Experimental Study on the Failure Mechanism of Finned Pile Foundation under Horizontal Cyclic Loads

Abstract

:1. Introduction

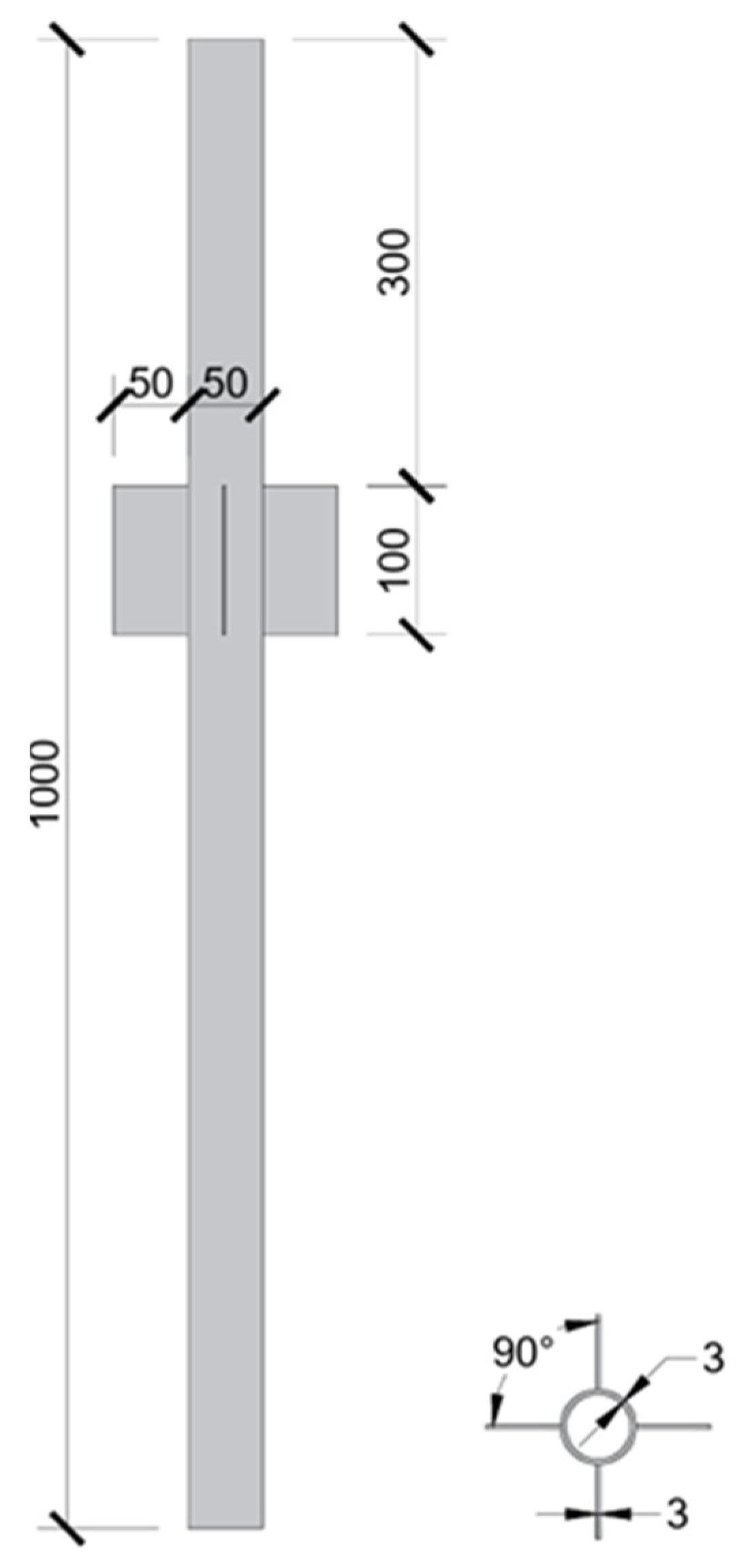

2. Physical Model Test

- (1)

- Design the horizontal cyclic loading system according to the research needs.

- (2)

- Make the model pile according to the requirements of scale and material, and prepare the model soil in combination with the soil characteristics in the wind farm.

- (3)

- Arrange the sensors and fix the model pile.

