An Evaluation of the Technologies Used for the Real-Time Monitoring of the Risk of Falling from Height in Construction—Systematic Review

Abstract

:1. Introduction

2. Materials and Methods

- General information: authors, year of publication, and country.

- Study characteristics: parameters assessed, procedures/methods, equipment and software, real-time monitoring, and the type of work or phase of work in which it was applied.

- Results of the studies, main conclusions, and limitations.

3. Results

3.1. Selection of Studies

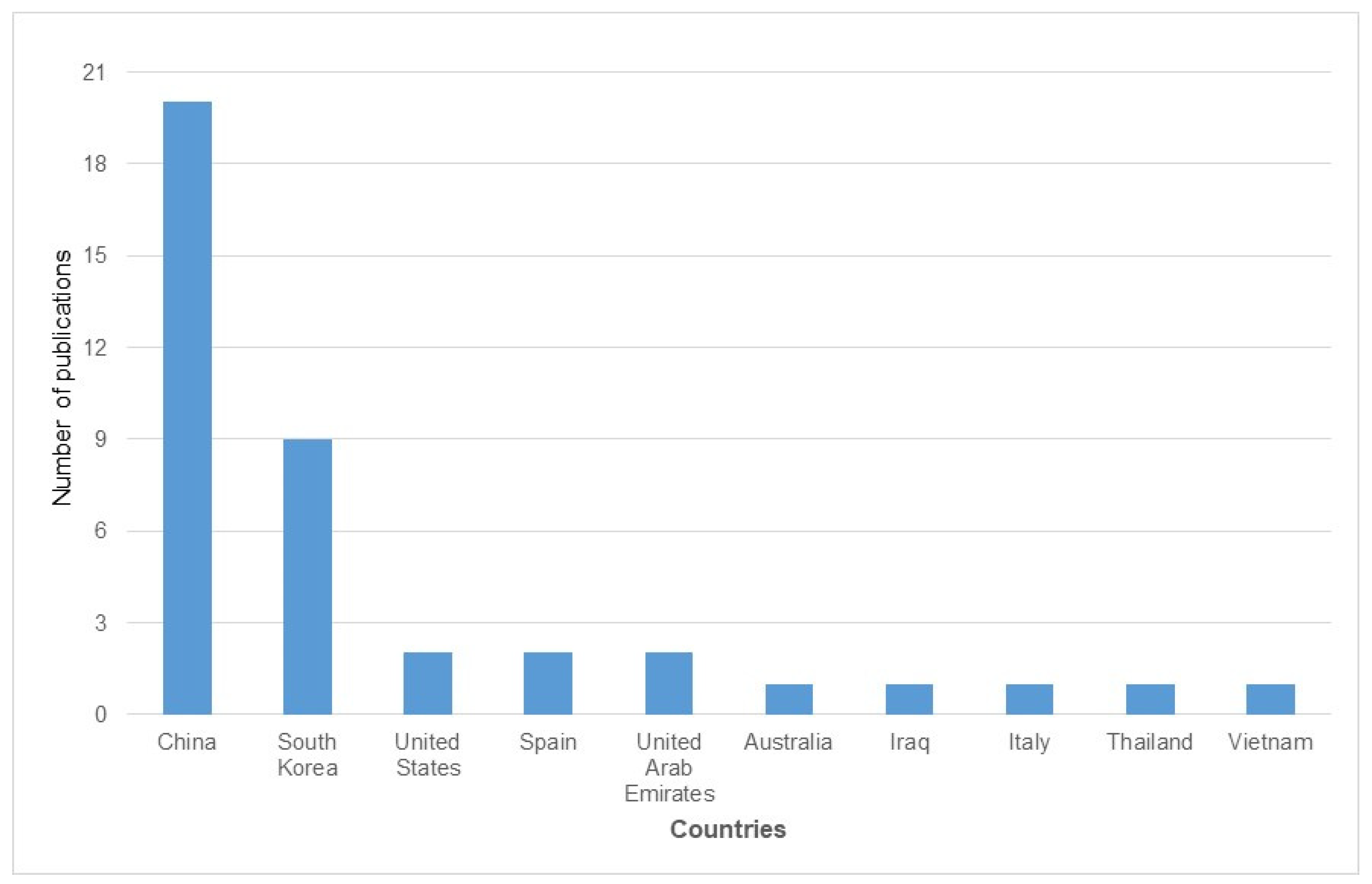

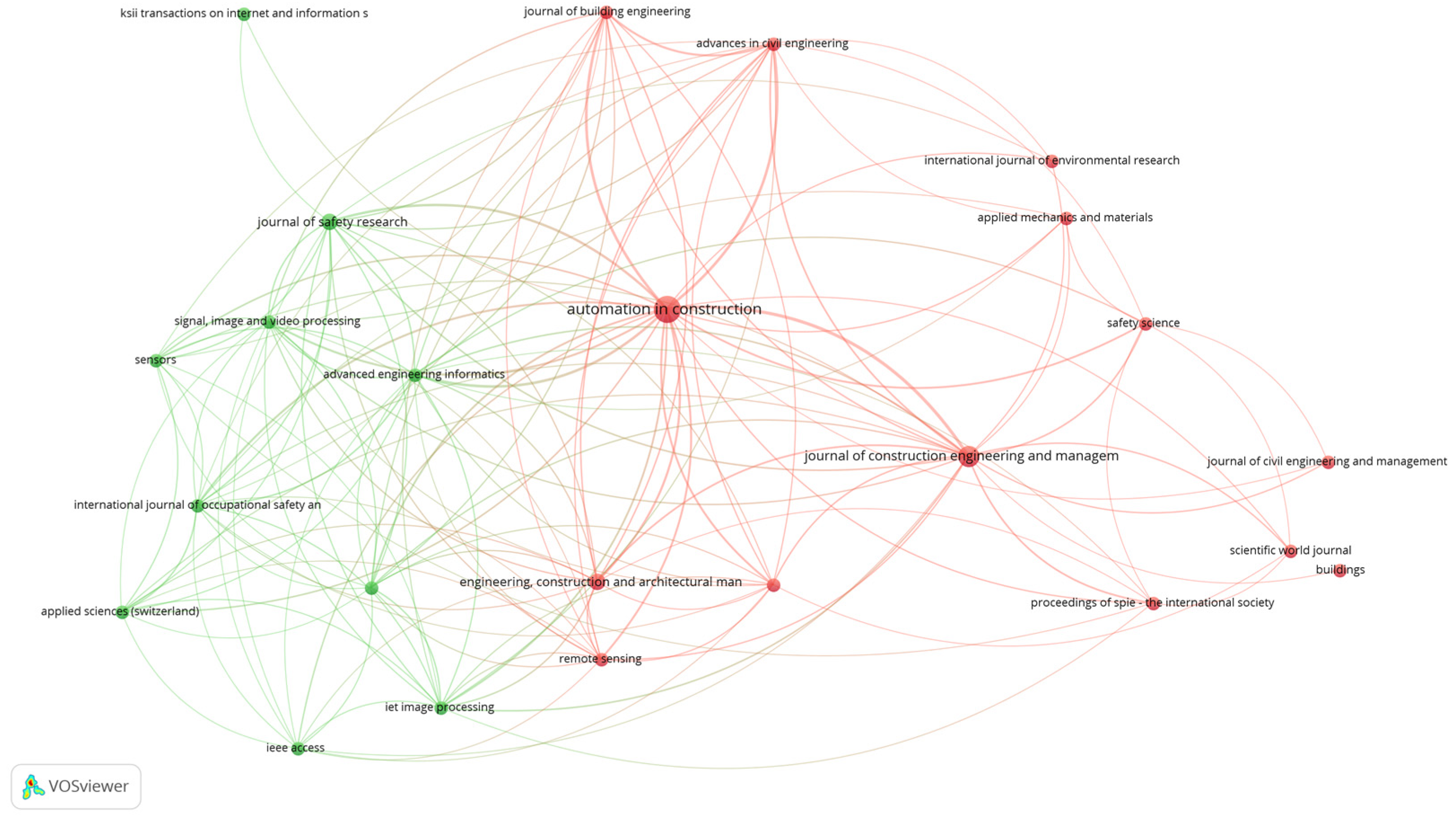

3.2. Characteristics of Included Studies

3.3. Real-Time Monitoring of Falling from Height

4. Discussion

4.1. Technologies to Prevent the Risk of Falling from Height

4.2. Challenges of Implementing Technology in Prevention

4.3. Emerging Trends in Construction Safety Technology

4.4. Future Studies

4.5. Limitations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- International Labour Organization. A Call for Safer and Healthier Working Environments. 2023. Available online: https://www.ilo.org/publications/call-safer-and-healthier-working-environments (accessed on 12 May 2024).

- Eurostat. Accidents at Work Statistics. 2021. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Accidents_at_work_statistics#Accidents_2010_to_2020 (accessed on 12 May 2024).

- Sacks, R.; Rozenfeld, O.; Rosenfeld, Y. Spatial and temporal exposure to safety hazards in construction. J. Constr. Eng. Manag. 2009, 135, 726–736. [Google Scholar] [CrossRef]

- Eurostat. Employment by Industry Breakdowns. 2024. Available online: https://ec.europa.eu/eurostat/databrowser/view/NAMA_10_A10_E__custom_8316234/default/table?lang=en&page=time:202 (accessed on 12 May 2024).

- Cabello, A.T.; Martínez-Rojas, M.; Carrillo-Castrillo, J.A.; Rubio-Romero, J.C. Occupational accident analysis according to professionals of different construction phases using association rules. Saf. Sci. 2021, 144, 105457. [Google Scholar] [CrossRef]

