Influence of Fine Content and Mean Diameter Ratio on the Minimum and Maximum Void Ratios of Sand–Fine Mixtures: A Discrete Element Method Study

Abstract

:1. Introduction

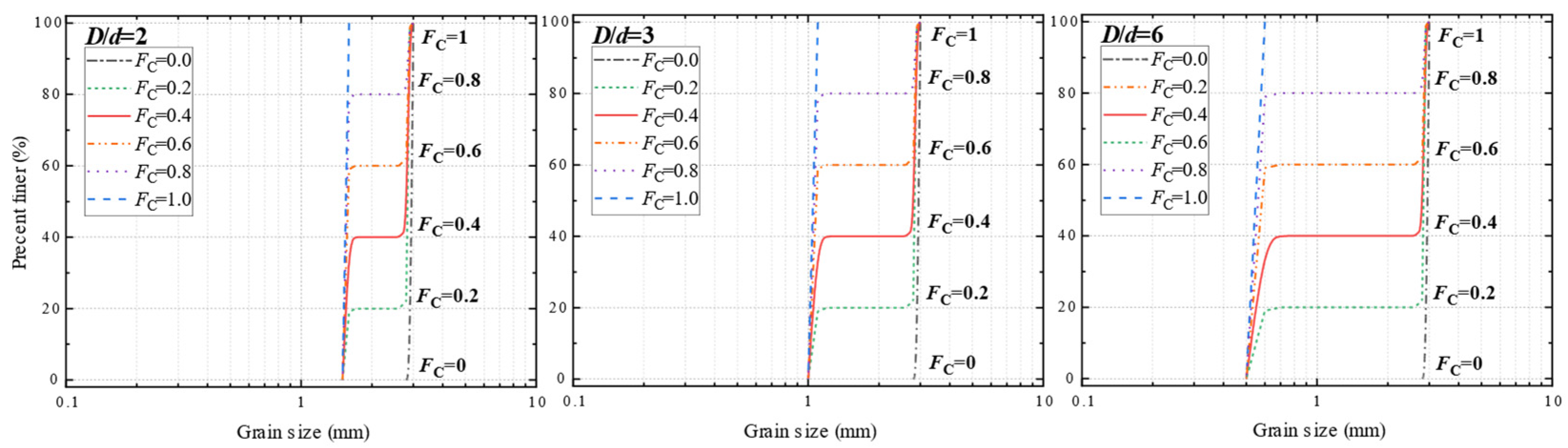

2. DEM Simulation

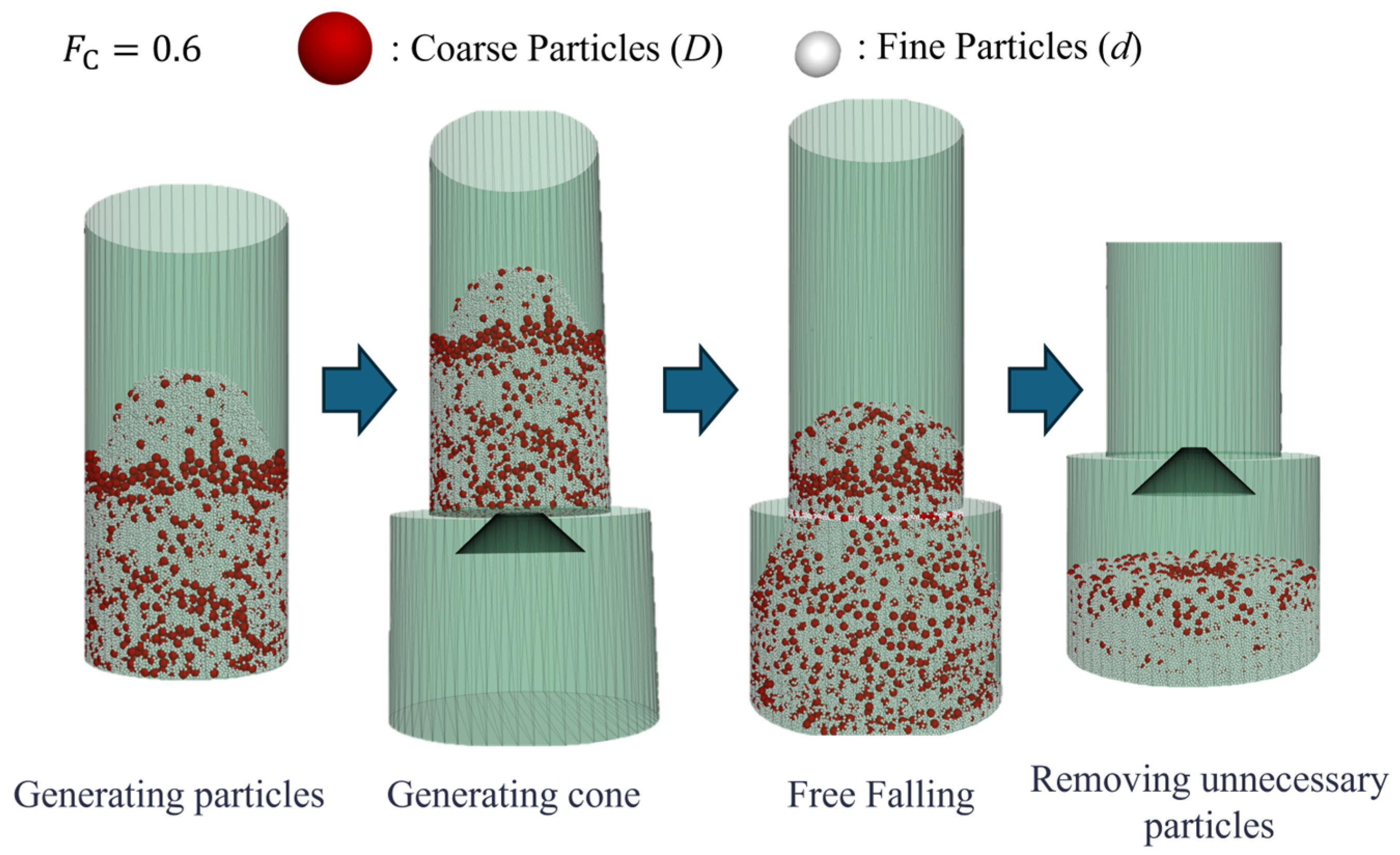

2.1. Minimum Void Ratio Test Simulation

2.2. Maximum Void Ratio Test Simulation

2.3. Initial Shear Modulus DEM Test

2.4. Validation of Contact Model Parameters

- (i)

- Spherical particles were generated within a cubic domain measuring 0.2 m × 0.2 m × 0.2 m, maintaining a uniform void ratio. The generated particle size distribution strictly followed the actual grain-size distribution curve of the HN31 sand. At the same time, the contact model was established between particle–particle and particle–facet interactions, and the unbalanced forces between particles were eliminated.

