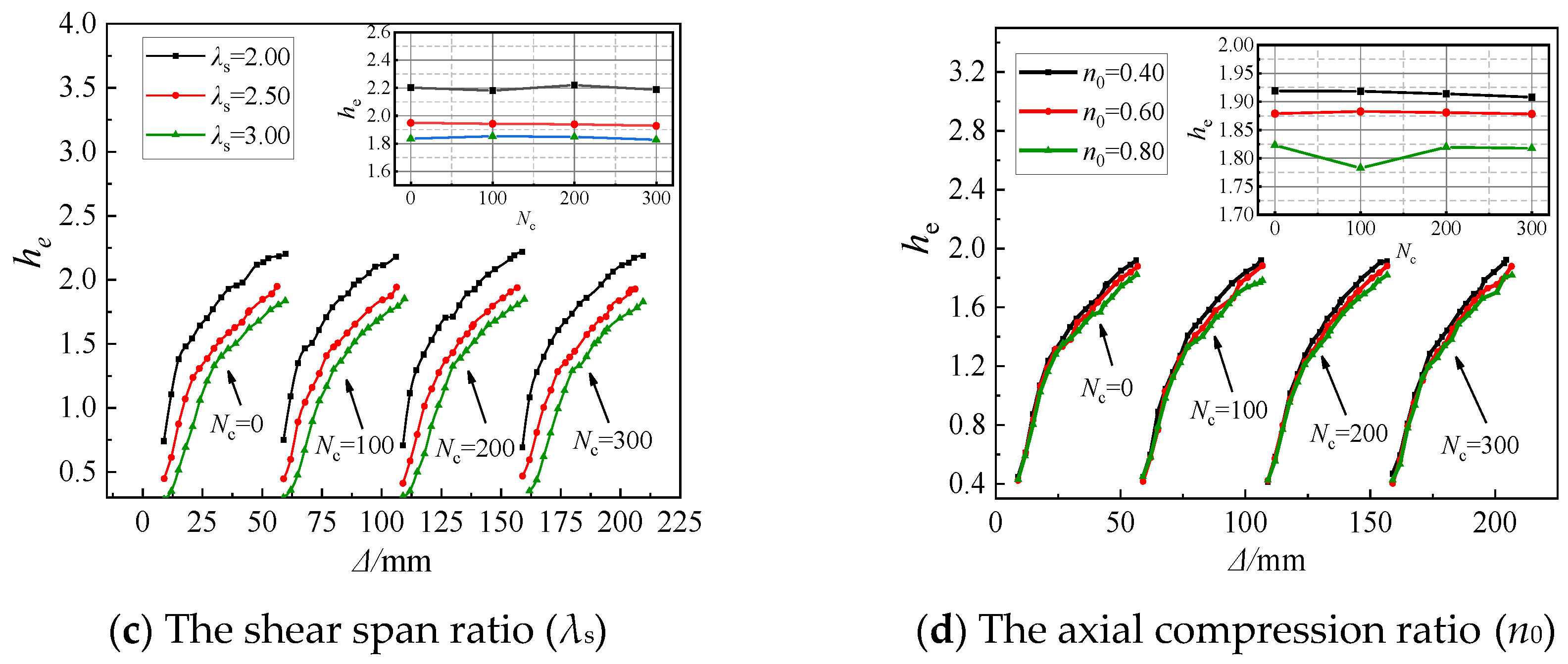

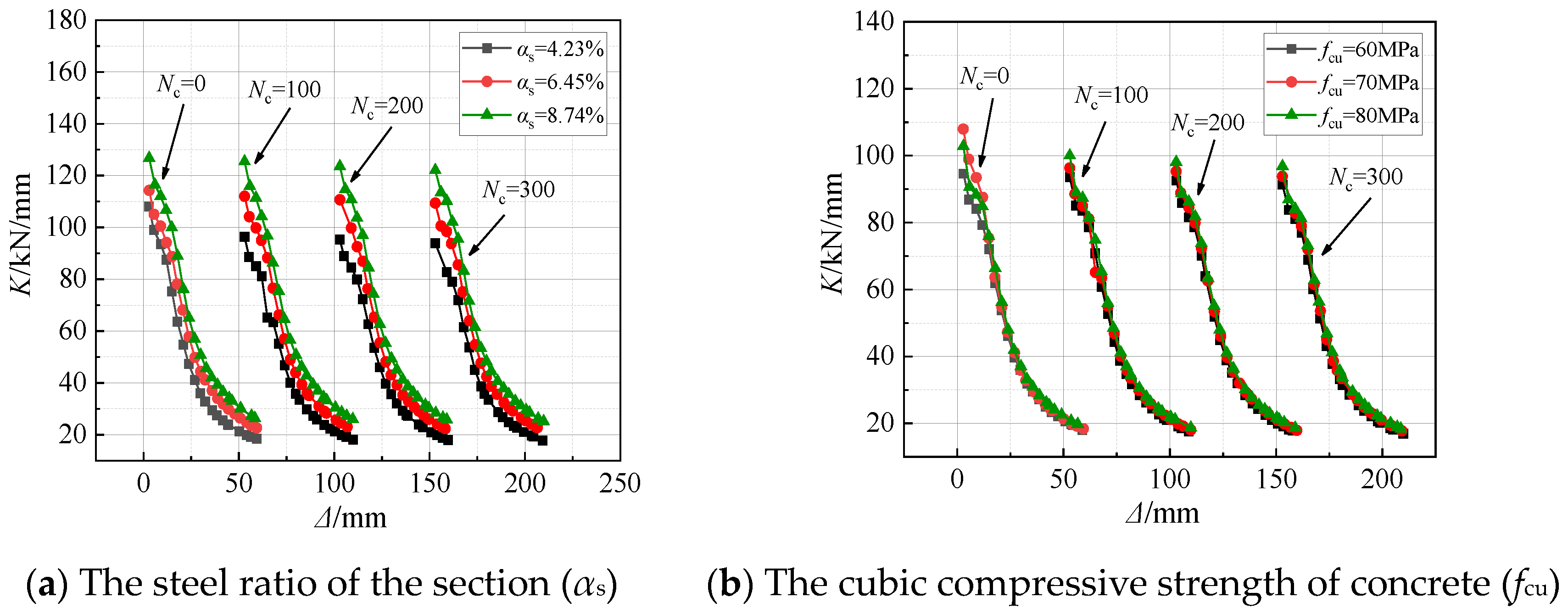

5.4. Stiffness Degradation

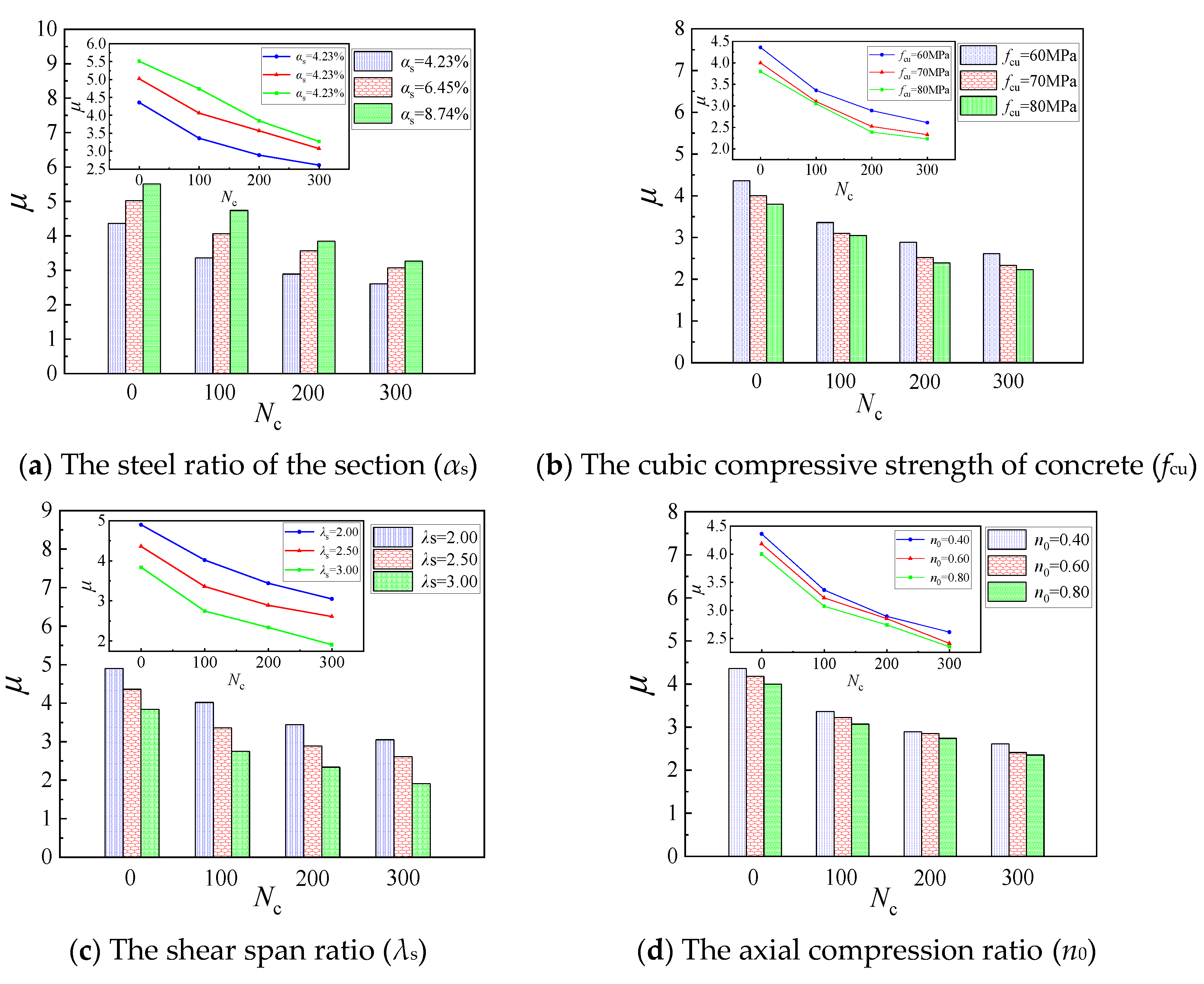

5.5. Ductility

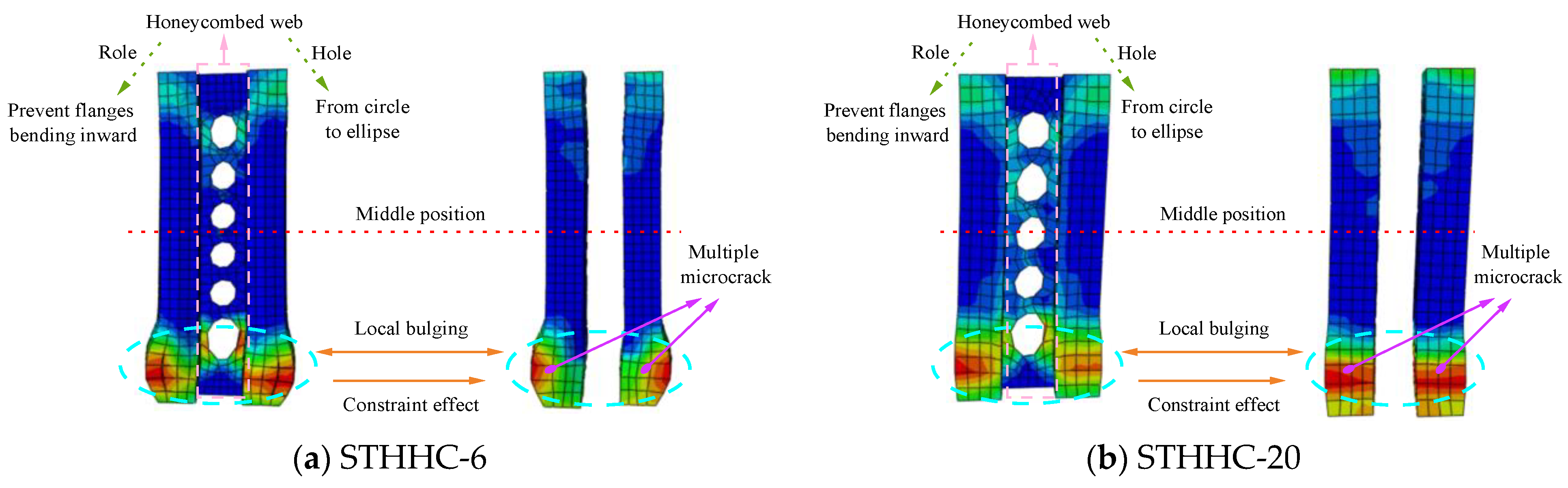

5.6. The Failure Mode of the Specimens

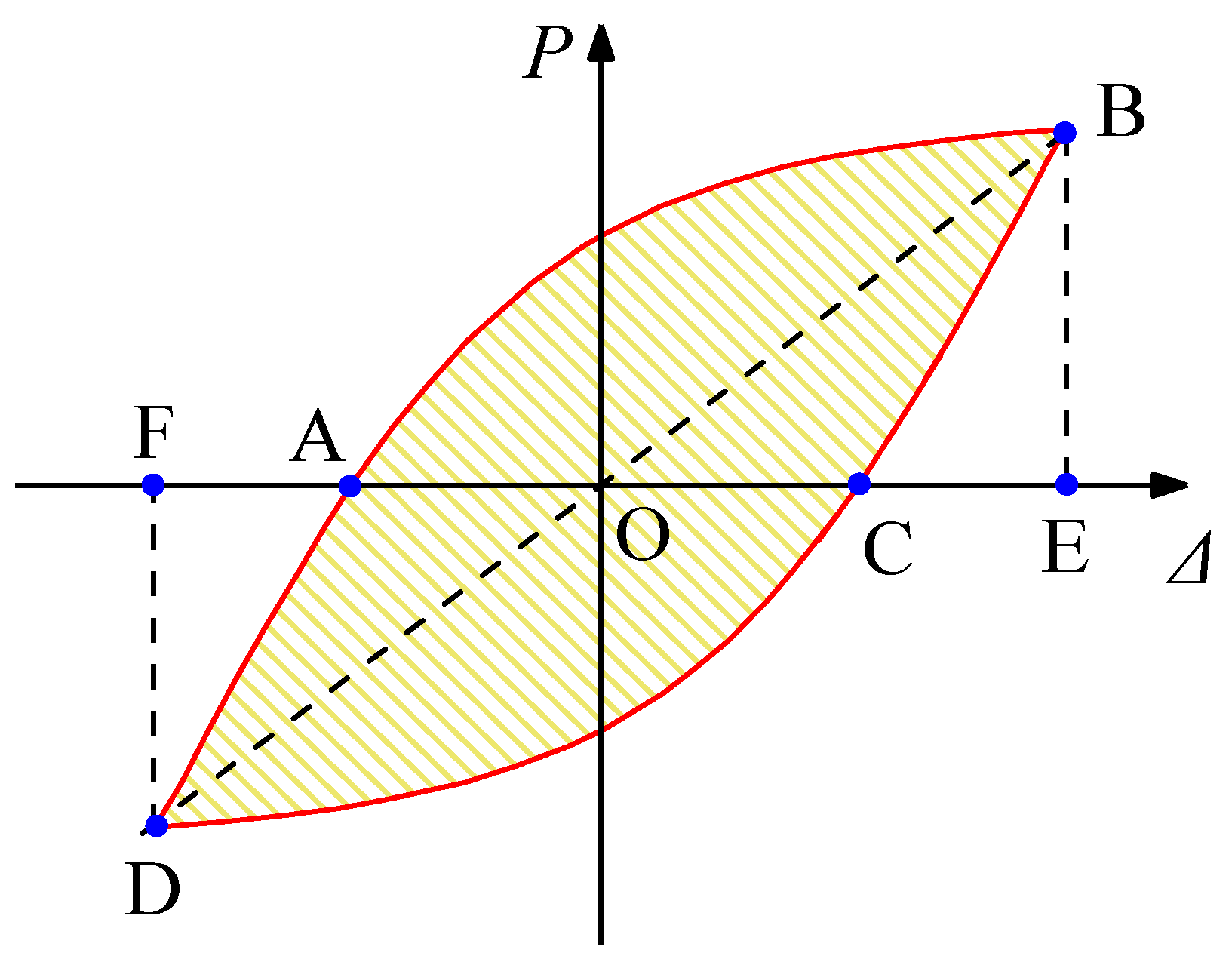

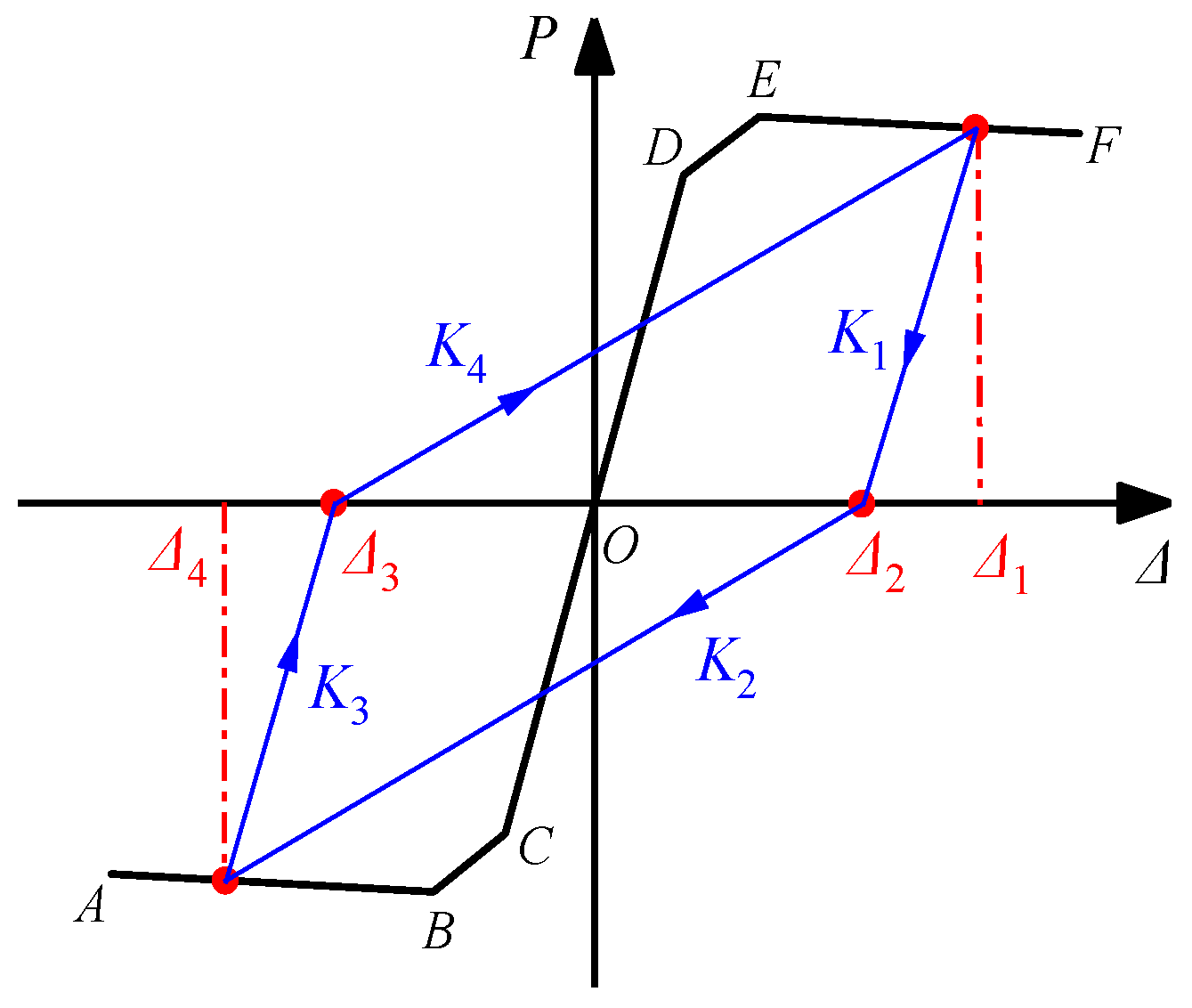

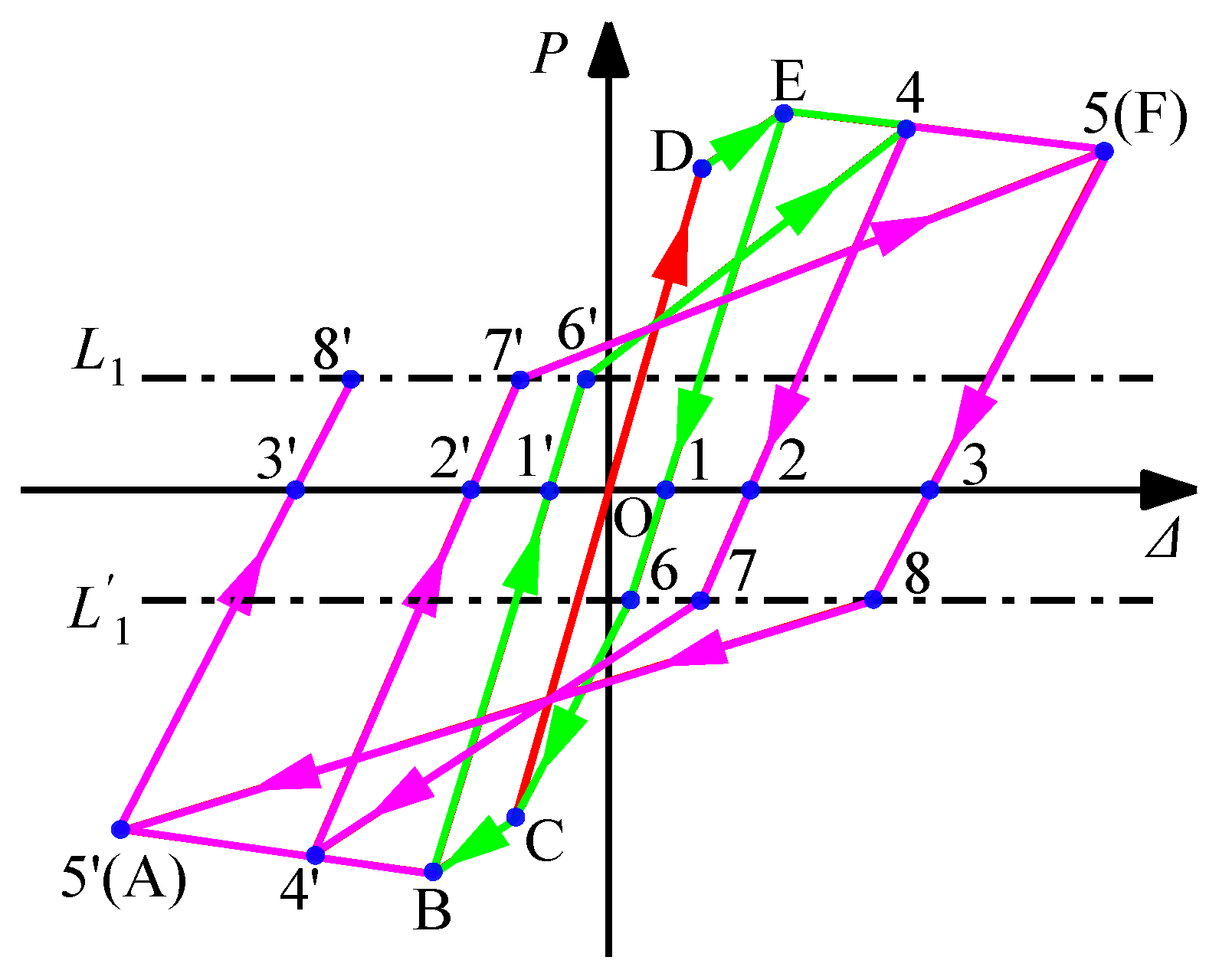

6. The Restoring Force Model

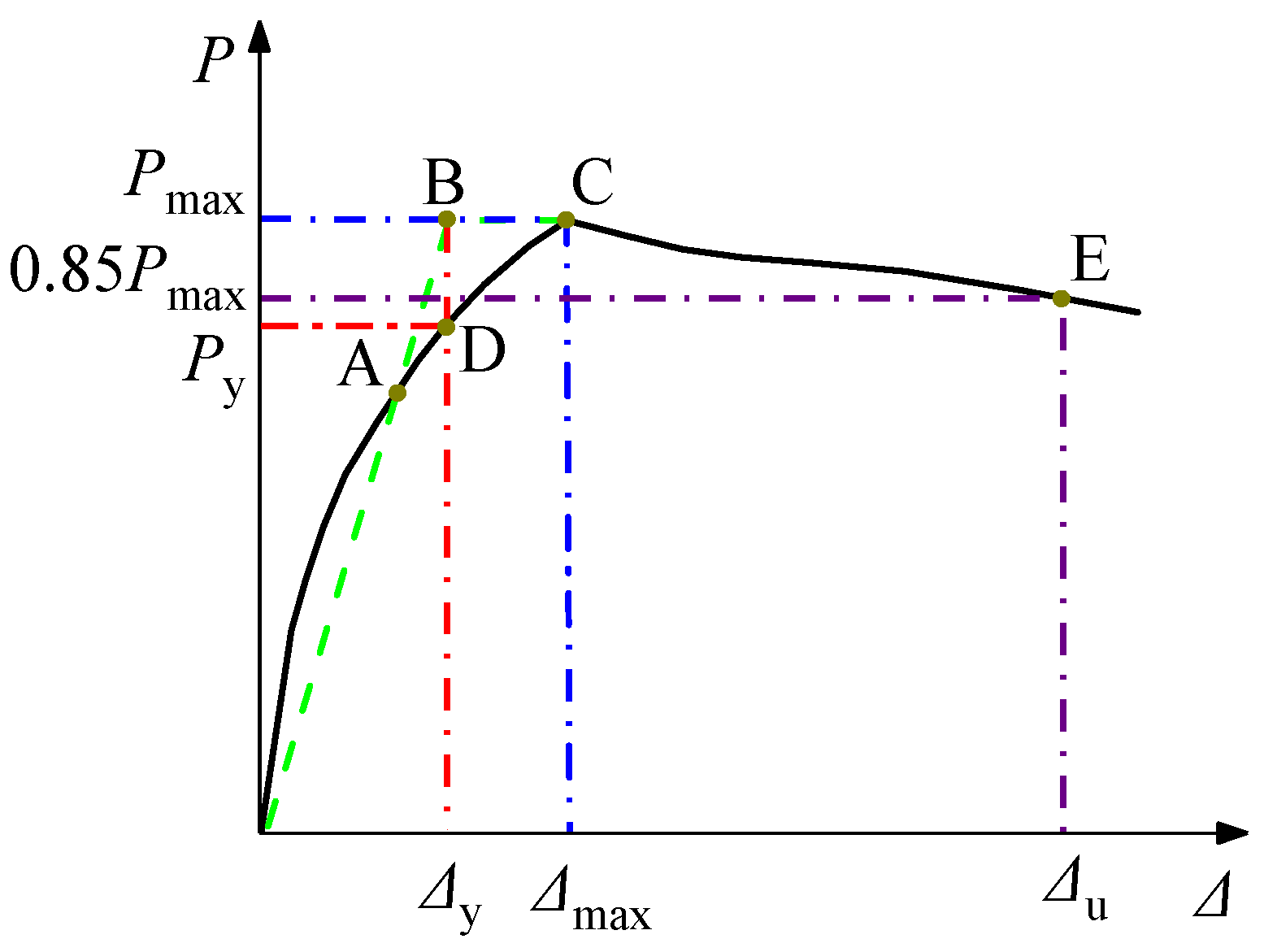

6.1. The Simplified Trilinear Skeleton Curve Model

6.2. Degradation Law of Stiffness

6.3. Restoring Force Model

6.4. Comparison of Skeleton Curves

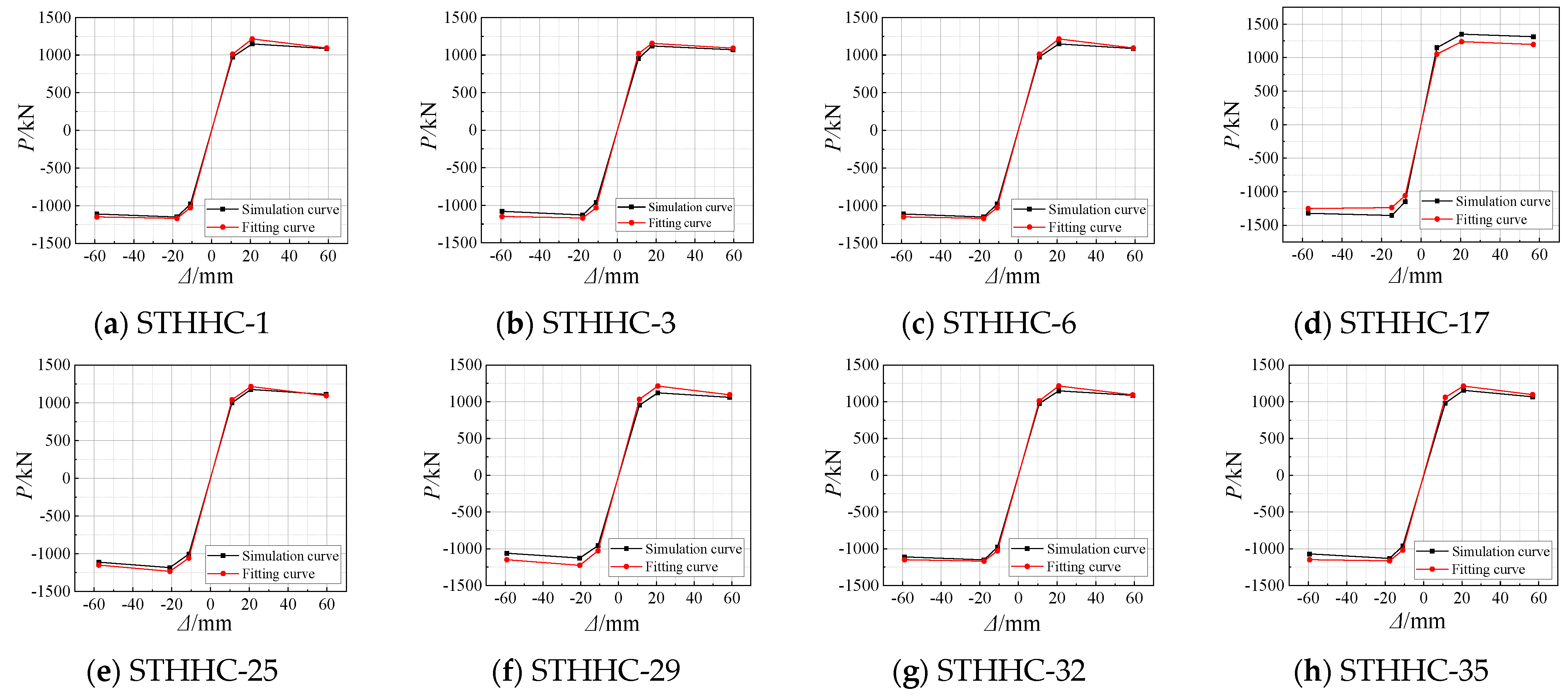

6.5. Comparison of Hysteresis Curves

6.6. Design Recommendations

- (1)

- As the steel ratio of the section increases, both the peak load and the ductility of the composite column’s horizontal bearing capacity significantly enhance. However, the increase in the steel ratio of the section has minimal influence on the column’s energy dissipation capacity. Therefore, a steel ratio of the section between 4.23% and 6.45% is recommended.

- (2)

- As the concrete strength increases, the composite column’s peak load and energy dissipation capacity improve. However, excessively high concrete strength leads to rapid load decay and reduced ductility after freeze-thaw cycles. The recommended cubic compressive strength of concrete is 70 MPa.