- Choi, S.D.; Guo, L.; Kim, J.; Xiong, S. Comparison of fatal occupational injuries in construction industry in the United States, South Korea, and China. Int. J. Ind. Ergon. 2019, 71, 64–74. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, W.; Xu, P.; Chen, N. Applicability of accident analysis methods to Chinese construction accidents. J. Saf. Res. 2019, 68, 187–196. [Google Scholar] [CrossRef] [PubMed]

- Macedo, A.C.; Silva, I.L. Analysis of occupational accidents in Portugal between 1992 and 2001. Saf. Sci. 2005, 43, 269–286. [Google Scholar] [CrossRef]

- Occupational Safety and Health Administration. Commonly Used Statistics, Occupational Safety and Health Administration. 2023. Available online: https://www.osha.gov/data/commonstats (accessed on 12 May 2024).

- Kim, I.; Lee, Y.; Choi, J. BIM-based hazard recognition and evaluation methodology for automating construction site risk assessment. Appl. Sci. 2020, 10, 2335. [Google Scholar] [CrossRef]

- Kang, K.; Ryu, H. Predicting types of occupational accidents at construction sites in Korea using random forest model. Saf. Sci. 2019, 120, 226–236. [Google Scholar] [CrossRef]

- Warrier, R. Top Causes of Global Construction Fatalities, and How to Avoid Site Risks. 2019. Available online: https://www.constructionweekonline.com/people/training/255830-top-10-causes-of-construction-deaths-and-how-to-prevent-site-accidents (accessed on 12 May 2024).

- Occupational Safety and Health Administration. US Department of Labor Announces National Emphasis Program to Reduce, Prevent Workplace Falls, a Leading Cause of Workplace Fatalities. 2023. Available online: https://www.osha.gov/news/newsreleases/national/05012023 (accessed on 12 May 2024).

- Shao, B.; Hu, Z.; Liu, Q.; Chen, S.; He, W. Fatal accident patterns of building construction activities in China. Saf. Sci. 2019, 111, 253–263. [Google Scholar] [CrossRef]

- Occupational Safety and Health Administration. Top 10 Most Frequently Cited Standards. 2023. Available online: https://www.osha.gov/top10citedstandards (accessed on 12 May 2024).

- Gabinete de Estratégia e Planeamento. Acidentes de Trabalho 2020. 2022. Available online: https://www.gep.mtsss.gov.pt/documents/10182/26338/at2020sint.pdf/e39fc2e0-fadb-475e-ab89-c7d26542c6ad (accessed on 12 May 2024).

