Improving Acoustic Properties of Sandwich Structures Using Recycled Membrane and HoneyComb Composite (RMHCC)

Abstract

:1. Introduction

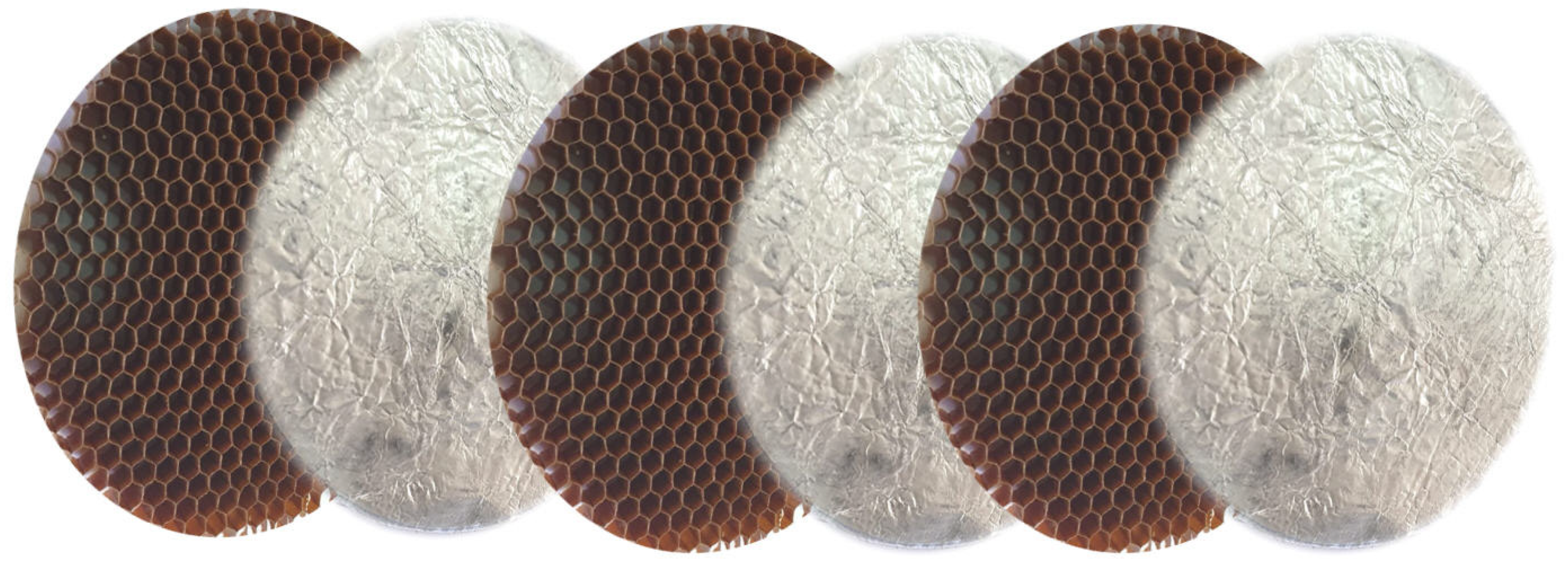

2. Materials and Methods

2.1. Sandwich Structure Definition

2.2. Sound Adsorption Coefficient Measurements

2.3. Modelling the Behaviour of the Material

3. Results and Discussion

3.1. Analysis of Acoustic Properties of the Sandwich Structure

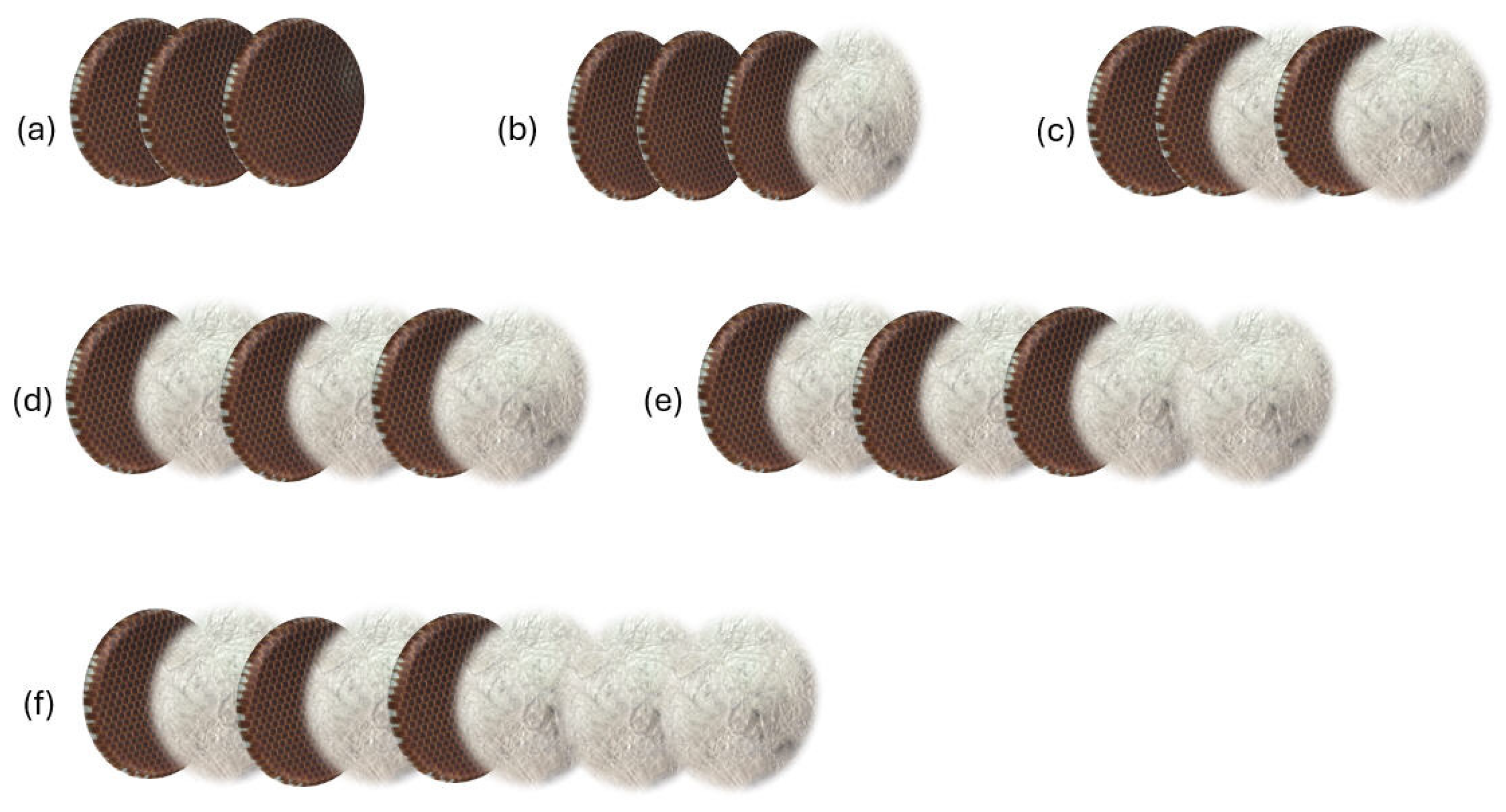

- (a)

- No membrane and three layers of Honeycomb.

- (b)

- One Membrane and three layers of Honeycomb: In this configuration, a single layer of membrane was placed in front of a layer of honeycomb structure.

- (c)

- Two Membranes and three layers of Honeycomb (Sandwich Configuration). Here, two layers of membrane were placed in front of two layers of honeycomb structure, creating a sandwich configuration, leaving a third layer at the end.

- (d)

- Three Membranes and Three Honeycomb Structures (Sandwich Configuration): This configuration involved three layers of the membrane in front of three layers of honeycomb structure.

- (e)

- Four Membranes and Three Honeycomb Structures (Sandwich Configuration): This configuration involved three layers of the membrane in front of three layers of honeycomb structure, in the first layer there were two overlapping membranes.

- (f)

- Five Membranes and Three Honeycomb Structures (Sandwich Configuration): This configuration involved three layers of the membrane in front of three layers of honeycomb structure, in the first layer there were three overlapping membranes.