- (3)

- As the shear span ratio increases, the composite column’s secant stiffness at the beginning of loading significantly decreases, leading to a reduction in energy dissipation capacity and peak horizontal bearing capacity. From the perspectives of good ductility and safety, the shear span ratio should be maintained between 2.5 and 3.0.

- (4)

- With an increase in the axial compression ratio, the related reduction in the composite column’s energy dissipation capacity and ductility is minor, but the rate of strength decay under various loads accelerates. From the perspectives of economics, energy dissipation, and ductility, the axial compression ratio should be around 0.6.

7. Conclusions

- Within the parameter range studied in this paper, the hysteretic curves of STHHCs show an ideal spindle shape, which reflects the excellent energy dissipation capacity of this new kind of composite column. The specimen is dominated by buckling deformation. The deformation at the column base is obvious, and an outer drum deformation occurs. The round hole at the bottom of the honeycomb steel web is buckled;

- All composite columns show excellent energy dissipation capacity. The equivalent viscous damping coefficient of STHHCs under different parameters decreases with the increase in Nc. The composite column’s equivalent viscous damping coefficient increases with an increase in αs and decreases along with λs and n0;

- After experiencing the freeze-thaw cycle, all the STHHCs experience the phenomenon of stiffness degradation under the action of horizontal reciprocating load. With the increase in Nc, the initial stiffness of the specimen under diverse parameters gradually decreases. With the increase of αs and n0, the stiffness of composite columns increases gradually. With the increase of λs, the stiffness of the specimen obviously decreases;

- After freeze-thaw cycles, all specimens showed good ductility. With the increase in Nc, n0, and λs, the displacement ductility coefficient of the specimen decreases gradually. With the increase in αs, the displacement ductility coefficient of the specimen obviously increases;

- According to the hysteresis curves and skeleton curves, the trilinear skeleton curve model and the restoring force model are established, and the hysteresis rules are defined. The curves calculated by the skeleton curve model and the restoring force model are in good agreement with the finite element analysis