- Fang, W.; Ding, L.; Luo, H.; Love, P.E.D. Falls from heights: A computer vision-based approach for safety harness detection. Autom. Constr. 2018, 91, 53–61. [Google Scholar] [CrossRef]

- Khan, M.; Khalid, R.; Anjum, S.; Tran, S.V.-T.; Park, C.; Asce, A.M. Fall Prevention from Scaffolding Using Computer Vision and IoT-Based Monitoring. J. Constr. Eng. Manag. 2022, 148, 7. [Google Scholar] [CrossRef]

- Newaz, M.T.; Ershadi, M.; Carothers, L.; Jefferies, M.; Davis, P. A review and assessment of technologies for addressing the risk of falling from height on construction sites. Saf. Sci. 2022, 147, 105618. [Google Scholar] [CrossRef]

- American Society of Safety Professionals. Why AI Is the Future of Construction Safety. 2019. Available online: https://www.assp.org/news-and-articles/why-ai-is-the-future-of-construction-safety (accessed on 12 May 2024).

- ViAct. Beyond Helmets and Harnesses: The Future of AI in Construction Safety. 2023. Available online: https://www.viact.ai/post/beyond-helmets-and-harnesses-the-future-of-ai-in-construction-safety (accessed on 12 May 2024).

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate healthcare interventions: Explanation and elaboration. BMJ 2009, 339, b2700. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, F.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Booth, A.; James, M.M.-S.; Clowes, M.; Sutton, A. Systematic Approaches to a Successful Literature Review; SAGE Publications Ltd.: London, UK, 2021; Available online: http://digital.casalini.it/9781529759648 (accessed on 2 September 2024).

- Guz, A.N.; Rushchitsky, J.J. Scopus: A system for the evaluation of scientific journals. Int. Appl. Mech. 2009, 45, 351–362. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 11. [Google Scholar] [CrossRef]

- Çevikbaş, M.; Işık, Z. An Overarching Review on Delay Analyses in Construction Projects. Buildings 2021, 11, 3. [Google Scholar] [CrossRef]

- Fang, W.; Zhong, B.; Zhao, N.; Love, P.E.; Luo, H.; Xue, J.; Xu, S. A deep learning-based approach for mitigating falls from height with computer vision: Convolutional neural network. Adv. Eng. Inform. 2019, 39, 170–177. [Google Scholar] [CrossRef]

- Alheeti, K.M.A.; Aldaiyat, R.M. A new labour safety in construction management based on artificial intelligence. Period. Eng. Nat. Sci. 2021, 9, 685–691. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, B.; Zhang, Q.; Wang, Z.; Dong, M.; Fang, T. Automatic detection of falling hazard from surveillance videos based on computer vision and building information modelling. Struct. Infrastruct. Eng. 2022, 18, 1049–1063. [Google Scholar] [CrossRef]

- Wu, H.T.; Zhong, B.T.; Li, H.; Love, P.; Pan, X.; Zhao, N. Combining computer vision with semantic reasoning for on-site safety management in construction. J. Build. Eng. 2021, 42, 103036. [Google Scholar] [CrossRef]

- Hou, X.; Li, C.; Fang, Q. Computer vision-based safety risk computing and visualization on construction sites. Autom. Constr. 2023, 156, 105129. [Google Scholar] [CrossRef]

- Xu, W.; Wang, T.-K. Dynamic safety prewarning mechanism of human–machine–environment using computer vision. Eng. Constr. Archit. Manag. 2020, 27, 1813–1833. [Google Scholar] [CrossRef]

- Park, J.; Kim, K.; Cho, Y.K. Framework of Automated Construction-Safety Monitoring Using Cloud-Enabled BIM and BLE Mobile Tracking Sensors. J. Constr. Eng. Manag. 2017, 143, 05016019. [Google Scholar] [CrossRef]

- Zhu, W.; Shi, D.; Cheng, R.; Huang, R.; Hu, T.; Wang, J. Human risky behaviour recognition during ladder climbing based on multi-modal feature fusion and adaptive graph convolutional network. Signal Image Video Process. 2024, 18, 2473–2483. [Google Scholar] [CrossRef]

- Heng, L.; Shuang, D.; Skitmore, M.; Qinghua, H.; Qin, Y. Intrusion warning and assessment method for site safety enhancement. Saf. Sci. 2016, 84, 97–107. [Google Scholar] [CrossRef]

- Fang, W.; Ma, L.; Love, P.E.D.; Luo, H.; Ding, L.; Zhou, A. Knowledge graph for identifying hazards on construction sites: Integrating computer vision with ontology. Autom. Constr. 2020, 119, 103310. [Google Scholar] [CrossRef]

- Luo, X.; Li, H.; Huang, T.; Skitmore, M. Quantifying Hazard Exposure Using Real-Time Location Data of Construction Workforce and Equipment. J. Constr. Eng. Manag. 2016, 142, 04016031. [Google Scholar] [CrossRef]

- Wu, S.; Hou, L.; Zhang, G.K.; Chen, H. Real-time mixed reality-based visual warning for construction workforce safety. Autom. Constr. 2022, 139, 104252. [Google Scholar] [CrossRef]

- Park, M.; Tran, D.Q.; Bak, J.; Kulinan, A.S.; Park, S. Real-time monitoring unsafe behaviors of portable multi-position ladder worker using deep learning based on vision data. J. Safety Res. 2023, 87, 465–480. [Google Scholar] [CrossRef]

- Jiang, H.; Lin, P.; Fan, Q.; Qiang, M. Real-time safety risk assessment based on a real-time location system for hydropower construction sites. Sci. World J. 2014, 2014, 235970. [Google Scholar] [CrossRef]

- Kolar, Z.; Chen, H.N.; Luo, X.W. Transfer learning and deep convolutional neural networks for safety guardrail detection in 2D images. Autom. Constr. 2018, 89, 58–70. [Google Scholar] [CrossRef]

- Ding, L.; Fang, W.; Luo, H.; Love, P.E.D.; Zhong, B.; Ouyang, X. A deep hybrid learning model to detect unsafe behavior: Integrating convolution neural networks and long short-term memory. Autom. Constr. 2018, 86, 118–124. [Google Scholar] [CrossRef]