- (ii)

- When the particle generation was completed, confining pressure was applied to the specimen by controlling the velocity of the walls, which was calculated by measuring the stress on all walls at each time step. Based on the difference between the measured value and the target value, the velocity and direction of each wall were adjusted to ensure precise servo control. Once the consolidation stress reached 200.5 kPa, it was maintained for a period until the void ratio stabilized.

- (iii)

- After consolidation, a stress-controlled constant-volume cyclic triaxial shear test was performed on the specimen using a sine wave consistent with that used in the laboratory tests. The sine wave had a frequency of 0.1 Hz with a cyclic stress ratio (CSR) of 0.22 (the amplitude of shear stress divided by the consolidation stress). During the application of shear stress, both the shear stress and the effective mean stress were recorded. After the sample failed, the effective stress path was plotted and compared with the results obtained from laboratory tests on the HN31 sand.

3. Results and Discussion

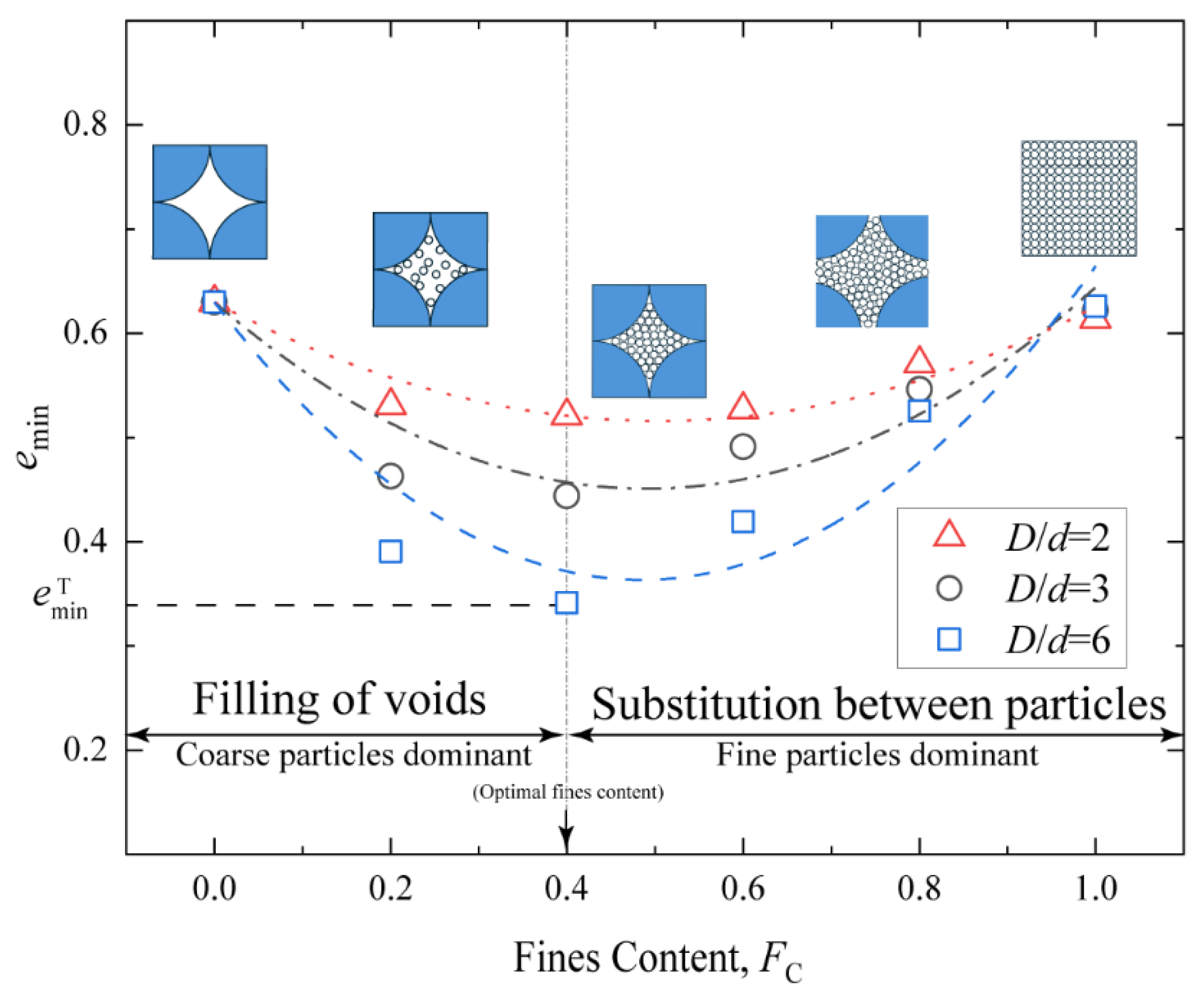

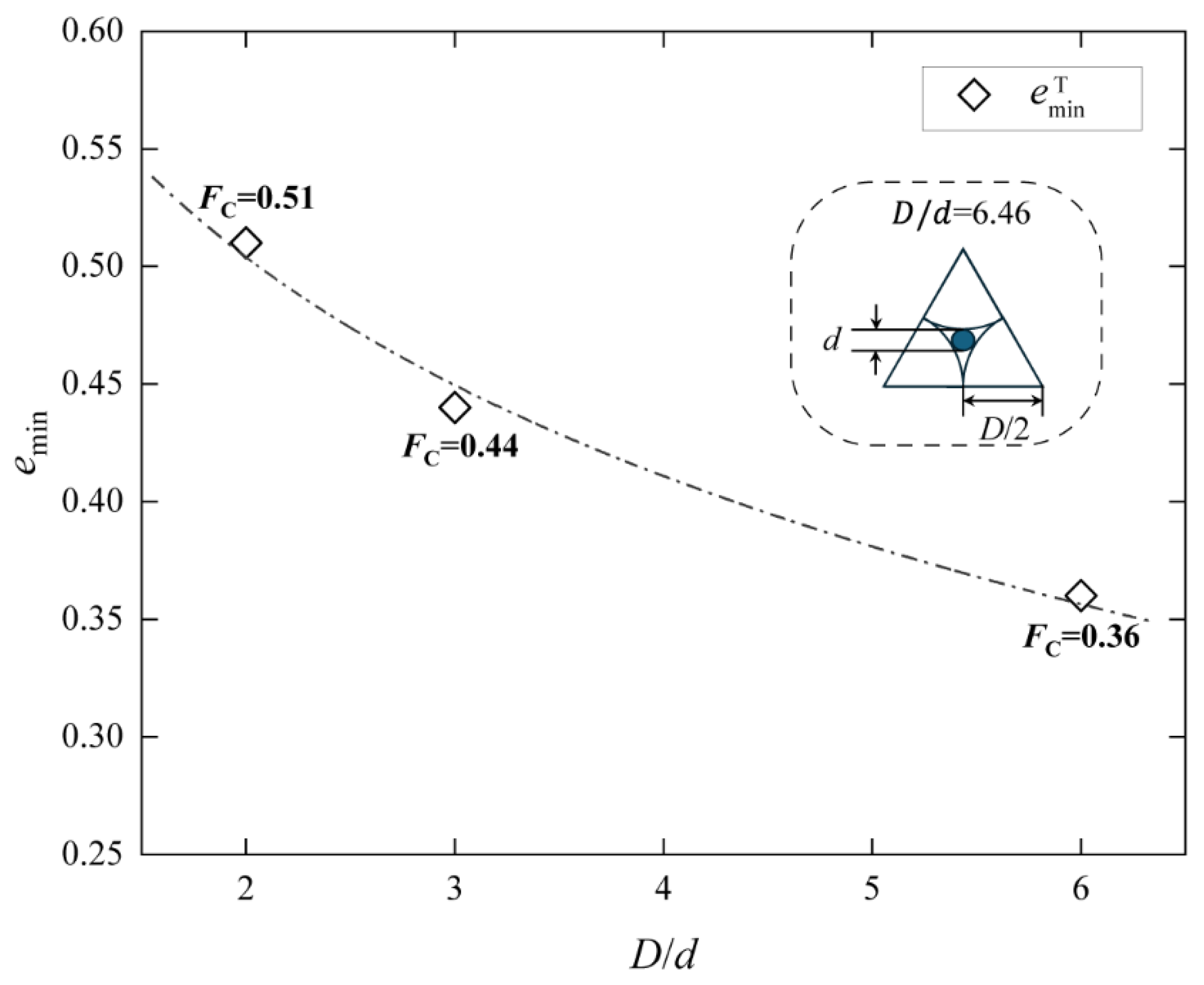

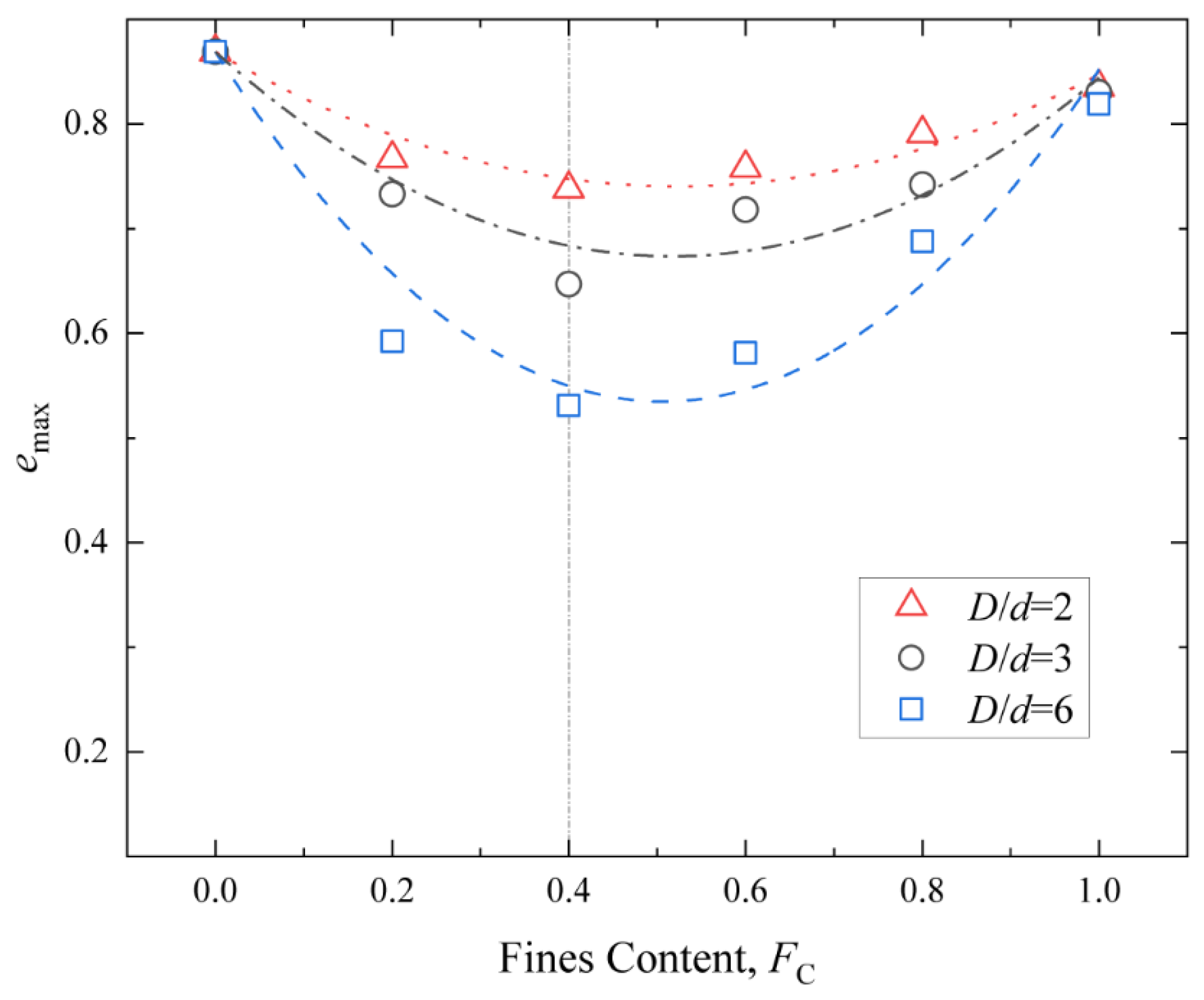

3.1. Minimum and Maximum Void Ratio

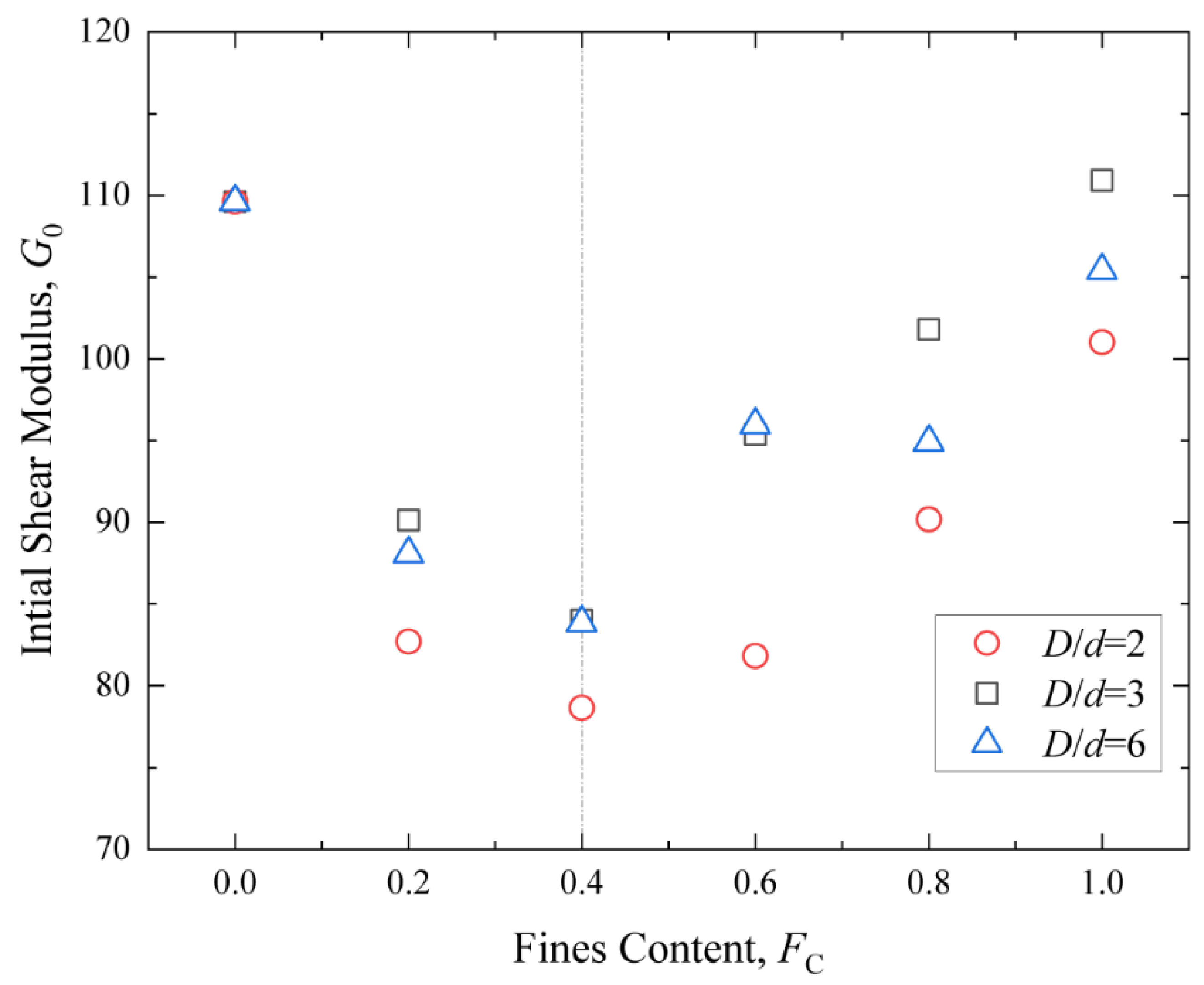

