Experimental and Numerical Simulation Study on Residual Stress of Single-Sided Full-Penetration Welded Rib-to-Deck Joint of Orthotropic Steel Bridge Deck

Abstract

1. Introduction

2. Experiment

2.1. Material

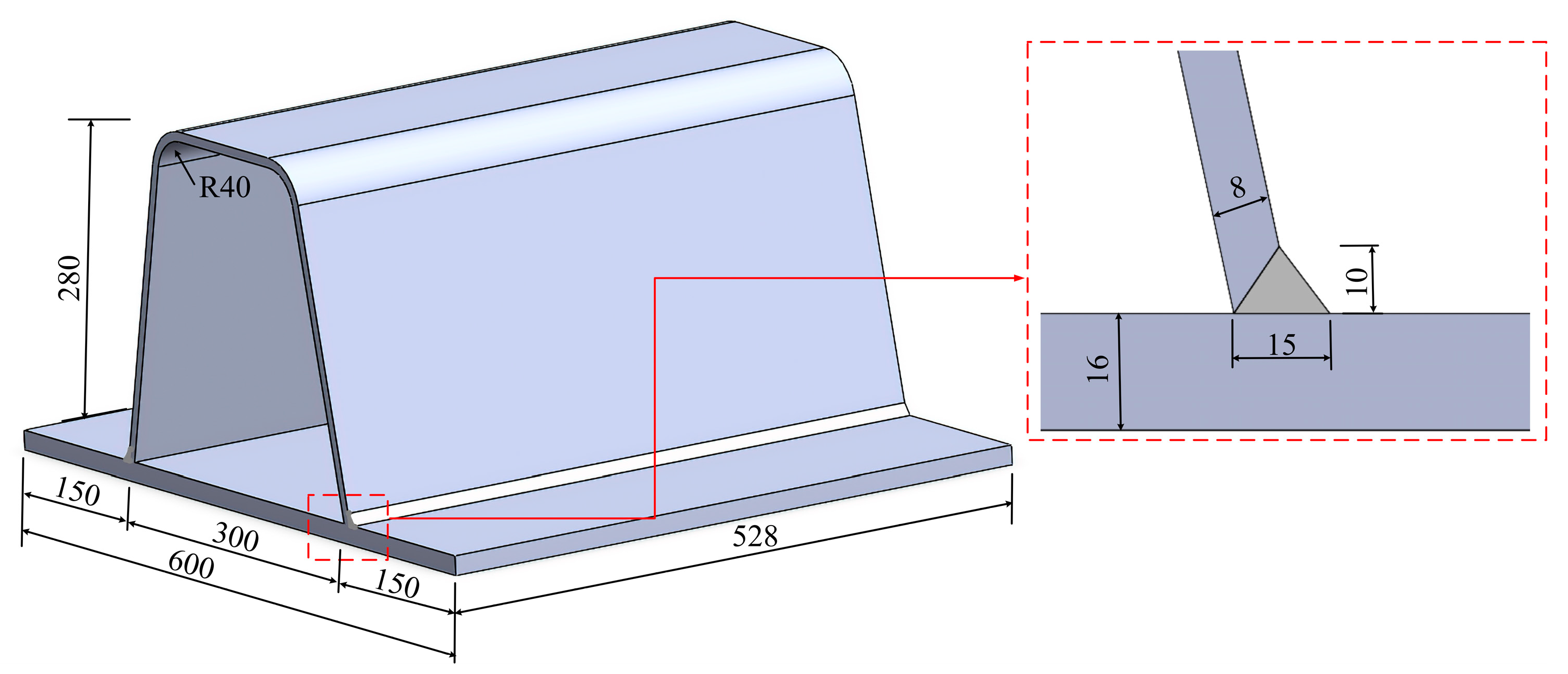

2.2. Sample and Welding Process