- Kim, K.; Kim, S.; Shchur, D. A UAS-based work zone safety monitoring system by integrating internal traffic control plan (ITCP) and automated object detection in game engine environment. Autom. Constr. 2021, 128, 103736. [Google Scholar] [CrossRef]

- Piao, Y.; Xu, W.; Wang, T.-K.; Chen, J.-H. Dynamic Fall Risk Assessment Framework for Construction Workers Based on Dynamic Bayesian Network and Computer Vision. J. Constr. Eng. Manag. 2021, 147, 12. [Google Scholar] [CrossRef]

- Xu, Z.J.; Huang, J.J.; Huang, K. A novel computer vision-based approach for monitoring safety harness use in construction. IET Image Process. 2023, 17, 1071–1085. [Google Scholar] [CrossRef]

- Shanti, M.Z.; Cho, C.S.; Byon, Y.J.; Yeun, C.Y.; Kim, T.Y.; Kim, S.K.; Altunaiji, A. A Novel Implementation of an AI-Based Smart Construction Safety Inspection Protocol in the UAE. IEEE Access 2021, 9, 166603–166616. [Google Scholar] [CrossRef]

- Giretti, A.; Carbonari, A.; Naticchia, B.; De Grassi, M. Design and first development of an automated real-time safety management system for construction sites. J. Civ. Eng. Manag. 2009, 15, 325–336. [Google Scholar] [CrossRef]

- Lee, K.P.; Lee, H.S.; Park, M.; Kim, H.; Han, S. A real-time location-based construction labor safety management system. J. Civ. Eng. Manag. 2014, 20, 724–736. [Google Scholar] [CrossRef]

- Wang, C.; Kim, Y.; Lee, S.H.; Sung, N.J.; Min, S.D.; Choi, M.H. Activity and safety recognition using smart work shoes for construction worksite. KSII Trans. Int. Inf. Syst. 2020, 14, 654–670. [Google Scholar] [CrossRef]

- Hong, Y.; Cho, J. Enhancing Individual Worker Risk Awareness: A Location-Based Safety Check System for Real-Time Hazard Warnings in Work-Zones. Buildings 2024, 14, 90. [Google Scholar] [CrossRef]

- Ngoc-Thoan, N.; Bui, D.Q.T.; Tran, C.N.N.; Tran, D.H. Improved detection network model based on YOLOv5 for warning safety in construction sites. Int. J. Constr. Manag. 2024, 24, 1007–1017. [Google Scholar] [CrossRef]

- Rey-Merchán, M.C.; Gomez-de-Gabriel, J.M.; Fernandez-Madrigal, J.A.; López-Arquillos, A. Improving the prevention of fall from height on construction sites through the combination of technologies. Int. J. Occup. Saf. Ergon. 2022, 28, 590–599. [Google Scholar] [CrossRef] [PubMed]

- Rey-Merchán, M.C.; López-Arquillos, A.; Soto-Hidalgo, J.M. Prevention of Falls from Heights in Construction Using an IoT System Based on Fuzzy Markup Language and JFML. Appl. Sci. 2022, 12, 12. [Google Scholar] [CrossRef]

- Shanti, M.Z.; Cho, C.-S.; de Soto, B.G.; Byon, Y.-J.; Yeun, C.Y.; Kim, T.-Y. Real-time monitoring of work-at-height safety hazards in construction sites using drones and deep learning. J. Saf. Res. 2022, 83, 364–370. [Google Scholar] [CrossRef] [PubMed]

- Cheng, M.-Y.; Vu, Q.-T.; Teng, R.-K. Real-time risk assessment of multi-parameter induced fall accidents at construction sites. Autom. Constr. 2024, 162, 105409. [Google Scholar] [CrossRef]

- Kim, H.-J.; Park, C.-S. Smartphone based real-time location tracking system for automatic risk alert in building project. Appl. Mech. Mater. 2013, 256–259, 2794–2797. [Google Scholar] [CrossRef]

- Khan, M.; Khalid, R.; Anjum, S.; Khan, N.; Cho, S.; Park, C. Tag and IoT based safety hook monitoring for prevention of falls from height. Autom. Constr. 2022, 136, 104153. [Google Scholar] [CrossRef]

- Fang, Q.; Li, H.; Luo, X.; Ding, L.; Luo, H.; Li, C. Computer vision aided inspection on falling prevention measures for steeplejacks in an aerial environment. Autom. Constr. 2018, 93, 148–164. [Google Scholar] [CrossRef]

- Lee, S.; Koo, B.; Yang, S.; Kim, J.; Nam, Y.; Kim, Y. Fall-from-Height Detection Using Deep Learning Based on IMU Sensor Data for Accident Prevention at Construction Sites. Sensors 2022, 22, 6107. [Google Scholar] [CrossRef]

- Panuwatwanich, K.; Roongsrisoothiwong, N.; Petcharayuthapant, K.; Dummanonda, S.; Mohamed, S. Ambient intelligence to improve construction site safety: Case of high-rise building in Thailand. Int. J. Environ. Res. Public. Health 2020, 17, 8124. [Google Scholar] [CrossRef]

- Wu, X.; Li, Y.; Long, J.; Zhang, S.; Wan, S.; Mei, S. A Remote-Vision-Based Safety Helmet and Harness Monitoring System Based on Attribute Knowledge Modeling. Remote Sens. 2023, 15, 347. [Google Scholar] [CrossRef]

- Liu, X.; Xu, F.; Zhang, Z.; Sun, K. Fall-portent detection for construction sites based on computer vision and machine learning. Eng. Constr. Archit. Manag. 2023. [Google Scholar] [CrossRef]

- Lim, J.; Jung, D.G.; Park, C.; Kim, D.Y. Computer Vision Process Development regarding Worker’s Safety Harness and Hook to Prevent Fall Accidents: Focused on System Scaffolds in South Korea. Adv. Civ. Eng. 2022, 2022, 4678479. [Google Scholar] [CrossRef]