3.2. Initial Shear Modulus

4. Summary and Conclusions

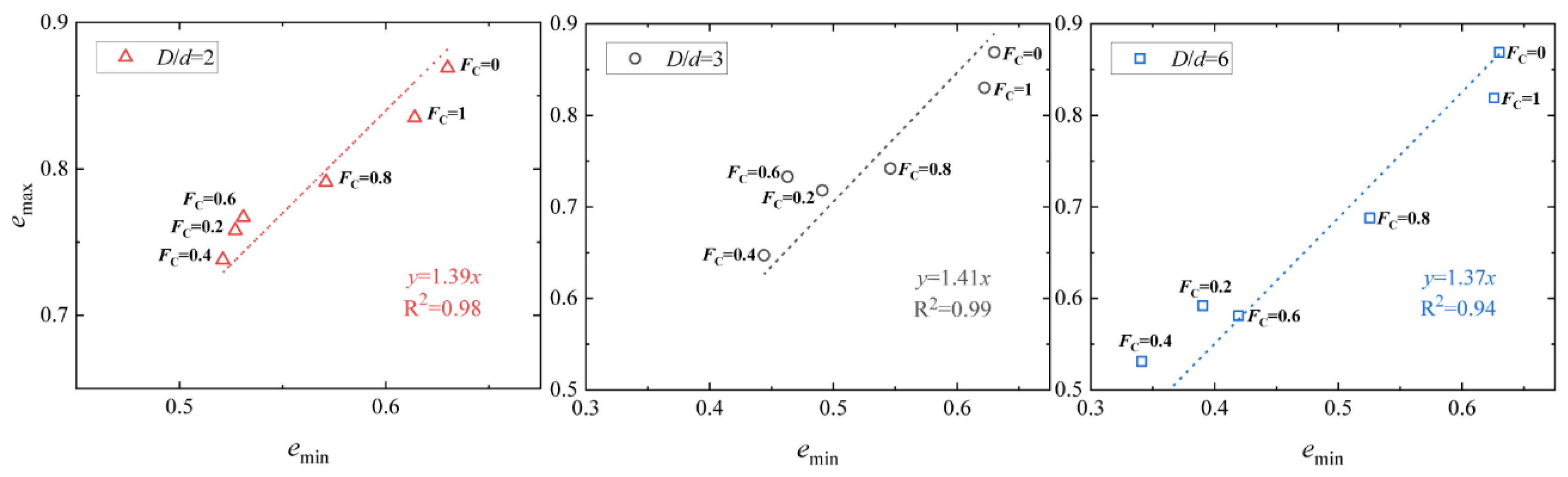

- Both the minimum and maximum void ratios initially decrease as the fine content increases until they reach a transitional fine content. The relationship between maximum and minimum void ratios exhibits an obvious linear pattern regardless of the fine content and mean diameter ratio.

- An increase in the mean diameter ratio corresponds to a decrease in both the minimum and maximum ratios. This trend loses its effect as the ratio approaches a critical value of 6.5. This suggests a bounded impact for the influence of the mean diameter ratio.

