The Synergistic Effect of Water Reducer and Water-Repellent Admixture on the Properties of Cement-Based Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Fluidity Measurement

2.4. Pore Structure Determination

2.5. Compressive Strength Test

2.6. Water Absorption Rate Measurement

3. Results

3.1. Fluidity

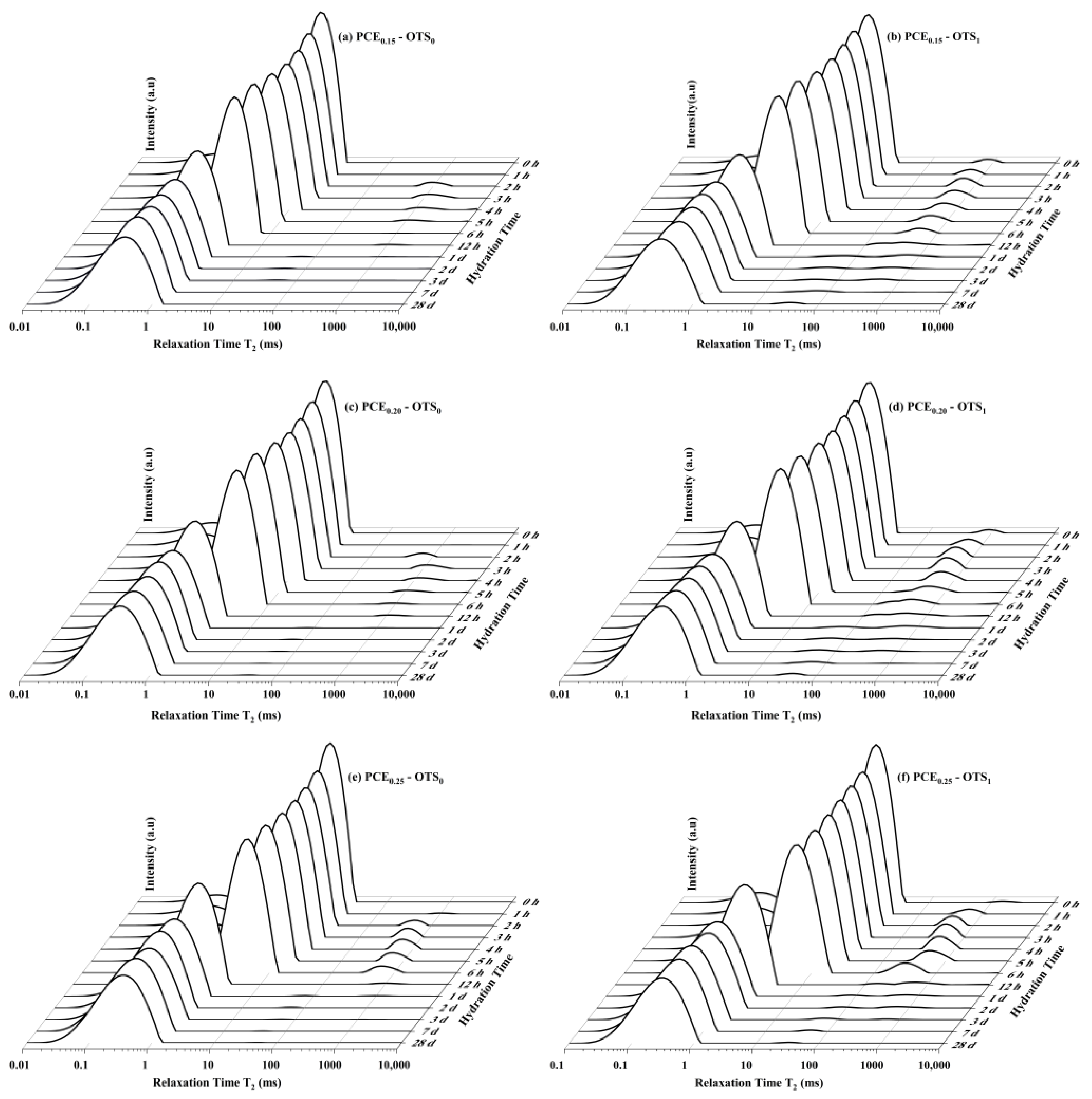

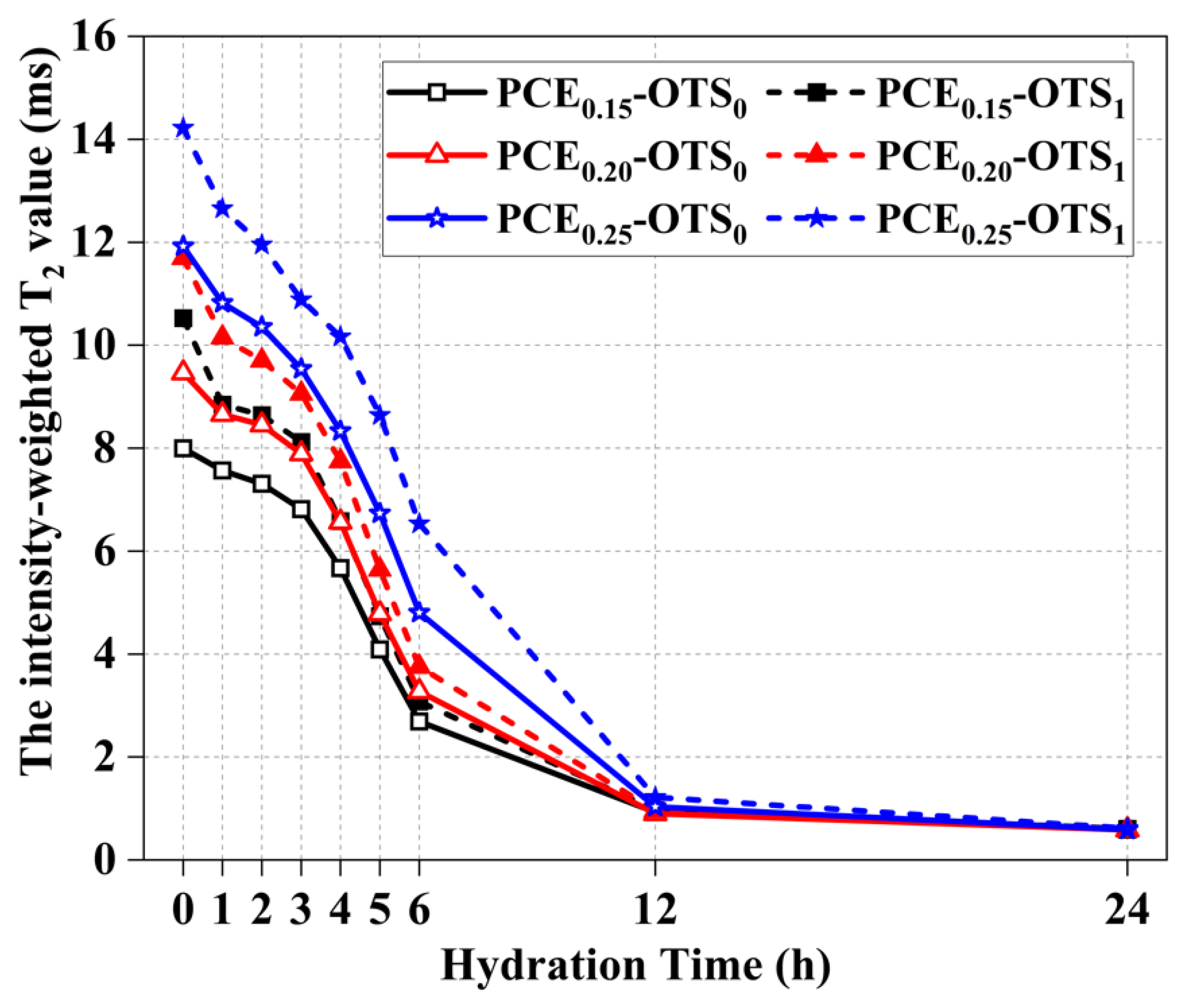

3.2. T2 Relaxation Time Distributions

- The bleeding water can be generated due to the addition of PCE and OTS. The higher the dosages of PCE, the more the bleeding water;

- The calculated revealed that the addition of PCE and OTS provided a retarding effect upon cement hydration. And this retarding effect weakened gradually with prolonged hydration time;

- The porosity of cement paste would be increased with the addition of PCE and OTS.