results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, W.L.; Yang, Z.Y. Seismic behavior of prefabricated lightweight steel frame-light steel keel-lightweight concrete shear wall structure. J. Beijing Univ. Technol. 2024, 50, 165–179. [Google Scholar]

- Ji, J.; Yang, M.M.; Xu, Z.C.; Jiang, L.Q.; Song, H.Y. Experimental Study of H-Shaped Honeycombed Stub Columns with Rectangular Concrete-Filled Steel Tube Flanges Subjected to Axial Load. Adv. Civ. Eng. 2021, 2021, 6678623. [Google Scholar] [CrossRef]

- Wang, K.; Liu, W.H.; Chen, Y.; Wang, J.; Xie, Y.; Fang, Y.; Liu, C. Investigation on mechanical behavior of square CFST stub columns after being exposed to freezing and thawing. J. Guangxi Univ. (Nat. Sci. Ed.) 2017, 42, 1250–1255. [Google Scholar]

- Zhang, T.; Lyu, X.; Yu, Y. Prediction and analysis of the residual capacity of concrete-filled steel tube stub columns under axial compression subjected to combined freeze-thaw cycles and acid rain corrosion. Materials 2019, 12, 3070. [Google Scholar] [CrossRef]

- Ji, J.; Li, Y.H.; Jiang, L.Q.; Zhang, Y.F.; Liu, Y.C.; He, L.J.; Zhang, Z.B.; Wang, Y. Axial compression behavior of strength-gradient composite stub columns encased CFST with small diameter: Experimental and numerical investigation. Structures 2023, 47, 282–298. [Google Scholar] [CrossRef]

