Fiber Showdown: A Comparative Analysis of Glass vs. Polypropylene Fibers in Hot-Mix Asphalt Fracture Resistance

Abstract

1. Introduction

2. Materials, Manufacturing Methodology, and Mechanical Testing

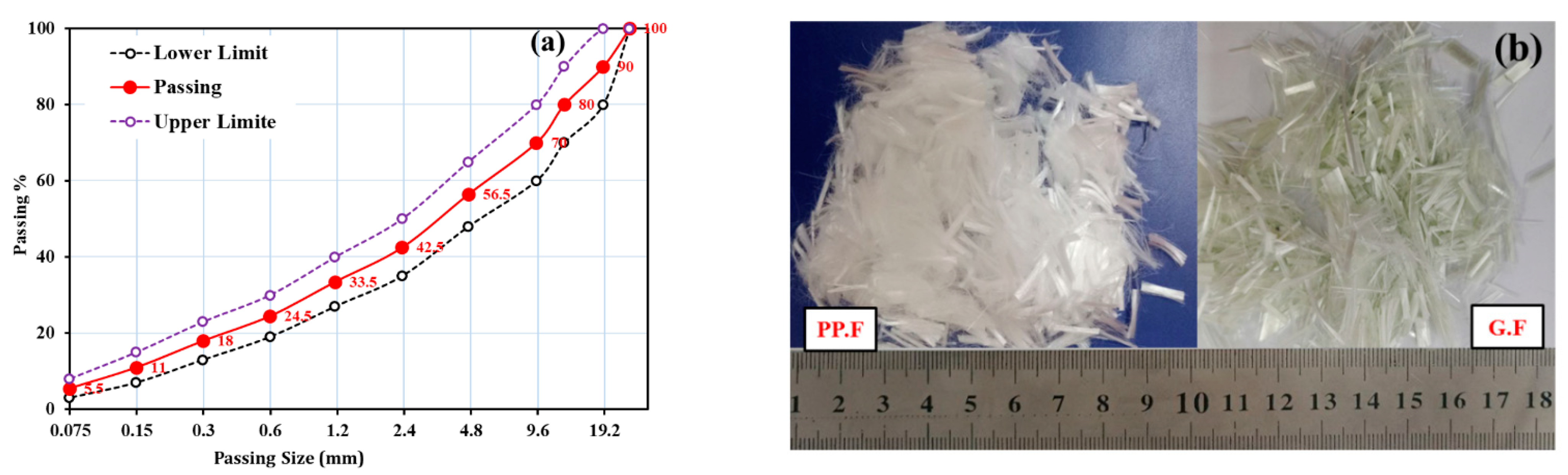

2.1. Materials

2.2. Manufacturing Method

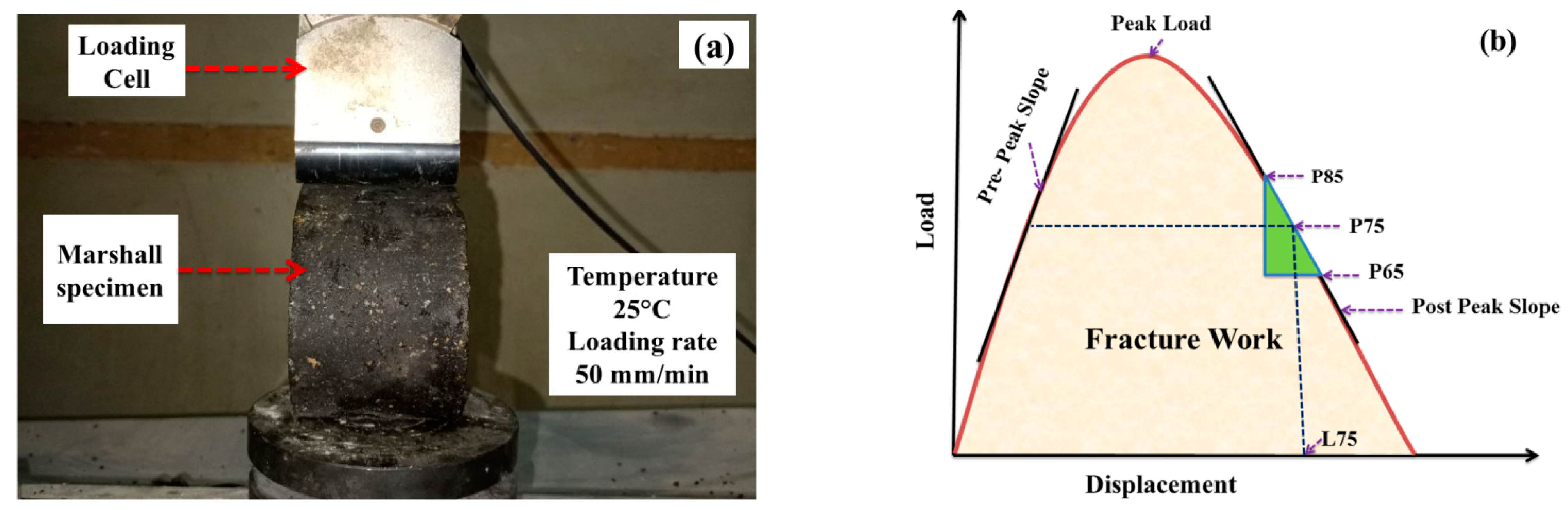

2.3. Mechanical Testing

2.3.1. Semi-Circular Bending (SCB) Test

2.3.2. Indirect Tensile Asphalt Cracking Test (IDEAL-CT)

2.3.3. Three-Point Bending (3-PB) Tests

3. Results and Discussion

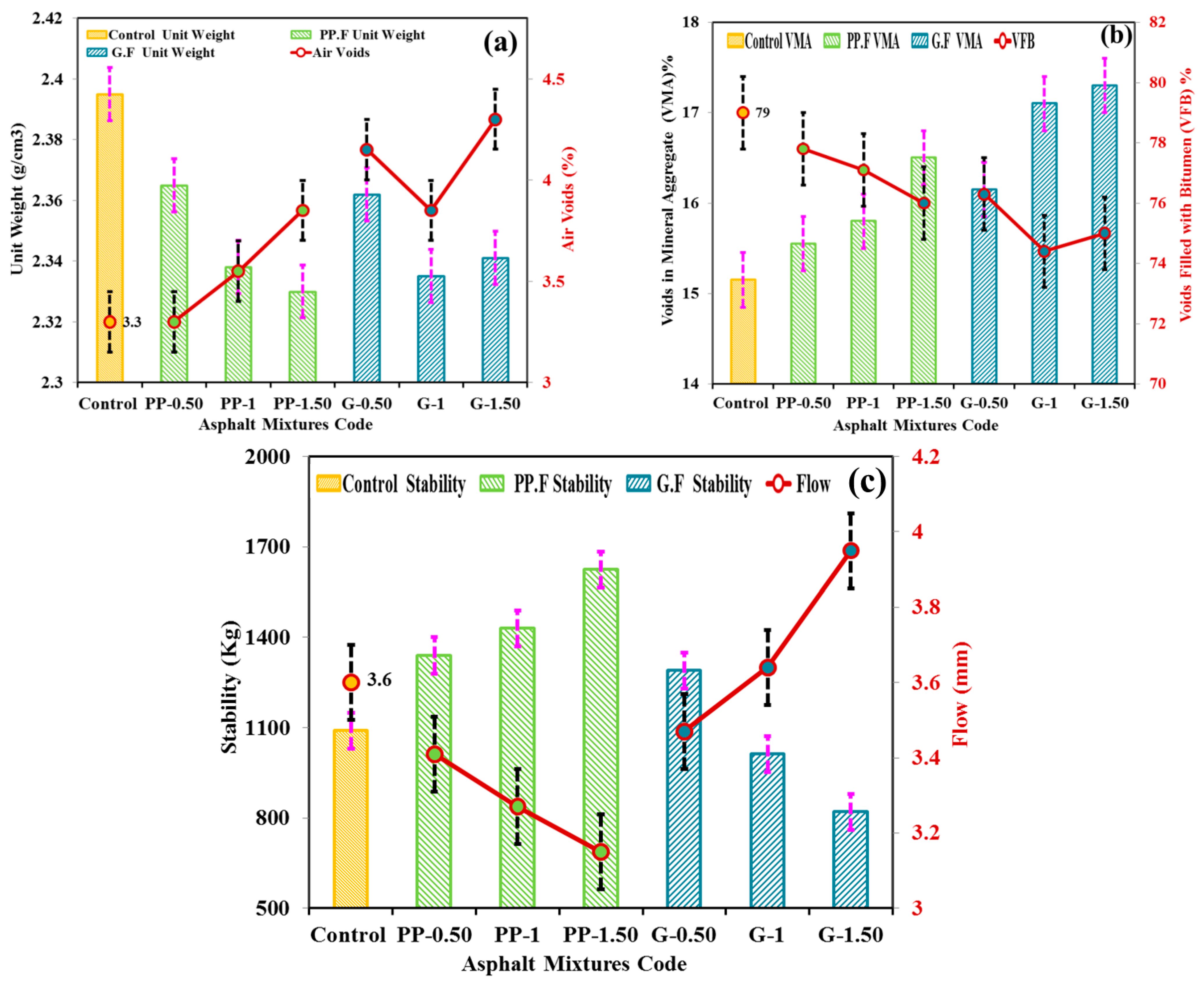

3.1. Physical Properties and Marshall Results of Fiber HMA

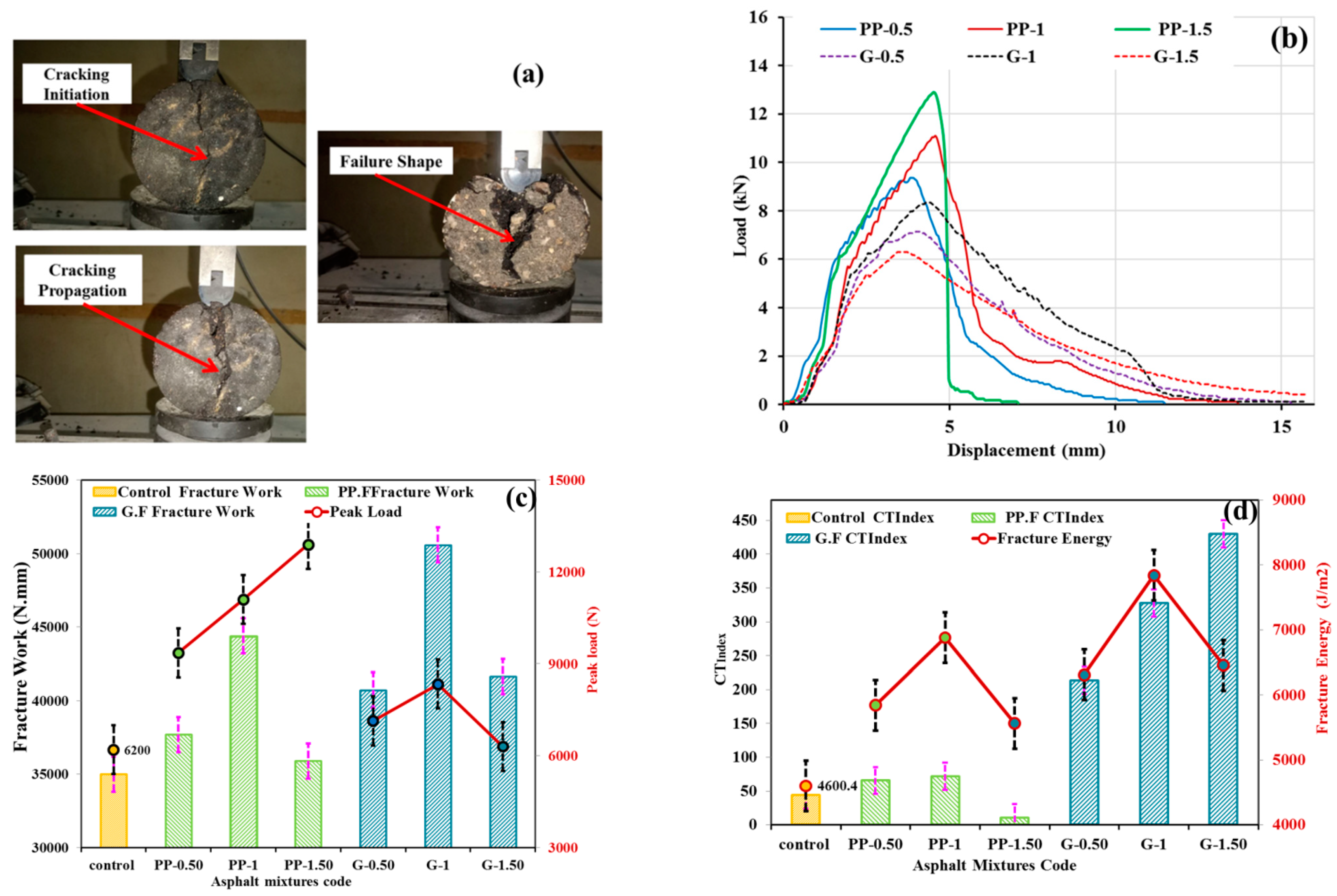

3.2. Semi-Circular Bending (SCB) Test Results

3.3. Indirect Tensile Asphalt Cracking Test (IDEAL-CT) Results

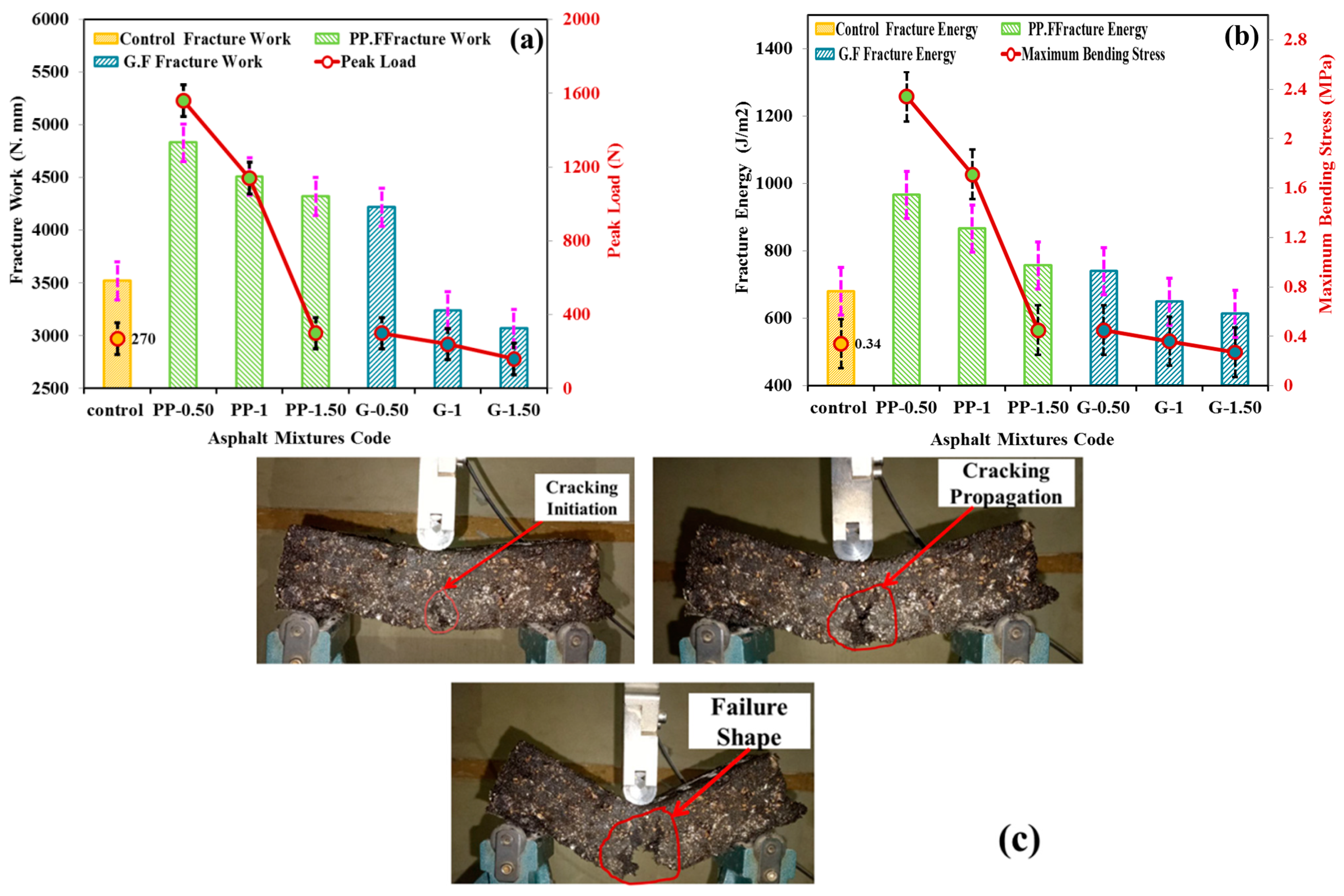

3.4. Three-Point Bending (3-PB) Test Results

4. Conclusions

- The results showed that both PP.Fs and GFs significantly affected the fracture behavior and mechanical properties of bituminous mixtures. Comparing and testing various specimen geometries in SCB, IDEAL-CT, and 3-PB tests highlighted how these fibers influence the fracture characteristics of the asphalt mixture.