- Zhang, M.; Cao, T.; Zhao, X. Using Smartphones to Detect and Identify Construction Workers’ Near-Miss Falls Based on ANN. J. Constr. Eng. Manag. 2019, 145, 04018120. [Google Scholar] [CrossRef]

- Sulowski, A.C. Collective Fall Protection for Construction Workers. Protección Colectiva contra caídas para Trabajadores de la Construcción. 2014. Available online: https://informesdelaconstruccion.revistas.csic.es/index.php/informesdelaconstruccion/article/view/2991/3315 (accessed on 26 May 2024). [CrossRef]

- Aneziris, O.N.; Papazoglou, I.A.; Baksteen, H.; Mud, M.; Ale, B.J.; Bellamy, L.J.; Hale, A.R.; Bloemhoff, A.; Post, J.; Oh, J. Quantified risk assessment for fall from height. Saf. Sci. 2008, 46, 198–220. [Google Scholar] [CrossRef]

- Kim, Y.; Jung, H.; Koo, B.; Kim, J.; Kim, T.; Nam, Y. Detection of pre-impact falls from heights using an inertial measurement unit sensor. Sensors 2020, 20, 5388. [Google Scholar] [CrossRef]

- Zhang, M.; Ghodrati, N.; Poshdar, M.; Seet, B.-C.; Yongchareon, S. A construction accident prevention system based on the Internet of Things (IoT). Saf. Sci. 2023, 159, 106012. [Google Scholar] [CrossRef]

- EU-OSHA. Digitalisation and Occupational Safety and Health—An EU-OSHA Research Programme. 2019. Available online: https://osha.europa.eu/en/publications/digitalisation-and-occupational-safety-and-health-eu-osha-research-programme (accessed on 26 May 2024).

- Zhu, Z.; Ren, X.; Chen, Z. Integrated detection and tracking of workforce and equipment from construction jobsite videos. Autom. Constr. 2017, 81, 161–171. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I.; Celik, T.; Arditi, D. The effectiveness of an integrated BIM/UAV model in managing safety on construction sites. Int. J. Occup. Saf. Ergon. 2020, 26, 829–844. [Google Scholar] [CrossRef]

- Wefki, H.; Elnahla, M.; Elbeltagi, E. BIM-based schedule generation and optimization using genetic algorithms. Autom. Constr. 2024, 164, 105476. [Google Scholar] [CrossRef]

- Sidani, A.; Martins, J.P.; Soeiro, A. Catalysing Construction Safety: A Comparative Analysis of Technological Advancements across High-Risk Industries. Buildings 2023, 13, 2885. [Google Scholar] [CrossRef]

- Kitagawa, T.; Masuda, Y.; Umezawa, M. Impact of technology development costs on licensing form in a differentiated Cournot duopoly. Int. J. Econ. Theory 2020, 16, 153–166. [Google Scholar] [CrossRef]

- Liu, P.; Xie, M.; Bian, J.; Li, H.; Song, L. A Hybrid PSO–SVM Model Based on Safety Risk Prediction for the Design Process in Metro Station Construction. Int. J. Environ. Res. Public Health 2020, 17, 1714. [Google Scholar] [CrossRef]

- Akanmu, A.; Olatunji, O.; Love, P.E.D.; Nguyen, D.; Matthews, J. Auto-generated site layout: An integrated approach to real-time sensing of temporary facilities in infrastructure projects. Struct. Infrastruct. Eng. 2016, 12, 1243–1255. [Google Scholar] [CrossRef]

- Guo, H.; Yu, Y.; Skitmore, M. Visualization technology-based construction safety management: A review. Autom. Constr. 2017, 73, 135–144. [Google Scholar] [CrossRef]

- Li, C.T.; Cheng, J.C.P.; Chen, K. Top 10 technologies for indoor positioning on construction sites. Autom. Constr. 2020, 118, 103309. [Google Scholar] [CrossRef]

- Zhang, S.; Sulankivi, K.; Kiviniemi, M.; Romo, I.; Eastman, C.M.; Teizer, J. BIM-based fall hazard identification and prevention in construction safety planning. Saf. Sci. 2015, 72, 31–45. [Google Scholar] [CrossRef]

- Martínez-Aires, M.D.; López-Alonso, M.; Martínez-Rojas, M. Building information modeling and safety management: A systematic review. Saf. Sci. 2018, 101, 11–18. [Google Scholar] [CrossRef]

- Yihai, F.; Yong, K.C.; Sijie, Z.; Esau, P. Case Study of BIM and Cloud–Enabled Real-Time RFID Indoor Localization for Construction Management Applications. J. Constr. Eng. Manag. 2016, 142, 5016003. [Google Scholar] [CrossRef]

- EU-OSHA. Impact of Artificial Intelligence on Occupational Safety and Health. 2021. Available online: https://osha.europa.eu/en/publications/impact-artificial-intelligence-occupational-safety-and-health (accessed on 26 May 2024).

- EU-OSHA. Foresight on New and Emerging Occupational Safety and Health Risks Associated with Digitalisation by 2025. 2018. Available online: https://osha.europa.eu/en/publications/foresight-new-and-emerging-occupational-safety-and-health-risks-associated (accessed on 26 May 2024).

| Keyword | Occurrences | Total Link Strength | Research Area |

|---|---|---|---|

| construction | 27 | 171 | Real-time monitoring techniques |

| accident | 22 | 151 | |

| safety | 22 | 129 | |

| occupational risks | 15 | 105 | |

| workers | 14 | 103 | |

| fall | 12 | 90 | |

| hazards | 12 | 75 | |

| human | 12 | 91 | |

| monitoring | 12 | 70 | |

| architectural design | 4 | 26 | |

| article | 4 | 19 | |

| risk perception | 4 | 32 | |

| unsafe behaviours | 4 | 20 | |

| workplace | 4 | 31 | |

| antennas | 3 | 19 | |

| building information model—BIM | 3 | 18 | |

| near-misses | 3 | 26 | |

| real time | 3 | 18 | |

| computer vision | 17 | 88 | Techniques for monitoring worker behaviour and PPE use |