- Shen, X.S.; Zhang, X.Y.; Fang, Y.; He, K.; Chen, Y. Experimental research on axial compression behavior of circular CFST short columns after freeze-thaw cycles. J. Build. Struct. 2019, 40, 105–114. [Google Scholar]

- Ji, J.; Zhang, Z.B.; Lin, M.F.; Li, L.Z.; Jiang, L.Q.; Ding, Y.; Yu, K.Q. Structural application of engineered cementitious composites (ECC): A state-of-the-art review. Constr. Build. Mater. 2023, 406, 133289. [Google Scholar] [CrossRef]

- Gao, S.; Peng, Z.; Guo, L.H.; Fu, F.; Wang, Y.G. Compressive behavior of circular concrete-filled steel tubular columns under freeze-thaw cycles. J. Constr. Steel Res. 2020, 166, 105934. [Google Scholar] [CrossRef]

- Li, X.E.; Miao, J.J.; Zeng, Z.P.; Chen, C. Experimental study on interfacial bonding properties of circular steel tube concrete columns after freeze-thaw cycles. J. Civ. Environ. Eng. 2023, 45, 114–123. [Google Scholar]

- Ji, J.; Yu, C.Y.; Jiang, L.Q.; Zhan, J.D.; Ren, H.G.; Hao, S.X.; Fan, S.J.; Jiang, L.; Lin, Y.B.; He, L.J. Bearing behavior of H-shaped honeycombed steel web composite columns with rectangular concrete-filled steel tube flanges under eccentrical compression load. Adv. Civ. Eng. 2022, 2022, 2965131. [Google Scholar] [CrossRef]