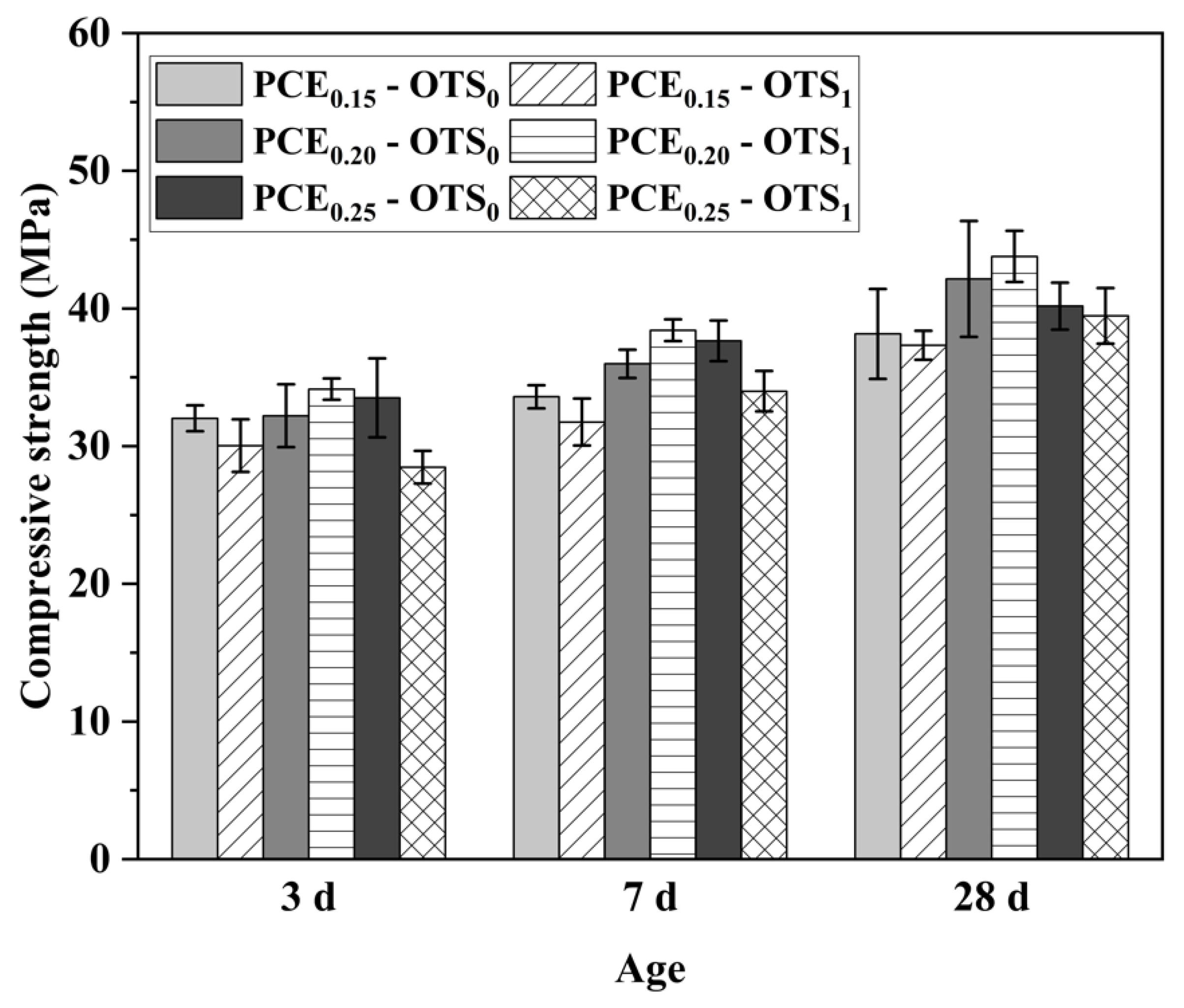

3.3. Compressive Strength

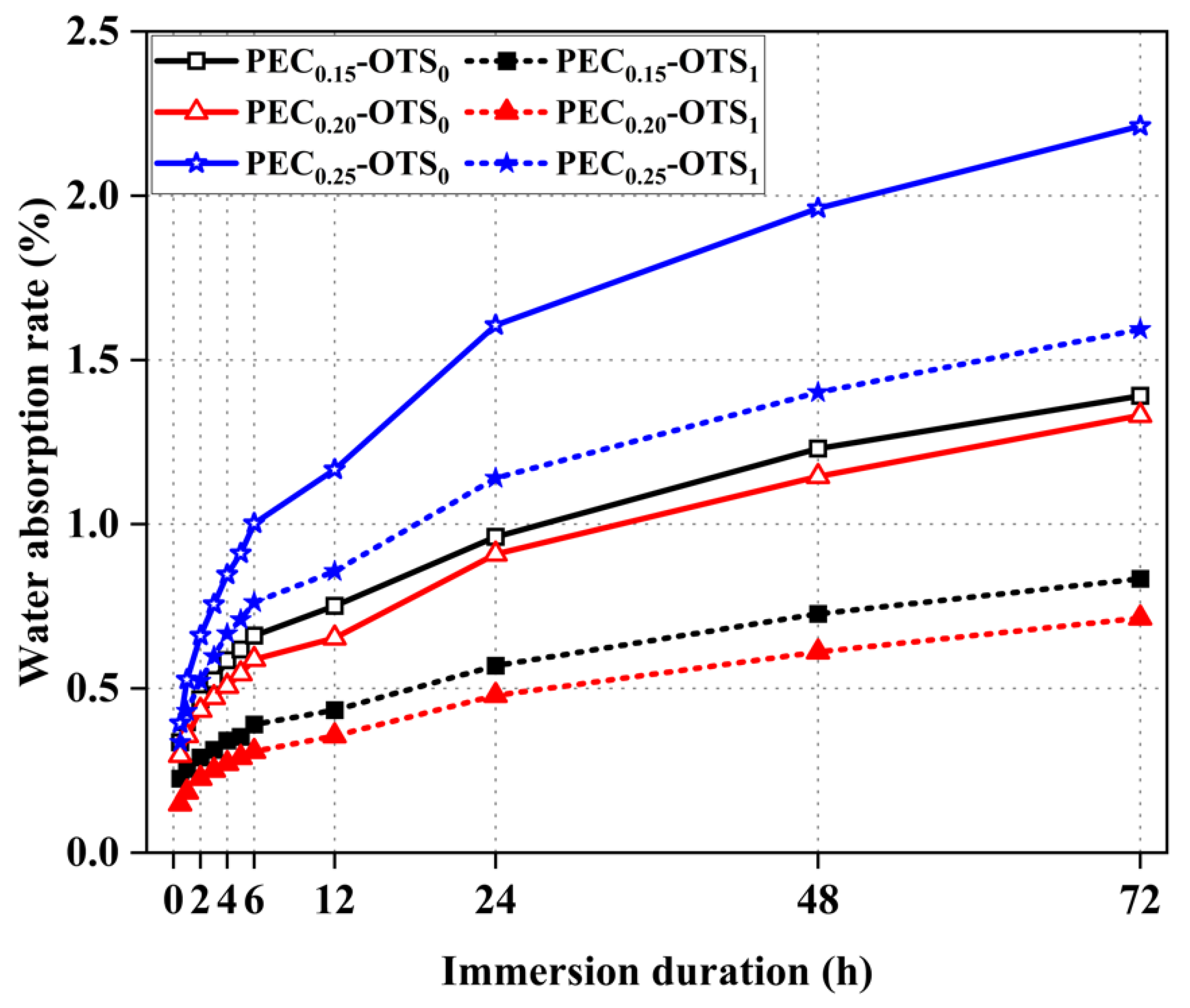

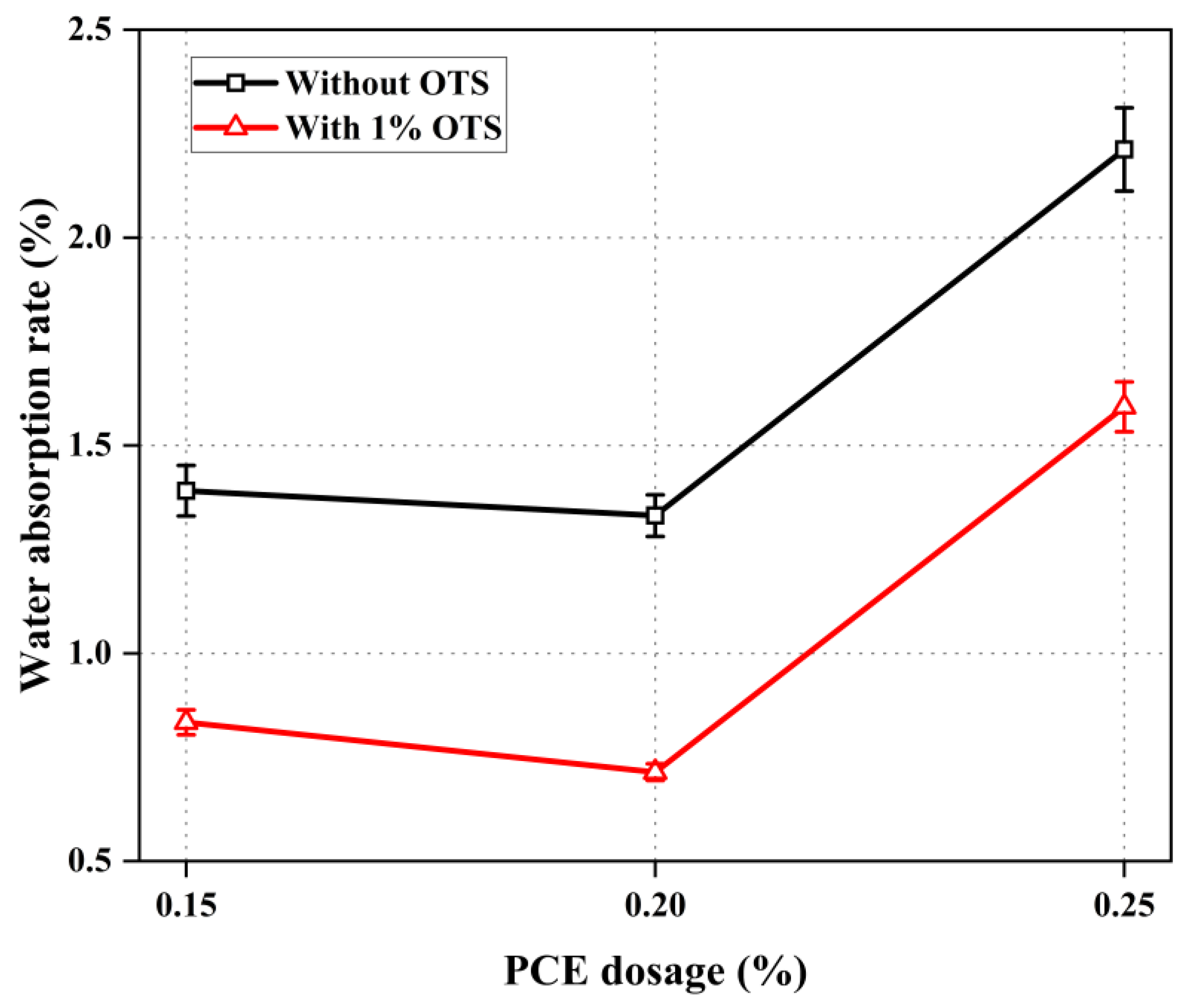

3.4. Water Absorption Rate

4. Conclusions

- The fluidity of cement paste was reduced with the addition of OTS for about 5–10 mm, especially at a low PCE dosage. On the one hand, OTS impairs the dispersion ability of PCE as OTS may hinder the adsorption of PCE on the surface of cement particles and a hydration product. On the other hand, OTS caused more bleeding water, thus reducing the free-water amount within the cement paste for dispersion;

- The 1H LF NMR results showed that incorporating PCE and OTS resulted in an increased pore size as well as total pore volume. In particular, more bleeding water was presented by using OTS. The intensity-weighted T2 values () revealed that the addition of PCE and OTS provided a retardation effect on cement hydration;

- Mortar compressive strength decreased by 15.0% at the age of 3 d with the addition of OTS at a high PCE dosage of 0.25%, which could be attributed to a more porous top layer resulting from increased bleeding water amount. Notably, a positive synergistic effect of PCE and OTS was endowed on the compressive strength when PCE dosage was 0.20%;