| smartphone | 3 | 24 | |

| risk assessment | 11 | 76 | Real-time site and/or equipment monitoring techniques |

| deep learning | 11 | 70 | Real-time monitoring techniques by creating databases of safe and unsafe behaviour |

| neural network | 8 | 38 | |

| machine learning | 4 | 36 | |

| learning systems | 3 | 27 | |

| personal protective equipment | 5 | 37 | Techniques for monitoring the correct use of PPE |

| object recognition | 3 | 16 |

| Type of Monitoring | Study | Proposed Approach | Equipment for Collecting Physical Information | Software for Information Analysis and Processing | Final Remarks |

|---|---|---|---|---|---|

| Site and/or equipment monitoring | [28] | Automatically detect the presence of people on concrete/steel supports to assess their safety | Computer vision is used to collect data from the site in real time. | Mask R-CNN is a deep learning model that detects structural supports and people to automatically determine worker safety. | Despite occlusion issues, the accuracy was considered good for the study. |

| [29] | Hazard detection system | Computer vision is used to collect data from the site in real time | Artificial intelligence and the Internet of Things for information processing | The study has shown that it is possible to manage risk monitoring in the field. | |

| [30] | Deep learning-based approach for exchanging information from physical sites with 3D digital models | Computer vision is used to collect data from the site in real time. | Object detection algorithm based on deep learning and existing BIM identifies existing hazards | The accuracy of the results was found to be good when compared with the results of the safety engineer’s manual judgement. | |

| [31] | Combines computer vision and ontology techniques to facilitate security management through semantic reasoning | Computer vision is used to collect data from the site in real time. | Mask R-CNN module used to check SWRL rules on extracted visual site information, automatically signalling situations where there is a risk of falling from a height | The result shows that the developed framework is successful in construction safety management. | |

| [32] | Combines computer vision and the TOPSIS method to automate the quantification and visualisation of security risks | Computer vision is used to collect data from the site in real time. | (1) Deep learning algorithms (YOLOv3) are used to process video feeds (2) The TOPSIS model assesses hazards and associated risks to help security engineers | Enhances traditional risk identification and forecasting, assessing risk through real-time monitoring | |

| [33] | It provides a safety early warning mechanism. | Computer vision is used to collect data from the site in real time. | (1) Uses the API platform (based on AI) to detect objects and classify behaviour (2) Data processing to analyse security information from the collected images and assess security risks (3) BIM used to simulate different security scenarios | Can analyse integrated human–machine-environment risks, categorising risks into different levels | |

| [34] | Automated safety monitoring system to support the construction safety monitoring process | BLE sensors distributed throughout the site and personal mobile devices are tracked to create an automated security monitoring system. | (1) BIM is used as a platform to identify, record and visualise hazards automatically. (2) Cloud servers are used to communicate with mobile devices to collect and share information in real time. | The results showed that it could help monitor construction sites and improve safety. | |

| [35] | A skeleton-based recognition method for detecting human stair-climbing behaviour | Computer vision is used to collect data from the site in real time. | (1) Deep learning extracts multimodal skeletal information from real-time video data (2) Compare this information with the IAGCN to recognise risky behaviour | Although it has not been applied in a real context, the results show that the method has advantages. | |

| [36] | Presents an approach to modify safety behaviour by integrating location-based technology with BBS | Real-time location system (RTLS) applies tags and reference anchors and transmits information wirelessly. | The virtual construction system (VCS) defines workers’ positions and danger zones and tracks their movements in real time. Warnings are sent to alert workers via tags attached to their helmets. | The study shows that unsafe behaviour can be accurately and objectively identified and assessed. | |

| [37] | Integrates computer vision algorithms with ontology models to automatically and accurately recognise dangers | Computer vision is used to collect data from the site in real time. | The R-CNN Mask algorithm processes the collected images and matches them against the ontology models to identify hazards | Despite the problems of object occlusion, the proposed model can accurately recognise the dangers of images. | |

| [38] | Addresses safety risk assessment using real-time location data of workers and existing equipment | PCMS is a real-time positioning system consisting of tags (attached to workers’ helmets or fixed to construction sites), anchors, and wireless communication devices. | CSS technology has been used to implement location-based proximity alert systems that send a voice message to tags worn by workers. | These assessments provide security managers with a powerful tool to maximise the cost-effectiveness of their decisions. | |

| [39] | Visual warning system that combines safety management and mixed reality (MR) scenarios to provide and visualise information about hazards in the field. | Computer vision is used to collect data from the site in real time. | (1) Deep learning (YOLOv4-Tiny) used to process the received information (2) 4D BIMs used to create a VCS (virtual construction site) (3) MR goggles to display hazard information to the worker when he is in a hazardous area | Presenting hazard information to workers with a level of accuracy deemed good using portable MRI equipment | |

| [40] | Deep learning model based on computer vision to automate the process of monitoring worker compliance with safety rules to prevent falls from ladders. | Computer vision is used to collect data from the site in real time. | Deep learning algorithm (YOLOv5) used to process the collected images and compare them with defined knowledge-based models to detect non-compliance with security rules | Although not applied in a real context, the results show that the method can contribute to safety in construction. | |

| [41] | The study provides a real-time safety risk assessment to reduce uncertainty and support rapid response by technicians. | Real-time location system (RTLS), in this specific case GPS from the worker’s smartphone | The HMM was used as a risk assessment algorithm in the construction of an RTSRA method for safety management, which can also send alerts to workers and supervisors. | The results of the study show that it reflects the real situation on the ground. | |

| [42] | The study developed a guardrail detection model based on a convolutional neural network (CNN) | Computer vision is used to collect data from the site in real time. | Machine learning to automatically detect missing guardrails in images collected from the site | The results show that the model is suitable for detecting objects in safety management on construction sites. | |

| [43] | Hybrid deep learning model that integrates a convolutional neural network (CNN) and long short-term memory (LSTM) to detect unsafe actions climbing a ladder | Computer vision is used to collect data from the site in real time. | The model integrates CNN and LSTM so that unsafe worker behaviour captured on site video is automatically detected. | The results show that the proposed hybrid model can automatically extract and classify unsafe behaviour. | |