- Fracture energy in bituminous mixtures was significantly enhanced with the addition of PP.Fs and G.Fs based on all study tests. The SCB test showed optimal results at 1–1.5% fiber content, with increases of 63.2% (PP-1) and 60.4% (G-1.5). Similarly, IDEAL-CT results peaked with PP-1 and G-1 at 49.6% and 70.4%, respectively. However, in the 3-PB test, optimal fiber content dropped to 0.5%, achieving 42% (PP-0.5) and 8.8% (G-0.5). Therefore, maintaining fiber content between 0.5% and 1% is recommended for optimal fracture energy.

- The addition of G.Fs significantly augmented the crack resistance of bituminous mixtures, over both the control and PP.F mixtures. The G-1.5 mixture achieved the highest CRI values, increasing by 87.9% over the control, while the PP-0.5 mixture in the PP.F group observed a 30.3% increase. However, increasing PP.F dosage by more than 1% reduced CRI values below the control, indicating reduced crack resistance and increased brittleness in PP.F mixtures.

- G.Fs notably enhanced the flexibility of the bituminous mixture over PP.Fs, with the G-1.5 mixture achieving peak FI and CT Index values, increasing by 269.8% and 886%, respectively, over the control. The PP-1 mixture in the PP.F group showed increases of 31.2% and 64.9%, but higher PP.F dosages beyond 1% led to reduced flexibility, indicating a decline in the mixture’s resistance to elastic deformations.