- Zhou, L.Q.; Gao, S.; Zhang, K.Y.; Chang, C.; Peng, Z. Study on bearing capacity of circular CFST stub column after being exposed to freeze-thaw cycle. Concrete 2022, 2022, 15–19+24. [Google Scholar]

- Zhou, D.W.; Liu, J.H.; Duan, P.J.; Cheng, L.N.; Lou, B.C. Damage evolution law and mechanism of concrete under cryogenic freeze-thaw cycles. J. Build. Mater. 2022, 25, 490–497. [Google Scholar]

- Wang, J.T.; Sun, Q.; Li, J.X. Experimental study on seismic behavior of high-strength circular concrete-filled thin-walled steel tubular columns. Eng. Struct. 2019, 182, 403–415. [Google Scholar] [CrossRef]

- Ji, J.; Lin, Y.B.; Jiang, L.Q.; Li, W.; Ren, H.G.; Wang, R.L.; Wang, Z.H.; Yang, M.M.; Yu, C.Y. Hysteretic behavior of H-shaped honeycombed steel web composite columns with rectangular concrete-filled steel tube flanges. Adv. Civ. Eng. 2022, 2022, 1546263. [Google Scholar] [CrossRef]

- Chen, Z.P.; Jing, H.G.; Xu, J.J.; Zhang, X. Seismic performance of recycled concrete-filled square steel tube columns. Earthq. Eng. Eng. Vib. 2017, 16, 119–130. [Google Scholar] [CrossRef]

- Tang, Y.C.; Li, L.J.; Feng, W.X.; Liu, F.; Liao, B. Seismic performance of recycled aggregate concrete-filled steel tube columns. J. Constr. Steel Res. 2017, 133, 112–124. [Google Scholar] [CrossRef]

- Ji, J.; He, L.J.; Jiang, L.Q.; Zhang, Y.F.; Liu, Y.C.; Li, Y.H.; Zhang, Z.B. Numerical study on the axial compression behavior of composite columns with Steel tube SHCC flanges and honeycombed steel web. Eng. Struct. 2023, 283, 115883. [Google Scholar] [CrossRef]

- Li, W. Seismic Behavior of Novel Concrete-Filled Rectangular Corrugated Steel Tubular Columns. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2023. [Google Scholar]

- Li, X.; Zhang, S.; Tao, Y.; Zhang, B. Numerical Study on the Axial Compressive Behavior of Steel-Tube-Confined Concrete-Filled Steel Tubes. Materials 2023, 17, 155. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, P.; Lu, Y.; Liu, Z. Hysteresis performance of steel fiber-reinforced high-strength concrete-filled steel tube columns. J. Constr. Steel Res. 2024, 219, 108755. [Google Scholar] [CrossRef]

- Chen, A.Y.; Wang, C.X.; Wang, H.Q. Compression-bending behavior of rectangular concrete-filled steel tubular columns with large aspect ratio. Prog. Steel Build. Struct. 2024, 26, 46–56. [Google Scholar]

- Montuori, R.; Nastri, E.; Piluso, V.; Todisco, P. Finite element analysis of concrete filled steel tubes subjected to cyclic bending. Eng. Struct. 2024, 314, 118364. [Google Scholar] [CrossRef]

- Sabih, M.S.; Hilo, J.S.; Hamood, J.M.; Salih, S.S.; Faris, M.M.; Yousif, M.A. Numerical Investigation into the Strengthening of Concrete-Filled Steel Tube Composite Columns Using Carbon Fiber-Reinforced Polymers. Buildings 2024, 14, 441. [Google Scholar] [CrossRef]

- Abdelrahman, A.; Wael, A. Numerical parametric investigation on the moment redistribution of basalt FRC continuous beams with basalt FRP bars. Compos. Struct. 2021, 277, 114618. [Google Scholar]

- Regita, J.J.; Helena, J.H. Concrete–filled steel tube truss girders—A state-of-the-art review. J. Eng. Appl. Sci. 2023, 70, 49. [Google Scholar]

- Liu, G.D.; Deng, L.X.; Shao, Y.B.; Wang, J. Load carrying capacity of locally compressed I-girders with rectangular concrete-filled tubular flange and corrugated web. J. Chongqing Univ. 2023, 46, 81–97. [Google Scholar]

- Wang, H.; Huai, H.Y.; Xu, Z.C.; Shang, S.C.; Zhou, H.; Jiang, C. Simulation experiment teaching platform for constrained concrete failure characteristics based on ABAQUS. Exp. Technol. Manag. 2023, 40, 125–131. [Google Scholar]

- Wu, C.; Xu, S.H.; Zhao, Q.S.; Yang, Y.K. Experimental research on seismic behavior of ultrahigh-performance concrete-filled square steel tubular short columns. Ind. Const. 2019, 49, 188–194. [Google Scholar]

- Zhang, W.; Li, R.R.; Xiong, Q.Q. Axial Compression Behavior of High-strength Concrete-filled Steel Tube Column after Corrosion. Sci. Technol. Eng. 2024, 24, 7288–7297. [Google Scholar]

- Han, L.H.; Tao, Z. Theoretical analysis and experimental study on axial compressive mechanical properties of concrete-filled square steel tube. Chin. Civ. Eng. J. 2001, 2001, 17–25. [Google Scholar]

- Cao, K. Study on Performance of Concrete Filled Steel Tubular Stub Columns after Being to Exposed Freezing and Thawing. Master’s Thesis, Dalian University of Technology, Dalian, China, 2013. [Google Scholar]

- Ji, J.; Jiang, L.; Jiang, L.Q.; Zhang, Y.F.; Teng, Z.C.; Liu, Y.C. Eccentric compression performance of H-type honeycomb composite medium-long columns with rectangular concrete-filled steel tube flange. J. Northeast Pet. Univ. 2020, 44, 121–132+13–14. [Google Scholar]

- Ji, J.; Xu, Z.C.; Jiang, L.Q.; Liu, Y.C.; Yu, D.Y.; Yang, M.M. Experimental study on compression behavior of H-shaped composite short column with rectangular CFST flanges and honeycombed steel web subjected to axial load. J. Build. Struct. 2019, 40, 63–73. [Google Scholar]

- Yang, Y.F.; Cao, K.; Yang, Z.Q.; Lin, J. Mechanical properties of concrete filled steel tubular stubs after freezing and thawing cycles under axial loading. China J. Highw. Transp. 2014, 27, 51–58. [Google Scholar]

- Li, B.; Ma, K.Z.; Liu, H.D. Seismic behavior of square high strength concrete-filled steel tubular columns. Eng. Mech. 2009, 26, 139–143. [Google Scholar]

- Wei, J.G.; Ying, H.D.; Yang, Y.; Zhang, W.; Yuan, H.H.; Zhou, J. Seismic performance of concrete-filled steel tubular composite columns with ultra high performance concrete plates. Eng. Struct. 2023, 278, 115500. [Google Scholar] [CrossRef]

- Yu, J.B.; Xia, Y.F.; Guo, Z.X.; Guo, X. Experimental study on the structural behavior of exterior precast concrete beam-column joints with high-strength steel bars in field-cast RPC. Eng. Struct. 2024, 299, 117128. [Google Scholar] [CrossRef]

- Qiu, Z.M.; Li, Y.C.; Yang, Z.J. Experimental research on seismic behavior of high-strength concrete filled high-strength square steel tubular columns. J. Build. Struct. 2021, 42, 295–303. [Google Scholar]

- Guo, Z.X.; Zhang, Z.W.; Huang, Q.X.; Liu, Y. Experimental study on hysteretic model of SRC columns. Earthq. Eng. Eng. Vib. 2009, 29, 79–85. [Google Scholar]