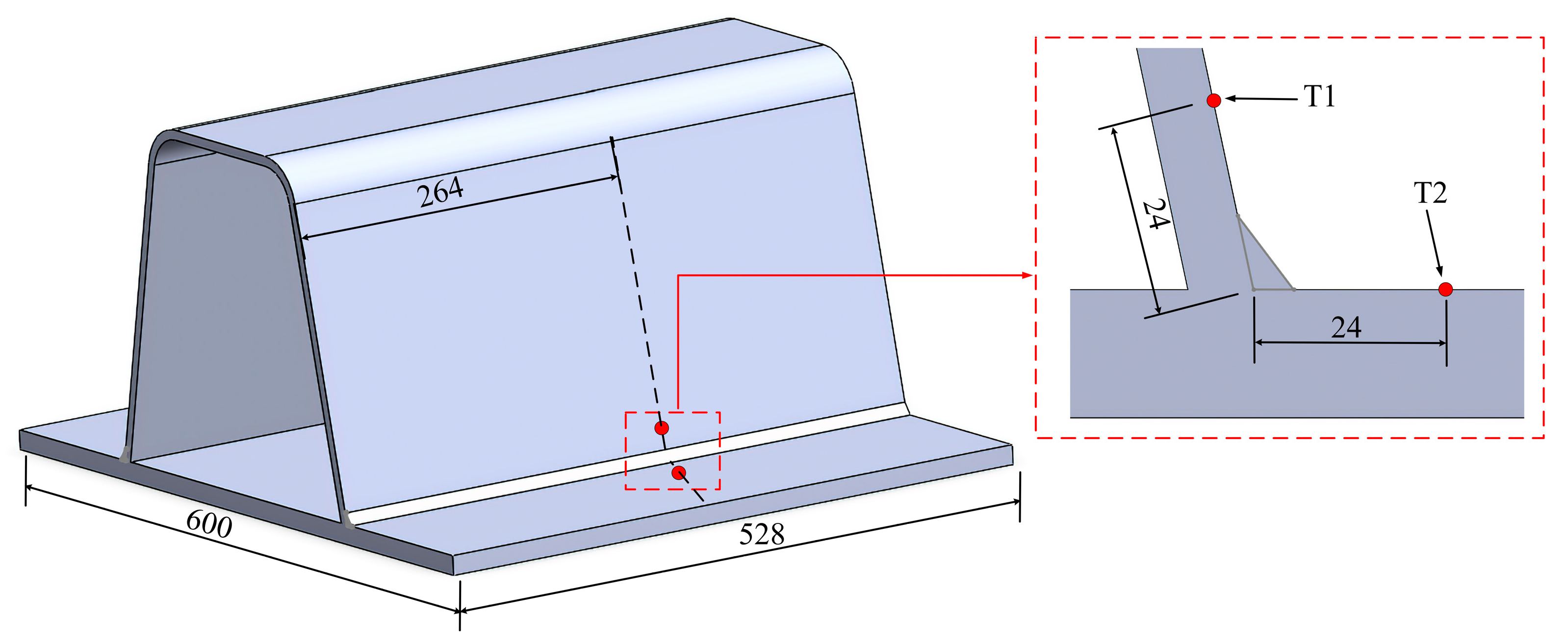

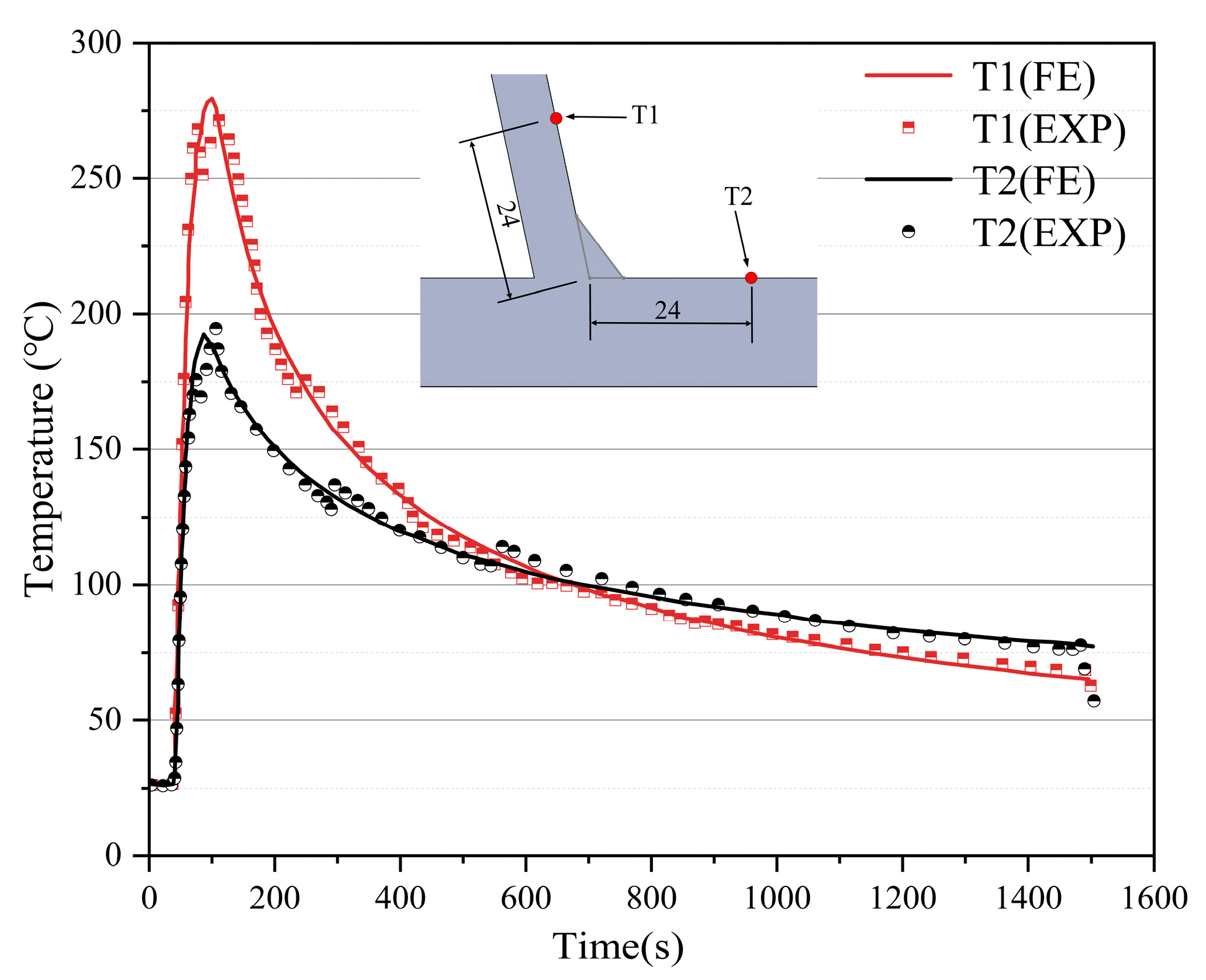

2.3. Temperature Measurement

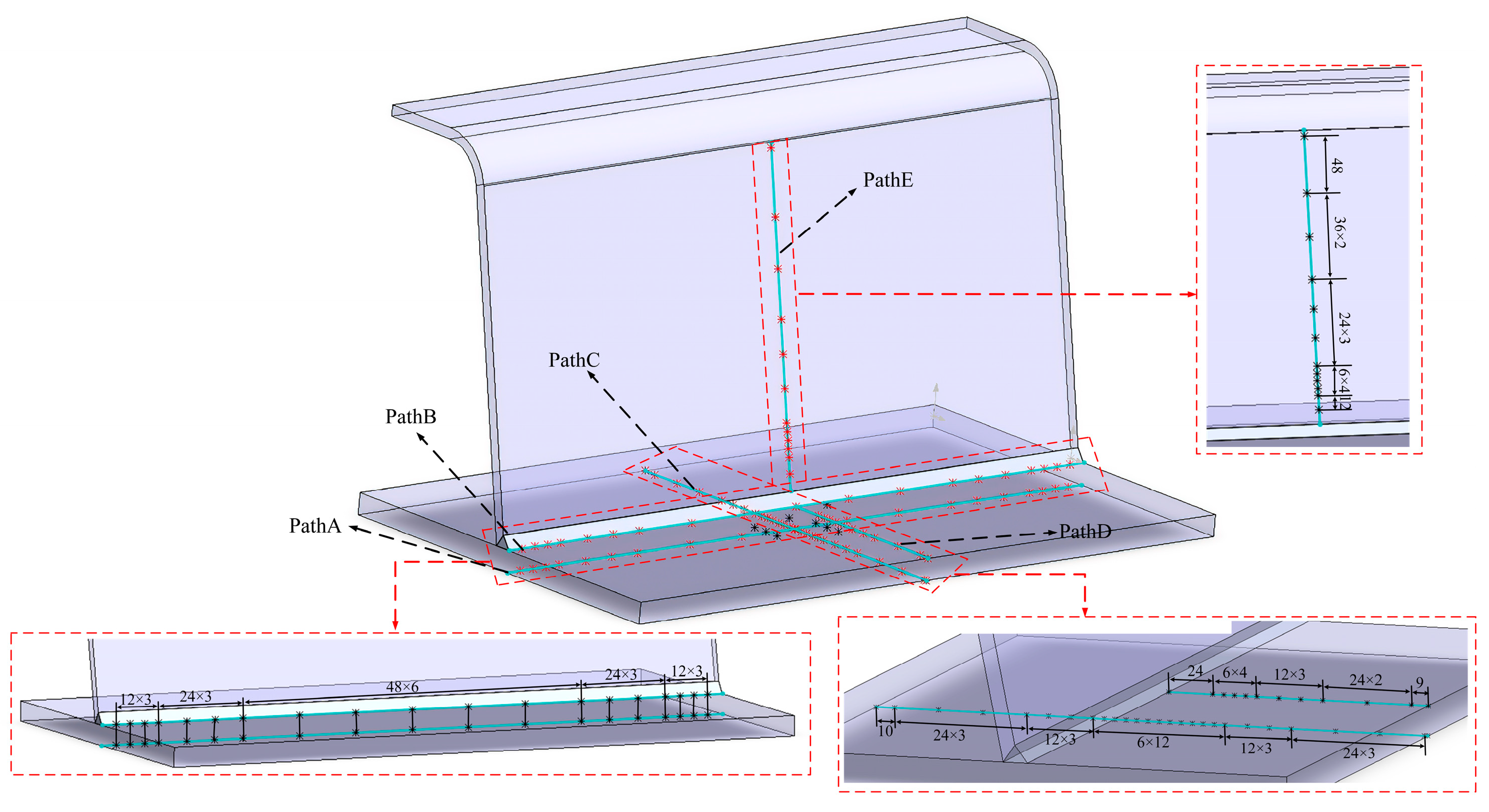

2.4. Stress Measurement

3. Numerical Simulation

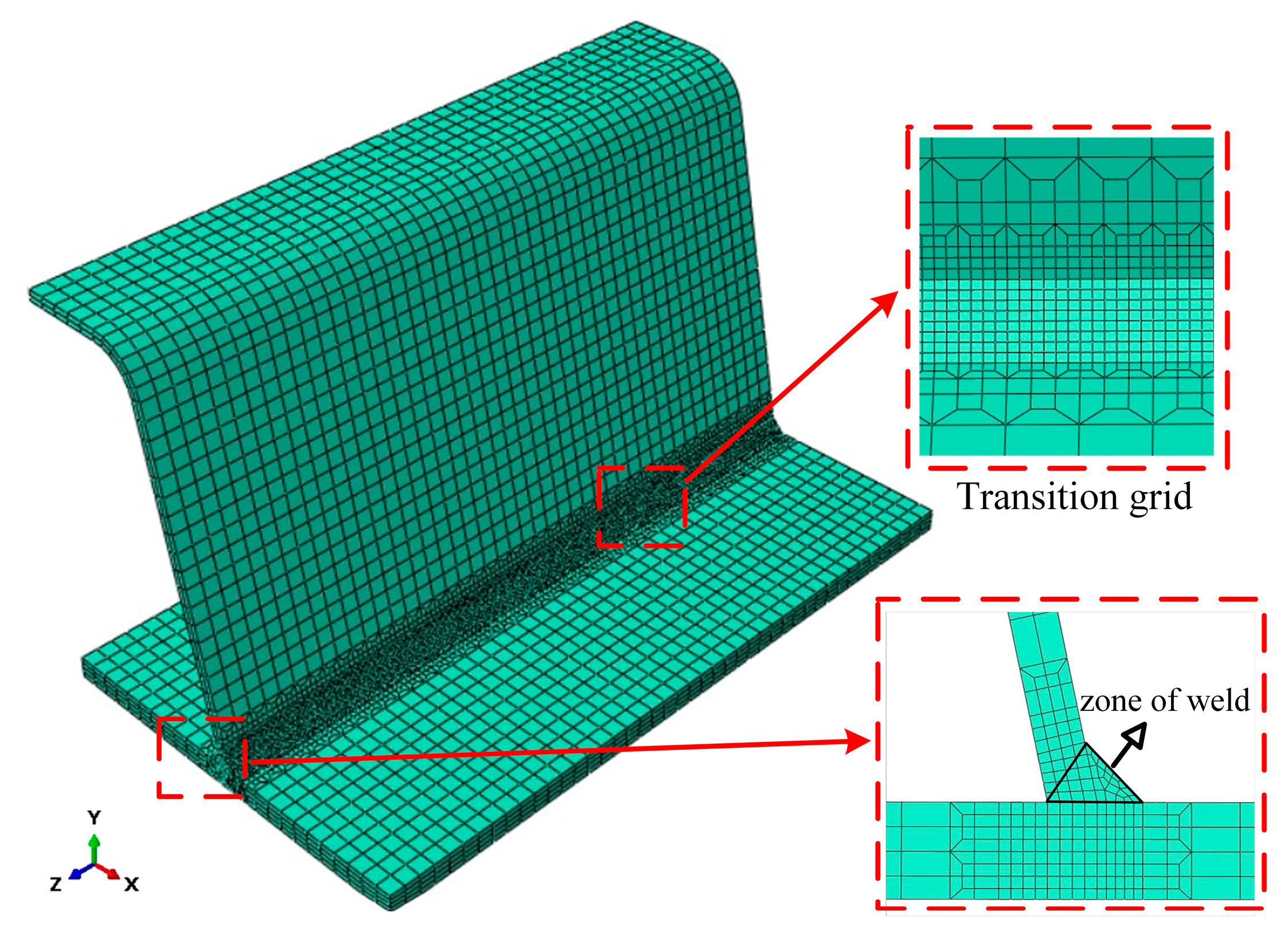

3.1. Finite Element Model