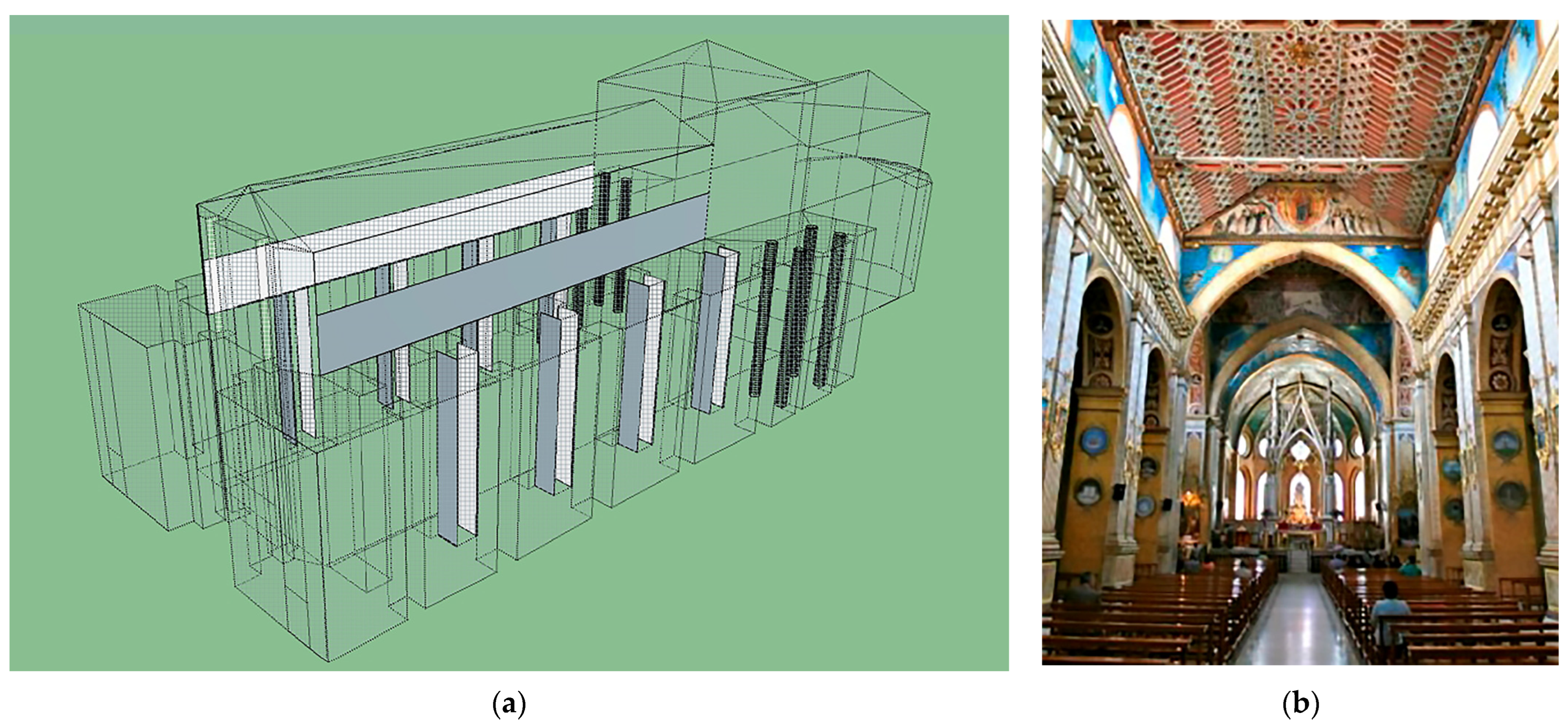

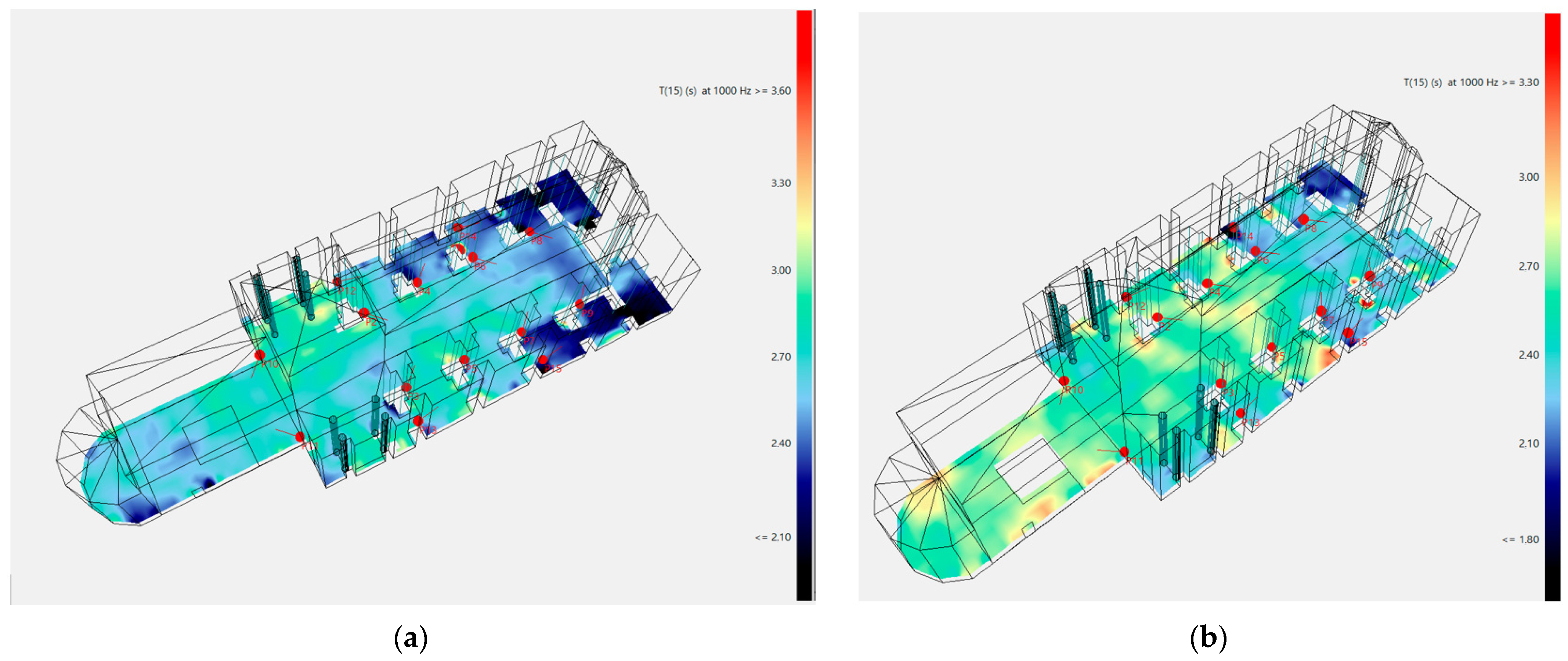

3.2. Optimizing Acoustic Environments through Room Acoustic Modelling

- EDT (Early Decay Time): This term refers to the time it takes for the sound level in a room to decrease by 10 decibels, measured right after the sound source is turned off. It is a crucial parameter because it provides information about how the clarity and definition of sounds in space are perceived, particularly in the early reflections that are vital for speech intelligibility [61].

- T(15): This is one of several parameters used to describe reverberation time. Specifically, T15 measures how long it takes the sound level to drop by 15 decibels from its initial level. It is then extrapolated to estimate the time it would take for a total 60-decibel reduction, giving insight into the acoustic behavior of a space [62].