- The 3-PB test results indicate that increasing doses of PP.Fs and G.Fs reduce maximum bending stress, with 0.5% being the optimal dosage for both fiber types. The PP-0.5 and G-0.5 mixtures show significant increases in maximum bending stress by 588.2% and 32.3%, respectively, compared to the control mixture.

- High doses of PP.F notably improve mechanical properties but result in poor fracture behavior. A 1% dosage of PP.F is optimal, offering a balanced enhancement in both mechanical properties and fracture resistance.

- G.Fs are more effective than PP.Fs in boosting fracture resistance and flexibility in asphalt mixtures. Reinforcing with 1% G.F is an optimal strategy for improving crack resistance while maintaining acceptable mechanical properties in G.F reinforcement applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Moe, A.L.; Lee, Y.P.K.; Ho, N.Y.; Wang, X. Rutting and Cracking Performance of Asphalt Concrete Incorporating Plastic Waste and Crumb Rubber. In Road and Airfield Pavement Technology: Proceedings of 12th International Conference on Road and Airfield Pavement Technology, Online, 8–10 June 2021; Springer: Amsterdam, The Netherlands, 2022; pp. 855–865. [Google Scholar]

- Zhang, J.; Tan, H.; Pei, J.; Qu, T.; Liu, W. Evaluating crack resistance of asphalt mixture based on essential fracture energy and fracture toughness. Int. J. Geomech. 2019, 19, 6019005. [Google Scholar] [CrossRef]

- Ding, X.; Ma, T.; Gu, L.; Zhang, Y. Investigation of surface micro-crack growth behavior of asphalt mortar based on the designed innovative mesoscopic test. Mater. Des. 2020, 185, 108238. [Google Scholar] [CrossRef]

- Tabasi, E.; Zarei, M.; Naseri, A.; Hosseini, S.G.; Mirahmadi, M.; Khordehbinan, M.W. Low temperature cracking behavior of modified asphalt mixture under modes I and III. Theor. Appl. Fract. Mech. 2023, 128, 104150. [Google Scholar] [CrossRef]

- Fatemi, S.; Zarei, M.; Ziaee, S.A.; Saadatjoo, S.A.; Khordehbinan, M.W. Evaluation of long-term fracture behavior of amorphous poly alpha olefin (APAO)-modified Hot Mix Asphalt (HMA) under modes I and II at low and intermediate temperatures. Constr. Build. Mater. 2023, 366, 130188. [Google Scholar] [CrossRef]

- Tabasi, E.; Zarei, M.; Mobasheri, Z.; Naseri, A.; Ghafourian, H.; Khordehbinan, M.W. Pre- and post-cracking behavior of asphalt mixtures under modes I and III at low and intermediate temperatures. Theor. Appl. Fract. Mech. 2023, 124, 103826. [Google Scholar] [CrossRef]