| [44] | Develop a structure for automatically monitoring the safety of work areas | Imaging by UAS (aircraft/drone systems) | CNN-based deep learning algorithm used to detect workers, vehicles and equipment from UAS images, automatically monitoring safety conditions on site. | This study has contributed to the expansion of the application of UAS in construction safety monitoring. | |

| [45] | Improve the efficiency of risk assessment and reduce the risk of falls from ladders by automatically detecting risk factor information in the field | (1) Computer vision is used to collect data from the site in real time. (2) The warning module can use computer vision to communicate risk information to the worker. | The Data Acquisition Module focuses on building a database of risk factor information. A Dynamic Bayesian Network (DBN) performs dynamic fall risk assessment. | Although not applied in a real context, the results show that the method can contribute to safety in construction. | |

| Worker monitoring | [46] | The study proposes a method to detect the use of safety harnesses by workers. | Computer vision is used to collect worker data in real time. | A deep learning algorithm (YOLOv5) is used to detect the harness. Loudspeakers installed on-site emit alarms to remind workers to wear their personal protective equipment. | A security monitoring and alarm system based on the latest computer technology supports the manual monitoring with a high degree of accuracy. |

| [47] | New technique for monitoring the use of personal fall arrest systems (PFASs) by workers | Computer vision is used to collect worker data in real time. | A deep learning algorithm (YOLOv3) was used to detect objects in real-time automatically, namely the harness and the lifeline. | The proposed model gave very good results. | |

| [48] | This article develops a methodology for the real-time monitoring of the position of workers and equipment on outdoor construction sites. | The UWB (worker location) system consists of active tags, UWB receivers and central processing units. Information is transmitted via ultra-wideband (UWB) technology. | Forecasting API software tool for real-time risk management | UWB systems can be successfully applied in the real-time management of construction sites. | |

| [49] | Location-based safety management system that tracks and visualises workers’ locations in real time and sends early warnings | An RTLS, consisting of a tag attached to a worker, a reader installed on the site, and a base station receives information, processes data, and sends them to the location engine. | (1) ArchiCAD 12 to map the location of workers on a computerised building model (2) Alarm technology to send early warnings with detailed information to workers at risk | The system has proven effective in tracking and monitoring workers in real time and preventing accidents. | |

| [50] | Pressure sensor for textile insole, evaluating its effectiveness in real-time safety management for construction workers | Lightweight, low-cost, and portable textile insole pressure sensor to assess stair climbing and descent, and to check that insoles detect changes in posture | Bluetooth-based worker monitoring system that predicts and alerts workers of falls as they ascend or descend ladders by processing information based on a k-NN algorithm | The results obtained provided reliable data and could be used in the future to predict worker falls. | |

| [51] | Proposes a technology for tracking the location of workers based on personal identification (ID) | (1) Location technology identifies workers and provides Job Hazard Analysis (JHA) information about the work area via a QR code or RFID (2) When the work zone and JHA are synchronised, workers entering the work zone automatically receive the site’s safety information | This study integrated ASRC (Automated Safety Rules Verification System) systems into BIM-based projects to identify work zones with hazards to workers | The results of this study will serve as an effective tool for preventing accidents in high-risk workplaces. | |

| [18] | Proposes a smart safety hook (SSH) monitoring method to eliminate the risk of falls from scaffolding | Computer vision is used to collect worker data from monitoring the status of the harness connection. | Internet of Things (IoT), inertial measurement unit (IMU) and altimeter used to assess worker behaviour and alert in case of hazard | Despite occlusion issues, accuracy is high for real-time detection and classification. | |

| [17] | This paper develops an automated method to determine whether workers are wearing a harness when performing tasks at height. | Computer vision is used to collect worker data in real time. | Deep learning (Faster R-CNN) has been used to accurately identify objects with minimal time delay, making it possible to assess whether workers are wearing the harness. | The results showed that by combining the CNNs, a high level of accuracy can be achieved in detecting the incorrect use of safety harness. | |

| [52] | Detection of personal protective equipment (PPE) on site, namely footwear, suits/vest, harnesses, gloves, goggles and helmets | Computer vision is used to collect worker data in real time. | A deep learning algorithm (YOLOv5) was run to detect objects automatically in real time, namely PPE. | Automated tools overcome the limitations of manual monitoring methods. | |

| [53] | Monitor the correct use of harnesses in the workplace to prevent falls from height | (1) Harness fitted with BLE receiver (2) Beacon installed on the lifeline karabiner and additional active BLE beacons installed in fall hazard areas | Use BIM to identify areas that should be marked out, i.e., where there is a risk of a fall from height | Solutions can help to improve worker safety by reducing the number of falls from height. | |

| [54] | Monitor the correct use of harnesses in the workplace to prevent falls from height | Various sensors distributed throughout the site: BLE receiver; harness with integrated BLE; virtual barrier of n BLE beacons to delimit the space; altimeter; anemometer. Communication between the sensors and the rest of the system is based on wireless Internet. | Fuzzy Combination Markup Language (FML) in JFML and Internet of Things (IoT) assess worker behaviour regarding the use of safety harnesses in specific areas | The developed system produced promising results, with the identified risk level matching the manual results defined by the security engineers. | |

| [55] | Developed a new system to monitor workers in real time when they are working at height | Imaging by UAS (aircraft/drone systems) | The deep learning algorithm (YOLOv4) was used to detect the main components of the PFAS (harness and lifeline) and the helmet. | This study shows that a UAV is a tool that can help technicians monitor the safety of workers working at height | |

| [56] | A model for assessing the risk of workers falling, taking into account the predominant and high temperature risk factors, as well as the physiological workload of the worker. | (1) Smartphone GPS is used to monitor the location of workers (2) WBGT values collected for indoor and outdoor environments were combined with the Clothing Adjustment Factor (CAF) (3) HR values collected using personal body measurements and HR sensors Data streams were transmitted via BLE. | The risk level is then used to calculate a downside risk score for each worker. | An overall downside risk score is calculated as the product of the two factors, providing a reference point for site managers to review the safety status of site workers and take timely action to improve areas of concern. | |