- Zhang, G.J.; Lu, X.L.; Liu, B.Q. Study on resilience models of high-strength concrete frame columns. Eng. Mech. 2007, 2007, 83–91. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Xue, J.Y.; Yang, Q.F. Experimental study on restoring force of solid-web steel reinforced concrete T-shaped column. J. Eng. Mech. 2017, 32, 800–810. [Google Scholar]

| Specimens | b × h1 × hw × t1 /mm | L /mm | Nc | λs | n0 | as /% | fcu /MPa |

|---|---|---|---|---|---|---|---|

| STHHC-1 | 500 × 320 × 400 × 4 | 2600 | 0 | 2.50 | 0.40 | 4.23 | 70 |

| STHHC-2 | 500 × 320 × 400 × 4 | 2600 | 100 | 2.50 | 0.40 | 4.23 | 70 |

| STHHC-3 | 500 × 320 × 400 × 4 | 2600 | 200 | 2.50 | 0.40 | 4.23 | 70 |

| STHHC-4 | 500 × 320 × 400 × 4 | 2600 | 300 | 2.50 | 0.40 | 4.23 | 70 |

| STHHC-5 | 500 × 320 × 400 × 6 | 2600 | 0 | 2.50 | 0.40 | 6.45 | 70 |

| STHHC-6 | 500 × 320 × 400 × 6 | 2600 | 100 | 2.50 | 0.40 | 6.45 | 70 |

| STHHC-7 | 500 × 320 × 400 × 6 | 2600 | 200 | 2.50 | 0.40 | 6.45 | 70 |

| STHHC-8 | 500 × 320 × 400 × 6 | 2600 | 300 | 2.50 | 0.40 | 6.45 | 70 |

| STHHC-9 | 500 × 320 × 400 × 8 | 2600 | 0 | 2.50 | 0.40 | 8.74 | 70 |

| STHHC-10 | 500 × 320 × 400 × 8 | 2600 | 100 | 2.50 | 0.40 | 8.74 | 70 |

| STHHC-11 | 500 × 320 × 400 × 8 | 2600 | 200 | 2.50 | 0.40 | 8.74 | 70 |

| STHHC-12 | 500 × 320 × 400 × 8 | 2600 | 300 | 2.50 | 0.40 | 8.74 | 70 |

| STHHC-13 | 500 × 320 × 400 × 4 | 2080 | 0 | 2.00 | 0.40 | 4.23 | 70 |

| STHHC-14 | 500 × 320 × 400 × 4 | 2080 | 100 | 2.00 | 0.40 | 4.23 | 70 |

| STHHC-15 | 500 × 320 × 400 × 4 | 2080 | 200 | 2.00 | 0.40 | 4.23 | 70 |

| STHHC-16 | 500 × 320 × 400 × 4 | 2080 | 300 | 2.00 | 0.40 | 4.23 | 70 |

| STHHC-17 | 500 × 320 × 400 × 4 | 3120 | 0 | 3.00 | 0.40 | 4.23 | 70 |

| STHHC-18 | 500 × 320 × 400 × 4 | 3120 | 100 | 3.00 | 0.40 | 4.23 | 70 |

| STHHC-19 | 500 × 320 × 400 × 4 | 3120 | 200 | 3.00 | 0.40 | 4.23 | 70 |

| STHHC-20 | 500 × 320 × 400 × 4 | 3120 | 300 | 3.00 | 0.40 | 4.23 | 70 |

| STHHC-21 | 500 × 320 × 400 × 4 | 2600 | 0 | 2.50 | 0.60 | 4.23 | 70 |

| STHHC-22 | 500 × 320 × 400 × 4 | 2600 | 100 | 2.50 | 0.60 | 4.23 | 70 |

| STHHC-23 | 500 × 320 × 400 × 4 | 2600 | 200 | 2.50 | 0.60 | 4.23 | 70 |

| STHHC-24 | 500 × 320 × 400 × 4 | 2600 | 300 | 2.50 | 0.60 | 4.23 | 70 |

| STHHC-25 | 500 × 320 × 400 × 4 | 2600 | 0 | 2.50 | 0.80 | 4.23 | 70 |

| STHHC-26 | 500 × 320 × 400 × 4 | 2600 | 100 | 2.50 | 0.80 | 4.23 | 70 |

| STHHC-27 | 500 × 320 × 400 × 4 | 2600 | 200 | 2.50 | 0.80 | 4.23 | 70 |

| STHHC-28 | 500 × 320 × 400 × 4 | 2600 | 300 | 2.50 | 0.80 | 4.23 | 70 |

| STHHC-29 | 500 × 320 × 400 × 4 | 2600 | 0 | 2.50 | 0.40 | 4.23 | 60 |

| STHHC-30 | 500 × 320 × 400 × 4 | 2600 | 100 | 2.50 | 0.40 | 4.23 | 60 |

| STHHC-31 | 500 × 320 × 400 × 4 | 2600 | 200 | 2.50 | 0.40 | 4.23 | 60 |

| STHHC-32 | 500 × 320 × 400 × 4 | 2600 | 300 | 2.50 | 0.40 | 4.23 | 60 |

| STHHC-33 | 500 × 320 × 400 × 4 | 2600 | 0 | 2.50 | 0.40 | 4.23 | 80 |

| STHHC-34 | 500 × 320 × 400 × 4 | 2600 | 100 | 2.50 | 0.40 | 4.23 | 80 |

| STHHC-35 | 500 × 320 × 400 × 4 | 2600 | 200 | 2.50 | 0.40 | 4.23 | 80 |

| STHHC-36 | 500 × 320 × 400 × 4 | 2600 | 300 | 2.50 | 0.40 | 4.23 | 80 |

| Specimens | h1 × b × hw × t2 × t1 /mm | λ | l /mm | ξ | fyf /MPa | fcu /MPa | /kN | /kN | /% |