- Despite the increased pore size and pore volume, as well as the retarded cement hydration, the water absorption rate was still reduced up to 46.6% with the addition of OTS. The conflict phenomenon powerfully revealed that the internal hydrophobic treatment by OTS has been successfully achieved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kawashima, S.; Hou, P.; Corr, D.J.; Shah, S.P. Modification of cement-based materials with nanoparticles. Cem. Concr. Compos. 2013, 36, 8–15. [Google Scholar] [CrossRef]

- Wu, H.; Gao, J.; Liu, C.; Zhao, Y.; Li, S. Development of nano-silica modification to enhance the micro-macro properties of cement-based materials with recycled clay brick powder. J. Build. Eng. 2024, 86, 108854. [Google Scholar] [CrossRef]

- Musale, A.; Hunashyal, A.M.; Patil, A.Y.; Kumar, R.; Ahamad, T.; Kalam, M.A.; Patel, M. Study on nanomaterials coated natural coir fibers as crack arrestor in cement composite. Adv. Civ. Eng. 2024, 2024, 6686655. [Google Scholar] [CrossRef]

- Roopa, A.K.; Hunashyal, A.M.; Patil, A.Y.; Kamadollishettar, A.; Patil, B.; Soudagar, M.E.M.; Shahapurkar, K.; Khan, T.M.Y.; Kalam, M.A. Study on interfacial interaction of cement-based nanocomposite by molecular dynamic analysis and an RVE approach. Adv. Civ. Eng. 2023, 2023, 8404335. [Google Scholar] [CrossRef]

- Hewlett, P.C.; Liska, M. Lea’s Chemistry of Cement and Concrete, 5th ed.; Butterworth-Heinemann: Cambridge, UK, 2019. [Google Scholar]

- Song, J.L.; Li, Y.X.; Xu, W.; Liu, H.; Lu, Y. Inexpensive and non-fluorinated superhydrophobic concrete coating for anti-icing and anti-corrosion. J. Colloid Interface Sci. 2019, 541, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.M.; Zhu, F.Z.; Zhao, T.J. Effects of surface modification of silane coupling agent on the properties of concrete with freeze-thaw damage. KSCE J. Civ. Eng. 2018, 22, 657–669. [Google Scholar] [CrossRef]

- Liu, G.; Zhao, T.; Fei, H.; Li, F.; Guo, W.; Yao, Z.; Feng, Z. A review of various self-cleaning surfaces, durability and functional applications on building exteriors. Constr. Build. Mater. 2023, 409, 134084. [Google Scholar] [CrossRef]