| [57] | Proposes an automatic worker location tracking and risk alert system for detection and effective risk management | The smartphone contains several sensors, such as a GPS receiver, accelerometer, magnetometer and gyroscope that measure the user’s location | Building Information Model (BIM), Revit 2013 software, and Visual Studio 2010 are used to develop the automated risk alert system. | Although the results have not yet been applied in a real-world context, they will help to improve the identification of fall risks in the workplace. | |

| [58] | Proposes a smart safety hook (SSH) monitoring method to eliminate the risk associated with falls from height | Computer vision is used to collect worker data from monitoring the status of the harness connection. | Machine learning (ML) is used to predict the status of the safety hook in real time. The SSH system generates an alarm (via buzzer and LED) if the hook is not secured as required. | The system detects and classifies hook status with high accuracy in real time. | |

| [59] | The purpose of this article is to promote the use of personal fall arrest systems (PFASs) when working at height | Computer vision is used to collect worker data, via cameras installed inside the building, as he passes through a window to carry out work at height on scaffolding outside the building | The ASC classifier detects climbers passing through a window in a work zone, and the SSD object detection method detects the use of harnesses and helmets. An alarm is given via a megaphone placed at the window | Although not applied in a real-world context, the results show that the method is robust to the risk of occlusion that may exist | |

| [60] | Use IMU sensor data to predict the risk of falling at height for accident prevention | An IMU sensor was attached to the worker to provide data on behaviours that are common or dangerous. | Several deep learning models (1D-CNN, 2D-CNN, LSTM and Conv-LSTM) were applied to the acceleration of three axes, the angular velocity of three axes, and their SVM feature vectors. | Although not used in a real-world context, the algorithm successfully predicted the risk of movement and was able to prevent fatal injuries. | |

| [61] | Investigate the effectiveness of a simple Environmental Intelligence (AmI) device as a tool to reduce the potential for fall accidents | The AmI is a device consisting of a microcontroller, microwave sensors, a light-emitting diode (LED), and an audible alarm | The analysis of the collected data is carried out by an application using X-bar graphs and one-way analysis of variance (ANOVA) | Data analysis revealed a reduction in the number of workers crossing fall hazard areas | |

| [62] | A helmet and harness monitoring system based on attribute knowledge modelling | Computer vision is used to collect worker data in real time. | A deep learning algorithm (YOLOv5) was used to detect the use of harnesses and helmets by workers. | Experimental results demonstrated the effectiveness and efficiency of this remote vision-based safety helmet and harness monitoring system. | |

| [63] | This study focused on the posture of workers to directly detect the signs of a fall. | Computer vision is used to collect worker data in real time. | An improved machine model fusion–KNN learning method was used to detect fall omens and divide the entire fall process into three stages (stable–unstable–fall). | Although it has not been used in a real-world context, it achieves good accuracy and can help to promote proactive risk assessment. | |

| [64] | The study proposes a method of monitoring safety hooks (SSHs) to eliminate the risk of falls from scaffolding. | Computer vision, using cameras installed in the workplace, is used to collect worker data in real time. | A deep learning algorithm (YOLO) is used to detect the correct use of the harness by monitoring the connection status of the harness’s safety hook. | The results showed that this method helped to reduce the number of falls caused by not using a harness. | |

| [65] | This article explores the potential applications of the smartphone as a data collection tool for near-miss detection and identification. | Smartphone strapped to the worker’s back with data collection software, accelerometer and gyroscope installed to collect and record sensor data | A machine learning algorithm using an artificial neural network (ANN) to process data | Although it has not been used in a real-world context, it demonstrates the feasibility of integrating smartphones and ANNs to measure near-miss falls. |

| Method and Approach | Number of Studies | |

|---|---|---|

| Type of monitoring | Workers | 22 |

| Site and/or equipment | 18 | |

| Type of evaluation | Evaluates the use of PPE to prevent falls | 11 |

| Evaluates the risk of falling from height | 29 | |

| Types of Technologies for Predicting the Risk of Falling from Height | No. of Studies | References |

|---|---|---|

| Image processing for fall hazard monitoring | 14 | [28,29,30,31,32,33,35,37,39,40,42,43,45,63] |

| Image processing to monitor the correct use of PPE to prevent falling from height | 9 | [17,18,46,47,52,58,59,62,64] |

| Predicting fall risk using IMU | 1 | [60] |

| Insole pressure sensor-based tracking system for BLE-based safety footwear | 1 | [50] |

| Sensors integrated into a smartphone with data collection software, an accelerometer and a gyroscope to detect near misses | 1 | [65] |

| Use of location-based and behaviour-based security (BBS) technology | 1 | [36] |

| Use of UAVs to monitor the risk of falling from height | 2 | [44,55] |

| Use of location technology based on UWB to monitor the risk of falling from height | 1 | [48] |

| Use of location technology based on RFID to monitor the risk of falling from height | 1 | [51] |

| Use of location technology based on BLE to monitor the risk of falling from height | 3 | [34,53,54] |

| Use of location technology based on GPS and RTLS to monitor the risk of falling from height | 4 | [41,49,56,57] |

| Use of location technology based on CSS to monitor the risk of falling from height | 1 | [38] |

| Sensor-based tracking system to alert workers to the risk of falling | 1 | [61] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, F.; González García, M.d.l.N.; Poças Martins, J. An Evaluation of the Technologies Used for the Real-Time Monitoring of the Risk of Falling from Height in Construction—Systematic Review. Buildings 2024, 14, 2879. https://doi.org/10.3390/buildings14092879

Pereira F, González García MdlN, Poças Martins J. An Evaluation of the Technologies Used for the Real-Time Monitoring of the Risk of Falling from Height in Construction—Systematic Review. Buildings. 2024; 14(9):2879. https://doi.org/10.3390/buildings14092879

Chicago/Turabian StylePereira, Filipa, María de las Nieves González García, and João Poças Martins. 2024. "An Evaluation of the Technologies Used for the Real-Time Monitoring of the Risk of Falling from Height in Construction—Systematic Review" Buildings 14, no. 9: 2879. https://doi.org/10.3390/buildings14092879