|---|---|---|---|---|---|---|---|---|---|

| STHCC-1 | 50 × 100 × 100 × 6 × 1.7 | 12.82 | 370 | 0.60 | 269 | 49.50 | 740.0 | 763.4 | 3.17 |

| STHCC-2 | 50 × 100 × 100 × 6 × 2.3 | 12.82 | 370 | 0.88 | 282 | 49.50 | 871.7 | 864.5 | 0.83 |

| STHCC-3 | 50 × 100 × 100 × 6 × 3.8 | 12.82 | 370 | 1.60 | 286 | 49.50 | 1175.6 | 1150.8 | 2.11 |

| STHCC-4 | 50 × 100 × 100 × 6 × 2.3 | 12.82 | 370 | 0.82 | 282 | 53.17 | 1070.4 | 1057.4 | 1.21 |

| STHCC-5 | 50 × 100 × 100 × 6 × 2.3 | 12.82 | 370 | 0.66 | 282 | 55.69 | 1172.7 | 1152.3 | 1.73 |

| STHCC-6 | 50 × 100 × 100 × 6 × 2.3 | 12.82 | 370 | 0.78 | 282 | 65.60 | 1015.9 | 1020.1 | 0.41 |

| STHCC-7 | 50 × 100 × 100 × 8 × 1.7 | 12.82 | 370 | 0.60 | 269 | 49.50 | 752.6 | 789.6 | 4.91 |

| STHCC-8 | 50 × 100 × 100 × 11 × 2.7 | 12.82 | 370 | 0.60 | 269 | 49.50 | 796.7 | 834.1 | 4.69 |

| STHCC-9 | 50 × 100 × 100 × 6 × 2.3 | 9.35 | 270 | 0.88 | 282 | 49.50 | 947.0 | 936.9 | 1.06 |

| STHCC-10 | 50 × 100 × 100 × 6 × 2.3 | 16.28 | 470 | 0.88 | 282 | 49.50 | 841.1 | 829.0 | 1.36 |

| STHCC-11 | 50 × 100 × 100 × 6 × 1.7 | 9.35 | 270 | 0.60 | 269 | 49.50 | 772.9 | 787.8 | 1.93 |

| STHCC-12 | 50 × 100 × 100 × 6 × 1.7 | 16.28 | 470 | 0.60 | 269 | 49.50 | 741.1 | 762.8 | 2.92 |

| STHCC-13 | 50 × 100 × 100 × 6 × 3.8 | 9.35 | 270 | 1.60 | 286 | 49.50 | 1276.0 | 1299.1 | 1.81 |

| STHCC-14 | 50 × 100 × 100 × 6 × 3.8 | 16.28 | 470 | 1.60 | 286 | 49.50 | 1069.0 | 1080.5 | 1.07 |

| Specimens | D /mm | L /mm | t /mm | fcu /MPa | α | fy /MPa | /kN | /kN | /% |

|---|---|---|---|---|---|---|---|---|---|

| SC2-0 | 100 | 300 | 2.06 | 63.7 | 0.113 | 338.4 | 808.38 | 834.96 | 3.34 |

| SC2-100 | 100 | 300 | 2.06 | 63.7 | 0.113 | 338.4 | 783.77 | 802.04 | 2.32 |

| SC2-200 | 100 | 300 | 2.06 | 63.7 | 0.113 | 338.4 | 808.99 | 832.09 | 2.83 |

| SC2-300 | 100 | 300 | 2.06 | 63.7 | 0.113 | 338.4 | 749.10 | 775.16 | 3.41 |

| S2-0 | 100 | 300 | 2.00 | 83.9 | 0.085 | 184.7 | 861.67 | 814.23 | 5.83 |

| S2-100 | 100 | 300 | 2.00 | 83.9 | 0.085 | 184.7 | 783.92 | 778.60 | 0.68 |

| S2-200 | 100 | 300 | 2.00 | 83.9 | 0.085 | 184.7 | 777.55 | 754.89 | 3.00 |

| S2-300 | 100 | 300 | 2.00 | 83.9 | 0.085 | 184.7 | 663.06 | 715.48 | 7.91 |

| S3-0 | 100 | 300 | 3.00 | 83.9 | 0.132 | 176.5 | 891.58 | 856.82 | 4.06 |

| S3-100 | 100 | 300 | 3.00 | 83.9 | 0.132 | 176.5 | 775.53 | 800.38 | 3.20 |

| S3-200 | 100 | 300 | 3.00 | 83.9 | 0.132 | 176.5 | 754.48 | 815.90 | 8.14 |

| S3-300 | 100 | 300 | 3.00 | 83.9 | 0.132 | 176.5 | 722.31 | 772.20 | 6.91 |

| Specimens | B × t × L /mm | λ | α | nt | fy /MPa | fcu,k /MPa | /kN | /kN | /% |

|---|---|---|---|---|---|---|---|---|---|

| FGZ-1 | 150 × 5.5 × 900 | 12.82 | 0.165 | 0.5 | 291.8 | 65.1 | 108.3 | 111.3 | 2.78 |

| FGZ-2 | 150 × 5.5 × 900 | 12.82 | 0.165 | 0.5 | 291.8 | 65.1 | 112.1 | 111.3 | 0.72 |

| FGZ-3 | 150 × 3.1 × 900 | 12.82 | 0.088 | 0.5 | 252.6 | 65.1 | 83.4 | 87.6 | 5.03 |

| FGZ-4 | 150 × 3.1 × 900 | 12.82 | 0.088 | 0.5 | 252.6 | 65.1 | 82.1 | 87.6 | 6.70 |

| FGZ-5 | 150 × 5.5 × 900 | 12.82 | 0.165 | 0.7 | 291.8 | 65.1 | 85.2 | 91.2 | 7.04 |

| FGZ-6 | 150 × 5.5 × 900 | 12.82 | 0.165 | 0.7 | 291.8 | 65.1 | 84.1 | 91.2 | 8.44 |

| FGZ-7 | 150 × 5.5 × 1250 | 12.82 | 0.165 | 0.5 | 291.8 | 65.1 | 87.9 | 89.7 | 2.04 |

| FGZ-8 | 150 × 5.5 × 1250 | 12.82 | 0.165 | 0.5 | 291.8 | 65.1 | 83.3 | 89.7 | 7.68 |

| Section | Regression Equation | Slope |

|---|---|---|

| OD | P/P+max = 4.604(Δ/Δ+max) | 4.604 |

| DE | P/P+max = 0.97(Δ/Δ+max) + 0.669 | 0.970 |

| EF | P/P+max = −0.0657(Δ/Δ+max) + 1.022 | −0.066 |

| OC | P/|P−max| = 4.608(Δ/|Δ−max|) | 4.608 |

| CB | P/|P−max| = 1.007(Δ/|Δ−max|) − 0.664 | 1.007 |

| BA | P/|P−max| = −0.0688(Δ/|Δ−max|) − 1.023 | −0.069 |

| Stage | Regression Equation | R2 |

|---|---|---|

| Positive unloading | K1/K+0 = 0.8176(Δ1/Δ+max)−0.4496 | 0.8577 |

| Negative loading | K2/K−0 = −1.982ln(Δ2/Δ+max + 0.0028) + 0.1774 | 0.9109 |

| Negative unloading | K3/K−0 = 0.6339(Δ3/Δ−max)−0.1434 | 0.8200 |

| Positive loading | K4/K+0 = 0.3344(Δ4/Δ−max)−1.0348 | 0.8506 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, J.; Yang, H.; Jiang, L.; Yuan, C.; Liu, Y.; Zhang, Y.; Hou, X.; Zhang, Z.; Chu, X. Seismic Behavior of Composite Columns with High-Strength Concrete-Filled Steel Tube Flanges and Honeycomb Steel Webs Subjected to Freeze-Thaw Cycles. Buildings 2024, 14, 2640. https://doi.org/10.3390/buildings14092640

Ji J, Yang H, Jiang L, Yuan C, Liu Y, Zhang Y, Hou X, Zhang Z, Chu X. Seismic Behavior of Composite Columns with High-Strength Concrete-Filled Steel Tube Flanges and Honeycomb Steel Webs Subjected to Freeze-Thaw Cycles. Buildings. 2024; 14(9):2640. https://doi.org/10.3390/buildings14092640

Chicago/Turabian StyleJi, Jing, Hengfei Yang, Liangqin Jiang, Chaoqing Yuan, Yingchun Liu, Yu Zhang, Xiaomeng Hou, Zhanbin Zhang, and Xuan Chu. 2024. "Seismic Behavior of Composite Columns with High-Strength Concrete-Filled Steel Tube Flanges and Honeycomb Steel Webs Subjected to Freeze-Thaw Cycles" Buildings 14, no. 9: 2640. https://doi.org/10.3390/buildings14092640

APA StyleJi, J., Yang, H., Jiang, L., Yuan, C., Liu, Y., Zhang, Y., Hou, X., Zhang, Z., & Chu, X. (2024). Seismic Behavior of Composite Columns with High-Strength Concrete-Filled Steel Tube Flanges and Honeycomb Steel Webs Subjected to Freeze-Thaw Cycles. Buildings, 14(9), 2640. https://doi.org/10.3390/buildings14092640