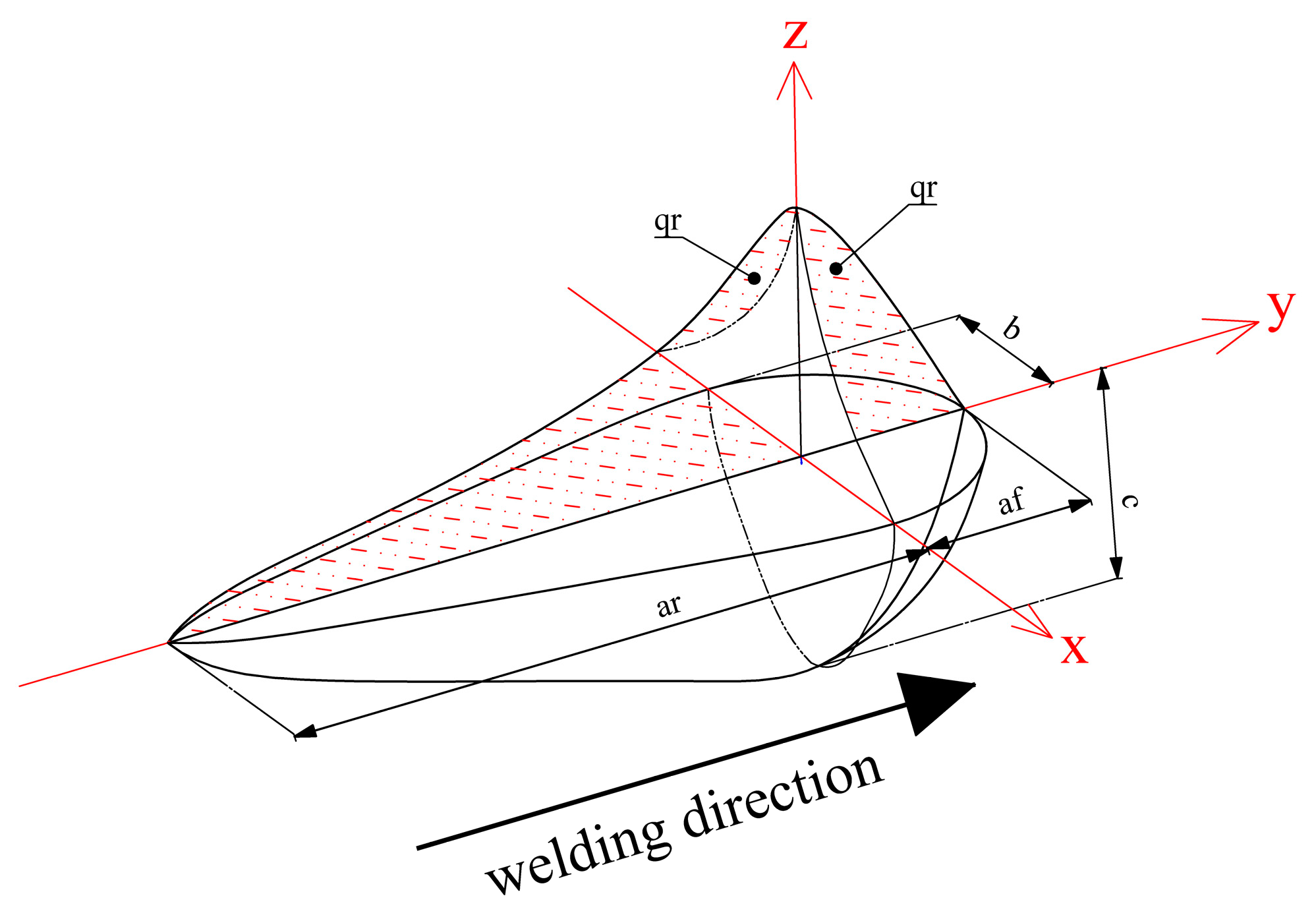

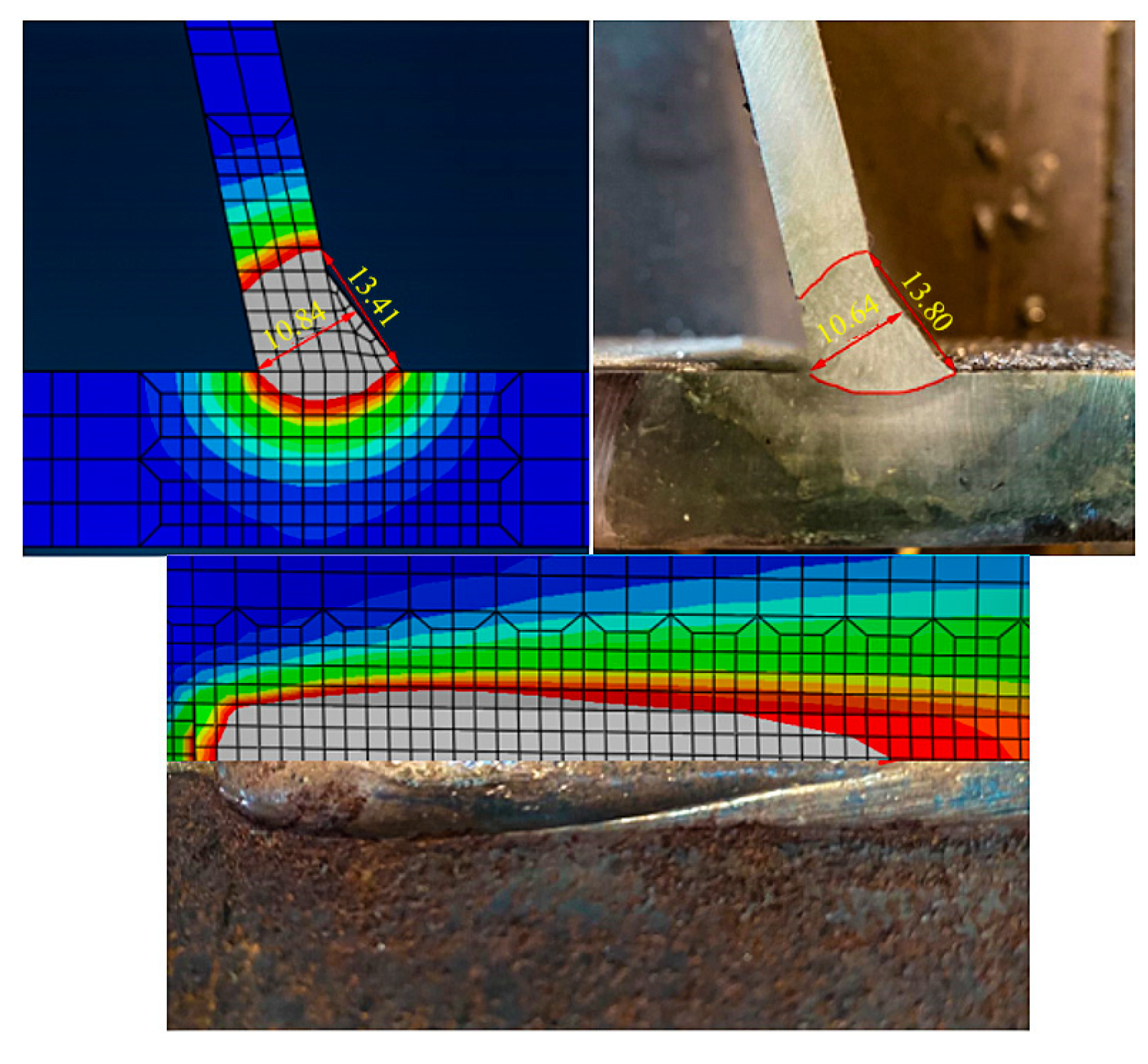

3.2. Heat Source and Thermal Analysis

3.3. Material and Mechanical Analysis

4. Result and Discussion

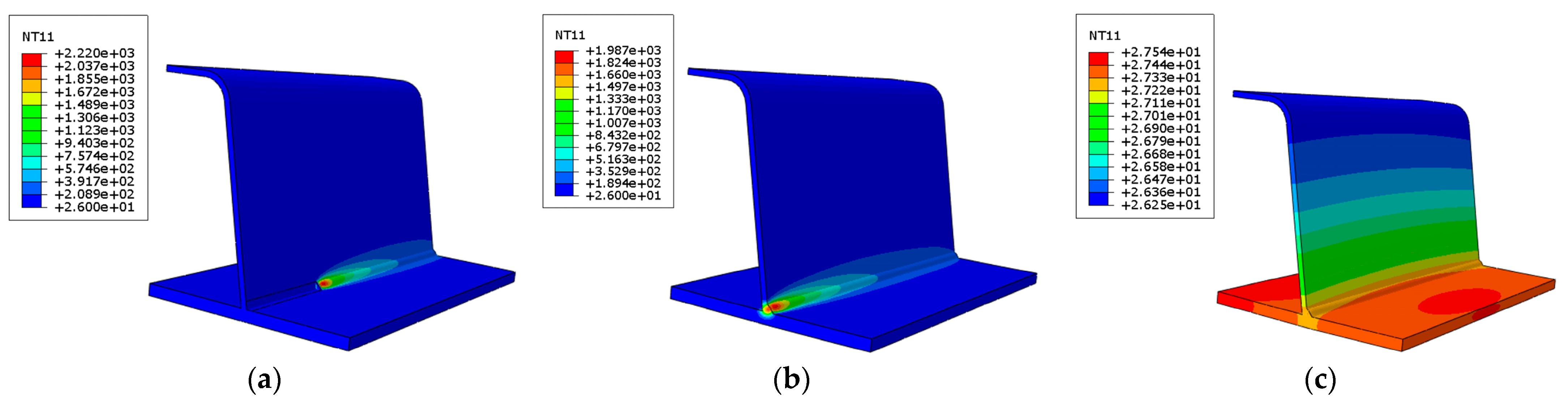

4.1. Temperature Field Results