- (4)

- Fill the model soil in layers to the test tank. Before filling the model soil, it is necessary to soak the soil with water to make it completely saturated.

- (5)

- Start the motor to apply horizontal cyclic load to the finned pile, and record the readings of each sensor.

3. Results and Discussions

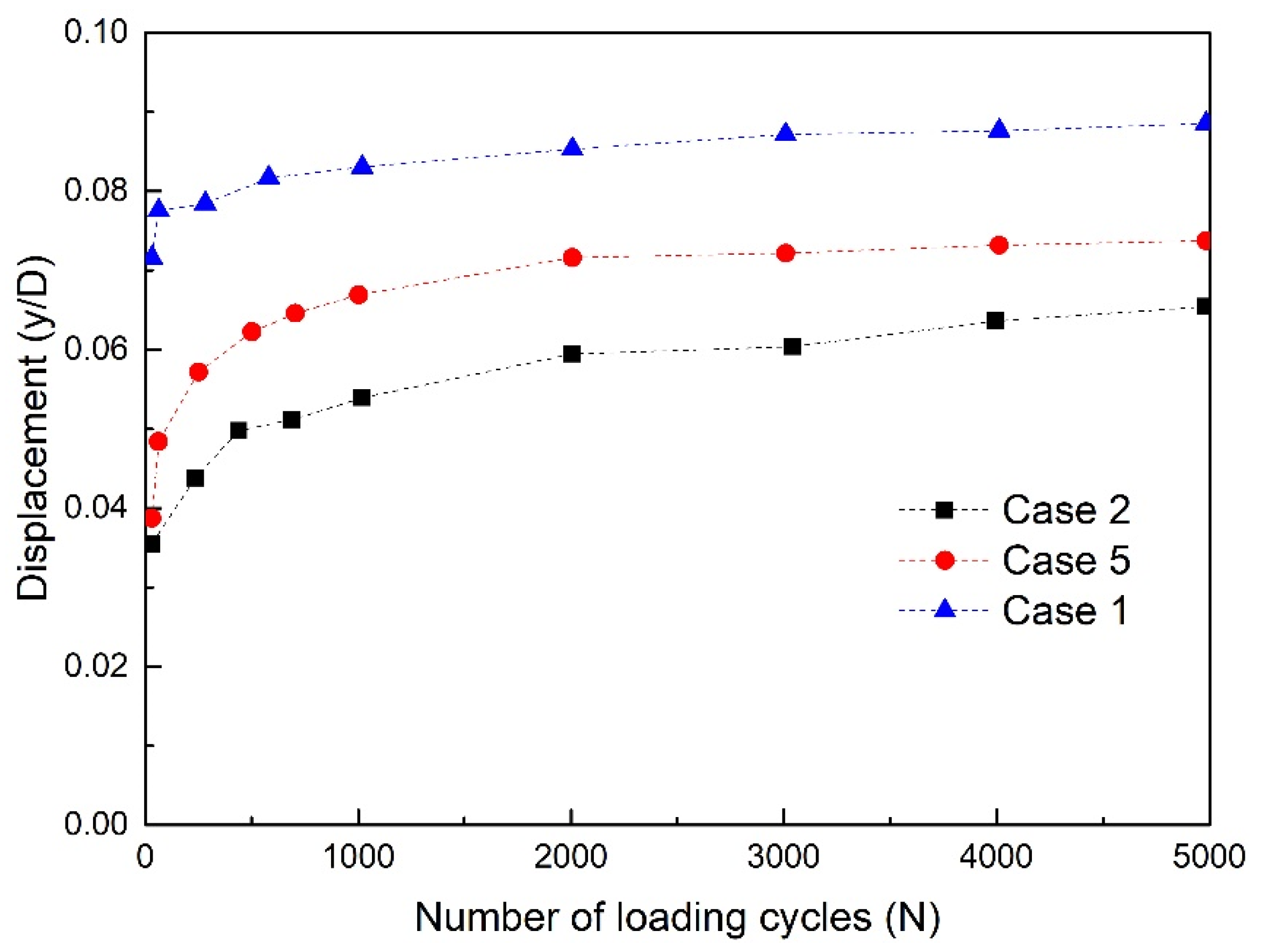

3.1. Pile Top Displacement

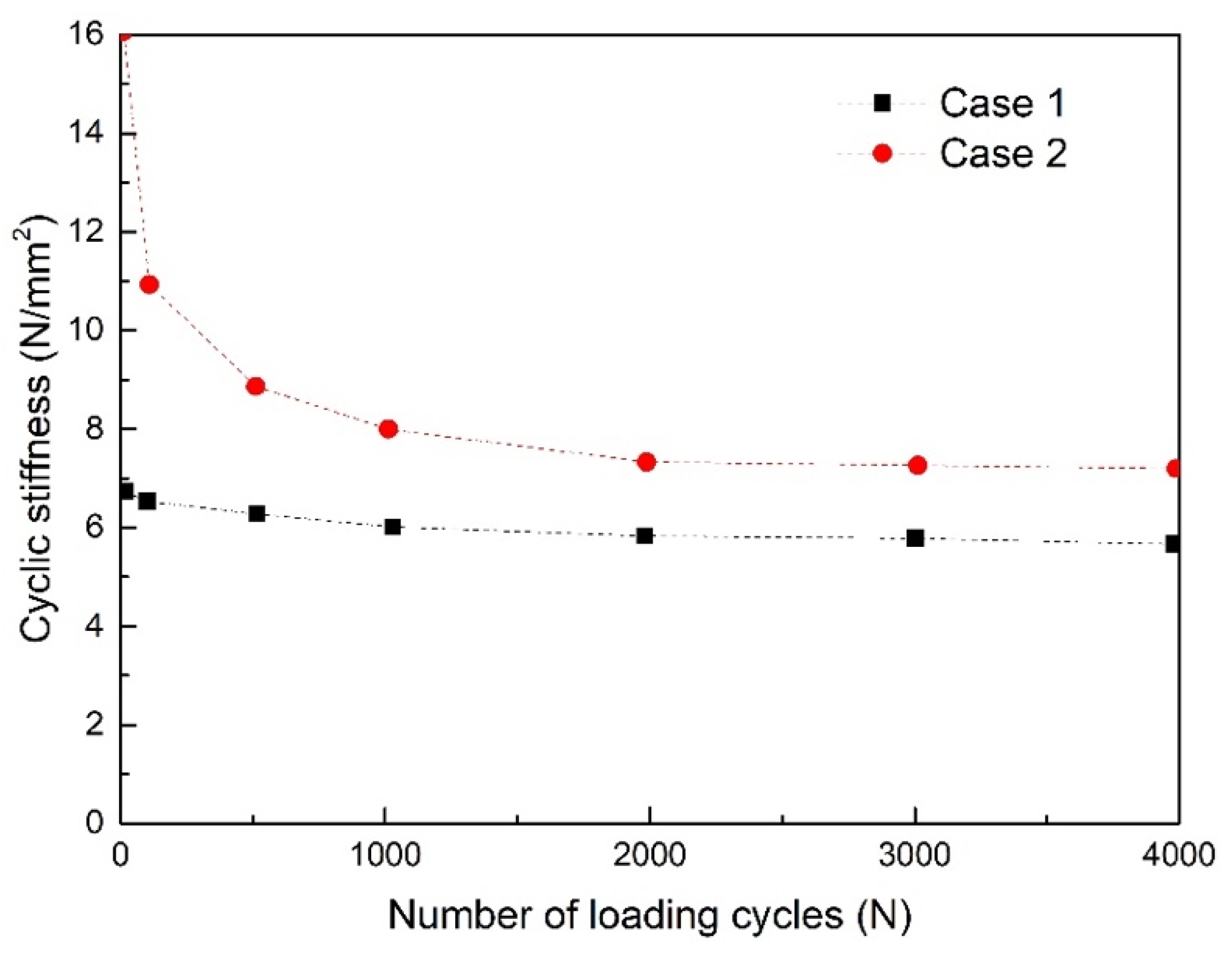

3.2. Cyclic Stiffness of Pile

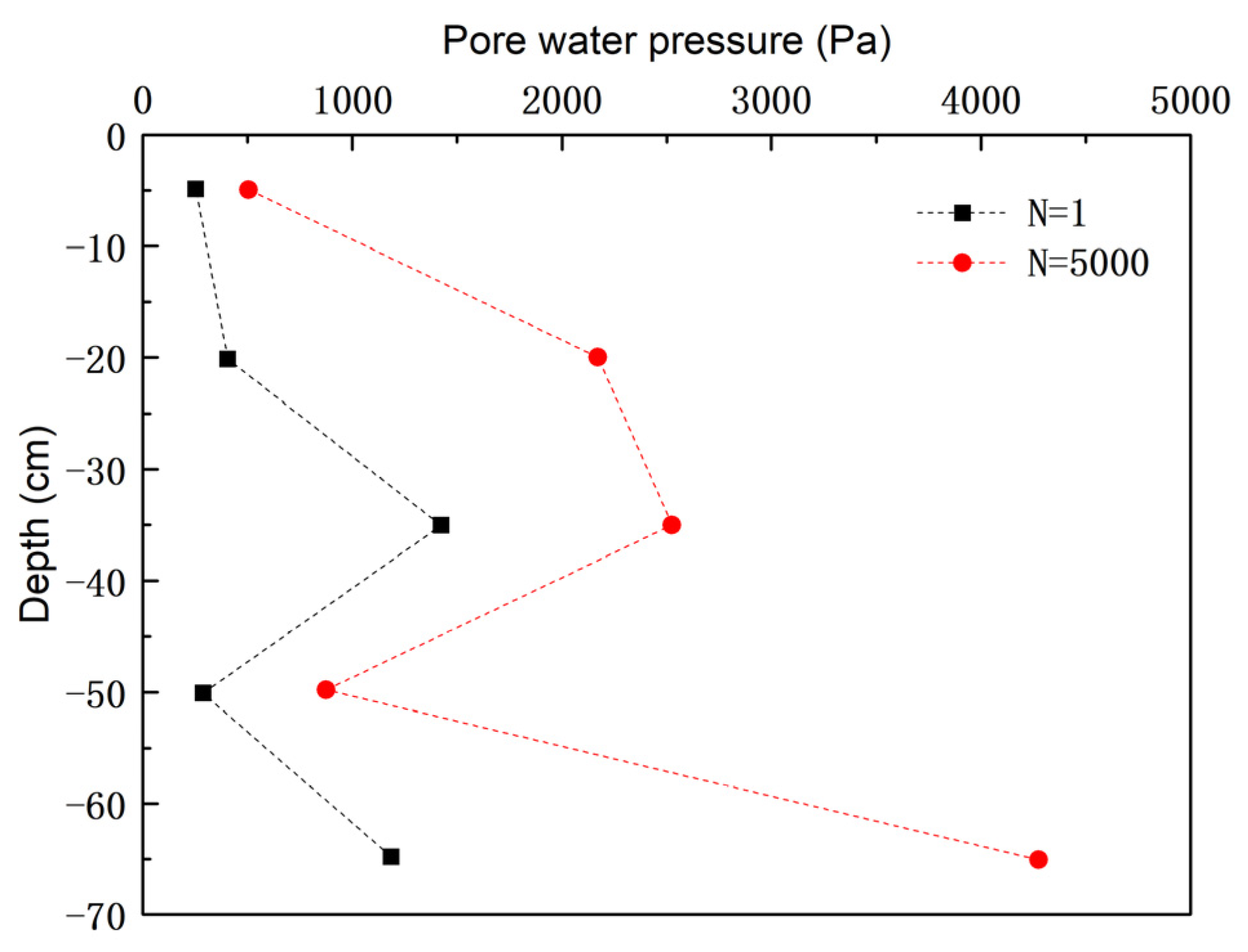

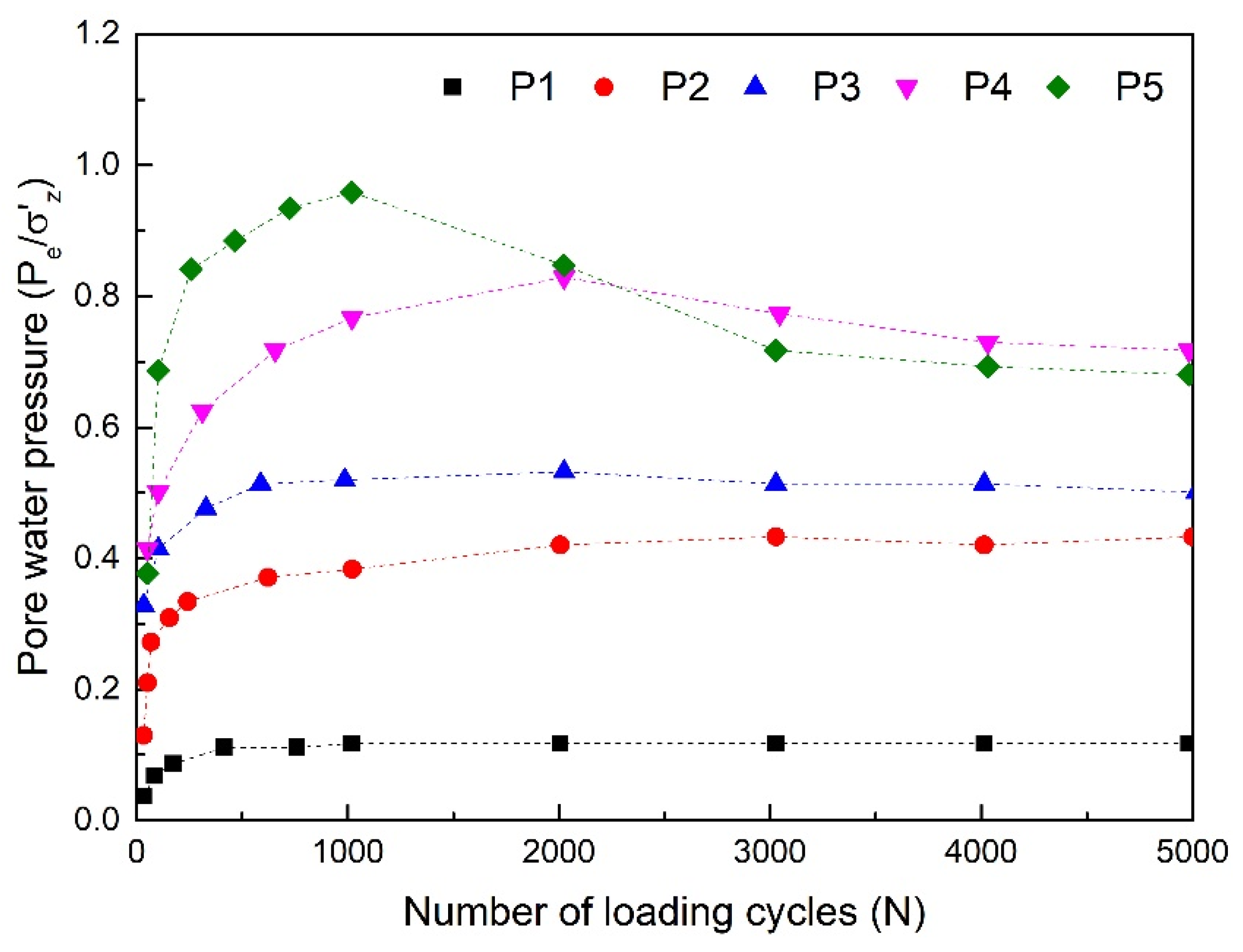

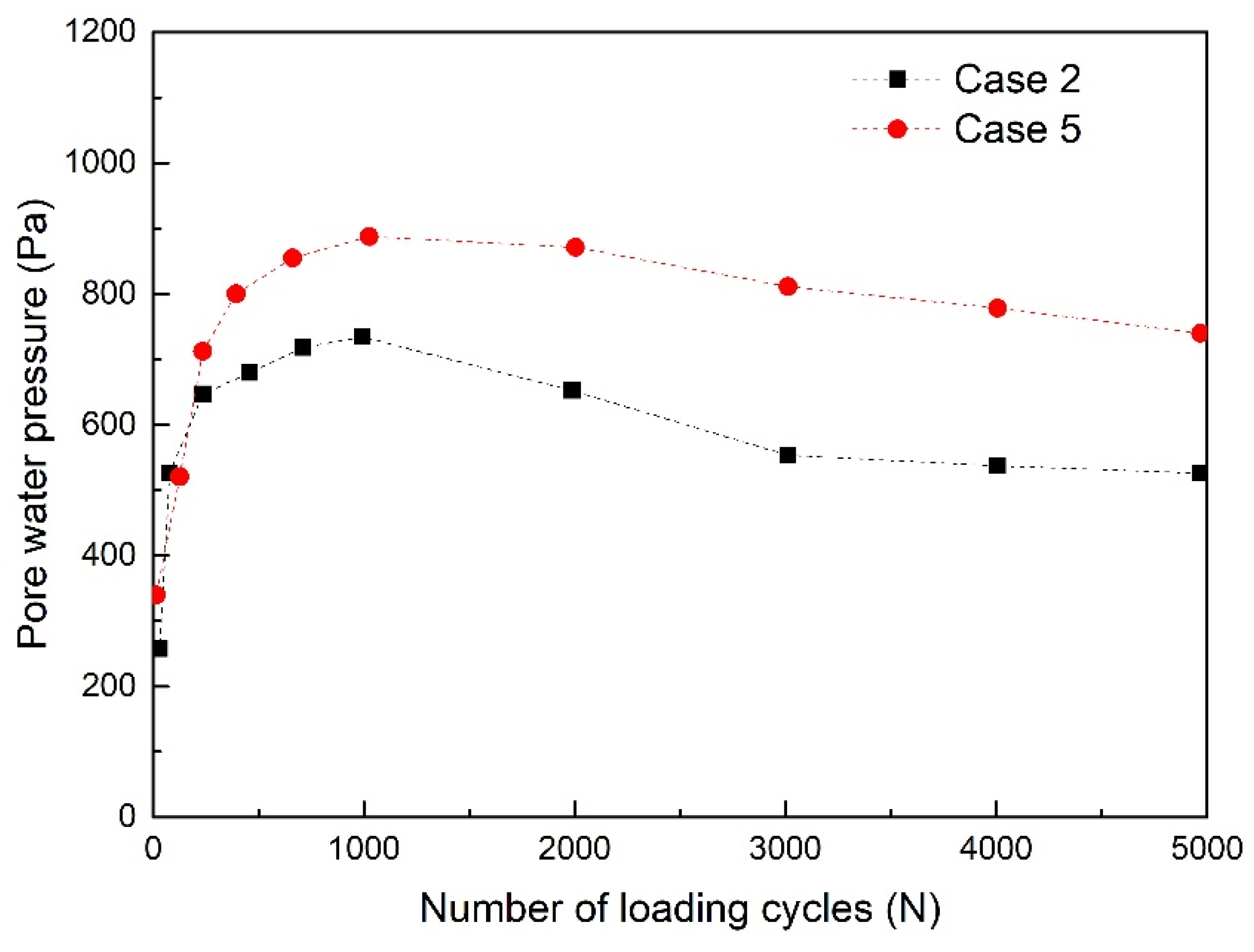

3.3. Pore Water Pressure Response around the Pile

4. Conclusions

- (1)

- Under cyclic loads, the presence of fin plates can reduce the horizontal displacement of the finned pile foundation, and when the width of the fin plate is reduced, the cumulative displacement of the finned pile foundation will increase. Therefore, in the design process, the horizontal displacement of the finned pile foundation can be reduced by increasing the width of the fin plate.

- (2)

- Compared with traditional single pile foundations, the cyclic stiffness attenuation of finned pile foundations is more severe, but the final equilibrium stiffness is still greater than that of traditional single pile foundations.

- (3)

- Increasing the size of the fin plate can reduce the response of pore water pressure in the soil of the finned pile foundation, and the pore pressure follows an S-shaped distribution along the soil depth, reaching its minimum value at the rotation center of the pile body and then increasing again.