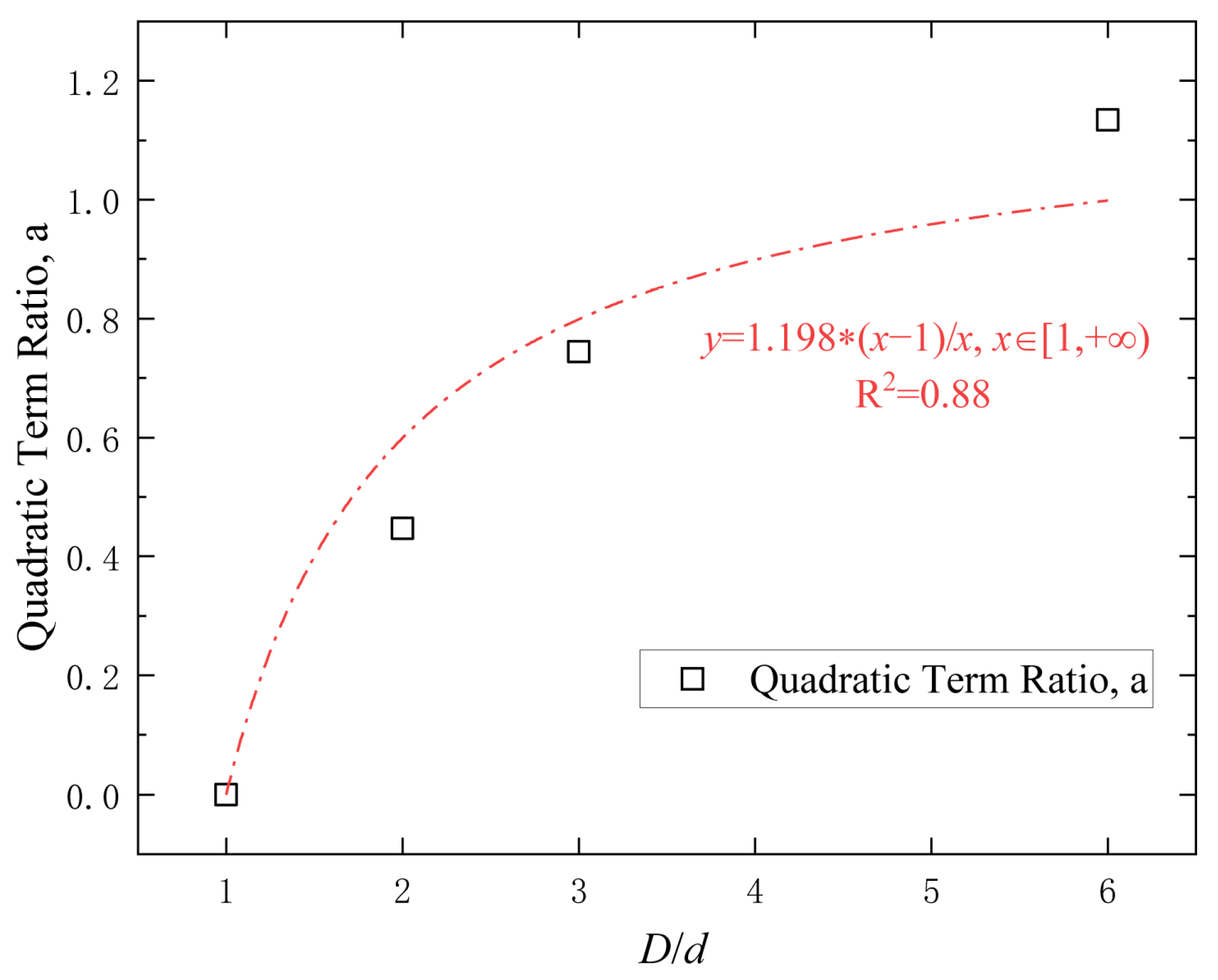

- The evolution of the minimum void ratio follows a quadratic function characterized by a single fitting parameter. Due to the strong linear correlation between the minimum and maximum void ratios being independent of the fine content and the mean diameter ratio, the latter can be effectively predicted using this linear function.

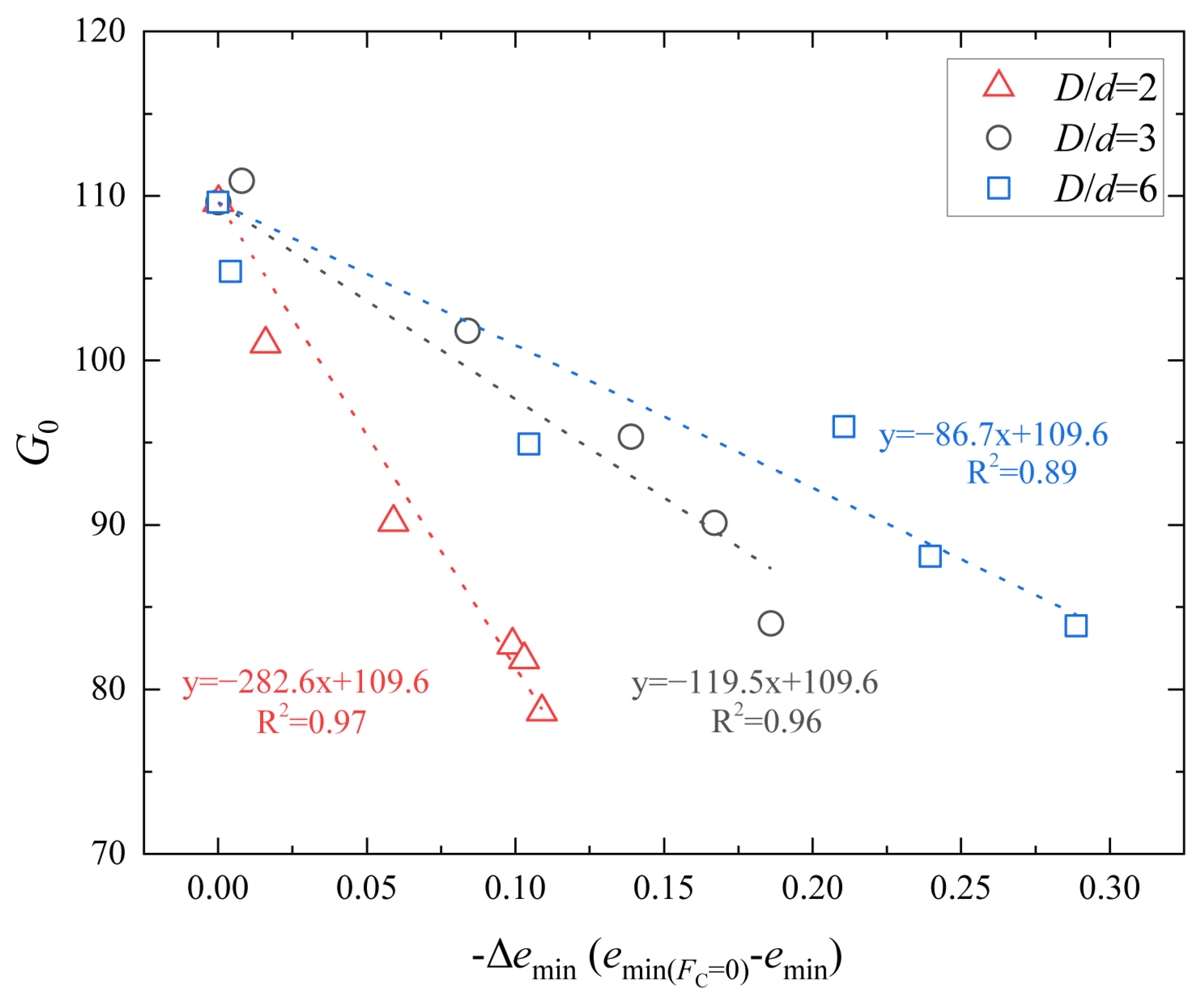

- In parallel with the evolution of the maximum and minimum void ratios, the initial shear modulus equally demonstrates a trend that begins with an increase and subsequently declines. This trend is punctuated by a transitional fine content, delineating the above two distinct regimes.