4.2. Residual Stress Results

4.3. Influence of Welding Parameters

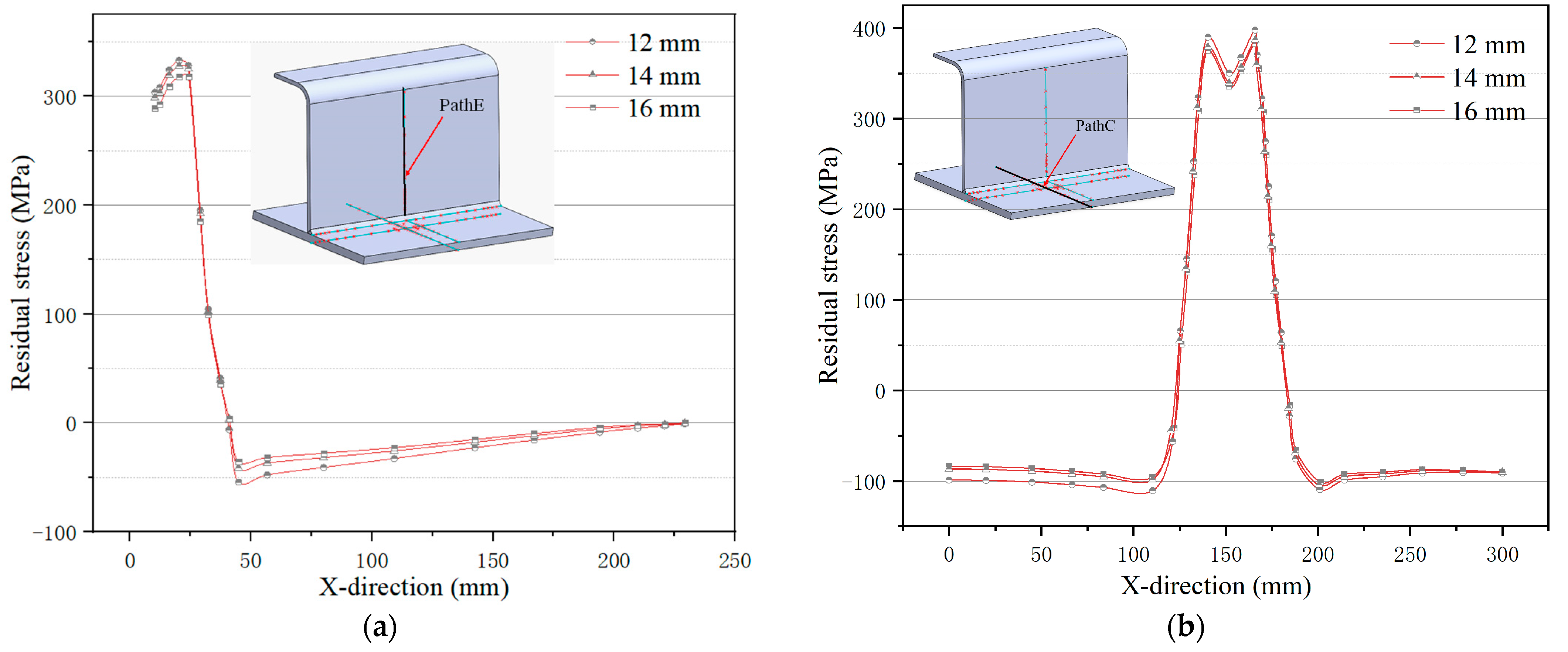

4.3.1. Roof Panel Thickness

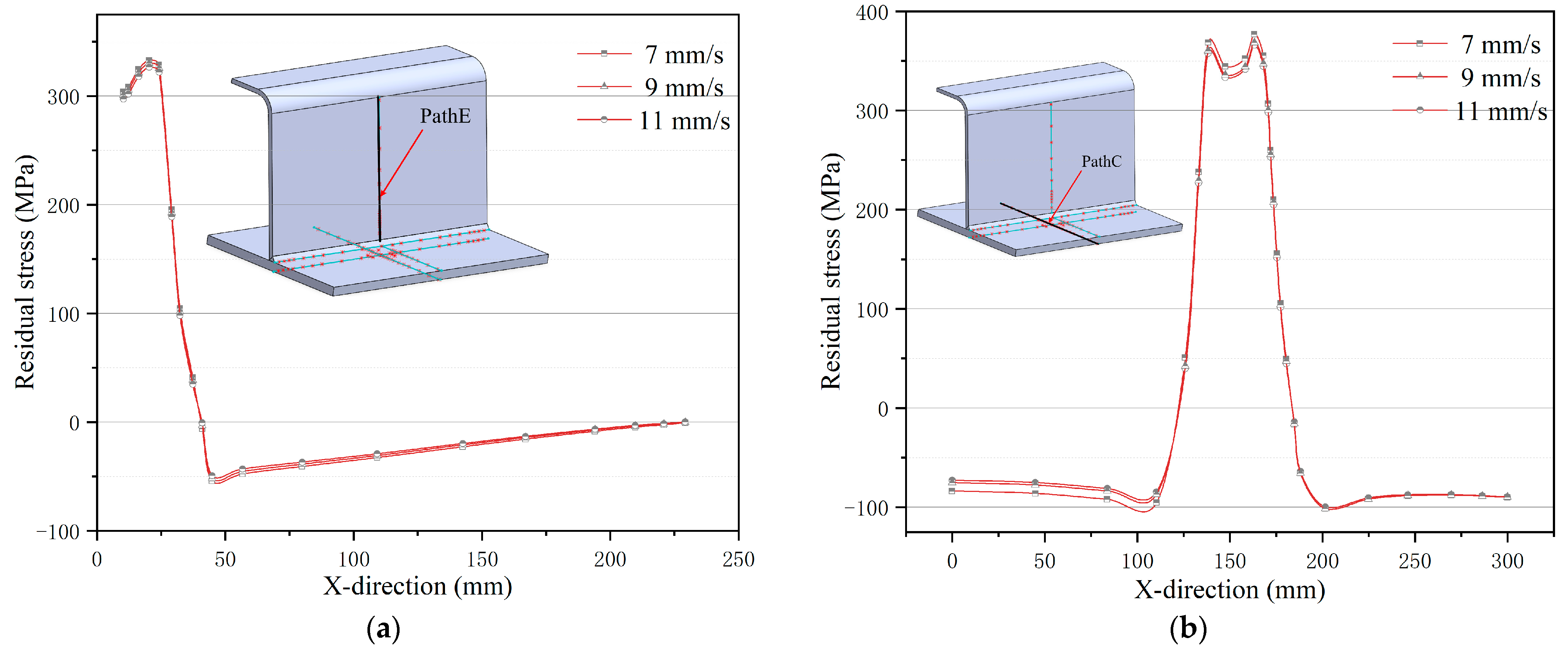

4.3.2. Welding Speed

5. Conclusions

- (1)

- Through the combination of simulation and experimental methods, the single-sided full-penetration welding effect of OSDs under specific welding process conditions was systematically explored. Under the experimental conditions, the welding current was set to 564 A, the welding voltage was 35 V, and the welding speed was 7 mm/s. The single-pass weld forming without a groove was successfully realized, and the weld penetration rate was ensured to meet the technical requirements of more than 100%. This finding provides an efficient and economical solution for the welding process of orthotropic steel bridge decks.