- (4)

- The finned pile foundation has broad application prospects in future offshore wind turbine construction. This paper only explores the failure law of finned pile foundation under horizontal cyclic load through experimental methods. In the future, the artificial intelligence method should be combined to further analyze the bearing performance and design standards of finned pile foundation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dennis, Y.C.L.; Yuan, Y. Wind energy development and its environmental impact: A review. Renew. Sustain. Energy Rev. 2012, 16, 1031–1039. [Google Scholar]

- International Energy Agency (IEA). Offshore Wind Outlook 2019: Offshore wind Outlook to 2040; International Energy Agency (IEA): Paris, France, 2020. [Google Scholar]

- Cerfontaine, B.; White, D.; Kwa, K.; Gourvenec, S.; Knappett, J.; Brown, M. Anchor geotechnics for floating offshore wind: Current technologies and future innovations. Ocean Eng. 2023, 279, 114327. [Google Scholar] [CrossRef]

- Chen, J.; Gilbert, R.B.; Choo, Y.S.; Marshall, P.W.; Murff, J.D. Two-dimensional lower bound analysis of offshore pile foundation systems. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 1321–1338. [Google Scholar] [CrossRef]

- He, R.; Zhang, J.; Zheng, J. Vertical dynamic interaction factors for offshore thin-walled pipe piles. Comput. Geotech. 2022, 145, 104656. [Google Scholar] [CrossRef]

- Zheng, C.; Lin, H.; Cao, G.; Luan, L. Horizontal dynamic response of offshore large-diameter pipe piles. Ocean Eng. 2023, 272, 113797. [Google Scholar] [CrossRef]

- Xu, D.S.; Xu, X.Y.; Li, W.; Fatahi, B. Field experiments on laterally loaded piles for an offshore wind farm. Mar. Struct. 2020, 69, 102684. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Wu, W.; Liu, H.; Yao, Y.; Zhang, P. New method to calculate the kinematic response of offshore pipe piles under seismic S-waves. Soil Dyn. Earthq. Eng. 2023, 165, 107651. [Google Scholar] [CrossRef]

- Hu, T.; Dai, G.; Wan, Z.; Fang, B.; Chen, X. Full-scale tests on the grouting effectiveness of offshore bored piles with various bearing strata. Appl. Ocean Res. 2023, 141, 103791. [Google Scholar] [CrossRef]

- Xiao, S.; Lin, K.; Liu, H.; Zhou, A. Performance analysis of monopile-supported wind turbines subjected to wind and operation loads. Renew. Energy 2021, 179, 842–858. [Google Scholar] [CrossRef]

- Li, W.; Zhao, S.J.; Zhou, Y.; Xu, X.Y. 1g-model test of large diameter monopile with wings for offshore wind turbine. China Civ. Eng. J. 2013, 46, 124–132. [Google Scholar]

- Li, W.; Hu, B.; Li, B.; Xu, X.Y.; Xiong, G.; Zhao, S.J. Centrifuge model tests on horizontal bearing capacity of a large diameter pile with wings. Chin. J. Rock Mech. Eng. 2015, 34, 831–837. [Google Scholar]

- Chen, C.M.; He, J.X.; Su, X.D.; Wang, X.P.; Huang, W.L. Analysis of calculation method for horizontal bearing capacity of wing-monopile. Hydro-Sci. Eng. 2018, 4, 1–8. [Google Scholar]

- Nasr, A.M. Experimental and theoretical studies of laterally loaded finned piles in sand. Can. Geotech. J. 2014, 51, 381–393. [Google Scholar] [CrossRef]

- Abongo, K.; Gu, J.; Pervizpour, M.; Quiel, S.; Pamukcu, S. Parametric lab-scale testing and numerical simulation of finned monopiles under directional loading. Ocean Eng. 2022, 259, 111871. [Google Scholar] [CrossRef]

- Pei, T.; Qiu, T. A Numerical Investigation of Laterally Loaded Steel Fin Pile Foundation in Sand. Int. J. Geomech. 2022, 22, 04022102. [Google Scholar] [CrossRef]

- Sakr, M.A.; Azzam, W.R.; Wahba, M.A. Model study on the performance of single-finned piles in clay under lateral load. Arab. J. Geosci. 2020, 13, 172. [Google Scholar] [CrossRef]

- Hu, Y.Z.; Lu, Z.A.; Zhai, Q.; Zhang, Y.Q. Discussion on p-y curve of large diameter winged pile in soft clay. Water Resour. Hydro-Power Eng. 2018, 49, 143–152. [Google Scholar]