- Feng, Z.J.; Wang, F.J.; Xie, T.; Ou, J.F.; Xue, M.S.; Li, W. Integral hydrophobic concrete without using silane. Constr. Build. Mater. 2019, 227, 116678. [Google Scholar] [CrossRef]

- Liu, S.; Yang, J.; Chen, X.H.; Yang, G.T.; Cai, D.G. Application of mastic asphalt waterproofing layer in high-speed railway track in cold regions. Appl. Sci.-Basel 2018, 8, 667. [Google Scholar] [CrossRef]

- Li, W.T.; Pour-Ghaz, M.; Castro, J.; Weiss, J. Water absorption and critical degree of saturation relating to freeze-thaw damage in concrete pavement joints. J. Mater. Civ. Eng. 2012, 24, 299–307. [Google Scholar] [CrossRef]

- Yuan, Q.; Xie, Z.; Tian, Y.; Sun, L.M.; Yang, C.; Chi, H.; Zhu, X. The driving force of water absorption in cementitious materials: An analysis of surface-free energies and pore structure. J. Mater. Res. Technol. 2024, 30, 4714–4724. [Google Scholar] [CrossRef]

- Pang, Y.; Wang, H.; Yang, L.; Tang, Q.; Li, H.; Zhang, J. Experimental study on freeze-thaw resistance of mortar: An attempt to modify hydrophobic materials with hydrophobic nano-silica. J. Build. Eng. 2024, 95, 110152. [Google Scholar] [CrossRef]

- Liu, P.; Chen, Y.; Wang, W.L.; Yu, Z.W. Effect of physical and chemical sulfate attack on performance degradation of concrete under different conditions. Chem. Phys. Lett. 2020, 745, 137254. [Google Scholar] [CrossRef]

- Bader, T.; Waldner, B.J.; Unterberger, S.H.; Lackner, R. On the performance of film formers versus penetrants as water-repellent treatment of (HPC) surfaces. Constr. Build. Mater. 2019, 203, 481–490. [Google Scholar] [CrossRef]

- Subbiah, K.; Park, D.J.; Lee, Y.S.; Velu, S.; Lee, H.S.; Jang, H.O.; Choi, H.J. Development of water-repellent cement mortar using silane enriched with nanomaterials. Prog. Org. Coat. 2018, 125, 48–60. [Google Scholar] [CrossRef]

- Wang, F.J.; Lei, S.; Ou, J.F.; Li, W. Effect of PDMS on the waterproofing performance and corrosion resistance of cement mortar. Appl. Surf. Sci. 2020, 507, 145016. [Google Scholar] [CrossRef]

- Falchi, L.; Zendri, E.; Müller, U.; Fontana, P. The influence of water-repellent admixtures on the behaviour and the effectiveness of Portland limestone cement mortars. Cem. Concr. Compos. 2015, 59, 107–118. [Google Scholar] [CrossRef]

- Li, F.P.; Liu, L.S.; Liu, K.; Zheng, A.H.; Liu, J.S. Investigation on waterproof mechanism and micro-structure of cement mortar incorporated with silicane. Constr. Build. Mater. 2020, 239, 117865. [Google Scholar] [CrossRef]

- Grabowska, K.B.; Koniorczyk, M. Internal hydrophobization of cementitious materials by using of organosilicon compounds. In Proceedings of the 12th Nordic Symposium on Building Physics (Nsb 2020), Tallinn, Estonia, 6–9 September 2020; Volume 172, p. 14006. [Google Scholar] [CrossRef]

- Tang, D.; Yang, C.; Shen, C.; Li, Z.; Lyu, Z.; Yu, L.; Huang, Q.; Zhu, X. Inhibiting efflorescence of alkali-activated slag mortar by improving its hydrophobicity with methyl-terminated polydimethylsiloxane (PDMS): Evidences showing the remained PDMS. Constr. Build. Mater. 2024, 443, 137688. [Google Scholar] [CrossRef]

- Raja, A.; Sun, Z.P.; Ji, Y.L.; Yang, J.B. The influence of water-repellent admixtures on the hydration process, water absorption, and mechanical properties of cement paste: An NMR study combined with additional methods. J. Mater. Civ. Eng. 2022, 34, 04022267. [Google Scholar] [CrossRef]

- Safiuddin, M. Concrete damage in field conditions and protective sealer and coating systems. Coatings 2017, 7, 90. [Google Scholar] [CrossRef]

- Wang, F.J.; Xie, T.; Ou, J.F.; Xue, M.S.; Li, W. Cement based superhydrophobic coating with excellent robustness and solar reflective ability. J. Alloys Compd. 2020, 823, 153702. [Google Scholar] [CrossRef]