- (2)

- The FE results are in good agreement with the EXP measurement results, indicating the accuracy of the FE model. In the vicinity of the weld, the longitudinal WRS was significantly higher than the transverse WRS, revealing the anisotropy of stress distribution during welding. The peak value of the residual tensile stress appeared near the weld. With the increase in distance, the stress gradually decreased along the vertical weld direction and transformed into compressive stress. In the stress distribution of the weld surface, the maximum tensile stress was 407.46 MPa, and the maximum compressive stress was −378.62 MPa. The average residual stress on the surface of the plate was about−95 MPa, indicating the dominant role of compressive stress. However, in the area of about 25 mm on both sides of the weld, the tensile stress increased significantly, and the maximum value reached 380.87 MPa. This phenomenon is of great significance for evaluating the fatigue performance of the welded structure. For the outer surface of the U-rib, the residual stress was mainly longitudinal. In the range of 38 mm from the root of the weld, the stress was mainly tensile stress, and the maximum recorded value was 334.09 MPa. This finding further emphasizes the influence of the welding details on the overall structural performance.

- (3)

- Based on the results of FE analysis, the effects of roof thickness and welding speed on WRS were discussed. The longitudinal stress of the RTD joint decreased with the increase in the welding speed, which indicates that the welding speed is an important factor affecting the residual stress. At the same time, the increase in the roof thickness also led to a decrease in the longitudinal residual stress, although the effect was relatively small. For the WRS of the top plate and the outer surface of the U-shaped rib, it was found that the influence of the thickness of the top plate and the welding speed was not significant, indicating that these parameters have limited influence on the residual stress distribution characteristics in a specific area.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Q.; Ma, Y.; Cui, C.; Chai, X.Y.; Han, S.H. Experimental investigation and numerical simulation on welding residual stress of innovative double-side welded rib-to-deck joints of orthotropic steel decks. J. Constr. Steel Res. 2021, 179, 106544. [Google Scholar] [CrossRef]

- Abdelbaset, H.; Cheng, B.; Tian, L.; Li, H.T.; Zhang, Q.H. Reduce hot spot stresses in welded connections of orthotropic steel bridge decks by using UHPC layer: Experimental and numerical investigation. Eng. Struct. 2020, 220, 110988. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhang, Q.; Bao, Y.; Deng, P.; Wei, C.; Li, M. Flexural behavior of corrugated steel-UHPC composite bridge decks. Eng. Struct. 2021, 246, 113066. [Google Scholar] [CrossRef]

- Wang, S.; Pei, J.; Ren, F.; Qin, S.; Li, Z.; Xu, G.; Wang, X. Numerical study of full penetration single-and double-sided U-rib welding in orthotropic bridge decks. Case Stud. Constr. Mater. 2024, 20, e03120. [Google Scholar] [CrossRef]

- Maddox, S.J. Fatigue Strength of Welded Structures; Woodhead Publishing: Sawston, UK, 2014. [Google Scholar]

- Maljaars, J.; Pijpers, R.; Wu, W.; Kolstein, H. Fatigue resistance of rib to deck, crossbeam to deck and deck to deck welds in orthotropic decks using structural stress. Int. J. Fatigue 2023, 175, 107742. [Google Scholar] [CrossRef]

- Martucci, D.; Civera, M.; Surace, C. Bridge monitoring: Application of the extreme function theory for damage detection on the I-40 case study. Eng. Struct. 2023, 279, 115573. [Google Scholar] [CrossRef]

- Civera, M.; Sibille, L.; Fragonara, L.Z.; Ceravolo, R. A DBSCAN-based automated operational modal analysis algorithm for bridge monitoring. Measurement 2023, 208, 112451. [Google Scholar] [CrossRef]

- Ueda, Y.; Yamakawa, T. Analysis of thermal elastic-plastic stress and strain during welding by finite element method. Jpn. Weld. Soc. Trans. 1971, 2, 116–123. [Google Scholar] [CrossRef]

- Cao, B.Y.; Ding, Y.L. Effect of plate thickness on welding residual stress of longitudinal ribs of steel bridge deck. J. Southeast Univ. (Nat. Sci. Ed.) 2016, 46, 565–571. [Google Scholar]

- Kainuma, S.; Jeong, Y.S.; Yang, M.; Inokuchi, S. Welding residual stress in roots between deck plate and U-rib in orthotropic steel decks. Measurement 2016, 92, 475–482. [Google Scholar] [CrossRef]

- Ji, B.H.; Li, K.K.; Fu, Z. Welding residual stress analysis of steel bridge deck roof and U rib joint. J. Jiangnan Univ. (Nat. Sci. Ed.) 2015, 14, 197–201. [Google Scholar]

- Lee, C.H.; Chang, K.H. Numerical analysis of residual stresses in welds of similar or dissimilar steel weldments under superimposed tensile loads. Comput. Mater. Sci. 2007, 40, 548–556. [Google Scholar] [CrossRef]

- Perić, M.; Garašić, I.; Tonković, Z.; Vuherer, T.; Nižetić, S.; Dedić-Jandrek, H. Numerical prediction and experimental validation of temperature and residual stress distributions in buried-arc welded thick plates. Int. J. Energy Res. 2019, 43, 3590–3600. [Google Scholar] [CrossRef]

- Mathar, J. Determination of initial stresses by measuring the deformations around drilled holes. Trans. Am. Soc. Mech. Eng. 1934, 56, 249–254. [Google Scholar] [CrossRef]

- Kang, L. Numerical Simulation of Welding Residual Stress of Longitudinal and Transverse Ribs of Orthotropic Steel Bridge Deck; Southwest Jiaotong University: Chengdu, China, 2015. [Google Scholar]

- Kung, C.L.; Lin, A.D.; Huang, P.W.; Hsu, C.M. Estimation formula for residual stress from the blind-hole drilling method. Adv. Mech. Eng. 2018, 10, 1687814018787409. [Google Scholar] [CrossRef]