- C(50): This index evaluates the clarity of perceived sound. C50 measures the ratio between the sound energy received in the first 50 milliseconds after the direct sound arrival and the energy that arrives after this interval. This parameter is particularly important in assessing speech clarity, where a higher value indicates better intelligibility [63].

- C(80): Similar to C50 but refers to a longer time interval of 80 milliseconds. C80 is often used in evaluating musical clarity, as an appropriate value improves the sharpness and detail of music in an enclosed environment [64].

- ALCONS (Articulation Loss of Consonants): This percentage indicates the loss of intelligibility in speech, focusing on the ability to distinguish consonants, which are crucial for correctly understanding language. A low %ALCONS value means that the acoustic conditions of the space allow good verbal comprehension, while a high value suggests difficulties in understanding speech [65].

| Parameter | Frequency | 125 | 250 | 500 | 1000 | 2000 |

|---|---|---|---|---|---|---|

| EDT (s) | Initial (Average) | 1.99 | 3.16 | 2.78 | 2.07 | 2.4 |

| Modified (Average) | 1.76 | 2.23 | 2.23 | 1.92 | 2.38 | |

| VAR % | 12% | 29% | 20% | 7% | 1% | |

| T(15) (s) | Initial (Average) | 2.08 | 3.12 | 3.05 | 2.53 | 2.59 |

| Modified (Average) | 1.89 | 2.64 | 2.82 | 2.47 | 2.59 | |

| VAR % | 9% | 15% | 8% | 2% | 0% | |

| C(50) (dB) | Initial (Average) | −1 | −2.5 | −0.7 | −0.5 | −2.9 |

| Modified (Average) | −0.3 | −0.8 | 0 | −0.5 | −2.5 | |

| VAR % | 70% | 68% | 100% | 0% | 14% | |

| C(80) (dB) | Initial (Average) | 0.8 | −1 | 1 | 1.9 | −0.6 |

| Modified (Average) | 1.6 | 1 | 1.9 | 1.9 | −0.3 | |

| VAR % | −100% | 200% | −90% | 0% | 50% | |

| Alcons (STI) | Initial (Average) | 12.51 | ||||

| Modified (Average) | 11.34 | |||||

| VAR % | 9% | |||||

- Initial (Average): This value refers to the initial average of the measured parameter across multiple measurement points or directions in the room before any corrections or modifications are applied. It represents the unaltered result directly from the simulation or measurements.

- Modified (Average): This term refers to the average value after applying specific modifications or corrections to the initial measurements. In Odeon, modifications might include adjustments for background noise, truncation corrections for the decay curve, or other room simulation adjustments to improve the accuracy of the parameter estimation.

- VAR % (Variation Percentage): VAR % indicates the variability or consistency of the parameter measurements across different positions in the room. It is a statistical measure that shows how much the values deviate from the average (either initial or modified). A lower VAR % suggests that the parameter is more uniformly distributed throughout the room, which can be desirable for consistent acoustic performance.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, W.; He, J.; He, C.; Cai, M. Evaluation of urban traffic noise pollution based on noise maps. Transp. Res. Part D: Transp. Environ. 2020, 87, 102516. [Google Scholar] [CrossRef]

- Morillas, J.M.B.; Gozalo, G.R.; González, D.M.; Moraga, P.A.; Vílchez-Gómez, R. Noise pollution and urban planning. Curr. Pollut. Rep. 2018, 4, 208–219. [Google Scholar] [CrossRef]

- Mohamed, A.M.O.; Paleologos, E.K.; Howari, F.M. Noise pollution and its impact on human health and the environment. In Pollution Assessment for Sustainable Practices in Applied Sciences and Engineering; Butterworth-Heinemann: Oxford, UK, 2021; pp. 975–1026. [Google Scholar]

- Münzel, T.; Sørensen, M.; Daiber, A. Transportation noise pollution and cardiovascular disease. Nat. Rev. Cardiol. 2021, 18, 619–636. [Google Scholar] [CrossRef] [PubMed]

- Fediuk, R.; Amran, M.; Vatin, N.; Vasilev, Y.; Lesovik, V.; Ozbakkaloglu, T. Acoustic properties of innovative concretes: A review. Materials 2021, 14, 398. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Jeon, J.Y. Design strategies and elements of building envelope for urban acoustic environment. Build. Environ. 2020, 182, 107121. [Google Scholar] [CrossRef]

- Ma, Q.; Rejab, M.R.M.; Siregar, J.P.; Guan, Z. A review of the recent trends on core structures and impact response of sandwich panels. J. Compos. Mater. 2021, 55, 2513–2555. [Google Scholar] [CrossRef]

- Khan, T.; Acar, V.; Aydin, M.R.; Hülagü, B.; Akbulut, H.; Seydibeyoğlu, M.Ö. A review on recent advances in sandwich structures based on polyurethane foam cores. Polym. Compos. 2020, 41, 2355–2400. [Google Scholar] [CrossRef]

- Lin, Q.; Lin, Q.; Wang, Y.; Di, G. Sound insulation performance of sandwich structure compounded with a resonant acoustic metamaterial. Compos. Struct. 2021, 273, 114312. [Google Scholar] [CrossRef]