- Li, Y.; Gou, L.; Wang, H.Q.; Wang, Y.Z.; Zhang, J.F.; Li, N.; Hu, S.L.; Yang, J.L. Fluorine-free superhydrophobic carbon-based coatings on the concrete. Mater. Lett. 2019, 244, 31–34. [Google Scholar] [CrossRef]

- Kong, X.Q.; Shen, Y.D.; Shi, J.R.; Zhang, N.; Kang, R.; Fu, Y. Superhydrophobic concrete coating with excellent mechanical robustness and anti-corrosion performances. Colloid Surface A 2024, 684, 133157. [Google Scholar] [CrossRef]

- Qu, Z.Y.; Yu, Q.L. Synthesizing super-hydrophobic ground granulated blast furnace slag to enhance the transport property of lightweight aggregate concrete. Constr. Build. Mater. 2018, 191, 176–186. [Google Scholar] [CrossRef]

- Wong, H.S.; Barakat, R.; Alhilali, A.; Saleh, M.; Cheeseman, C.R. Hydrophobic concrete using waste paper sludge ash. Cem. Concr. Res. 2015, 70, 9–20. [Google Scholar] [CrossRef]

- Yao, H.; Xie, Z.L.; Huang, C.H.; Yuan, Q.; Yu, Z.W. Recent progress of hydrophobic cement-based materials: Preparation, characterization and properties. Constr. Build. Mater. 2021, 299, 124255. [Google Scholar] [CrossRef]

- Xue, X.; Li, Y.W.; Yang, Z.; He, Z.Y.; Dai, J.G.; Xu, L.J.; Zhang, W.D. A systematic investigation of the waterproofing performance and chloride resistance of a self-developed waterborne silane-based hydrophobic agent for mortar and concrete. Constr. Build. Mater. 2017, 155, 939–946. [Google Scholar] [CrossRef]

- Zhang, W.J.; Li, S.C.; Hou, D.S.; Geng, Y.J.; Zhang, S.L.; Yin, B.; Li, X.G. Study on unsaturated transport of cement-based silane sol coating materials. Coatings 2019, 9, 427. [Google Scholar] [CrossRef]

- Grabowska, K.; Koniorczyk, M. Influence of organosilicon admixtures on the hydration of Portland cement. J. Therm. Anal. Calorim. 2022, 147, 6131–6145. [Google Scholar] [CrossRef]

- Vdovin, E.; Mavliev, L.; Stroganov, V. Interaction of clay soil components with Portland cement and complex additive based on octyltriethoxysilane and sodium hydroxide. IOP Conf. Ser. Mater. Sci. Eng. 2020, 890, 012031. [Google Scholar] [CrossRef]

- Zhu, Y.G.; Kou, S.C.; Poon, C.S.; Dai, J.G.; Li, Q.Y. Influence of silane-based water repellent on the durability properties of recycled aggregate concrete. Cem. Concr. Compos. 2013, 35, 32–38. [Google Scholar] [CrossRef]

- Bader, T.; Unterberger, S.H.; Lackner, R. Effect of substrate moisture on the weatherability of surface treatment for High-Performance Concrete (HPC). Cem. Concr. Compos. 2017, 83, 57–65. [Google Scholar] [CrossRef]

- Huang, H.L.; Qian, C.X.; Zhao, F.; Qu, J.; Guo, J.Q.; Danzinger, M. Improvement on microstructure of concrete by polycarboxylate superplasticizer (PCE) and its influence on durability of concrete. Constr. Build. Mater. 2016, 110, 293–299. [Google Scholar] [CrossRef]

- Ma, Y.H.; Bai, J.J.; Shi, C.J.; Sha, S.N.; Zhou, B.B. Effect of PCEs with different structures on hydration and properties of cementitious materials with low water-to-binder ratio. Cem. Concr. Res. 2021, 142, 106343. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Hooton, R.D. Effects of organosilane-modified polycarboxylate superplasticizer on the fluidity and hydration properties of cement paste. Constr. Build. Mater. 2017, 132, 112–123. [Google Scholar] [CrossRef]

- Fan, W.; Stoffelbach, F.; Rieger, J.; Regnaud, L.; Vichot, A.; Bresson, B.; Lequeux, N. A new class of organosilane-modified polycarboxylate superplasticizers with low sulfate sensitivity. Cem. Concr. Res. 2012, 42, 166–172. [Google Scholar] [CrossRef]

- Casagrande, C.A.; Jochem, L.F.; Onghero, L.; de Matos, P.R.; Repette, W.L.; Gleize, P.J.P. Effect of partial substitution of superplasticizer by silanes in Portland cement pastes. J. Build. Eng. 2020, 29, 101226. [Google Scholar] [CrossRef]

- GB/T 1346-2001; Test Methods fot Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cements. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China Press: Beijing, China, 2011.