- Zhang, G.; Tang, C.; Chen, P.; Long, G.; Cao, J.; Tang, S. Advancements in phase-field modeling for fracture in nonlinear elastic solids under finite deformations. Mathematics 2023, 11, 3366. [Google Scholar] [CrossRef]

- Zhu, Y.; Dave, E.V.; Rahbar-Rastegar, R.; Daniel, J.S.; Zofka, A. Comprehensive evaluation of low-temperature fracture indices for asphalt mixtures. Road Mater. Pavement Des. 2017, 18, 467–490. [Google Scholar] [CrossRef]

- Zhou, F.; Im, S.; Hu, S.; Newcomb, D.; Scullion, T. Selection and preliminary evaluation of laboratory cracking tests for routine asphalt mix designs. Road Mater. Pavement Des. 2017, 18, 62–86. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Li, K.; Ding, Y.; Geng, L. Cracking analysis of asphalt mixture using semi-circle bending method. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 269–279. [Google Scholar] [CrossRef]

- Sarkar, M.T.A.; Elseifi, M.A. Experimental evaluation of asphalt mixtures with emerging additives against cracking and moisture damage. J. Road Eng. 2023, 3, 336–349. [Google Scholar] [CrossRef]

- Zou, C.; Hua, Z.; Mo, L.; Qi, C.; Liu, Z.; Xie, Y.; Yu, H.; Ke, J. Evaluation on the performance of hydraulic bitumen binders under high and low temperatures for pumped storage power station projects. Materials 2022, 15, 1890. [Google Scholar] [CrossRef]

- Safazadeh, F.; Romero, P.; Asib, A.S.M.; VanFrank, K. Methods to evaluate intermediate temperature properties of asphalt mixtures by the semi-circular bending (SCB) test. Road Mater. Pavement Des. 2022, 23, 1694–1706. [Google Scholar] [CrossRef]

- Limón-Covarrubias, P.; Cueva, D.A.; Vidal, G.V.; Ortiz, O.J.R.; Hernández, R.O.A.; González, J.R.G. Analysis of the behavior of SMA mixtures with different fillers through the semicircular bend (SCB) fracture test. Materials 2019, 12, 288. [Google Scholar] [CrossRef]

- Meng, Y.; Lu, Y.; Kong, W.; Chen, J.; Zhang, C.; Meng, F. Study on the influence factors of fatigue properties of large-stone asphalt mixtures based on semi-circular bending tests. Constr. Build. Mater. 2024, 414, 134947. [Google Scholar] [CrossRef]

- Mubaraki, M.; Sallam, H.E.M. Reliability study on fracture and fatigue behavior of pavement materials using SCB specimen. Int. J. Pavement Eng. 2020, 21, 1563–1575. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, J.; Zhou, L.; Ni, F. Improving the calculation accuracy of FEM for asphalt mixtures in simulation of SCB test considering the mesostructure characteristics. Int. J. Pavement Eng. 2022, 23, 80–94. [Google Scholar] [CrossRef]

- Zhou, F.; Newcomb, D.; Gurganus, C.; Banihashemrad, S.; Park, E.S.; Sakhaeifar, M.; Lytton, R.L. Experimental design for field validation of laboratory tests to assess cracking resistance of asphalt mixtures. NCHRP Proj. 2016, 9, 6–9. [Google Scholar]

- Du, H.; Ni, F.; Ma, X. Crack resistance evaluation for In-service asphalt pavements by using SCB tests of layer-core samples. J. Mater. Civ. Eng. 2021, 33, 04020418. [Google Scholar] [CrossRef]

- Kavussi, A.; Naderi, B. Application of SCB test and surface free energy method in evaluating crack resistance of SBS modified asphalt mixes. Civ. Eng. Infrastruct. J. 2020, 53, 103–114. [Google Scholar]

- Falchetto, A.C.; Moon, K.H.; Wang, D.; Riccardi, C.; Wistuba, M.P. Comparison of low-temperature fracture and strength properties of asphalt mixture obtained from IDT and SCB under different testing configurations. Road Mater. Pavement Des. 2018, 19, 591–604. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, Y.; Bahia, H.U. Comparison between SCB-IFIT, un-notched SCB-IFIT and IDEAL-CT for measuring cracking resistance of asphalt mixtures. Constr. Build. Mater. 2020, 252, 119060. [Google Scholar] [CrossRef]

- Zhang, J.; Little, D.N.; Grajales, J.; You, T.; Kim, Y.-R. Use of semicircular bending test and cohesive zone modeling to evaluate fracture resistance of stabilized soils. Transp. Res. Rec. J. Transp. Res. Board 2017, 2657, 67–77. [Google Scholar] [CrossRef]

- Zhou, F.; Im, S.; Sun, L.; Scullion, T. Development of an IDEAL cracking test for asphalt mix design and QC/QA. Road Mater. Pavement Des. 2017, 18, 405–427. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Bahia, H.U. The role of binders in mixture cracking resistance measured by ideal-CT test. Int. J. Fatigue 2021, 142, 105947. [Google Scholar] [CrossRef]

- Chen, H.; Wang, R.; Bahia, H.U. Effect of air voids on the fracture resistance of HMA in the indirect tensile cracking (IDEAL-CT) test. Int. J. Pavement Eng. 2023, 24, 2252148. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, F.; Cao, P.; Liu, K. The fracture toughness analysis on the basalt fiber reinforced asphalt concrete with prenotched three-point bending beam test. Case Stud. Constr. Mater. 2022, 16, e01079. [Google Scholar] [CrossRef]