- Ciaburro, G.; Berardi, U.; Iannace, G.; Trematerra, A.; Puyana-Romero, V. The acoustics of ancient catacombs in Southern Italy. Build. Acoust. 2021, 28, 411–422. [Google Scholar] [CrossRef]

- Wang, D.W.; Wen, Z.H.; Glorieux, C.; Ma, L. Sound absorption of face-centered cubic sandwich structure with micro-perforations. Mater. Des. 2020, 186, 108344. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Yang, S. Advanced honeycomb designs for improving mechanical properties: A review. Compos. Part B Eng. 2021, 227, 109393. [Google Scholar] [CrossRef]

- Wei, X.; Xiong, J.; Wang, J.; Xu, W. New advances in fiber-reinforced composite honeycomb materials. Sci. China Technol. Sci. 2020, 63, 1348–1370. [Google Scholar] [CrossRef]

- Li, F.; Yuan, W.; Zhang, C. Free vibration and sound insulation of functionally graded honeycomb sandwich plates. J. Sandw. Struct. Mater. 2022, 24, 565–600. [Google Scholar] [CrossRef]

- Scarpa, F.; Gattamelata, D.; Giliberti, M.; Oliva, S. Tailoring the negative Poisson’s ratio of honeycomb sandwich structures for enhanced blast-resistance. Compos. Struct. 2018, 188, 594–605. [Google Scholar]

- Li, Q.; Yang, D. Vibration and sound transmission performance of sandwich panels with uniform and gradient auxetic double arrowhead honeycomb cores. Shock. Vib. 2019, 2019, 6795271. [Google Scholar] [CrossRef]

- Griese, D.; Summers, J.D.; Thompson, L. The effect of honeycomb core geometry on the sound transmission performance of sandwich panels. J. Vib. Acoust. 2015, 137, 021011. [Google Scholar] [CrossRef]

- Meng, J.; Deng, Z.; Zhang, K.; Xu, X.; Wen, F. Band gap analysis of star-shaped honeycombs with varied Poisson’s ratio. Smart Mater. Struct. 2015, 24, 095011. [Google Scholar] [CrossRef]

- Ciaburro, G.; Parente, R.; Iannace, G.; Puyana-Romero, V. Design optimization of three-layered metamaterial acoustic absorbers based on PVC reused membrane and metal washers. Sustainability 2022, 14, 4218. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Membrane-type acoustic metamaterial using cork sheets and attached masses based on reused materials. Appl. Acoust. 2022, 189, 108605. [Google Scholar] [CrossRef]

- Cameron, C.J.; Nordgren, E.L.; Wennhage, P.; Göransson, P. On the balancing of structural and acoustic performance of a sandwich panel based on topology, property, and size optimization. J. Sound Vib. 2014, 333, 2677–2698. [Google Scholar] [CrossRef]

- Meng, H.; Galland, M.A.; Ichchou, M.; Bareille, O.; Xin, F.X.; Lu, T.J. Small perforations in corrugated sandwich panel significantly enhance low frequency sound absorption and transmission loss. Compos. Struct. 2017, 182, 1–11. [Google Scholar] [CrossRef]

- Khandeparkar, A.S.; Paul, R.; Sridhar, A.; Lakshmaiah, V.V.; Nagella, P. Eco-friendly innovations in food packaging: A sustainable revolution. Sustain. Chem. Pharm. 2024, 39, 101579. [Google Scholar] [CrossRef]

- He, M.; Hu, W. A study on composite honeycomb sandwich panel structure. Mater. Des. 2008, 29, 709–713. [Google Scholar] [CrossRef]

- Ingrole, A.; Hao, A.; Liang, R. Design and modeling of auxetic and hybrid honeycomb structures for in-plane property enhancement. Mater. Des. 2017, 117, 72–83. [Google Scholar] [CrossRef]

- Gai, X.L.; Guan, X.W.; Cai, Z.N.; Li, X.H.; Hu, W.C.; Xing, T.; Wang, F. Acoustic properties of honeycomb like sandwich acoustic metamaterials. Appl. Acoust. 2022, 199, 109016. [Google Scholar] [CrossRef]

- Sui, N.; Yan, X.; Huang, T.Y.; Xu, J.; Yuan, F.G.; Jing, Y. A lightweight yet sound-proof honeycomb acoustic metamaterial. Appl. Phys. Lett. 2015, 106, 171905. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Xie, S. A lightweight multilayer honeycomb membrane-type acoustic metamaterial. Appl. Acoust. 2020, 168, 107427. [Google Scholar] [CrossRef]

- Ge, Y.; Xue, J.; Liu, L.; Wan, H.; Yang, Y. Advances in multiple assembly acoustic structural design strategies for honeycomb composites: A review. Mater. Today Commun. 2024, 38, 108013. [Google Scholar] [CrossRef]

- Wang, D.; Xie, S.C.; Yang, S.C.; Li, Z. Sound absorption performance of acoustic metamaterials composed of double-layer honeycomb structure. J. Cent. South Univ. 2021, 28, 2947–2960. [Google Scholar] [CrossRef]

- Li, J.; Guo, H.; Sun, P.; Wang, Y.; Huang, S.; Yuan, T.; Zhang, H. Topology optimization of anisotropy hierarchical honeycomb acoustic metamaterials for extreme multi-broad band gaps. Mech. Adv. Mater. Struct. 2023, 30, 3540–3552. [Google Scholar] [CrossRef]

- EN ISO 10534-2; Acoustics—Determination of Acoustic Properties in Impedance Tubes. Part 2: Two-Microphone Technique for Normal Sound Absorption Coefficient and Normal Surface Impedance. ISO: Geneva, Switzerland, 2023.