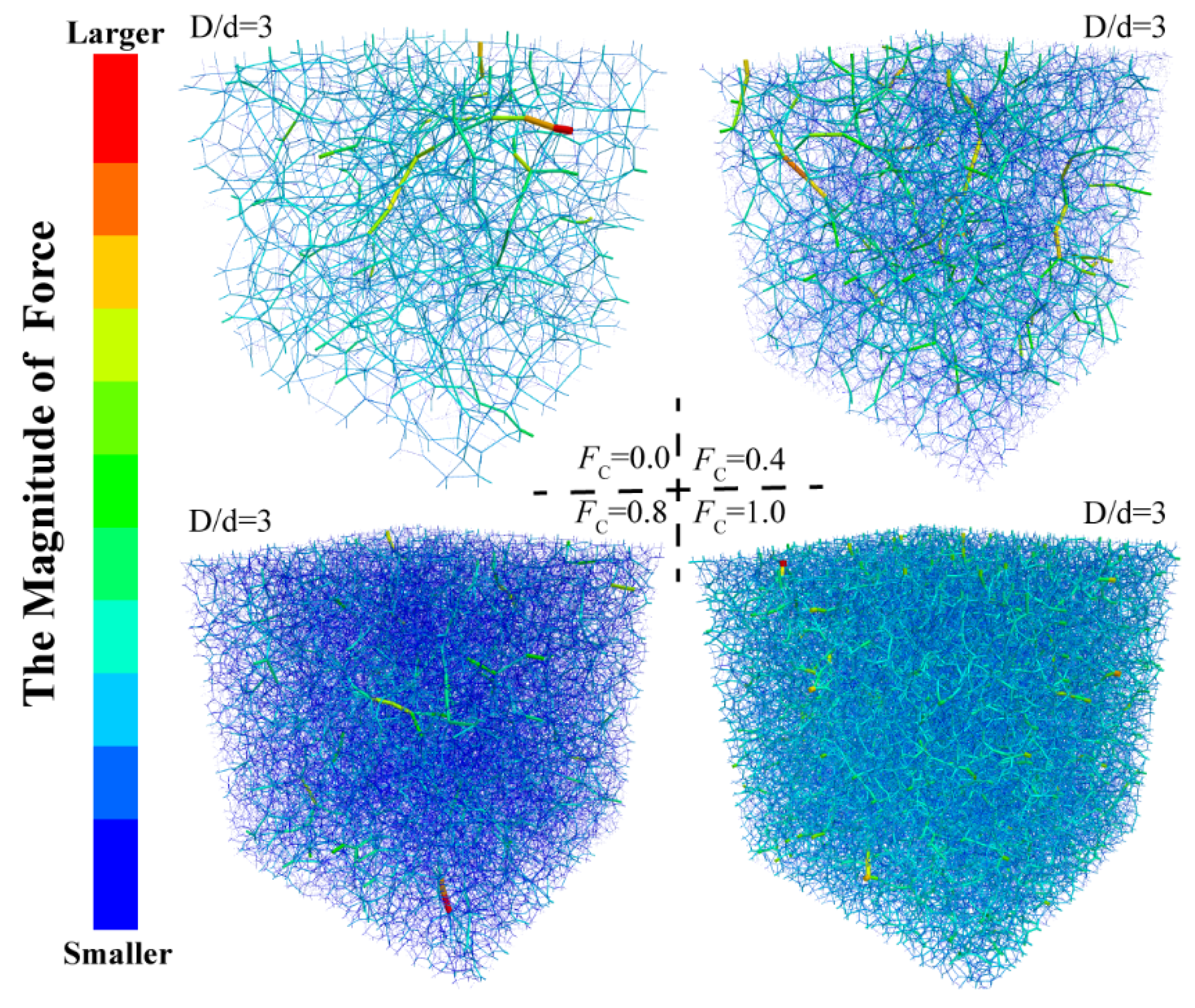

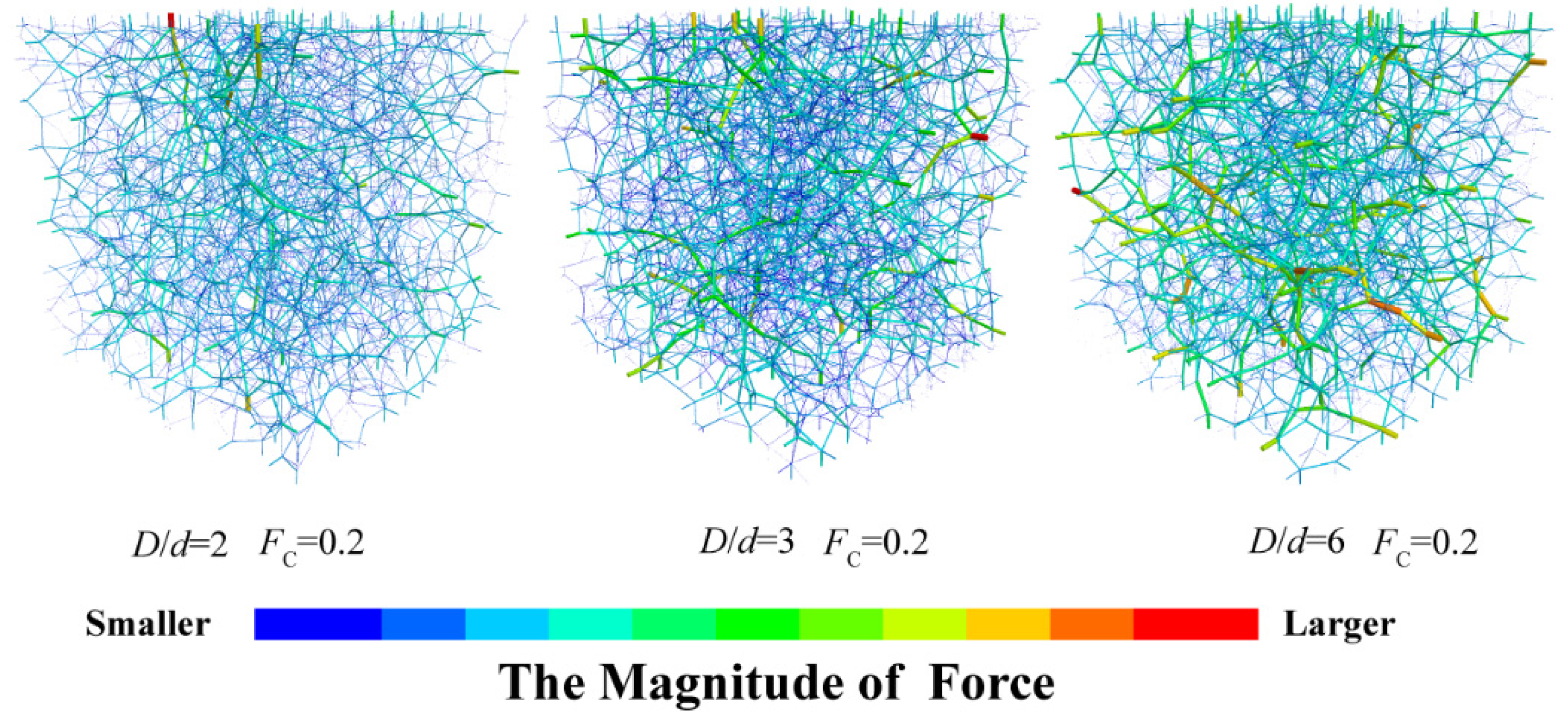

- From the microscopic perspective, an increase in fine content leads to a transformation of the global force chain. While approaching the transitional fine content, the stress concentrates at limited contact points and the force chain thus becomes much more localized. This explains the initial decrease with the addition of fines ( < 0.4). With the further addition of fines ( > 0.4), fine particles prevail in the global force chain. At this stage, the addition of fine particles significantly enhances the homogeneity of the global chain. Because most particles contribute to these force chains, the initial shear modulus is consequently increased.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jebelli, J.; Meguid, M.A.; Sedghinejad, M.K. Excavation Failure during Micro-Tunneling in Fine Sands: A Case Study. Tunn. Undergr. Space Technol. 2010, 25, 811–818. [Google Scholar] [CrossRef]

- Cubrinovski, M.; Ishihara, K. Maximum and Minimum Void Ratio Characteristics of Sands. Soils Found. 2002, 42, 65–78. [Google Scholar] [CrossRef] [PubMed]

- Iwasaki, T.; Tatsuoka, F. Effects of Grain Size and Grading on Dynamic Shear Moduli of Sands. Soils Found. 1977, 17, 19–35. [Google Scholar] [CrossRef]

- Liu, X.; Yang, J.; Zou, D.; Li, Z.; Chen, Y.; Cao, X. Utilizing DEM and Interpretable ML Algorithms to Examine Particle Size Distribution’s Role in Small-Strain Shear Modulus of Gap-Graded Granular Mixtures. Constr. Build. Mater. 2024, 428, 136232. [Google Scholar] [CrossRef]

- Sarkar, D.; Goudarzy, M.; König, D.; Wichtmann, T. Influence of Particle Shape and Size on the Threshold Fines Content and the Limit Index Void Ratios of Sands Containing Non-Plastic Fines. Soils Found. 2020, 60, 621–633. [Google Scholar] [CrossRef]

- Cho, G.-C.; Dodds, J.; Santamarina, J.C. Particle Shape Effects on Packing Density, Stiffness, and Strength: Natural and Crushed Sands. J. Geotech. Geoenviron. Eng. 2006, 132, 591–602. [Google Scholar] [CrossRef]

- Chaney, R.; Demars, K.; Lade, P.; Liggio, C.; Yamamuro, J. Effects of Non-Plastic Fines on Minimum and Maximum Void Ratios of Sand. Geotech. Test. J. 1998, 21, 336. [Google Scholar] [CrossRef]

- Rahman, M.M.; Lo, S.R.; Gnanendran, C.T. On Equivalent Granular Void Ratio and Steady State Behaviour of Loose Sand with Fines. Can. Geotech. J. 2008, 45, 1439–1456. [Google Scholar] [CrossRef]