- Saed, S.A.; Karimi, H.R.; Rad, S.M.; Aliha, M.; Shi, X.; Haghighatpour, P.J. Full range I/II fracture behavior of asphalt mixtures containing RAP and rejuvenating agent using two different 3-point bend type configurations. Constr. Build. Mater. 2022, 314, 125590. [Google Scholar] [CrossRef]

- Klinsky, L.; Kaloush, K.; Faria, V.; Bardini, V. Performance characteristics of fiber modified hot mix asphalt. Constr. Build. Mater. 2018, 176, 747–752. [Google Scholar] [CrossRef]

- Alfalah, A.; Offenbacker, D.; Ali, A.; Decarlo, C.; Lein, W.; Mehta, Y.; Elshaer, M. Assessment of the impact of fiber types on the performance of fiber-reinforced hot mix asphalt. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 337–347. [Google Scholar] [CrossRef]

- Khaled, T.T.; Kareem, A.I.; Mohamad, S.A.; Al-Hamd, R.K.S.; Minto, A. The Performance of Modified Asphalt Mixtures with Different Lengths of Glass Fiber. Int. J. Pavement Res. Technol. 2024, 1–17. [Google Scholar] [CrossRef]

- Phan, T.M.; Nguyen, S.N.; Seo, C.-B.; Park, D.-W. Effect of treated fibers on performance of asphalt mixture. Constr. Build. Mater. 2021, 274, 122051. [Google Scholar] [CrossRef]

- Shanbara, H.K.; Ruddock, F.; Atherton, W. A laboratory study of high-performance cold mix asphalt mixtures reinforced with natural and synthetic fibres. Constr. Build. Mater. 2018, 172, 166–175. [Google Scholar] [CrossRef]

- Wang, M.; Huo, T.; Xing, C.; Wang, Y. Influence of fiber mixing process on the cracking resistance of cold recycled asphalt mixture. Appl. Sci. 2023, 13, 999. [Google Scholar] [CrossRef]

- Bellatrache, Y.; Ziyani, L.; Dony, A.; Taki, M.; Haddadi, S. Effects of the addition of date palm fibers on the physical, rheological and thermal properties of bitumen. Constr. Build. Mater. 2020, 239, 117808. [Google Scholar] [CrossRef]

- Guo, F.; Li, R.; Lu, S.; Bi, Y.; He, H. Evaluation of the effect of fiber type, length, and content on asphalt properties and asphalt mixture perfor-mance. Materials 2020, 13, 1556. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, H.; Zhang, Q.; Xiong, C. Glass fiber reinforced asphalt membrane for interlayer bonding between asphalt overlay and concrete pavement. Constr. Build. Mater. 2015, 101, 918–925. [Google Scholar] [CrossRef]

- Shafei, B.; Kazemian, M.; Dopko, M.; Najimi, M. State-of-the-art review of capabilities and limitations of polymer and glass fibers used for fiber-reinforced concrete. Materials 2021, 14, 409. [Google Scholar] [CrossRef] [PubMed]

- Ziari, H.; Aliha, M.R.M.; Moniri, A.; Saghafi, Y. Crack resistance of hot mix asphalt containing different percentages of reclaimed asphalt pavement and glass fiber. Constr. Build. Mater. 2020, 230, 117015. [Google Scholar] [CrossRef]

- Bayat, R.; Talatahari, S. Influence of polypropylene length on stability and flow of fiber-reinforced asphalt mixtures. Civ. Eng. J. 2016, 2, 538–545. [Google Scholar] [CrossRef]

- Gupta, A.; Castro-Fresno, D.; Lastra-Gonzalez, P.; Rodriguez-Hernandez, J. Selection of fibers to improve porous asphalt mixtures using multi-criteria analysis. Constr. Build. Mater. 2021, 266, 121198. [Google Scholar] [CrossRef]

- Jia, H.; Sheng, Y.; Guo, P.; Underwood, S.; Chen, H.; Kim, Y.R.; Li, Y.; Ma, Q. Effect of synthetic fibers on the mechanical performance of asphalt mixture: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 331–348. [Google Scholar] [CrossRef]

- Oyelere, A.; Wu, S.; Hsiao, K.-T.; Kang, M.-W.; Dizbay-Onat, M.; Cleary, J.; Venkiteshwaran, K.; Wang, J.; Bao, Y. Evaluation of cracking susceptibility of asphalt binders modified with recycled high-density polyethylene and polypropylene microplastics. Constr. Build. Mater. 2024, 438, 136811. [Google Scholar] [CrossRef]

- Rashid, M.F.; Ahmed, N.; Ahmed, A. The Effect of Using Polypropylene Fiber on Deformation Resistance of Asphalt Concrete. In Proceedings of the 2nd Conference on Sustainability in Civil Engineering (CSCE’20), Islamabad, Pakistan, 12 August 2020; pp. 1–6. [Google Scholar]

- Eisa, M.S.; Basiouny, M.E.; Daloob, M.I. Effect of adding glass fiber on the properties of asphalt mix. Int. J. Pavement Res. Technol. 2021, 14, 403–409. [Google Scholar] [CrossRef]

- Al-Hadidy, A. Engineering behavior of aged polypropylene-modified asphalt pavements. Constr. Build. Mater. 2018, 191, 187–192. [Google Scholar] [CrossRef]