- Bienen, B.; Dührkop, J.; Grabe, J.; Randolph, M.F.; White, D.J. Response of Piles with Wings to Monotonic and Cyclic Lateral Loading in Sand. J. Geotech. Geoenviron. Eng. 2012, 138, 364–375. [Google Scholar] [CrossRef]

- Peng, J.R.; Rouainia, M.; Clarke, B.G. Finite element analysis of laterally loaded fin piles. Comput. Struct. 2010, 88, 1239–1247. [Google Scholar] [CrossRef]

- Albusoda, B.S.; Al-Saadi, A.F.; Jasim, A.F. An experimental study and numerical modeling of laterally loaded regular and finned pile foundations in sandy soils. Comput. Geotech. 2018, 102, 102–110. [Google Scholar] [CrossRef]

- Moein, K.; Mir, A.H.; Alireza, S.A. Performance of finned piles as a protection for a 2*2 group pile subjected to liquefaction-induced lateral spreading: A shake table investigation. Soil Dyn. Earthq. Eng. 2023, 170, 107915. [Google Scholar]

- Qin, H.Y.; Hung, C.Y.; Wang, H.; Zhang, J. Response of laterally loaded finned piles in sand. Acta Geotech. 2023, 19, 1765–1786. [Google Scholar] [CrossRef]

- Naggar, M.H.E.; Bentley, K.J. Dynamic analysis for laterally loaded piles and dynamic p-y curves. Can. Geotech. J. 2000, 37, 1166–1183. [Google Scholar] [CrossRef]

| Parameters | Values | Units |

|---|---|---|

| Median size (d50) | 0.0046 | mm |

| Relative density (Gs) | 2.57 | - |

| Poisson’s ratio (us) | 0.47 | - |

| Liquid limit (wI) | 43.07 | - |

| Plastic limit (wp) | 24.70 | - |

| Plasticity index (Ip) | 18.37 | - |

| Moisture content (w) | 35 | - |

| Volume-weight (r) | 17.3 | kN/m3 |

| Cohesive force (c) | 15 | kPa |

| Internal friction angle (α) | 20 | ° |

| Case | Pile Type | Fin Width | Fin Length | Load Type | Loading Eccentricity |

|---|---|---|---|---|---|

| Case 1 | Single pile | - | - | Cyclic loads | 5 mm |

| Case 2 | Fined Pile 1 | 1 D | 2 D | Cyclic loads | 5 mm |

| Case 3 | Fined Pile 1 | 1 D | 2 D | Cyclic loads | 10 mm |

| Case 4 | Fined Pile 1 | 1 D | 2 D | Cyclic loads | 17 mm |

| Case 5 | Fined Pile 2 | 0.5 D | 2 D | Cyclic loads | 5 mm |

| Case 6 | Fined Pile 2 | 0.5 D | 2 D | Cyclic loads | 10 mm |

| Case 7 | Fined Pile 2 | 0.5 D | 2 D | Static loads | - |

| Type of Pile Foundation | A | c |

|---|---|---|

| Finned pile foundation (W = 1 D) | 0.0061 | 0.0131 |

| Finned pile foundation (W = 0.5 D) | 0.0067 | 0.0193 |

| Monopile foundation | 0.0031 | 0.0625 |

| Case | B | j |

|---|---|---|

| Case 1 | 0.2 | 7.4 |

| Case 2 | 1.5 | 19.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, L.; Fan, M.; Zhan, B.; Wang, H.; Liu, H.; Tang, G.; Geng, B. Experimental Study on the Failure Mechanism of Finned Pile Foundation under Horizontal Cyclic Loads. Buildings 2024, 14, 2814. https://doi.org/10.3390/buildings14092814

Duan L, Fan M, Zhan B, Wang H, Liu H, Tang G, Geng B. Experimental Study on the Failure Mechanism of Finned Pile Foundation under Horizontal Cyclic Loads. Buildings. 2024; 14(9):2814. https://doi.org/10.3390/buildings14092814

Chicago/Turabian StyleDuan, Lunliang, Meiling Fan, Bolin Zhan, Haicui Wang, Haiming Liu, Guangwu Tang, and Bo Geng. 2024. "Experimental Study on the Failure Mechanism of Finned Pile Foundation under Horizontal Cyclic Loads" Buildings 14, no. 9: 2814. https://doi.org/10.3390/buildings14092814