- Van Puymbroeck, E.; Nagy, W.; De Backer, H. Influence of the welding process on the residual welding stresses in an orthotropic steel bridge deck. Procedia Struct. Integr. 2018, 13, 920–925. [Google Scholar] [CrossRef]

- Lee, C.K.; Chiew, S.P.; Jiang, J. Residual stress study of welded high strength steel thin-walled plate-to-plate joints part 2: Numerical modeling. Thin Walled Struct. 2012, 59, 120–131. [Google Scholar] [CrossRef]

- Sterling, D.; Sterling, T.; Zhang, Y.; Chen, H. Welding parameter optimization based on Gaussian process regression Bayesian optimization algorithm. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 1490–1496. [Google Scholar] [CrossRef]

- Chen, X.R.; Zhao, Z.Y.; Jiang, Y.Y. Experimental study on welding residual stress of box section with over-limit width-thickness ratio. J. Civ. Eng. 2010, 43, 281–285. [Google Scholar]

- Lurie, A.I. Theory of Elasticity; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Mater. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Kalita, K.; Burande, D.; Ghadai, R.K.; Chakraborty, S. Finite element modelling, predictive modelling and optimization of metal inert gas, tungsten inert gas and friction stir welding processes: A comprehensive review. Arch. Comput. Methods Eng. 2023, 30, 271–299. [Google Scholar] [CrossRef]

- Yang, W.; Shi, Y.; Wang, Y.; Shi, G. Three-dimensional finite element analysis of welding residual stress of structural steel. J. Jilin Univ. 2007, 3, 347–352. [Google Scholar]

- Yaghi, A.; Hyde, T.H.; Becker, A.A.; Sun, W.; Williams, J.A. Residual stress simulation in thin and thick-walled stainless steel pipe welds including pipe diameter effects. Int. J. Press. Vessels Pip. 2006, 83, 864–874. [Google Scholar] [CrossRef]

- Shankar Goud, B.; Dharmaiah, G. Role of Joule heating and activation energy on MHD heat and mass transfer flow in the presence of thermal radiation. Numer. Heat Transf. Part B Fundam. 2023, 84, 620–641. [Google Scholar] [CrossRef]

- Zhou, S.T. Study on Residual Stresses in Full Penetration U-Ribs Stiffened Orthotropic Anisotropic Steel Bridge Panels; Southwest Jiaotong University: Chengdu, China, 2018. [Google Scholar]

- Huang, L. Study on High Temperature Performance and Stress Analysis of Slab Continuous Casting; Chongqing University: Chongqing, China, 2007. [Google Scholar]

- Lu, W.L.; Sun, J.L.; Su, H.; Chen, L.J.; Zhou, Y.Z. Experimental research and numerical analysis of welding residual stress of butt welded joint of thick steel plate. Case Stud. Constr. Mater. 2023, 18, e01991. [Google Scholar] [CrossRef]

- Raftar, H.R.; Ahola, A.; Lipiäinen, K.; Björk, T. Simulation and experiment on residual stress and deflection of cruciform welded joints. J. Constr. Steel Res. 2023, 208, 108023. [Google Scholar] [CrossRef]

- Wang, M.; Ning, F.; Pei, Y.; Wang, Y.; Cao, J.; Zhao, L.; Xu, Q.; Zhu, Z. A novel Aluminium-stabilized Stacked REBCO Tape Cable. IEEE Trans. Appl. Supercond. 2024, 34, 4802509. [Google Scholar] [CrossRef]

| Chemical Composition | C | Si | Mn | P | S | Cr | Cu | Nb | Ti | NI | Als | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q345qE (%) | 0.11 | 0.24 | 1.39 | 0.022 | 0.009 | 0.02 | 0.02 | 0.011 | 0.016 | 0.13 | 0.026 | 0.005 |

| BFH08Mn2E (%) | 0.08 | 0.032 | 1.81 | 0.012 | 0.008 | 0.025 | 7 | 0.015 |

| Mechanical Property | Yield Strength (MPa) | Tensile Strength (Mpa) |

|---|---|---|

| Q345qE | 392 | 533 |

| BFH08Mn2E | 479 | 561 |

| Welding Technique | Current (A) | Voltage (V) | Welding Speed (mm/s) | Welding Torch Tilt Angle |

|---|---|---|---|---|

| Submerged arc welding | 560~568 | 34~36 | 7 | 30° |

| Parameter | ||||||

|---|---|---|---|---|---|---|

| Value | 13.8 | 13.3 | 43.26 | 10.64 | 0.5 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pei, J.; Wang, X.; Qin, S.; Xu, G.; Su, F.; Wang, S.; Li, Z. Experimental and Numerical Simulation Study on Residual Stress of Single-Sided Full-Penetration Welded Rib-to-Deck Joint of Orthotropic Steel Bridge Deck. Buildings 2024, 14, 2641. https://doi.org/10.3390/buildings14092641

Pei J, Wang X, Qin S, Xu G, Su F, Wang S, Li Z. Experimental and Numerical Simulation Study on Residual Stress of Single-Sided Full-Penetration Welded Rib-to-Deck Joint of Orthotropic Steel Bridge Deck. Buildings. 2024; 14(9):2641. https://doi.org/10.3390/buildings14092641

Chicago/Turabian StylePei, Jiangning, Xinzhi Wang, Songlin Qin, Guangpeng Xu, Fulin Su, Shengbao Wang, and Zhonglong Li. 2024. "Experimental and Numerical Simulation Study on Residual Stress of Single-Sided Full-Penetration Welded Rib-to-Deck Joint of Orthotropic Steel Bridge Deck" Buildings 14, no. 9: 2641. https://doi.org/10.3390/buildings14092641

APA StylePei, J., Wang, X., Qin, S., Xu, G., Su, F., Wang, S., & Li, Z. (2024). Experimental and Numerical Simulation Study on Residual Stress of Single-Sided Full-Penetration Welded Rib-to-Deck Joint of Orthotropic Steel Bridge Deck. Buildings, 14(9), 2641. https://doi.org/10.3390/buildings14092641