- Marescotti, C.; Pompoli, F. Geometric optimisation of a multiple coiled-up resonator for broadband and octave band acoustic absorption. Appl. Acoust. 2024, 221, 110000. [Google Scholar] [CrossRef]

- Urdanpilleta, M.; del Rey, R.; Leceta, I.; Rodríguez, J.C.; Alba, J.; Guerrero, P. Empirical modelling of the acoustic behavior of sheep wool/soy protein biocomposites. J. Build. Eng. 2024, 89, 109290. [Google Scholar] [CrossRef]

- Odeon—Room Acoustics Software. Available online: https://odeon.dk/ (accessed on 21 August 2024).

- ISO 3382-1:2009; Acoustics—Measurement of Room Acoustic Parameters—Part 1: Performance Spaces. ISO: Geneva, Switzerland, 2009.

- Ciaburro, G.; Iannace, G. Modeling acoustic metamaterials based on reused buttons using data fitting with neural network. J. Acoust. Soc. Am. 2021, 150, 51–63. [Google Scholar] [CrossRef] [PubMed]

- Osa-Uwagboe, N.; Silberschimdt, V.V.; Aremi, A.; Demirci, E. Mechanical behaviour of fabric-reinforced plastic sandwich structures: A state-of-the-art review. J. Sandw. Struct. Mater. 2023, 25, 591–622. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Numerical simulation for the sound absorption properties of ceramic resonators. Fibers 2020, 8, 77. [Google Scholar] [CrossRef]

- Corredor-Bedoya, A.C.; Acuña, B.; Serpa, A.L.; Masiero, B. Effect of the excitation signal type on the absorption coefficient measurement using the impedance tube. Appl. Acoust. 2021, 171, 107659. [Google Scholar] [CrossRef]

- Caballol, D.; Raposo, Á.P. Measurement of transmission loss with a standing wave tube in porous materials with and without open cells porosity. Constr. Build. Mater. 2020, 256, 119297. [Google Scholar] [CrossRef]

- Abbas, M.S.; Gourdon, E.; Glé, P.; McGregor, F.; Ferroukhi, M.Y.; Fabbri, A. Relationship between hygrothermal and acoustical behavior of hemp and sunflower composites. Build. Environ. 2021, 188, 107462. [Google Scholar] [CrossRef]

- Ciaburro, G.; Puyana-Romero, V.; Iannace, G.; Jaramillo-Cevallos, W.A. Characterization and modeling of corn stalk fibers tied with clay using support vector regression algorithms. J. Nat. Fibers 2022, 19, 7141–7156. [Google Scholar] [CrossRef]

- Thomas, T.; Tiwari, G. Crushing behavior of honeycomb structure: A review. Int. J. Crashworthiness 2019, 24, 555–579. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired engineering of honeycomb structure–Using nature to inspire human innovation. Prog. Mater. Sci. 2015, 74, 332–400. [Google Scholar] [CrossRef]

- Liu, C.R.; Wu, J.H.; Yang, Z.; Ma, F. Ultra-broadband acoustic absorption of a thin microperforated panel metamaterial with multi-order resonance. Compos. Struct. 2020, 246, 112366. [Google Scholar]

- Ma, F.; Wang, C.; Liu, C.; Wu, J.H. Structural designs, principles, and applications of thin-walled membrane and plate-type acoustic/elastic metamaterials. J. Appl. Phys. 2021, 129, 231103. [Google Scholar] [CrossRef]

- Zhou, G.; Wu, J.H.; Lu, K.; Tian, X.; Huang, W.; Zhu, K. Broadband low-frequency membrane-type acoustic metamaterials with multi-state anti-resonances. Appl. Acoust. 2020, 159, 107078. [Google Scholar] [CrossRef]

- Du, C.; Song, S.; Bai, H.; Wu, J.; Liu, K.; Lu, Z. An investigation on synergistic resonances of membrane-type acoustic metamaterial with multiple masses. Appl. Acoust. 2024, 220, 109988. [Google Scholar] [CrossRef]

- Xu, Q.; Qiao, J.; Sun, J.; Zhang, G.; Li, L. A tunable massless membrane metamaterial for perfect and low-frequency sound absorption. J. Sound Vib. 2021, 493, 115823. [Google Scholar] [CrossRef]

- Khoudja, D.; Taallah, B.; Izemmouren, O.; Aggoun, S.; Herihiri, O.; Guettala, A. Mechanical and thermophysical properties of raw earth bricks incorporating date palm waste. Constr. Build. Mater. 2021, 270, 121824. [Google Scholar] [CrossRef]

- Zhang, D.; Zhou, X.; Gao, Y.; Lyu, L. Structural characteristics and sound absorption properties of waste hemp fiber. Coatings 2022, 12, 1907. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Vatin, N.; Al-Fakih, A. Sound-absorbing acoustic concretes: A review. Sustainability 2021, 13, 10712. [Google Scholar] [CrossRef]