- Nasr, D.; Babagoli, R.; Rezaei, M.; Borujeni, P.R. Evaluating the substitution potential of SBS with crumb rubber-polypropylene blends as asphalt binder and mixture modifiers. Constr. Build. Mater. 2022, 359, 129503. [Google Scholar] [CrossRef]

- Callomamani, L.A.P.; Bala, N.; Hashemian, L. Comparative analysis of the impact of synthetic fibers on cracking resistance of asphalt mixes. Int. J. Pavement Res. Technol. 2023, 16, 992–1008. [Google Scholar] [CrossRef]

- Omranian, S.R.; Bergh, W.V.D.; He, L.; Manthos, E. Incorporating 3D image analysis and response surface method to evaluate the effects of moisture damage on reinforced asphalt mixtures using glass and polypropylene fibers. Constr. Build. Mater. 2022, 353, 129177. [Google Scholar] [CrossRef]

- Lu, D.X.; Bui, H.H.; Saleh, M. Effects of specimen size and loading conditions on the fracture behaviour of asphalt concretes in the SCB test. Eng. Fract. Mech. 2021, 242, 107452. [Google Scholar] [CrossRef]

- Wu, H.; Ji, X.; Song, W.; Deng, Z.; Zhan, Y.; Zou, X.; Li, Q.; He, F. Multi-scale analysis on fracture behaviors of asphalt mixture considering moisture damage. Constr. Build. Mater. 2024, 416, 135234. [Google Scholar] [CrossRef]

- Song, W.; Fan, Y.; Wu, H.; Zhou, L. I-II mixed fracture characterization of hot mix asphalt under tensile test using notched semi-circular specimens. Theor. Appl. Fract. Mech. 2024, 129, 104200. [Google Scholar] [CrossRef]

- Talebi, H.; Bahrami, B.; Ahmadian, H.; Nejati, M.; Ayatollahi, M.R. An investigation of machine learning algorithms for estimating fracture toughness of asphalt mixtures. Constr. Build. Mater. 2024, 435, 136783. [Google Scholar] [CrossRef]

- Qiu, J.; Tabasi, E.; Hammoud, A.; Benjeddou, O.; Zarei, M.; Khordehbinan, M.W. Determining the fracture stiffness of modified Hot and Warm Mix Asphalt using semi-circular bending (SCB) geometry. Theor. Appl. Fract. Mech. 2024, 129, 104237. [Google Scholar] [CrossRef]

- Valdes-Vidal, G.; Calabi-Floody, A.; Sanchez-Alonso, E.; Miró, R. Effect of aggregate type on the fatigue durability of asphalt mixtures. Constr. Build. Mater. 2019, 224, 124–131. [Google Scholar] [CrossRef]

- Sodeyfi, S.; Kordani, A.A.; Zarei, M. Moisture damage resistance of hot mix asphalt made with recycled rubber materials and determining the optimal percentage with an economic approach. Int. J. Pavement Res. Technol. 2021, 15, 970–986. [Google Scholar] [CrossRef]

- Liu, G.; Cheng, W.; Chen, L. Investigating and optimizing the mix proportion of pumping wet-mix shotcrete with polypropylene fiber. Constr. Build. Mater. 2017, 150, 14–23. [Google Scholar] [CrossRef]

- Upadhya, A.; Thakur, M.S.; Sihag, P. Predicting Marshall stability of carbon fiber-reinforced asphalt concrete using machine learning techniques. Int. J. Pavement Res. Technol. 2024, 17, 102–122. [Google Scholar] [CrossRef]

- Ziari, H.; Moniri, A. Laboratory evaluation of the effect of synthetic Polyolefin-glass fibers on performance properties of hot mix asphalt. Constr. Build. Mater. 2019, 213, 459–468. [Google Scholar] [CrossRef]

- Guo, Q.; Li, L.; Cheng, Y.; Jiao, Y.; Xu, C. Laboratory evaluation on performance of diatomite and glass fiber compound modified asphalt mixture. Mater. Des. 2015, 66, 51–59. [Google Scholar] [CrossRef]

- Hong, R.-B.; Wu, J.-R.; Cai, H.-B. Low-temperature crack resistance of coal gangue powder and polyester fibre asphalt mixture. Constr. Build. Mater. 2020, 238, 117678. [Google Scholar] [CrossRef]

- Khater, A.; Luo, D.; Abdelsalam, M.; Yue, Y.; Hou, Y.; Ghazy, M. Laboratory evaluation of asphalt mixture performance using composite admixtures of lignin and glass fi-bers. Appl. Sci. 2021, 11, 364. [Google Scholar] [CrossRef]

- Serin, S.; Önal, Y.; Emiroğlu, M.; Demir, E. Comparison of the effect of basalt and glass fibers on the fracture energy of asphalt mixes using semi-circular bending test. Constr. Build. Mater. 2023, 406, 133460. [Google Scholar] [CrossRef]

- Ramesh, A.; Ramayya, V.V.; Reddy, G.S.; Ram, V.V. Investigations on fracture response of warm mix asphalt mixtures with Nano glass fibres and partially replaced RAP material. Constr. Build. Mater. 2022, 317, 126121. [Google Scholar] [CrossRef]

- Kaseer, F.; Yin, F.; Arámbula-Mercado, E.; Martin, A.E.; Daniel, J.S.; Salari, S. Development of an index to evaluate the cracking potential of asphalt mixtures using the semi-circular bending test. Constr. Build. Mater. 2018, 167, 286–298. [Google Scholar] [CrossRef]