- Cabalar, A.F. The Effects of Fines on the Behaviour of a Sand Mixture. Geotech. Geol. Eng. 2011, 29, 91–100. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, F.; Dupla, J.-C.; Canou, J.; Foerster, E. Investigation on the Undrained Shear Strength of Loose Sand with Added Materials at Various Mean Diameter Ratios. Soil Dyn. Earthq. Eng. 2020, 137, 106276. [Google Scholar] [CrossRef]

- Hang, T.; Fan, H.; Xiao, X.; Zhang, L.; Liang, K.; Wu, Q.; Chen, G. Prediction Model for Small-Strain Shear Modulus of Non-Plastic Fine–Coarse-Grained Soil Mixtures Based on Extreme Void Ratios. Soil Dyn. Earthq. Eng. 2024, 176, 108279. [Google Scholar] [CrossRef]

- Chang, C.S.; Wang, J.-Y.; Ge, L. Modeling of Minimum Void Ratio for Sand–Silt Mixtures. Eng. Geol. 2015, 196, 293–304. [Google Scholar] [CrossRef]

- Chang, C.S.; Wang, J.Y.; Ge, L. Maximum and Minimum Void Ratios for Sand-Silt Mixtures. Eng. Geol. 2016, 211, 7–18. [Google Scholar] [CrossRef]

- Polito, C.P. Correlations for Estimating Coefficients for the Prediction of Maximum and Minimum Index Void Ratios for Mixtures of Sand and Non-Plastic Silt. Geotechnics 2023, 3, 1033–1046. [Google Scholar] [CrossRef]

- De Larrard, F. Concrete Mixture Proportioning; CRC Press: Boca Raton, FL, USA, 1999; ISBN 978-1-4822-7205-5. [Google Scholar]

- Shen, C.; Liu, S.; Xu, S.; Wang, L. Rapid Estimation of Maximum and Minimum Void Ratios of Granular Soils. Acta Geotech. 2019, 14, 991–1001. [Google Scholar] [CrossRef]

- Belkhatir, M.; Schanz, T.; Arab, A. Effect of Fines Content and Void Ratio on the Saturated Hydraulic Conductivity and Undrained Shear Strength of Sand–Silt Mixtures. Environ. Earth Sci. 2013, 70, 2469–2479. [Google Scholar] [CrossRef]

- Selig, E.; Ladd, R. (Eds.) Evaluation of Relative Density Measurements and Applications. In Evaluation of Relative Density and Its Role in Geotechnical Projects Involving Cohesionless Soils; ASTM International: West Conshohocken, PA, USA, 1973; ISBN 978-0-8031-0081-7. [Google Scholar]

- Lo Presti, D.; Pedroni, S.; Crippa, V. Maximum Dry Density of Cohesionless Soils by Pluviation and by ASTM D 4253-83: A Comparative Study. Geotech. Test. J. 1992, 15, 180–189. [Google Scholar] [CrossRef]

- GB/T 50123; Standard for Soil Test Method. China Planning Press: Beijing, China, 2015.