- Taban, E.; Soltani, P.; Berardi, U.; Putra, A.; Mousavi, S.M.; Faridan, M.; Samaei, S.E.; Khavanin, A. Measurement, modeling, and optimization of sound absorption performance of Kenaf fibers for building applications. Build. Environ. 2020, 180, 107087. [Google Scholar] [CrossRef]

- Pereira, A.; Gaspar, A.; Godinho, L.; Amado Mendes, P.; Mateus, D.; Carbajo, J.; Ramis, J.; Poveda, P. On the use of Perforated sound absorption systems for variable acoustics room design. Buildings 2021, 11, 543. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Li, X. Acoustic performance of honeycomb sandwich panels with embedded Helmholtz resonators. J. Sound Vib. 2018, 419, 295–309. [Google Scholar]

- Zhang, X.; Liu, Y.; Chen, G. Acoustic properties of carbon fiber-reinforced honeycomb structures for noise reduction. Compos. Struct. 2020, 240, 112017. [Google Scholar]

- Lee, J.; Kim, H.; Park, S. Investigation of sound absorption characteristics of polymer-reinforced honeycomb structures. Appl. Acoust. 2019, 150, 94–101. [Google Scholar]

- Liu, H.; Zhou, Z.; Wang, J. Sound absorption performance of metallic foam honeycomb composites. Mater. Des. 2017, 121, 321–330. [Google Scholar]

- Chen, L.; Gao, M.; Yang, P. Enhanced sound absorption of reinforced plastic honeycomb structures through microstructural design. Polym. Compos. 2021, 42, 678–687. [Google Scholar]

- Barron, M. Interpretation of early decay times in concert auditoria. Acta Acust. United Acust. 1995, 81, 320–331. [Google Scholar]

- Vorländer, M.; Bietz, H. Comparison of methods for measuring reverberation time. Acta Acust. United Acústica 1994, 80, 205–215. [Google Scholar]

- Bradley, J.S.; Reich, R.; Norcross, S.G. A just noticeable difference in C50 for speech. Appl. Acoust. 1999, 58, 99–108. [Google Scholar] [CrossRef]

- Larrosa-Navarro, M.; de la Prida, D.; Pedrero, A. Influence of musical stimulus on the perception of clarity in rooms and its relation to C80. Appl. Acoust. 2023, 208, 109370. [Google Scholar] [CrossRef]

- Bistafa, S.R.; Bradley, J.S. Revisiting algorithms for predicting the articulation loss of consonants Alcons. J. Audio Eng. Soc. 2000, 48, 531–544. [Google Scholar]

- Ciaburro, G. Machine fault detection methods based on machine learning algorithms: A review. Math. Biosci. Eng. 2022, 19, 11453–11490. [Google Scholar] [CrossRef] [PubMed]

| Properties | Membrane | Honeycomb | Glue |

|---|---|---|---|

| Material type | aluminum–polyester | aromatic polyamide | polyurethane |

| Thickness (cm) | 0.03 | 1.3 | -- |

| Radius (cm) | 5 | 5 | -- |

| Mass (g) | 2.3 | 3.2 | -- |

| Density (g/cm3) | 0.976 | 0.157 | 1.3 |

| Cell type | -- | exagonal | -- |

| Cell size (cm) | -- | 0.4 | -- |

| Void Fraction | 0.8 |

| Parameter | RMHCC | Raw Earth Bricks | Hemp | Recycled Glass | Kenaf | Celenit |

|---|---|---|---|---|---|---|

| Thermal insulation | 0.035 W/m·K | 0.40 W/m·K | 0.040 W/m·K | 0.80 W/m·K | 0.037 W/m·K | 0.045 W/m·K |

| Soundproofing | 45 dB | 35 dB | 50 dB | 30 dB | 45 dB | 55 dB |

| Fire resistant (class) | A2 | B | C | A1 | C | B |

| Durability (years) | 50 | 30 | 20 | 50 | 20 | 30 |

| Weight | 0.5 kg/m2 | 2 kg/m2 | 1 kg/m2 | 3 kg/m2 | 0.6 kg/m2 | 1.5 kg/m2 |

| Environmental impact | Low (use of recycled materials) | Very low (natural) | Medium (cultivation required) | Medium (energy for recycling) | Low (natural) | Low (use of natural materials) |

| Mechanical Resistance | High | Medium | Medium | High | Medium | High |

| Easy Installation | High | Medium | High | Low | High | High |

| Frequency (Hz) | 5 Layers (RMHCC) | Raw Earth Bricks | Kenaf dt (50 kg/m3 6 cm) | Hemp | Glass | Celenit s (3 cm 70 g) |

|---|---|---|---|---|---|---|

| 250 | 0.95 | 0.10 | 0.14 | 0.11 | 0.10 | 0.15 |

| 315 | 0.99 | 0.09 | 0.21 | 0.16 | 0.09 | 0.06 |

| 400 | 0.73 | 0.14 | 0.25 | 0.18 | 0.07 | 0.10 |

| 500 | 0.47 | 0.15 | 0.31 | 0.21 | 0.06 | 0.07 |

| 630 | 0.27 | 0.13 | 0.44 | 0.32 | 0.05 | 0.03 |

| 800 | 0.29 | 0.18 | 0.56 | 0.40 | 0.05 | 0.06 |

| 1000 | 0.11 | 0.20 | 0.67 | 0.47 | 0.04 | 0.16 |

| 1250 | 0.20 | 0.22 | 0.80 | 0.61 | 0.03 | 0.17 |

| 1600 | 0.10 | 0.25 | 0.84 | 0.67 | 0.03 | 0.35 |

| Material Type | Thickness (cm) | Frequency Range (Hz) | Density (g/m3) | SAC (Maximum) |