- GB/T 17671-2021; Test Methods of Cement Mortar Strength (ISO Method). Standardization Administration of the People’s Republic of China Press: Beijing, China, 2021.

- Ji, Y.L.; Sun, Z.P.; Yang, J.B.; Pel, L.; Raja, A.; Ge, H.S. NMR study on bleeding properties of the fresh cement pastes mixed with polycarboxylate (PCE) superplasticizers. Constr. Build. Mater. 2020, 240, 117938. [Google Scholar] [CrossRef]

- Elkhadiri, I.; Palacios, M.; Puertas, F. Effect of curing temperature on hydration process of different cement. Ceramics-Silikaty 2009, 53, 65–75. [Google Scholar]

- Felekoglu, B. Rheological behaviour of self-compacting micro-concrete. Sadhana 2014, 39, 1471–1495. [Google Scholar] [CrossRef]

- Fischer, N.; Haerdtl, R.; McDonald, P.J. Observation of the redistribution of nanoscale water filled porosity in cement based materials during wetting. Cem. Concr. Res. 2015, 68, 148–155. [Google Scholar] [CrossRef]

- Muller, A.C.A.; Scrivener, K.L.; Gajewicz, A.M.; McDonald, P.J. Densification of C-S-H Measured by 1H NMR Relaxometry. J. Phys. Chem. C 2013, 117, 403–412. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhong, F.W.; Zuo, S.H.; Xie, Z.L.; Xue, K.W.; Yao, H. Understanding the water transport behaviors of hydrophobic cement mortar by paraffin modification. Constr. Build. Mater. 2024, 435, 136845. [Google Scholar] [CrossRef]

- Massoussi, N.; Keita, E.; Roussel, N. The heterogeneous nature of bleeding in cement pastes. Cem. Concr. Res. 2017, 95, 108–116. [Google Scholar] [CrossRef]

- Li, H.; Mu, R.; Qing, L.B.; Chen, H.S.; Ma, Y.F. The influence of fiber orientation on bleeding of steel fiber reinforced cementitious composites. Cem. Concr. Compos. 2018, 92, 125–134. [Google Scholar] [CrossRef]

- Feng, H.J.; Le, H.T.N.; Wang, S.S.; Zhang, M.H. Effects of silanes and silane derivatives on cement hydration and mechanical properties of mortars. Constr. Build. Mater. 2016, 129, 48–60. [Google Scholar] [CrossRef]

- Guo, X.L.; Shi, H.S.; Xia, M. Geopolymerization process at early age by low field nuclear magnetic resonance. J. Chin. Ceram. Soc. 2015, 43, 138–143. [Google Scholar] [CrossRef]

- Liu, H.; Sun, Z.P.; Yang, J.B.; Ji, Y.L. A novel method for semi-quantitative analysis of hydration degree of cement by 1H low-field NMR. Cem. Concr. Res. 2021, 141, 106329. [Google Scholar] [CrossRef]

| CaO | SiO2 | MgO | SO3 | Al2O3 | K2O | Fe2O3 | Na2O | P2O5 | Others |

|---|---|---|---|---|---|---|---|---|---|

| 60.1 | 18.2 | 13.5 | 2.5 | 2.2 | 0.5 | 0.3 | 0.3 | 0.1 | 2.3 |

| Mw (Da) | Mn (Da) | PDI (Mw/Mn) | Conversion Rate of the Macromonomer (%) |

|---|---|---|---|

| 58,910 | 24,980 | 2.4 | 90.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al jarmouzi, R.; Sun, Z.; Yang, H.; Ji, Y. The Synergistic Effect of Water Reducer and Water-Repellent Admixture on the Properties of Cement-Based Material. Buildings 2024, 14, 2734. https://doi.org/10.3390/buildings14092734

Al jarmouzi R, Sun Z, Yang H, Ji Y. The Synergistic Effect of Water Reducer and Water-Repellent Admixture on the Properties of Cement-Based Material. Buildings. 2024; 14(9):2734. https://doi.org/10.3390/buildings14092734

Chicago/Turabian StyleAl jarmouzi, Raja, Zhenping Sun, Haijing Yang, and Yanliang Ji. 2024. "The Synergistic Effect of Water Reducer and Water-Repellent Admixture on the Properties of Cement-Based Material" Buildings 14, no. 9: 2734. https://doi.org/10.3390/buildings14092734

APA StyleAl jarmouzi, R., Sun, Z., Yang, H., & Ji, Y. (2024). The Synergistic Effect of Water Reducer and Water-Repellent Admixture on the Properties of Cement-Based Material. Buildings, 14(9), 2734. https://doi.org/10.3390/buildings14092734