- Reddy, N.S.C.; He, H.; Senetakis, K. DEM Analysis of Small and Small-to-Medium Strain Shear Modulus of Sands. Comput. Geotech. 2022, 141, 104518. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A Discrete Numerical Model for Granular Assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Zhao, J.; Zhu, Z.; Liu, J.; Zhong, H. Damping Ratio of Sand Containing Fine Particles in Cyclic Triaxial Liquefaction Tests. Appl. Sci. 2023, 13, 4833. [Google Scholar] [CrossRef]

- Zhao, J.; Zhu, Z.; Zhang, D.; Wang, H.; Li, X. Assessment of Fabric Characteristics with the Development of Sand Liquefaction in Cyclic Triaxial Tests: A DEM Study. Soil Dyn. Earthq. Eng. 2024, 176, 108343. [Google Scholar] [CrossRef]

- Zou, G.; Yang, B.; Yu, J.; Yang, S.; Chen, Q. Strength Formation and Failure Mechanism Analysis of Cement-Stabilized Laterite Granules Based on Numerical Simulation. Buildings 2023, 13, 3093. [Google Scholar] [CrossRef]

- Tan, X.; Qiu, Z.; Yin, X.; Hu, Y.; Liu, X.; Zeng, L. Effects of Particle Shape and Packing Density on the Mechanical Performance of Recycled Aggregates for Construction Purposes. Buildings 2023, 13, 2153. [Google Scholar] [CrossRef]

- Barnett, N.; Rahman, M.M.; Karim, M.R.; Nguyen, H.B.K.; Carraro, J.A.H. Equivalent State Theory for Mixtures of Sand with Non-Plastic Fines: A DEM Investigation. Géotechnique 2021, 71, 423–440. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, W.; Nie, W.; Deng, L. DEM and Theoretical Analyses of the Face Stability of Shallow Shield Cross-River Tunnels in Silty Fine Sand. Comput. Geotech. 2021, 130, 103905. [Google Scholar] [CrossRef]

- Gu, X.; Zhang, J.; Huang, X. DEM Analysis of Monotonic and Cyclic Behaviors of Sand Based on Critical State Soil Mechanics Framework. Comput. Geotech. 2020, 128, 103787. [Google Scholar] [CrossRef]

- Gu, X.; Huang, M.; Qian, J. DEM Investigation on the Evolution of Microstructure in Granular Soils under Shearing. Granul. Matter 2014, 16, 91–106. [Google Scholar] [CrossRef]

- Hardin, B.O.; Black, W.L. Sand Stiffness Under Various Triaxial Stresses. J. Soil Mech. Found. Div. 1966, 92, 27–42. [Google Scholar] [CrossRef]

- Viggiani, G.; Atkinson, J.H. Stiffness of Fine-Grained Soil at Very Small Strains. Géotechnique 1995, 45, 249–265. [Google Scholar] [CrossRef]

- Atkinson, J.H. Non-Linear Soil Stiffness in Routine Design. Géotechnique 2000, 50, 487–508. [Google Scholar] [CrossRef]

- Miwa, S.; Ikeda, T. Shear Modulus and Strain of Liquefied Ground and Their Application to Evaluation of The Response of Foundation Structures. Struct. Eng. Earthq. Eng. 2006, 23, 167s–179s. [Google Scholar] [CrossRef]

- Clayton, C.R.I. Stiffness at Small Strain: Research and Practice. Géotechnique 2011, 61, 5–37. [Google Scholar] [CrossRef]

- Chiaro, G.; Koseki, J.; Sato, T. Effects of Initial Static Shear on Liquefaction and Large Deformation Properties of Loose Saturated Toyoura Sand in Undrained Cyclic Torsional Shear Tests. Soils Found. 2012, 52, 498–510. [Google Scholar] [CrossRef]

- Yao, C.; Zhong, H.; Zhu, Z. Development of a Large Shaking Table Test for Sand Liquefaction Analysis. 2024. Available online: https://pubs.geoscienceworld.org/gsw/lithosphere/article/2024/2/lithosphere_2024_137/645133/Development-of-a-Large-Shaking-Table-Test-for-Sand (accessed on 9 September 2024).

- Benahmed, N. Comportement Mécanique d’un Sable Sous Cisaillement Monotone et Cyclique: Application Aux Phénomènes de Liquéfaction et Mobilité Cyclique. Ph.D. Theis, ENPC, Champs-sur-Marne, France, 2001. [Google Scholar]

- McGEARY, R.K. Mechanical Packing of Spherical Particles. J. Am. Ceram. Soc. 1961, 44, 513–522. [Google Scholar] [CrossRef]

| Linear Group | Particle–Particle | Particle–Facet | Unity | |

|---|---|---|---|---|

| Effective Modulus | 1.0 × 108 | 1.0 × 108 | Pa | |

| Normal-to-Shear Stiffness Ratio | 2.0 | 2.0 | - | |

| Friction Coefficient | 0.55 | 0 | - | |

| Dashpot Group | ||||

| Normal Critical Damping Ratio | 0.2 | 0.2 | - | |

| Shear Critical Damping Ratio | 0.2 | 0.2 | - | |

| Dashpot Mode | 3 | 3 | - | |

| Rolling Resistance Group | ||||

| Rolling Friction Coefficient | 0.20 | 0 | - |

| D/d | Fitting Function () | a | b | c | |

|---|---|---|---|---|---|

| 2 | 0.44 | −0.45 | 0.63 | 0.91 | |

| 3 | 0.74 | −0.73 | 0.63 | 0.86 | |

| 6 | 1.13 | −1.10 | 0.63 | 0.87 |

| D/d | Fitting Function () | a | b | c | |

|---|---|---|---|---|---|

| 2 | 0.46 | −0.49 | 0.86 | 0.91 | |

| 3 | 0.73 | −0.75 | 0.86 | 0.89 | |

| 6 | 1.30 | −1.31 | 0.86 | 0.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, H.; Zhu, Z.; Zhao, J.; Wei, L.; Zhang, Y.; Li, J.; Wang, J.; Yao, W. Influence of Fine Content and Mean Diameter Ratio on the Minimum and Maximum Void Ratios of Sand–Fine Mixtures: A Discrete Element Method Study. Buildings 2024, 14, 2877. https://doi.org/10.3390/buildings14092877

Zhong H, Zhu Z, Zhao J, Wei L, Zhang Y, Li J, Wang J, Yao W. Influence of Fine Content and Mean Diameter Ratio on the Minimum and Maximum Void Ratios of Sand–Fine Mixtures: A Discrete Element Method Study. Buildings. 2024; 14(9):2877. https://doi.org/10.3390/buildings14092877

Chicago/Turabian StyleZhong, Huaqiao, Zhehao Zhu, Jiajin Zhao, Lanyi Wei, Yanyan Zhang, Jiayu Li, Jiajun Wang, and Wenguo Yao. 2024. "Influence of Fine Content and Mean Diameter Ratio on the Minimum and Maximum Void Ratios of Sand–Fine Mixtures: A Discrete Element Method Study" Buildings 14, no. 9: 2877. https://doi.org/10.3390/buildings14092877