- Wu, B.; Pei, Z.; Xiao, P.; Lou, K.; Wu, X. Influence of fiber-asphalt interface property on crack resistance of asphalt mixture. Case Stud. Constr. Mater. 2022, 17, e01703. [Google Scholar] [CrossRef]

- Zarei, A.; Zarei, M.; Janmohammadi, O. Evaluation of the effect of lignin and glass fiber on the technical properties of asphalt mixtures. Arab. J. Sci. Eng. 2019, 44, 4085–4094. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, Y.; Si, C.; Shi, X.; Qiao, Y.; Li, H. Laboratory Evaluation on Performance of Fiber-Modified Asphalt Mixtures Containing High Percentage of RAP. Adv. Civ. Eng. 2020, 2020, 5713869. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Pascual-Muñoz, P.; Castro-Fresno, D. Mechanical performance of fibers in hot mix asphalt: A review. Constr. Build. Mater. 2019, 200, 756–769. [Google Scholar] [CrossRef]

- Ong, J.; Gungat, L.; Hamzah, M. Fracture properties of reclaimed asphalt pavement mixtures with rejuvenator. Constr. Build. Mater. 2020, 259, 119679. [Google Scholar] [CrossRef]

- Behnia, B.; Askarinejad, P.; LaRussa-Trott, N. Investigating low-temperature cracking behavior of fiber-reinforced asphalt concrete materials. Int. J. Pavement Res. Technol. 2023, 17, 815–826. [Google Scholar] [CrossRef]

- Kim, S.S.; Yang, J.J.; Etheridge, R.A. Effects of mix design variables on flexibility index of asphalt concrete mixtures. Int. J. Pavement Eng. 2020, 21, 1275–1280. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Shokorlou, Y.M.; Amani, B. Laboratory investigations on fracture toughness of asphalt concretes reinforced with carbon and kenaf fibers. Eng. Fract. Mech. 2020, 226, 106875. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, X.; Lv, J. Effect of basalt fiber distribution on the flexural–tensile rheological performance of asphalt mortar. Constr. Build. Mater. 2018, 179, 307–314. [Google Scholar] [CrossRef]

| Aggregate: | |||||||||

| Property | Results | Specification | Specification Limit | ||||||

| Bulk relative density | 2.695 | ASTM C 127 | ------------ | ||||||

| Apparent relative density | 2.713 | ASTM C 127 | ------------ | ||||||

| Water absorption (%) | 2.40 | ASTM C 127 | <2.6 | ||||||

| Los Angeles abrasion (%) | 25 | ASTM C 131 | <28 | ||||||

| Bitumen: | |||||||||

| Property | Test Results | Test Method | |||||||

| Specific gravity | 1.02 | ASTM D70 | |||||||

| Penetration at 25 °C (0.1 mm) | 65 | ASTM D5 | |||||||

| Softening point (°C) | 54 | ASTM D36 | |||||||

| Kinematics viscosity (at 120 °C), (cSt) | 745 | ASTM D2170 | |||||||

| Kinematic viscosity (at 135 °C), (cSt) | 330 | ASTM D2170 | |||||||

| Kinematic viscosity (at 160 °C), (cSt) | 103 | ASTM D2170 | |||||||

| Flash point (°C) | 319 | ASTM D92 | |||||||

| Fiber: | |||||||||

| Fiber Type | Fiber Length (mm) | Specific Gravity | Modulus of Elasticity (GPa) | Tensile Strength (GPa) | Fracture Deformation | ||||

| PP. F | 18 | 0.91 | 4.048–5.674 | 0.467–0.548 | ----- | ||||

| G. F | 18 | 2.60 | 70–80 | 2.40 | 2–3.5 | ||||

| Mixture | Dosage of synthetic fibers added to the asphalt mixture |

| Control | Asphalt mixture without fiber modifier |

| PP-0.5 | Asphalt mixture enhanced with 0.5% polypropylene fiber |

| PP-1 | Asphalt mixture enhanced with 1% polypropylene fiber |

| PP-1.5 | Asphalt mixture enhanced with 1.5% polypropylene fiber |

| G-0.5 | Asphalt mixture enhanced with 0.5% glass fiber |

| G-1 | Asphalt mixture enhanced with 1% glass fiber |

| G-1.5 | Asphalt mixture enhanced with 1.5% glass fiber |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akram, H.; Hozayen, H.A.; Abdelfatah, A.; Khodary, F. Fiber Showdown: A Comparative Analysis of Glass vs. Polypropylene Fibers in Hot-Mix Asphalt Fracture Resistance. Buildings 2024, 14, 2732. https://doi.org/10.3390/buildings14092732

Akram H, Hozayen HA, Abdelfatah A, Khodary F. Fiber Showdown: A Comparative Analysis of Glass vs. Polypropylene Fibers in Hot-Mix Asphalt Fracture Resistance. Buildings. 2024; 14(9):2732. https://doi.org/10.3390/buildings14092732

Chicago/Turabian StyleAkram, Hesham, Hozayen A. Hozayen, Akmal Abdelfatah, and Farag Khodary. 2024. "Fiber Showdown: A Comparative Analysis of Glass vs. Polypropylene Fibers in Hot-Mix Asphalt Fracture Resistance" Buildings 14, no. 9: 2732. https://doi.org/10.3390/buildings14092732

APA StyleAkram, H., Hozayen, H. A., Abdelfatah, A., & Khodary, F. (2024). Fiber Showdown: A Comparative Analysis of Glass vs. Polypropylene Fibers in Hot-Mix Asphalt Fracture Resistance. Buildings, 14(9), 2732. https://doi.org/10.3390/buildings14092732