|---|---|---|---|---|

| Recycled material membrane + honeycomb | 4 | 100–600 | 0.32 | 0.99 |

| Aluminum + honeycomb [56] | 3 | 600–1200 | 0.75 | 0.88 |

| Carbon fiber + honeycomb [57] | 5 | 500–1000 | 0.65 | 0.90 |

| Reinforced Polymer [58] | 4.5 | 700–1300 | 0.80 | 0.85 |

| Metallic Foam + honeycomb [59] | 3.5 | 450–950 | 0.78 | 0.92 |

| Reinforced Plastic + honeycomb [60] | 4.2 | 650–1250 | 0.72 | 0.87 |

| Location | Distances (m) |

|---|---|

| Total interior maximum length | 66.68 |

| Total interior maximum width | 20.99 |

| Main nave maximum width | 10.47 |

| Side aisle maximum width | 4.62 |

| Transept maximum height | 20.24 |

| Main nave maximum height | 16.54 |

| Side aisle maximum height | 9.01 |

| Source-entrance distance | 37.2 |

| Source-m1 distance | 30.55 |

| Frequency (Hz) | 125 | 250 | 500 | 1 K | 2 K |

|---|---|---|---|---|---|

| RT Average Measured (s) | 2.0 | 3.8 | 3.8 | 2.6 | 2.7 |

| Type of Surface | Sound Absorption Coefficient (Dimensionless) | Area (m2) | Scatter | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Material/Octave Band (Hz) | 63 | 125 | 250 | 500 | 1000 | 2000 | |||

| Wall | Gypsum 32 mm | 0.28 | 0.28 | 0.12 | 0.1 | 0.17 | 0.13 | 2280.07 | 0.70 |

| Floor | Marble or glazed tile | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 1106.07 | 0.01 |

| Roof | Gypsum 32 mm | 0.28 | 0.28 | 0.12 | 0.10 | 0.17 | 0.13 | 1167.99 | 0.70 |

| Columns | Plaster, gypsum, or lime, rough finish on lath | 0.14 | 0.14 | 0.10 | 0.06 | 0.05 | 0.04 | 2000.92 | 0.70 |

| Altarpiece | Plasterboard 9.5 mm with 6 mm holes in squared pattern with approx. 11% perforation | 0.08 | 0.08 | 0.2 | 0.5 | 0.4 | 0.4 | 675.14 | 0.7 |

| Type of Surface | Sound Absorption Coefficient (Dimensionless) | Area (m2) | Scatter | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Material/Octave Band (Hz) | 63 | 125 | 250 | 500 | 1000 | 2000 | |||

| Wall | * | * | * | * | * | * | * | 2100.97 | * |

| Floor | * | * | * | * | * | * | * | * | * |

| Roof | * | * | * | * | * | * | * | * | * |

| Columns | * | * | * | * | * | * | * | 1754.30 | * |

| Altarpiece | * | * | * | * | * | * | * | * | * |

| Upper part of the walls near the vault in the main nave, and the front and back faces of the side aisle columns | Metamaterial 5 L | 0.176 | 0.4536 | 0.796 | 0.4906 | 0.201 | 0.102 | 425.72 | 0.01 |

| Metamaterial 2 L | 0.172 | 0.448 | 0.47 | 0.736 | 0.2146 | 0.065 | 425.72 | 0.01 | |

| Band Frequency | ||||||

|---|---|---|---|---|---|---|

| Reverberation Time (RT) | 63 | 125 | 250 | 500 | 1000 | 2000 |

| RT initial predicted (s) | 2.1 | 2.1 | 3.5 | 3.1 | 2.6 | 2.8 |

| RT with 2 L metamaterial prediction (s) | 2.1 | 1.9 | 2.9 | 2.3 | 2.5 | 2.8 |

| RT with 5 L metamaterial prediction (s) | 2.1 | 1.9 | 2.5 | 2.6 | 2.5 | 2.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciaburro, G.; Romero, V.P.; Iannace, G.; Bravo Moncayo, L. Improving Acoustic Properties of Sandwich Structures Using Recycled Membrane and HoneyComb Composite (RMHCC). Buildings 2024, 14, 2878. https://doi.org/10.3390/buildings14092878

Ciaburro G, Romero VP, Iannace G, Bravo Moncayo L. Improving Acoustic Properties of Sandwich Structures Using Recycled Membrane and HoneyComb Composite (RMHCC). Buildings. 2024; 14(9):2878. https://doi.org/10.3390/buildings14092878

Chicago/Turabian StyleCiaburro, Giuseppe, Virginia Puyana Romero, Gino Iannace, and Luis Bravo Moncayo. 2024. "Improving Acoustic Properties of Sandwich Structures Using Recycled Membrane and HoneyComb Composite (RMHCC)" Buildings 14, no. 9: 2878. https://doi.org/10.3390/buildings14092878